Page 1

Register Online!

hatcocorp.com

WARNING

ADVERTENCIA

AVERTISSEMENT

(see page 2)

S'inscrire en ligne!

(voir page 31)

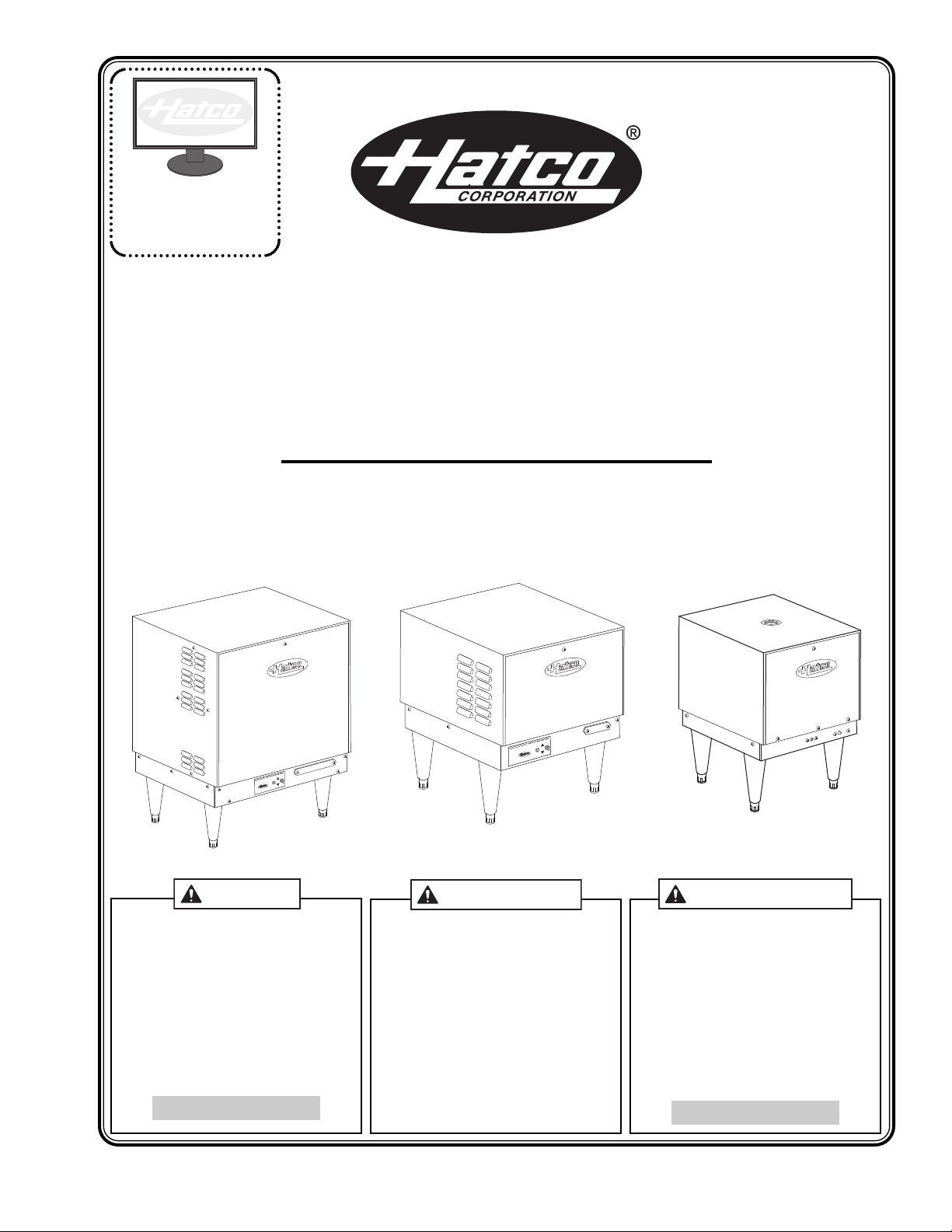

Electric Booster Water Heaters

Réchauffeurs d'eau électriques

Imperial, Compact, Mini-Compact Series

Série Imperial, Compact, Mini-Compact

Installation and Operating Manual

Manuel d'installation et d'utilisation

Do not operate this equipment unless you

have read and understood the contents of

this manual! Failure to follow the

instructions contained in this manual may

result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

P/N 07.04.111.00 © 2016 Hatco Corporation

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel !

Le non-respect des instructions

contenues dans ce manuel peut entraîner

de graves blessures ou la mort. Ce

manuel contient des informations

importantes concernant l'entretien,

l'utilisation et le fonctionnement de ce

produit. Si vous ne comprenez pas le

contenu de ce manuel, veuillez le signaler

à votre supérieur. Conservez ce manuel

dans un endroit sûr pour pouvoir vous y

référer plus tard.

Français = p 31

Page 2

NOTICE

CAUTION

WARNING

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

CONTENTS

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................5

All Models ............................................................................5

Imperial Models “S” Series ..................................................5

Compact Models “C” Series.................................................5

Mini-Compact Models “MC” Series ......................................5

Specifications........................................................................6

Circuit Breaker and Fused Disconnect Switch Sizes ..........6

Sizing Chart for Low-Temp Dish Machines .........................9

Booster Heater Sizing Chart..............................................10

Capacity Charts .................................................................14

Dimensions ........................................................................15

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the unit). Please have this information available

when calling Hatco for service assistance.

Model No. __________________________________

Serial No. __________________________________

Voltage ____________________________________

Installation...........................................................................17

General ..............................................................................17

Plumbing Installation..........................................................18

Electrical-All Sizes and Voltages .......................................23

Operation.............................................................................24

General ..............................................................................24

Maintenance ........................................................................25

General ..............................................................................25

Thermostat Adjustment......................................................25

High Temperature Limit Safety Switch...............................25

Options and Accessories...................................................26

Troubleshooting Guide ......................................................27

Limited Warranty.................................................................30

Authorized Parts Distributors............................Back Cover

Business

Hours: 7:00

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

AM to 5:00 PM Central Standard Time (CST)

(Summer Hours: June to September—

AM to 5:00 PM CST Monday–Thursday

7:00

7:00

AM to 4:00 PM CST Friday)

Date of Purchase ____________________________

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco Electric Booster Water Heaters are designed

for use with commercial dish machines to boost the temperature

of the regularly available hot water, usually 115°–150°F

(46°–66°C) up to 180°F (82°C). Water at 180°F (82°C) can be

used as sanitizing rinse water in commercial dish machines in

accordance with Health Codes, NSF Standard #5 and plumbing

codes.

All Hatco Booster Heaters are ready for electrical and plumbing

service connections, with an adjustable ambient compensated

immersion thermostat(s) and a high temperature limit switch.

The service area is accessible from the front of the unit,

permitting easy access.

