Page 1

POWERMITE®GAS BOOSTER HEATER

INSTALLATION, OPERATING, SERVICE AND PARTS MANUAL

MODEL: PMG-100 & PMG-200

I&W #07.05.055.00

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electrical switch;

do not use any phone in your building.

•Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

•If you cannot reach your gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

- Ne pas entreposer ni utiliser d’essence

ou ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE

ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucun interrupteur; ne

pas vous servir des téléphones se

trouvant dans le bâtiment.

• Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le

fournisseur, appelez le service des

incendies.

- L’installation et l’entretien doivent être

assurés par un installateur ou un

service d’entretien qualifié ou par le

fournisseur de gaz.

W

ATER HEATERS FOR OTHER THAN RECREATIONAL

VEHICLE INSTALLATION

ONLY

CHAUFFE-EAU POUR INSTALLATION AUTRE QUE DANS DES VÉHICULES DE

LOISIR UNIQUEMENT

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

AVERTISSEMENT: Assurez-vous de

bien suivre les instructions données dans

cette notice pour réduire au minimum le

risque d’incendie ou d’explosion ou pour

éviter tout dommage matériel, toute

blessure ou la mort.

Page 2

Form No. PMG-100/200M-0805

i

CONTENTS

Record the model number, serial number

(identification plate located on the lower right hand

side, front corner of the unit), voltage and purchase

date of your Powermite

®

Gas Booster Heater in the

spaces below. Please have this information

available when calling Hatco for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.D.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.D.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts & Service)

(414) 671-3976 (International)

Additional information can be found by visiting our

web site at www.hatcocorp.com.

24-Hour 7-Day Parts & Service

Assistance available in the

United States and Canada

by calling (800) 558-0607.

INTRODUCTION

Hatco Powermite Gas Booster Heaters are

instantaneous fin tube type heaters designed to

boost the temperature of regularly available hot

water, usually 110°F to 150°F (43°C to 66°C) up to

180°F (82°C). Water at 180°F (82°C) can be used

as sanitizing rinse water in commercial dishwashers

in accordance with Health Codes and National

Sanitation Foundation Standard #5.

The Hatco Gas Booster Heater is design certified

by CSA International and tested under the

requirements of the American National Standard,

ANS Z21.10.3*CSA 4.3-2001, Current Edition.

All Hatco Gas Booster Heaters are factory

pre-plumbed and pre-wired to allow for easy

installation. The control compartment area is

accessible from the front, which permits easy

installation, even when near other equipment.

Hatco Gas Booster Heaters are quality built for long

life and rugged dependability. Dependability of the

booster heater is preserved through proper, safe

installation and operation.

This manual provides the installation, safety and

operating instructions for the Powermite Gas

Booster Heater. We recommend all installation,

operating and safety instructions appearing in this

manual be read prior to installation or operation of

your Hatco PMG-100 or PMG-200 Gas Booster

Heater. Safety instructions that appear in this

manual after a warning symbol and the words

WARNINGor CAUTION printed in bold face are very

important. WARNING means there is the

possibility of serious injury or death to yourself or

others. CAUTION means there is the possibility

of minor or moderate injury. CAUTION without the

symbol signifies the possibility of equipment or

property damage only.

Hatco Gas Booster Heaters are a product of

extensive research and field testing. The materials

used were selected for maximum durability,

attractive appearance and optimum performance.

Every unit is thoroughly inspected and tested prior to

shipment.

Important Safety Instructions............Front Cover

Important Owner Information...............................i

Introduction ...........................................................i

Model Description................................................1

All Models........................................................1

System Overview .................................................1

Specifications.......................................................2

Dimensions......................................................3

Booster Heater Sizing Chart...........................4

Installation............................................................7

General............................................................7

Plumbing........................................................11

Gas................................................................15

Electrical........................................................18

Venting..........................................................19

Operation............................................................22

Start-Up Procedures......................................22

Maintenance .......................................................24

Wiring Diagram...................................................29

Replacement Parts List.....................................30

Hatco Limited Warranty.....................................32

Authorized Parts Distributors............Back Cover

IMPORTANT OWNER INFORMATION

Page 3

Form No. PMG-100/200M-0805

1

MODEL DESCRIPTION

The Hatco Powermite Gas Booster Heater is

designed to maintain a temperature of 180°F

(82°C) water required for the rinse cycle of a

commercial dishwasher. An inlet water temperature

of at least 110°F (43°C) will produce optimum

results (See Capacity Chart and Booster Heater

Sizing Chart in SPECIFICATIONS).

After the necessary power, water and gas

connections are completed, start the unit by turning

on the toggle switch located on the lower front base.

The water circulating pump will start at this time.

Providing the operating and safety controls are

satisfied, the ignition module will begin a 20 second

safety pre purge, next it will energize the spark

igniter and turn on the gas for the pilot. The igniter

will spark for about 90 seconds or until proof of fire.

If there is a confirmed pilot fire, and the water

temperature is below the setpoint, the unit will go

into full burn. The unit will stay in full burn until the

desired setpoint temperature is met, then the burner

will shut off. During standby periods of limited use,

the burner will cycle on only to replace standby

water temperature loss. If for some reason the unit

did not ignite there is an automatic 5 minute delay

before the unit attempts to ignite again.

If the unit overheats above the setpoint temperature,

the safety high limit will open, shutting down the

burner, locking out the controller, and turning on the

alarm pilot light. In order to reset the unit, turn the

unit off and depress the reset button on the

appropriate high limit switch, the tank high limit is

located behind front panel on the left hand side of

the vertical control panel. The heat exchanger high

limit is located on the front of the heat exchanger.

The switches will not reset until the temperature has

dropped to a safe level. This unit must remain off for

at least 10 seconds before it can be restarted.

NOTE: The operating thermostat control is factory

preset at 190°F (88°C).

NOTE: The circulator pump will stay on as long as

the toggle switch is in the ON position.

SYSTEM OVERVIEW

ALL MODELS

Water enters the booster heater at the inlet water

connection and flows into the stainless steel tank. It

then is pumped through the finned tube heat

exchanger where it is heated to the proper

temperature. The heated water then returns back to

the top half of the stainless steel tank for supply to

the dishwashing machine. Water that is not

immediately used by the dishwashing machine is

recirculated through the heat exchanger by the

water pump.

This system is designed to assure the availability of

the proper temperature water at the heater outlet.

All Hatco booster heaters are warranted to be free

of defects in material and workmanship under

normal use and service, and when installed in

accordance with factory recommendations.

NOTE: Hatco Booster Water Heaters are approved

for use with commercial dishwashers only.

Page 4

Form No. PMG-100/200M-0805

2

SPECIFICATIONS

Type: Gas-fired, instantaneous recirculating booster heater with accumulator for use with

door type dishwashers. Unit is floor mounted.

Capacity: PMG-100: Input 105,000 BTUs/Hour. Output 84,800 BTUs/Hour = 24.8 kW

PMG-200: Input 195,000 BTUs/Hour. Output 156,000 BTUs/Hour = 45.7 kW

Fuel: Natural gas @ 5 iwc or Propane @ 11 iwc – minimum inlet gas pressure.

Operating

Water Pressure: 150 PSI max. Relief valve set at 150 PSI, 210°F (99°C).

Power: Supply 120 VAC, 15 amp service (unit uses 3.0 amps @ 120 volts).

Ignition: Electronic spark pilot with flame proofing by rectification.

Temperature Control: Electronic, temperature control probe/microprocessor based. Factory preset at

190°F (88°C).

Safety Systems: Energy cut off devices include manual reset heat exchanger high limit and manually

reset tank high limit. Redundant gas solenoid valve with integral regulator.

Temperature/Pressure relief valve on tank.

Fluing: Direct – combustion air enters bottom, flue gases exit right side or back at top of

unit.

Vent: Forced draft system with 4" (102 mm) diameter vent pipe adapter.

Pump: Recirculating with bronze housing.

Connections: Gas – 3/4" NPT, Water – 3/4" NPT, Electric – 120 VAC, 15 Amp.

Ship Weight: PMG-100: 155 pounds (70 kg) dry.

PMG-200 195 pounds (89 kg) dry.

NOTE: Capacity is reduced @ altitudes above 2000 feet (610 m). See HIGH ALTITUDE INSTALLATION &

OPERATION section for sizing considerations.

