HBC radiomatic MICRON5 User Manual

Operating Instructions

Original Operating Instructions

micron 5

AOM5LU01

Table of Contents

Safety Instructions

Intended Use

Safety Instructions for Installation and Operation FCC notes

Operation

Activating the Transmitter Deactivating the Transmitter Automatic Switch-OFF (APO Function)

Battery and Battery Charger

NiMH Battery Battery Charger

Options

Safety Features Frequency Management Catch-Release

Tandem Operation Catch-Release-Tandem Operation Cable Control

radiomatic® masterkey

Address Changeover via Coding Plug

Utilization of Button  as Shift Key

as Shift Key

Enabling of the Proportional Outputs Rotary Switch for Preselected Speed Slewing Gear Release

Feedback by LED RF-amplifier

Pre-selection of Trolley or Hoist Transmitter Key up

Technical Data Dimensions Troubleshooting Maintenance

Attachments: Return delivery note, system specific views, circuit diagrams and /or output wiring

Pictographs

Danger due to electrical voltage. Touching live parts inside the unit can be fatal or cause serious injuries.

Instructions for occupational health and safety. Not following these instructions can cause accidents, which can cause damage, serious injuries or even death.

Important information about the operation of the radio system

Manufacturer:

HBC-radiomatic GmbH • Haller Straße 45 – 53 • 74564 Crailsheim • Germany • Tel. +49 7951 393-0 • info@radiomatic.com. HBC.radiomatic GmbH is not liable for any misprints or errors! – Specifications and design subject to change without notice. ® radiomatic and radiobus are registered German trademarks.

© 40 / 2010, HBC-radiomatic GmbH, 74564 Crailsheim, Germany

No part of this document may be reproduced in any manner whatsoever without the expressed written permission of HBC-radiomatic GmbH.

Safety Instructions

Read through these operating instructions carefully before working with the radio system. This applies in particular to the installation, commissioning and maintenance of the radio system.

The operating instructions are a constituent part of the radio control system and must always be kept close at hand for the responsible personnel.

The term ‘machine’ is used in the operating instructions for the different possible uses of the radio system.

Intended Use

The radio system serves to control machines and for data transfer. Observe the job safety and accident prevention regulations applicable to each application.

The intended use also includes reading the operating instructions and adhering to all safety information contained therein.

The radio system must not be used in areas where there is a risk of explosion, nor for the control of machines used to convey persons, unless it is explicitly approved by the manufacturer for these uses.

Modifications to the radio system may only be carried out by specialist personnel who have been trained and authorized by HBC-radiomatic. All modifications must be documented at the factory in the radio control master file.

The radio control system safety devices must not be modified, removed or bypassed. In particular, modifications to any part of the radio system's complete emergency-stop system are impermissible.

Safety Instructions for Installation and Operation

The electrical connection per the accompanying output wiring diagram must be established by a qualified electrician exclusively.

The receiver may only be opened by trained personnel. Components inside the receiver can be energized at life-threatening voltages. The supply voltage for the machine must be deactivated before the receiver is opened.

Please also note with radio systems, that the presence of persons in the danger zone - in particular beneath the load (cranes!) - is prohibited in every instance.

Select a safe location for radio control, from which you have a good and complete view of the working movements of the machine, the load movements and the surrounding working conditions.

It is not permissible to put a radio transmitter unattended to one side whilst activated. Always switch the radio transmitter off when it is not required. This applies in particular if you change location, when working without radio control, during breaks and at the end of work. Always safeguard the radio transmitter against use by unauthorized persons, for example by locking it away.

In the event of an emergency and with all faults, switch the radio transmitter off immediately by pressing the STOP switch.

Only operate the radio system when it is in perfect working order. Faults and defects that could influence safety must be rectified before the system is put back into operation, by specialists who have been trained and authorized by HBC-radiomatic.

Note that the operational directions of the operating elements may appear inverted depending on location and viewing angle to the machine. This applies in particular to rotary cranes, if your location changes from inside to outside the radius of the crane. The operator must make himself familiar with the directional markings on the machine before the start of work.

Repairs may only be carried out by specialist personnel who have been trained and authorized by HBC-radiomatic. Use original replacement parts and accessories (e.g. rechargeable batteries) exclusively; otherwise it is possible that the equipment safety can no longer be guaranteed and our extended warranty will be voided.

