Page 1

hatcocorp.com

ADVERTENCIA

Register Online!

(see page 2)

S’inscrire en ligne!

(voir page 26)

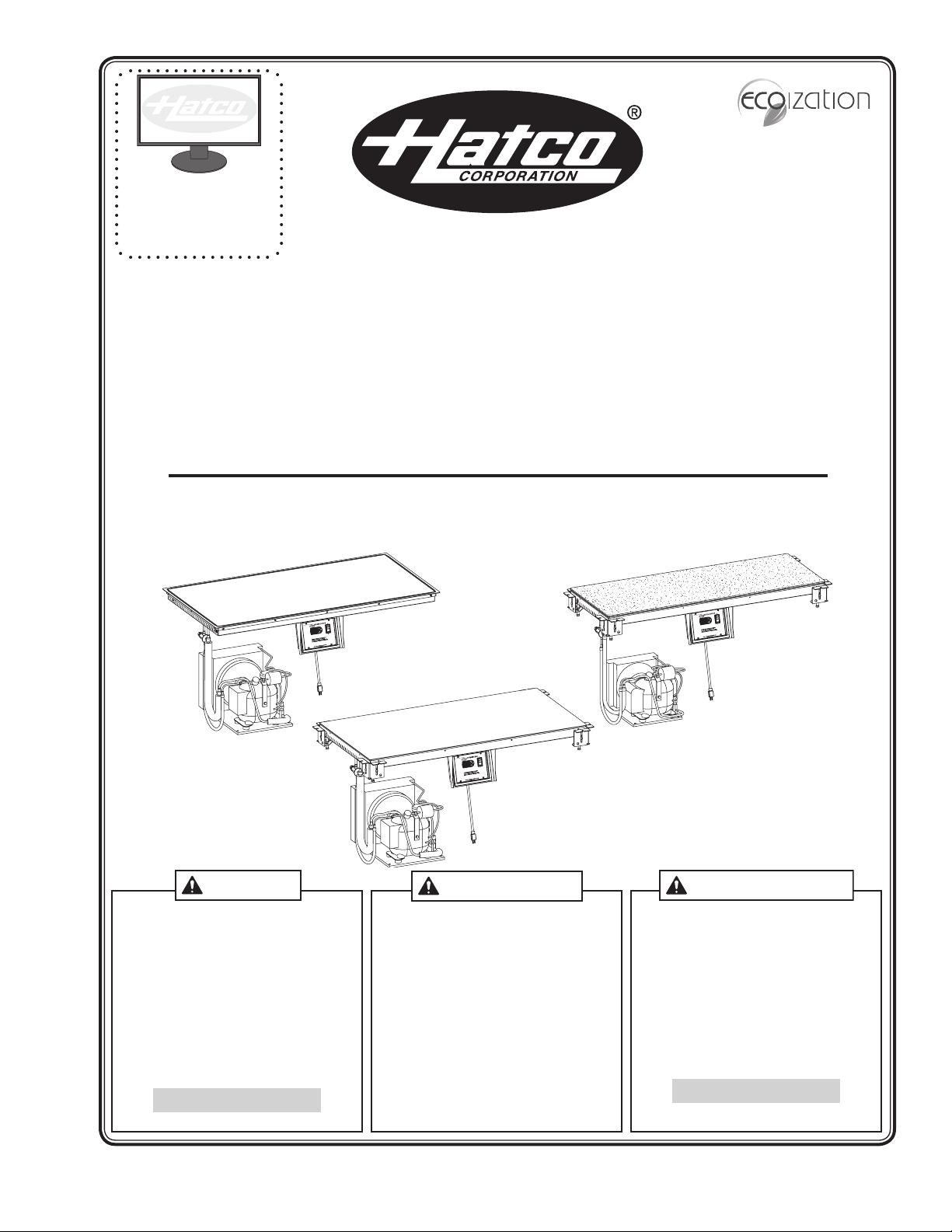

Cold Shelves Built-In

Plaques réfrigérantes

encastrables

CSU, CSBF, CSSB, CSSBF Series/Série

Installation and Operating Manual

Manuel d’installation et d’utilisation

Do not operate this equipment unless you

have read and understood the contents

of this manual! Failure to follow the

instructions contained in this manual

may result in serious injury or death.

This manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

P/N 07.04.721.00 © 2017 Hatco Corporation

WARNING

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en

este manual puede resultar en un serio

lesión o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted

no puede entender el contenido de

este manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

AVERTISSEMENT

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel ! Le

non-respect des instructions contenues

dans ce manuel peut entraîner de

graves blessures ou la mort. Ce manuel

contient des informations importantes

concernant l’entretien, l’utilisation et le

fonctionnement de ce produit. Si vous ne

comprenez pas le contenu de ce manuel,

veuillez le signaler à votre supérieur.

Conservez ce manuel dans un endroit

sûr pour pouvoir vous y référer plus tard.

Français = p 26

Page 2

CONTENTS

English

Important Owner Information .............................................. 2

Introduction ...........................................................................2

Important Safety Information .............................................. 3

Model Designation ...............................................................4

Model Description ................................................................5

Specifications ....................................................................... 6

Plug Configuration ............................................................... 6

Electrical Rating Charts ....................................................... 6

Refrigerant Information ........................................................ 9

Dimensions ........................................................................ 10

Installation ...........................................................................13

General .............................................................................. 13

Preparing the Installation Site ...........................................13

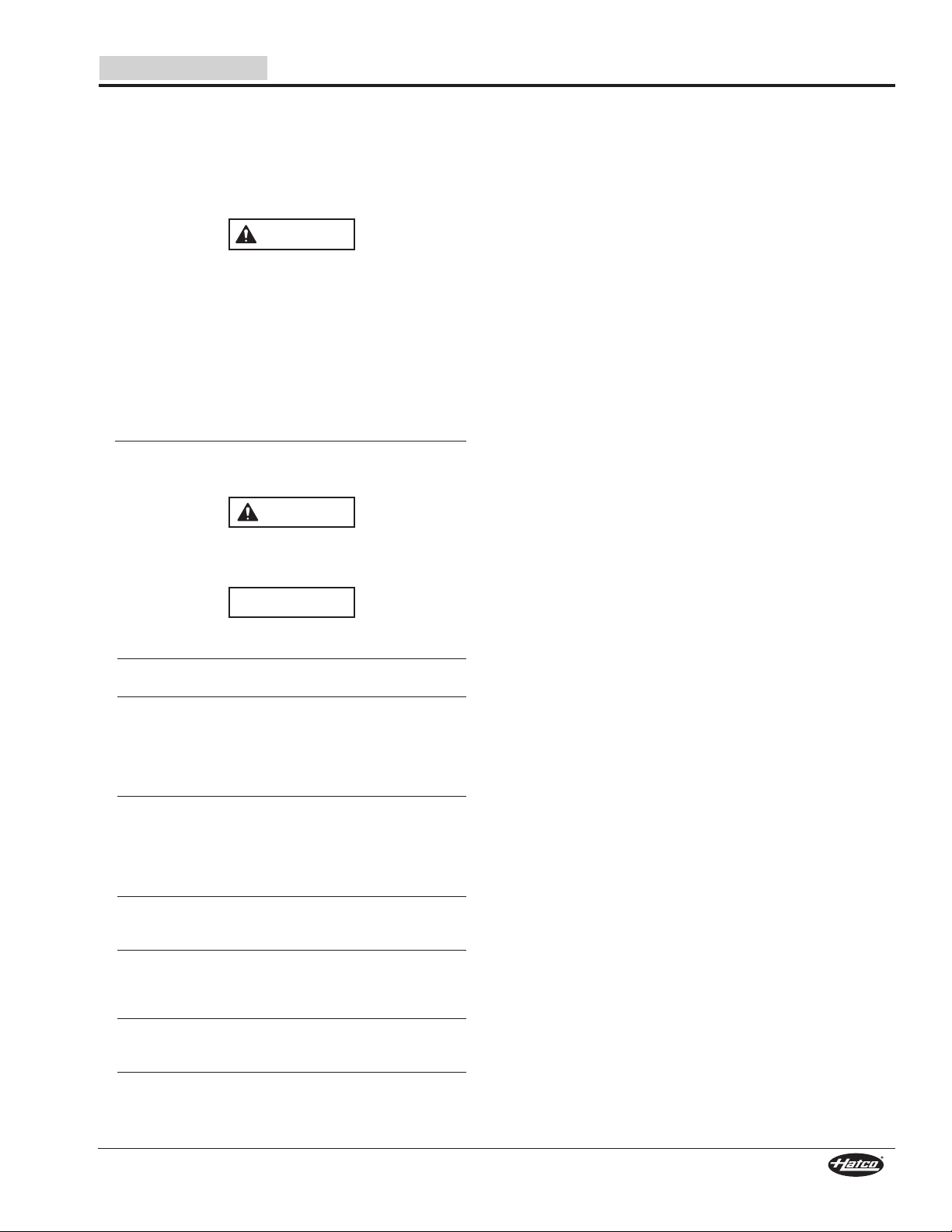

Installing a Top Mounted Unit (CSBF Models) ..................14

Countertop Cutout Dimensions (CSBF Models) ................ 14

Countertop Cutout and Mounting Bolt Dimensions

(CSSB and CSSBF Models) ...........................................15

Installing a Bottom Mounted Unit

(CSSB and CSSBF Models) ...........................................16

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the side of the control enclosure). Please

have this information available when calling Hatco for service

assistance.

Model No. ________________________________________

Serial No. _________________________________________

Voltage ___________________________________________

Date of Purchase ___________________________________

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

Installing an Under Mounted Unit (CSU Models) .............. 17

Installing the Control Enclosure Remotely ........................18

Mounting Bolt Dimensions (CSU Models) ......................... 19

Operation .............................................................................20

General .............................................................................. 20

Changing the Setpoint Temperature ..................................21

Setting the Auto-Defrost Cycle ..........................................21

Changing Fahrenheit and Celsius Setting .........................21

Maintenance ........................................................................ 22

General .............................................................................. 22

Daily Cleaning ...................................................................22

Cleaning the Stone Surface

(CSSB and CSSBF Models) ...........................................23

Monthly Cleaning ............................................................... 23

Troubleshooting Guide ......................................................24

Options and Accessories .................................................. 25

Limited Warranty ................................................................25

Authorized Parts Distributors ........................... Back Cover

Business

Hours: 7:00 am to 5:00 pm Central Standard Time (CST)

(Summer Hours: June to September—

7:00 am to 5:00 pm CST Monday–Thursday

7:00 am to 4:00 pm CST Friday)

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

INTRODUCTION

Hatco Cold Shelves are specially designed to hold chilled

foods at safe serving temperatures. The insulated, top mount

or bottom mount units are available in several sizes.

Hatco Cold Shelves are products of extensive research and

field testing. The materials used were selected for maximum

durability, attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior to shipment.

This manual provides the installation, safety, and operating

instructions for Cold Shelves. Hatco recommends all

installation, operating, and safety instructions appearing in this

manual be read prior to installation or operation of the unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to

personal injury.

2

Form No. CSM-0417

Page 3

English

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid serious

injury or death and to avoid damage to equipment or property.

WARNING

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install proper voltage and

size electrical receptacle.

• Turn OFF power switch and unplug power cord before

performing any cleaning, adjustments, or maintenance.

• Unit is not weatherproof. Locate unit indoors.

• Control enclosure must be mounted in a vertical

surface. Mounting control enclosure in a horizontal

surface may result in the collection of liquids and lead

to electric shock.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• This unit is not “jet-proof” construction. Do not use

jet-clean spray to clean this unit.

• Do not steam clean or use excessive water on unit.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power

cord. Cord must be replaced by an Authorized Hatco

Service Agent or a person with similar qualifications.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

FIRE HAZARD:

• Install condensingunitwithaminimumof2″(51mm)

of space between all sides of unit and any combustible

surfaces.

• Do not use flammable cleaning solutions to clean this

unit.

EXPLOSION HAZARD: Do not store or use gasoline or

other flammable vapors or liquids in the vicinity of this or

any other appliance.

Make sure food product and food pans have been chilled

to the proper food-safe temperature before placing on

unit. Failure to chill food product properly may result in

serious health risks. This unit is for holding pre-chilled

food product only.

This unit is for holding food for short periods of time.

Never hold food longer than 4 hours.

Hatco Corporation is not responsible for actual food

product serving temperature. It is the responsibility of the

user to ensure that food product is held and served at a

safe temperature.

Form No. CSM-0417

WARNING

Maintain proper cleanliness of unit. Proper cleanliness and

sanitation is critical for food-safe operation. Refer to the

MAINTENANCE section for cleaning procedures.

Do not place food product directly onto hardcoat or

simulated stone surface. Food product must be wrapped,

boxed, or on a food pan.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them

away from the unit.

Make sure all operators have been instructed on the safe

and proper use of the unit.

This unit has no “user-serviceable” parts. If service

is required on this unit, contact an Authorized Hatco

Service Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350.

CAUTION

Locate the unit at proper counter height in an area that is

convenient for use. The location should be level and strong

enough to support the weight of the unit and contents.

DO NOT tip unit/mounting surface after final installation.

Unit is free-floating and could fall out if tipped—for

permanent, horizontal installations only.

Make sure to clean and sanitize stone surface properly

after deep cleaning the surface using abrasives and before

placing food product on unit.

NOTICE

This unit is designed for use in environments where

ambient temperature is between 65°F (18°C) and 86°F

(30°C).

