Hauler Racks C-12 S User Manual

(52)

(2)

ASSEMBLY INSTRUCTIONS FOR

C-10, C-11 & C-12 SERIES RACKS

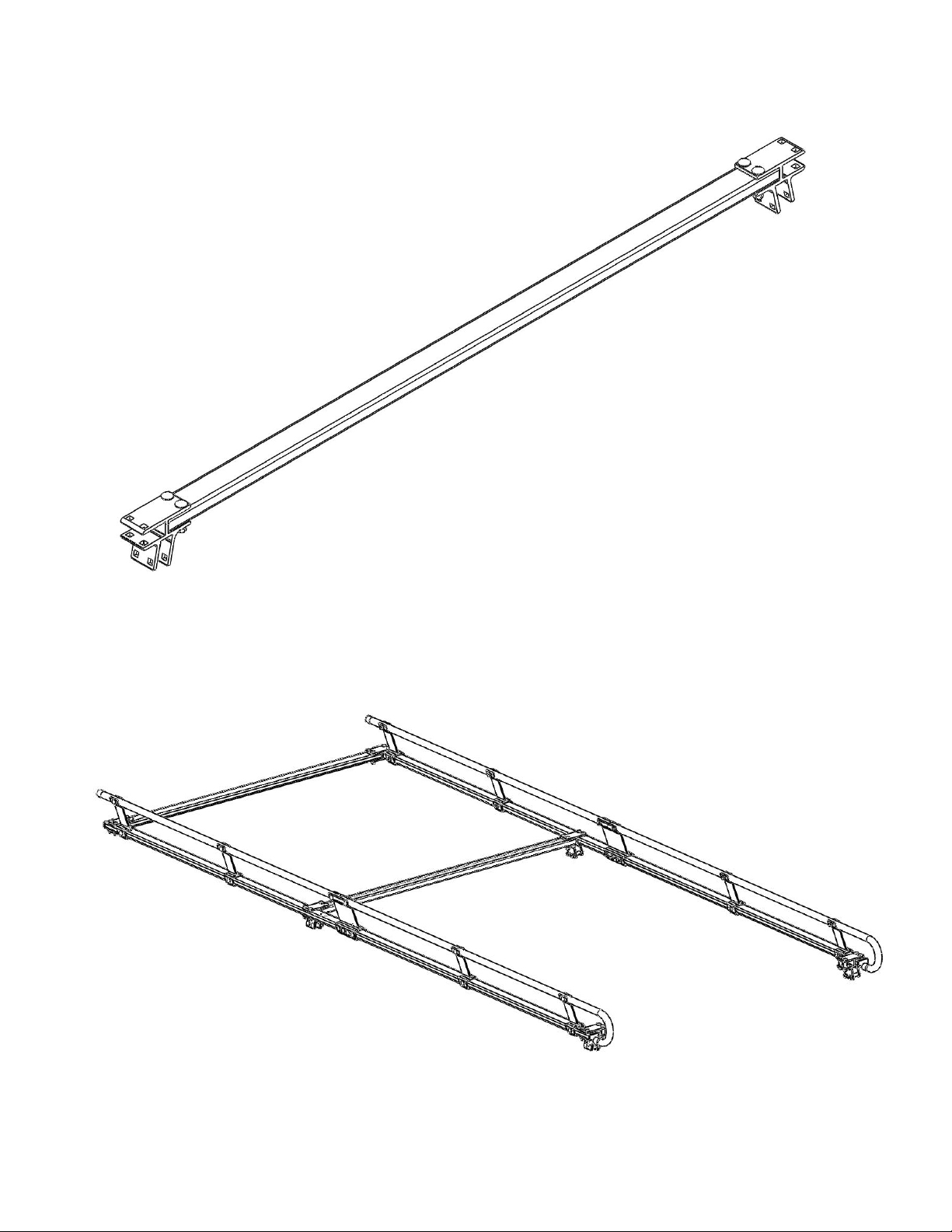

C12S-1 with 26” Legs shown above.