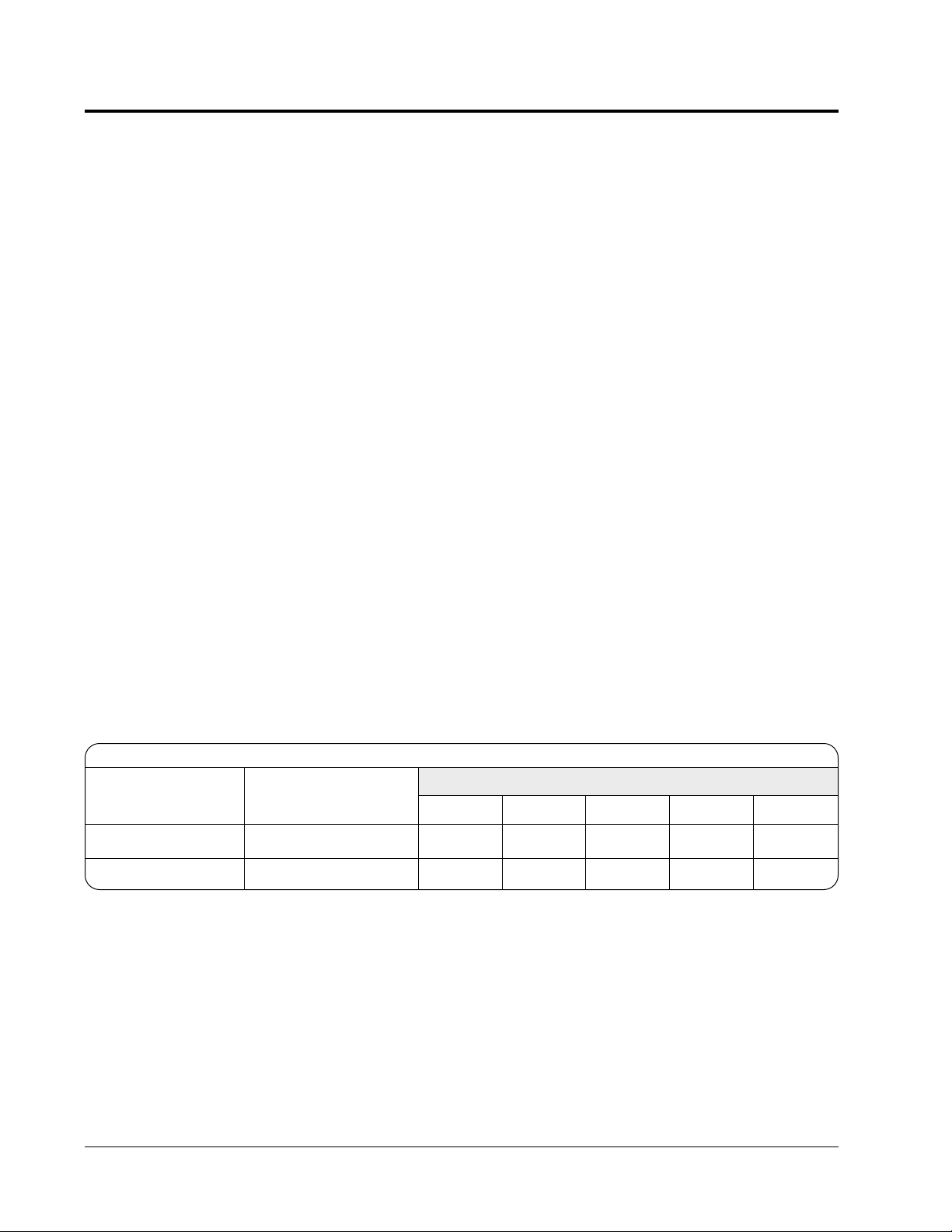

WATER TEMPERATURE RECOVERY TABLE - FAHRENHEIT

INPUT MBH Gallons per Hour (GPH) at Indicated Temperature Rise (F°)

MODEL (1,000 BTU/HR) 30° 40° 50° 60° 70°

PMG-100 105 321 241 193 161 138

PMG-200 195 602 452 361 301 258

Page 5

Form No. PMG-100/200M-0805

3

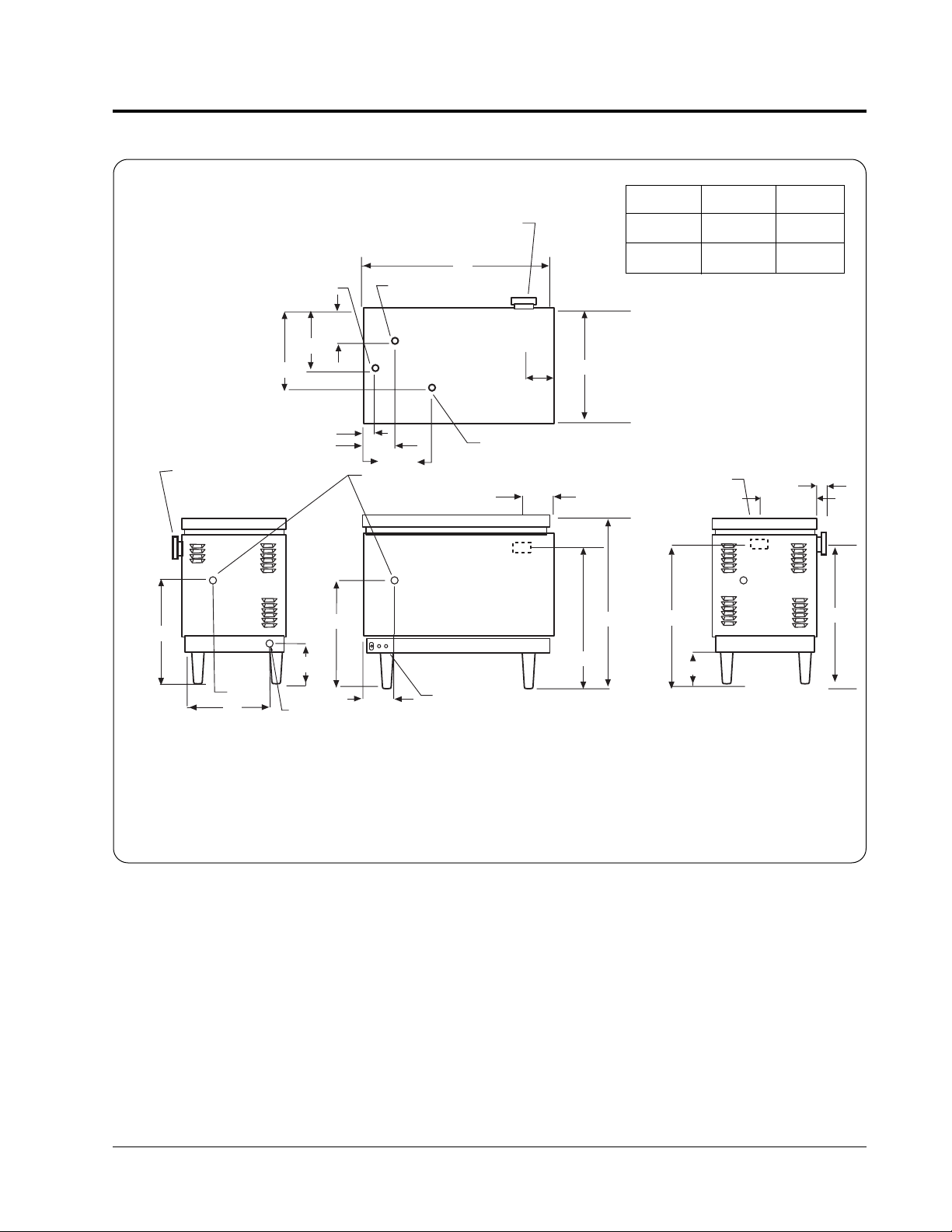

SPECIFICATIONS

DIMENSIONS

Figure 1. Top View

Straight out duct adaptor

shown. Replace with 90°

adaptor for other duct

configurations.

120-150°F (49-66°C)

Water Inlet

180°F (82°C) Water Outlet

6-1/16

2-1/4

19-5/8

6-1/16

Power switch

Power on lamp

Reset safety switch lamp

T/P relief valve may

be field installed at

side or rear

Unit may be adapted in

field with supplied parts

for side exhaust exit.

17

7-3/16

19-5/8

6-1/4

Ø7/8 hole for

1/2" conduit

Primary exhaust

exit location at rear

6-1/4

13

B

31-1/4

25-3/4

25-7/8

11-1/16

1-13/16

6-5/16

25-13/16

Gas Inlet

5-3/4

20-3/4

11-1/8

14-1/2

A

Model A DIM. B DIM.

PMG-100 27-7/16 2-15/16

PMG-200 35-15/16 5-11/16

NOTE: Dimensions listed are in inches.

NOTE: Overall Dimensions PMG 100: 27-1/2" W x 20-3/4" D x 31" H (699 x 527 x 787 mm)

PMG 200: 36" W x 20-3/4" D x 31" H (914 x 527 x 787 x mm)

Page 6

Form No. PMG-100/200M-0805

4

SPECIFICATIONS

BOOSTER HEATER SIZING CHART

GAS

POWERMITE

®

BOOSTER†

Dishwasher Model Number Temperature Rise

40°F (22°C) 70°F (39°C)

ADAMATION CSL-1390, CA-2, CA-3, CA-4, SLAP 44, CA, CA-1 . . . . . . . . . . . . .PMG-200 . . . . . . .(2)PMG-200

BLAKESLEE Series “R & “F”-CC, -EE, -LL, -MM, -LLL, -MMM, -PCC,

-PEE, -PLL, -PMM (multi-tank) with suffix “LC” . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

Series XF-LL, XF-PLL, XF-MM, XF-PMM, XF-EEE,

XF-LLL, XF-MMM, (Multi-tank) with suffix “LC” . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . .---

DD-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . .PMG-200

Series R-L, R-PL, R-M, R-PM, F-L, F-PL, F-M, F-PM (single tank) .PMG-200 . . . . . . .(2)PMG-200

Series XF-PEE, XF-PLL, XF-PMM, XF-EEE, XF-LLL, XF-MMM

(multi-tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .(2)PMG-200

FA(Flight-A-Round) and RA (Rack-A-Round) use comparable “F” listing.

