Hatco NLX-24 Installation Manual

Register Online!

hatcocorp.com

WARNING

ADVERTENCIA

AVERTISSEMENT

(see page 2)

S'inscrire en ligne!

(voir page 12)

Installation and Operating Manual

Manuel d'installation et d'utilisation

Narrow Display Lights

Tubes d'Éclairage Étroit

NLX Series/Série

P/N 07.04.560.00

Do not operate this equipment unless you

have read and understood the contents of

this manual! Failure to follow the

instructions contained in this manual may

result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel !

Le non-respect des instructions

contenues dans ce manuel peut entraîner

de graves blessures ou la mort. Ce

manuel contient des informations

importantes concernant l'entretien,

l'utilisation et le fonctionnement de ce

produit. Si vous ne comprenez pas le

contenu de ce manuel, veuillez le signaler

à votre supérieur. Conservez ce manuel

dans un endroit sûr pour pouvoir vous y

référer plus tard.

Français = p 12

© 2013 Hatco Corporation

CONTENTS

WARNING

NOTICE

CAUTION

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................4

Model Designation................................................................4

Specifications........................................................................5

Dimensions — Strip Heater................................................5

Dimensions — Control Box ................................................5

Electrical Rating Chart .......................................................5

Installation.............................................................................6

General...............................................................................6

Installation Site Requirements............................................6

Installing the Unit................................................................7

Installing the Control Box....................................................7

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the side of the unit). Please have this

information available when calling Hatco for service assistance.

Model No. ________________________________________

Serial No. ________________________________________

Voltage __________________________________________

Date of Purchase __________________________________

Operation...............................................................................8

General...............................................................................8

Maintenance ..........................................................................9

General...............................................................................9

Daily Cleaning ....................................................................8

Replacing a Display Light Bulb...........................................9

Troubleshooting Guide ......................................................10

Options and Accessories...................................................10

Limited Warranty.................................................................11

Authorized Parts Distributors............................Back Cover

Business

Hours: 8:00

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

Fax: 800-690-2966 (Parts and Service)

AM to 5:00 PM Central Standard Time (CST)

(Summer Hours: June to September—

8:00

AM to 5:00 PM CST Monday–Thursday

8:00

AM to 2:30 PM CST Friday)

414-671-3976 (International)

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco NLX Series Narrow Display Lights provide effective and

stylish lighting for non-critical food holding and display areas.

The narrow housing of the NLX Series is ideal for installation in

tight spaces.

NLX Series Narrow Display Lights are products of extensive

research and field testing. The materials used were selected

for maximum durability, attractive appearance, and optimum

performance. Every unit is inspected and tested thoroughly

prior to shipment.

This manual provides the installation, safety, and operating

instructions for NLX Series Narrow Display Lights. Hatco

recommends all installation, operating, and safety instructions

appearing in this manual be read prior to installation or

operation of a unit.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

ed by

i

f

i

dent

s i

s manual

hi

S

the f

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal

injury.

ng s

owi

l

ol

gnal

i

word panel

appears i

hat

on t

i

ormat

nf

y i

et

af

n t

:

s

i

2

Form No. NLXM-1213

English

NOTICE

CAUTION

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid

serious injury or death and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Unit must be installed by a qualified electrician.

Installation must conform to all local electrical codes.

Installation by unqualified personnel will void unit

warranty and may lead to electric shock or burn, as well

as damage to unit and/or its surroundings.

• Consult a licensed electrical contractor for proper

electrical installation conforming to local electrical

codes and the National Electrical Code (N.E.C.).

• When mounting above a steam table, each individual

well opening must not exceed 12" (30.5 mm) wide with

a maximum electrical rating of 2000 W per well.

• Turn OFF power at fused disconnect switch/circuit

breaker and allow unit to cool before performing any

cleaning, adjustments, or maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not clean unit when it is energized or hot.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• Do not steam clean or use excessive water on the unit.

• This unit is not “jet-proof” construction. Do not use jetclean spray to clean this unit.

• Control box must be mounted in a vertical surface.

Mounting control box in a horizontal surface may result

in the collection of liquids and lead to electric shock.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

FIRE HAZARD:

• Locate unit the correct distance from combustible walls

and materials. If safe distances are not maintained,

discoloration or combustion could occur. Refer to

specific installation and mounting information in this

manual for proper clearances.

• Make sure to follow the installation information listed

below for xenon display lights. If safe distances are not

maintained, discoloration or combustion could occur.

a. Do not install xenon display lights less than 10"

(254 mm) above combustible surfaces.

b. Do not install xenon display lights less than

7" (178 mm) above non-combustible surfaces.

c. Install all xenon display lights with a minimum

distance of 2" (51 mm) from any wall or adjacent

vertical surface.

