Page 1

Installation, Operating, Service and Parts Manual For:

Accessory Flue Gas Hood

Model: PMGH-60

I&W #07.05.054.00

WATER HEATERS FOR OTHER THAN RECREATIONAL VEHICLE

INST

ALLATION ONLY

CHAUFFE-EAU POUR INSTALLATION AUTRE QUE DANS DES VÉHICULES DE

LOISIR UNIQUEMENT

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHA

T TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

• Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING: If the information in these

instructions is not followed exactly, a

fire or explosion may result causing

property damage, personal injury or

death.

AVERTISSEMENT: Assurez-vous de

bien suivre les instructions données

dans cette notice pour réduire au

minimum le risque d’incendie ou

d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la

mort.

Ne pas entreposer ni utiliser d’essence

ou ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

QUE F

AIRE SI VOUS SENTEZ UNE

ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucun interrupteur; ne

pas vous servir des téléphones se

trouvant dans le bâtiment.

• Appelez immediatement votre

fournisseur de gaz depuis un voisin.

Suivex les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le

fournisseur, appelez le service des

incendies.

• L’installation et l’entretien doivent être

assurés par un installateur ou un

service d’entretien qualifié ou par le

fournisseur de gaz.

Page 2

Form No. PMGH-60M-0405

i

CONTENTS

INTRODUCTION

The PMGH-60 Accessory Flue Hood is designed to

re-direct flue gas exiting the PMG-60 Gas Booster

Heater away from the unit and to a location behind

the dishtable or to a nearby exhaust hood.

The Hatco Accessory Hood is design certified for

use in conjunction with the PMG-60 Booster Water

Heater by the American Gas Association and tested

under the requirements of the American National

Standard ANSI Z21.10.3 - CSA 4.3, Current

Edition.

Hatco Gas Booster Heater Accessories are quality

built for long life and rugged dependability.

Dependability of the booster heater is preserved

through proper, safe installation and operation. We

recommend all installation, operating instructions

and safety precautions appearing in this manual be

read prior to installation and operation of the Hatco

Gas Booster Heater.

This manual provides the installation, safety and

operating instructions for the Powermite Gas

Booster Heater. We recommend all installation,

operating and safety instructions appearing in this

manual be read prior to installation or operation of

your Hatco PMG-60. Safety instructions that appear

in this manual after a warning symbol and the

words WARNING or CAUTION printed in bold face

are very important. WARNING means there is the

possibility of serious personal injury or death to

yourself or others. CAUTION means there is the

possibility of minor or moderate injury. CAUTION

without the symbol signifies the possibility of

equipment or property damage only.

Hatco Accessory Flue Hoods are a product of

extensive research and field testing. The materials

used were selected for maximum durability,

attractive appearance and optimum performance.

Every unit is thoroughly inspected and tested prior

to shipment.

Important Owner Information........................................i

Introduction ....................................................................i

Model Description.........................................................1

All Models................................................................1

Specifications................................................................2

Dimensions..............................................................2

Installation .....................................................................3

General....................................................................3

Electric.....................................................................4

Maintenance ..................................................................4

General....................................................................4

Wiring Diagram..............................................................4

Hatco Limited Warranty................................................5

Authorized Parts Distributors.....................Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number

(identification plate located on the lower right hand

side, front corner of the unit), voltage and purchase

date of your PMGH-60 Accessory Flue Hood in the

spaces below. Please have this information

available when calling Hatco for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.D.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.D.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts & Service)

(414) 671-3976 (International)

Additional information can be found by visiting our

web site at www.hatcocorp.com

24-Hour 7-Day Parts & Service

Assistance available in the United

States and Canada by calling

(800) 558-0607.