Hatco Electric Booster Water Heaters are products of extensive

research and field testing. The materials used were selected for

maximum durability, attractive appearance, and optimum

performance. Every unit is inspected and tested thoroughly prior

to shipment.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

This manual provides the installation, safety, and operating

instructions for the Hatco Electric Booster Water Heaters. Hatco

recommends all installation, operating, and safety instructions

appearing in this manual be read prior to installation or

operation of the unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

2

Form No. EBOOSTERM-0816

Page 3

English

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid

serious injury or death and to avoid damage to equipment or property

.

ELECTRIC SHOCK HAZARD:

• Unit must be installed by qualified, trained installers.

Installation must conform to all local electrical and

plumbing codes. Installation by unqualified personnel

will void the unit warranty and may lead to electric

shock or burn, as well as damage to unit and/or its

surroundings. Check with local plumbing and electrical

inspectors for proper procedures and codes.

• Turn OFF power at fused disconnect switch/circuit

breaker and allow unit to cool before performing any

cleaning, adjustments, or maintenance.

• Consult a licensed electrical contractor for proper

electrical installation conforming to local electrical

codes and the National Electrical Code (N.E.C.).

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• Do not place aftermarket covers on or over booster

heater. Doing so can cause temperature and moisture

build-up resulting in premature failure and electrical

shock.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

Valves supplied by Hatco are designed for hightemperature commercial operation. Do not substitute Hatco

valves with valves designed for domestic water heaters.

Temperature/pressure protective equipment should not be

less than a combination temperature/pressure relief valve

certified by a nationally recognized testing laboratory that

maintains periodic inspection of the production of this

equipment and meets the requirements for Relief Valves

and Automatic Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22-1979. The temperature/pressure

relief valve must be marked with a minimum set pressure

not to exceed the marked hydrostatic test pressure of the

booster heater as noted on the unit specifications.

EXPLOSION HAZARD: Do not store or use gasoline or

other flammable vapors or liquids in the vicinity of this or

any other appliance.

FOR INSTALLING PRESSURE AND TEMPERATURE

RELIEF VALVES IN ACCORDANCE WITH AMERICAN

NATIONAL STD. Z21.22-1979. Combination pressure and

temperature relief valves with extension thermostats must

be installed so that the temperature-sensing element is

immersed in the water within the top 6" (152 mm) of the

tank. They must be installed directly in a tank tapping.

Combination pressure and temperature relief valves that

do not have extension elements must be mounted directly

in a tank tapping located within the top 6" (152 mm) of the

tank, and shall be adequately insulated and located so as

to assure isolation from ambient conditions that are not

indicative of stored water temperature. TO AVOID WATER

DAMAGE OR SCALDING DUE TO VALVE OPERATION,

DRAIN PIPE MUST BE CONNECTED TO VALVE OUTLET

AND RUN TO A SAFE PLACE OF DISPOSAL. Discharge line

must be as short as possible and be the same size as the

valve discharge connection throughout its entire length.

Drain line must pitch downward from the valve and must

terminate between 1-1/2" (38 mm) and 6" (152 mm) above

the floor drain where any discharge will be clearly visible.

The drain line shall terminate plain, not threaded, with

material serviceable for temperatures up to 250°F (121°C)

or greater. Excessive length, over 30' (9.1 m), or use of

more than four elbows can cause a restriction and reduce

the discharge capacity of the valve. No shut-off valve shall

be installed between the relief valve and tank, or in the

drain line. Valve lever must be tripped periodically to

assure that waterways are clear. This device is designated

for emergency safety relief and shall not be used as an

operating control. The valves are set to relieve at 150 psi

(1034 kPa) or when water temperature reaches 210°F

(99°C). Read tag on valve for additional information.

Use only copper plumbing material. Non-copper plumbing

material may create an unsafe condition.

Units are equipped with a high temperature limit safety

switch that will shut off the power if the unit overheats.

Contact an Authorized Hatco Service Agent if the high

temperature limit safety switch cannot be reset or

continues to trip.

Install booster water heater in a horizontal position with the

base parallel to the floor and the inlet connection at the

lowest point. Improper installation could create an unsafe

condition.

Do not connect booster water heaters to domestic

(consumer) dish machines or other domestic utilized

equipment. This booster may damage domestic equipment.

Form No. EBOOSTERM-0816

3

Page 4

IMPORTANT SAFETY INFORMATION

CAUTION

WARNING

CAUTION

NOTICE

Read the following important safety information before using this equipment to avoid

serious injury or death and to avoid damage to equipment or property

English

.

This product contains fiberglass, a product known to the

state of California to cause cancer, birth defects, or other

reproductive harm.

Install booster water heater as close as possible to a

commercial dish machine. Employ re-circulation if distance

between water heater and dish machine exceeds National

Sanitation Foundation (NSF) specifications of five (5) linear

feet (1524 mm).

Follow standard welding safety and operational procedures

when attaching sliderails to bottom of dishtable.

Make sure the dishtable is strong enough to support the

weight of the heater AND water when installing with slide

mounting brackets.

Refer to the BOOSTER HEATER SIZING CHART in this

manual to ensure proper sizing and avoid personal injury

and/or damage to the booster heater.

It is essential to recognize that even though a water heater

may be properly installed initially and approved, there

always exists the possibility that unknowing individuals

might alter or change the installation in a manner that

would render it unsafe. Therefore, it is important that all

safety programs provide some mechanism to assure that

these installations are inspected periodically.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350.

BURN HAZARD:

• Water in unit is very hot. Wear protective gloves and

proper attire when operating to avoid injury.

• Valves supplied by Hatco are designed for high

temperature commercial operation. Do not substitute

Hatco valves with valves designed for domestic water

heaters.

Do not use anti-siphon valves on incoming water line.

Check valves on incoming water line is not recommended.

Damages caused by the use of check valves on unit will

not be covered by warranty.

Do not connect booster heater directly to a boiler or

furnace coil or any other uncontrolled temperature source.

The booster heater thermostat could be damaged causing

unit to overheat.

Do not connect an expansion tank of any type to booster

heater water lines.

Hatco requires that two temperature/pressure gauges

(Hatco P/N 03.01.003.00) be installed to ensure proper

operation. Install one in the supply line before the pressure

reducing valve and one in the outlet line as close to the

booster heater as possible. This provides a visual check

of the water temperature and pressure before and after the

water heater.

If water supply pressure to the booster inlet is over 20 psi

(138 kPa) during flow, install pressure reducing valve with

built-in bypass (Hatco P/N 03.02.004.00) for proper

operation of dish machine rinse nozzles.

NOTE: The pressure reducing valve must be the type equipped

with a high pressure bypass, as supplied by Hatco.

DO NOT turn on power to the booster heater until tank has

been filled with water and all air has been vented through

the dish machine rinse nozzles. Heating elements will burn

out in seconds if operated when not immersed in water.

Always drain booster heater with power to the unit off or

element burnout could occur.

Use dielectric couplings when connecting dissimilar

metals, such as galvanized to copper. This will prevent

electrolysis or premature plumbing damage.

Do not turn or adjust outlet water connection on all Large

Compact Series units (C-24 to C-57).

