Page 1

PMG Spec sheet only (Je D) May 2015

Powermite® Gas Booster

Water Heaters

Model: PMG-100, -200

Project

Item #

Quantity

The Hatco Powermite® Gas Booster Water Heater

provides 180°F (82°C) sanitizing hot water and long life

dependability. Designed to t under the dishtable, near

the dishwasher, to minimize the heat loss that can occur

when heaters are installed in a remote location. They can

operate on either natural or propane gas and feature a

burner system that utilizes both primary and secondary

air for consistent ignition.

Standard features

• Stainless steel tanks

• Stainless steel front and top, with powdercoat sides and back

(stainless steel body available)

• Finned tube copper heat exchanger

• Spark to light with standing pilot

• Three tube type burners in the PMG-100, six tube type burners

in the PMG-200

• Temperature/pressure relief valve

• Pressure reducing valve

• Two temperature/pressure gauges

• Low-water cut-off

• Blended phosphate water treatment system

• Shock absorber

PMG-100

PMG-200

Options

c

Stainless steel body and base

c

Security package (Torx® screws and control cover)

(available at time of purchase only)

Accessories

c

Brass Pressure Reducing Valve

c

Stainless steel floor mounting leg assembly

c

6"-7" (152-178 mm) Adjustable Stainless Steel Legs (4)

c

Air Interlock Switch

c

Back Pressure Relief Valve

c

High Altitude Orifice Kit (PMG-200 only)

BOOSTER SIZING

Water Temperature Recovery Table in GPH (LPH) and °F (°C)

Model

PMG-100

PMG-200

Note: Installations above 2,000 ft. (610 m) will reduce the above capacities and may require orice changes

to meet IAS safety compliance. Consult “Installation and Operating Manual” for sizing adjustments and

orice changes.

WATER QUALITY REQUIREMENTS

Incoming water in excess of 3.0 grains of hardness per gallon (GPG) (.75 grains of hardness per liter) must

be treated and softened before being supplied to booster heater(s).Water containing over 3.0 GPG (.75 GPL)

will decrease the efciency and reduce the operating life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

Input MBH

(1,000 BTU/HR)

105

195

30° (16°) 40° (22°) 50° (28°) 60° (33°) 70° (39°)

321 (1215) 241 ( 912) 193 ( 731) 161 ( 610) 138 (522)

602 (2279) 452 (1711) 361 (1367) 301 (1139) 258 (977)

HATCO CORPORATION

(800) 558-0607

Form No. PMG 100/200 Spec Sheet Page 1 of 2 June 2015

(414) 671- 6 3 50

l

Temperature Rise

l

www.hatcocorp.com

l

P.O. Box 340500 Milwaukee, WI 53234-0500 U.S.A.

