Hatco SAL-1 Installation Manual

E

L

E

M

E

N

T

S

E

L

E

C

T

O

R

R

E

F

E

R

T

O

O

P

E

R

A

T

O

R

’

S

M

A

N

U

A

L

F

O

R

M

O

R

E

I

N

F

O

R

M

A

T

I

O

N

WARNING

ADVERTENCIA

AVERTISSEMENT

Register Online!

hatcocorp.com

(see page 2)

S'inscrire en ligne!

(voir page 14)

Installation and Operating Manual

Manuel d'installation et d'utilisation

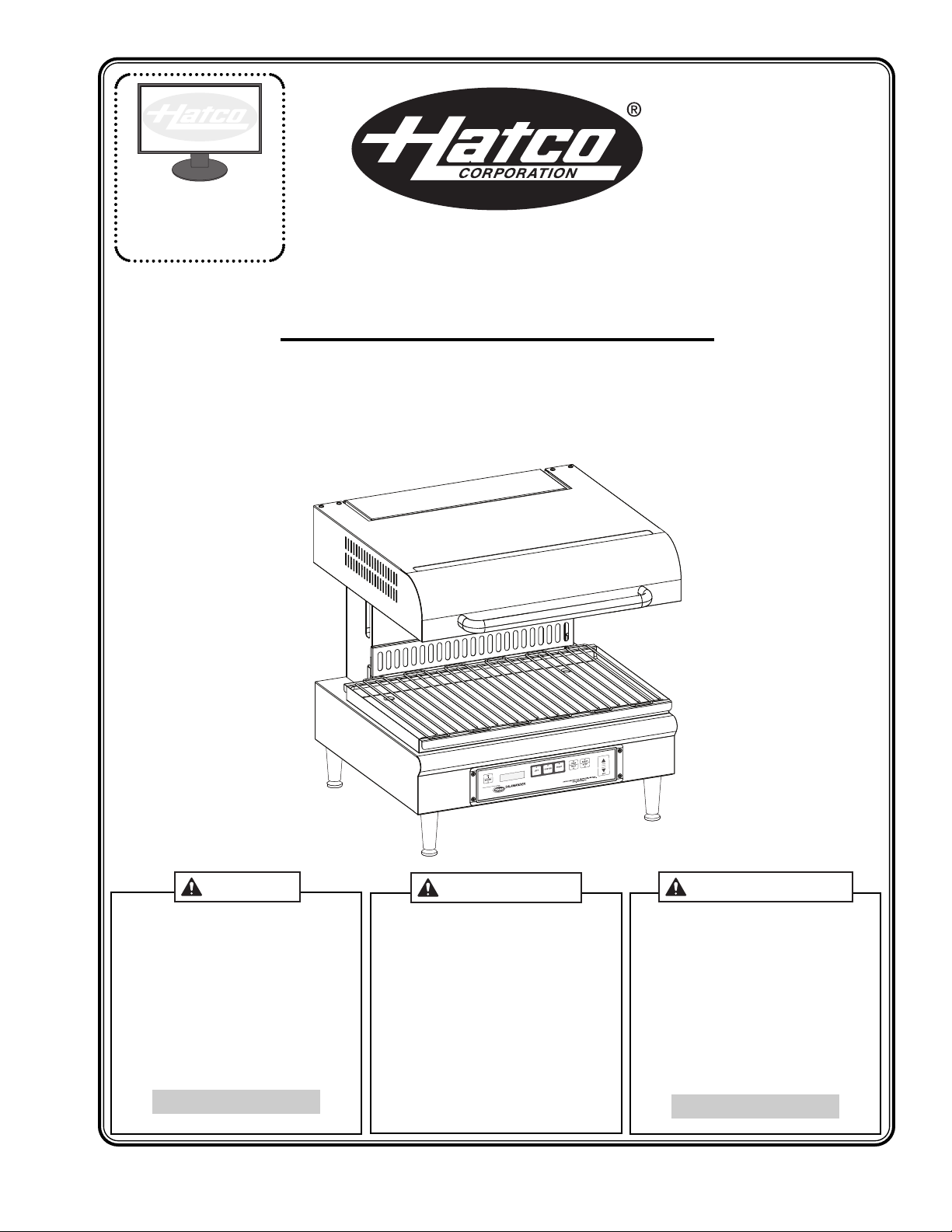

Salamander

SAL Series • Série SAL

P/N 07.04.616.00

Do not operate this equipment unless you

have read and understood the contents of

this manual! Failure to follow the

instructions contained in this manual may

result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel !

Le non-respect des instructions

contenues dans ce manuel peut entraîner

de graves blessures ou la mort. Ce

manuel contient des informations

importantes concernant l'entretien,

l'utilisation et le fonctionnement de ce

produit. Si vous ne comprenez pas le

contenu de ce manuel, veuillez le signaler

à votre supérieur. Conservez ce manuel

dans un endroit sûr pour pouvoir vous y

référer plus tard.

Français = p 14

© 2015 Hatco Corporation

WARNING

CAUTION

NOTICE

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

CONTENTS

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................4

Model Designation................................................................4

Specifications........................................................................4

Plug Configuration ...............................................................4

Electrical Rating Chart .........................................................5

Dimensions ..........................................................................5

Installation.............................................................................6

General ................................................................................6

Installing a Wall-Mounted Unit .............................................7

Hardwired Connection .........................................................8

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the side of the unit near the power inlet area).

Please have this information available when calling Hatco for

service assistance.

Model No. ____________________________________

Serial No. ____________________________________

Voltage ______________________________________

Date of Purchase ______________________________

Operation...............................................................................9

General ................................................................................9

Control Panel .......................................................................9

Operating the Salamander.................................................10

Maintenance ........................................................................11

General ..............................................................................11

Daily Cleaning ....................................................................11

Troubleshooting Guide ......................................................12

Limited Warranty.................................................................13

Authorized Parts Distributors............................Back Cover

Business

Hours: 7:00

Telephone: 800-558-0607; 414-671-6350

E-mail: partsandservice@hatcocorp.com

Fax: 800-690-2966 (Parts and Service)

AM to 5:00 PM Central Standard Time (CST)

(Summer Hours: June to September—

AM to 5:00 PM CST Monday–Thursday

7:00

7:00

AM to 4:00 PM CST Friday)

414-671-3976 (International)

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco’s Salamanders are specially-designed for cooking,

grilling, reheating, and keeping foods hot. Their unparalleled

startup speed is a direct result of Hatco’s “instant on” heating

elements located in the upper housing of each salamander. The

three independently-controlled heating elements provide for the

benefits of flexibility and energy conservation. The plate

detection feature, a versatile HOLD function, and the reduced

transfer of heat to the surrounding area make the Hatco

Salamander energy efficient and easy to operate.

Hatco Salamanders are products of extensive research and

field testing. The materials used were selected for maximum

durability, attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior to shipment.