Page 3

Form No. PMGH-60M-0405

1

MODEL DESCRIPTION

ALL MODELS

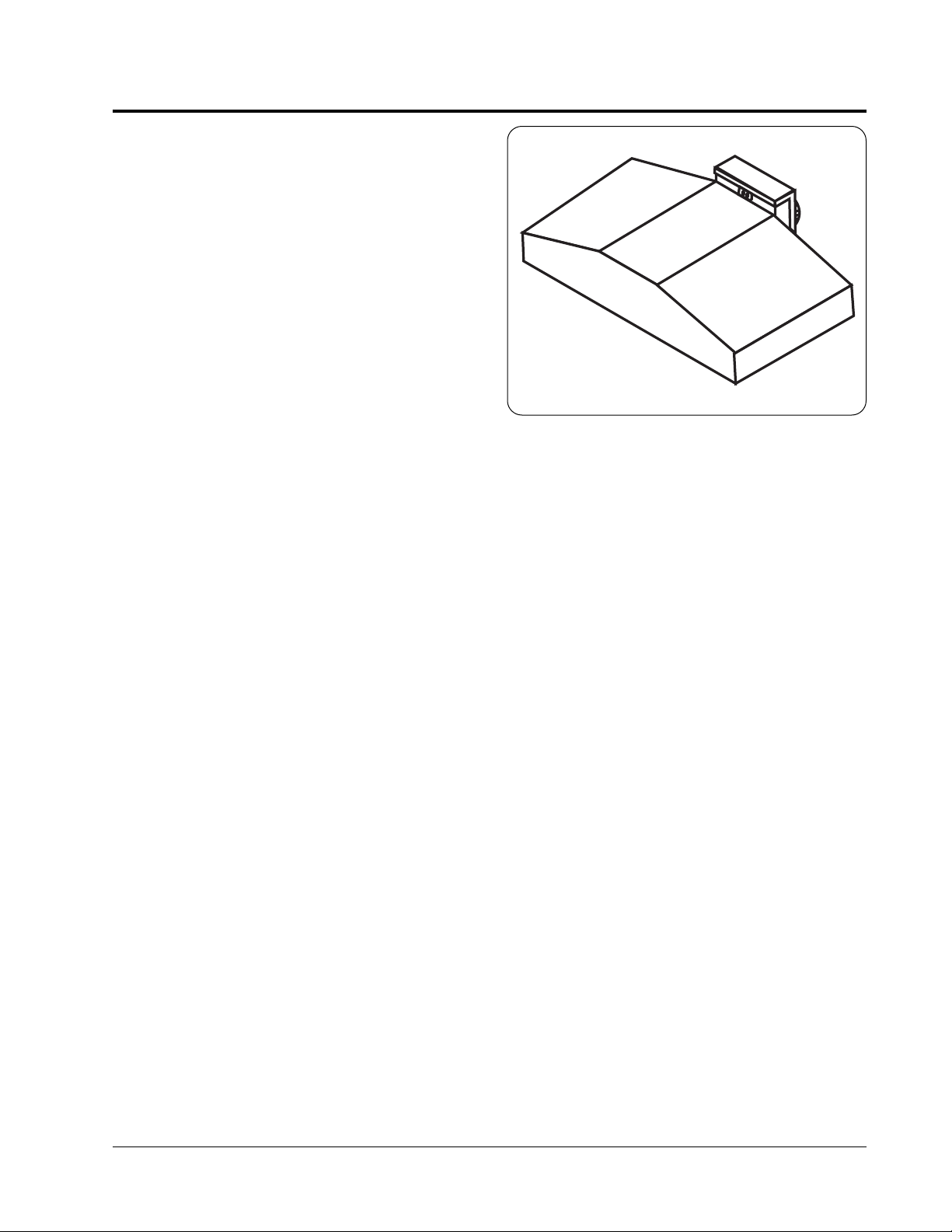

The Flue Gas Diverter Hood is designed to sit

directly on top of the PMG-60 Booster Water Heater .

It will collect the flue gases that exit the PMG-60 unit

and direct them through a 4" (102 mm) diameter

pipe to a location within the same room up to 20

linear feet (6 m) away from the unit.