Do not turn or adjust inlet water connection on Compact

Series Booster Heaters or internal water flow will change.

Do not back out or loosen any pipe fittings or leaks may

occur.

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

Incoming water in excess of 3 grains of hardness per

gallon (GPG) (0.75 grains of hardness per liter [GPL]) must

be treated and softened before being supplied to booster

heater(s). Water containing over 3 GPG (0.75 GPL) will

decrease efficiency, increase energy use, and reduce the

operating life of the unit through increased lime build-up.

Product failure caused by liming or sediment buildup is not

covered under warranty.

Do not use deionized water. Deionized water will shorten

the life of water reservoir and heating element.

Units are voltage-specific. Refer to specification label for

electrical requirements before beginning installation.

Connecting unit to incorrect power supply will void product

warranty and may damage unit.

4

Form No. EBOOSTERM-0816

Page 5

English

MODEL DESCRIPTION

All Models

Hatco Electric Water Booster Heaters are available in three

models: Imperial, Compact, and Mini-Compact. All standard

models include a booster heater with low-water cut-off system,

temperature/pressure relief valve, pressure reducing valve with

built-in high pressure bypass, two temperature/pressure gauges

and a high temperature limit safety switch.

Imperial Models “S” Series

Hatco Imperial models feature a Castone®tank with a 10 year

limited tank warranty, a Power ON/OFF (I/O) switch, an indicator

light and 6" (152 mm) legs. Imperial units have a capacity of 16

gallons (61 liters) and provide up to 573 gallons per hour (gph)

(2169 liters per hour [lph]) of sanitizing rinse water based on a

40°F (22°C) temperature rise.

Mini-Compact Models “MC” Series

Hatco Mini-Compact models feature a stainless steel tank with

a 10 year limited tank warranty and 6" (152 mm) legs. MiniCompact units have a capacity of 3.2 gallons (12 liters) and

provide up to 172 gph (651 lph) of sanitizing rinse water based

on a 40°F (22°C) temperature rise. Ideal for either hot water

sanitizing or point-of-use hot water dispensing.

NOTE: Mini-Compact models can be configured with an

optional Power ON/OFF (I/O) switch.

Mini-Compact Model

Imperial Model

Compact Models “C” Series

Hatco Compact models feature a Castone®tank with a 10 year

limited tank warranty, a Power ON/OFF (I/O) switch, an indicator

light and either 6" (152 mm) legs or slide mounting brackets for

mounting under a dish table. Compact units have a capacity of

6 gallons (23 liters) and provide up to 573 gph (2169 lph) of

sanitizing rinse water based on a 40°F (22°C) temperature rise.

Compact Model

Form No. EBOOSTERM-0816

5

Page 6

SPECIFICATIONS

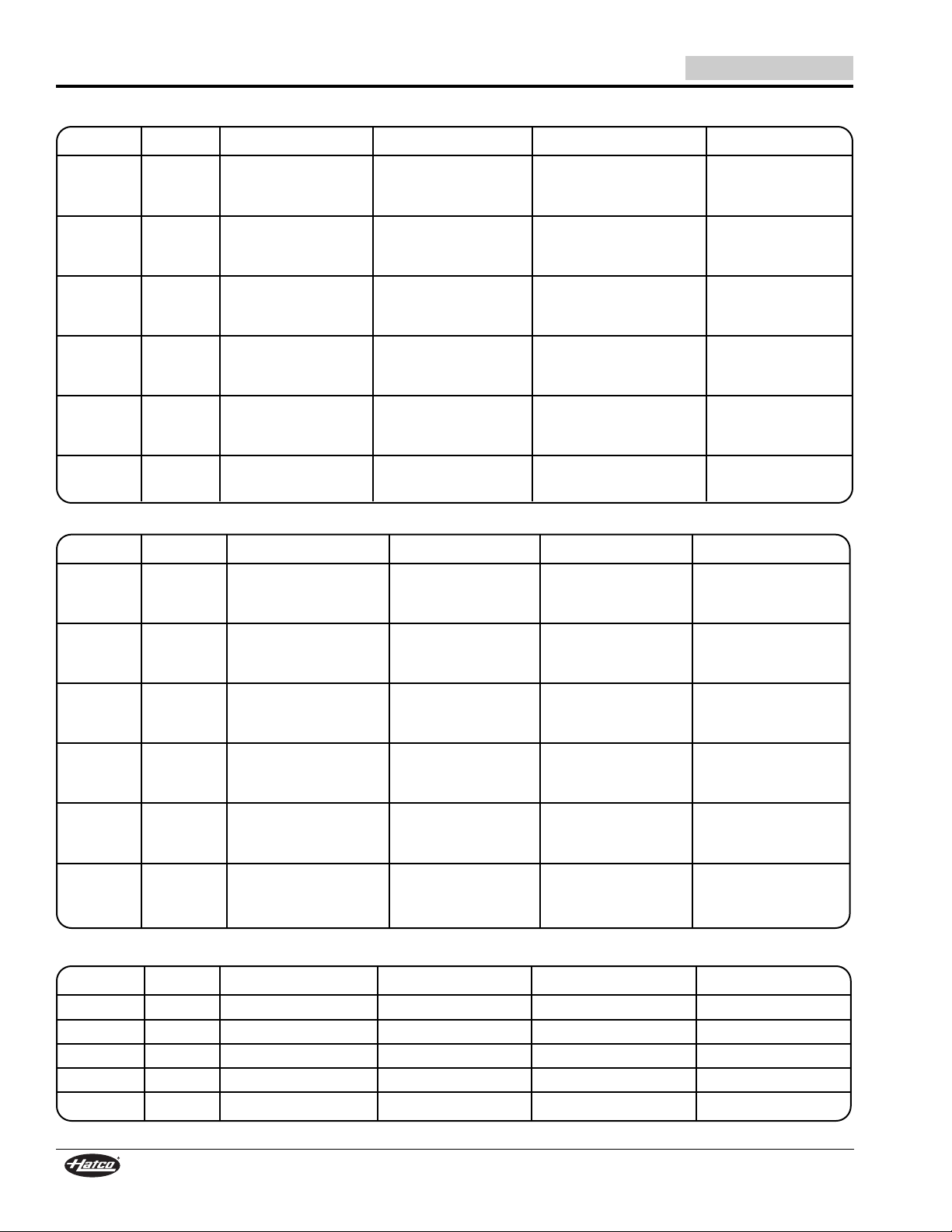

Circuit Breaker and Fused Disconnect Switch Sizes — 4 to 12 kW

English

Amp Draw

kW Voltage Phase

4 208 1 19 19 -- 30 10 1/2″ (13 mm)

240 1 17 17 -- 30 10 1/2″ (13 mm)

480 188-- 15 14 1/2″ (13 mm)

5 208 1 24 24 -- 30 10 1/2″ (13 mm)

240 1 21 21 -- 30 10 1/2″ (13 mm)

480 1 10 10 -- 15 14 1/2″ (13 mm)