When shipped during cold weather months, store unit

for at least 10 hours in an environment where ambient

temperature is between 65°F (18°C) and 86°F (30°C) to

prevent compressor and/or refrigerant line damage. If unit

is turned on and there is excessive noise and vibration,

turn off immediately and allow additional warmup time.

Provide louvered or grill-style openings with a minimum

sizeof12″x12″/144squareinches(31x31cm/961square

cm) in the cabinetry in front of and behind the condensing

unit for proper ventilation. Failure to provide adequate air

flow through the condensing unit may cause unit failure

and will void the unit warranty.

Do not recirculate exhaust air inside cabinet when multiple

condensing units are installed together. Intake air should

enter from outside of cabinet.

Transport and install unit in upright position only. Failure

to do so may result in damage to the refrigeration system.

Use caution and avoid hitting condensing unit hoses/lines

when installing unit. Damage caused during installation is

not covered under warranty.

3

Page 4

IMPORTANT SAFETY INFORMATION

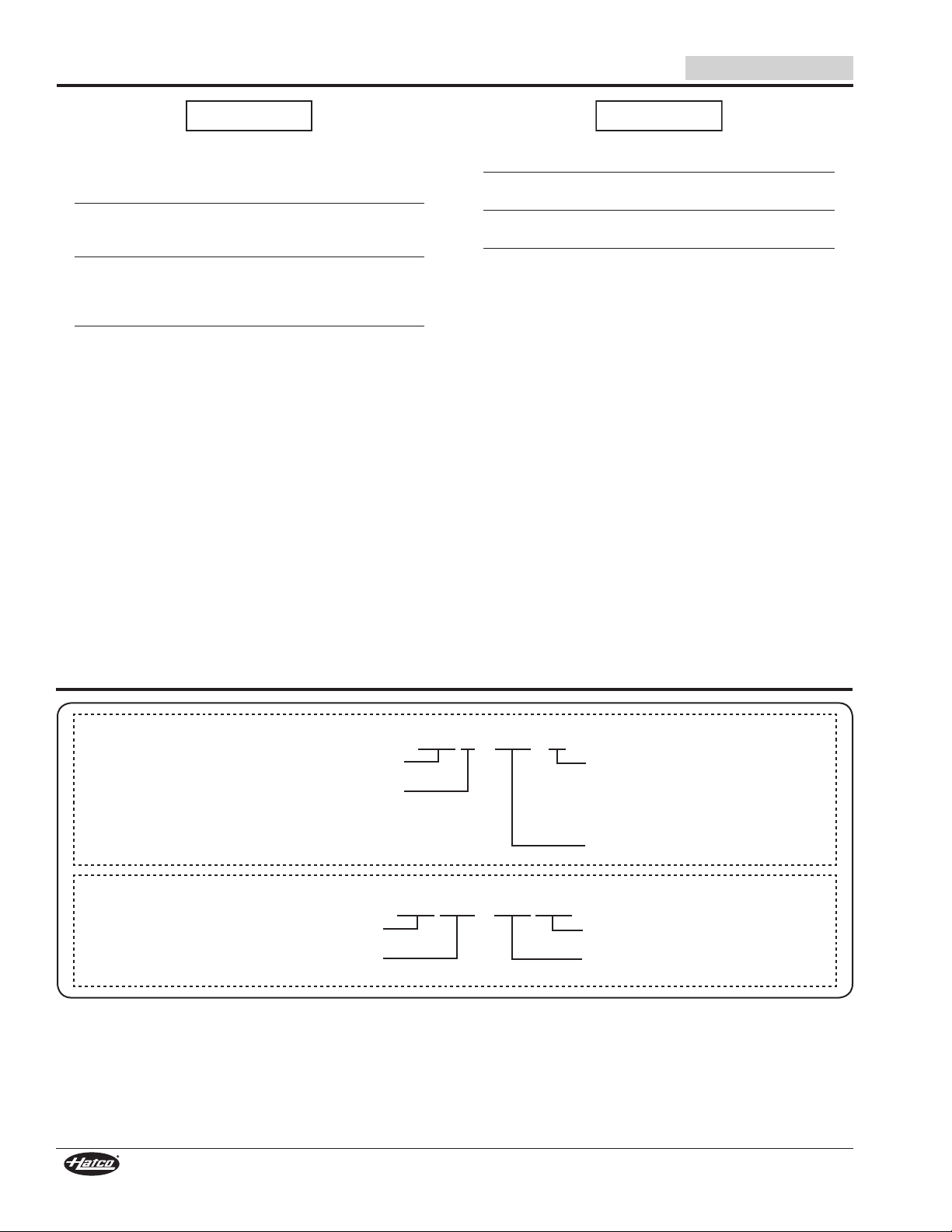

C S B - X X - X

Cold Shelf

B = Hardcoat Surface, Built-In, Bottom-Mount

SBF = Stone Surface, Built-In, Top-Mount

U = Under Counter-Mount

Cooled Width of Shelf (inches)

Cooled Depth of Shelf:

F = 15-1/2" (394 mm)

I = 19-1/2" (495 mm)

S = 24" (610 mm)

C S S B - X X X X

Cold Shelf

Stone Surface, Built-In, Bottom-Mount

Width of Shelf (inches)

Depth of Shelf (inches)

English

NOTICE

Do not locate unit in area with excessive air movement

around unit. Avoid areas that may be subject to active air

movements or currents (i.e., near exhaust fans/hoods, air

conditioning ducts, and exterior doors).

Do not locate unit in an area subject to excessive

temperatures or grease from grills, fryers, etc. Excessive

temperatures could cause damage to the unit.

Damage to any countertop material caused by heat or cold

generated from Hatco equipment is not covered under

the Hatco warranty. Contact manufacturer of countertop

material for application information.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch the finish of the unit,

marring its appearance and making it susceptible to soil

accumulation.

NOTICE

Do not use steel wool for cleaning. Steel wool will scratch

the finish.

Do not use harsh chemicals such as bleach, cleaners

containing bleach, or oven cleaners to clean the unit.

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

This unit is intended for commercial use only—NOT for

household use.

MODEL DESIGNATION

4

Form No. CSM-0417

Page 5

English

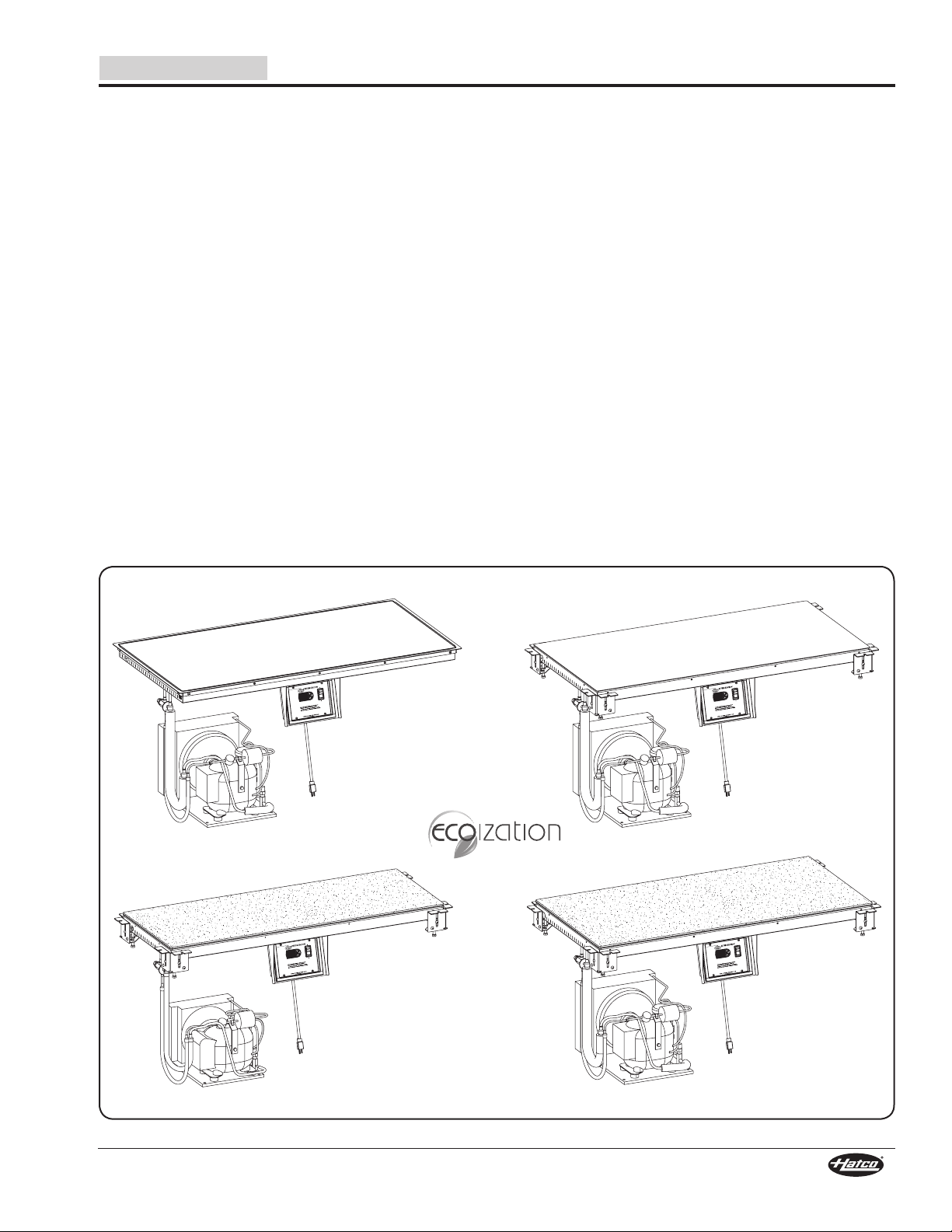

Model CSBF-48-S

Model CSSBF-48-S

Model CSSB-4818

Model CSU-48-S

MODEL DESCRIPTION

All Models

Hatco Cold Shelves are reliable and versatile. Each unit has

an insulated, stainless steel and aluminized steel housing.

A copper evaporator coil wound under the entire hardcoat

aluminum or stone surface provides even chilling from edge

to edge. A condensing unit is connected to the evaporator

coil with a flexible tubing assembly. Hatco Cold Shelves are

designed, manufactured, and tested to maintain safe food

holding temperatures.

Controls for the Cold Shelves are housed in a single, remotemountable control enclosure. They include a Power I/O (on/

off) Switch and a digital temperature controller. The control

enclosure is connected to the condensing unit with a 4′

(1219 mm) power cord. A 6′ (1829 mm) power cord and plug

connected to the control panel provides power to the entire

unit.

Depending on the model, Built-In Cold Shelves are designed to

be mounted to the top side, bottom side, or underneath various

types of countertop material including stainless steel, wood,

Corian, and Swanstone.

The ecoization logo identifies products designed to reflect

Hatco’s commitment to improving, protecting, and preserving

the global environment. Hatco Built-In Cold Shelves qualify for

the ecoization logo through the use of eco-friendly insulation as

well as a highly efficient condensing unit.

CSBF Models

CSBF models have a hardcoat aluminum surface and are top

mounted.

CSSB and CSSBF Models

CSSB and CSSBF models have a decorative stone surface

and are bottom mounted.

NOTE: Stone surfaces are a simulated stone solid surface.

CSU Models

CSU models have an aluminum surface and are mounted

directly against the underside of a granite or quartz countertop

(no cutout required). Cooling transfers through the countertop

to the top side for a true, seamless installation.

Form No. CSM-0417

Cold Shelves

5

Page 6

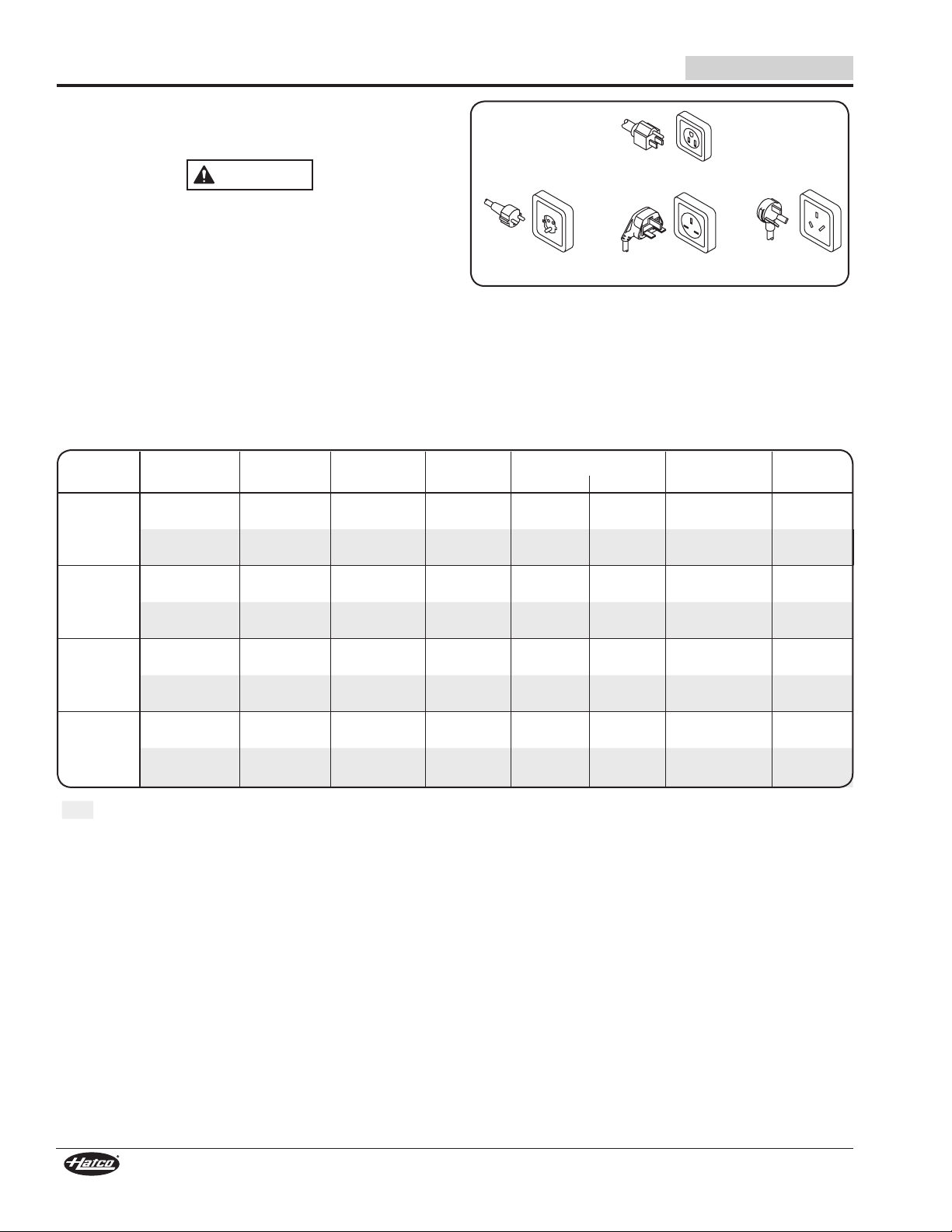

NEMA 5-15P

CEE 7/7 Schuko AS 3112

BS-1363

SPECIFICATIONS

Plug Configuration

Units are supplied from the factory with an electrical cord and

plug installed. Plugs are supplied according to the applications.