Form No. NLXM-1213

EXPLOSION HAZARD: Do not store or use gasoline or

other flammable vapors or liquids in the vicinity of this or

any other appliance.

Make sure all operators have been instructed on the safe

and proper use of the unit.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them away

from the unit.

The light fixtures in this unit have glass safety shields

covering the light bulbs to meet National Sanitation

Foundation (NSF) standards. To avoid personal injury

and/or food contamination, always operate the unit with

the glass safety shields properly installed.

Hatco Corporation is not responsible for actual food

product serving temperature. It is the responsibility of the

user to ensure that food product is held and served at a

safe temperature.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350; fax 800-690-2966; or

International fax 414-671-3976.

Standard and approved manufacturing oils may smoke up

to 30 minutes during initial startup. This is a temporary

condition. Operate unit without food product until smoke

dissipates.

Ensure safe and proper operation. Refer to the “Installation

Site Requirements” listed in the INSTALLATION section of

this manual.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch finish of unit, marring

its appearance and making it susceptible to soil

accumulation.

3

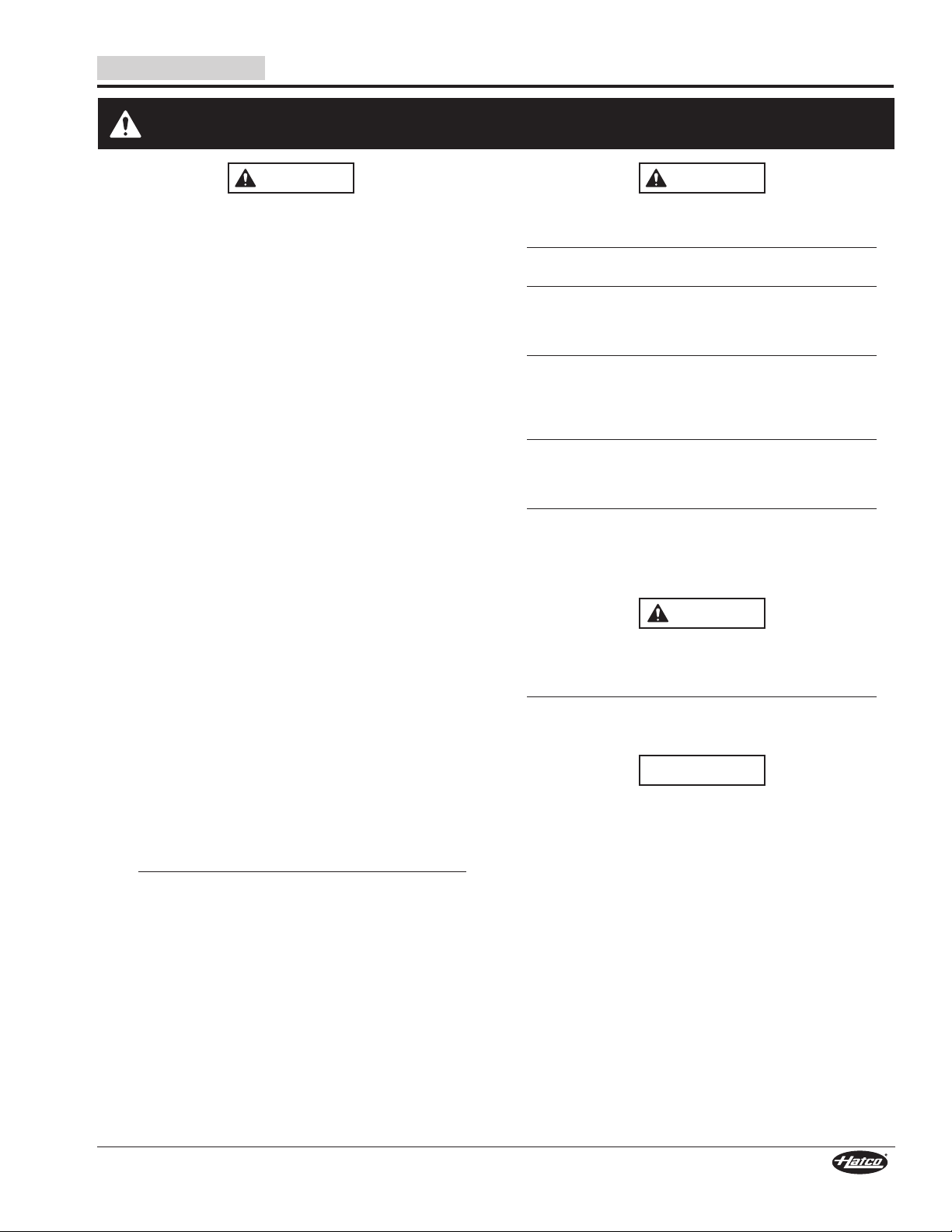

MODEL DESCRIPTION

Xenon Display Light

Angle Bracket

N L X - XX

Narrow Housing

Display Light

Xenon Light Source

Width (inches)