NOTE: One elbow equals 5 linear feet (1.5 m).

All Hatco booster heater accessories are warranted

to be free of defects in material and workmanship

under normal use and service, and when installed in

accordance with factory recommendations.

NOTE: Hatco Booster Water Heaters are approved

for use with commercial dishwashers only.

Figure 1. Model PMGH-60

Page 4

Form No. PMGH-60M-0405

2

SPECIFICATIONS

DIMENSIONS

Figure 2. Dimensional Drawings

4-5/8"

(118 mm)

4"

(102 mm)

13-1/4"

(337 mm)

6-7/8"

(175 mm)

24-3/8"

(619 mm)

7/8" KO HOLE

4" (102 MM) DIA. FLUE

ADAPTOR

Type: Accessory Hood Exhaust Fan.

Power: Supply 120 VAC, 18 watt, 1 amp.

Dimensions: 24-3/8" wide, 15-1/2" deep, 6-7/8" high (619 x 394 x 175 mm).

Adding 5-7/8" (149 mm) to height and 4" (102 mm) to width.

Weight: 10 pounds (5 kg).

Page 5

Form No. PMGH-60M-0405

3

INSTALLATION

GENERAL

Code Requirements

Installation must be in accordance with local codes,

or in the absence of local codes, with the latest

edition of the National Fuel Gas Code, ANSI Z223.1,

(a portion of the 1996 code relating to ventilation is

excerpted in Figure 3) the National Electrical Code,

ANSI/NFPA 70. Canadian installations should

conform with CSA-B149.1, Natural Gas and

Propane Installation Code, and CSA-C22.1,

Electrical code, and/or local installation codes. {Les

installations canadiennes doivent se conformer aux

CODES D’INSTALLATION CSA-B149.1, Natural

Gas and Propane Installation Code, et CSA-C22.1,

Electrical Code, et/ou aux codes locaux

d’installation.}

1. Place the unit (with the 4" [102 mm] diameter flue

adapter facing toward the rear) directly on top of

the Hatco PMG-60 Gas Booster Heater, nesting

the assembly with the brackets inside of the

Auxiliary Hood.

2. Connect 4" (102 mm) diameter flue pipe to the

adapter to direct the flue gas up to 20 linear feet

(6 meters) away from the unit.

NOTE: Each elbow equals 5 linear feet (1.5 m).

3. Terminate the flue pipe at a location that will not

become obstructed, so that it will not exhaust

directly toward any combustibles.

EXCERPT FROM ANSIZ223.1/NFPA #54

7.2.1 Connection To Venting Systems. Excerpt as

permitted in 7.2.2 through 7.2.6, all gas utilization

equipment shall be connected to venting systems.

7.2.2 Equipment Not Required To Be Vented.

A single booster-type [automatic instantaneous] water

heater, when designed and used solely for the

sanitizing rinse requirements of a dishwashing

machine, provided that the equipment is installed, with

the draft hood in place and unaltered, if a draft hood is

required in a commercial kitchen having a mechanical

exhaust system. Where installed in this manner, the

draft hood shall not be less than 36 inches (914 mm)

vertically and 6 inches (152 mm) horizontally from any

surface other than the equipment.

Where any or all of this equipment is installed so the

aggregate input rating exceeds 20 Btu per hour per

cubic foot (207 watts per m

3

) of room space in which it

is installed, one or more shall be provided with venting

systems or other approved means for removing the

vent gases to the outside atmosphere so the aggregate

input rating of the remaining unvented equipment does

not exceed the 20 Btu per hour per cubic foot (207

watts per m

3

) figure. Where the room or space in which

the equipment is installed is directly connected to

another room or space by a doorway, archway or other

opening of comparable size that cannot be closed, the

volume of adjacent room or space shall be permitted to

be included in the calculation.

WARNING

The flow of air to the heater for combustion and

ventilation must not be obstructed. Air vents on

the bottom and side of the unit should never

be blocked.