CHAMPION D-H1C, D-H1TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . . .PMG-100

66 WSPW, 44-WS, 66-WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . . .PMG-100

UC-CW6-WS, US-CW8-WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . .PMG-200

44, 66 PW, 70FFPW, 80HDPW, 54, 76PW, 80FFPW,90HDPW 64,

90FFPW, 100HDPW, 86 PW . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . .PMG-200

40-KB, 40-KB-2-2, 40-KFWB, 40-KPRB, 40-KPRB-2-2,

40KPRB-2-3, 60-KB, 60-KB-2-2, 60-KFWB, 60-KFWB-2-2,

60-KPRB, 60-KPRB-2-3, 64KB, 64-KB Corner, 64-KPRB,

64-KPRB Corner, 64 Modular, 86 Modular . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

44-KB, 44-KB Corner, 44-KPRB, 44-KPRB Corner, 54-KB,

54-KB Corner, 54-KPRB, 54-KPRB Corner, 44 Modular,

66 PW Modular, UC

**

Series 6’ Center, UC-C4 . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

UC-CW4, UC-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

UC

**

CW Series 6’ Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .(2)PMG-200

W-6-WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .(2)PMG-200

CMA

DISHMACHINES

CMA-44H with tank heater, CMA-66H . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . .PMG-200

HOBART AM-12, AM-12C

*

, AM-14, AM-14C . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . . .PMG-100

Opti-RinSe C44A, CRS-66A, CCS-66A, CPW-80A, C54A,

CRS-76A, CCS-76A, CPW-90A, C64A, CRS-86A, CCS-86A,

CPW-100A, C-88A, CRS-110A, CCS-110A, CPW-124A . . . . . . . .PMG-100 . . . . . . . .PMG-200

C-54A, CRS-76A, CPW-90A, CCS-76A . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

C-44A, CRS-66A, CCS-66A, CPW-80A, C-64A, CRS-86A,

CCS-86A, CPW-100A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

C-88A, CRS-110A, CPW-124A, CCS-110A . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

Opti-RinSe C44AW, CRS-66AW, CCS-66AW, CPW-80AW . . . . . . . . . .--- . . . . . . . . . . .PMG-100

C-44AW, CRS-66AW, CPW-80AW, CCS-66AW . . . . . . . . . . . . . . . .PMG-100 . . . . . . . .PMG-100

C-44, CRS-66, CPW-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

C-54, CRS-76, CPW-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200/100 . . . . .(2)PMG-200

C-64W, CRS-86W, CPW-100W, C-88W, CRS-100W,

CPW-124W, CCS-86W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . .PMG-200

C-64, CRS-86, CPW-100C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

FT800W, FT-900W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . .PMG-200

FT-600, FT-700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200/100 . . . . .(2)PMG-200

FT800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .(2)PMG-200

FT-900, FT800S, FT-900S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . .PMG-200/100

FRC and FR (Fast Rack Series) use comparable “C” line listing.

Page 7

Form No. PMG-100/200M-0805

5

SPECIFICATIONS

BOOSTER HEATER SIZING CHART (CONTINUED)

GAS

POWERMITE

®

BOOSTER†

Dishwasher Model Number Temperature Rise

40°F (22°C) 70°F (39°C)

INSINGER Commander 18-5, 18-5H, Ensign 40-2 . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . . . .PMG-100

Admiral 44-4, 66-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

Speeder 64, 86-3, Century (all) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

Trac 321, Trac 321-2/RPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

Trac 878 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

Clipper (all), R106-2, Super 106-2 . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

Defender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

Master (all) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

CA-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

For outdated models, consult factory for correct booster.

JACKSON 44CE

*

, 66 CERPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

54CE, 76 CERPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

64CE, 86 CERPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . . . . .---

150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . . . .PMG-100

AJ-44, AJ-66, AJ-80, WH-44, ES-4400, ES-6600

(ECOLAB/JACKSON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

AJ-54, AJ-76, AJ-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . . . .---

AJ-64, AJ-86, AJ-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

*

Model #44CE w/SN1999 or below requires larger booster than listed.

MEIKO K-44, K-66, K-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

K-54, K-76, K-90, K-64, K-86, K-100 . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . . . .PMG-200

METALWASH/INTEDGE

FW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . . . .PMG-100

Page 8

Form No. PMG-100/200M-0805

6

SPECIFICATIONS

* Hobart Model AM-12 with serial no. 12-067-357 or below and model AM-12C with serial no. 12-067-537 or

below require slightly larger booster than listed. Or C Models with serial no. 85-1041605 or greater use

Opti-RinSe.

Shaded area indicates older models prior to Opti-RinSe.

† Powermite installations above 2,000 ft. (610 m) will reduce the above capacities and may require change

of pressure and/or orifices in certain models at time of install to meet IAS safety compliance. These

modifications are the responsibility of the installer. Consult “Installation and Operating Manual” for sizing

adjustments and orifice changes.

This selector chart is based on 40°F (22°C) and 70°F (39°C) temperature rises, 20 psi flow pressure, and minimum

rinse cycle timer setting in NSF listing.

All booster heaters are rated at 100% of the capacity of the dishwashers as recommended by the National Sanitation

Foundation. Where make-up water for wash tank is provided from final rinse supply, chart recommendations are

based upon this additional demand (not over 2 GPM) as required by NSF.

All sizings shown are that of the dishwasher manufacturers. Hatco Corporation is not responsible for incorrect sizing

applications.

GAS

POWERMITE

®

BOOSTER†

Dishwasher Model Number Temperature Rise

40°F (22°C) 70°F (39°C)

STERO SCT-44-10-LW, SCT-44-LW, SCT-66S-LW, SCT-76S-LW, SCT-90S-LW . . . . . . . . . .--- . . . . . . . . . .PMG-100

SC-1-2-4-LW, SC 1-6-4-LW, SC-2-4-LW, SC-5-2-4-LW, SC-5-6-4-LW,

SC-6-4-LW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . .PMG-200

SCT-64, SCT-86S, SCT-94S, SCT-94SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . .PMG-200

SCT-108S, SCT-108SC, SCT-76, SCT-94SM . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . .PMG-200/100

SC-6-4, SCT-44, SCT-44-10, SCT-66S, SCT-76S, SCT-76SC, SCT-90S . . . . . .PMG-200 . . . . .PMG-200/100

SCT-120S, SCT-120SC, SCT-120SM, SCT-150SM . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . .PMG-200/100

STW-110, SC-1-2-7-4, SC-1-6-3-4, SC-1-6-7-4, SC-2-7-4, SC-5-2-7-4,

SC-5-6-3-4, SC-5-6-7-4, SC-6-3-4, SC-6-7-4 . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . .PMG-200/100

SC-1-2-4, SC-1-6-4, SC-2-4, SC-5-2-4, SC-5-6-4 . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . .(2)PMG-200

SCT-44-10-SC-1-3-4, SCT-44-10-3-4, SCT-44-SC-1-3-4, SCT-44-SC-3-4,

SCT-54-SC-1-3-4, SCT-54-SC-3-4, SCT-76S-SC-3-4 . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . .(2)PMG-200

STPC (Four Tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . .PMG-200

STPCW (Four tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . .PMG-200

STPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . .PMG-200/100

STPCW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . .PMG-200/100

SCBT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . .PMG-200/100

SF-2RA, SF-2DRA, SD-2RA, SDRA, SDRA-PACK . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . .PMG-100

SCT-54, SCT-76SM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . .(2)PMG-200

SCT-76, SCT-80, SCT-94, SCT-108, SCT-120 . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . .(2)PMG-200

U-31-A, U-31-AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . .PMG-200

U-31-A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . .(2)PMG-200

SC-2-3-4, SC-5-2-3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-200 . . . . . . . . . .---

SC20-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . . .PMG-100

SC-2-8, SC-2-9, SC-1-2-8, SC-5-6-8, SC-6-8, SC-6-9, SC-1-6-8, SC-5-6-9,

SC-5-2-9, SC-1-6-9, SC-5-2-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PMG-100 . . . . . . .PMG-200

BOOSTER HEATER SIZING CHART (CONTINUED)

Page 9

Form No. PMG-100/200M-0805

7

INSTALLATION

GENERAL

Code Requirements

Installation must be in accordance with local codes,

or in the absence of local codes, with the latest

edition of the National Fuel Gas Code, ANSI Z223.1,

the National Electrical Code, ANSI/NFPA 70.

Canadian installations should conform with CSAB149.1, Natural Gas and Propane Installation Code,

and CSA-C22.1 Electrical Code, and/or local

installation codes. {Les installations canadiennes

doivent se conformer aux CODES

D’INSTALLATION CSA-B149.1, Natural Gas and

Propane Installation Code, et CSA-C22.1 Electrical

Code, et/ou aux codes locaux d’installation.}

NOTE: In the Commonwealth of Massachusetts,

Hatco Booster Heaters shall be installed by a

licensed plumber and gasfitter.

