Hawkeye Marsh Hawk User Manual

► 3/4 in. Box / Socket Wrench

► 1/2 in. Box / Socket Wrench

► 9/64 in. Allen Wrench

This document contains the recommended procedures installing and maintaining a Hawkeye Marshhawk Thief Hatch.

Requirements

The Marshhawk has a standard 8” API flange connection, and re-

quires a SCH 40 or lighter nozzle. Other mounting options, such

as ANSI flange or other API connections are accommodated with

adaptor spools and risers. Consult the vapor control section of our

website, or call us for more information.

Tools

Parts Required

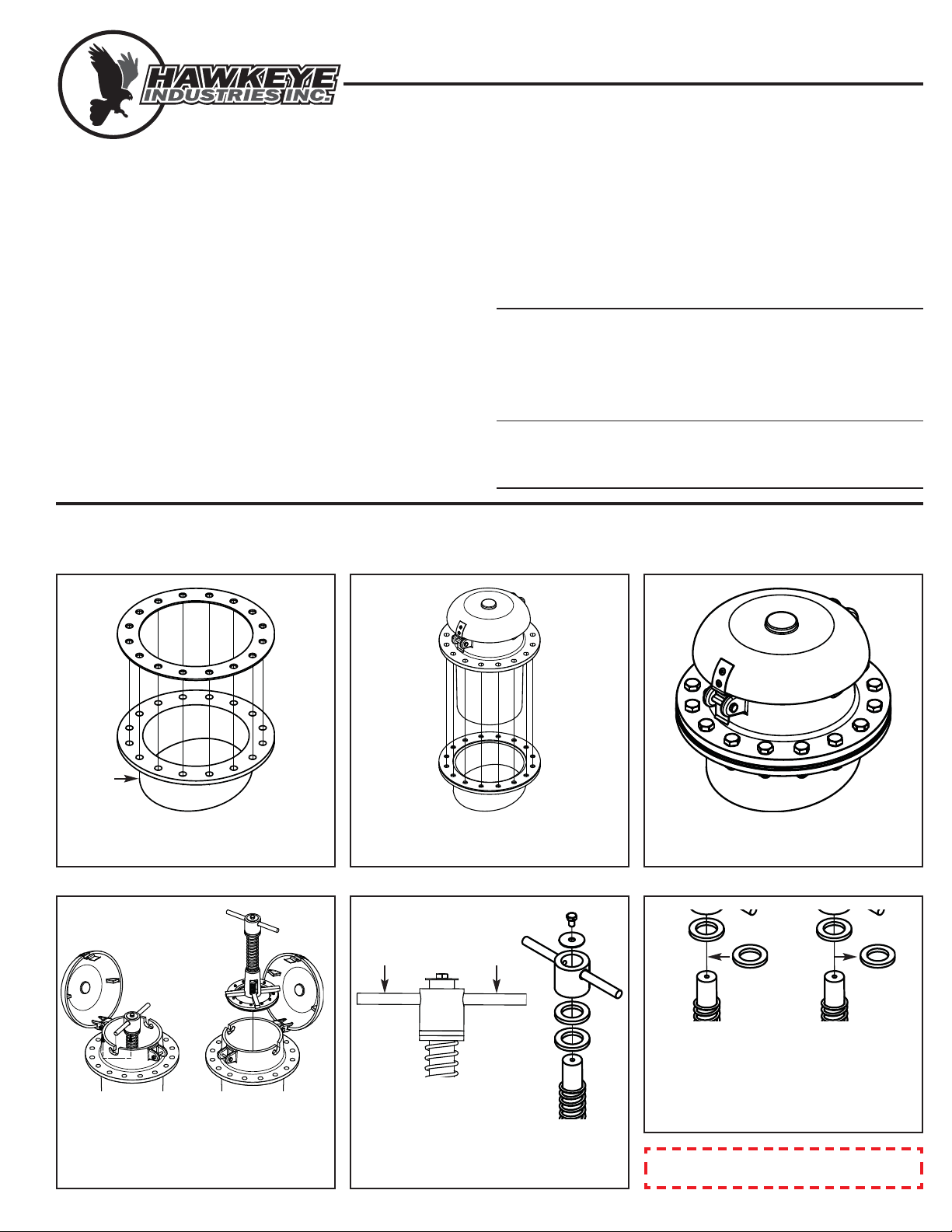

A.) Installing the Marshhawk Thief Hatch

Place Tank Gasket on the 8” API Tank Flange

and align holes.