WARNING

Flue gases exit top sides of this unit and must

not be obstructed, specified clearances must

be maintained for safe operation.

WARNING

DO NOT VENT THIS UNIT OUTDOORS. This

unit is designed to vent directly into the room

and is intended for commercial food service

water heating only. IT IS NOT FOR

RESIDENTIAL USE.

Figure 3. National Fuel Gas Code

WARNING

If an external electrical source is utilized, the

appliance, when installed, must be electrically

grounded in accordance with local codes, or,

in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, CSA C22.1,

Electrical Code.

COMPONENTS

The Hatco Gas Booster Heater Exhaust Hood

operates on 120 VAC, 60 Hz, 15 amp, single phase

service. All internal electrical connections have been

made at the factory.

ELECTRICAL CONNECTIONS

To connect the field wiring to the booster hood:

1. Remove the exhaust outlet cover to expose the

wiring compartment.

2. Connect the power supply leads to the pigtails

provided.

3. Replace the exhaust cover.

Page 6

Form No. PMGH-60M-0405

4

MAINTENANCE

WARNING

Always disconnect the power and shut off gas

supply prior to performing any maintenance on

the booster heater to avoid possible personal

injury or damage to the booster heater.

WARNING

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

WARNING

If service is required on this unit, contact your

Authorized Hatco Service Agent, or contact the

Hatco Service Department at 800-558-0607 or

414-671-6350; fax 800-690-2966 or International

fax 414-671-3976.

WARNING

This product has no “user” serviceable parts.

To avoid damage to the unit or injury to

personnel, use only Authorized Hatco Service

Agents and Genuine Hatco Replacement Parts

when service is required.

WARNING

Genuine Hatco Replacement Parts are

specified to operate safely in the environments

in which they are used. Some aftermarket or

generic replacement parts do not have the

characteristics that will allow them to operate

safely in Hatco equipment. It is essential to use

Hatco Replacement Parts when repairing Hatco

equipment. Failure to use Hatco Replacement

Parts may subject operators of the equipment

to hazardous electrical voltage, resulting in

electrical shock or burn.

GENERAL

Inspect the fan monthly to make sure it is operating

freely and is free of lint and dirt.

Figure 4. Replacement Parts

WIRING DIAGRAM

FAN 02.12.001.00

SWITCH 02.19.080.00

Page 7

Form No. PMGH-60M-0405

5

HATCO LIMITED WARRANTY

1. PRODUCT WARRANTY

Hatco warrants the products that it manufactures

(the “Products”) to be free from defects in

materials and workmanship, under normal

use and service, for a period of one (1) year from

the date of purchase when installed and

maintained in accordance with Hatco’s written

instructions or 18 months from the date of

shipment from Hatco. Buyer must establish the

product’s purchase date by returning Hatco’s

Warranty Registration Card or by other means

satisfactory to Hatco in its sole discretion.

Hatco warrants the following Product components

to be free from defects in materials and

workmanship from the date of purchase (subject

to the foregoing conditions) for the period(s) of

time and on the conditions listed below:

a) One (1) Year Parts and Labor PLUS One

(1) Additional Year Parts-Only Warranty:

Toaster Elements (metal sheathed)

Drawer Warmer Elements (metal sheathed)

Drawer Warmer Drawer Rollers and Slides

Food Warmer Elements (metal sheathed)

Display Warmer Elements (met al sheathed

air heating)

Holding Cabinet Elements (metal sheathed

air heating)

b) One (1) Year Parts and Labor PLUS Four

(4) Years Parts-Only Warranty on

pro-rated terms that Hatco will explain

at Buyer’s request:

3CS and FR Tanks

c) One (1) Year Parts and Labor PLUS Nine

(9) Years Parts-Only Warranty on:

Electric Booster Heater Tanks

Gas Booster Heater Tanks

THE FOREGOING WARRANTIES ARE

EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE

OR PATENT OR OTHER INTELLECTUAL

PROPERTY RIGHT INFRINGEMENT. Without

limiting the generality of the foregoing, SUCH

WARRANTIES DO NOT COVER: Coated

incandescent light bulbs, fluorescent lights, lamp

warmer heat bulbs, glass components, Product

failure in booster tank, fin tube heat exchanger, or

other water heating equipment, caused

by liming, sediment buildup, chemical attack or

freezing, Product misuse, tampering or

misapplication, improper installation or application of

improper voltage.