WARNING

ELECTRIC SHOCK HAZARD: Plug unit into a properly

grounded electrical receptacle of the correct voltage,

size, and plug configuration. If plug and receptacle do not

match, contact a qualified electrician to determine and

install proper voltage and size electrical receptacle.

NOTE: Receptacle not supplied by Hatco.

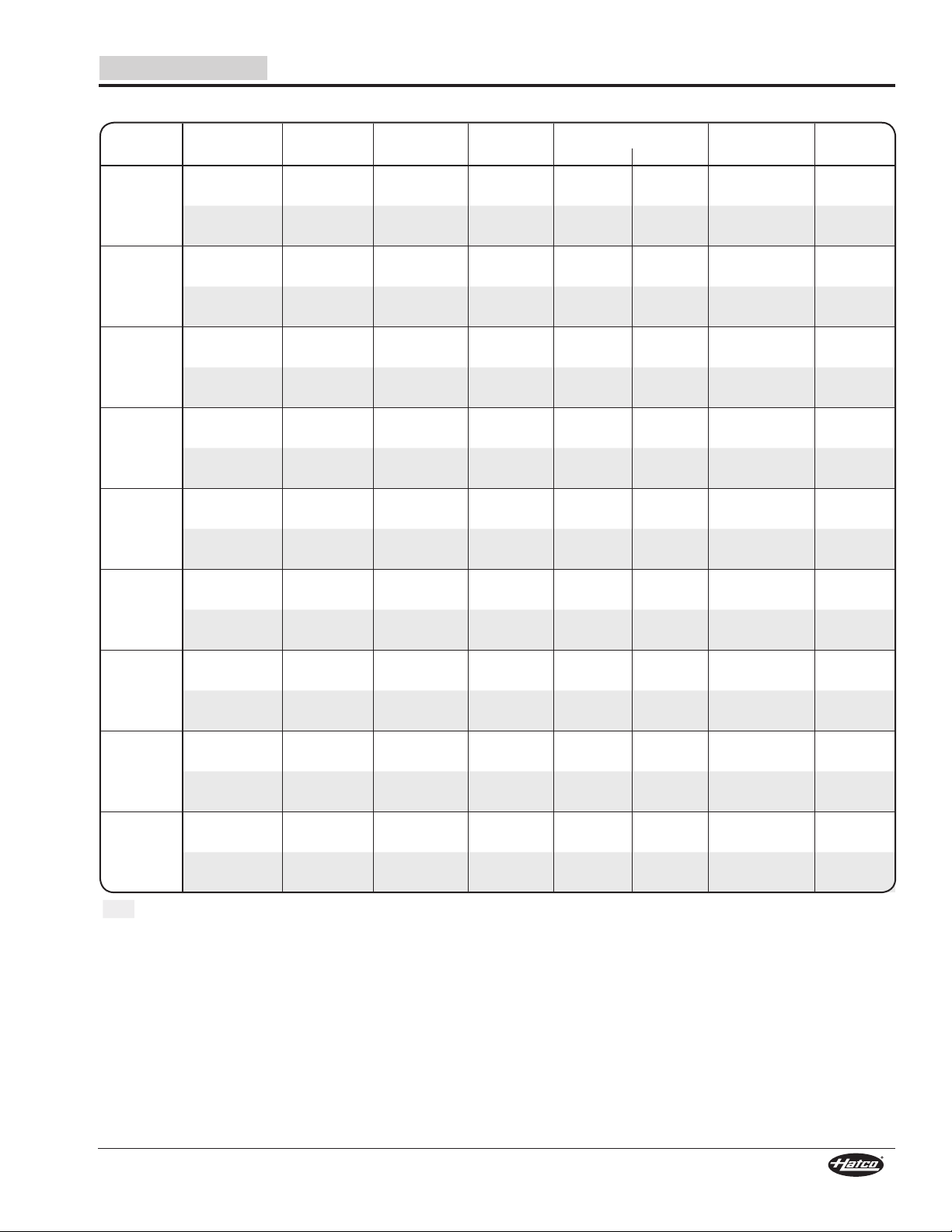

Electrical Rating Chart — CSSB Models

English

Plug Configuration

NOTE: The specification labels are located on the bottom of the

unit and the back of the control panel. See the label for the

serial number and verification of unit electrical information.

Compressor

Design Pressure

Plug Shipping

Model Size Volts Watts Amps High Side Low Side Configuration Weight

CSSB-2418 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSSB-3018 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSSB-3618 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSSB-4818 1/3 hp (60 Hz) 120 1044 8.7

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

The shaded areas contain electrical information for

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

NOTE: Shipping weights are estimated.

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

International models only.

NOTE: Shipping weight includes packaging.

105 lbs.

(48 kg)

105 lbs.

(48 kg)

131 lbs.

(59 kg)

131 lbs.

(59 kg)

149 lbs.

(68 kg)

149 lbs.

(68 kg)

171 lbs.

(78 kg)

171 lbs.

(78 kg)

6

Form No. CSM-0417

Page 7

English

SPECIFICATIONS

Electrical Rating Chart — CSBF Models

Compressor

Design Pressure

Model Size Volts Watts Amps High Side Low Side Configuration Weight

CSBF-24-F 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSBF-24-I

CSBF-24-S 1/4 hp (60 Hz) 120 804 6.7

CSBF-36-F 1/4 hp (60 Hz) 120 804 6.7

CSBF-36-I 1/3 hp (60 Hz) 120 1044 8.7

CSBF-36-S 1/3 hp (60 Hz) 120 1044 8.7

CSBF-48-F 1/3 hp (60 Hz) 120 1044 8.7

CSBF-48-I 1/3 hp (60 Hz) 120 1044 8.7

CSBF-48-S 1/2 hp (60 Hz) 120 1380 11.5

1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

1/2 hp (50 Hz) 220–230–240 1190–1300–1416 5.4–5.6–5.9

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

331 psig

(22.8 bar)

331 psig

(22.8 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

Plug Shipping

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

96 lbs.

(44 kg)

96 lbs.

(44 kg)

109 lbs.

(49 kg)

109 lbs.

(49 kg)

124 lbs.

(56 kg)

124 lbs.

(56 kg)

121 lbs.

(55 kg)

121 lbs.

(55 kg)

137 lbs.

(62 kg)

137 lbs.

(62 kg)

163 lbs.

(74 kg)

163 lbs.

(74 kg)

144 lbs.

(65 kg)

144 lbs.

(65 kg)

173 lbs.

(78 kg)

173 lbs.

(78 kg)

176 lbs.

(80 kg)

176 lbs.

(80 kg)

The shaded areas contain electrical information for

International models only.

NOTE: Shipping weight includes packaging.

Form No. CSM-0417

NOTE: Shipping weights are estimated.

7

Page 8

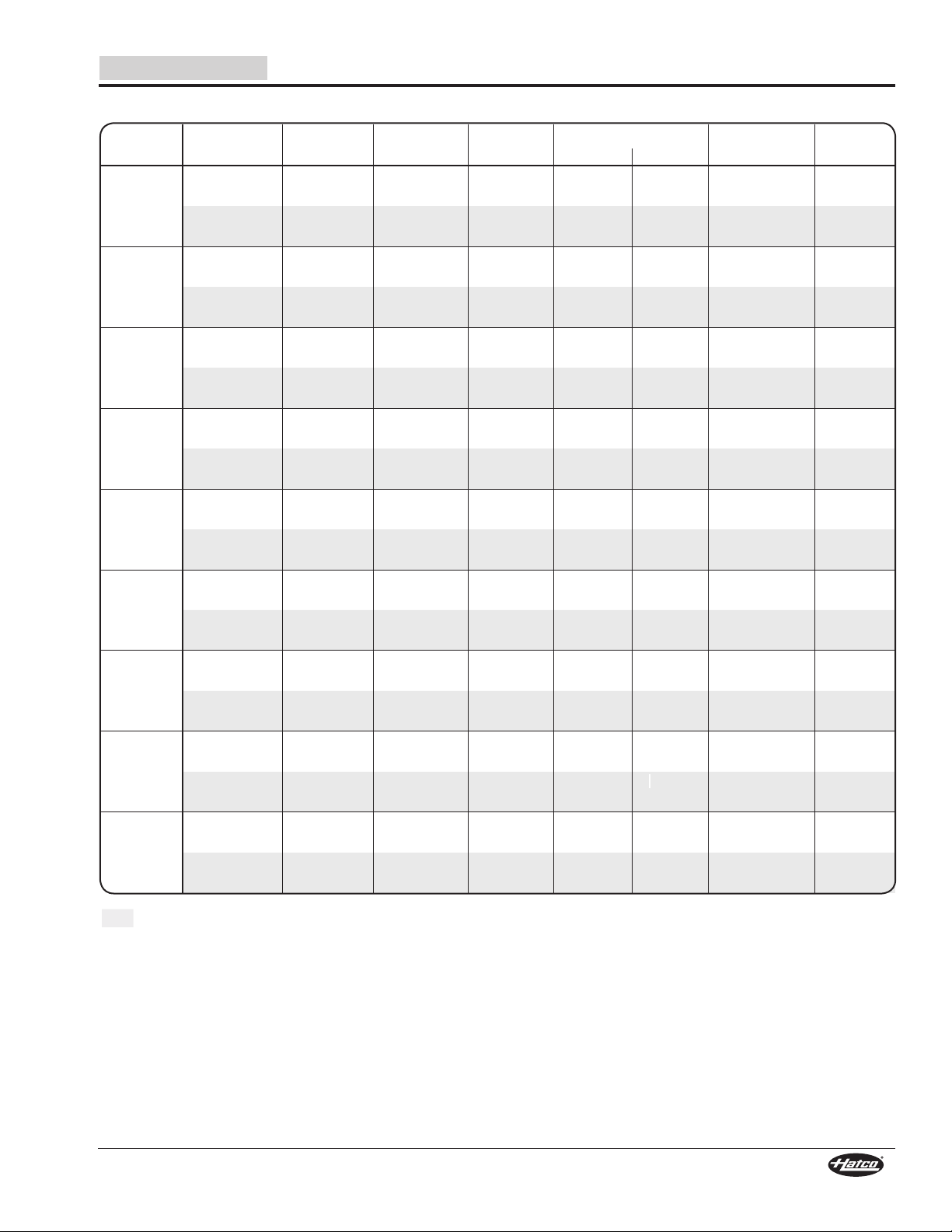

Electrical Rating Chart — CSSBF Models

English

Compressor

Design Pressure

Plug Shipping

Model Size Volts Watts Amps High Side Low Side Configuration Weight

CSSBF-24-F 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSSBF-24-I

CSSBF-24-S 1/4 hp (60 Hz) 120 804 6.7

CSSBF-36-F 1/4 hp (60 Hz) 120 804 6.7

CSSBF-36-I 1/3 hp (60 Hz) 120 1044 8.7

CSSBF-36-S 1/3 hp (60 Hz) 120 1044 8.7

CSSBF-48-F 1/3 hp (60 Hz) 120 1044 8.7

CSSBF-48-I 1/3 hp (60 Hz) 120 1044 8.7

CSSBF-48-S 1/2 hp (60 Hz) 120 1380 11.5

1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

1/2 hp (50 Hz) 220–230–240 1190–1300–1416 5.4–5.6–5.9

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

331 psig

(22.8 bar)

331 psig

(22.8 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

101 lbs.

(46 kg)

101 lbs.

(46 kg)

115 lbs.

(52 kg)

115 lbs.

(52 kg)

131 lbs.

(59 kg)

131 lbs.

(59 kg)

130 lbs.

(59 kg)

130 lbs.

(59 kg)

146 lbs.

(66 kg)

146 lbs.

(66 kg)

173 lbs.

(78 kg)

173 lbs.