6 208 1 29 29 -- 40 8 1/2″ (13 mm)

208 3 14 25 14 40 8 1/2″ (13 mm)

240 1 25 25 -- 40 8 1/2″ (13 mm)

240 3 13 22 13 30 10 1/2″ (13 mm)

380 3 9.2 9.2 9.2 15 14 1/2″ (13 mm)

480 3611 6 15 14 1/2″ (13 mm)

600 3 5.7 5.7 5.7 15 14 1/2″ (13 mm)

7 208 1 34 34 -- 50 8 1/2″ (13 mm)

208 3 17 29 17 40 8 3/4″ (19 mm)

240 1 29 29 -- 40 8 1/2″ (13 mm)

240 3 15 25 15 40 8 1/2″ (13 mm)

380 3 11.4 11.4 11.4 15 14 1/2″ (13 mm)

480 3713 7 20 12 1/2″ (13 mm)

600 3 6.7 6.7 6.7 15 14 1/2″ (13 mm)

9 208 1 43 43 -- 60 6 1/2″ (13 mm)

208 3 22 38 22 50 8 1/2″ (13 mm)

240 1 38 38 -- 50 8 1/2″ (13 mm)

240 3 19 33 19 50 8 1/2″ (13 mm)

380 3 13.3 13.3 13.3 20 12 1/2″ (13 mm)

480 3916.3 9 30 12 1/2″ (13 mm)

600 3 8.7 8.7 8.7 15 14 1/2″ (13 mm)

9.9 208 1 47.5 47.5 -- 60 6 1/2″ (13 mm)

208 3 27.5 27.5 27.5 40 8 1/2″ (13 mm)

10.4 208 3 28.8 28.8 28.8 40 8 1/2″ (13 mm)

10.5 208 1 51 51 -- 70 4 3/4″ (19 mm)

208 3 29 29 29 40 8 1/2″ (13 mm)

240 1 44 44 -- 60 6 1/2″ (13 mm)

240 3 25.3 25.3 25.3 40 8 1/2″ (13 mm)

480 3 12.6 12.6 12.6 20 12 1/2″ (13 mm)

600 3 10 10 10 15 14 1/2″ (13 mm)

11.4 240 1 47.5 47.5 -- 60 6 1/2″ (13 mm)

240 3 27.5 27.5 27.5 40 8 1/2″ (13 mm)

480 3 13.7 13.7 13.7 20 12 1/2″ (13 mm)

12 208 1 58 58 -- 90 31″ (25 mm)

208 3 33 33 33 50 8 1/2″ (13 mm)

240 1 50 50 -- 70 4 3/4″ (19 mm)

240 3 29 29 29 40 8 1/2″ (13 mm)

380 3 19.1 19.1 19.1 30 10 1/2″ (13 mm)

480 3 14.5 14.5 14.5 20 12 1/2″ (13 mm)

600 3 11.6 11.6 11.6 15 14 1/2″ (13 mm)

L1 L2 L3

Breaker or Fuse

Size

Copper Wire

Size Conduit Size

The shaded area contains electrical information for International models only.

NOTE: 250 kcmil maximum wire size for terminal block.

6

Form No. EBOOSTERM-0816

Page 7

English

SPECIFICATIONS

Circuit Breaker and Fused Disconnect Switch Sizes — 13.5 to 30 kW

Amp Draw

kW Volts Phase

13.5 208 1 65 65 -- 90 31″ (25 mm)

208 1 38 38 38 50 8 1/2″ (13 mm)

240 1 56.3 56.3 -- 90 31″ (25 mm)

240 1 33 33 33 50 8 1/2″ (13 mm)

480 1 16.3 16.3 16.3 30 10 1/2″ (13 mm)

600 1 13 13 13 20 12 1/2″ (13 mm)

15 208 1 72 72 -- 90 31″ (25 mm)

208 3 41.7 41.7 41.7 60 6 3/4″ (19 mm)

240 1 62.5 62.5 -- 90 31″ (25 mm)

240 3 36.1 36.1 36.1 50 8 1/2″ (13 mm)

380 3 23.0 23.0 23.0 30 10 1/2″ (13 mm)

480 3 18.1 18.1 18.1 30 10 1/2″ (13 mm)

600 3 14.5 14.5 14.5 20 12 1/2″ (13 mm)

17.25 208 3 47.9 47.9 47.9 60 6 3/4″ (19 mm)

18 208 1 86.5 86.5 -- 125 1 1-1/4″ (32 mm)

208 3 50 50 50 70 4 1″ (25 mm)

240 1 75 75 -- 100 31″ (25 mm)

240 3 43.4 43.4 43.4 60 6 3/4″ (19 mm)

380 3 27.3 27.3 27.3 40 8 1/2″ (13 mm)

480 3 21.7 21.7 21.7 30 10 1/2″ (13 mm)

600 3 17 17 17 30 10 1/2″ (13 mm)

24 208 1 115.4 115.4 -- 150 1/0 1-1/4″ (32 mm)

208 3 66.7 66.7 66.7 90 31″ (25 mm)

240 1 100 100 -- 125 1 1-1/4″ (32 mm)

240 3 57.8 57.8 57.8 90 3 1-1/4″ (32 mm)

380 3 38.0 38.0 38.0 50 8 1/2″ (13 mm)

480 3 29.9 29.9 29.9 40 8 1/2″ (13 mm)

600 3 23 23 23 30 10 1/2″ (13 mm)

27 208 1 129.8 129.8 -- 175 2/0 1-1/4″ (32 mm)

208 3 75 75 75 100 31″ (25 mm)

240 1 112.5 112.5 -- 150 1/0 1-1/4″ (32 mm)

240 3 65 65 65 90 31″ (25 mm)

380 3 38.1 38.1 38.1 50 8 1/2″ (13 mm)

480 3 32.5 32.5 32.5 50 8 1/2″ (13 mm)

600 3 26 26 26 40 8 1/2″ (13 mm)

30 208 1 144 144 -- 200 3/0 1-1/2″ (38 mm)

208 3 83.3 83.3 83.3 125 1 1-1/4″ (32 mm)

240 1 125 125 -- 175 2/0 1-1/2″ (38 mm)

240 3 72.3 72.3 72.3 100 31″ (25 mm)

380 3 45.7 45.7 45.7 60 6 3/4″ (19 mm)

480 3 36 36 36 50 8 1/2″ (13 mm)

600 3 28.9 28.9 28.9 40 8 1/2″ (13 mm)

L1 L2 L3

Breaker or Fuse

Size

Copper Wire

Size Conduit Size

Wire size is based on THHN insulated, copper wire for branch circuit protection at .91 derate factor. Circuit breakers and fused

disconnects are to be mounted remote and wired by contractor. Sizes are based on the 2002 NECtable 310-16. Conduit size

based on conductors plus ground wire sizing per Table C1 from Appendix C.