This manual provides the installation, safety, and operating

instructions for Hatco Salamanders. Hatco recommends all

installation, operating, and safety instructions appearing in this

manual be read prior to installation or operation of a unit.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

b

d

tifie

n

e

l is id

a

u

n

is ma

th

s in

r

a

e

p

p

t a

a

th

n

tio

ma

r

fo

ty in

fe

Sa

he

t

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal

injury.

fol

owi

l

ng s

word panel

gnal

i

:

s

y

2

Form No. SALM-0915

English

CAUTION

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid

serious injury or death and to avoid damage to equipment or property

.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install the proper voltage

and size electrical receptacle.

• Units supplied without an electrical cord and plug

require a hardwired connection to on-site electrical

system. Connection must be properly grounded and of

correct voltage, size, and configuration for electrical

specifications of unit. Contact a qualified electrician to

determine and install proper electrical connection.

• Unit must be installed by a qualified electrician.

Installation must conform to all local electrical codes.

Installation by unqualified personnel will void unit

warranty and may lead to electric shock or burn, as well

as damage to unit and/or its surroundings.

• When installing a hardwired unit, a disconnect switch

must be installed between unit and main electrical supply.

The switch must be rated properly and have contacts with

a minimum opening distance of 1/8″ (3 mm).

• Turn OFF power switch, unplug power cord/turn off

power at circuit breaker, and allow unit to cool before

performing any cleaning, adjustments, or maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C)

and a maximum of 113°F (45°C).

• Do not steam clean or use excessive water on unit.

• This unit is not “jet-proof” construction. Do not use jetclean spray to clean this unit.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power

cord. The cord must be replaced by Hatco, an

Authorized Hatco Service Agent, or a person with

similar qualifications.

• Do not clean unit when it is energized or hot.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

FIRE HAZARD:

• To reduce the risk of fire, the appliance is to be installed in

non-combustible surroundings only, with no combustible

material within 18″ (46 cm) of the sides, front, or rear of

the appliance or within 40″ (102 cm) above the appliance.

The appliance is to be mounted on floors of noncombustible construction with non-combustible flooring

and surface finish and with no combustible material

against the underside, or on non-combustible slabs or

arches that have no combustible material against the

underside. Such construction shall in all cases extend not

less than 12″ (30 cm) beyond the equipment on all sides.

• Locate unit a minimum of 2″ (51 mm) from any walls. If

safe distances are not maintained, discoloration or

combustion could occur.

• Do not obstruct air intake openings or air exhaust

openings on outer housing of unit. Unit combustion or

malfunction may occur.

• Do not place anything on top of unit.

EXPLOSION HAZARD: Do not store or use gasoline or

other flammable vapors or liquids in the vicinity of this or

any other appliance.

For wall mounting, use special wall mount bracket

provided with unit only. Secure wall mount bracket to a

solid, non-combustible surface using appropriate hardware

for mounting surface and weight of unit.

Make sure all operators have been instructed on the safe

and proper use of the unit.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them away

from the unit.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350; fax 800-690-2966; or

International fax 414-671-3976.

BURN HAZARD:

• Some exterior surfaces on unit will get hot. Use caution

when touching these areas.

• Plate/tray will be very hot upon removal—use oven mitt,

protective clothing, or pan gripper to remove.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent unit

or its contents from falling accidentally and strong enough

to support the weight of the unit and contents.

Do not place anything on top of unit; doing so may subject

personnel to injury or damage unit.

Do not use Pyrex

Pyrex glass may break causing personal injury and/or food

contamination.

®

glass plates or serving pieces in unit.

Form No. SALM-0915

3

IMPORTANT SAFETY INFORMATION

E

L

E

M

E

N

T

S

E

L

E

C

T

O

R

R

E

F

E

R

T

O

O

P

E

R

A

T

O

R

’

S

M

A

N

U

A

L

F

O

R

M

O

R

E

I

N

F

O

R

M

A

T

I

O

N

Upper

Housing

Cooking

Grate

Control

Panel

Plate

Detection

Bar

Drip

Tray

S A L - 1

Salamander

Capacity = Quantity of Half Size Pans

NOTICE

NOTICE

WARNING

NEMA 6-30P

English

Units are voltage-specific. Refer to specification label for

electrical requirements before beginning installation.

Do not install unit above grills, fryers, or other appliances

that will expose unit to high temperature, excessive

moisture, or grease-laden air. Improper installation will

void warranty.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch finish of unit, marring its

appearance and making it susceptible to soil accumulation.