(78 kg)

153 lbs.

(69 kg)

153 lbs.

(69 kg)

187 lbs.

(85 kg)

187 lbs.

(85 kg)

195 lbs.

(89 kg)

195 lbs.

(89 kg)

The shaded areas contain electrical information for

International models only.

NOTE: Shipping weight includes packaging.

NOTE: Shipping weights are estimated.

8

Form No. CSM-0417

Page 9

English

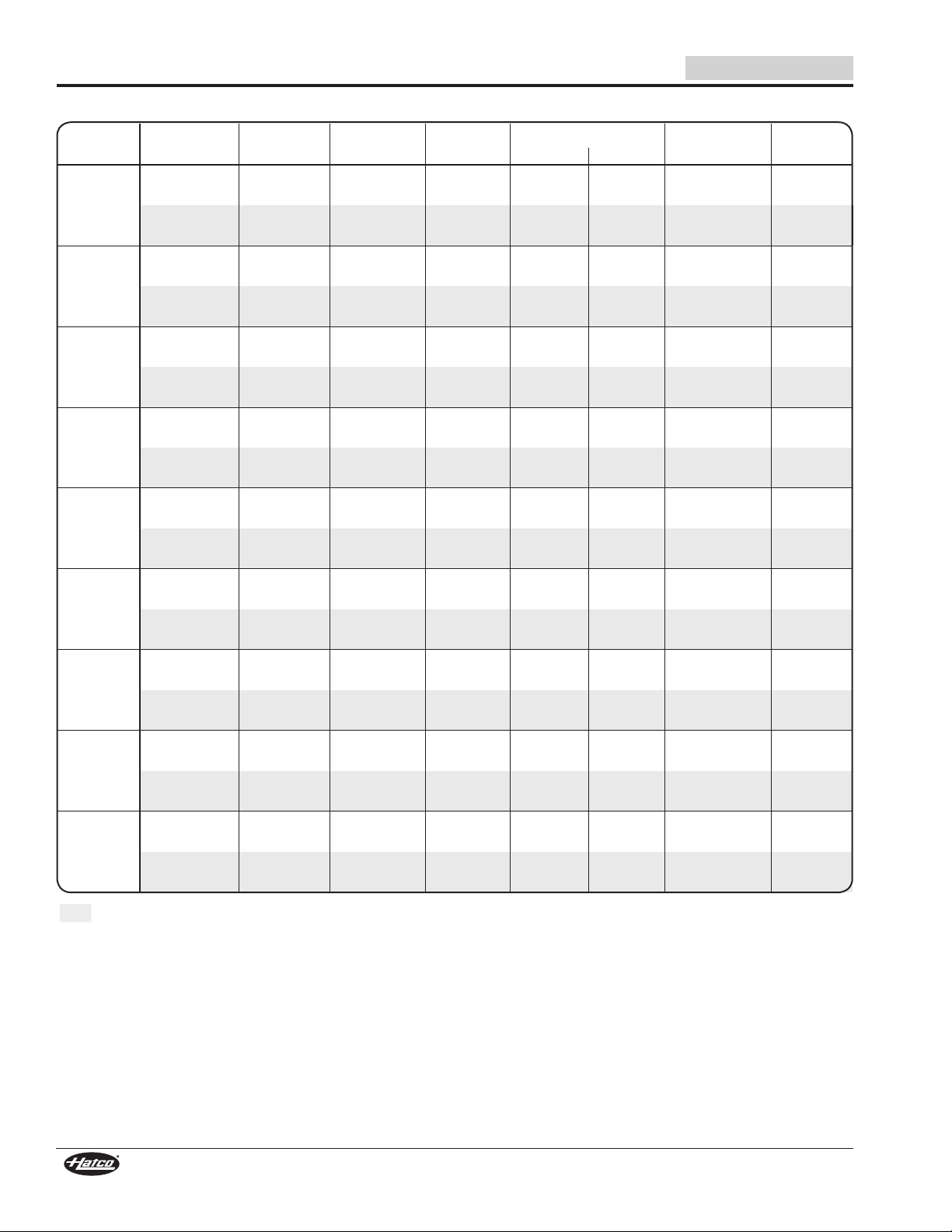

Electrical Rating Chart — CSU Models

Compressor

Design Pressure

Plug Shipping

Model Size Volts Watts Amps High Side Low Side Configuration Weight

CSU-24-F 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSU-24-I 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSU-24-S 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSU-36-F 1/4 hp (60 Hz) 120 804 6.7

1/3 hp (50 Hz) 220–230–240 616–667–744 2.8–2.9–3.1

CSU-36-I 1/3 hp (60 Hz) 120 1044 8.7

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

CSU-36-S 1/3 hp (60 Hz) 120 1044 8.7

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

CSU-48-F 1/3 hp (60 Hz) 120 1044 8.7

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

CSU-48-I 1/3 hp (60 Hz) 120 1044 8.7

3/8 hp (50 Hz) 220–230–240 807–882–960 3.7–3.8–4.0

CSU-48-S 1/2 hp (60 Hz) 120 1380 11.5

1/2 hp (50 Hz) 220–230–240 1190–1300–1416 5.4–5.6–5.9

The shaded areas contain electrical information for

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

373 psig

(25.7 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

423 psig

(29.1 bar)

331 psig

(22.8 bar)

331 psig

(22.8 bar)

NOTE: Shipping weights are estimated.

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

174 psig

(12 bar)

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

NEMA 5-15P

CEE 7/7,

BS-1363, AS 3112

International models only.

NOTE: Shipping weight includes packaging.

101 lbs.

(46 kg)

101 lbs.

(46 kg)

115 lbs.

(52 kg)

115 lbs.

(52 kg)

131 lbs.

(59 kg)

131 lbs.

(59 kg)

130 lbs.

(59 kg)

130 lbs.

(59 kg)

146 lbs.

(66 kg)

146 lbs.

(66 kg)

173 lbs.

(78 kg)

173 lbs.

(78 kg)

153 lbs.

(69 kg)

153 lbs.

(69 kg)

187 lbs.

(85 kg)

187 lbs.

(85 kg)

195 lbs.

(89 kg)

195 lbs.

(89 kg)

Refrigerant Information

All Hatco Cold Shelves use R404A refrigerant in the condensing unit.

Form No. CSM-0417

9

Page 10

SPECIFICATIONS

A B

C

E

D

Front View Side View

Top View

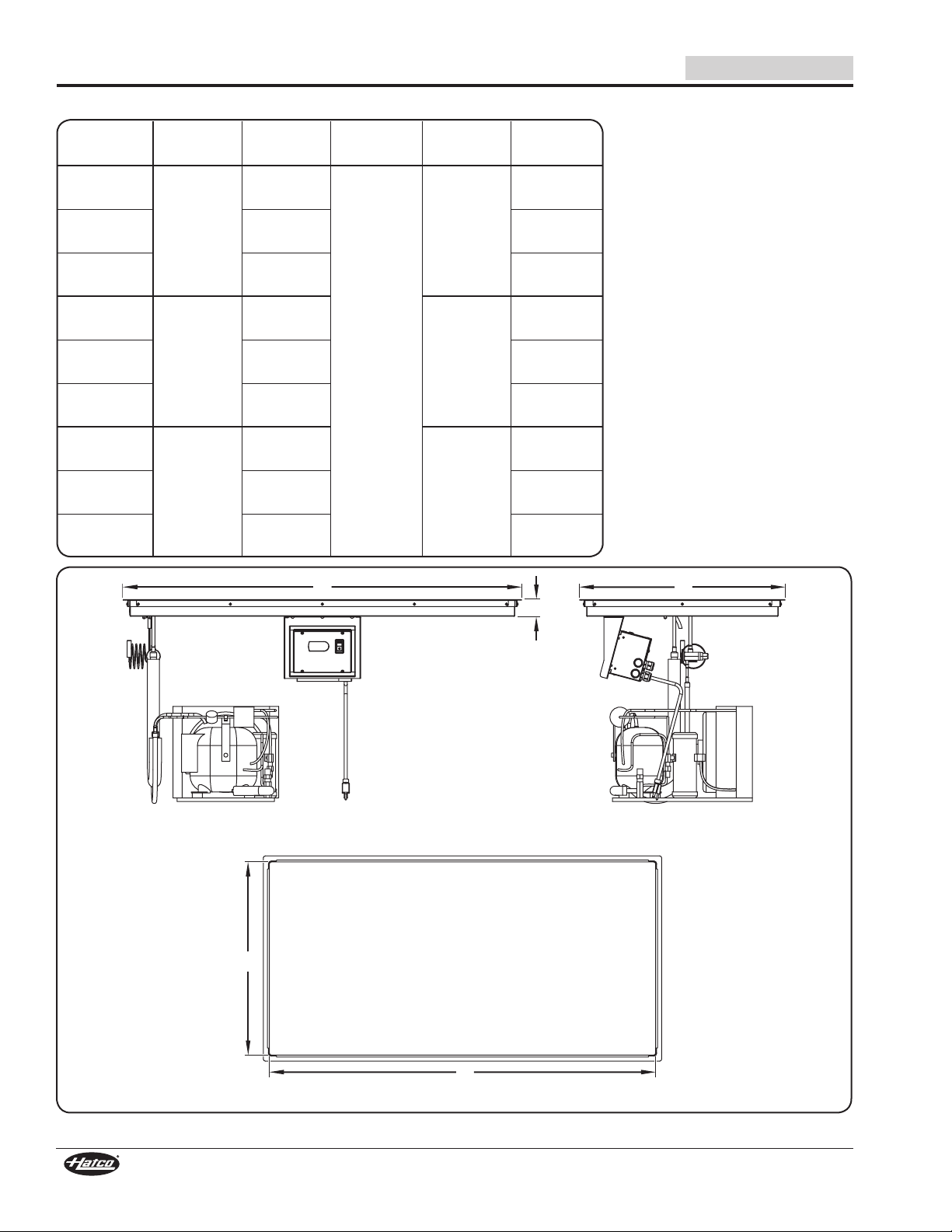

Dimensions — CSBF Models

English

Model

CSBF-24-F

CSBF-24-I

CSBF-24-S

CSBF-36-F

CSBF-36-I

CSBF-36-S

CSBF-48-F

CSBF-48-I

CSBF-48-S

Width

(A)

25-1/2″

(648 mm)

37-1/2″

(953 mm)

49-1/2″

(1257 mm)

Depth

(B)

17″

(432 mm)

21″

(533 mm)

25-1/2″

(648 mm)

17″

(432 mm)

21″

(533 mm)

25-1/2″

(648 mm)

17″

(432 mm)

21″

(533 mm)

25-1/2″

(648 mm)

Height

(C)

2-1/8″

(53 mm)

Cooled

Width (D)

24″

(610 mm)

36″

(914 mm)

48″

(1219 mm)

Cooled

Depth (E)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

10

Form No. CSM-0417

Page 11

English

A B

C

E

D

Front View Side View

Top View

Dimensions — CSSB and CSSBF Models

Model Width (A) Depth (B) Height (C) Cooled Width (D) Cooled Depth (E)

CSSB-2418

CSSB-3018

CSSB-3618

CSSB-4818

CSSBF-24-F

27″

(686 mm)

33″

(838 mm)

39″

(991 mm)

51″

(1295 mm)

21″

(533 mm)

18-1/2″

(470 mm)

2-3/8″

(60 mm)

24″

(610 mm)

30″

(762 mm)

36″

(914 mm)

48″

(1219 mm)

SPECIFICATIONS

18″

(457 mm)

15-1/2″

(394 mm)

CSSBF-24-I

CSSBF-24-S

CSSBF-36-F

CSSBF-36-I

CSSBF-36-S

CSSBF-48-F

CSSBF-48-I

CSSBF-48-S

27″

(686 mm)

39″

(991 mm)

51″

(1295 mm)

22-1/2″

(572 mm)

27″

(686 mm)

18-1/2″

(470 mm)

22-1/2″

(572 mm)

27″

(686 mm)

18-1/2″

(470 mm)

22-1/2″

(572 mm)

27″

(686 mm)

2-3/8″

(60 mm)

24″

(610 mm)

36″

(914 mm)

48″

(1219 mm)

19-1/2″

(495 mm)

24″

(610 mm)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

Form No. CSM-0417

11

Page 12

SPECIFICATIONS

D

A

B

C

4X Ø 10 mm

(0.375″)