Package Contents:

HARDWARE KIT PARTS

(8) 3/8”-16 x 3” CARRAIGE BOLTS (1) RAIL DRIVER’S SIDE ASSEMBLIES

(20) 3/8”-16 x 2” CARRAIGE BOLTS (1) RAIL PASSENGER’S ASSEMBLIES

(4) 3/8”-16 x 1-3/4” CARRAIGE BOLTS (1) FRONT RECTANGLULAR CROSSBAR

(12) 3/8”-16 x 1-3/4” HEX BOLTS (1) MIDDLE CROSSBAR ASSEMBLY

(4) 3/8”-16 x 1-1/2” HEX BOLTS (1) REAR CROSSBAR

(4) 3/8”-16 x 1-1/4” HEX BOLTS (4) LEGS

(4) 3/8” x 1-1/4” LAG BOLTS (4) CAMPER FEET

(52) 3/8”-16 NUTS (4) HD BRACES

3/8” SPLIT LOCK WASHERS

Before you begin:

EXTENDED CAB BRACES & HARDWARE (EX VERSION ONLY)

Remove all components from the shipping carton.

The rack should be assembled on a padded surface such as carpet to prevent scratching of aluminum surfaces. Remove bands

securing components together.

Read the instructions thoroughly to familiarize yourself with the assembly sequence.

Note that you DO NOT tighten any nuts and bolts until the completed rack is installed on the vehicle unless specified. This allows for

minor adjustments to the rack during the installation process.

Gather the following tools used to assemble and install the rack.

9/16” Socket or open end wrench

3/8” Drill bit and drill

Pencil or marker

Tape measure

Center punch and hammer (optional)

Level (optional)

2 Clamps (optional)

Boards (optional)