Only 6, 7 and 9 kW models can be field converted to single or three phase (open delta on 3 phase). Check wiring diagram supplied

with the unit when converting the phase of the unit. Larger branch circuit required than for balanced 3 phase of equal kW. Balanced

3 phase available, consult factory.

Form No. EBOOSTERM-0816

7

Page 8

SPECIFICATIONS

WARNING

Circuit Breaker and Fused Disconnect Switch Sizes — 36 to 57 kW

English

Amp Draw

kW Volts Phase

36 208 1 173 173 -- 225 4/0 1-1/2″ (38 mm)

208 3 100 100 100 125 1 1-1/4″ (32 mm)

240 1 150 150 -- 200 3/0 1-1/2″ (38 mm)

240 3 86.7 86.7 86.7 125 1 1-1/4″ (32 mm)

380 3 54.7 54.7 54.7 70 4 1″ (25 mm)

480 3 43.3 43.3 43.3 60 6 3/4″ (19 mm)

600 3 34.7 34.7 34.7 50 8 1/2″ (13 mm)

39 208 1 187.5 187.5 -- 250 250 kcmil 2″ (51 mm)

208 3 108 108 108 150 1/0 1-1/4″ (32 mm)

240 1 163.5 163.5 -- 225 4/0 2″ (51 mm)

240 3 94 94 94 125 1 1-1/4″ (32 mm)

380 3 59.3 59.3 59.3 90 3 1″ (25 mm)

480 3 47 47 47 60 6 3/4″ (19 mm)

600 3 37.6 37.6 37.6 50 8 1/2″ (13 mm)

40

40.5 208 3 112.5 112.5 112.5 150 1/0 1-1/4″ (32 mm)

45 208 3 125 125 125 175 2/0 1-1/2″ (38 mm)

54 208 3 150 150 150 200 3/0 2″ (51 mm)

57 208 3 158.4 158.4 158.4 200 3/0 2″ (51 mm)

208 3 61.6 61.6 61.6 90 3 1″ (25 mm)

240 3 97.5 97.5 97.5 125 1 1-1/4″ (32 mm)

480 3 48.8 48.8 48.8 70 41″ (25 mm)

600 3 39 39 39 50 8 3/4″ (19 mm)

240 1 188 188 -- 250 250 kcmil 2″ (51 mm)

240 3 108 108 108 150 1/0 1-1/4″ (32 mm)

380 3 68.6 68.6 68.6 90 3 1″ (25 mm)

480 3 54 54 54 70 41″ (25 mm)

600 3 43.4 43.4 43.4 60 6 3/4″ (19 mm)

240 3 130 130 130 175 2/0 1-1/2″ (38 mm)

380 3 82 82 82 125 1 1-1/4″ (32 mm)

480 3 65 65 65 90 31″ (25 mm)

600 3 52 52 52 70 41″ (25 mm)

240 3 137.3 137.3 137.3 175 2/0 1-1/2″ (38 mm)

380 3 86.7 86.7 86.7 125 1 1-1/4″ (32 mm)

480 3 68.6 68.6 68.6 90 31″ (25 mm)

600 3 54.9 54.9 54.9 70 41″ (25 mm)

L1 L2 L3

Breaker or Fuse

Size

Copper Wire

Size Conduit Size

The shaded area contains electrical information for International models only.

Wire size is based on THHN insulated, copper wire for branch circuit protection at .91 derate factor. Circuit breakers and fused

disconnects are to be mounted remote and wired by contractor. Sizes are based on the 2002 NECtable 310-16. Conduit size

based on conductors plus ground wire sizing per Table C1 from Appendix C.

NOTE: 250 kcmil maximum wire size for terminal block.

ELECTRIC SHOCK HAZARD: Consult a licensed electrical

contractor for proper electrical installation conforming to

local electrical codes and the National Electrical Code

(N.E.C.).

8

Form No. EBOOSTERM-0816

Page 9

English

SPECIFICATIONS

Sizing Chart for Low-Temp Dish Machines

BOOSTERS RATED AT 30°F (16°C) RISE Compact Imperial

Dish Machine Model Number Booster Booster

American Dish AH, AH-3D, AH-3D-S, AHC, AHC-3D, AHC-3D-S, ET-A, ET-AF, ET-AH,

Service ET-A-M, ET-AH-M, ET-A-3, ET-AH-3, L-90-3D, L-90-3D-K, L-90-3D-K-S,

L-90-3D-S, L-90-3DC, L-90-3DC-K, L-90-3DC-K-S, L-90-3DC-S, L-90-3DW,

L-90-3DW-K, L-90-3DW-K-S, L-90-3DW-S, L-90-3DWC, L-90-3DWC-K,

L-90-3DWC-K-S, L-90-3DWC-S, WH, WHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .S-6

A-3D, A-3D-S, A, AC, AC-3D, AC-3D-S, AH-B, ET-AF-3, ET-AF-M, HT-25,

L-60-3D, L-60-3D-K, L-60-3D-K-S, L-60-3D-S, L-60-3DC, L-60-3DC-K,

L-60-3DC-K-S, L-60-3DC-S, L-60-3DW, L-60-3DW-K, L-60-3DW-K-S,

L-60-3DW-S, L-60-3DWC, L-60-3DWC-K, L-60-3DWC-K-S, L-60-3DWC-S,

L-72-3D, L-72-3D-K, L-72-3D-K-S, L-72-3D-S, L-72-3DC, L-72-3DC-K,

L-72-3DC-K-S, L-72-3DC-S, L-72-3DW, L-72-3DW-K, L-72-3DW-K-S,

L-72-3DWC-S, L-72-3DWC, L-72-3DWC-K, L-72-3DWC-K-S, L-72-3DWC-S,

W, WC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5 . . . . . . . .S-6

A-B, AD-25, SS-25, 5-AH, 5-AHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .S-6

AF, AF-3D, AF-3D-S, AF-B, AFC, AFC-3D, AFC-3D-S, AFW, AFWC, 5, 5-S . . . . . . . . . . . .C-7 . . . . . . . .S-7

ADC-44, ADC-66, 5-AG, 5-AGS, 5-CD-LF, 5-CD-RF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .S-9

Blakeslee U21-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .S-6

Champion ULD, ULF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .S-6

CMA

Dish Machines A-1, AH-1, C-1, VAC-1, A-3, AH-3, C-3, L-1C, VAC-3, VAC-4, VAC-5, L-1X . . . . . . . . . . . .C-4 . . . . . . . .S-6

Hobart LX-18C, LX-30C, LX-40C, WM-5C, SR24C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .S-6

D-8-LT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .S-6

DD-8-LT, R-CC64-LT, R-EE-LT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .S-12

Series XF-EE-LT, XF-PEE-LT, XF-LL-LT, XF-PLL-LT, XF-MM-LT, XF-PMM-LT,

XF-EEE-LT, XF-LLL-LT, XF-MMM-LT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-13 . . . . . . .S-13

Series R-L-LT, R-PL-LT, R-M-LT, R-PM-LT, F-L-LT, F-PL-LT, F-M-LT,

F-PM-LT (single tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .S-36

Series “R” & “F”-CC-LT, -EE-LT, -LL-LT, -MM-LT, -LLL-LT, -MMM-LT, -PCC-LT,

-PEE-LT, -PLL-LT, -PMM-LT (multi-tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .S-24

Series XF-L-LT, XF-PL-LT, XF-M-LT, XF-PM-LT (single tank) . . . . . . . . . . . . . . . . . . . . . . .C-54 . . . . . . .S-54

Series XF-PEE-LT, XF-PLL-LT, XF-PMM-LT, XF-EEE-LT, XF-LLL-LT,

XF-MMM-LT (multi-tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .S-36

FA (Flight-A-Round) and RA (Rack-A-Round) use comparable “F” listing.