Top ViewFront View

Air Flow

Side View

E

F

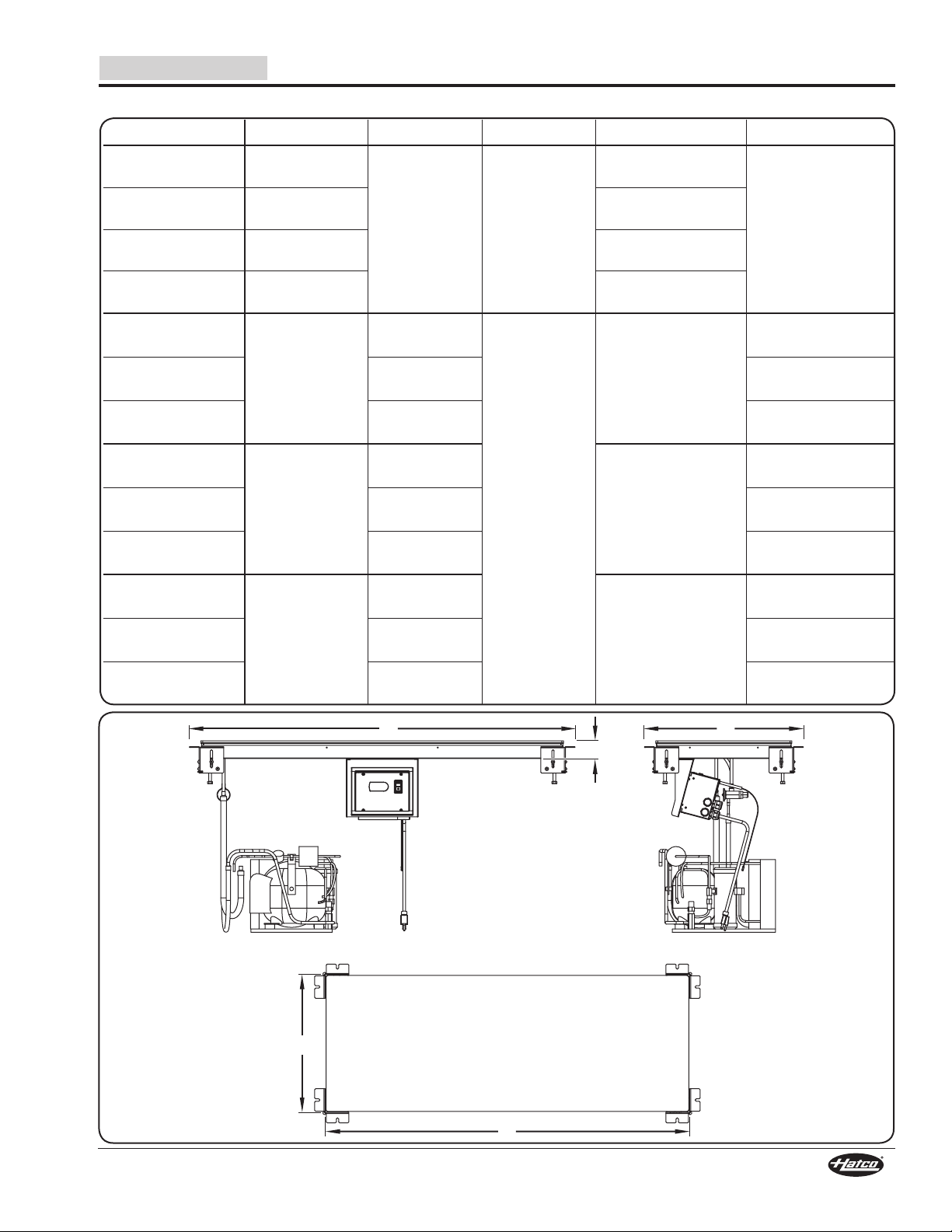

Dimensions — CSU Models

NOTE: See dimension illustration for CSSB and CSSBF Models on previous page for reference.

English

Model

CSU-24-F

CSU-24-I

CSU-24-S

CSU-36-F

CSU-36-I

CSU-36-S

CSU-48-F

CSU-48-I

CSU-48-S

Width

(A)

27-5/16″

(694 mm)

39-5/16″

(998 mm)

51-3/16″

(1295 mm)

Depth

(B)

18-13/16″

(478 mm)

22-13/16″

(579 mm)

27-5/16″

(694 mm)

18-13/16″

(478 mm)

22-13/16″

(579 mm)

27-5/16″

(694 mm)

18-13/16″

(478 mm)

22-13/16″

(579 mm)

27-5/16″

(694 mm)

Height

(C)

2-1/8″

(53 mm)

Cooled

Width (D)

24″

(610 mm)

36″

(914 mm)

48″

(1219 mm)

Cooled

Depth (E)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

15-1/2″

(394 mm)

19-1/2″

(495 mm)

24″

(610 mm)

Dimensions — Condensing Unit

Compressor

Size

1/4 hp

1/3 hp

1/2 hp

3/8 hp

Base

Width (A)

13-11/16″

(347 mm)

17-3/8″

(441 mm)

16″

(406 mm)

Base

Depth (B)

10-3/4″

(273 mm)

12-1/8″

(307 mm)

12-1/8″

(307 mm)

Overall

Depth (C)

(305 mm)

13-1/8″

(334 mm)

13-1/8″

(334 mm)

12″

Height

(D)

11-3/8″

(289 mm)

11-13/16″

(300 mm)

11-3/8″

(289 mm)

Mounting

Hole Width

(E)

6-1/2″

(165 mm)

10″

(254 mm)

11-1/4″

(286 mm)

Mounting

Hole Depth

(F)

9-9/16″

(242 mm)

11-1/4″

(286 mm)

9-1/4″

(235 mm)

12

Form No. CSM-0417

Page 13

English

INSTALLATION

General

Cold Shelves Built-In are shipped from the factory completely

assembled and ready for use. Use the following information and

procedures to prepare the unit and the installation site.

NOTE: Make sure the installation location provides enough

room for the condensing unit and the remote mounted

control enclosure.

WARNING

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install proper voltage and

size electrical receptacle.

• Unit is not weatherproof. Locate unit indoors.

• Remote control enclosure must be mounted on vertical

wall and installed in vertical position. Mounting remote

control enclosure in horizontal position may result in

collection of liquids and lead to electric shock.

FIRE HAZARD: Install condensing unit with a minimum

of2″ (51mm)of spacebetweenall sidesofunit andany

combustible surfaces.

CAUTION

Locate the unit at the proper counter height in an area that is

convenient for use. The location should be level and strong

enough to support the weight of the unit and contents.

NOTICE

Transport and install unit in upright position only. Failure

to do so may result in damage to refrigeration system.

This unit is designed for use in environments where ambient

temperature is between 65°F (18°C) and 86°F (30°C).

When shipped during cold weather months, store unit

for at least 10 hours in an environment where ambient

temperature is between 65°F (18°C) and 86°F (30°C) to

prevent compressor and/or refrigerant line damage. If unit

is turned on and there is excessive noise and vibration, turn

off immediately and allow additional warmup time.

Provide louvered or grill-style openings with a minimum

sizeof12″x12″/144squareinches(31x31cm/961square

cm) in the cabinetry in front of and behind the condensing

unit for proper ventilation. Failure to provide adequate air

flow through the condensing unit may cause unit failure

and will void the unit warranty.

Do not recirculate exhaust air inside cabinet when multiple

condensing units are installed together. Intake air should

enter from outside of cabinet.

Do not locate unit in area with excessive air movement

around unit. Avoid areas that may be subject to active air

movements or currents (i.e., near exhaust fans/hoods, air

conditioning ducts, and exterior doors).

Do not locate unit in an area subject to excessive

temperatures or grease from grills, fryers, etc. Excessive

temperatures could cause damage to the unit.

Damage to any countertop material caused by heat or cold

generated from Hatco equipment is not covered under

the Hatco warranty. Contact manufacturer of countertop

material for application information.

Form No. CSM-0417

All built-in shelves are shipped in a shipping frame for protection

and stability. Keep the unit in the shipping frame until the unit

and the installation site are completely prepared for the unit to

be installed.

Survey the installation site. Take into account the need for

louvered or grill-style openings in the cabinetry to provide

proper ventilation for the condensing unit as well as access to

the control panel. One of these ventilation openings must be in

front of the condensing coils with the other on the opposite side.

If multiple condensing units are installed in the same counter,

each unit should intake cool air and expel hot air.

1. Remove all external packaging from the unit.

NOTE: To prevent delay in obtaining warranty coverage, complete

online warranty registration. See the IMPORTANT

OWNER INFORMATION section for details.

2. Remove tape, protective packaging, and literature from all

surfaces of the unit.

Preparing the Installation Site

1. Prepare the appropriate opening and mounting bolt holes

in the countertop for the unit being installed.

• For top mounted CSBF models, refer to the “Countertop

Cutout Dimensions — CSBF Models,” in this section.

• For bottom mounted CSSB and CSSBF models, refer to

the “Countertop Cutout and Mounting Bolt Dimensions —

CSSB and CSSBF Models,” in this section.

• For underside, surface mounted CSU models, refer to the

“Mounting Bolt Dimensions—CSU Models” in this section.

Make sure the countertop is a solid surface material with

good heat transfer characteristics, such as stainless

steel, granite, quartz, Corian®, etc... The thickness of the

countertop should be 1-3/16″ (30 mm) or less.

NOTE: The performance of each type of solid surface material

will vary dependant upon the material’s characteristics.

2. If installing the control enclosure remotely, cut and drill the

appropriate holes in the vertical surface where the control

enclosure will be installed. Refer to the “Installing the Control

Enclosure Remotely” procedure for cutout dimensions.

• The installation depth required for the control enclosure

is 8-1/2″ (216 mm).

3. Make structural modifications or add bracing underneath

the countertop to ensure the countertop will support the

weight of the unit and its contents.

4. Make sure the following cabinet interior specifications and

clearances are available:

• A level, stable surface for mounting the condensing unit

within 4′ (1219 mm) of the connections on the bottom of

the cold shelf. Refer to the SPECIFICATIONS section

for installation dimensions.

• A minimum 6″ (152 mm) clearance between the

condensing unit and any combustible surface.

5. Cut two openings in the cabinetry to provide proper

ventilation to the condensing unit as well as access to

the control panel. Louvered or grill-style panels should be

installed in the openings to protect the condensing unit.

• Openings should be a minimum of 12″ x 12″ (31 x 31 cm)

or 144 square inches (961 square cm).

• One opening should be located in front of the condenser

coils with the other opening on the opposite side.

6. Install the unit. Refer to the appropriate procedure in this

section for the model being installed.

13

Page 14

INSTALLATION

B

A

CAUTION

Air Flow

Condenser coils

on back of

condensing unit.

Countertop

Cutout

Ventilation/Control

Access Openings

(on both sides

of cabinet)

Condensing

unit enters

countertop

cutout first.

Installing a Top Mounted Unit (CSBF Models)

English

NOTICE

Use caution and avoid hitting condensing unit hoses/lines

when installing unit. Damage caused during installation is

not covered under warranty.

1. Lift the unit out of the shipping frame and carefully lower it

into the countertop cutout.This step requires two or more

people, depending on the unit.

2. Apply a bead of National Sanitation Foundation (NSF)approved silicone sealant on the top edge of the countertop

cutout and the underside of the trim mounting ring. The

sealant must be rated for use at temperatures between

-10°F (-23°C) and 250°F (121°C).

IMPORTANT NOTE

The condensing unit is shipped “loose” from the cold shelf.

They are attached only by the flexible tubing that connects

the condensing unit to the evaporator coil in the cold shelf.

Use caution during installation and avoid putting strain on the

flexible tubing.

3. Lift the cold shelf followed by the condensing unit out of the

wooden shipping frame and carefully lower them into the

countertop cutout. This step requires two or more people.

• The condensing unit must go into the cutout first and

be fastened to a level, stable surface within 4′ (1219

mm) of the connections on the bottom of the cold shelf.

Refer to the SPECIFICATIONS section for installation

dimensions.

4. Install the control panel in the desired location, if installing

remotely.

• The control enclosure can be installed remotely within

4′ (1219 mm) of the condensing unit. Refer to the

“Installing the Control Enclosure Remotely” procedure

in this section.

DO NOT tip unit/mounting surface after final installation.

Unit is free-floating and could fall out if tipped—for

permanent, horizontal installations only.

5. Clean the cold surface thoroughly in preparation for initial

operation. Refer to the MAINTENANCE section for proper

cleaning procedures.

6. Plug the unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

Installing a CSBF Model Cold Shelf

Countertop Cutout Dimensions — CSBF Models

CSBF-24-F

CSBF-24-I

CSBF-24-S

CSBF-36-F

CSBF-36-I

CSBF-36-S

CSBF-48-F

CSBF-48-I

CSBF-48-S

Model Width (A) Depth (B)

24-5/8″ to 25″

(625 to 635 mm)

24-5/8″ to 25″

(625 to 635 mm)

24-5/8″ to 25″

(625 to 635 mm)

36-5/8″ to 37″

(930 to 940 mm)

36-5/8″ to 37″

(930 to 940 mm)

36-5/8″ to 37″

(930 to 940 mm)

48-5/8″ to 49″

(1234 to 1245 mm)

48-5/8″ to 49″

(1234 to 1245 mm)

48-5/8″ to 49″

(1234 to 1245 mm)

16-1/8″ to 16-1/2″

(409 to 419 mm)

20-1/8″ to 20-1/2″

(511 to 521 mm)

24-5/8″ to 25″

(625 to 635 mm)

16-1/8″ to 16-1/2″

(409 to 419 mm)

20-1/8″ to 20-1/2″

(511 to 521 mm)

24-5/8″ to 25″

(625 to 635 mm)

16-1/8″ to 16-1/2″

(409 to 419 mm)

20-1/8″ to 20-1/2″

(511 to 521 mm)

24-5/8″ to 25″

(625 to 635 mm)

14

Form No. CSM-0417

Page 15

English

BE F

A

C

D

R = 0.375" (9.5 mm) x 4

Mounting brackets shown for hole location reference. Holes must be pre-drilled

on underside of countertop where brackets will be mounted.