NLX Series Narrow Display Lights consist of a narrow-style

steel housing that is ideal for installation in tight spaces. They

are equipped with xenon light bulbs that provide bright display

lighting to bring focus on the product below. Controls are

housed in a remote-mounted control box and consist of a

Lights I/O (on/off) switch. Finish options include stainless steel,

several powdercoated colors, gloss finishes, and plated finishes.

NLX Series Narrow Display Lights are available in widths from

18" (457 mm) to 72" (1829 mm). They are supplied with angle

brackets for under-shelf mounting. Optional, non-adjustable

tubular stands are available for countertop mounting (refer to

the OPTIONS AND ACCESSORIES section for details).

MODEL DESIGNATION

English

NLX-48 Model

4

Form No. NLXM-1213

English

A

B

Front View

Side View

C

AB

D

E

C

Front View

Front Cover

Side View

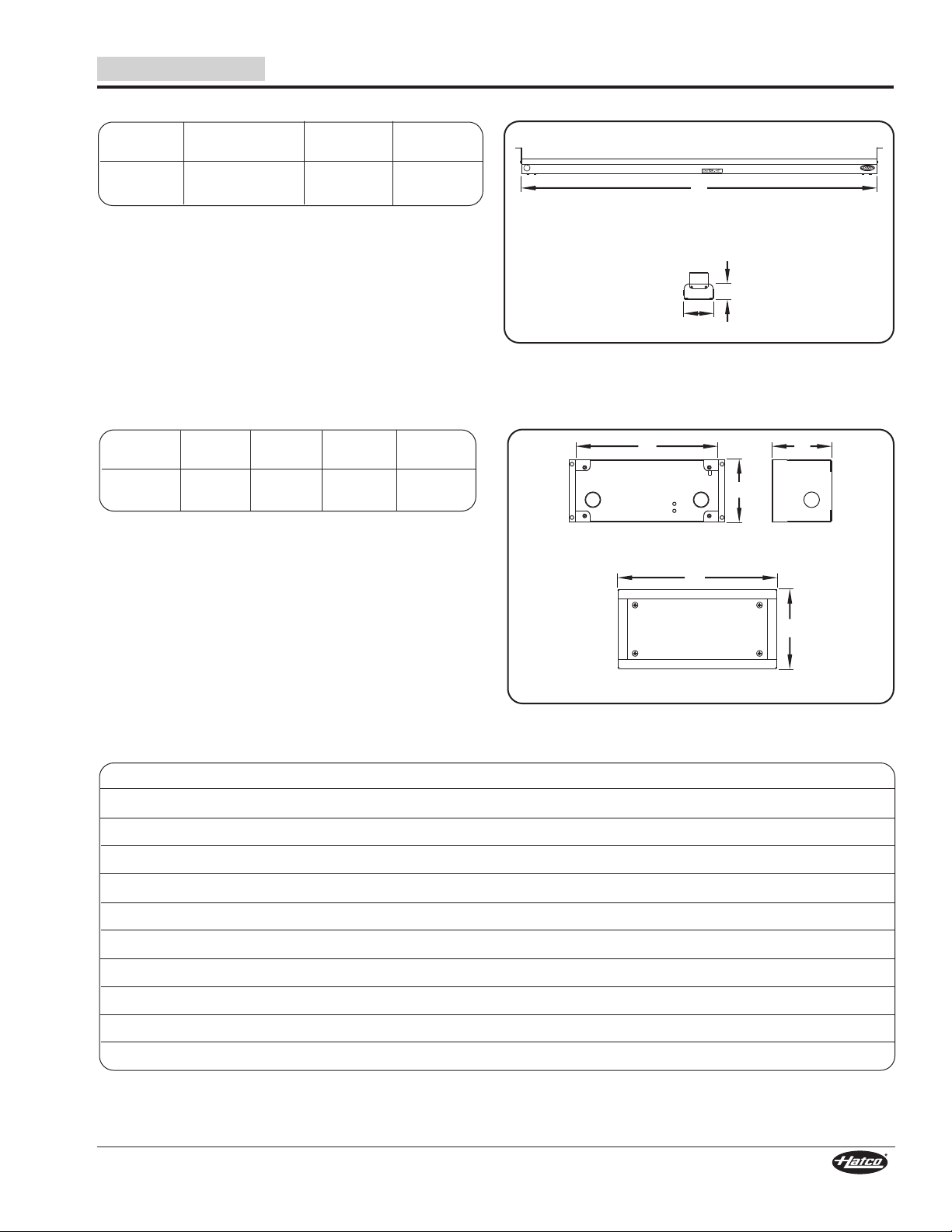

Dimensions — Display Light

Model (A) (B) (C)