2. LIMITATION OF REMEDIES AND

DAMAGES

Hatco’s liability and Buyer’s exclusive remedy

hereunder will be limited solely, at Hatco’s option,

to repair or replacement by a Hatco-authorized

service agency (other than where Buyer is

located outside of the United States, Canada,

United Kingdom or Australia in which case

Hatco’s liability and Buyer’s exclusive remedy

hereunder will be limited solely to replacement of

part under warranty) with respect to any claim

made within the applicable warranty period

referred to above. Hatco reserves the right to

accept or reject any such claim in whole or in part.

Hatco will not accept the return of any Product

without prior written approval from Hatco, and all

such approved returns shall be made at Buyer’s

sole expense. HATCO WILL NOT BE LIABLE,

UNDER ANY CIRCUMSTANCES, FOR

CONSEQUENTIAL OR INCIDENTAL

DAMAGES, INCLUDING BUT NOT LIMITED TO

LABOR COSTS OR LOST PROFITS

RESUL TING FROM THE USE OF OR INABILITY

TO USE THE PRODUCTS OR FROM THE

PRODUCTS BEING INCORPORATED IN OR

BECOMING A COMPONENT OF ANY OTHER

PRODUCT OR GOODS.

Page 8

HATCO CORPORATION

P.O. Box 340500, Milwaukee, WI 53234-0500 U.S.A.

(800) 558-0607 (414) 671-6350

Parts & Service Fax (800) 690-2966 Int’l. Fax (414) 671-3976

www.hatcocorp.com

HATCO AUTHORIZED PARTS DISTRIBUTORS

Printed in U.S.A. April 2005

ALABAMA

Jones McLeod Appl. Svc.

Birmingham 205-251-0159

ARIZONA

Auth. Comm. Food Equip.

Phoenix 602-234-2443

Byassee Equipment Co.

Phoenix 602-252-0402

CALIFORNIA

Industrial Electric

Huntington Beach 714-379-7100

Chapman Appl. Service

San Diego 619-298-7106

P & D Appliance

S. San Francisco 650-635-1900

COLORADO

Hawkins Commercial Appliance

Englewood 303-781-5548

DELA

WARE

Food Equipment Service

Wilmington 302-996-9363

FLORIDA

Whaley Foodservice Repair

Jacksonville 904-725-7800

Universal Restaurant Services

Miami 305-593-5488

Nass Service Co., Inc.

Orlando 407-425-2681

B.G.S.I.

Pompano Beach 954-971-0456

Comm. Appliance Service

Tampa 813-663-0313

GEORGIA

TWC Services

Smyrna 770-438-9797

Heritage Service Group

Norcross 866-388-9837

Southeastern Rest. Svc.

Norcross 770-446-6177

HA

WAII

Burney’s Comm. Service, Inc.

Honolulu 808-848-1466

Food Equip Parts & Service

Honolulu 808-847-4871

ILLINOIS

Parts Town

Lombard 708-865-7278

Eichenauer Elec. Service

Decatur 217-429-4229

Midwest Elec. Appl. Service

Elmhurst 630-279-8000

Cone’s Repair Service

Moline 309-797-5323

INDIANA

GCS Service

Indianapolis 317-545-9655

IOW

A

Electric Motor Service Co.