INSTALLATION

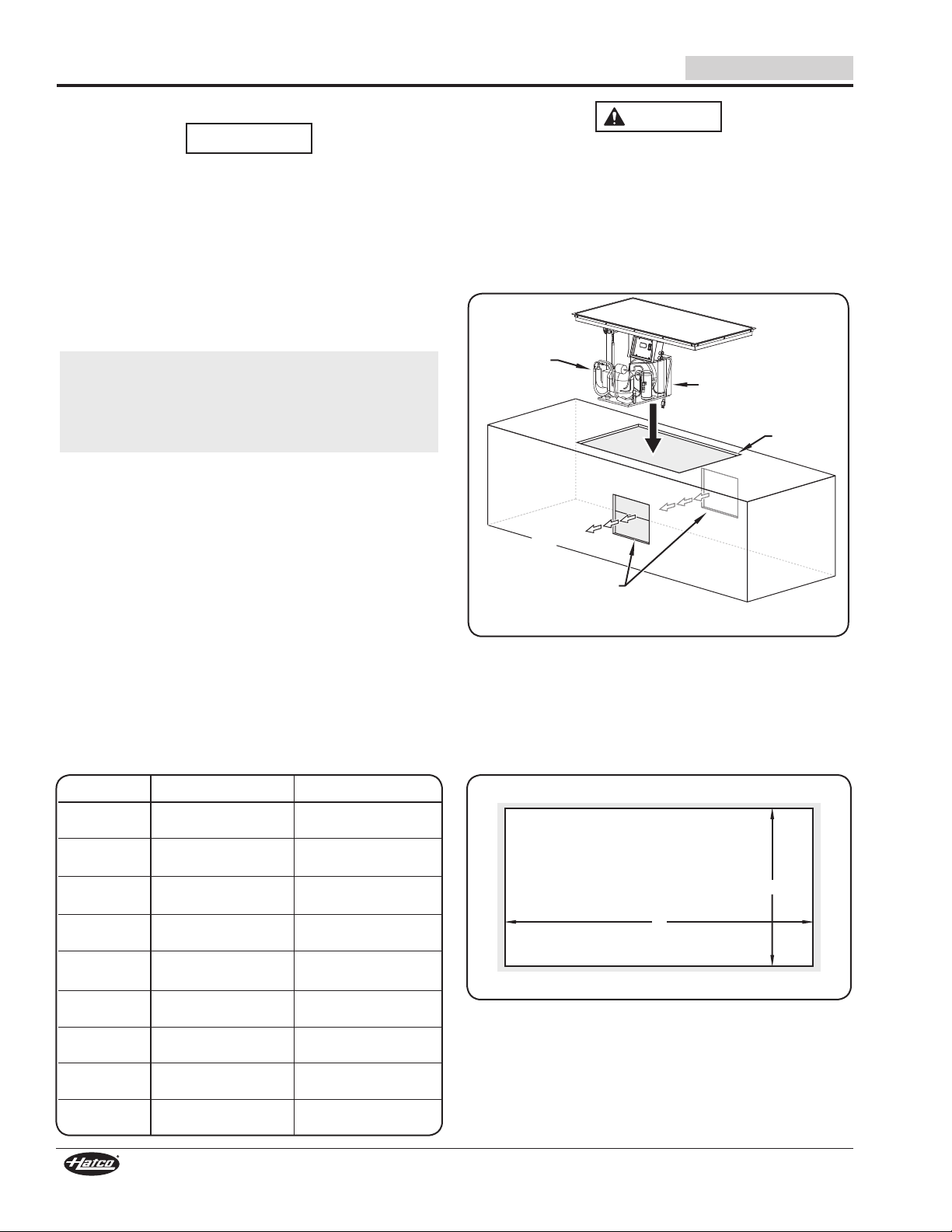

Countertop Cutout and Mounting Bolt Dimensions — CSSB and CSSBF Models

Model

CSSB-2418

CSSB-3018

CSSB-3618

CSSB-4818

CSSBF-24-F

CSSBF-24-I

CSSBF-24-S

CSSBF-36-F

CSSBF-36-I

CSSBF-36-S

CSSBF-48-F

CSSBF-48-I

CSSBF-48-S

Cutout

Width (A)

24-3/8″

(619 mm)

30-3/8″

(772 mm)

36-3/8″

(924 mm)

48-3/8″

(1229 mm)

24-3/8″

(619 mm)

24-3/8″

(619 mm)

24-3/8″

(619 mm)

36-3/8″

(924 mm)

36-3/8″

(924 mm)

36-3/8″

(924 mm)

48-3/8″

(1229 mm)

48-3/8″

(1229 mm)

48-3/8″

(1229 mm)

Cutout

Depth (B)

18-3/8″

(467 mm)

18-3/8″

(467 mm)

18-3/8″

(467 mm)

18-3/8″

(467 mm)

15-7/8″

(403 mm)

19-7/8″

(505 mm)

24-3/8”

(619 mm)

15-7/8″

(403 mm)

19-7/8″

(505 mm)

24-3/8”

(619 mm)

15-7/8″

(403 mm)

19-7/8″

(505 mm)

24-3/8″

(619 mm)

Bolt Hole

Location (C)

26-3/8″

(670 mm)

32-3/8″

(822 mm)

38-3/8″

(974 mm)

50-3/8″

(1279 mm)

26-3/8″

(670 mm)

26-3/8″

(670 mm)

26-3/8″

(670 mm)

38-3/8″

(974 mm)

38-3/8″

(974 mm)

38-3/8″

(974 mm)

50-3/8″

(1279 mm)

50-3/8″

(1279 mm)

50-3/8″

(1279 mm)

Bolt Hole

Location (D)

21″

(533 mm)

27″

(685 mm)

33″

(837 mm)

45″

(1142 mm)

21″

(533 mm)

21″

(533 mm)

21″

(533 mm)

33″

(837 mm)

33″

(837 mm)

33″

(837 mm)

45″

(1142 mm)

45″

(1142 mm)

45″

(1142 mm)

Bolt Hole

Location (E)

20-3/8″

(517 mm)

20-3/8″

(517 mm)

20-3/8″

(517 mm)

20-3/8″

(517 mm)

17-7/8″

(454 mm)

21-7/8″

(555 mm)

26-3/8″

(670 mm)

17-7/8″

(454 mm)

21-7/8″

(555 mm)

26-3/8″

(670 mm)

17-7/8″

(454 mm)

21-7/8″

(555 mm)

26-3/8″

(670 mm)

Bolt Hole

Location (F)

15″

(380 mm)

15″

(380 mm)

15″

(380 mm)

15″

(380 mm)

12-1/2″

(317 mm)

16-1/2″

(418 mm)

21″

(533 mm)

12-1/2″

(317 mm)

16-1/2″

(418 mm)

21″

(533 mm)

12-1/2″

(317 mm)

16-1/2″

(418 mm)

21″

(533 mm)

Form No. CSM-0417

15

Page 16

Bottom

of unit.

Washer

Shipping

Screw

Mounting

Bracket

A

ssembly

Shipping

Bracket

Shipping

Screw

Air Flow

Condenser coils

on back of

condensing unit.

Countertop

Cutout

Accessory

Gasket

Inside surface of

mounting bracket

assembly flush with

inside of cutout.

Lock Nut

Leveling Bolt

INSTALLATION

English

Installing a Bottom Mounted Unit

(CSSB and CSSBF Models)

NOTICE

Use caution and avoid hitting condensing unit hoses/lines

when installing unit. Damage caused during installation is

not covered under warranty.

NOTE: Accessory Installation Kits that include a self-

adhesive gasket for caulk backing as well as colored

silicone sealant are available. Refer to the OPTIONS

AND ACCESSORIES section.

1. Remove the mounting

bracket assembly from

each corner of the cold

shelf. To remove:

a. Remove the two shipping

screws and washers that

attach each mounting

bracket assembly to the

bottom of the unit.

b. Carefully lift the cold

shelf above the wooden

shipping frame, and rotate it far enough to allow the unit

to be set back down on top of the frame (the mounting

brackets will stay on the frame or fall out the bottom).

Make sure the flexible tubes from the condensing unit

are not strained or damaged. This step requires two or

more people, depending on the unit.

c. Remove the mounting bracket assemblies from the

frame, if necessary.

2. On each mounting bracket

assembly, remove the

shipping screws and the

triangular shipping bracket

that was used to attach the

mounting bracket assembly

to the bottom of the cold

shelf, and discard.

3. Attach a mounting bracket

assembly to the underside

of the prepared countertop

at each corner of the cutout.

a. Align the u-shaped mounting holes on the mounting

bracket with the two pre-drilled mounting holes on the

underside of the countertop. The inside surface of the

mounting bracket should be vertically flush with the inner

surface of the countertop cutout.

b. Insert appropriate fasteners through the mounting

bracket and into appropriate anchoring devices in the

mounting holes on the underside of the countertop.

Tighten securely.

4. Install the accessory, self-adhesive gasket around the

inner, vertical surface of the countertop cutout, if available.

• The gasket should be positioned 1/4″ (6 mm) below the

top surface of the countertop.

NOTE: If the accessory, self-adhesive gasket is not available,

provide a caulk backing around the inner, vertical

surface of the countertop cutout 1/4″ (6 mm) below

the top surface of the countertop. This will prevent the

silicone sealant applied later in this procedure from

falling through the gap between the countertop and the

cold shelf.

Installing a CSSBF Model Cold Shelf

16

Form No. CSM-0417

Page 17

English

Seal this gap with foam sealant

underneath the entire unit.

Bottom

of unit.

Washer

Shipping

Screw

Mounting

Bracket

A

ssembly

Shipping

Bracket

Shipping

Screw

INSTALLATION

5. Carefully lower the condensing unit followed by the cold

shelf into the countertop cutout. This step requires two or

more people.

• The condensing unit must go into the cutout first and be

fastened to a level, stable surface within 4′ (1219 mm) of

the connections on the bottom of the cold shelf. Refer to

the SPECIFICATIONS section for installation dimensions.

• The cold shelf rests on top of the four leveling bolts,

which are part of the mounting bracket assembly

installed at each corner of the countertop cutout.

6. Adjust the leveling bolts underneath each corner of the unit so

that the shelf is flush or slightly below the countertop surface.

7. Tighten the lock nut on each leveling bolt to secure the

position.

8. Apply a bead of NSF-approved silicone sealant in the gap

above the countertop and the cold shelf. To apply a clean,

consistent sealant bead:

a. Make sure the shelf is centered in the countertop cutout.

b. Install masking tape on each side of the gap to define

the edge of the sealant.

c. Carefully apply sealant into the gap.

d. Quickly smooth the sealant surface.

e. Carefully remove the masking tape before the sealant dries.

NOTE: The silicone sealant must be rated for use at temperatures

between -10°F (-23°C) and 250°F (121°C).

9. Apply polyurethane-based foam sealant in the gap

underneath the countertop and the cold shelf.

Foam Sealant Gap

CAUTION

DO NOT tip unit/mounting surface after final installation.

Unit is free-floating and could fall out if tipped—for

permanent, horizontal installations only.

10. Install the control panel in the desired location, if installing

remotely.

• The control panel can be installed remotely within

4′ (1219 mm) of the condensing unit. Refer to the

“Installing the Control Enclosure Remotely” procedure

in this section.

11. Clean the cold shelf surface thoroughly in preparation for

initial operation. Refer to the MAINTENANCE section for

proper cleaning procedures.

12. Plug the unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

Form No. CSM-0417

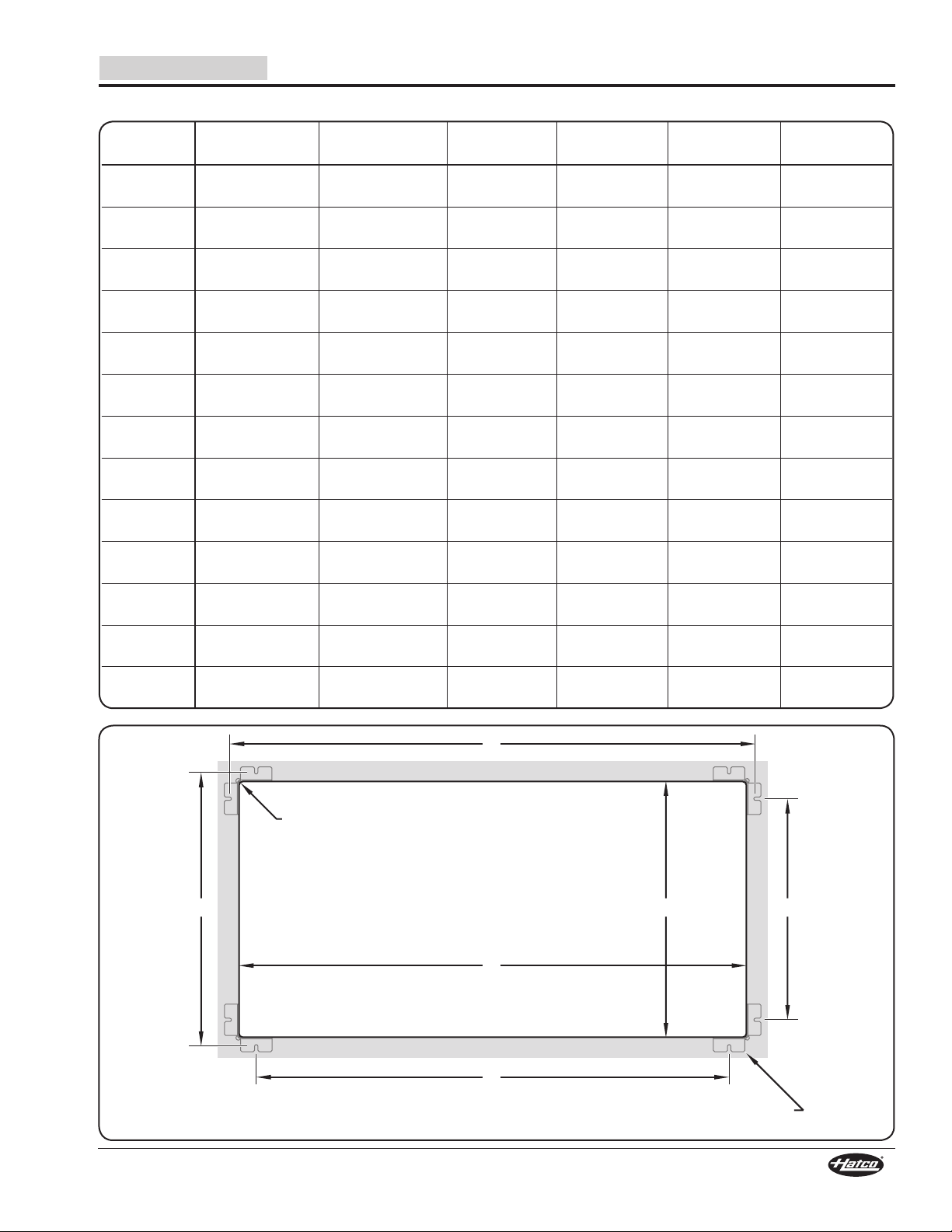

Installing an Under Mounted Unit

(CSU Models)

CSU Series units are surface mounted directly against the

underside of a solid surface countertop (no cutout is required).