DLF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-13 . . . . . . .S-13

KL44, KL66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .S-36

A-2, AH-1, AH-2, AH-3, B-3, C-1, C-2, C-3, EVA-1, EVA-2, EVA-3, EVA-4,

EVA-5, VAC-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .S-6

B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .S-7

B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .S-9

CMA-44L with tank heater, CMA-66L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .S-24

CVA-1, CVA-2, CVA-3, CVA-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .S-6

CVA-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .S-7

LT-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .S-6

AM-14, AM-14C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .S-7

C44A, CRS66A, CPW80A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-27 . . . . . . .S-27

FT-800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30 . . . . . . .S-30

Jackson Conserver 24LT, 200LT, ES1000, (Ecolab/Jackson) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .S-6

Knight Equipment

LTD. KLE-112-HL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5 . . . . . . . .S-6

Form No. EBOOSTERM-0816

Conserver 1, Conserver XL, ES2000 (Ecolab/Jackson) . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .S-9

Conserver 2, Conserver XL2, ES4000 (Ecolab/Jackson) . . . . . . . . . . . . . . . . . . . . . . . . . .C-15 . . . . . . .S-15

AJ-44, AJ-66, AJ-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18 . . . . . . .S-18

KLE-117i, KLE-117c, KLE-175GT, KLE-175GTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .S-9

KLE-235d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-13 . . . . . . .S-13

KLE-175GT Corner, KLE-175GTM Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .S-12

9

Page 10

SPECIFICATIONS

English

Booster Heater Sizing Chart

ELECTRIC ELECTRIC

COMPACT BOOSTER IMPERIAL BOOSTER

Dish Machine Model Number Temperature Rise Temperature Rise

40°F (22°C) 70°F (39°C) 40°F (22°C) 70°F (39°C)

Adamation CSL-1390, CA-2, CA-3, CA-4, SLAP 44 . . . . . . . . . . . . . . . . . .C-39 . . . . . .(2)C-36 . . . . .S-39 . . . . .(2)S-36

Alvey FLC-10, SL-2S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . . .S-6 . . . . . . .S-9

American Dish

Service AF-ES, AFC-ES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-7 . . . . . . .C-4 . . . . . . .C-7

Blakeslee UC-21A, UC-21B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-4 . . . . . . .S-6 . . . . . . .S-6

CA, CA-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-54 . . . . . .(2)C-45 . . . . .S-54 . . . . .(2)S-45

FLC-12, CL-1, CL-1 Turntable, SA-5A . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . . .S-7 . . . . . . .S-12

FL-2S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . . .S-9 . . . . . . .S-13

KS-70, KS70M SB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . . .S-9 . . . . . . .S-15

SL-2D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-13 . . . . . .S-18

FLC-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-15 . . . . . .S-27

KS-88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-18 . . . . . .S-30

KS-70-N, KS-88-N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-39 . . . . .(2)S-40

HT-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .C-12 . . . . . . .S-7 . . . . . . .S-12

ACD-44, ADC-66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-24 . . . . . .S-12 . . . . . .S-24

UC-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .C-12 . . . . . . .S-6 . . . . . . .S-12

D-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .C-13 . . . . . . .S-9 . . . . . . .S-13

D-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-17 . . . . . .S-12 . . . . . .S-17

Series “R” & “F” -CC, -EE, -LL, -MM, -LLL, -MMM, -PCC,

-PEE, -PLL, -PMM (multi-tank) with suffix “LC” . . . . . . . . . . .C-13 . . . . . . .C-24 . . . . . .S-13 . . . . . .S-24

Series XF-EE, XF-LL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-17 . . . . . . .C-30 . . . . . .S-17 . . . . . .S-30

Series XF-LL, XF-PLL, XF-MM, XF-PMM, XF-EEE, XF-LLL,

XF-MMM (multi-tank) with suffix “LC” . . . . . . . . . . . . . . . . . . .C-17 . . . . . . .C-30 . . . . . .S-17 . . . . . .S-30

DD-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18 . . . . . . .C-30 . . . . . .S-18 . . . . . .S-30

Series F-E, FA-EE, FA-PEE, FA-LL, FA-PLL, FA-MM,

FA-PMM, F-EEE, FA-EEE, FA-LLL, FA-MMM, F-PE . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

Series R-L, R-PL, R-M, R-PM, F-L, F-PL, F-M,

F-PM (single tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-54 . . . . . .S-36 . . . . . .S-54

Series XF-L, XF-PL, XF-M, XF-PM, (single tank) . . . . . . . . . .(2)C-36 . . . . . . .--- . . . . . .(2)S-36 . . . . . .---

Series R-E, R-PE, XF-PEE, XF-PLL, XF-PMM, XF-EEE,

XF-LLL, XF-MMM (multi-tank) . . . . . . . . . . . . . . . . . . . . . . . .C-45 . . . . . .(2)C-30 . . . . .S-45 . . . . .(2)S-30

FA (Flight-A-Round) and RA (Rack-A-Round) use comparable “F” listing.

XF-EE, XF-EE-LT (with LT suffix) . . . . . . . . . . . . . . . . . . . . . . .C-17 . . . . . . .C-36 . . . . . .S-17 . . . . . .S-36

Champion U-H1, UH-200, UH-200B, U-HB . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-6 . . . . . . .S-6 . . . . . . .S-6

UL-100, UH-100B, UH-170B, UH-200B, DH-2000 . . . . . . . . . . .C-6 . . . . . . . .C-9 . . . . . . .S-6 . . . . . . .S-9

UL-150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-7 . . . . . . .S-6 . . . . . . .S-7

UH-150, UH-150B, UH-100, UH-100B, DHB-VS . . . . . . . . . . . .C-5 . . . . . . . .C-9 . . . . . . .S-6 . . . . . . .S-9

D-H1, D-HB, D-H1T, D-HBT . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .C-12 . . . . . . .S-6 . . . . . . .S-12

44 DRWS, 66 DRPWWS, 80 DRHDPWWS, 70 DRFFPWWS .C-9 . . . . . . . .C-13 . . . . . . .S-9 . . . . . . .S-13

PP-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .C-15 . . . . . . .S-9 . . . . . . .S-15

D-H1C, D-H1TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .C-18 . . . . . . .S-9 . . . . . . .S-18