Remain vigilant when working with the radio system and familiarize yourself with its functions. This applies in particular if you are working with it for the first time or if you work with it only occasionally.

Check each time before starting work the function of the STOP switch.

When you press the STOP switch with the transmitter on, the status LED of the transmitter has to go

out. If the status LED does not go out then you have to disable the radio control system immediately. Remove the battery and the radiomatic® iLOG from the transmitter and inform a service technician.

FCC notes

Part 15.19 Statement

This device complies with Part 15 of the FCC Rules [and with ICES-003 of Industry Canada]. Operation is subject to the following two conditions:

1.this device may not cause harmful interference, and

2.this device must accept any interference received, including interference that may cause undesired operation

Part 15.21 Statement

Changes or modifications made to this equipment not expressly approved by HBC-radiomatic GmbH may void the FCC authorization to operate this equipment.

Part 15.105 Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

RF Exposure Statement

Radiofrequency radiation exposure information

The radiated output power of the device is far below the FCC radio frequency exposure limits. Nevertheless, the device shall be used in such a manner that the potential for human contact during normal operation is minimized.

Operation

The transmitter is equipped with an electronic radiomatic® iLOG key. radiomatic® iLOG contains all the data required for operating the transmitter. Operation is not possible without radiomatic® iLOG! Depending on the version the radiomatic® iLOG can also be used for operation of replacement transmitters of identical construction.

In the event of an interruption of the radio link during a working cycle – what can occasionally happen – both transmitter and receiver automatically shut down (so-called "compulsory switch-off").

To reactivate the system release all operator controls and allow the control elements to return to their zero position. After that the machine can react again to control commands. This feature hinders any uncontrolled or unwanted machine movement, should the radio link be interrupted.

Note:

If the machine is equipped with a main contactor you must actuate the start button before the machine can react again to control commands.

Activating the Transmitter

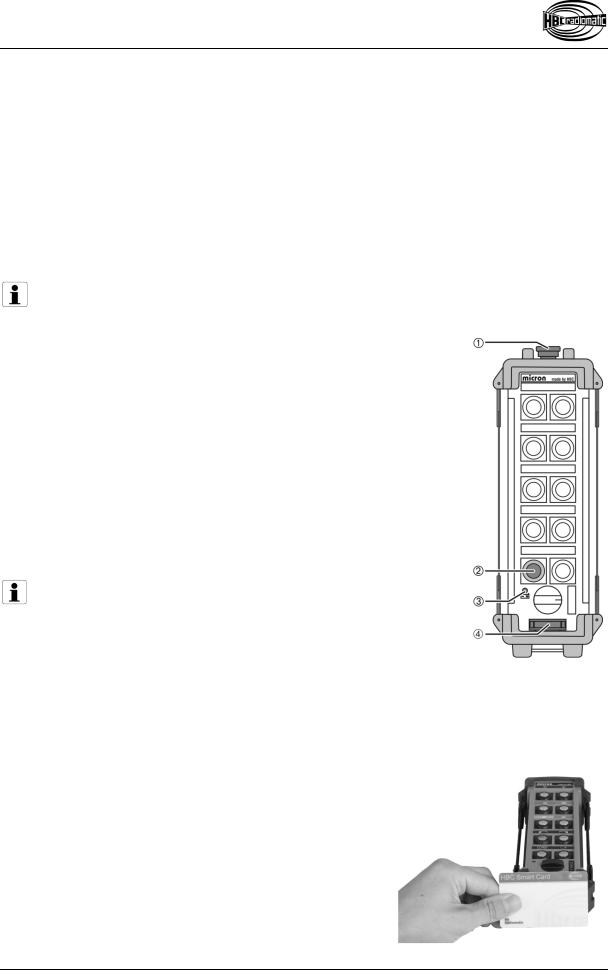

With start sequence

Insert a charged battery into the battery compartment.

The following steps need to be carried out within 4 seconds:

1.Pull the STOP switch.

2.Shortly actuate the start button and then release. The transmitter will switch off if the button is pressed for longer than half a second!

3.Actuate the start button again until the status LED flashes green. Then release the button.

The transmitter is now ready for operation.