Cooling transfers through the countertop to the top side for a

true, seamless installation.

1. Remove the mounting

bracket assembly from

each corner of the cold

shelf. To remove:

a. Remove the two shipping

screws and washers that

attach each mounting

bracket assembly to the

bottom of the unit.

b. Carefully lift the cold

shelf above the wooden shipping frame, and rotate it far

enough to allow the unit to be set back down on top of

the frame (the mounting brackets will stay on the frame

or fall out the bottom). Make sure the flexible tubes from

the condensing unit are not strained or damaged. This

step requires two or more people, depending on the unit.

c. Remove the mounting bracket assemblies from the

frame, if necessary.

2. On each mounting bracket

assembly, remove the

shipping screws and the

triangular shipping bracket

that was used to attach the

mounting bracket assembly

to the bottom of the cold

shelf, and discard.

3. Attach three of the mounting

bracket assemblies to the

underside of the prepared

countertop at the pre-drilled locations. To attach each:

NOTE: See installation illustration on the following page.

a. Align the u-shaped mounting holes on the mounting

bracket with the two pre-drilled mounting holes on the

underside of the countertop. The inside surface of the

mounting bracket should be facing the unit.

b. Insert appropriate fasteners through the mounting

bracket and into appropriate anchoring devices in the

mounting holes on the underside of the countertop.

Tighten securely.

4. Apply a layer of thermal mastic to the top of the shelf using

a 3/16″ (5 mm) notched trowel.

5. Carefully lift the cold shelf up and into the three mounting

brackets on the underside of the countertop. This step

requires two or more people.

• The cold shelf rests on top of the leveling bolts, which

are part of the mounting bracket assembly installed at

each corner of the cold shelf.

• Slide one end of the cold shelf into the two brackets on

one end while rotating it into the single bracket on the

opposite end.

• The condensing unit must be fastened to a level, stable

surface within 4′ (1219 mm) of the connections on the

bottom of the cold shelf. Refer to the SPECIFICATIONS

section for installation dimensions.

17

Page 18

INSTALLATION

Seal this gap with foam sealant

underneath the entire unit.

WARNING

7/16″

(11 mm)

3/8″

(9 mm)

Silicone Sealant

5-5/8″

(143 mm)

7-7/16″

(189 mm)

7-3/4″

(196 mm)

3-1/2″

(89 mm)

1-1/16″

(27 mm)

Underside of

Countertop

Mounting Bracket

Assembly

Lock Nut

Leveling Bolt

English

6. Attach the fourth mounting bracket assembly to the

underside of the countertop at the open corner of the cold

shelf.

7. Adjust the leveling bolts underneath each corner of the

unit so that the shelf is flush against the underside of the

countertop.

8. Tighten the lock nut on each leveling bolt to secure the

position.

9. Apply polyurethane-based foam sealant in the gap

between the countertop and the cold shelf.

Foam Sealant Gap

Installing the Control Enclosure Remotely

Use the following procedure to install the control enclosure

remotely within 4′ (1219 mm) of the condensing unit.

2. Remove the four trim cover screws from the control panel

and remove the trim cover.

3. Position the control panel into the cutout opening through

the backside.

4. Fasten the control panel to the vertical surface using four

screws (not supplied).

5. Apply a 1/4″ (6 mm) bead of NSF-approved silicone sealant

where the trim cover will contact the cabinet surface. Refer

to the “Control Panel Cutout and Screw Hole Dimensions”

illustration for more information.

6. Reinstall the trim cover on the control panel and secure

in position using the four trim cover screws. Make sure to

embed the trim cover edge into the silicone.

Control Panel Cutout and Screw Hole Dimensions

NOTE: Make sure the width of the control panel cutout does

not exceed the above dimension.

Control enclosure must be mounted in a vertical surface.

Mounting control enclosure in a horizontal surface may

result in the collection of liquids and lead to electric shock.

1. Cut and drill the appropriate holes in the mounting surface.

Refer to the “Control Panel Cutout and Screw Hole

Dimensions” chart for the cutout dimensions.

Installing a CSU Model Cold Shelf

18

Form No. CSM-0417

Page 19

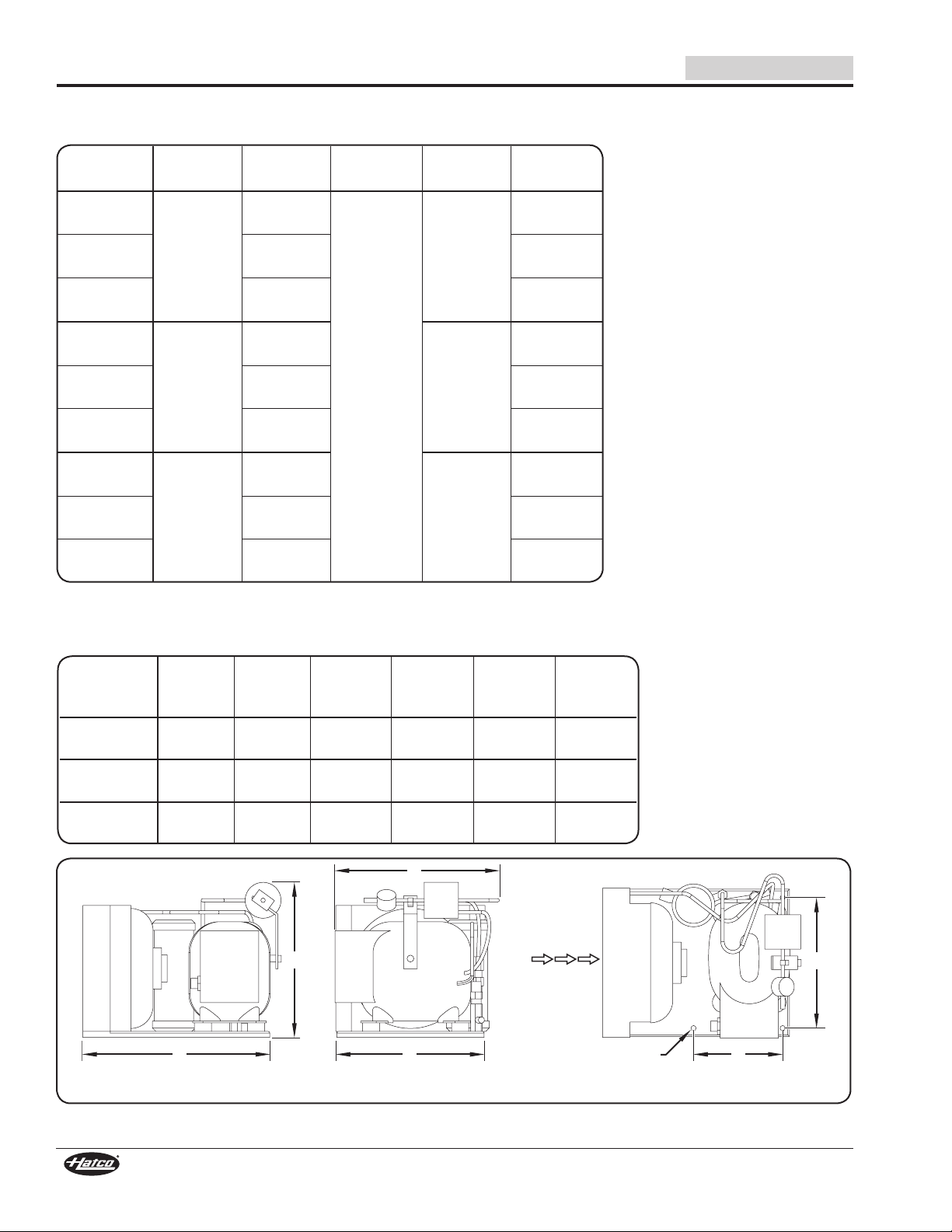

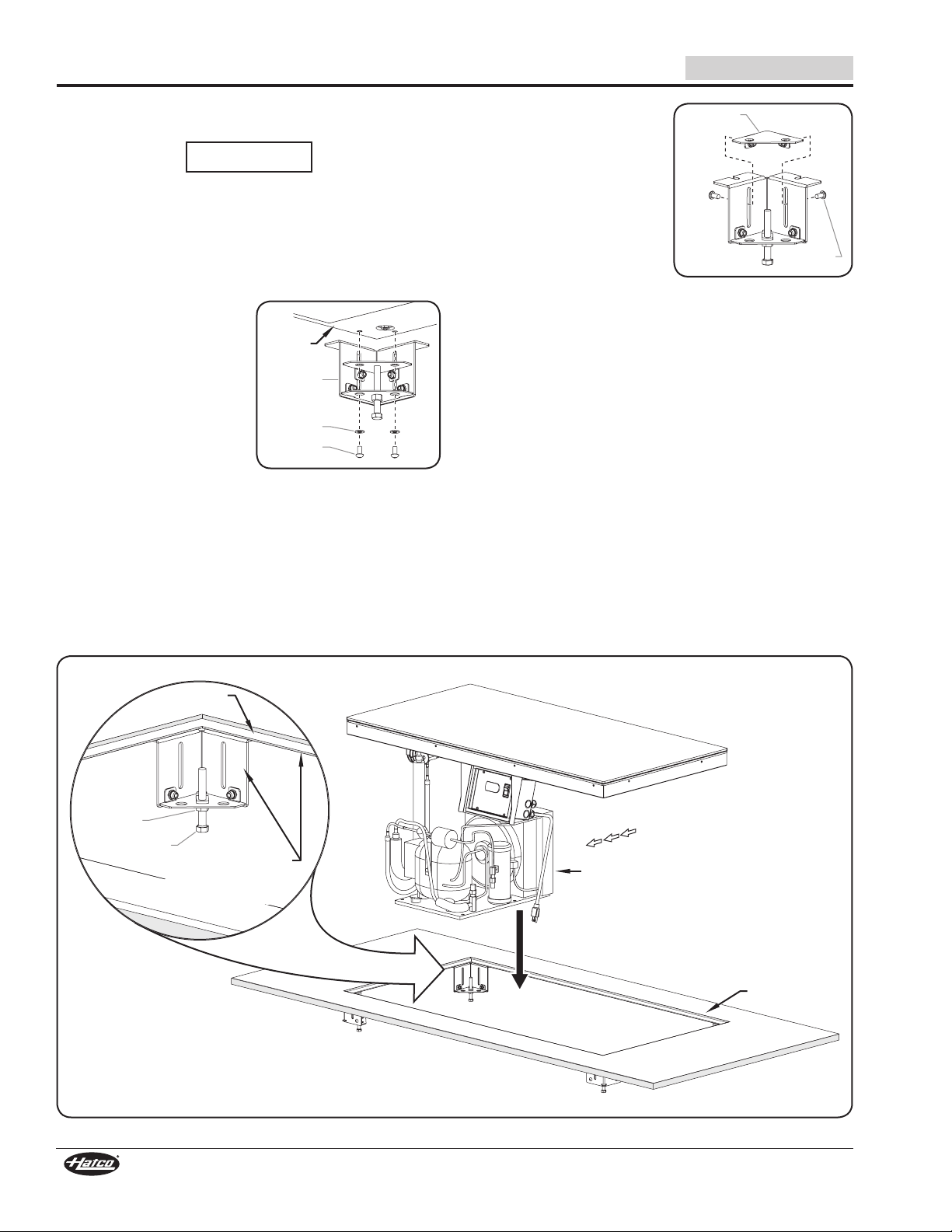

English

C D

A

B

Mounting brackets shown for hole location reference. Holes must be pre-drilled

on underside of countertop where brackets will be mounted.