NOTE: The Commonwealth of Massachusetts

requires that if a water treatment system is

installed in line with the Hatco Booster Heaters,

a water backflow protector shall also be

installed.

NOTE: If a check valve or water backflow protector

is installed and cannot be removed install a back

pressure relief valve, Hatco part number

03.02.039.00, set at 125 psi (862 kPa) on the

incoming line between the pressure reducing valve

and the inlet to the booster heater. Discharge must

be to open site drain.

For the most effective operation, install the Hatco

Gas Booster Heater as close as possible to the

dishwashing machine.

NOTE: Employ external recirculation if distance

between booster and dishwasher exceeds the

National Sanitation Foundation specifications of five

(5) feet (1.5 m).

WARNING

To assure proper operation and avoid a

possible unsafe condition, the booster heater

must be installed in a horizontal position with

the base parallel to the floor and the inlet

connection at the lowest point.

The Booster Heater must not be installed directly on

carpeting, but on top of a metal, wood (or

equivalent) panel extending beyond the full width

and depth of the booster heater by at least 3"

(76 mm) in any direction or, if the heater is installed

in an alcove, the entire floor must be covered by the

panel. The panel must be strong enough to carry the

weight of the heater when full of water.

Adequate front clearance is required to allow for

accessibility to the control compartment.

The booster heater should be located in an area

where leakage of the tank or connections will not

result in damage to the area adjacent to the heater

or to lower floors of the structure. When such

locations cannot be avoided, it is recommended that

a suitable drain pan, adequately drained, be

installed under the booster heater . The p an must not

restrict combustion air flow.

CAUTION

Unit is not weatherproof. For safe and proper

operation the unit must be located indoors

where the ambient air temperature is constant

and is a minimum of 70°F (21°C).

Page 10

Form No. PMG-100/200M-0805

8

INSTALLATION

WARNING/CAUTION

The flow of air to the heater for combustion

and ventilation must not be obstructed. Air

vents on the bottom and side of the unit

should never be blocked. All panels should be

in place during normal operation for optimal

performance and safety.

WARNING/CAUTION

This unit is designed to vent to the outside or

into an open Equipment Hood, and is intended

for commercial food service water heating

only. IT IS NOT FOR RESIDENTIAL

USE. See

VENT section of this manual.

WARNING/CAUTION

Flue gases exit top side or back of this unit and

must not be obstructed, specified clearances

must be maintained for safe operation. See

VENT section for vent piping alternatives.

Combustion/Ventilation Air

The booster heater must be located in an area

which allows for an adequate supply of air for proper

combustion and ventilation in accordance with

Section 5.3 and 7.2.2 of the National Fuel Gas Code

NFPA54/ANSI Z223.1 or applicable provisions of

the local building codes. Only a single booster

appliance may be installed in this manner.

Installations under the jurisdiction of Canadian

CSA-B149.1, Natural Gas and Propane

Installation Code, require a gas interlock tied

into the ventilation hood system. {Les

installations sous la juridiction des CODES

D’INSTALLATION canadiens CSA-B149.1,

Natural Gas and Propane Installation code,

nécessitent un verrouillage réciproque de gaz

raccordé au système de capot de ventilation.}

Page 11

Form No. PMG-100/200M-0805

9

INSTALLATION

High

Altitude Installation and Operation

Atmospheric conditions at elevations above 2000 ft.

(610 m) have an effect on the performance of most

gas fired products. For this reason, historical models

for altitude de-rating were developed for gas

appliances with atmospheric burners. The National

Fuel Gas Code, ANSI Z223.1 is an accepted model

which requires a de-rating of 4% per 1000 ft.

(305 m) elevation when no testing to the contrary

exists for that product. This could require modifying

the equipment and adjusting settings in the field to

achieve de-rating. Testing has shown this to be a

very conservative approach.

Manufacturers discourage unnecessary field

adjustments in order to maintain a level of

performance and quality designed into the product.

For these and other reasons, testing was

underwritten through CSA International to verify an

improved satisfactory performance with little or no

modification to effect input rate or control. The

following text and charts are a result of this testing

and should be used during application sizing and

installation.

• The PMG-100 can operate at better levels than

ANSI Z223.1 without manifold pressure setting

adjustments or orifice changes up to the 8500 ft.

(2593 m) elevation for both natural gas and liquid

propane gas units. Above this level only a slight

decrease in manifold pressure may be needed to

meet the approved BTU rate. This is shown in

the Altitude Summary chart. Also, note that GPH

capacity will be reduced and a guideline is given

as to the percent of sea level capacity expected.

For Canadian installations between 2000-4500 feet

(610-1370 m) de-rate unit by 10% to 94,500 BTU.

{Pour les installations au Canada entre 610 et 1370

m (2000 et 4500 pi) reclassifier l’appareil de 10% à

94 500 BTU.}

• PMG-200 will require orifice changes at levels

shown in the Altitude Summary chart. This

follows the 4% de-rating scheme outlined in

ANSI Z223.1 for both natural gas and liquid

propane gas. Also note that the GPH capacity

will be reduced and a guideline is given as to the

percent of sea level capacity expected.

For Canadian installations between 2000-4500 feet

(610-1370 m) de-rate unit by 10% to 175,500 BTU.

{Pour les installations au Canada entre 610 et

1370 m (2000 et 4500 pi) reclassifier l’appareil de

10% à 175 500 BTU}

Orifice Kits for altitude installations may be ordered

through Hatco Customer Service. Please call for

orifice sizing information.

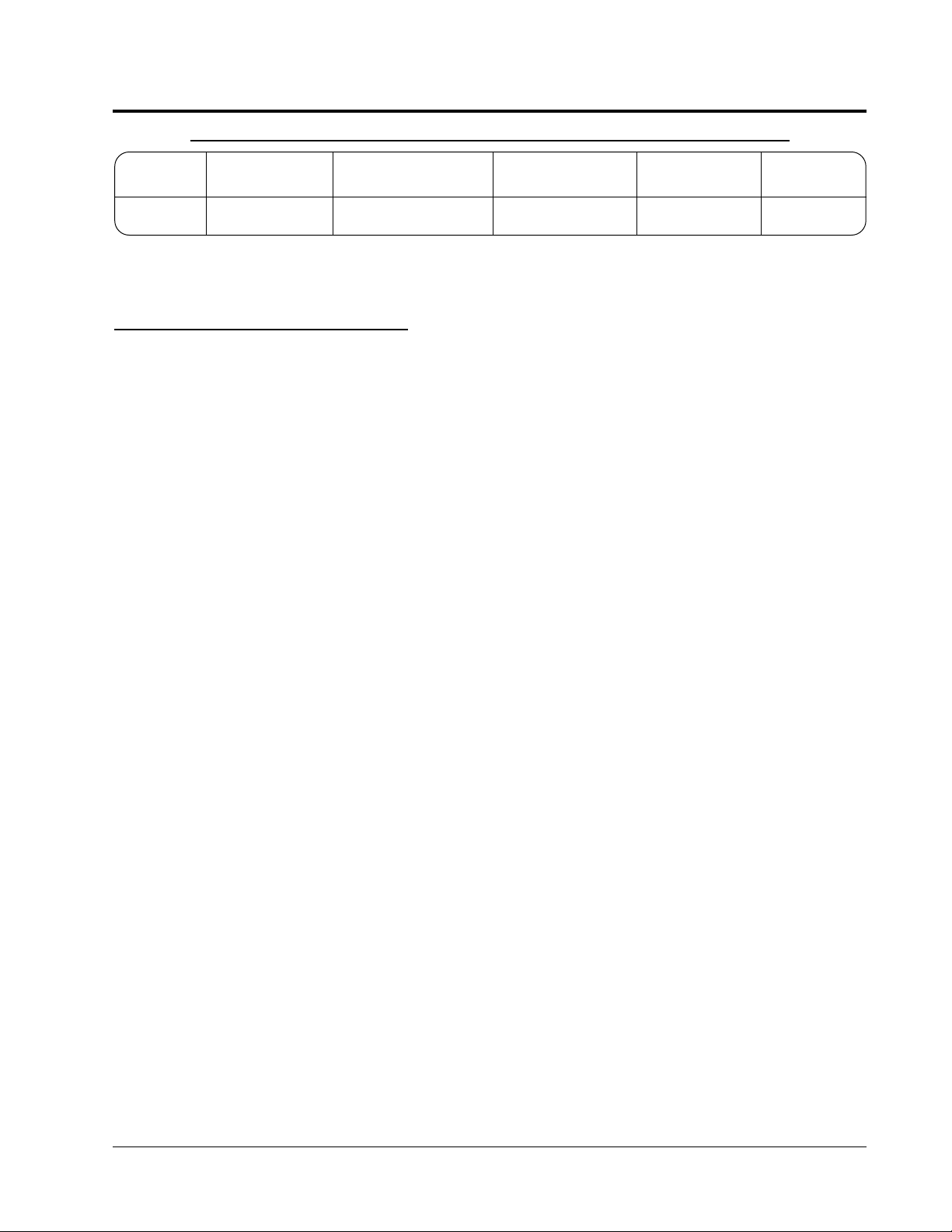

Minimum Clearance Requirements: {Exigences quant au dégagement minimum:}

Floor Top Left Side Right Side Front Back

{Sol} {Dessus} {Côté gauche} {Côté droit} {Devant} {Derrière}

6"* (152 mm) 1" (25 mm) 2" (51 mm) 2" (51 mm) 20" (508 mm) 2" (51 mm)†

* Includes legs supplied with booster heater {Comrend pieds fournis avec appareil de chauffage auxiliare}.