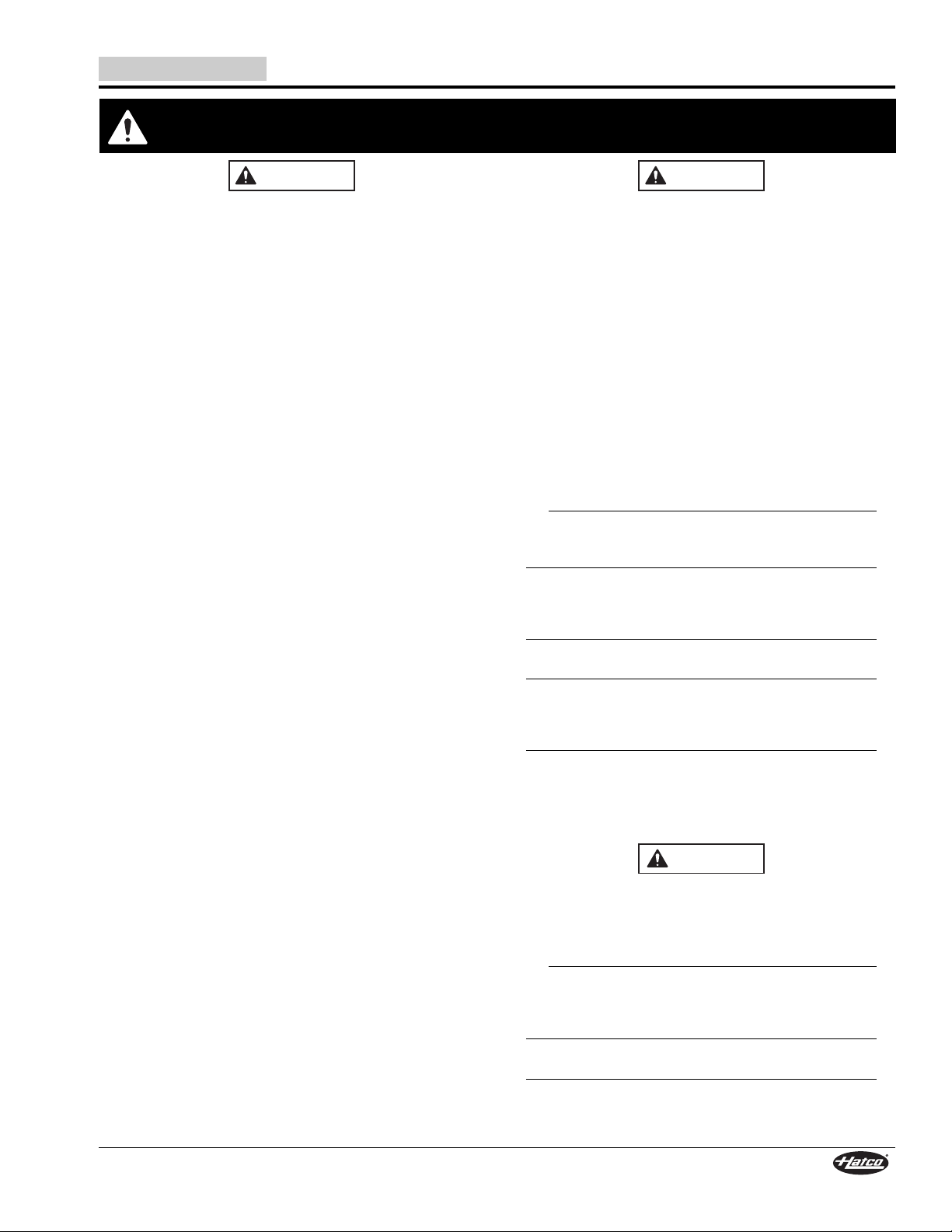

MODEL DESCRIPTION

All Models

Hatco’s Salamander is specially-designed for versatility in the

kitchen with the capabilities to cook, grill, reheat, and keep

foods hot. The salamander is constructed of stainless steel for

easy cleaning and durability. The high-powered heating

elements are ready for use within 8 seconds. The plate

detection feature activates the heating elements automatically

when a food plate comes into contact with the plate detection

bar. Removal of the food plate turns off the heating elements

automatically. The three heating elements can be controlled

independently using the individual ELEMENT SELECTOR keys

located on the control panel. The heating elements are

strategically positioned inside the moveable upper housing to

reduce the transfer of heat to the surrounding area. The HOLD

function has eight temperature levels and is ideal for keeping

foods hot or reheating foods. The removable cooking grate and

drip tray allow for easy cleanup. The unique features and

flexibility of the Hatco Salamander make it easy to operate,

energy efficient, and highly functional in any kitchen.

Do not operate unit without drip tray and cooking grate

installed. Damage to unit could occur.

This unit is intended for commercial use only—NOT for

household use.

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

Do not lay unit on the side with the control panel or damage

to unit could occur.

Model SAL-1

MODEL DESIGNATION

SPECIFICATIONS

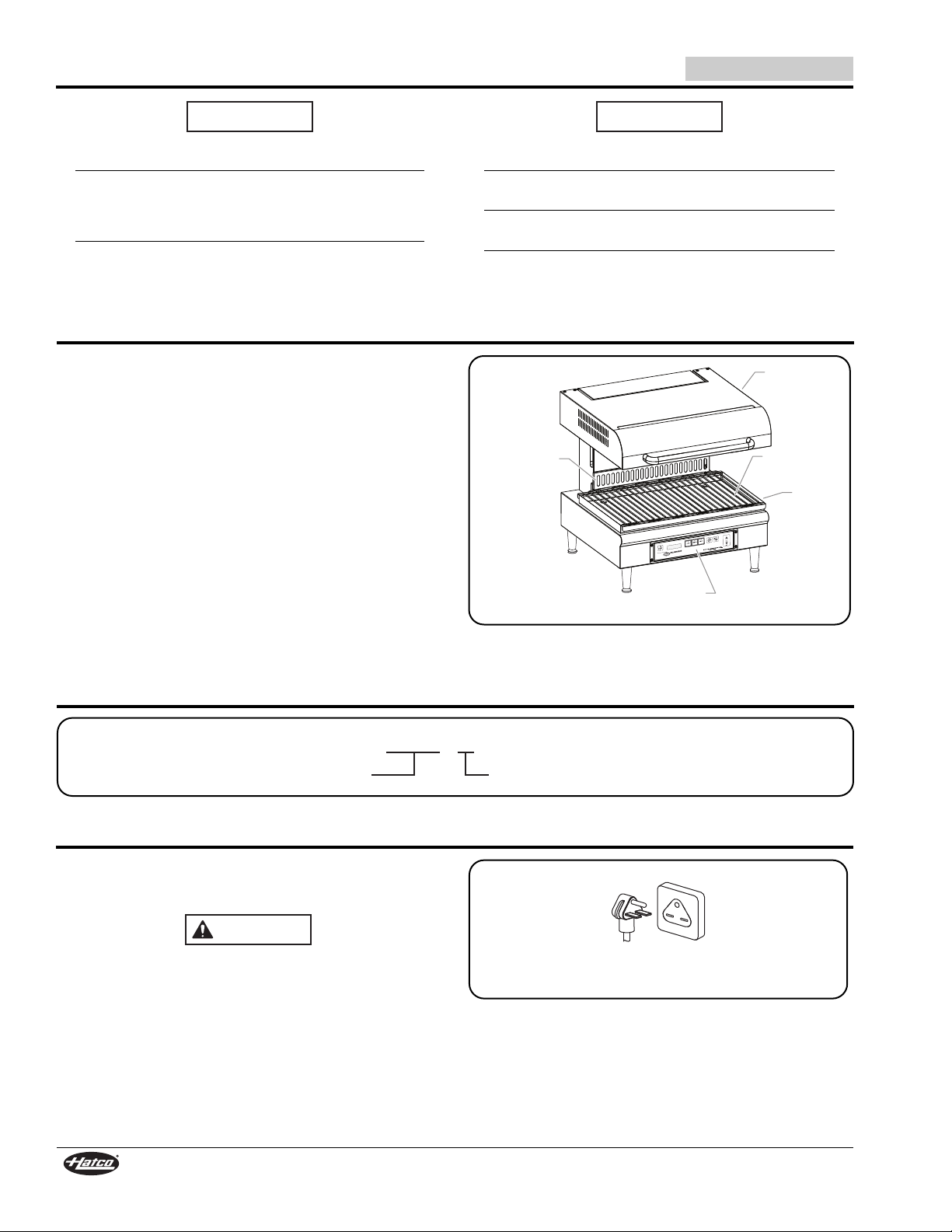

Plug Configuration

Some units are supplied from the factory with an electrical cord

and plug installed.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install the proper voltage

and size electrical receptacle.

• Units supplied without an electrical cord and plug

require a hardwired connection to on-site electrical

system. Connection must be properly grounded and of

correct voltage, size, and configuration for electrical

specifications of unit. Contact a qualified electrician to

determine and install proper electrical connection.

Plug Configuration

NOTE: Receptacle not supplied by Hatco.