Unit Outline

Mounting Bolt Dimensions — CSU Models

INSTALLATION

Model

CSU-24-F

CSU-24-I

CSU-24-S

CSU-36-F

CSU-36-I

CSU-36-S

CSU-48-F

CSU-48-I

CSU-48-S

Bolt Hole

Location (A)

26-11/16″

(677 mm)

26-11/16″

(677 mm)

26-11/16″

(677 mm)

38-11/16″

(982 mm)

38-11/16″

(982 mm)

38-11/16″

(982 mm)

50-11/16″

(1287 mm)

50-11/16″

(1287 mm)

50-11/16″

(1287 mm)

Bolt Hole

Location (B)

21-5/16″

(541 mm)

21-5/16″

(541 mm)

21-5/16″

(541 mm)

33-5/16″

(845 mm)

33-5/16″

(845 mm)

33-5/16″

(845 mm)

45-5/16″

(1150 mm)

45-5/16″

(1150 mm)

45-5/16″

(1150 mm)

Bolt Hole

Location (C)

18-3/16″

(462 mm)

22-3/16″

(563 mm)

26-11/16″

(677 mm)

18-3/16″

(462 mm)

22-3/16″

(563 mm)

26-11/16″

(677 mm)

18-3/16″

(462 mm)

22-3/16″

(563 mm)

26-11/16″

(677 mm)

Bolt Hole

Location (D)

12-13/16″

(325 mm)

16-13/16″

(426 mm)

21-5/16″

(541 mm)

12-13/16″

(325 mm)

16-13/16″

(426 mm)

21-5/16″

(541 mm)

12-13/16″

(325 mm)

16-13/16″

(426 mm)

21-5/16″

(541 mm)

Form No. CSM-0417

19

Page 20

OPERATION

WARNING

Digital Temperature

Controller

Power I/O (on/off) Switch

Unit “Active”

Symbol

English

General

Use the following procedures to operate a Cold Built-In Shelf.

WARNING

Read all safety messages in the Important Safety

Information section before operating this equipment.

Make sure food product has been chilled to the proper

food-safe temperature before placing in the unit. Failure

to chill food product properly may result in serious health

risks. This unit is for holding pre-chilled food product only.

This unit is for holding food for short periods of time.

Never hold food longer than 4 hours.

NOTICE

This unit is designed for use in environments where ambient

temperature is between 65°F (18°C) and 86°F (30°C).

When shipped during cold weather months, store unit in

proper ambient temperature environment for 10 hours to

prevent compressor and/or refrigerant line damage. If unit

is turned on and there is excessive noise and vibration,

turn off immediately and allow additional warm up time.

NOTE: If the display flashes between “OFF” and the current

temperature, the unit is in standby mode. Press and

hold the key for three seconds to return the unit to

normal operation.

If the display flashes bewteen “df” and the current

temperature, the unit is in defrost mode. Press and

hold the key for three seconds to return the unit to

normal operation.

Startup

1. For CSSB and CSSBF models, clean and sanitize the

stone shelf using a clean, damp cloth and a sanitizer

approved for food contact surfaces.

2. Move the Power I/O (on/off) Switch to the “I” (on) position

(located on the control panel).

• The digital temperature controller will energize and

“ON” will appear on the display, followed by the current

temperature of the unit.

• The symbol on the display will illuminate to show

the condensing unit is active and chilling the shelf.

NOTE: The unit is pre-set at the factory to a setpoint temperature

of 25°F (-4°C). If ambient conditions require adjustment

to the setpoint temperature, refer to the “Changing the

Setpoint Temperature” in this section.

4. Verify on the display that the unit has reached the proper

setpoint temperature, and load the shelf with pans that

contain pre-chilled food product.

• For CSBF units, always use a food pan on the hardcoat

aluminum surface. Do not place food directly onto

surface.

• Stir thick food items frequently to keep food chilled

uniformly.

Control Panel

Shutdown

1. Move the Power I/O (on/off) Switch to the “O” (off) position.

The digital temperature controller and condensing unit will

shut off.

2. Perform the “Daily Cleaning” procedure in the

MAINTENANCE section of this manual.

NOTICE

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

Hatco Corporation is not responsible for the actual food

product serving temperature. It is the responsibility of the

user to ensure that the food product is held and served at

a safe temperature.

3. Allow the unit approximately 60 minutes to reach the

setpoint temperature.

20

Form No. CSM-0417

Page 21

English

Display

Down Arrow/

Defrost Key

Unit

“Active”

Symbol

Up Arrow/

Standby Key

SET

Key

OPERATION

Changing the Setpoint Temperature

Use the following procedure to change the setpoint temperature

on the digital temperature controller.

NOTE: Changes to the setpoint temperature should be made

in small increments (1 to 2 degrees). Wait at least two

hours after a change in setpoint temperature before

checking for the desired result.

1. Press and hold the key for one second until the

display flashes the current setpoint temperature.

2. Press the or key to increase or decrease the

setpoint temperature. If no key is pressed within 60

seconds, the display will revert to normal operation and

the current temperature of the unit will be shown on the

display.

3. Press the key to lock in the new setpoint temperature.

The display will revert to show the current temperature of

the unit.

5. Press the key to select “dI”. The current number of

defrost cycles will be shown on the display. For new units,

this value will be “0”.

6. Press the or key within 60 seconds to scroll to

the desired number of hours between defrost cycles. See

below for examples of how the defrost cycle(s) operate:

“0” = auto-defrost is deactivated

“1” = unit will defrost every hour

“4” = unit will defrost every four hours

“12” = unit will defrost every twelve hours

If no key is pressed within 60 seconds, the display will

revert to normal operation and the current temperature of

the unit will be shown on the display.

7. Press the key to lock in the new defrost cycle setting.

8. Press and hold the key for three seconds to exit

programming mode. The display will revert to show the

current temperature of the unit.

Changing Fahrenheit and Celsius Setting

Use the following procedure to change between Fahrenheit and

Celsius on the display.

1. Press and hold the key for three seconds to access

programming mode. “PS” (password) will appear on the

display.

2. Press the key again. A numeric value will appear on

the display.

Digital Temperature Controller

NOTE: If the display flashes between “OFF” and the current

temperature, the unit is in standby mode. Press and

hold the key for three seconds to return the unit to

normal operation.

If the display flashes bewteen “df” and the current

temperature, the unit is in defrost mode. Press and

hold the key for three seconds to return the unit to

normal operation.

Setting the Auto-Defrost Cycle

The digital temperature controller is programmed at the factory

with the auto-defrost cycle deactivated. Use the following

procedure to activate the auto-defrost cycle if ambient or

operational conditions require the unit to defrost occasionally.

When the unit is in a defrost cycle, will appear on the

display.

1. Press and hold the key for three seconds to access

programming mode. “PS” (password) will appear on the

display.

2. Press the key again. A numeric value will appear on

the display.

3. Press the or key until the number “22” appears

on the display, then press the key.

4. Use the or key to scroll through the programmable

parameters until appears on the display.

5. Press the key to select .

6. Press the or key within 60 seconds to scroll to

the desired setting. See below for the correct setting:

“0” = Displays Celsius

“1” = Displays Fahrenheit

If no key is pressed within 60 seconds, the display will

revert to normal operation and the current temperature of

the unit will be shown on the display.

7. Press the key to lock in the new setting.

8. Press and hold the key for three seconds to exit

programming mode. The display will revert to show the

current temperature of the unit.

3. Press the or key until the number “22” appears

on the display, then press the key.

4. Use the or key to scroll through the programmable

parameters until “dI” (defrost interval) appears on the

display.

Form No. CSM-0417

21

Page 22

MAINTENANCE

English

General

Hatco Built-In Cold Shelves are designed for maximum

durability and performance, with minimum maintenance.

WARNING

ELECTRIC SHOCK HAZARD:

• Turn OFF power switch and disconnect unit from power

source before performing any cleaning, adjustments,

or maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• This unit is not “jet-proof” construction. Do not use

jet-clean spray to clean this unit.

• Do not steam clean or use excessive water on unit.

WARNING

ELECTRIC SHOCK HAZARD: This unit must be serviced by

qualified personnel only. Service by unqualified personnel

may lead to electric shock or burn.

FIRE HAZARD: Do not use flammable cleaning solutions

to clean this unit.

This unit has no “user-serviceable” parts. If service

is required on this unit, contact an Authorized Hatco

Service Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350.

Daily Cleaning

To preserve the finish and maintain operation of the unit,

perform the following cleaning procedure daily.

1. Before turning on a CSSB or CSSBF model each day,

clean and sanitize the stone shelf using a clean, damp

cloth and a sanitizer approved for food contact surfaces. If

additional cleaning is necessary, refer to the “Cleaning the

Stone Surface” information in this section.

2. At the end of each day:

a. Move the Power I/O (on/off) Switch to the “O” (off)

position and allow the unit to defrost.

b. Remove and wash all food pans, if present.

c. Clean the shelf using a clean cloth or sponge and mild

detergent. Use a plastic scouring pad to remove any

hardened food particles or mineral deposits.

d. Rinse the shelf thoroughly with hot water to remove all

detergent residue.

e. Wipe down shelf with a clean, sanitized cloth to remove

the detergent residue. Repeat until all detergent residue

is gone and the shelf is clean.

f. Wipe dry the entire unit using a non-abrasive, dry cloth.

g. Wipe down the outside of the louvered or grill-style

panels installed in the cabinet ventilation openings.

NOTICE

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

Do not use steel wool for cleaning. Steel wool will scratch

the finish.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch the finish of the unit,

marring its appearance and making it susceptible to soil

accumulation.

Do not use harsh chemicals such as bleach, cleaners

containing bleach, or oven cleaners to clean this unit.

22

Form No. CSM-0417

Page 23

English

Condenser Coil

Cooling Fins

MAINTENANCE

Cleaning the Stone Surface

(CSSB and CSSBF Models)

Proper use of the products listed below will not damage the

stone shelf (follow the directions on the product labels).

NOTE: Stone surfaces are a simulated stone solid surface.

CAUTION

After deep cleaning stone surface using abrasives, make

sure to clean and sanitize surface properly before placing

food product.

IMPORTANT NOTE

Bottom-mounted units are installed with a bead of silicone

sealant between the unit and the countertop. Use caution

when cleaning with the abrasive pad and avoid contact with

the silicone sealant.

Hard to Remove Stains

For hard-to-remove stains, use the supplied abrasive pad

along with an abrasive cleaner such as Ajax, Comet, Bon Ami,

Magic Scrub, or Bar Keeper’s Friend. Additional abrasive pads

are available from Hatco (P/N 04.39.049.00). NOTICE: Use

supplied abrasive pad on stone surface only.

NOTE: Do not use steel wool or metal scouring pads.

Mineral Based Stains

For a mineral-based stain, cleaners designed to remove iron or

rust are recommended and should not harm the stone surface.

Monthly Cleaning

Perform the following procedure monthly to maintain proper

and efficient operation as well as prevent malfunction of the

condensing unit.

1. Remove and clean both sides of the louvered or grill-style

panels that are installed in the ventilation openings. Dirt

and dust build-up in the panels can restrict air flow to the

condensing unit and cause over-heating.

2. Clean the condenser coil cooling fins. Dirt, dust, and lint

build-up in the cooling fins will prevent proper cooling of

the refrigerant in the refrigeration system. This build-up will

cause inefficient operation and can lead to unit failure. Use

the following methods to clean the condenser coil cooling

fins:

• Vacuum the cooling fins.

• Brush the cooling fins vertically using a condenser

coil brush. NOTICE: Use caution when brushing

the cooling fins, they are delicate and can be bent

easily. DO NOT use a wire brush.

Scratches

For scratches, use sandpaper starting with the coarsest grit and

going to finest grit until the scratch disappears. Blend area in

with the supplied abrasive pad.

Condenser Coil Cooling Fins

NOTE: Depending on the conditions of the installation site, this

cleaning procedure may need to be performed more

often or less often than monthly. Monitor the level of dirt,

dust, and lint buildup on the panels and cooling fins,

and make adjustments to the frequency of cleanings as

necessary.

Form No. CSM-0417

23

Page 24

WARNING

WARNING

TROUBLESHOOTING GUIDE

English

This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

ELECTRIC SHOCK HAZARD: Turn OFF power switch and

disconnect unit from power source before performing any

cleaning, adjustments, or maintenance.

Symptom Probable Cause Corrective Action

Shelf too cold. Setpoint temperature too low. Adjust the setpoint temperature to a higher setting. Refer to

Digital temperature controller not working

properly.

Shelf not cold enough. Food product not pre-chilled before loading

in unit.

Unit not filled with food pans/one or more open

pan positions.

Setpoint temperature set too high. Adjust the setpoint temperature to a lower setting. Refer to

Condenser coil and/or ventilation panels are

plugged with dirt/dust.

Too much frost built up top of unit. Turn off, defrost, and clean the unit. Activate an auto-

Digital temperature controller not working

properly.

the “Changing the Setpoint Temperature” procedure in the

OPERATION section.

Contact Authorized Service Agent or Hatco for assistance.

Load unit with pre-chilled food product only.

Fill the refrigerated shelf with food pans. The shelf will chill

to the setpoint temperature more quickly and hold more

efficiently when filled with pans.

the “Changing the Setpoint Temperature” procedure in the

OPERATION section.

Clean the condenser coil and ventilation panels. Refer to

the “Monthly Cleaning” procedure in the MAINTENANCE

section.

defrost cycle, if necessary (refer to the procedure in the

OPERATION section).

Contact Authorized Service Agent or Hatco for assistance.

Unit makes excessive noise

and vibration when turned on.

Controller display flashes

“OFF” and unit is not working.

Controller display flashes “df”

and unit is not working.

Unit plugged in, but not

working.

Refrigerant low/leaking or other internal

condensing unit malfunction.

Internal components have not been adequately

warmed before operation.

The unit is in Standby mode.

The unit is in Defrost mode.

Unit turned off. Turn on unit.

Circuit breaker tripped. Reset circuit breaker. If circuit breaker continues to trip,

Digital temperature controller not working

properly.

Condensing unit overheated. Contact Authorized Service Agent or Hatco for assistance.

Internal condensing unit malfunction. Contact Authorized Service Agent or Hatco for assistance.

Contact Authorized Service Agent or Hatco for assistance.

Turn off unit immediately. Unit should be stored in a warm