NLX-XX

Width Depth Height

18–72" 4" 2-1/8"

(457–1829 mm) (102 mm) (54 mm)

Dimensions — Control Box

Width Depth Height Cover Cover

(A) (B) (C) Width (D) Height (E)

8-1/16" 3-1/4" 3-1/2" 9" 4-1/2"

(205 mm) (82 mm) (89 mm) (229 mm) (114 mm)

SPECIFICATIONS

Dimensions

Electrical Rating Chart

Model Voltage Watts Amps # Xenon Bulbs Shipping Weight

NLX-18 120 100 0.8 2 10 lbs. (5 Kg)

NLX-24 120 150 1.3 3 11 lbs. (5 Kg)

NLX-30 120 150 1.3 3 12 lbs. (5 Kg)

NLX-36 120 250 2.1 5 13 lbs. (6 Kg)

NLX-42 120 250 2.1 5 14 lbs. (6 Kg)

NLX-48 120 250 2.1 5 15 lbs. (7 Kg)

NLX-54 120 350 2.9 7 17 lbs. (8 Kg)

NLX-60 120 350 2.9 7 18 lbs. (8 Kg)

NLX-66 120 450 3.8 9 19 lbs. (9 Kg)

NLX-72 120 450 3.8 9 20 lbs. (9 Kg)

NOTE: Specification label located on the side of the unit. See label for serial number and verification of unit electrical information.