NOTE: Specification label located on the side of the unit. See

label for serial number and verification of unit electrical

information.

4

Form No. SALM-0915

English

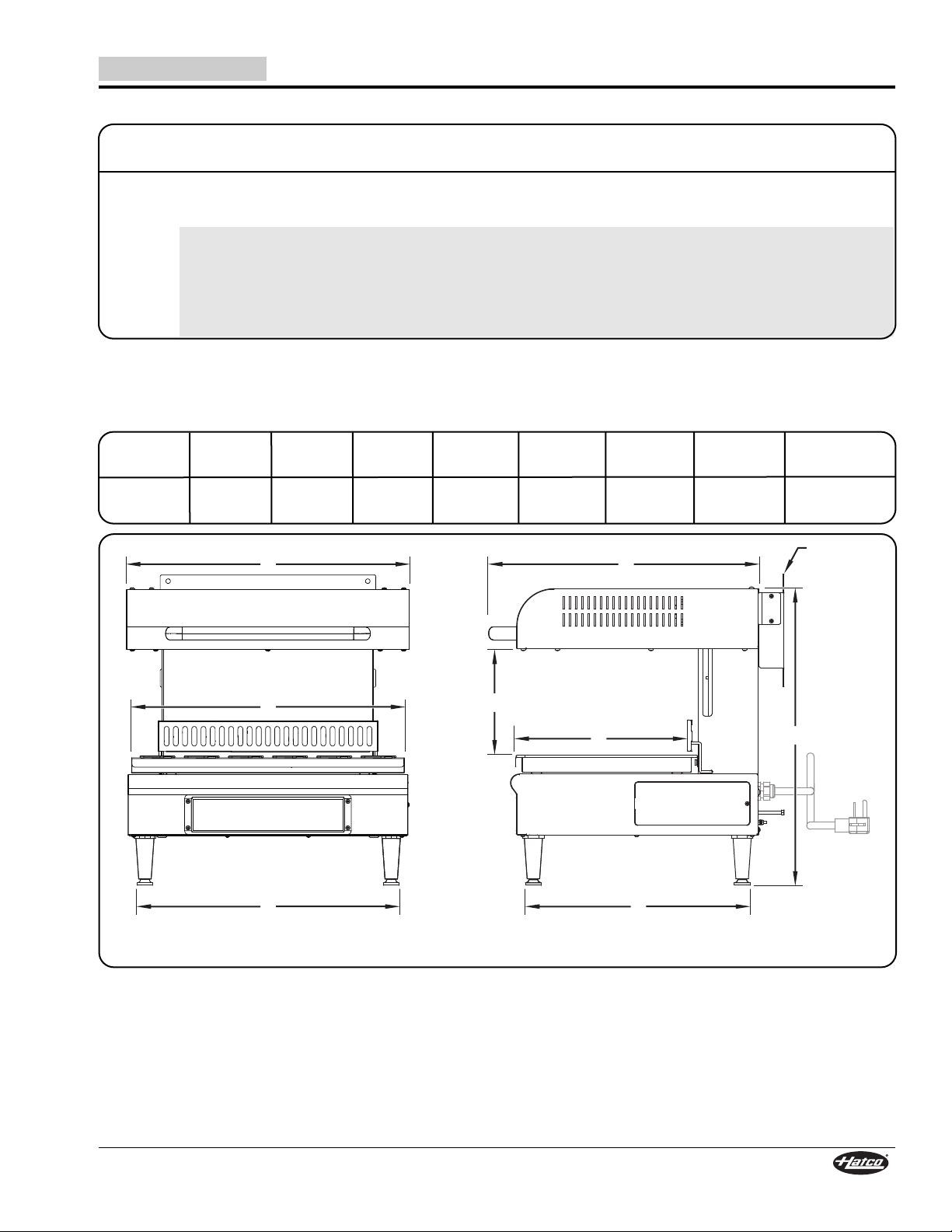

Front View Side View

A

FFF

D E

G

C

Wall

Bracket

H

B

SPECIFICATIONS

Electrical Rating Chart

Model Voltage Watts Amps Phase Hertz PlugConfiguration Unit Weight

Shipping

Weight

SAL-1

230/400Y 4500 6.5 3 50/60 Hardwired 113 lbs. (52 kg) 144 lbs. (65 kg)

230/400Y 4133 5.7 3 50/60 Hardwired 113 lbs. (52 kg) 144 lbs. (65 kg)

Dimensions

odel

M

L-1

SA

208 4500 21.6 1 50/60 NEMA 6-30P or Hardwired 113 lbs. (52 kg) 144 lbs. (65 kg)

240 4500 18.8 1 50/60 NEMA 6-30P or Hardwired 113 lbs. (52 kg) 144 lbs. (65 kg)

230 4500 19.6 1 50/60 Hardwired 113 lbs. (52 kg) 144 lbs. (65 kg)

230 4133 17.2 1 50/60 Hardwired 113 lbs. (52 kg) 144 lbs. (65 kg)

Width

(A)

22-11/16″

m

(576 m

)

Depth

(B)*

22-11/16″

m

(576 m

)

Height

(C)

23-13/16″

m

(603 m

)

Footprint

Width (D)

20-1/2″

m

(520 m

)

Footprint

Depth (E

17-1/2″

m

(443 m

)

)

Cooking

Width (F)

21-7/8″

m

(556 m

)

Cooking

Depth (G

13-3/4″

m

(350 m

)

Cooking

Height (H)

)

to 8-1/2″

4″

(102 to 216 m

)

m

* Add 2-1/16″ (51 mm) to Depth (B) for wall-mounted units.