44DR, 66DRPW, 80DRHDFW, 70DRFFPW, 54DR . . . . . . . . .C-12 . . . . . . .C-24 . . . . . .S-12 . . . . . .S-24

66WSPW, 44-WS, 66-WS, 64, 90FFPW, 100HDPW,

86 PW, 84, 106 PW,120 HDPW, 110 FFPW . . . . . . . . . . . . . .C-13 . . . . . . .C-24 . . . . . .S-13 . . . . . .S-24

UC-CW6-WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-36

US-CW8-WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-39 . . . . . .S-24 . . . . . .S-39

44, 66 PW, 70FFPW, 80HDPW, 54, 76PW, 80FFPW,

90HDPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-45 . . . . . .S-24 . . . . . .S-45

40-KB, 40-KB-2-2, 40-KFWB, 40-KPRB, 40KPRB-2-2,

40KPRB-2-3, 60-KB, 60-KB-2-2, 60-KFWB, 60-KFWB-2-2,

60-KPRB, 60-KPRB-2-3, 64KB, 64-KB Corner, 64-KPRB,

64-KPRB Corner, 64 Modular, 86 Modular . . . . . . . . . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

44-KB, 44-KB Corner, 44-KPRB, 44-KPRB Corner, 54-KB,

54-KB Corner, 54-KPRB, 54-KPRB Corner, 44 Modular,

66 PW Modular, UC** Series 6' Center, UC-C4 . . . . . . . . . . .C-36 . . . . . . .C-57 . . . . . .S-36 . . . . . .S-57

UC-CW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . .(2)C-36 . . . . .S-36 . . . . .(2)S-36

UC-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-45 . . . . . .(2)C-36 . . . . .S-45 . . . . .(2)S-36

UC**CW Series 6' Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-45 . . . . . .(2)C-39 . . . . .S-45 . . . . .(2)S-40

W-6-WS, W6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-45 . . . . . .(2)C-45 . . . . .S-45 . . . . .(2)S-40

10

Form No. EBOOSTERM-0816

Page 11

English

SPECIFICATIONS

Booster Heater Sizing Chart (continued)

ELECTRIC ELECTRIC

COMPACT BOOSTER IMPERIAL BOOSTER

Dish Machine Model Number Temperature Rise Temperature Rise

40°F (22°C) 70°F (39°C) 40°F (22°C) 70°F (39°C)

CMA

Dish CMA-180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .C-12 . . . . . . .S-7 . . . . . . .S-12

Machines CMA-44/66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-36

CMA-44H with tank heater, CMA-66H . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-45 . . . . . .S-36 . . . . . .S-45

EST-44/66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-24 . . . . . .S-12 . . . . . .S-24

Hobart AM-15F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-6 . . . . . . .S-6 . . . . . . .S-6

LXiC, LXiGC, LX-18C, LX-30C, LX-40C, AM-15F . . . . . . . . . . . . . . .C-4 . . . . . . . .C-7 . . . . . . .S-6 . . . . . . .S-6

LX-30, SR24, SR24H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-7 . . . . . . .S-6 . . . . . . .S-7

LX-18, AM-14F, AM-15, AM-15T . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5 . . . . . . . .C-9 . . . . . . .S-6 . . . . . . .S-9

WM-5C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .C-9 . . . . . . .S-6 . . . . . . .S-9

WM-5 (without sump heater) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .C-12 . . . . . . .S-7 . . . . . . .S-12

AM-14T, AM-14TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .C-12 . . . . . . .S-7 . . . . . . .S-12

AM-14, AM-14C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .C-12 . . . . . . .S-9 . . . . . . .S-12

AM-12, AM-12C* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9 . . . . . . . .C-12 . . . . . . .S-9 . . . . . . .S-12

UW-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-15 . . . . . .S-24

or Opti-Rinse C44A, CRS-66A, CCS-66A, CPW-80A, C54A,

CRS-76A, CCS-76A, CPW-90A, C64A, CRS-86A, CCS-86A,

CPW-100A, C-88A, CRS-110A, CCS-110A, CPW-124A . . . . . . . . . .C-15 . . . . . . .C-27 . . . . . .S-15 . . . . . .S-27

C-54A, CRS-76A, CPW-90A, CCS-76A . . . . . . . . . . . . . . . . . . . . . .C-39 . . . . . .(2)C-36 . . . . .S-30 . . . . .(2)S-36

C-44A, CRS-66A, CCS-66A, CPW-80A, C-64A, CRS-86A,

CCS-86A, CPW-100A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

C-88A, CRS-110A, CPW-124A, CCS-110A . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-54 . . . . . .S-36 . . . . . .S-54

or Opti-Rinse C44AW, CRS-66AW, CCS-66AW, CPW-80AW . . . . . .C-9 . . . . . . . .C-15 . . . . . . .S-9 . . . . . . .S-15

C-44AW, CRS-66AW, CPW-80AW, CCS-66AW . . . . . . . . . . . . . . . .C-12 . . . . . . .C-24 . . . . . .S-12 . . . . . .S-24

C-44, CRS-66, CPW-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-54 . . . . . .S-36 . . . . . .S-54

C-54, CRS-76, CPW-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-54 . . . . . .(2)C-39 . . . . .S-54 . . . . .(2)S-39

C-64W, CRS-86W, CPW-100W, C-88W, CRS-110W,

CPW-124W, CCS-86W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-36

C-64, CRS-86, CPW-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-45 . . . . . .(2)C-36 . . . . .S-45 . . . . .(2)S-36

FT800W, FT-900W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-39 . . . . . .S-24 . . . . . .S-39

FT-600, FT-700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-54 . . . . . .(2)C-39 . . . . .S-54 . . . . .(2)S-39

FT800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-39 . . . . . .(2)C-39 . . . . .S-39 . . . . .(2)S-39

FT900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-57 . . . . . .S-36 . . . . . .S-57

FT800S, FT-900S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-39 . . . . . .(2)C-36 . . . . .S-39 . . . . .(2)S-36

UTW-28, UTW-28C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-18 . . . . . .S-36

FRC and FR (Fast Rack Series) use comparable “C” line listing.