† Minimum clearance of 8" (203 mm) from the side of the appliance where the vent is installed.

Page 12

Form No. PMG-100/200M-0805

10

INSTALLATION

Altitude:

Ft. Above Sea Level 0-2000 2001-3000 3001-4000 4001-5000 5001-6000 6001-7000 7001-8000 8001-8500 8501-9500 9501-10500

(Meters) (0-610) (610-915) (915-1220) (1220-1525) (1525-1830) (1830-2135) (2135-2440) (2440-2593) (2593-2898) (2898-3203)

PMG-100

Approved

Input Rate* 105000 103363 101726 100089 98452 96815 95178 94360 90585 86811

Suggested Orifice

Size†

#34DMS #34DMS #34DMS #34DMS #34DMS #34DMS #34DMS #34DMS #34DMS #34DMS

GPH Capacity

De-Rate• 1 0.98 0.97 0.95 0.94 0.92 0.91 0.90 0.86 0.83

PMG-200

Approved Input

Rate* 195000 171600 163800 156000 148200 140400 132600 128700 123552 118404

Suggested Orifice

Size† #35DMS #36DMS #36DMS #37DMS #37DMS #38DMS #39DMS #40DMS #41DMS #42DMS

GPH Capacity

De-rate• 1 0.88 0.84 0.80 0.76 0.72 0.68 0.66 0.63 0.61

LIQUID PROPANE GAS

Notes:

* This is the maximum allowable BTU rate certified by CSA. These are to be verified by the qualified gas

installer on site. Check Heat Value with local Gas Utility

† The first orifice size is the factory built unit.

The next sizes are shown at the altitudes where a change is required to allow pressure adjustments to

the approved input rates.

• This is a de-rate multiplier to use when sizing a gas booster for a given application.

Take this value and multiply it by the GPH found on the Hatco sizing chart to ensure it will provide the

capacity you need.

You can also use this value by dividing it into your capacity needs and take the resulting adjusted GPH to

the sizing chart to select a gas booster.

Altitude:

Ft. Above Sea Level 0-2000 2001-3000 3001-4000 4001-5000 5001-6000 6001-7000 7001-8000 8001-8500 8501-9500 9501-10500

(Meters) (0-610) (610-915) (915-1220) (1220-1525) (1525-1830) (1830-2135) (2135-2440) (2440-2593) (2593-2898) (2898-3203)

PMG-100 LPG

Approved

Input Rate* 105000 102937 100874 98810 96747 94684 92621 91589 87925 84262

Suggested Orifice

Size†

#50DMS #50DMS #50DMS #50DMS #50 DMS #50DMS #50DMS #50DMS #50DMS #50DMS

GPH Capacity

De-Rate• 1 0.98 0.96 0.94 0.92 0.90 0.88 0.87 0.84 0.80

PMG-200 LPG

Approved Input

Rate* 195000 171600 163800 156000 148200 140400 132600 128700 123552 118404

Suggested Orifice

Size†

#50DMS #51DMS #51DMS #51DMS #51 DMS # 52DMS #52DMS #52DMS #53DMS #53DMS

GPH Capacity

De-rate• 1 0.88 0.84 0.80 0.76 0.72 0.68 0.66 0.63 0.61

Altitude Summary Publication Data for PMG Boosters

NATURAL GAS

Page 13

Form No. PMG-100/200M-0805

11

INSTALLATION

PLUMBING

Components

SUPPLIED WITH UNIT OPTIONAL WITH UNIT SUPPLIED BY INSTALLER

• Temperature/Pressure • Back Pressure Relief • 3/4" Gate or Ball Valve

Relief Valve Valve • Drain Valve

• Blended Phosphate Water

Treatment System • 3/4" Unions

• Pressure Reducing Valve • 3/4" Piping

• Temperature/Pressure Gauges (2)

• Shock Absorber

• 3/4" Plug (installed)

Pressure And Temperature Relief Valves

For protection against excessive pressures and

temperatures in the booster heater, install

temperature and pressure protective equipment by

local codes. Hatco supplies valves constructed with

brass working parts and heat resistant silicone seat

discs for all booster heater models.

WARNING

Valves supplied by Hatco are designed for high

temperature commercial operation. Do not

substitute Hatco valves with valves designed

for domestic water heaters.

Temperature/pressure protective equipment

should not be less than a combination

temperature/pressure relief valve certified by a

nationally recognized testing laboratory that

maintains periodic inspection of the

production of this equipment and meets the

requirements for Relief Valves and Automatic

Shutoff Devices for Hot Water Supply Systems,

ANSI Z21.22*CSA 4.4. The

temperature/pressure relief valve must be

marked with a minimum set pressure not to

exceed the marked maximum working

pressure of the booster heater.

CAUTION

Do not use an anti-siphon or check valve on

the incoming water line.

CAUTION

FOR INSTALLING PRESSURE AND

TEMPERATURE RELIEF VALVES IN

ACCORDANCE WITH ANSI Z21.22*CSA 4.4.

Combination pressure and temperature relief

valves with extension thermostats must be

installed so that the temperature-sensing

element is immersed in the water within the top

6" (152 mm) of the tank. They must be installed

either in the hot outlet service line or directly in

a tank tapping. Combination pressure and

temperature relief valves that do not have

extension elements must be mounted directly

in a tank tapping located within the top 6"

(152 mm) of the tank, and shall be adequately

insulated and located so as to assure isolation

from flue gas heat or other ambient conditions

that are not indicative of stored water

temperature. TO AVOID WATER DAMAGE OR

SCALDING DUE TO VALVE OPERATION,

DRAIN PIPE MUST BE CONNECTED TO VALVE

OUTLET AND RUN TO A SAFE PLACE OF

DISPOSAL. Drain pipe must be as short as

possible and be the same size as the valve

discharge connection throughout its entire

length. Drain line must pitch downward from

the valve and terminate at least 6" (152 mm)

above the floor drain where any discharge will

be clearly visible. The drain line shall terminate

plain, not threaded, with a material serviceable

for temperatures up to 250°F (121°C) or

greater. Excessive length, over 15' (4.57 m), or

use of more than two elbows can cause a

restriction and reduce the discharge capacity

of the valve. No shut-off valve shall be installed

between the relief valve and tank, or in the

drain line. Valve lever must be tripped

periodically to ensure that waterways are clear.

This device is designated for emergency

safety relief and shall not be used as an

operating control. The valves are set to relieve

at 150 pounds pressure or when water

temperature reaches 210°F (99°C). Read tag on

valve for additional information.

NOTE: If a check valve or water backflow protector

is installed and cannot be removed install a back

pressure relief valve, Hatco part number

03.02.039.00, set at 125 psi (862 kPa) on the

incoming line between the pressure reducing valve

and the inlet to the booster heater. Discharge must

be to open site drain.

Page 14

Form No. PMG-100/200M-0805

12

INSTALLATION

Temperature/Pressure Gauges

Hatco requires a temperature/pressure gauge be

installed in both the inlet and outlet lines to the

booster heater. These gauges provide an instant

visual check of the water temperature and pressure

entering and leaving the booster heater. The visual

check is helpful in eliminating unnecessary service

calls.

Install the temperature sensing bulb in the water

system. See Figures 2 and 3 for methods of

installation.

Figure 2. Installation Temperature/Pressure Gauge

Figure 3. Installation Temperature/Pressure Gauge

Pressure Reducing Valve

Proper operation of most dishwasher rinse nozzles

require available water flow pressure at the nozzle

to be 20 PSI.

If water pressure available to the booster heater

inlet is over 20 PSI, a pressure reducing valve with

bypass must be installed in the hot water supply line

to the booster heater.

The valve supplied by Hatco has a built-in high

pressure bypass which prevents excessive pressure

build-up as the booster heats up.

CAUTION

Pressure regulating valve must have a built-in

high pressure bypass.

Blended Phosphate Water Treatment System

Hatco requires that the Blended Phosphate Water

Treatment System supplied be installed with unions

on the incoming 3/4" water supply line after the

pressure reducing valve and before the booster

heater.

Cartridges supplied have a usage rating of 100,000

gallons of water. To ensure proper operation the

cartridges must be replaced when expired.

NOTE: Product failure caused by liming or sediment

buildup is not covered under warranty.

NOTE: The Commonwealth of Massachusetts

requires that if a water treatment system is

installed in line with the Hatco Booster Heaters,

a water backflow protector shall also be

installed.

NOTE: If a check valve or water backflow protector

is installed and cannot be removed install a back

pressure relief valve, Hatco part number

03.02.039.00, set at 125 psi (862 kPa) on the

incoming line between the pressure reducing valve

and the inlet to the booster heater. Discharge must

be to open site drain.

