Hawkeye Torque Anchor User Manual

This document contains the recommended procedures to install and refurbish the Dynamic Torque Anchor.

A.) Installation - Initial Function Test

B.) Installation

C.) Disengage

D.) Service & Refurbishment

Installation and Refurbishment Instructions

Dynamic Torque Anchor

Torque Anchor Installation / Refurb Instructions, April 2014

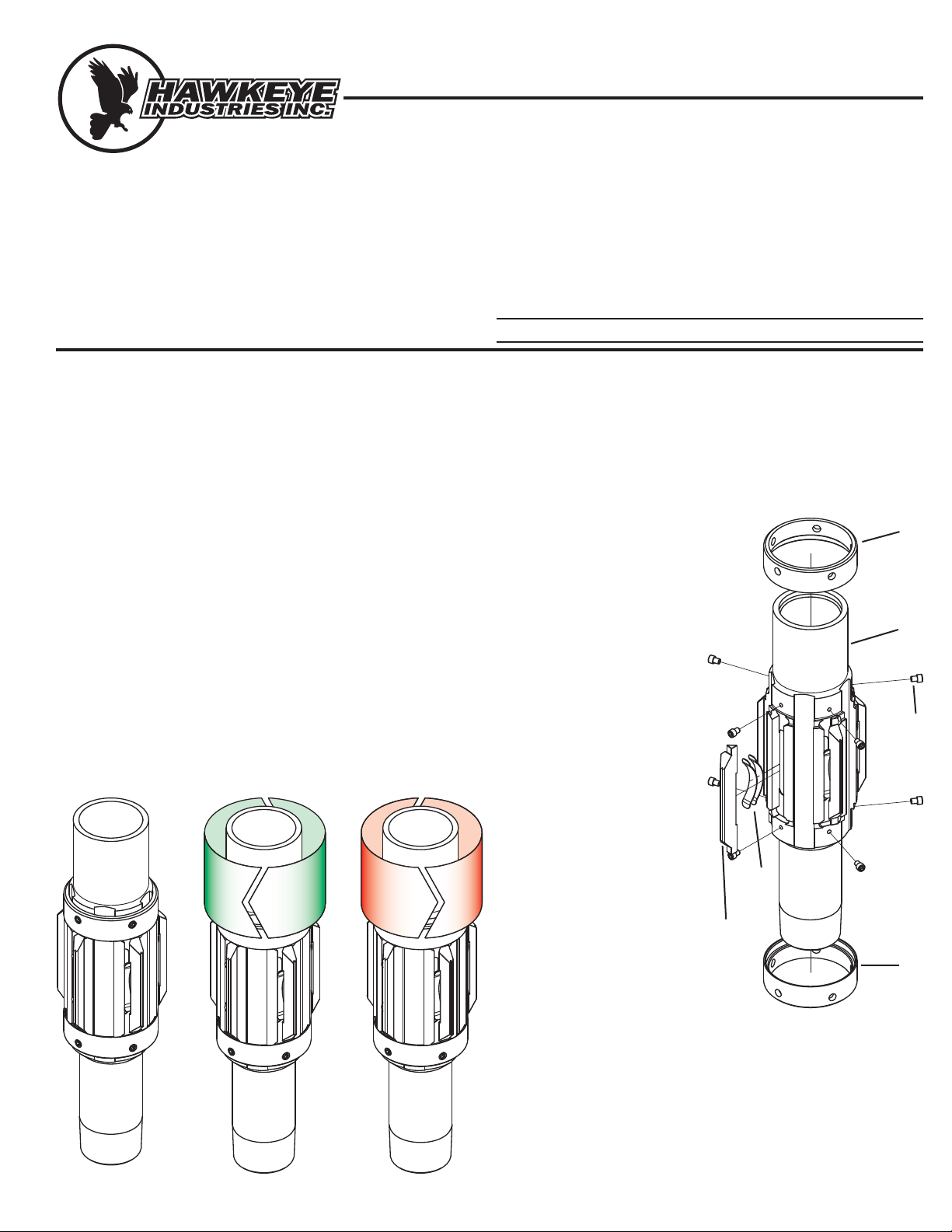

Figure 1 Figure 2 Figure 3

Figure 4

1

1.) Run the Torque Anchor, box end up, into the first joint of casing (Fig.

1)

2.) Set the Torque Anchor with 300 ft-lb of right-hand torque (Fig. 2)

3.) Examine the contact points to ensure proper engagement of the an-

chor blocks in the ID of the casing.

4.) Once satisfied, relax the right-hand torque (Fig. 3) and the anchor is

ready to be run to the desired depth.

1.) Run the torque anchor to the desired depth. The anchor must be in-

stalled box end up and below the pump (Fig. 1).

2.) At the desired depth, apply approximately 300 ft-lb of right-hand

torque (Fig. 2) on the anchor to engage the anchor blocks to the cas-

ing wall.

3.) The setting torque can be locked in and pump operation started.

Note: To avoid disengaging the anchor when starting or stopping the

pump, pre-torque the tubing string.

1.) Stop pump.

2.) Relax setting torque (Fig. 3).

1.) Disassemble the torque an-

chor to its individual compo-

nents (Fig. 4):

► Body (A)

► Anchor Blocks (B)

► Retaining Ring (C)

► Spring (D) *

► Hex Socket Screw (E) *

* Do not reuse these components.

2.) Clean the body, anchor

blocks and retaining rings

using varsol, sand blasting or

other means to provide a

clean part for inspection

3.) Inspect the parts for cracks,

deformations from over-

torque and corrosion. Dam-

aged parts should not be

reused. Use discretion when

examining the anchor blocks.