HAULER RACKS, INC. Toll Free: 1-800-843-5445

st

7109 31

Minneapolis, MN 55427-2848 Fax: 763-546-0933

Avenue North Phone: 763-546-5620

Page 1 of 14 WWW.HAULERRACKS.COM

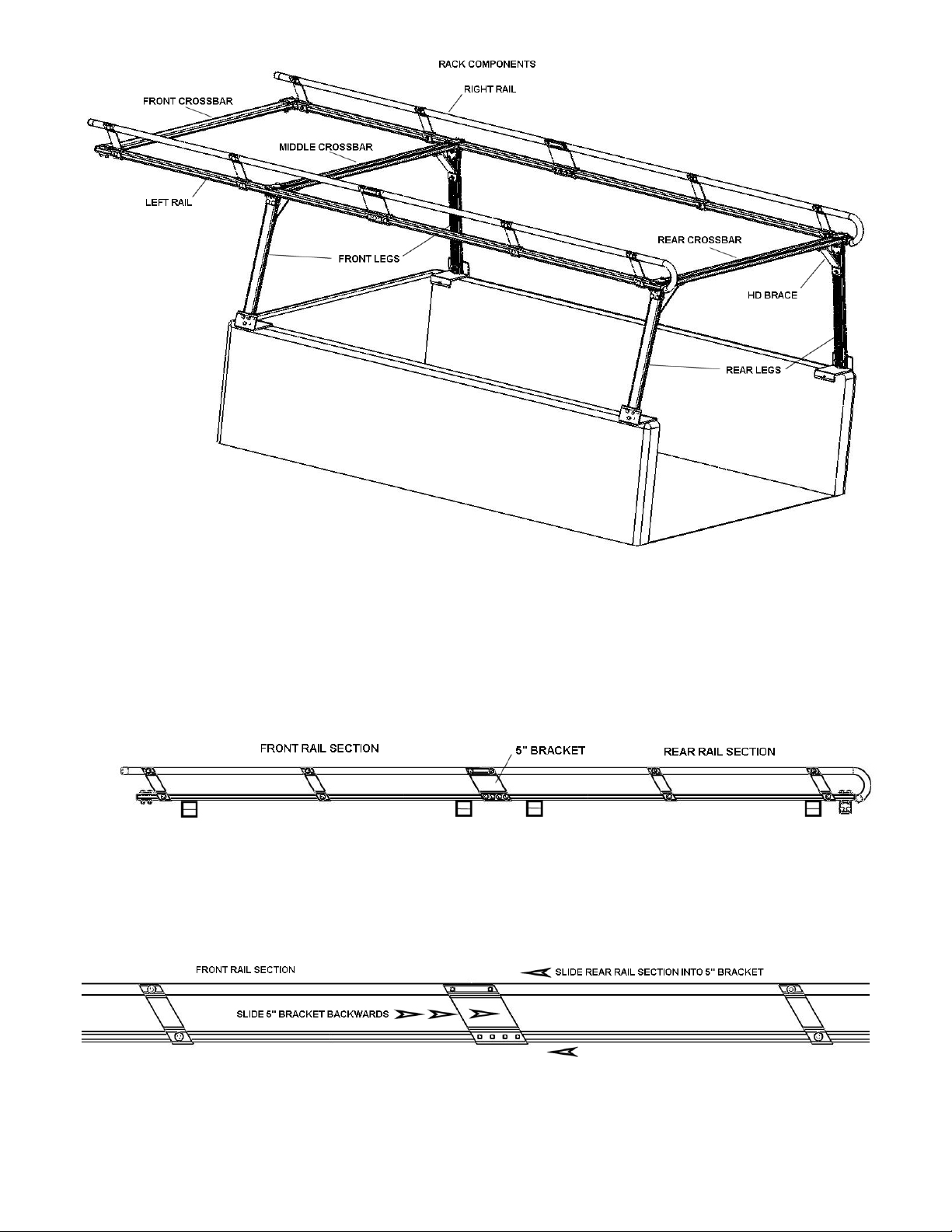

1. Connect front and rear sections

Each side rail side contains a front and rear section preassembled for easier assembly. The front and

rear sections are banded together.

Remove the banding and separate the front and rear rail sections from packaging.

On a flat surface, place boards under the front and rear rail sections as shown so that the rear ‘Y’

bracket does not touch the ground. This will make aligning the front and rear rail sections faster.

On the front section (the end with the straight round tube), slide the 5” bracket backwards until the two

back holes on the 5” bracket line up with the two holes on the end of the lower rectangle tube.

Insert the rear rail section into the 5” bracket and line up with two remaining holes.