Installation & Maintenance Guide

Marshhawk Thief Hatch

QTY Part

Installation

► 1 Marshhawk Thief Hatch

► 1 8” API Tank Gasket

► 16 1/2 UNC x 1-3/4 Bolts & Nuts

► varies 2 ozsi and 1 ozsi Pressure Spacers as required.

Maintenance

► 1 Replacement Pressure / Vacuum Gasket

► Dow Corning #4 Electrical Insul. Compound (or eq.)

1.)

Fasten with the supplied 1/2 UNC Bolts and

Nuts with a 3/4 Box or Socket Wrench

3.)

Mount Marshhawk on base gasket and align

holes.

2.)

Remove the spider cage assembly by pressing

down on spring retainer and rotating counter

clockwise to disengage from J-slot. Lift spider-

cage assembly straight out of the hatch body.

G

1.)

Use spring retainer to compress the spring.

Remove the retainer screw and washer with

the 1/2 wrench, and remove the spring retainer.

2.)

Add or remove pressure spacers to increase or

decrease activation pressure, respectively.

Each standard pressure spacer changes acti-

vation pressure by 2 ozsi. Follow directions in

reverse to reassemble the thief hatch.

Hawkeye recommends activation pressure 2 ozsi

below the tank’s pressure rating.

3.)

Marshhawk Installation Instructions, May 2010

1

Contents

A.) Installing the Marshhawk Thief Hatch

A1.) Hatch Installation

A2.) Pressure Spacer Adjustment

B.) Maintaining the Marshhawk Thief Hatch

B1.) Replacing Pressure / Vacuum Gasket

B2.) Relubrication

B3.) Antifreeze solutions

A1.) Hatch Installation

A2.) Pressure Spacer Adjustment

↑P ↓P

►►

►

►

SCH 40

or lighter

Hawkeye Industries Inc.

2

B.) Maintaining the Marshhawk Thief Hatch

B1.) Replacing the Pressure / Vacuum Gasket

B2.) Relubrication

B3.) Antifreeze Solutions

Remove the 12 #8-32 NC Socket Head Cap

screws with the 9/64 Allen wrench, freeing the

gasket retaining ring.

Using light pressure, push the vacuum plate

out of the way, and slide the gasket around it,

and off of the spider cage.

Generally, the more active the vent action of the hatch, the more frequent

relubrication should be performed. Specific relubrication requirements are

application specific, and are determined by the following variables:

► Chemical exposure

► Elevated pressure

► High flow velocity

► Elevated temperature

► Utilization (i.e. if hatch is primary relief)

Hawkeye factory-applies Dow Corning 4 Electrical Insulating Compound

to the vacuum and pressure gasket, and recommends the same com-

pound for any field relubrication.

►Excellent seal and release properties

►-57°C to 204°C

► Moisture Resistant

► 4.5% Bleed, 24 hr/200°C

► 1.4% Evaporation, 24 hr/200°C

► Non-toxic and odorless

It is not recommended to use any kind of antifreeze solution on a nor-

mally-operating Marshhawk thief hatch -- even as a preventative meas-

ure. However, if there is evidence of the hatch icing up, a compound with

suitable gasket compatibility is required. Please consult the supplied

chart and ensure that the solution used will not compromise the sealing

effectiveness of the Marshhawk Thief Hatch.

Align holes on new gasket with holes on spider

cage and retaining ring. With light an even

torque, replace the 12 #8-32 NC Socket Head

Cap Screws (I)

Remove the spider cage assembly from the hatch body as in Section A2, Step 1 before proceeding.

1.) 2.) 3.)