Form No. NLXM-1213

Control Box Dimensions

5

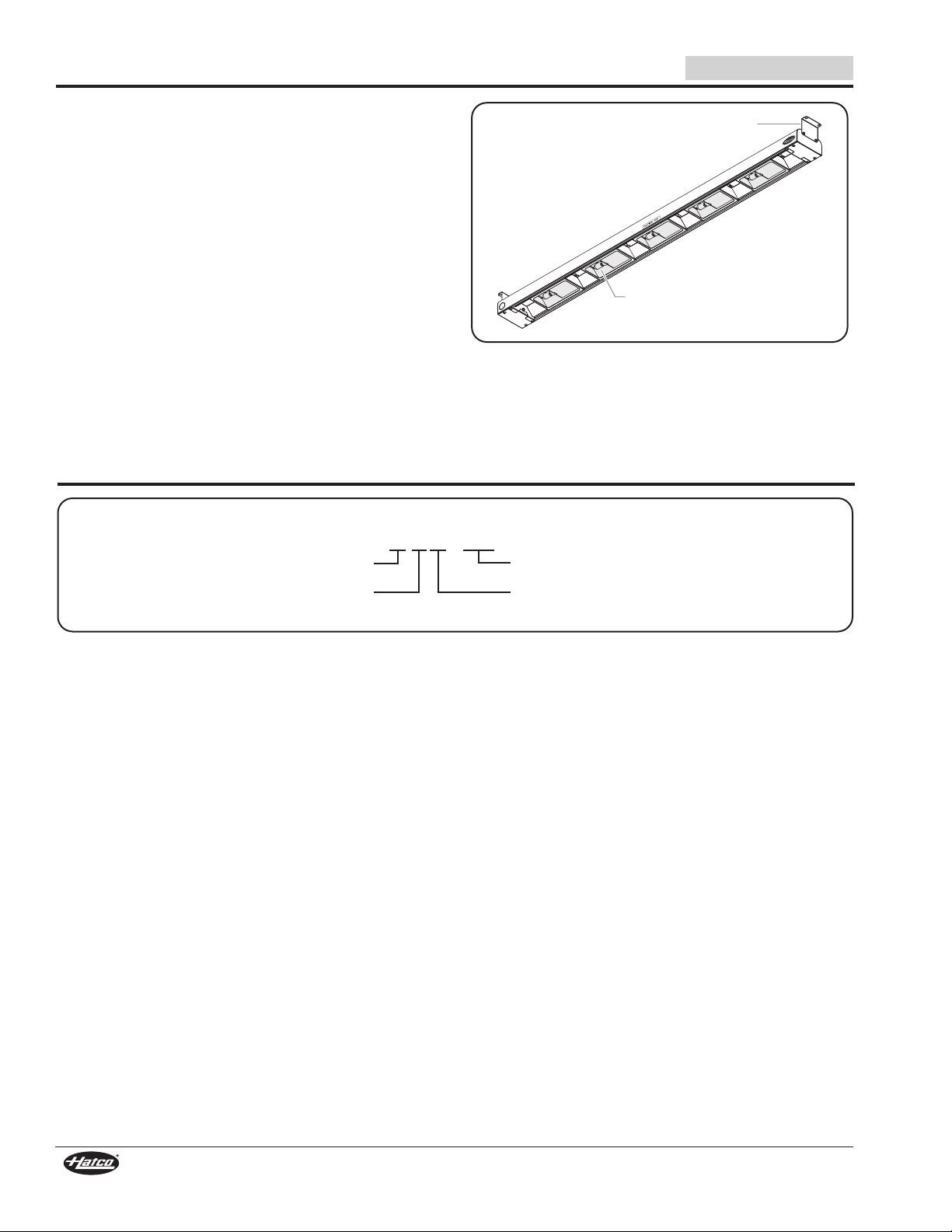

INSTALLATION

WARNING

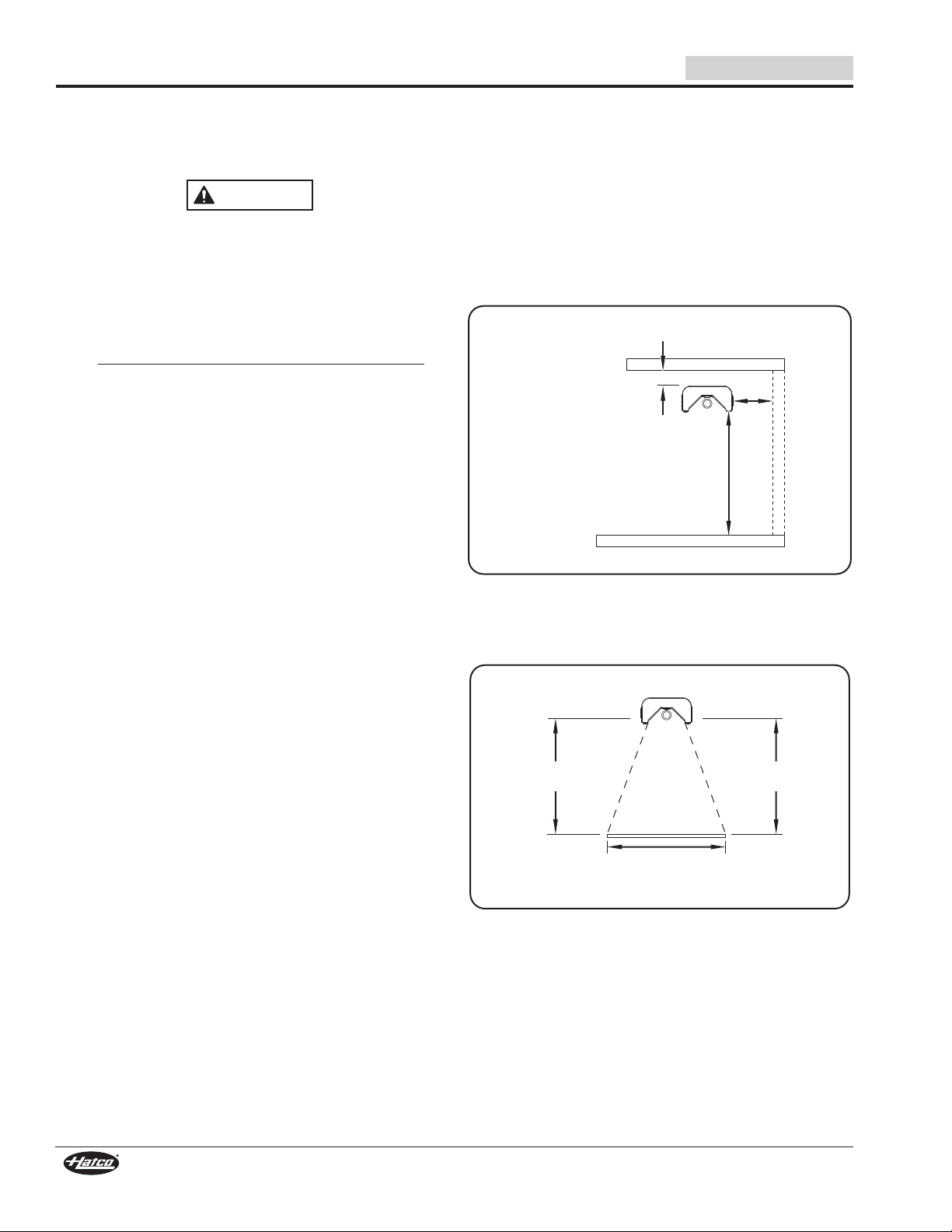

1-1/2″

(38 mm)