Page 15

Form No. PMG-100/200M-0805

13

INSTALLATION

PLUMBING CONNECTIONS (See Figure 4)

Inlet

Hatco Booster Heaters are designed to be

connected with 3/4" pipe at the inlet pipe from the

primary water heater. Water temperature from the

primary water heater must be at least 110°F (43°C)

and should not exceed 160°F (71°C). Minimum

temperature differential between the inlet and outlet

temperature must never be less than 20°F (11°C).

NOTE: Refer to BOOSTER HEATER SIZING

CHART for application information.

Inlet line must

be installed with a shut-off valve, a

full open gate or ball type valve, a 3/4" union,

together with the blended phosphate water

treatment system, pressure reducing valve set at

20 PSI (1.4 kg/cm2) flow pressure and a

temperature/pressure gauge supplied by Hatco.

NOTE: Do not run a cold ground water line to the

Booster Heater.

CAUTION

Incoming water supply in excess of 3 grains of

hardness per gallon ([GPG] .75 grains of

hardness per liter [GPL]) must be

treated/softened before being supplied to

booster heater(s). Water that contains over

3 GPG or .75 GPL will decrease efficiency and

reduce the operating life of the unit.

NOTE: Product failure caused by liming or

sediment buildup is not covered under

warranty.

CAUTION

To avoid development of a leak, do not back

up or loosen any water pipe fittings.

WARNING

Do not connect the heater directly to a boiler

or furnace coil or any other uncontrolled

temperature source. Such hook-up could

cause the thermostat to lose control and the

unit could overheat.

CAUTION

Incoming water supply to booster heater must

be a minimum of 20 psi, (1.4 kg/cm2) water

pressure less than 20 psi (1.4 kg/cm

2

) will

decrease the operating life of the recirculating

pump and the unit.

NOTE: Product failure caused by incoming

water pressure less than 20 psi (1.4 kg/cm

2

)is

not covered under warranty.

Page 16

Form No. PMG-100/200M-0805

14

INSTALLATION

NOTE: Be sure water flows through the pressure

reducing valve in the proper direction. Check the

directional arrow. Valve will reduce pressure only

during flow conditions.

A 3/4" union fitting and a drain valve must also be

installed to allow for easy servicing.

The temperature/pressure relief valve must be

installed into one of two locations on the heater:

either the right side or the back of the unit. See

Figure 4 for exact locations.

To prevent water leakage and damage to the unit,

the location for the temperature/pressure relief valve

that is not used must

be plugged. (One plug is

supplied by Hatco with the heater.) Both

temperature/pressure fittings MUST NOT be

plugged.

Figure 4. Plumbing Connections – PMG-100/200 Gas Booster Heaters

*Not Supplied With Booster Heater

Optional Accessory

z

†

NOTE: The Commonwealth of Massachusetts

requires that if a water treatment system is

installed in line with the Hatco Booster Heaters, a

water backflow protector shall also be installed.

Page 17

Form No. PMG-100/200M-0805

15

INSTALLATION

Figure 5. PMG-100/200 Gas Booster Heaters Connected in Series

Outlet

Using a 3/4" union and piping, connect the booster

heater water outlet to the dishwasher sanitizing

rinse pipe connection.

NOTE: Be certain the connection is made to the final

rinse and not to the wash tank.

Install a temperature/pressure gauge in outlet line.

Water temperature at outlet should be 180°F

(82°C).

NOTE: The temperature sensing element must be in

water stream. (See Figures 2 and 3.)

Shock Absorber

In areas of high water pressure, Hatco recommends

a shock absorber be installed in the outlet line as

close as possible to the dishwasher. The shock

absorber softens the water hammer caused by

automatic dishwasher valves. (See Figure 4.)

NOTE: Fill booster heater with water to test for

installation leaks. Leave the water in booster to

prevent pump damage in the event the electrician

should apply power.

GAS

Components

SUPPLIED WITH UNIT OPTIONAL WITH UNIT SUPPLIED BY INSTALLER

• Internal Gas Valve (installed) None • Gas Supply Line

• External Gas Shutoff Valve (loose) • Sediment Trap

• Union

• Vent System

†NOTE: The Commonwealth of Massachusetts

requires that if a water treatment system is

installed in line with the Hatco Booster Heaters, a

water backflow protector shall also be installed.

Optional Accessory

z

*Not Supplied With Booster Heater

Page 18

CAUTION

Do not use Teflon tape on gas line pipe

threads. Aflexible sealant suitable for use with

applied gas is recommended.

Form No. PMG-100/200M-0805

16

INSTALLATION

Gas Piping

The gas inlet pipe size is 3/4" NPT pipe thread fitting

to the gas valve. Provide an adequate size gas

supply line. The line should never be smaller than

3/4" NPT and should follow according to the gas

piping diagram below. The fitting is accessed

through the bottom of the case. (See Figure 6.)

Figure 6. Gas Hook-up and Pressure Tap Location and Piping Diagram.

NOTE: Gas line should be of the approved type for

use with natural gas or propane.

Gas line should be kept as short as possible, sized

to furnish the rated BTU, and installed in a way to

protect it from damage. Gas piping must be installed

in accordance with local plumbing codes including a

sediment trap, ahead of the heater gas controls and

a manual shut-off valve located outside the jacket.

NOTE: The internal gas valve is supplied with the

heater, the external manual gas valve supplied with

unit must be plumbed in by the installer. See Figure

6 for gas piping diagram.

Page 19

Form No. PMG-100/200M-0805

17

INSTALLATION

WARNING/CAUTION

The gas used with this unit must be the type

specified on the spec plate on this unit. To

avoid personal injury or damage to the unit,

never use any other than the specified gas.

The heater and its gas connection must be leak

tested before placing the booster heater in

operation.

The booster heater and its individual shut-off

valve must be disconnected and isolated from

the gas supply piping system during any

pressure testing of the system at test

pressures in excess of 1/2 PSI (3.5 kPa.).

This appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5 kPa).

Dissipate test pressure from the gas supply

line before re-connecting the heater and its

manual shut-off cock to the gas supply line.

FAILURE TO FOLLOW THIS PROCEDURE MAY

DAMAGE THE GAS VALVE. OVER

PRESSURED GAS VALVES ARE NOT

COVERED BY THE WARRANTY.

The heater and its gas connections shall be

leak tested before placing the appliance in

operation. Use soapy water or commercially

available fluid for leak test. DO NOT use open

flame to test for leaks.

The maximum inlet gas pressure must not exceed

the values shown above. The minimum gas

pressure listed is for the purposes of input

adjustment.

The manifold inside the heater is provided with a

pressure tap to measure the gas pressure. The

chart below lists the proper pressure amounts at the

manifold pressure tap when testing.

See Figure 6 for hook-up location and pressure tap

location.

Incoming Gas Pressure Specifications

Operating Pressure Specifications at Manifold

Inches Water Column

Gas Type Minimum Maximum

Natural 5.0 10.5

Propane/LP 11.0 13.0

Inches Water Column At Pressure Tap

Gas Type High Burn

Natural 3.5

Propane/LP 10.0

Page 20

Form No. PMG-100/200M-0805

18

INSTALLATION

SUPPLIED WITH UNIT OPTIONAL WITH UNIT SUPPLIED BY INSTALLER

• 7/8" Hole Plugs None • 120 VAC, 60 Hz, 15 Amp

Single Phase Service

• Electrical Ground

ELECTRICAL

Components

The Hatco Gas Booster Heater operates on

120 VAC, 60 Hz, 15 amp, single phase service. All

internal electrical connections have been made at

the factory.

WARNING

If an external electrical source is utilized, the

appliance, when installed, must be electrically

grounded in accordance with local codes, or,

in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, and CSA C22.1,

Electrical Code.

Electrical Connections

To connect the field wiring to the booster heater:

1. Remove the front access panel from the unit by

lifting up on the front panel and pulling upper

edge away from unit until it clears the lower

edge.

2. Open electrical enclosure at the lower left corner

of the base by removing two screws.

3. Bring power leads from a properly sized fused

disconnect switch or circuit breaker through 7/8"

hole provided on lower left hand side or bottom

of base. Connect supply lines to terminal block

provided. (See Figure 7.) Use copper wire only

.

4. A green grounding terminal is provided internally.

An equipment grounding conductor must be

properly connected to the green terminal block.

(See Figure 7.)

1. Rotate Screwdriver into top opening.

2. Insert 3/8" Stripped Wire Lead.

3. Remove Screwdriver.

Figure 7. Terminal Block Wiring Instructions.

CAUTION

To avoid damage to both the pump and heater

assembly, do not turn on the power switch to

the heater until the installation is complete and

the booster water tank is filled with water and

all air in the system has been vented through

the dishwasher rinse nozzles.

Page 21

Form No. PMG-100/200M-0805

19

INSTALLATION

b. Horizontally vented through an outside wall

directly to the outdoors. See additional

instructions below. (See Figure 9.)

c. Exhausted into a vertical masonry chimney

that has a listed steel liner installed in the

chimney. Locate appliance as close as

practicable to a chimney or gas vent.