Form No. SALM-0915

5

INSTALLATION

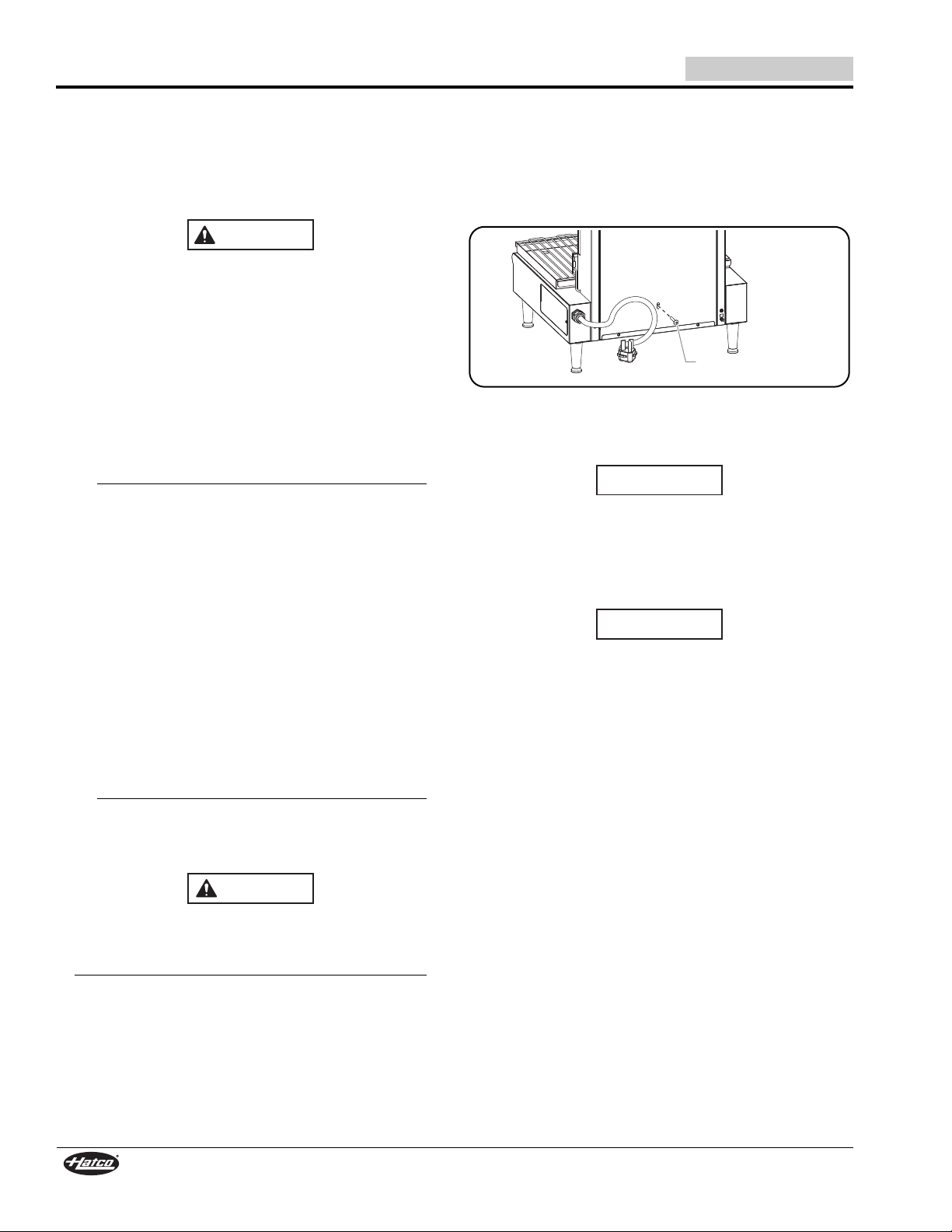

WARNING

CAUTION

Transport Locking

Screw

NOTICE

NOTICE

English

General

Hatco Salamanders are shipped with most components preassembled. Care should be taken when unpacking the shipping

carton to avoid damage to the unit and the components enclosed.

The salamander can be placed on a countertop or mounted to

an appropriate wall surface. The following installation instructions

must be performed before operating the salamander.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install the proper voltage

and size electrical receptacle.

• Unit must be installed by a qualified electrician.

Installation must conform to all local electrical codes.

Installation by unqualified personnel will void unit

warranty and may lead to electric shock or burn, as well

as damage to unit and/or its surroundings.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C)

and a maximum of 113°F (45°C).

FIRE HAZARD:

• To reduce the risk of fire, the appliance is to be installed

in non-combustible surroundings only, with no

combustible material within 18″ (46 cm) of the sides,

front, or rear of the appliance or within 40″ (102 cm)

above the appliance. The appliance is to be mounted on

floors of non-combustible construction with noncombustible flooring and surface finish and with no

combustible material against the underside, or on noncombustible slabs or arches that have no combustible

material against the underside. Such construction shall

in all cases extend not less than 12″ (30 cm) beyond the

equipment on all sides.

• Locate unit a minimum of 2″ (51 mm) from any walls. If

safe distances are not maintained, discoloration or

combustion could occur.

• Do not obstruct air intake openings or air exhaust

openings on outer housing of unit. Unit combustion or

malfunction may occur.

For wall mounting, use special wall mount bracket provided

with unit only. Secure wall mount bracket to a solid, noncombustible surface using appropriate hardware for

mounting surface and weight of unit.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent unit

or its contents from falling accidentally and strong enough

to support the weight of the unit and contents.

Do not place anything on top of unit; doing so may subject

personnel to injury or damage unit.

NOTE: A qualified person must check possible placements of

the salamander to ensure that the proper electrical

supply line is available.

1. Remove the unit from the shipping carton.

NOTE: To prevent delay in obtaining warranty coverage, complete

online warranty registration. See the IMPORTANT

OWNER INFORMATION section for details.

2. Remove tape and protective packaging from all surfaces

of unit.

3. Clean the unit thoroughly to remove all protective industrial

grease. NOTICE: Use non-abrasive cleaners and cloths

only.

4. Remove the transport locking screw used to secure the

upper housing during shipping. Discard the screw.

Transport Locking Screw

NOTE: Do not plug in or hardwire the unit until either

countertop installation or wall mounting is complete.

Do not install unit above grills, fryers, or other appliances

that will expose unit to high temperature, excessive

moisture, or grease-laden air. Improper installation will void

warranty.

5. For wall mounting, refer to the “Installing a Wall-Mounted

Unit” procedure in this section.

Do not lay unit on the side with the control panel or damage

to unit could occur.

6. For countertop installation, install the 4″ legs.

NOTE: Additional help may be needed to maneuver the unit to

the proper position for installing legs.

a. Carefully position the unit with the control panel facing

up.

b. Attach the four legs by turning the legs clockwise into

one of the threaded holes in each of the four corners on

the bottom of the unit. Tighten the legs securely.

c. Return the unit to the upright position.

7. Place the unit in the desired location.

• Locate the unit directly underneath an exhaust hood if

possible. This will ensure total suction of steam produced

during cooking.

• Make sure the unit is installed where the ambient air

temperature will not rise above 113°F (45°C) and where

it will not be exposed to excessive moisture or greaseladen air.

• Make sure the unit is at the proper height in an area

convenient for use.

• Make sure the countertop is level and strong enough to

support the weight of the unit and food product.

• Make sure all the feet on the bottom of the unit are

positioned securely on the countertop with a minimum of

2″ (51 mm) between the unit and any wall.