Note:

The transmitter switches off when

the start button is actuated for longer than half a second (see above, point 2).

switching on takes over 4 seconds.

another button is pressed when switching on.

You must then press the STOP switch and repeat steps 1 to 3.

With HBC Smart Card

1.Insert a charged battery into the battery compartment.

2.Pull the STOP switch.

The status LED flashes green 2 times and red 1 time per second.

3.Hold the HBC Smart Card in front of the transmitter (see illustration).

The transmitter vibrates and an acoustic signal sounds.

When the status LED flashes green, the transmitter is ready to operate.

If an invalid HBC Smart Card is used, the transmitter vibrates 3 times. At the same time an acoustic signal sounds. Then the transmitter switches off.

STOP-switchStart buttonStatus LED

radiomatic® iLOG

Caution:

Before starting work always trigger the acoustic signal. This warns all colleagues that the machine is about to move.

Deactivating the Transmitter

Press the STOP switch.

Note:

Replace the battery when the status LED in the transmitter flashes red, an acoustic signal sounds and the transmitter vibrates (option). Otherwise, the transmitter will switch off in a few minutes. Recharge the empty battery in the respective charger.

Automatic Switch-OFF (APO Function)

For safety reasons we have equipped the transmitter with an automatic switch-OFF (APO function). The transmitter is automatically put out of circuit after approx. 15 minutes of non-use.

The automatic switch-OFF also saves battery power.

After an automatic switch-OFF you must reactivate the transmitter as described in chapter Operation.

Caution:

The automatic switch-OFF does not relieve the operator of his responsibility to turn off the transmitter with the STOP switch when not in use.

Battery and Battery Charger

NiMH Battery

The battery capacity depends on the age of the battery and the ambient temperature. Older batteries lose their capacity over time. The battery capacity diminishes more quickly at temperatures below 0 °C (32 °F) and above 40 °C (104 °F).

Note:

Charge the battery fully before initial use and/or after storing for longer than 6 months. When doing so note that the battery will only reach its full capacity after 3 - 5 charge cycles (complete charging and discharging)

Use only the associated HBC charger to charge the battery

Charge the battery at an ambient temperature of 0 – 40 °C (32 – 104 °F).

Recharge the battery only when the status LED on the transmitter flashes red, the acoustic signal sounds and the transmitter vibrates (option).

Charge the battery fully before storing it for a prolonged period. Otherwise total discharge may occur.

Always store rechargeable batteries at room temperature.

Protect the battery from short circuits and always store it in the protective cover provided.

When handled properly the battery can exceed 500 charging cycles

Battery Charger

Depending on customer selection, an AC or DC charger is available.

Ensure that you observe the following instructions:

Use this charger only to charge the batteries specified on the type plate.

The charger may not be used in hazardous areas.

The charger has to be operated with the voltage indicated on the back.

The charger has to be used in vehicles or indoors only.

Use the charger only within the specified temperature range.

Protect the charger against heat, dust and humidity.

Do not cover the charger while it is in use.

Disconnect the charger from the power supply when it is not in use.

In case of any fault of the charger or the connecting cable disconnect it immediately and put it out of operation.

Do not make technical changes to the charger or the connecting cable.

Defects must be repaired by qualified personnel only.

Three LEDs indicate the actual operating state of the battery.

LED green: Illuminates when battery is charged.

LED orange: Illuminates when battery is charging.

LED red: Illuminates when battery is deep discharged or defective.

Note:

If a deep discharged battery is inserted into the charger, the red LED will illuminate for a few seconds before charging is started (LED orange illuminates).

QA108600 / QD108300 / QD308300 with EC type-approval

The charger is supplied with a connecting cable with a matching power plug.

Charging the battery:

1.Connect the charger via the connecting cable to the power supply.

2.Insert the battery into the compartment.

Charging will start automatically.

|

Technical Data |

|

|

|

|

Operating voltage |

|

100 – 240 V AC (QA108600) |

|

|

10 – 30 V DC (QD108300 / QD308300) |

Charging time |

|

ca. 3 h |

Operating temperature |

|

10 – 40 °C (50 – 104 °F) |

|

|

|

Housing material |

|

Plastic |

Protection class |

|

II |

Loading...

Loading...