Because of the low flue gas temperature, do

not vent into an unlined or masonry lined

chimney. Note that all venting into a vertical

chimney of any type must comply with the

horizontal and vertical ratios and sizing

requirements that are detailed in the National

Fuel Gas Code.

d. V ented vertically using type B vent pipe that is

5" (127 mm) in diameter provided the

termination above the roof uses a listed wind

cap.

1

AL 29-4C is a Registered Trademark of Allegheny Ludlum

Corp.

VENTING

The PMG-100 and PMG-200 may be vented by two

methods, both of which have been tested for

compliance with national safety standards for gas

water heaters. Whichever method is used must

comply with local codes. The installation of the

venting system must comply with local codes and in

the absence of local codes, in accordance with the

National Fuel Gas Code and the guidelines in this

manual. Before installing any method of venting

you should contact the local code authority of

your gas supplier to make sure that the final

installation will be acceptable to the authorities

having jurisdiction.

The proper method of venting a power vented gas

appliance is too complicated to cover in this manual

and is explained in detail in the National Fuel Gas

Code. Before installing the venting system the

person or agency making the installation must be

familiar and experienced with the guidelines of the

National Fuel Gas Code.

The temperature of the flue gases from this booster

water heater operates at approximately 225°F to

275°F (107°C to 135°C).

The two methods that have been tested for

compliance with the national safety standards are:

1. The first method of venting permits the

connection of 4" (102 mm) diameter, AL 29-4C

1

stainless steel vent pipe. Use only the specific

types of materials currently listed by a nationally

recognized testing agency for category III

venting. The maximum combined horizontal

vent length must not exceed a length of

40 feet (12 m) [each sweep elbow is the

equivalent of 5' (1.5 m) of straight pipe and a

standard right elbow is the equivalent of

10 feet (3 m)]. The venting may be done in such

a way that the exhaust products are:

a. Conveyed to another area in the kitchen such

as under a ventilator or near an exhaust fan

(both of which exhaust outdoors).

(See Figure 8.)

When using this method the booster water

heater must be electrically interlocked with

the vent hood to prevent operation if the vent

hood is not operating.

The termination end must be placed so that it

vents above the bottom of the hood skirt. Do

not penetrate the filter with the vent.

Figure 8. Venting Through Typical Exhaust System.

Page 22

Form No. PMG-100/200M-0805

20

INSTALLATION

2. The second method of venting is to directly

exhaust the flue products into the kitchen work

area provided the size and installation of the

open room meet the requirements of the National

Fuel Gas Code [ANSI Z223.1 or NFPA bulletin

#54]. Aportion of the 1996 code is as follows.

Figure 9. Typical Through-the-Wall Venting

EXCERPT FROM ANSIZ223.1/NFPA #54

7.2.1 Connection To Venting Systems. Excerpt as

permitted in 7.2.2 through 7.2.6, all gas utilization

equipment shall be connected to venting systems.

7.2.2 Equipment Not Required To Be Vented.

A single booster-type [automatic instantaneous] water

heater, when designed and used solely for the sanitizing

rinse requirements of a dishwashing machine, provided

that the equipment is installed, with the draft hood in

place and unaltered, if a draft hood is required in a

commercial kitchen having a mechanical exhaust

system. Where installed in this manner, the draft hood

shall not be less than 36 inches (91 cm) vertically and 6

inches (15 cm) horizontally from any surface other than

the equipment.

Where any or all of this equipment is installed so the

aggregate input rating exceeds 20 Btu per hr per cu ft

(207 watts per m

3

) of room space in which it is installed,

one or more shall be provided with venting systems or

other approved means for removing the vent gases to

the outside atmosphere so the aggregate input rating of

the remaining unvented equipment does not exceed the

20 Btu per hr per cu ft (207 watts per m

3

) figure. Where

the room or space in which the equipment is installed is

directly connected to another room or space by a

doorway, archway, or other opening of comparable size

that cannot be closed, the volume of adjacent room or

space shall be permitted to be included in the

calculation.

General Notes On Venting:

• Whenever a vent pipe goes through a

combustible wall, the clearance between the

vent material and the combustible material

must be in accordance with the listing

requirements of the vent system chosen. See

the vent manufacturer’s instructions.

• All horizontal runs of vent pipe must be

supported at every elbow and every 3 feet

(1 m).

• All horizontals must have an upward pitch of

at least 1/4" per foot.

• When venting through a side wall to the

outdoors the following must be observed:

• A vent termination [Tee Fitting] must be used

that is positioned with the backside of the

TEE at least 12" (305 mm) from the exterior

wall.

• The vent termination must be away from

areas where the general public will walk or

vehicle may damage the vent cap.

• The cap must be at least 3 feet (1 m) above

any forced inlet openings [into the building]

that are within 10 feet (3 m) of the cap.

• The cap must be one foot above any

windows, doors or other openings into the

building.

Page 23

Form No. PMG-100/200M-0805

21

INSTALLATION

• The cap must be 4 feet (1.2 m) horizontally

from any doors, windows, etc.

• The cap must be at least 7 feet (2 m) above

any public walkway.

• The bottom of the cap must be at least 1 foot

(.3 m) above ground and possibly higher if the

snow accumulation normally exceeds

1 foot (.3 m).

• The cap should be positioned such that any

condensate that drips from the cap will not

damage plants, shrubs or onto other

equipment located on the outside of the

restaurant.

Figure 10. Right Angle Adapter Mounting Options.

NOTE: The standard Vent Outlet is shown in Figure 10 exiting from the rear. To adjust the outlet exit to the

right side see the COMPONENT-ADJUSTMENT/REPLACEMENT section of this manual.

• The cap should be positioned so that

condensate that drips from the cap will not

allow the water to accumulate on walkways or

other areas, which may freeze and cause an

accident.

• Right angle adapter is provided to minimize

radius of initial bend toward flue piping

required for tight quarters. See Figure 10 for

direction options.

CAUTION

To avoid FREEZING WATER DAMAGE to the booster heater

when the outside temperature is below 32°F (0°C) the unit must be

left ON and the venting must be protected from migrating cold air.

Page 24

Form No. PMG-100/200M-0805

22

OPERATION

START UP PROCEDURES

NOTE: Remove the front access panel during start

up.

Filling The System With Water

1. With the external gas supply and electric

supply turned off, close the drain pipe valve.

NOTE: Water temperature at the inlet should be

between 1 10°F(43°C) and 150°F (66°C) and should

never exceed 160°F (71°C) for the unit to operate

properly and meet the demands of the dishwashing

machine. Minimum temperature differential between

inlet and outlet temperatures should never be less

than 20°F (11°C).

NOTE: Do not run a cold ground water line to the

Booster Heater(s).

WARNING

If you do not follow these instructions exactly,

a fire or explosion may result, causing

property damage, personal injury or loss of

life.

AVERTISSEMENT: Assurez-vous de bien

suivre les instructions données dans cette

notice pour réduire au minimum le risque

d’incendie ou d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la mort.

1. This appliance is equipped with an ignition

device which automatically lights the pilot. DO

NOT TRY TO LIGHT THE PILOT BY HAND.

2. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air

and will settle on the floor.

What To Do If

You Smell Gas:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

3. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, don’t try to repair it - call

a qualified service technician. Force or

attempted repair may result in a fire or explosion.

4. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to

replace any part of the control system and any

gas control which has been under water.

Operating Instructions

:

Les Instructions quant a la nise en service de ce

chauffe-eau se trouvent sur la surface interieure du

ponneau avant. Pour retirer le panneau, saisar les

cotes avont interieurs du panneau avant et soulever

vers le haut, tirer le bord inferieur vers l’exterieur et

laisser le bord superieur tomber.

WARNING/CAUTION

Should overheating occur or the gas supply

fail to shut off, turn off the manual gas control

valve to the appliance.

En cas de surchauffe ou si l’alimentation en

gaz ne s’arrête pas, fermez manuellement le

robinet d’arrêt de l’admission de gaz.

CAUTION

Product failure caused by dry firing is not

covered under warranty.

CAUTION

Incoming water supply in excess of 3 grains of

hardness per gallon ([GPG] .75 grains of

hardness per liter [GPL]) must be

treated/softened before being supplied to

booster heater(s). Water that contains over

3 GPG or .75 GPL will decrease efficiency and

reduce the operating life of the unit.

NOTE: Product failure caused by liming or

sediment buildup is not covered under

warranty.

2. When the water tank is full, turn on the electric

supply and the power switch to allow the

circulator pump to purge air from it. The circulator

pump should start immediately. Additional air in

the tank can be vented through the dishwasher

rinse nozzle.

NOTE: Dishwasher should be cycled a minimum of

three times before the gas supply to the booster is

turned on.

3. After all the air has been vented out of the

system, turn off the power to the booster

heater.

Lighting The Heater

FOR YOUR SAFETY, READ BEFORE OPERATING:

Page 25

Form No. PMG-100/200M-0805

23

OPERATION

1. STOP! Read the safety information on the

appliance label or in this manual.

2. Turn off all electric power to the appliance.

3. This booster heater is equipped with an ignition

device which automatically lights the pilot. DO

NOT try to light the pilot by hand.