6

Form No. SALM-0915

English

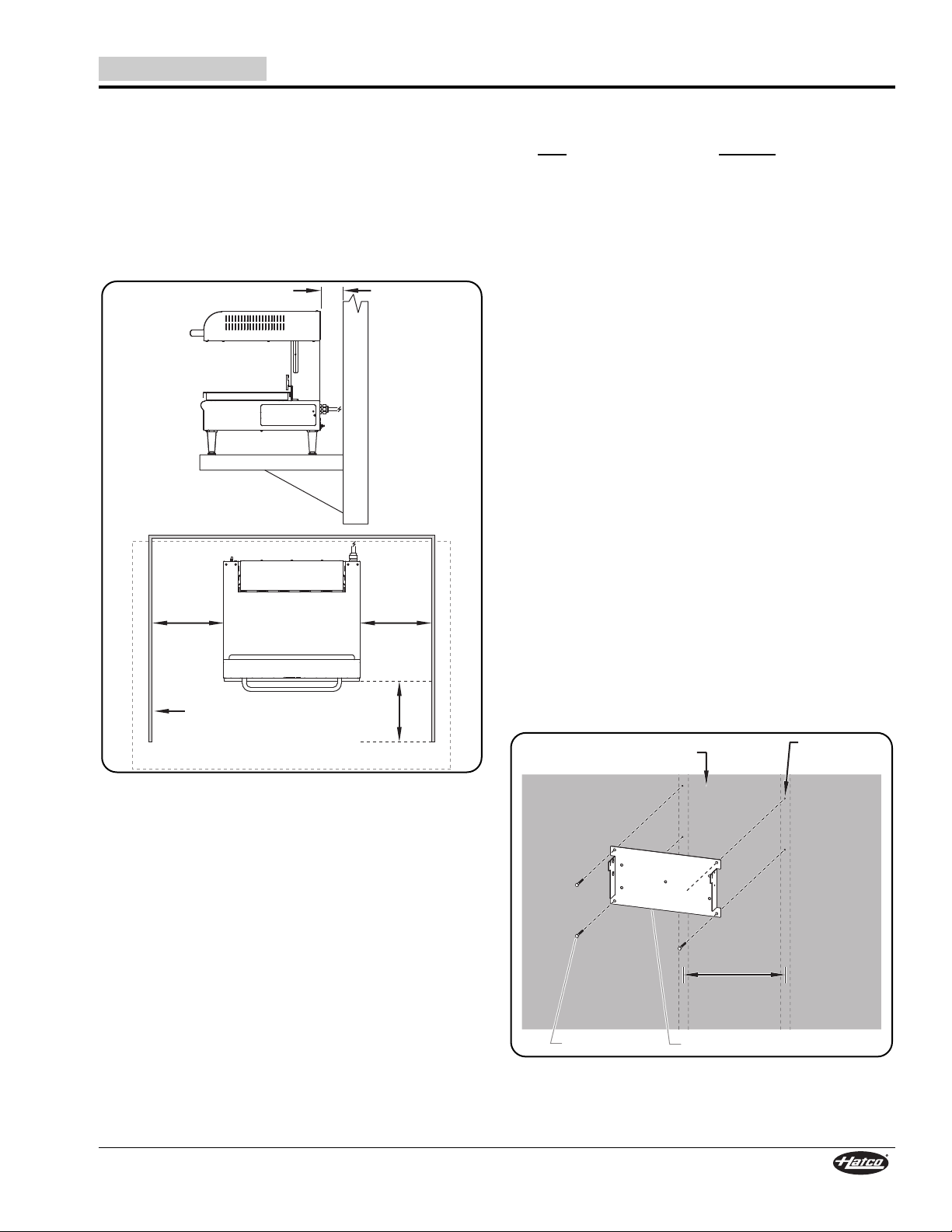

Wall

Countertop

2″ (51 mm)

18"

(46 cm)

18"

(46 cm)

12"

(30 cm)

Non-Combustible

Construction

Top View

1/2″ (13 mm) Sheathing

Wall Bracket

3/16″ (5 mm)

Pilot Holes

Lag Screw

2x4 Wood

Studs 16″

(406 mm)

On Center

2x4 Wood

Studs 16″

(406 mm)

On Center

INSTALLATION

8. Level the unit by turning the leveling feet on each leg, if

necessary.

9. Install the drip tray and cooking grate.

10. For corded units, plug the unit into a properly grounded

electrical receptacle of the correct voltage, size, and plug

configuration. See the SPECIFICATIONS section for details.

11. For non-corded units, have a qualified electrician install a

hardwired connection between the unit and the on-site

electrical system (refer to “Hardwired Connection” in this

section for additional information).

Parts Included

The following parts are included with wall-mounted units.

Item

Quantity

Wall Bracket 1

Mounting Clip 2

1/4″ x 2-1/2″ (6 x 64 mm)

Lag Screw 4

Hex Screw 4

Installation Procedure

Use the following procedure to install a wall-mounted unit.

1. Make sure the mounting location meets the requirements

listed previously in this procedure.

2. Determine the height for the unit installation.

• Mark the wall at the desired height for the top of the unit.

NOTE: The top of the wall bracket is approximately 1-1/2″

(38 mm) inches above the top of the unit after

installation.

3. Locate the wood stud positions in the wall.

• Determine which studs to use for installation. The studs

used must allow the wall bracket to be installed with the

mounting holes a distance of 16″ (406 mm) on center

from each other.

4. Install the wall bracket onto the wall.

a. Center and level the wall bracket on the desired studs.

Mark the locations for the four lag screws through the

holes in each side of the bracket.

b. Drill four 3/16″ (5 mm) pilot holes in the wall at each

marked location for the lag screws. The lag screws are

1/4″ (6 mm) in diameter and 2-1/2″ (64 mm) long.

c. Insert four lag screws through the wall bracket and into

the pre-drilled pilot holes in the wall.

d. Tighten each lag screw securely.

Installing a Wall-Mounted Unit

Mounting the unit on a wall requires special considerations and

procedures due to the weight of the unit. Follow the guidelines

below when determining the location for wall mounting as well

as during installation.

• The wall brackets must be fastened to a wall with 16″

(406 mm) on center, solid wood 2x4 stud construction

covered by a minimum of 1/2″ (13 mm) thick sheathing.

• The wall bracket must be installed with four 1/4″ x 2-1/2″

(6 x 64 mm) lag screws that solidly hit the wood studs in

the wall.

• Locate the unit directly underneath an exhaust hood if

possible. This will ensure total suction of steam produced

during cooking.

• Make sure the unit is installed where the ambient air

temperature will not rise above 113°F (45°C) and where it will

not be exposed to excessive moisture or grease-laden air.

• Make sure the unit is at the proper height in an area

convenient for use.

Form No. SALM-0915

Minimum Distance Requirement

Attaching the Wall Bracket

continued...

