Hawkeye 750 User Manual

► Pipe Wrench

► Cresent Wrench

► Thread Sealant

► Cable Cutter

This document contains the recommended procedures for installing a Hawkeye Industries Model 750 & Model 750 LS Gauge Head.

Requirements

Ensure that the tank is prepared to accept a Model 750 Gauge

Head (per Tank Preperation Instructions,) and has been fitted with

a float and float guide kit.

Contents

Tools

Parts Required

A.) Installing Model 750 Gauge Head

A.) Installing Model 750 Gauge Head

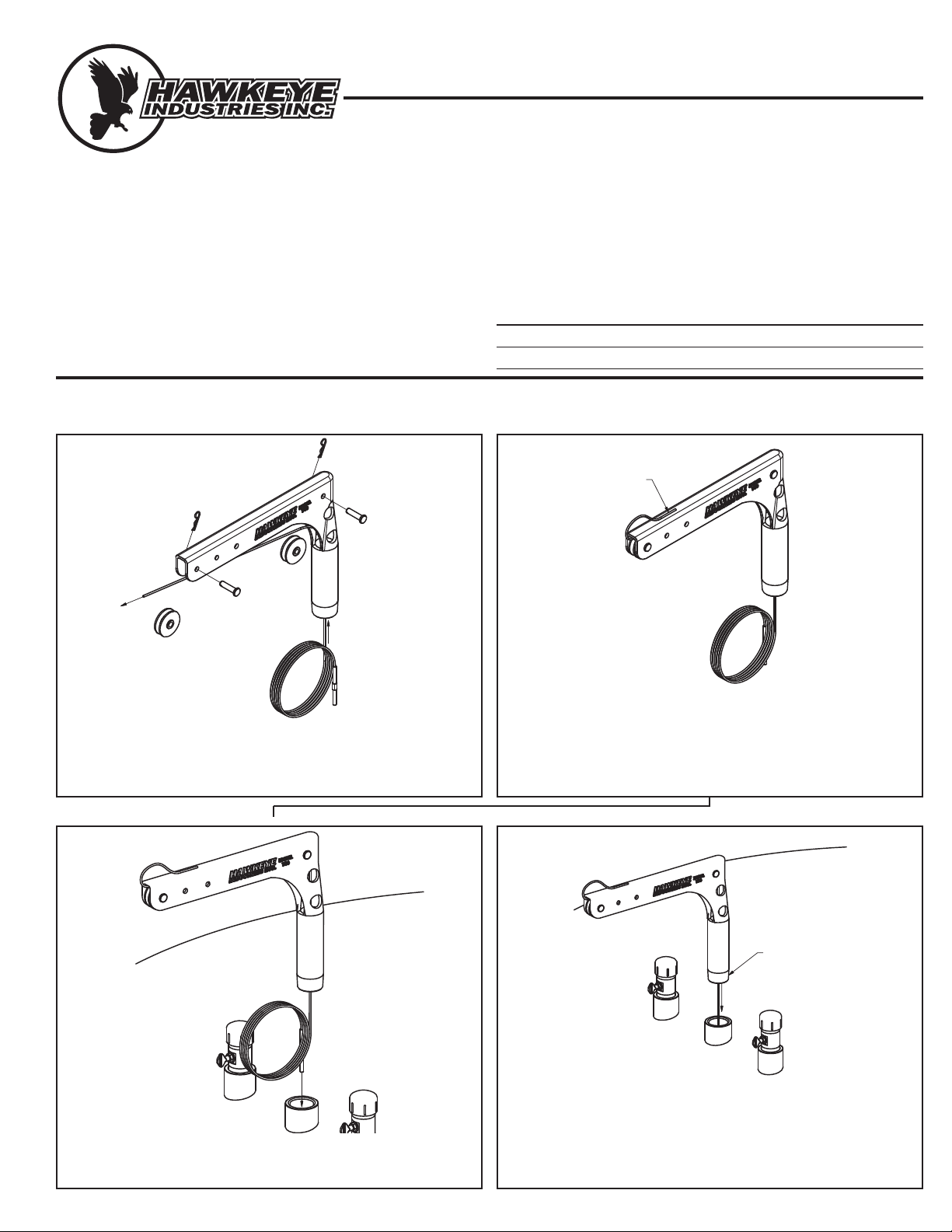

Remove the idler pulleys by pulling the hair pins and axle pins. Thread the

float cable, cut end first, through the 1½ NPT connection on the gauge

head.

Feed the stud end of the float cable through the gauge head coupling

down into the tank.

Replace the idler pulleys and pins so that the cable runs over top of both

pulleys. Secure the cut end of the float cable in position so that it does not

slide back through the gauge head.

TANK PREPARATION | GAUGE BOARD KIT INSTALLATION | FLOAT GUIDE KIT INSTALLATION | GAUGE HEAD INSTALLATION | GOSHAWK INSTALLATION

Installation Instructions

Model 750 / 750 LS Gauge Head

QTY Part

► 1 Model 750 or Model 750LS Gauge Head

► 1 Float Cable Assembly for specified tank height

1.) 2.)