l

equipsales@hatcocorp.com

intlsales@hatcocorp.com

l

Page 2

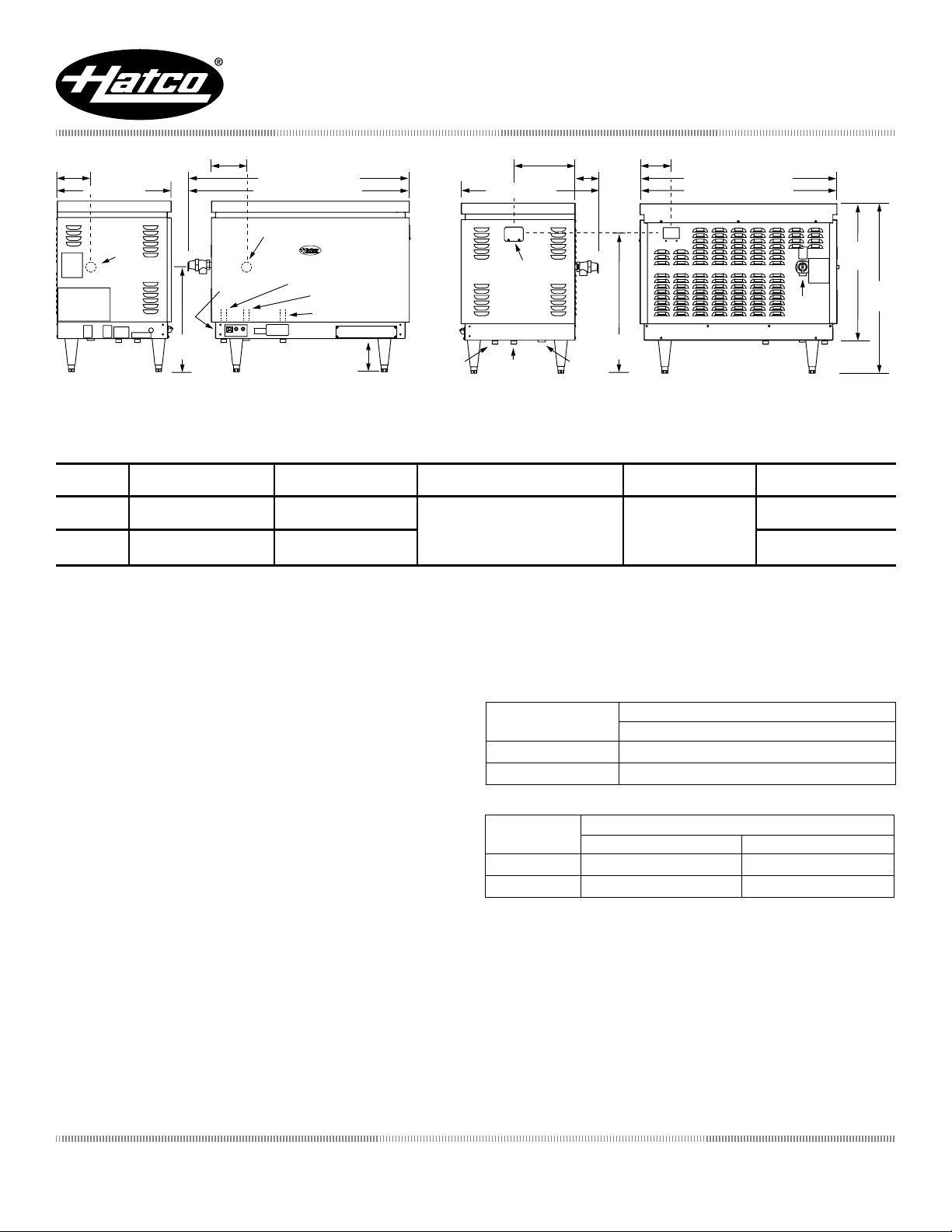

(787 mm)

Powermite® Gas Booster Water Heaters

Model: PMG-100, -200

6.1" (155 mm)

20.73" (526 mm)

Alternate

TPRV

Location

LEFT SIDE VIEW

19.36"

(492 mm)

6.25" (159 mm) 11.8" (300 mm)

31.65" (804 mm) PMG-100

40.15" (1020 mm) PMG-200

Alternate TPRV Location

Electrical

Water Outlet

Water Inlet

Gas Inlet

FRONT VIEW

6"

(152 mm)

Gas

Inlet

4.2" (107 mm)

24.64" (625 mm)

Alternate

Flue

Location

Water

Outlet

RIGHT SIDE VIEW

Water

Inlet

25.25"

(641 mm)

PMG-100 2.9 (73 mm) / PMG-200 5.7" (145 mm)

27.45" (697 mm) PMG-100

35.95" (913 mm) PMG-200

TPRV

REAR VIEW

24.93"

(633 mm)

Models PMG-100 & PMG-200

SPECIFICATIONS

Atmospheric Hot Water Dispenser

Model

PMG-100

PMG-200

*

Shipping weight includes packaging.

•

Height includes 6" (152 mm) legs.

If using supplied right angle duct adaptor, add 6" (152 mm) to width or depth of unit.