HAULER RACKS, INC. Toll Free: 1-800-843-5445

st

7109 31

Minneapolis, MN 55427-2848 Fax: 763-546-0933

Avenue North Phone: 763-546-5620

Page 2 of 14 WWW.HAULERRACKS.COM

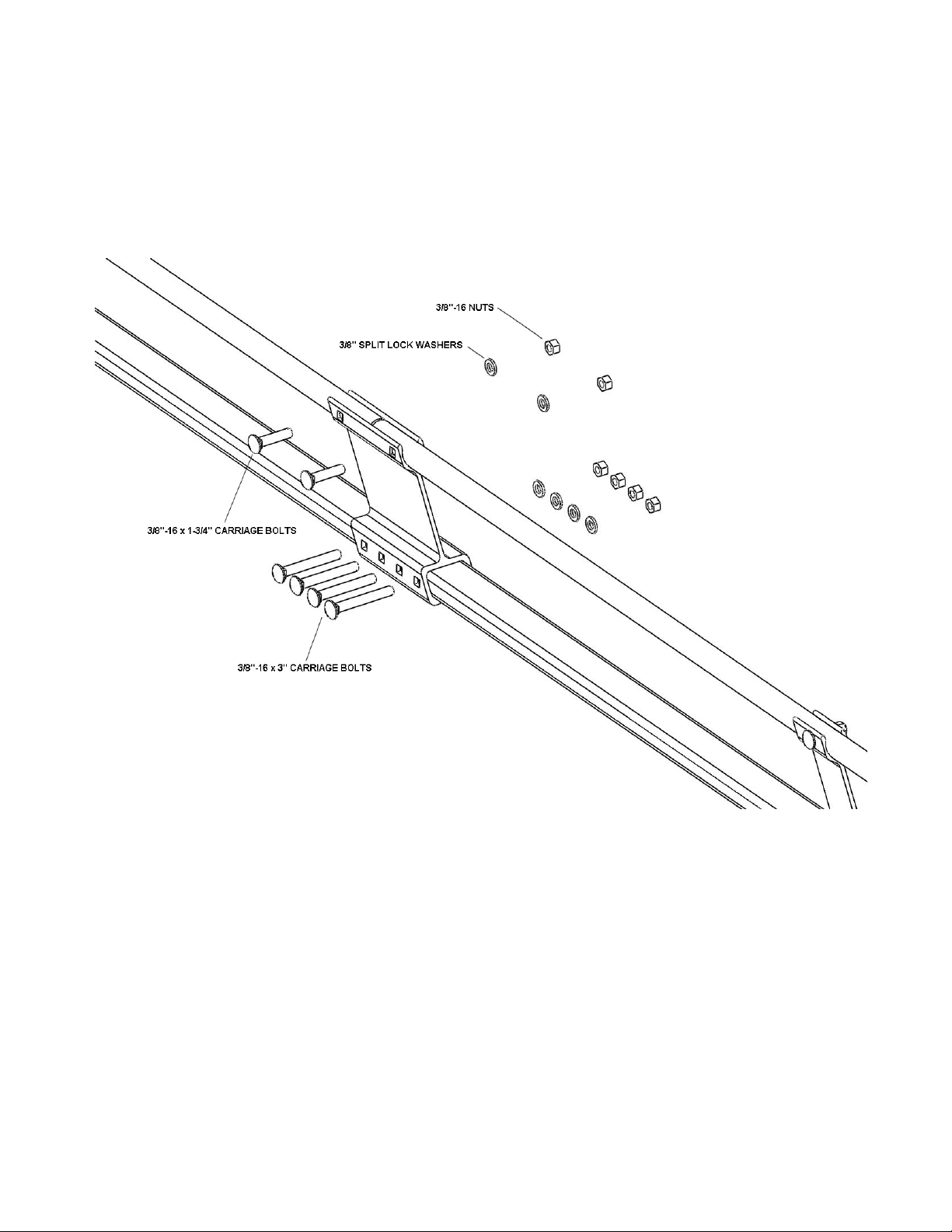

1. (Continued) Connect front and rear sections

Note the orientation of the other carriage bolts on rail assemblies.

For the top round tube, use (2) 3/8”-16 x 1-3/4” carriage bolts, (2) 3/8” split lock washers and (2) 3/8”16 nuts, install hardware finger tight. Repeat for other side rail.

For the lower rectangle tube, use (4) 3/8”-16 x 3” carriage bolts, (4) 3/8” split lock washers and (4) 3/8”16 nuts, install hardware finger tight. Repeat for other side rail.