2″ (51 mm)2″ (51 mm)

Shelf

Back or

Side Wall

Counter

7″

(178 mm)

Minimum Clearance Above

Non-Combustible Surface

=

10″

(254 mm)

Minimum Clearance Above

Combustible Surface

=

Light Pattern Dimension

(determined by mounting height —

approximately 12″ [305 mm])

9–13″

(229–330 mm)

Recommended Install

Height Above

Non-Combustible Surface

Recommended Install

Height Above

Combustible Surface

10–13″

(254–330 mm)

English

General

Use the information in this section to prepare for installation of

a NLX Series Narrow Display Light. Make sure to locate the

specific information for the type of installation.

ELECTRIC SHOCK HAZARD:

• Unit must be installed by a qualified electrician.

Installation must conform to all local electrical codes.

Installation by unqualified personnel will void unit

warranty and may lead to electric shock or burn, as well

as damage to unit and/or its surroundings.

• Consult a licensed electrical contractor for proper

electrical installation conforming to local electrical

codes and the National Electrical Code (N.E.C.).

FIRE HAZARD:

• Locate unit the correct distance from combustible walls

and materials. If safe distances are not maintained,

discoloration or combustion could occur. Refer to

specific installation and mounting information in this

manual for proper clearances.

• Make sure to follow the installation information listed

below for xenon display lights. If safe distances are not

maintained, discoloration or combustion could occur.

a. Do not install xenon display lights less than 10"

(254 mm) above combustible surfaces.

b. Do not install xenon display lights less than

7" (178 mm) above non-combustible surfaces.

c. Install all xenon display lights with a minimum

distance of 2" (51 mm) from any wall or adjacent

vertical surface.

1. Remove the unit from the carton.

NOTE: To prevent delay in obtaining warranty coverage,

complete online warranty registration. See the

IMPORTANT OWNER INFORMATION section for

details.

2. Remove tape and protective packaging from all surfaces of

the unit.

3. Install the unit in the desired location. Refer to the

“Installing the Unit” procedure in this section.

• Locate the unit in an area where the ambient air

temperature is constant and a minimum of 70°F (21°C).

• Make sure the unit is installed with the proper

clearances from adjacent surfaces.

4. Install the control box in the desired location. Refer to

“Installing the Control Box” procedure in this section.

Installation Site Requirements

The installation site must meet specific requirements for safe

and proper installation of the unit.

• Make sure the installation site provides the proper

minimum clearances for adjacent surfaces. The following

are the required minimum clearances:

Above Unit = 1-1/2" (38 mm)

Sides of Unit = 2" (51 mm)

Below Unit = 7" (178 mm), non-combustible base surface

10" (254), combustible base surface

Minimum Clearances

NOTE: Xenon display lights can be installed over a steam table.

Follow the clearance requirements for installation over

a non-combustible base surface.