3.) 4.)

►

►

Model 750 Instructions, September 2013

1

►

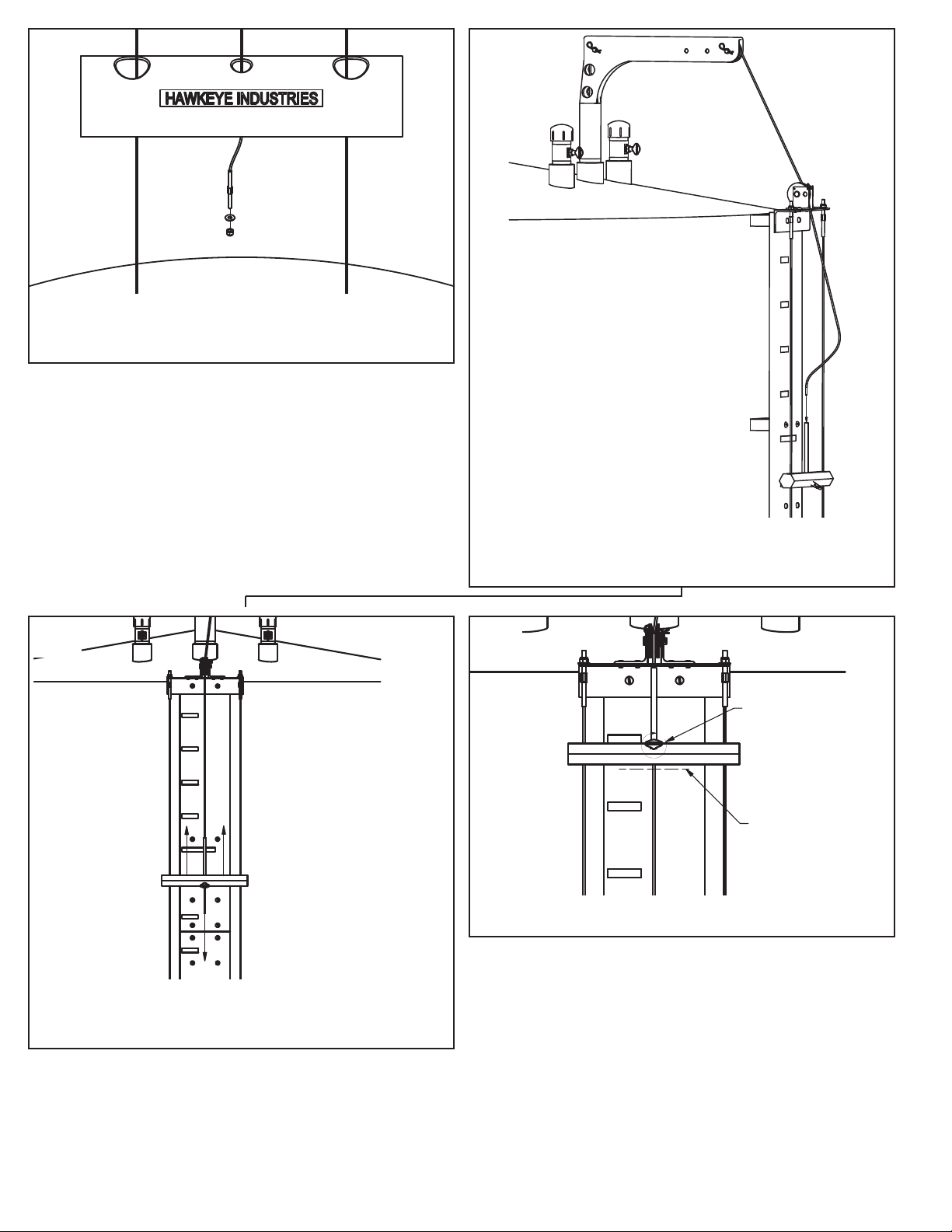

Apply thread sealant to the 1½ NPT threads of the gauge head and

tighten it into the 1½ NPT coupling on the tank with a pipe wrench. Ensure

that the open side of the gauge is aligned with the gauge board and faces

towards the board.

Skip this step for Model

750 LS Gauge Heads.

CLAMP OR

TAPE IN PLACE

APPLY THREAD SEALANT

Hawkeye Industries Inc.

2

Pass the cut end of the cable over the indicator cable pulley and through

the hole in the top bracket of the indicator guide assembly. Feed the cable

through the center hole of the indicator.

6.)

With slight tension on the cable to keep the float barely off the tank floor,

slide the indicator over the cable to the minimum level on the gauge

board.

SLIGHT TENSION TO KEEP FLOAT

BARELY ON TANK FLOOR

SLIDE INDICATOR TO THE MINIUMUM

LEVEL ON THE GAUGEBOARD

7.)

Tighten the indicator set screw. Cut off the excess cable.

CUT OFF EXCESS

TIGHTEN THUMB SCREW

7.)

►

►

Model 750 Installaton Complete

►

Feed the stud and cable through the center hole of the float and replace

the nut and washer. Tighten the nut until there are three threads showing.

5.)

Loading...

Loading...