HAULER RACKS, INC. Toll Free: 1-800-843-5445

st

7109 31

Minneapolis, MN 55427-2848 Fax: 763-546-0933

Avenue North Phone: 763-546-5620

Page 3 of 14 WWW.HAULERRACKS.COM

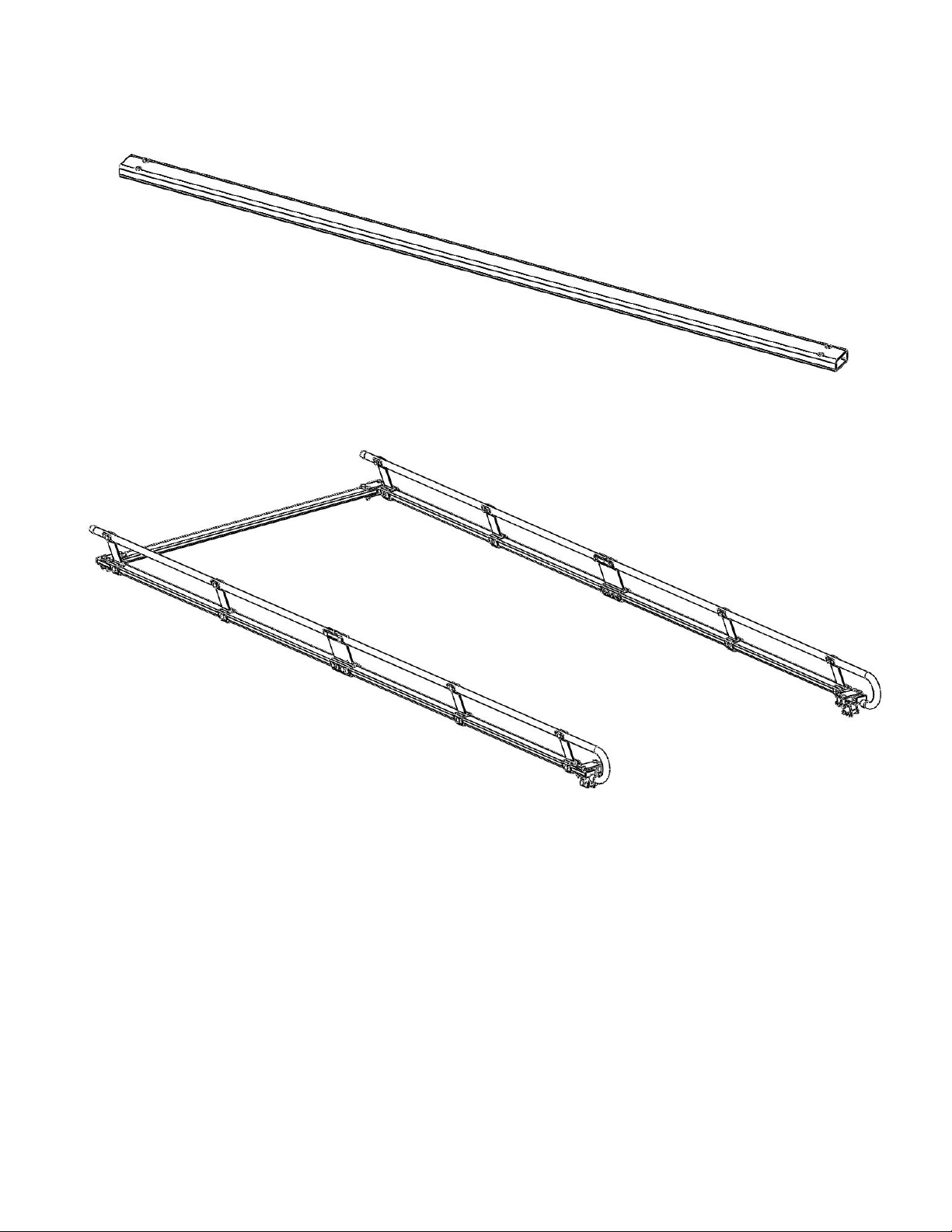

2. Install front Crossbar.

The front crossbar is the smooth rectangle tube with the round bolt holes in each end.

Secure the front cross bar to the ‘H’ brackets mounted on the side of the front rail sections using (4)

3/8”-16 x 2” carriage bolts, (4) 3/8” split lock washers and (4) 3/8”-16 nuts. Finger tighten only.

HAULER RACKS, INC. Toll Free: 1-800-843-5445

st

7109 31

Minneapolis, MN 55427-2848 Fax: 763-546-0933

Avenue North Phone: 763-546-5620

Page 4 of 14 WWW.HAULERRACKS.COM

3. Set middle crossbar assembly in place.

The middle crossbar assembly is the ribbed rectangle extrusion with a slotted bottom with ‘Y’ brackets

attached to each end.

Orientate the crossbar so the ribbed bottom is facing down.

Position the middle crossbar assembly on the front side rails forward of the 5” bracket and about

halfway between the 5” bracket and the next support bracket. The middle crossbar assembly will be

secured in place after the final adjustments on the vehicle.

HAULER RACKS, INC. Toll Free: 1-800-843-5445

st

7109 31

Minneapolis, MN 55427-2848 Fax: 763-546-0933

Avenue North Phone: 763-546-5620

Page 5 of 14 WWW.HAULERRACKS.COM

Loading...

Loading...