If there is any doubt with con-

tinued use, replace the an-

chor blocks.

4.) Reassemble the Torque An-

chor using the Assembly Pro-

cedure.

► 1/4” Allen Key

► Torque Wrench

► Solvent / Cleaning Solution

► Sand Blaster

► Heavy Duty rubber band

► Band clamp / Cinch Rope

Contents Refurb / Reassembly Tools

Parts Required

A.) Installation - Initial Function Test

B.) Installation

C.) Disengage

D.) Service and Refurbishment

E.) Reassembly

QTY Part

► 1 Torque Anchor Refurb. Kit for your size of anchor.

C

A

E

C

D

B

300 FT-LB

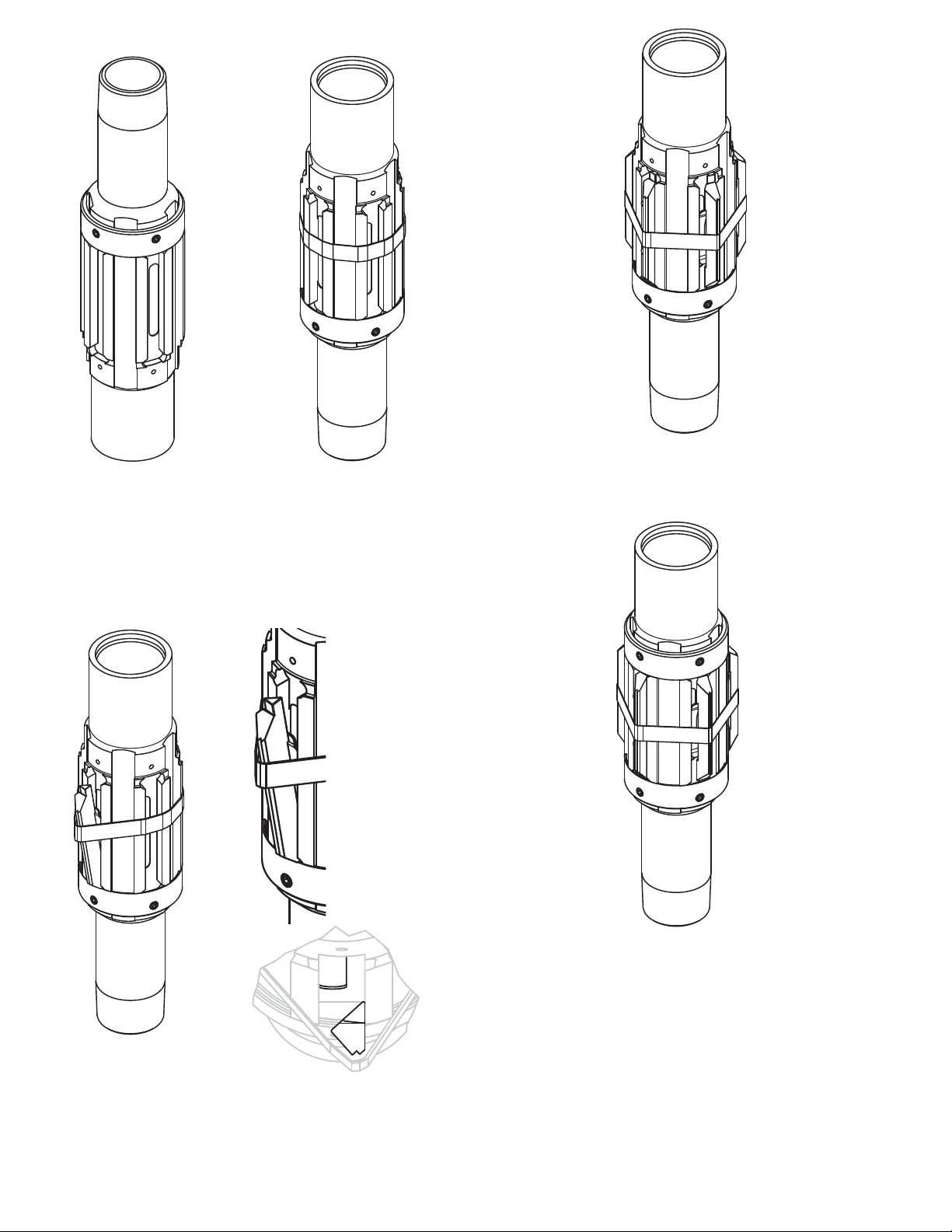

E.) Reassembly

1.) Stand the anchor body up-

side down (pin end up) and

install the retaining ring, and

secure into place using the

hex-socket cap screws.

Torque the screws to at least

30 ft-lb (Fig. 5)

2.) Flip the anchor body over

(box end up) and wrap a

heavy-duty elastic band

around the mid-section (Fig.

6).

3.) Place one anchor block into each anchor block groove (Fig. 7), tak-

ing care to note proper orientation (Figs. 8a & 8b). Anchor block

grooves are identified as having circular relief “ears” at the ends of

the groove. Two springs, dished-side towards the body should be

placed behind the anchor block. The springs should sit in the shal-

low relief in the body, and on the underside of the anchor block.

4.) Use an assembly ring or cinch rope to draw in the anchor blocks

close to the body. (Fig 9.)

5.) Drop the second retaining ring onto the torque anchor. Ensure the

retaining ring is seated fully and all anchor blocks are secured by the

retaining ring. Secure the ring using the hex-socket cap screws, and

torque to at least 30 ft-lb. (Fig 10.)

2

Figure 5 Figure 6

Figure 9

Figure 10

Figure 7

Figure 8a

Figure 8b

Loading...

Loading...