7

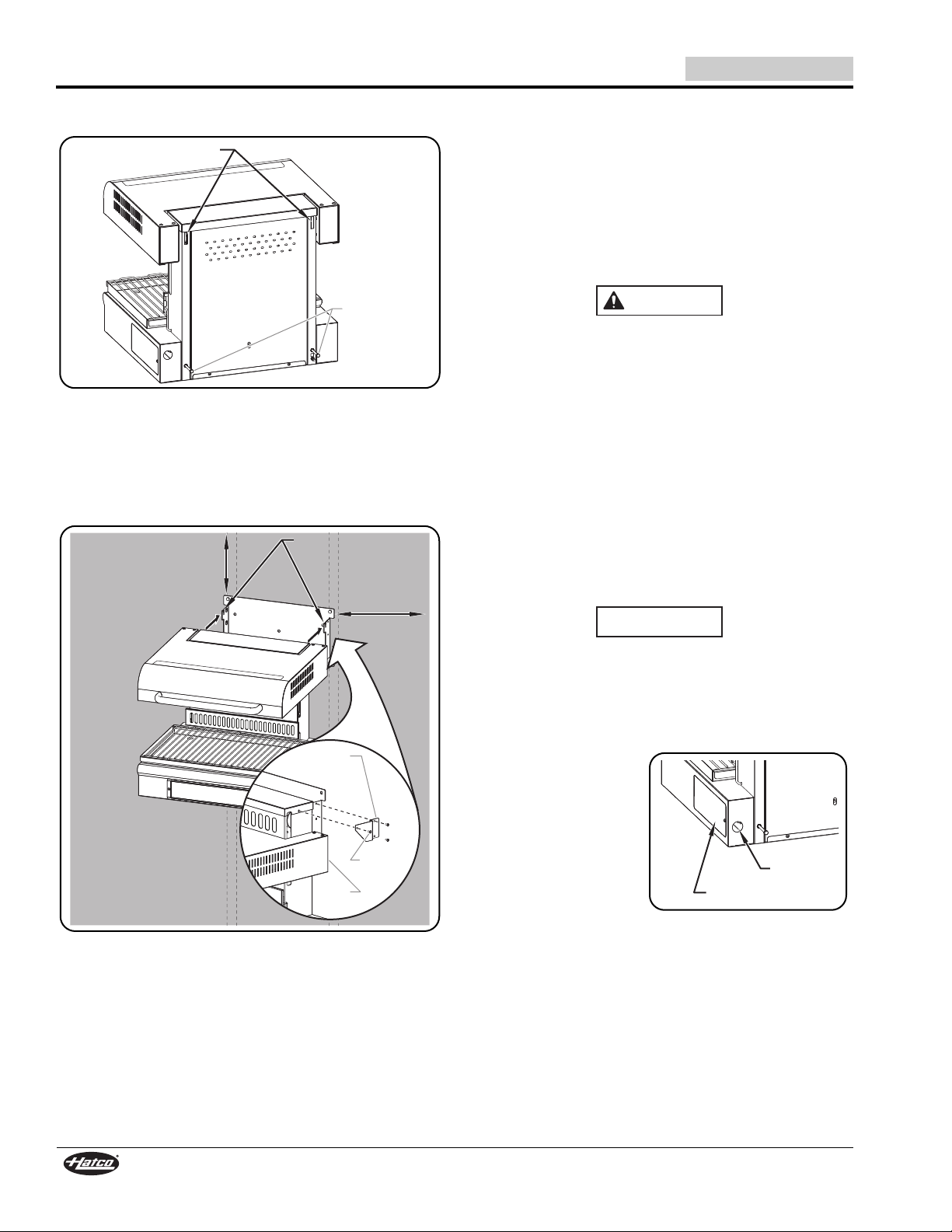

INSTALLATION

Leveling

Studs

Mounting Slots

Upper

Housing

Upper

Housing

Existing

Screw

Bracket

Hooks

Bracket

Hooks

Right

Mounting

Clip

No surfaces

within 18″

(46 cm)

of either side.

No surfaces within 40″

(102 cm)

No surfaces

within 18″

(46 cm)

of either side.

No surfaces within 40″

(102 cm)

NOTICE

Power Inlet

Access Panel

WARNING

English

5. Install the two leveling studs (included with unit) into the

two threaded holes on the back of the unit.

Mounting Slots on Back of Unit

6. Lift the unit, and align the mounting slots on the back of the

unit with the hooks on the wall bracket. Set the unit securely

on the hooks. This step will require at least two people.

7. Check that the unit is level from front to back. Adjust the

level by turning the leveling studs on the back of the unit,

if necessary.

9. Install the drip tray and cooking grate.

10. For corded units, plug the unit into a properly grounded

electrical receptacle of the correct voltage, size, and plug

configuration. See the SPECIFICATIONS section for details.

11. For non-corded units, have a qualified electrician install a

hardwired connection between the unit and the on-site

electrical system (refer to “Hardwired Connection” in this

section for additional information).

Hardwired Connection

Hatco Salamanders can be hardwired to the electrical supply.

ELECTRIC SHOCK HAZARD:

• Units supplied without an electrical cord and plug

require a hardwired connection to on-site electrical

system. Connection must be properly grounded and of

correct voltage, size, and configuration for electrical

specifications of unit. Contact a qualified electrician to

determine and install proper electrical connection.

• Unit must be installed by a qualified electrician.

Installation must conform to all local electrical codes.

Installation by unqualified personnel will void unit

warranty and may lead to electric shock or burn, as well

as damage to unit and/or its surroundings.

• When installing a hardwired unit, a disconnect switch

must be installed between unit and main electrical

supply. The switch must be rated properly and have

contacts with a minimum opening distance of 1/8″

(3 mm).

8. Install the mounting clips onto the back of the unit to secure

the unit to the wall bracket. There is a right clip and a left clip.

a. Move the upper housing down to expose the screw on

each side of the unit that will be used to attach the

mounting clips. Remove the screws.

b. Using the correct mounting clip on each side of the unit:

i. Attach the angled edge of the mounting clip to the

unit using the removed screw.

ii. Attach the straight edge of the mounting clip to the

wall bracket using the screws provided.

Hanging the Unit

Make sure electrical supply matches voltage and frequency

rating on specification label. Incorrect electrical supply

may damage unit.

NOTE: The specification label is located on the side of the unit

8

near the power inlet. See the label for verification of unit

electrical information.

1. Remove the access

panel to expose the

power inlet area of the

unit. It is located on the

right rear side of the unit

when facing the controls.

2. Locate the terminal block

inside the unit.

3. Bring power leads from a

properly sized circuit

breaker or disconnect switch through the power inlet on the

unit.

4. Make the appropriate connections.

• Use copper wire only.

• Tighten connections to a minimum of 40 inch pounds

(4.25 newton meters).

• A grounding screw is provided near the electrical

terminals. An equipment grounding conductor must be

properly connected to it.