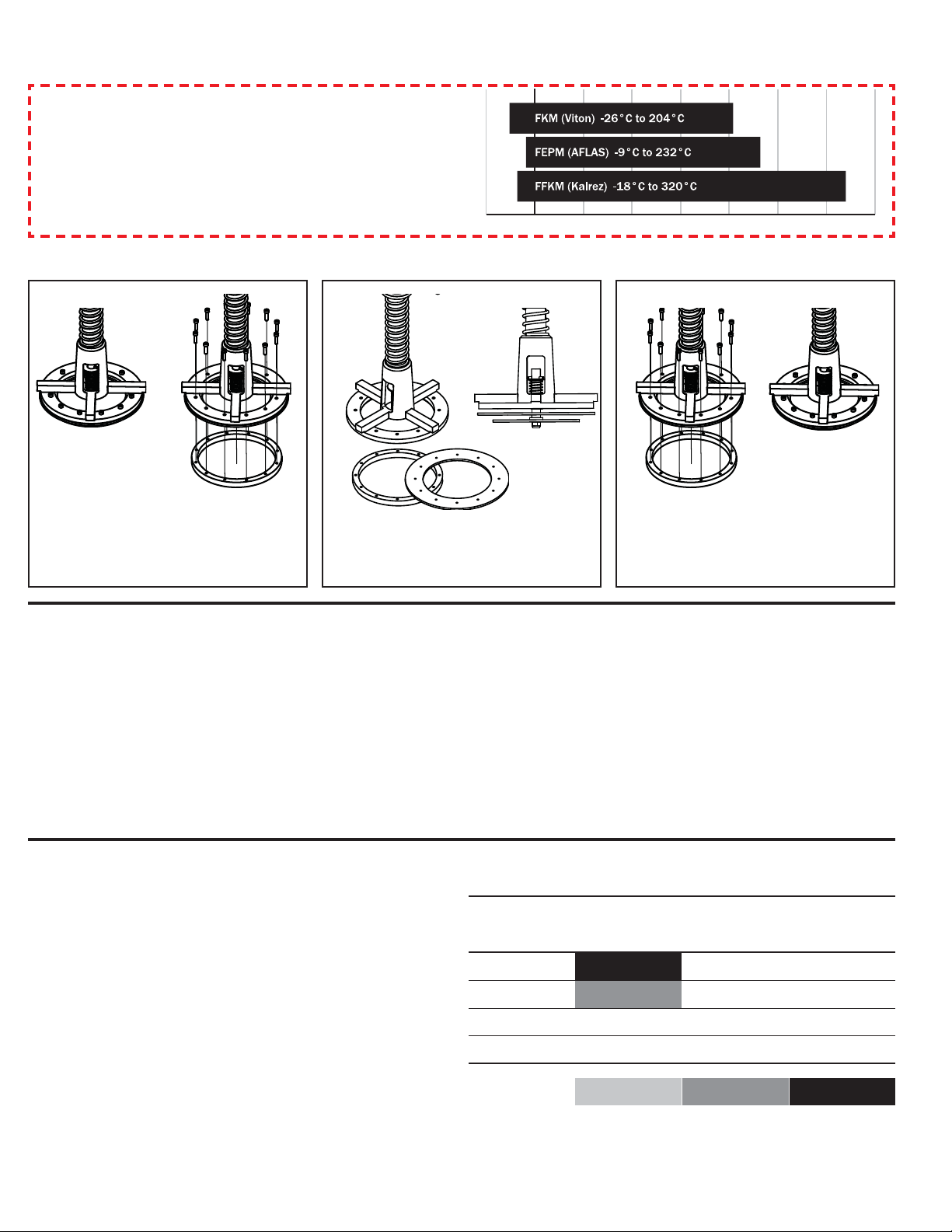

Hawkeye offers three gasket materials for the Marshhawk Thief Hatch:FKM

(Viton), FEPM (Aflas) and FFKM (Kalrez). Each with different properties,

temperature ranges and chemical compatibilities. Please ensure the se-

lected gasket materials suitable for your application prior to ordering a re-

placement. Call us for assistance. The following operating temperature

range table is provided for information only.

-

Gasket Material

Antifreeze Solution FKM (Viton) FEPM (AFLAS) FFKM (Kalrez)

Methanol

4 11

Ethanol

311

Isopropanol

111

Ethylene Glycol

111

1 - Satisfactory 2 - Fair 3 - Doubtful 4 - Unsatisfactory

►►

50 0 50 100 150 200 250 300 350

Loading...

Loading...