Davenport 319-323-1823

Goodwin Tucker Group

Des Moines 515-262-9308

KENTUCKY

GCS Service

Louisville 502-367-1788

LOUISIANA

Chandlers Parts & Service

Baton Rouge 225-272-6620

MAR

YLAND

Electric Motor Service

Baltimore 410-467-8080

GCS Service

Silver Spring 301-585-7550

MASSACHUSETTS

Ace Service Co., Inc.

Needham 781-449-4220

MICHIGAN

Commercial Kitchen Service

Bay City 517-893-4561

Bildons Appliance Service

Detroit 248-478-3320

Midwest Food Equip. Service

Grandville 616-261-2000

MINNESOT

A

GCS Service

Minneapolis 612-546-4221

MISSOURI

General Parts

Kansas City 816-421-5400

Commercial Kitchen Services

St. Louis 314-890-0700

Kaemmerlen Parts & Service

St. Louis 314-535-2222

NEBRASKA

Anderson Electric

Omaha 402-341-1414

NEV

ADA

Burney’s Commercial

Las Vegas 702-736-0006

Hi. Tech Commercial Service

N. Las Vegas 702-649-4616

NEW JERSEY

Jay Hill Repair

Fairfield 973-575-9145

Service Plus

Flanders 973-691-6300

NEW

YORK

Acme American Repairs, Inc.

Brooklyn 718-456-6544

Alpro Service Co.

Brooklyn 718-386-2515

Appliance Installation

Buffalo 716-884-7425

Northern Parts Dist.

Plattsburgh 518-563-3200

J.B. Brady, Inc.

Syracuse 315-422-9271

NORTH CAROLINA

Authorized Appliance

Charlotte 704-377-4501

OHIO

Akron/Canton Comm. Svc. Inc.

Akron 330-753-6635

Certified Service Center

Cincinnati 513-772-6600

Commercial Parts and Service

Columbus 614-221-0057

Electrical Appl. Repair Service

Independence 216-459-8700

E. A. Wichman Co.

Toledo 419-385-9121

OKLAHOMA

Hagar Rest. Service, Inc.

Oklahoma City 405-235-2184

Krueger, Inc.

Oklahoma City 405-528-8883

OREGON

Bressie Electric Co.

Portland 503-231-7171

Ron’s Service, Inc.

Portland 503-624-0890

PENNSYL

VANIA

Elmer Schultz Services

Philadelphia 215-627-5401

FAST Comm. Appl. Service

Philadelphia 215-288-4800

GCS Service

Pittsburgh 412-787-1970

K & D Service Co.

Harrisburg 717-236-9039

Electric Repair Co.

Reading 610-376-5444

RHODE ISLAND

Marshall Electric Co.

Providence 401-331-1163

SOUTH CAROLINA

Whaley Foodservice Repair

W. Columbia 803-791-4420

TENNESSEE

Camp Electric

Memphis 901-527-7543

TEXAS

Stove Parts Supply

Fort Worth 817-831-0381

Armstrong Repair Service

Houston 713-666-7100

Commercial Kitchen Repair Co.

San Antonio 210-735-2811

UT

AH

La Monica’s Rest. Equip. Service

Murray 801-263-3221

VIRGINIA

Daubers

Norfolk 757-855-4097

Daubers

Springfield 703-866-3600

W

ASHINGTON

Restaurant Appl. Service

Seattle 206-524-8200

WISCONSIN

A.S.C., Inc.

Madison 608-246-3160

A.S.C., Inc.

Milwaukee 414-543-6460

CANADA

BRITISH COLUMBIA

Key Food Equipment Service

Vancouver 604-433-4484

MANIT

OBA

Denko Mechanical Ltd.

Winnipeg 204-233-8003

ONT

ARIO

R.G. Henderson Ltd.

Toronto 416-422-5580

Choquette CKS

Ottawa 613-739-8458

QUÉBEC

Choquette CKS

Montreal 514-722-2000

Choquette CKS

Québec City 418-681-3944

Part No. 07.04.243.00 Form No. PMGH-60M-0405

Loading...

Loading...