5. Replace and secure the access panel.

Form No. SALM-0915

English

WARNING

NOTICE

E

L

E

M

E

N

T

S

E

L

E

C

T

O

R

R

E

F

E

R

T

O

O

P

E

R

A

T

O

R

’

S

M

A

N

U

A

L

F

O

R

M

O

R

E

I

N

F

O

R

M

A

T

I

O

N

Upper

Housing

Cooking

Grate

Control

Panel

Plate

Detection

Bar

Drip

Tray

ELEMENT SELECTOR

ON (I)/STANDBY Key COOK/HOLD Key

START/STOP Key

Display

SET Slider Key

ELEMENT

SELECTOR

Keys

20:00

OPERATION

General

Hatco Salamanders are designed with two main functions,

COOK and HOLD. The COOK function uses the full intensity of

the overhead, “instant on” heating elements to cook food. The

HOLD function activates only the two outside overhead heating

elements at a lower intensity to maintain the temperature

reached during the cooking cycle.

Use the following information and procedures to operate Hatco

Salamanders.

Read all safety messages in the IMPORTANT SAFETY

INFORMATION section before operating this equipment.

Do not operate unit without drip tray and cooking grate

installed. Damage to unit could occur.

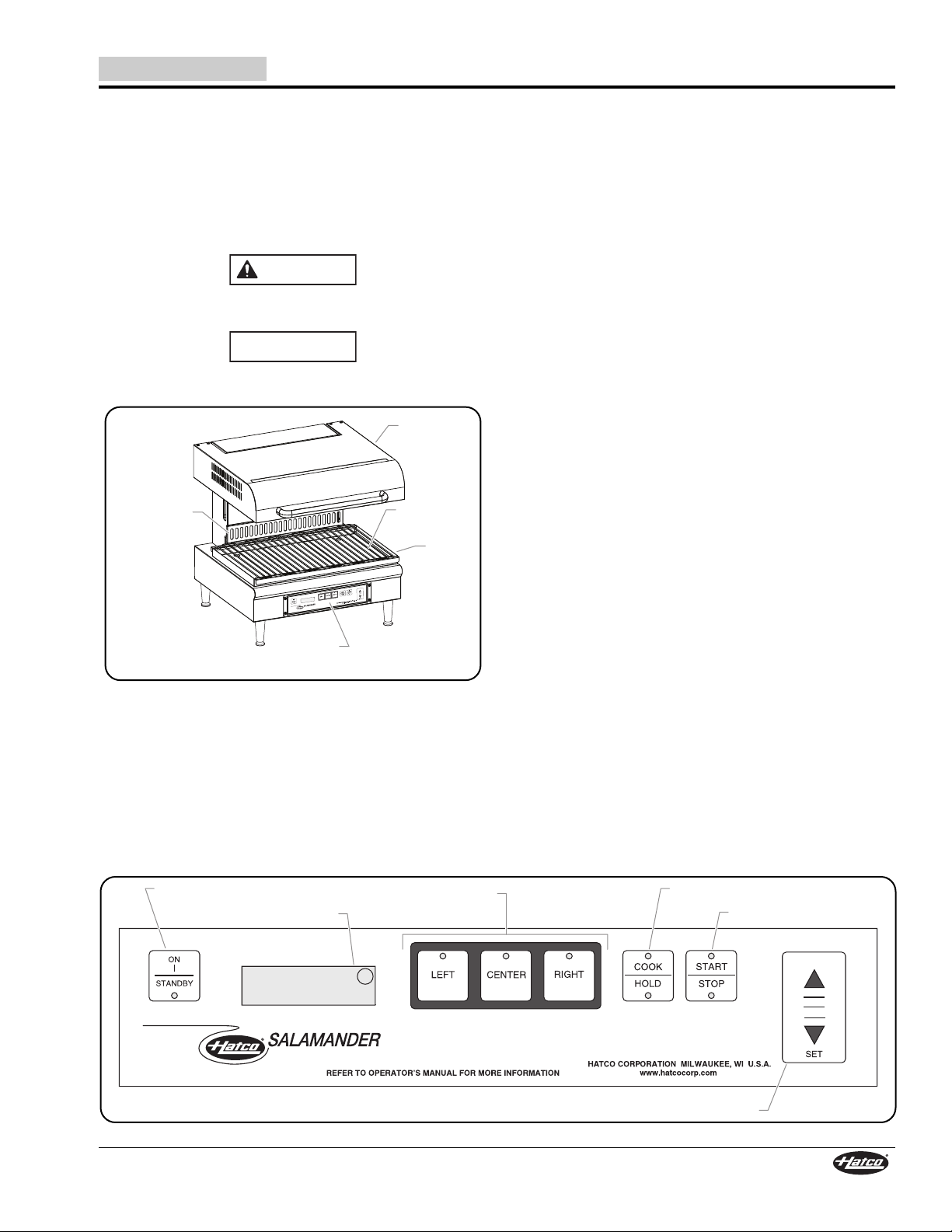

Components

Control Panel

The following are descriptions of the controls used to operate

Hatco Salamanders. All controls are located on the control

panel at the front of the unit.

ON (I)/STANDBY Key

The ON (I)/STANDBYkey controls the power to the unit. Touching

the ON (I)/STANDBY key toggles the unit between “On” and

“Standby” (off). When the unit is in Standby, the indicator light is

illuminated. When the unit is On, the indicator light is off.

ELEMENT SELECTOR Keys

The ELEMENT SELECTOR keys control the operation of each

of the three overhead heating elements. Touching the LEFT,

CENTER, or RIGHT ELEMENT SELECTOR key toggles the

corresponding element between “On” and “Off”. Each key has

an indicator light that illuminates when the corresponding

element is activated.

COOK/HOLD Key

The COOK/HOLD key determines the function of the

salamander. Touching the COOK/HOLD key toggles the

salamander between the COOK function and the HOLD

function. Each function has an indicator light that illuminates

when the corresponding function is active.

START/STOP Key

The START/STOP key controls the cycle of the COOK and HOLD

functions. Touching the START/STOP key will either start or stop

a COOK or HOLD cycle. Each operating mode has an indicator

light that illuminates when the corresponding mode is active.

SET Slider Key

The function of the SET slider key is determined by which

function is selected by the COOK/HOLD key. When the COOK

function is active, the SET slider key is used to set the timer for

the desired cook time. When the HOLD function is active, the

SET slider key is used to select the desired holding temperature

from one of eight (8) preset temperature levels. The SETslider

key can be operated in two ways, touching or sliding:

Touching: Touching the Up Arrow increases the timer setting

or selects a higher temperature setting. Touching the

Down Arrow decreases the timer setting or selects a

lower temperature setting.

Sliding: Sliding a finger from the bottom to the top of the SET

slider key increases the timer setting or selects a

higher temperature setting. Sliding a finger from the

top to the bottom of the SET slider key decreases the

timer setting or selects a lower temperature setting.

Display

The display shows the timer settings or temperature settings,

depending on the function selected by the COOK/HOLD key.

When a COOK or HOLD cycle is activated by the START/STOP

key, the settings will flash in the display.

Form No. SALM-0915

Salamander Control Panel

9

Loading...

Loading...