Recommended Installation Heights

6

Form No. NLXM-1213

English

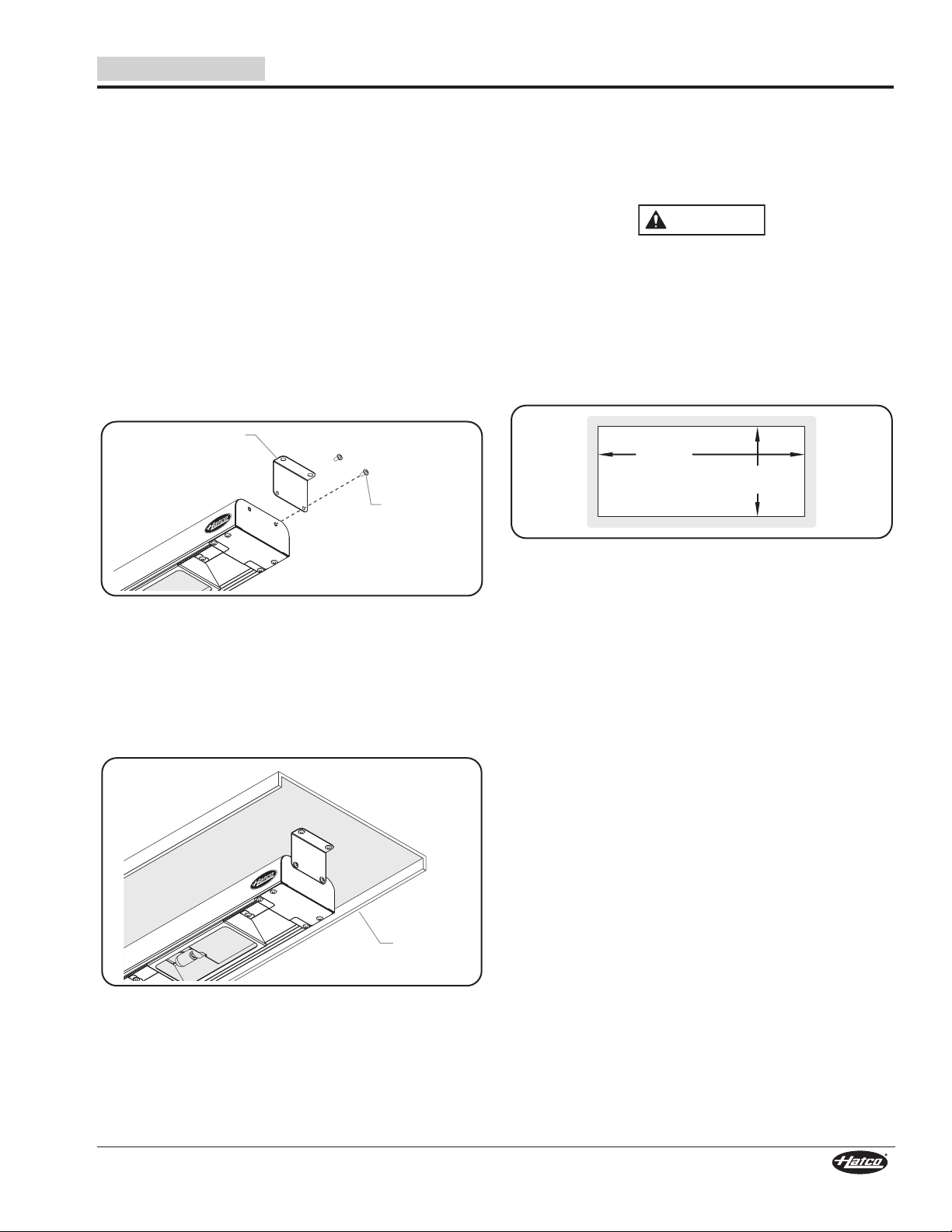

Angle Bracket

Angle Bracket

Screw

Shelf

WARNING

205 mm

(8-1/8″)

98 mm

(3-7/8″)

INSTALLATION

Installing the Unit

Use the following procedure to install the unit using the supplied

angle brackets. Refer to the OPTIONS AND ACCESSORIES

section near the back of this manual for other installation

options.

NOTE: Consult the manufacturer of the countertop material for

application information before installing the unit.

1. Position the unit on a flat surface with the display lights

facing down.

2. Install the angle brackets on each end of the unit.

NOTE: The angle brackets are shipped loose in the carton.

On each end of the unit:

a. Remove the two angle bracket screws.

b. Align the angle bracket with the mounting holes on the

unit. Secure the bracket with the two angle bracket

screws.

Angle Bracket Installation

NOTE: The angle brackets provide the required 1-1/2" (38 mm)

minimum clearance above the unit.

3. Fasten the angle brackets to the underside of the shelf

using appropriate fasteners (not supplied by Hatco). Make

sure the unit is facing the desired direction with the wire

leads on the proper side before fastening the unit to the

shelf.