4. To gain access to controls remove front panel by

sliding it up and pulling lower edge out and down

away from the appliance.

Figure 11. Gas Valve - Top View

5. Turn gas control knob clockwise to OFF.

(See Figure 11.)

6. Wait five (5) minutes to clear out any gas. If you

smell gas STOP! Follow “B” in the safety

information under Start Up Procedures. If you do

not smell gas, continue to the next step.

7. Turn gas control knob counterclockwise to ON.

8. Replace front access panel.

9. Turn on all electric power to the appliance.

10.Turn on power switch and:

a. After approximately 20 seconds the ignition

sequence should begin and light the pilot. If

the water temperature is below the setpoint

the heating process will start.

b. Allow the booster heater to run until the

burner shuts down. The booster heater is now

at its setpoint, stabilized working

temperature.

c. Run the dishwashing machine through at

least two rinse cycles. After the first rinse

cycles. After the first rinse cycle the burner

should re-light and remain lit until the water

maintains 180°-185°F (82°-85°C) output @

20 psi through the second cycle.

NOTE: If this test does not proceed as

described, contact the Hatco Corporation or

your authorized service agent for technical

assistance.

11.If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance” and

call your service technician or gas supplier.

To Turn Off Gas To Appliance:

1. Turn off power switch on heater.

2. Turn off all electric power to the appliance if

service is to be performed.

3. Shut off external manual gas valve.

4. Remove front cover of heater for access to the

control compartment.

5. Turn gas control knob clockwise to OFF.

Do not force.

6. Replace front access panel.

CAUTION

To avoid FREEZING WATER DAMAGE to the

booster heater when the outside temperature

is below 32°F (0°C) the unit must be left ON and

the venting must be protected from migrating

cold air.

Page 26

Form No. PMG-100/200M-0805

24

MAINTENANCE

WARNING

Before performing this operation, care should

be taken that any of the discharged water does

not come into contact with the operator or

surrounding surfaces. The water can be

extremely hot and can cause severe scalding

and damage to the property.

If the relief valve discharges periodically, do

not

plug it. If replacing the valve does not stop

the discharge, contact your local authorized

service agent or the Hatco Corporation.

BURNER REMOVAL/INSPECTION

(TO BE PERFORMED BY YOUR AUTHORIZED

SERVICE AGENCY)

1. Shut-off the electrical power and gas supply

to the heater.

2. Disconnect the internal flexible gas supply line

connector at the gas regulator valve.

3. Disconnect the ignition module spark cable.

4. Remove two nuts holding the burner tray to the

base.

5. Remove four screws from the front cover of the

combustion chamber and remove the cover.

Broad Blue Outer Flame

Slotted Burner Element

Light Blue Inner Cone

• The flame during full burn is a broad blue color. An

inner cone slightly lighter in color will also be visible.

• The flame should not be rising off of the face of the

burner element.

• Yellow tipped flames suggest a need for adjustment

or cleaning of the burner assembly.

3/8-1/2"

Figure 12. Gas Flame.

Figure 13. Pilot Flame.

CAUTION

Using or storing chlorine based products on

or near the booster heater may shorten the life

of the unit and void the product warranty.

NOTE: Refer to the REPLACEMENT PARTS LIST

for exploded views, part identification and location.

NOTE: Refer to the WIRING DIAGRAM for specific

electrical information.

GENERAL

1. Keep the area around the heater free and clear

of debris and flammable materials. Do not block

air intakes or vents.

2. The recirculating water pump motor is

permanently lubricated and requires no other

maintenance.

3. Visually observe and inspect the burner and pilot

flame every six months. When the burner is

operating properly a clean blue flame will be

visible. (See Figures 12 and 13.) Depending on

the condition of the kitchen environment, the

burner may need to be cleaned of lint or greaseladen dust. If any problems are apparent,

discontinue use of the heater and contact the

Hatco Corporation or your authorized service

agent.

4. Visually observe and inspect the heat exchanger

and exhaust blower fan. Depending on the

condition of the kitchen environment, the heat

exchanger and fan may need to be cleaned of

lint or grease laden dust. If any problems are

apparent, discontinue use of the heater and

contact the Hatco Corporation or your authorized

service agent.

5. Once a month check and clean (if necessary) all

air inlet holes on the side or back of the unit.

6. The front access panel should be removed and

all components visually inspected at least twice a

year. Check for evidence of chafing or heat

damage to any wiring or components. Check

also for any signs of water leakage at any of the

plumbing connections. If there are signs of any

damage or leakage contact the Hatco

Corporation or your authorized service agent.

7. The relief valve should be manually operated at

least once a year to ensure proper operation.

8. Visually observe and inspect the Blended

Phosphate Water Treatment System weekly

: To

ensure proper operation replace depleted

cartridges immediately

.

Page 27

Form No. PMG-100/200M-0805

25

MAINTENANCE

CAUTION

Failure to drain the heat exchanger prior to

exposing it to freezing conditions will damage

the heat exchanger and void the warranty.

COMPONENT ADJUSTMENTS/REPLACEMENTS

WARNING/CAUTION

Always disconnect the power and shut off gas

supply prior to performing any maintenance on

the booster heater to avoid possible personal

injury or damage to the booster heater.

WARNING

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

ATTENTION

Au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher.

Des erreurs de câblage peuvent entrâiner un

fonctionnement inadéquat et dangereux.

S’assurer que l’appareil fonctionne

adéquatement une fois l’entretien terminé.

1. Gas Valve Replacement

a. Shut off electrical power and gas supply to

the heater.

b. Remove front panel.

c. Remove flexible gas piping to gas valve inlet.

d. Disconnect wiring connections to gas valve.

e. Remove burner tray assembly as outlined

above.

f. Remove valve from manifold pipe.

g. Reverse above procedure to re-install,

checking burner and seals to prevent gas

leakage.

2. Ignition Module Replacement

a. Shut off electrical power to the booster.

b. Disconnect spark plug igniter wire.

c. Remove mounting screws holding module.

d. Remove module.

e. Reverse above procedure to re-install.

3. T

ransformer Replacement

a. Shut off electrical power to the heater.

b. Remove screws from electrical box and lift

off.

c. Disconnect wire leads from transformer at the

power supply. (See Figure 9.)

d. Remove mounting screws that hold

transformer in place.

e. Remove transformer from unit and replace

with new one.

f. Reverse above procedure to re-install.

6. Lift and slide burner assembly out.

7. Disconnect spark electrode wire from pilot

igniter.

8. Perform intended service.

9. Reverse above procedure to re-install, checking

burner assembly and seal to prevent gas

leakage.

DRAINING THE HEA

T EXCHANGER

1. Shut-off the electrical power, gas and water

supply to the heater.

2. Allow unit to cool down to room temperature.

3. Open the drain valve under the booster heater to

remove water from the tank and pump assembly.

4. Remove the drain plug located on the front of the

heat exchanger and allow the water to drain from

the heat exchanger into a pan or pail.

Approximately 16 oz. (498 g) of water will drain

from the unit.

5. Reverse above procedure using a food grade

thread sealant to seal the plug threads and

prevent leakage.

NOTE: Freeze damage to the heat exchanger and

unit can be avoided by doing the following:

• After draining heat exchanger, blow 30 psi of air

into the heat exchanger drain opening which will

purge the exchanger of any residual water.

• Leaving drain valves open until performing startup procedures.

• Stop migrating cold air from entering the unit

from the vent.

Page 28

Form No. PMG-100/200M-0805

26

MAINTENANCE

4. Temperature Control Probe Replacement.

a. Shut off electrical power to the heater.

b. Shut off water supply to the heater and open

drain valve to remove water below the

temperature control probe level.

c. Remove the front panel cover.

d. Disconnect temperature control probe wire

leads from thermostat body.

e. Remove temperature control probe from tank.

f. Reverse above procedure to re-install.

5. Recirculating Pump Replacement

a. Shut off gas supply.

b. Shut off electrical supply.

c. Shut off water supply and allow unit to

cool sufficiently.

d. Open the drain valve under the booster

heater to remove water from the tank and

pump assembly.

e. Remove front cover and left side panel for

access to pump.

f. Remove two (2) screws from the electrical

box cover and lift off.

g. Remove pump motor cover and disconnect

wiring connections to the pump motor.

h. Remove bolts and nuts holding pump

assembly to flanges (save bolts and nuts).

i. Install new pump assembly using new

O-rings (supplied with pump assembly)

starting with lower bolts first (FLOW ARROW

MUST POINT UPWARD).

j. Close the drain valve under the booster

heater and turn the water supply ON

checking for leaks at all fittings.

k. Connect wiring to new pump motor and install

wiring compartment cover.

l. Purge the air from the system. Turn on the

electrical supply and allow pump to displace

air out of the heat exchanger and holding tank

by running several rinse cycles on the

dishwashing machine. Test all connections

for tightness.

m. Turn on gas supply (CHECK ALL FITTINGS

FOR LEAKS) and follow start-up procedures.

6. T

emperature/Pressure Gauge Replacement

a. Shut off electrical power to the heater.

b. Shut off water supply and open drain valve to

remove water in the piping.