^

Before installing any method of venting you should contact the local code authority or your gas supplier to make sure that the nal installation will be acceptable to the

authorities who have jurisdiction. The proper method of venting a power vented gas appliance is too complicated to cover in this specication sheet and is explained in detail

in the National Fuel Gas Code. Before installing the venting system, the person or agency making the installation must be familiar and experienced with the guidelines of the

National Fuel Gas Code.

ALL INSTALLATIONS MUST BE MADE BY A QUALIFIED INSTALLER IN ACCORDANCE WITH THE NATIONAL FUEL GAS CODE OR LOCAL CODES.

Dimensions

(Width x Depth x Height•)

27.45" x 20.73" x 31"

(720 x 625 x 787 mm)

35.95" x 24.64" x 31"

(913 x 625 x 787 mm)

Capacity Fuel Vent^ Ship Weight*

Input 105,000 BTUs/Hour

Output – 84,800 = 24.8kW

Input 195,000 BTUs/Hour

Output – 156,000 = 45.7kW

Natural at 3.5" (89 mm) high burn

Propane/LP at 10" (254 mm) high burn

or

Forced draft system with

4" (102 mm) diameter

vent pipe adapter

180 lbs. (82 kg) dry

215 lbs. (98 kg) dry

31"

Electrical

120 VAC, 360 watt, 3.00 amps

Connections

Gas – ¾" NPT,Water – ¾" NPT

Electric – 120 VAC, 15 amp

Fluing

Direct – combustion air enters bottom, ue gasses exit right side or back at top

of unit. 4" (102mm) ue round

Operating Pressue Specications at Manifold

Gas Type

Natural

Propane/LP

Gas Inlet Pressure

Operating Water Pressure

150 PSI (1034 kPa) max. Relief valve set at 150 PSI (1034 kPa), 210° F (99° C)

Gas Type

Natural

Propane/LP

PRODUCT SPECS

Gas Booster Water Heater

The Gas Booster Water Heater to supply the nal 180°F (82°C) rinse for the

dishwasher shall be a Hatco Powermite® Model ... as manufactured for commercial

use by the Hatco Corporation, Milwaukee, WI 53234 U.S.A.

The booster shall have the capacity to heat ... gph (lph) from 110°F to 180°F

(43°C to 82°C) and it shall berated at ... btu, 120 volts, single phase. The stainless

steel tank shall be designed for a working pressure of 150 psi (1034 kPa) and

hydrostatically tested at 300 psi (2069 kPa).

The heater shall be complete with all internal plumbing, including 3⁄4" NPT pipe and

ttings from inlet and outlet. All controls shall be built-in, and carry safety approval in

accordance with ANSI 21.10.3. Sanitary approval shall be in accordance with NSF

Standard 5. Proper surface mounting circuit breaker or fused disconnect switch shall

be provided by electrical contractor.

The gas red heating system shall be controlled by close tolerance immersion

thermostats. The booster shall be protected with high temperature limit switch (ECO)

and low water cut-off.

The heater shall consist of stainless steel front, top and stainless steel adjustable

legs or stainless steel front and silver-gray hammertone sides and back with standard

6" (152 mm) legs.

The heater shall include a temperature/pressure relief valve, high-temperature limit,

pressure reducing valve with bypass, indicating temperature/pressure gauge, shock

absorber, and blended phosphate water treatment system.

Warranty consists of 24/7 parts and service assistance (US and Canada only).

Water Column at Pressure Tap

High Burn

3.5" ( 89 mm)

10"

(254 mm)

Water Column

Minimum Maximum

5"

(127 mm) 10.5" (267 mm)

11" (254 mm) 13" (330 mm)

(800) 558-0607

HATCO CORPORATION

(414) 671- 6 3 50

l

l

www.hatcocorp.com

l

P.O. Box 340500 Milwaukee, WI 53234-0500 U.S.A.

l

equipsales@hatcocorp.com

intlsales@hatcocorp.com

l

Form No. PMG 100/200 Spec Sheet Page 2 of 2 June 2015

Loading...

Loading...