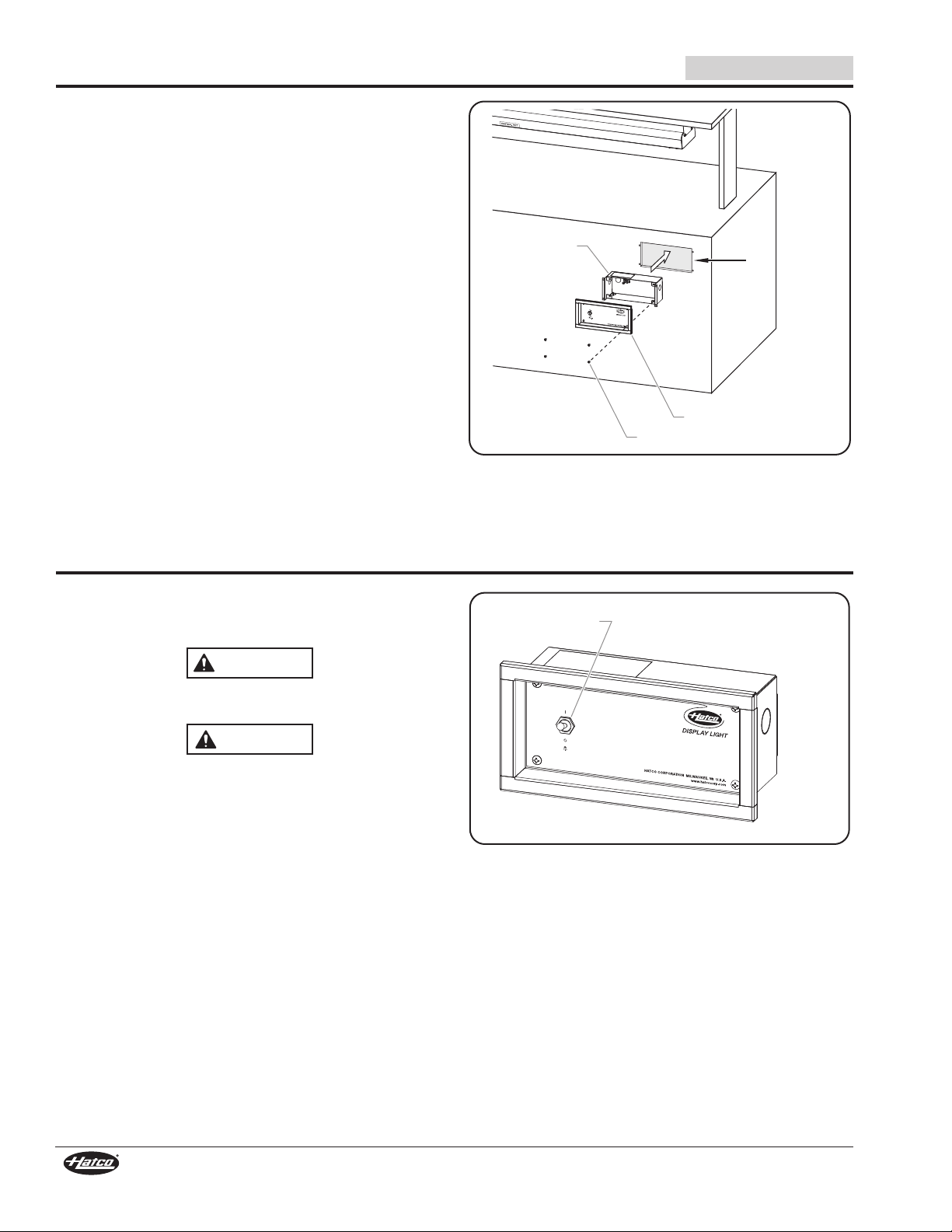

Installing the Control Box

Use the following procedure to install the control box.

NOTE: Units can be ordered with up to ten feet (3 m) of wire

leads, depending on the installation location of the

control box.

Control box must be mounted in a vertical surface.

Mounting control box in a horizontal surface may result in

the collection of liquids and lead to electric shock.

1. Make the appropriate cutout in the vertical surface where

the control box will be installed. Refer to the illustration

below for cutout dimensions specific to the size of the unit.

NOTE: Make sure a minimum depth of 5-1/4" (133 mm) is

available behind the vertical surface for the depth of the

control box and wires.

Control Box Cutout Dimensions

NOTE: Make sure the width of the control box cutout does not

exceed the above dimension.

2. Complete the routing of the wire leads from the unit to meet

up with the wire leads on the control box.

3. Route the wire leads from the power supply to meet up with

the wire leads on the control box.

4. Remove the four front cover mounting screws and pull the

front cover off of the control box.

continued...

4. Route the wire leads toward the installation location for the

Form No. NLXM-1213

control box.

Shelf Installation

7

INSTALLATION

CAUTION

WARNING

Lights I/O

(On/Off) Switch

Front Cover

Front Cover Screw

Control Box

Control Box

Cutout

Control Box

Cutout

5. Make the electrical connections between the unit and the

control box. Refer to the wiring diagram included with the

unit.

6. Make the electrical connections between the control box

and the power supply. Refer to the wiring diagram included

with the unit.

7. Install the control box in the cutout. Make sure the wiring

on the back of control box is not pinched during installation.

8. Fasten the control box to the vertical surface using four

screws (not supplied).

9. Position the front cover on the control box and secure in

position using the four front cover screws.

English

Installing the Control Box

OPERATION

General

Use the following information to operate a NLX Series Narrow

Display Light.

Read all safety messages in the IMPORTANT SAFETY

INFORMATION SECTION before operating this equipment.

Standard and approved manufacturing oils may smoke up

to 30 minutes during initial startup. This is a temporary

condition. Operate unit without food product until smoke

dissipates.

Startup

1. Move the Lights I/O (on/off) switch to the “I” (on) position.

The xenon display lights will illuminate.

Shutdown

1. Move the Lights I/O (on/off) switch to the “O” (off) position.

2. Perform the “Daily Cleaning” procedure in the

MAINTENANCE section of this manual.

NLX Series Standard Control Box

8

Form No. NLXM-1213

Loading...

Loading...