Hawkeye Gauge Board User Manual

► Drill with 17/64 or 9/32 bit

► Robertson Screw Driver

► Allen Key

► Tape Measure

► 7/16 wrench

► Crescent wrench

► Thread Lubricant (KOPR-

KOTE recommended)

This document provides the procedures, dimensions and parts list for the installation of a Hawkeye Industries Inc. Gauge board and Indi-

cator & Guide Kit.

Requirements

Ensure that the tank has been prepared to accept a gauge board +

Indicator & Guide kit. Refer to the Tank Preparation instructions for

details on modifying a tank to accept a Hawkeye Gauge Board.

Contents

Tools

Parts Required

A.) Gauge Board

B.) Indicator and Guide Kit

A.) Gauge Board

B.) Indicator & Guide Kit.

C.) Gauge Board with Magnetic Clips

D.) Determining # of Magnetic Clips Required

Attach the gauge board to the clips using 1/4

in. X 3/4 in. machine screws, washers and

nuts, leaving the top and bottom clips free for

installation of the indicator and guide kit. If the

indicator and guide kit is not required then se-

cure all clips with hardware as stated above.

TANK PREPARATION | GAUGE BOARD KIT INSTALLATION | FLOAT GUIDE KIT INSTALLATION | GAUGE HEAD INSTALLATION | GOSHAWK INSTALLATION

Installation Instructions

Gauge Board + Indicator & Guide Kit

Installation

QTY Part

► varies Gauge Board sections c/w decals & splices (if req)

► varies Indicator & Guide Kit

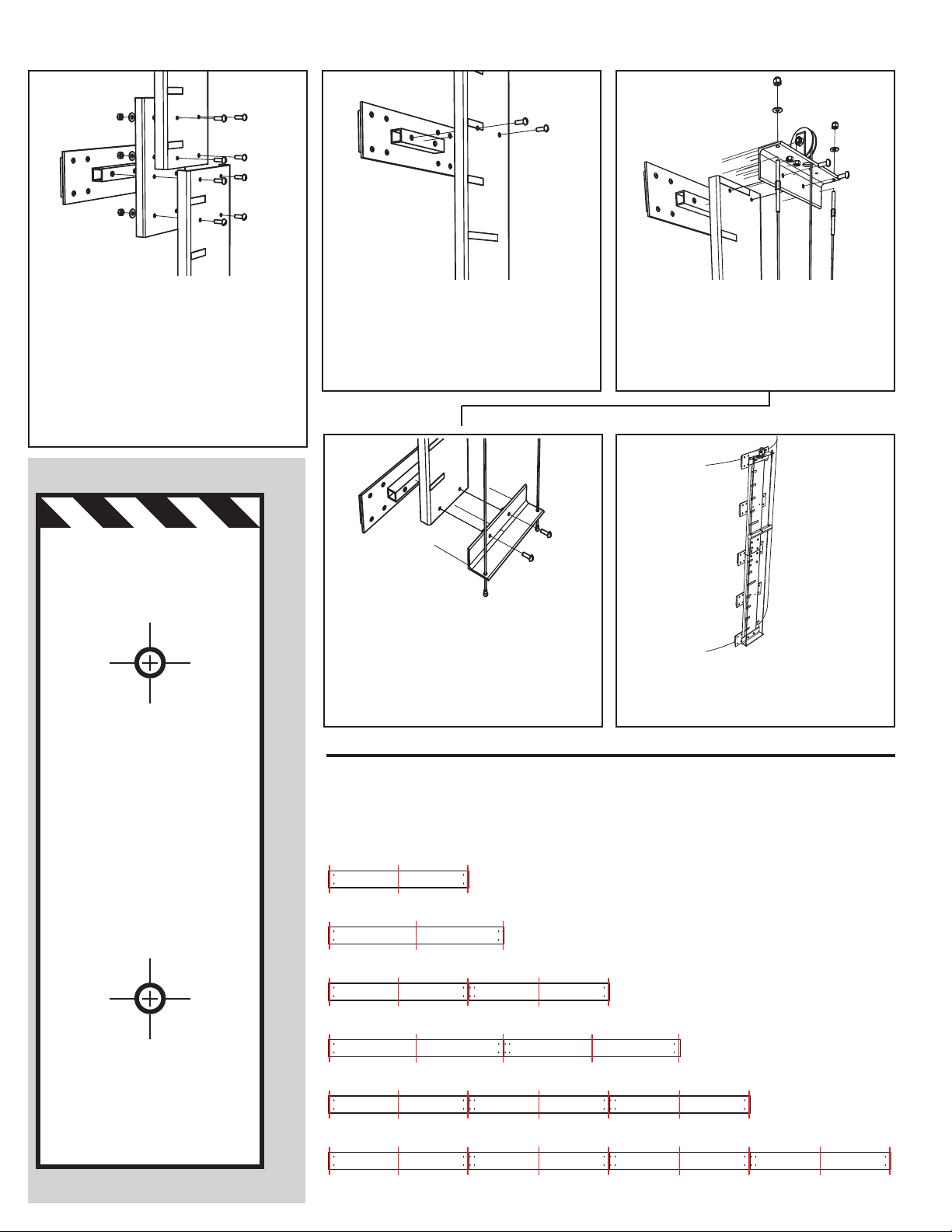

Note the order of the gauge boards by the de-

cals and connect each piece together using the

supplied splices and the 1/4 in. X 3/4 in. ma-

chine screws, nuts, and washers.

Secure the top bracket with the indicator cable

pulley to the existing holes, 0.75 in. from the

top of the gauge board and the corresponding

gauge board clip using the 1/4 in. X 3/4 in. ma-

chine screws, nuts, and washers.

Secure the bottom bracket to the existing

holes, 0.75 in. from the bottom of the gauge

board and corresponding gauge board clip

using the 1/4 in. X 3/4 in. machine screws,

nuts, and washers.

Apply KOPR-KOTE to threads and tighten both

cable studs on the top bracket until guide ca-

bles are taut.

Drill 17/64 (or 9/32) holes in the gauge board

aligned with the additional gauge board clips

that have been installed onto the tank (if re-

quired).

1.)

1.) 2.) 3.)

2.)

3.)

►

►

►

►

Gauge Board + Indicator & Guide Kit Instructions, Dec 2011

1

Note! For single-section Gauge Boards start at step 2.)

Note! When using Magnetic Gauge Board Clips, proceed to Part C.

Installation Complete. Proceed to Float Guide Kit or Gauge Head Installation

Gauge Board Installation Complete. Proceed to B.)

C.) Gauge Board & Indicator Kit with Magnetic Clips

D.) Required Number of Magnetic Clips

Note the order of the gauge boards by the de-

cals and connect each piece together using the

supplied splices and the 1/4 in. X 3/4 in. ma-

chine screws, nuts, and washers.

Omit the nuts and washers on the top pair of

bolts of the lower gauge board, and fasten di-

rectly to the magnetic gauge board clips.

At the midpoint of each gauge board section,

drill two 17/64 (or 9/32) holes, 3” apart sym-

metric about the long axis of the board.

Use the supplied template below.

►►

►

►

8 Ft Gauge Board (1x 8ft section) - 3 magnetic clips required

10 Ft Gauge Board (1x 10ft section) - 3 magnetic clips required

16 Ft Gauge Board (2x 8ft sections) - 5 magnetic clips required

20 Ft Gauge Board (2x 10ft section) - 5 magnetic clips required

24 Ft Gauge Board (3x 8ft section) - 7 magnetic clips required

32 Ft Gauge Board (4x 8ft section) - 9 magnetic clips required

Secure the top bracket with the indicator cable

pulley to the existing holes, 0.75 in. from the

top of the gauge board and the corresponding

gauge board clip using the 1/4 in. X 3/4 in. ma-

chine screws, nuts, and washers.

Secure the bottom bracket to the existing

holes, 0.75 in. from the bottom of the gauge

board and corresponding gauge board clip

using the 1/4 in. X 3/4 in. machine screws,

nuts, and washers.

Install the complete gauge board and indicator

assembly on the tank. Align and move as re-

quired to match gauge head.

The following chart outlines the minimum required number of magnetic gauge board clips recom-

mended by Hawkeye. For sizes not listed here, please consult Technical Bulletin TB-1211-GB for

calculating the required number of clips.

1.) 2.) 3.)

4.) 5.)

Installation Complete. Proceed to Float Guide Kit or Gauge Head Installation

Cut Along Solid Lines

GAUGE BOARD

ALIGN TO EDGE OF

DRILL 17/64 OR 9/32 THROUGH

2 PLACES 3.00 APART

DRILL TEMPLATE

Loading...

Loading...