Insinger GS 302, GS-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-4 . . . . . . .S-6 . . . . . . .S-6

45SA-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-7 . . . . . . .S-6 . . . . . . .S-7

Commander 18-5 Series, CS-5, CS-5C, CS-5CH, CS-5H, Ensign . .C-6 . . . . . . . .C-12 . . . . . . .S-6 . . . . . . .S-12

Commander 18-6 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .C-12 . . . . . . .S-6 . . . . . . .S-12

Admiral 44-4, 66-4, Speeder 64, 86-3, Clipper (all) . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-39

Admiral 44-4, 66-4, (Built-In) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ABB-15-8 . . .ABB-27-8 . . . . .--- . . . . . . . .---

135-20, 185-20, 250-20, 60-20, 85-20, R-106-2 . . . . . . . . . . . . . . . .C-24 . . . . . . .C-25 . . . . . .S-24 . . . . . .S-45

Century (all) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-45 . . . . . .S-24 . . . . . .S-45

Trac 878 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-36

Century 14, Clipper RC-##-RPW-W . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-39 . . . . . .S-24 . . . . . .S-39

Super 106-2, Trac 321, Trac 321-2/RPW . . . . . . . . . . . . . . . . . . . . .C-27 . . . . . . .C-45 . . . . . .S-27 . . . . . .S-45

Defender Flight Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

Defender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-54 . . . . . .S-36 . . . . . .S-54

Master RC 3-tank Flight Machine . . . . . . . . . . . . . . . . . . . . . . . . . . .C-15 . . . . . . .C-27 . . . . . .S-15 . . . . . .S-27

Master RC 4-tank Flight Machine . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-57 . . . . . .S-36 . . . . . .S-57

CA-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . . .S-9 . . . . . . .S-24

DA-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .(2)S-9 . . . . .(2)S-24

For outdated models, consult factory for correct booster.

* Hobart Model AM-12 with serial no. 12-067-357 or below and model AM-12C with serial no. 12-067-537 or below require slightly

larger booster than listed. ‘C’ Models with serial no. 85-1041605 or greater use Opti-Rinse.

Shaded area indicates older models prior to Opti-Rinse.

Form No. EBOOSTERM-0816

11

Page 12

SPECIFICATIONS

English

Booster Heater Sizing Chart (continued)

ELECTRIC ELECTRIC

COMPACT BOOSTER IMPERIAL BOOSTER

Dish machine Model Number Temperature Rise Temperature Rise

40°F (22°C) 70°F (39°C) 40°F (22°C) 70°F (39°C)

Jackson JP-24, JP-24B, JP-24F, JP-24BF . . . . . . . . . . . . . . . . . . . . . . . .C-4 . . . . . . . .C-6 . . . . . . .S-6 . . . . . . .S-6

24B Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .C-4 . . . . . . . .--- . . . . . . . .S-6

10AB, 10APRB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .C-5 . . . . . . . .--- . . . . . . . .S-6

44CE*, 66 CERPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

54CE, 76 CERPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . .(2)C-30 . . . . .S-36 . . . . .(2)S-30

64CE, 86 CERPW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-27 . . . . . . .C-39 . . . . . .S-27 . . . . . .S-39

100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-24 . . . . . .S-12 . . . . . .S-24

100B, 100PRB, 150B, 150PRB . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .C-9 . . . . . . . .--- . . . . . . . .S-9

150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-18 . . . . . .S-12 . . . . . .S-18

200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .C-12 . . . . . . .S-7 . . . . . . .S-12

200B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .C-6 . . . . . . . .--- . . . . . . . .S-6

Tempstar, Tempstar SDS, Tempstar HH . . . . . . . . . . . . . . . . . . .C-6 . . . . . . . .C-12 . . . . . . .S-6 . . . . . . .S-12

TS-44, TS-66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-36

AJ-44, AJ-66, AJ-80, WH-44, ES-4400,

ES-6600 (Ecolab/Jackson) . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-45 . . . . . .S-24 . . . . . .S-45

AJ-54, AJ-76, AJ-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . .(2)C-36 . . . . .S-36 . . . . .(2)S-36

AJ-64, AJ-86, AJ-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-39 . . . . . .S-24 . . . . . .S-39

*Model #44CE w/SN1999 or below requires larger booster than listed.

Knight

Equipment LTD. KLE-112-HL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7 . . . . . . . .C-12 . . . . . . .S-7 . . . . . . .S-12

Meiko K-44, K-66, K-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-36 . . . . . .S-24 . . . . . .S-36

K-54, K-76, K-90, K-64, K-86, K-100 . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-45 . . . . . .S-24 . . . . . .S-45

Metalwash/Intedge FW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-18 . . . . . .S-12 . . . . . .S-18

RS-30A, RS-28L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-15 . . . . . .S-24

RT-74, RT-60, RT-42B, RT-42BC . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-27 . . . . . .S-40

RS-2R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-30 . . . . . .S-45

12

Form No. EBOOSTERM-0816

Page 13

English

SPECIFICATIONS

Booster Heater Sizing Chart (continued)

ELECTRIC ELECTRIC

COMPACT BOOSTER IMPERIAL BOOSTER

Dish machine Model Number Temperature Rise Temperature Rise

40°F (22°C) 70°F (39°C) 40°F (22°C) 70°F (39°C)

Stero ER-44, ER-44-10, ER-66S, ER-76S, ER-76SC . . . . . . . . . . . .C-15 . . . . . . .C-24 . . . . . .S-15 . . . . . .S-24

ER-64, ER-86S, ER-94S, ER-94SC . . . . . . . . . . . . . . . . . . . . .C-15 . . . . . . .C-24 . . . . . .S-15 . . . . . .S-24

SCT-44-10-LW, SCT-44-LW, SCT-66S-LW, SCT-76S-LW,

SCT-76SC-LW, SCT-90S-LW . . . . . . . . . . . . . . . . . . . . . . . . .C-15 . . . . . . .C-24 . . . . . .S-15 . . . . . .S-24

SC-1-2-4-LW, SC-1-6-4-LW, SC-2-4-LW, SC-5-2-4-LW,

SC-5-6-4-LW, SC-6-4-LW . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-15 . . . . . . .C-24 . . . . . .S-15 . . . . . .S-24

SCT-64, SCT-86S, SCT-94S, SCT-94SC . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-45 . . . . . .S-24 . . . . . .S-45

SCT-108S, SCT-108SC, SCT-76, SCT-94SM . . . . . . . . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

SC-6-4, SCT-44, SCT-44-10, SCT-66S, SCT-76S,

SCT-76SC, SCT-90S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-54 . . . . . .S-36 . . . . . .S-54

SCT-120S, SCT-120SC, SCT-120SM, SCT-150SM . . . . . . . . .C-36 . . . . . . .C-57 . . . . . .S-36 . . . . . .S-57

STW-110, SC-1-2-7-4, SC-1-6-3-4, SC-1-6-7-4, SC-2-7-4,

SC-5-2-7-4, SC-5-6-3-4, SC-5-6-7-4, SC-6-3-4, SC-6-7-4 . . .C-30 . . . . . . .C-54 . . . . . .S-30 . . . . . .S-54

SC-1-2-4, SC-1-6-4, SC-2-4, SC-5-2-4, SC-5-6-4 . . . . . . . . . .C-36 . . . . . .(2)C-57 . . . . .S-36 . . . . .(2)S-57

SCT-44-10-SC-1-3-4, SCT-44-10-3-4, SCT-44-SC-1-3-4,

SCT-44-SC-3-4, SCT-54-SC-1-3-4, SCT-54-SC-3-4,

SCT-76S-SC-3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . . .C-54 . . . . . .S-36 . . . . . .S-54

STPC (Four tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24 . . . . . . .C-45 . . . . . .S-24 . . . . . .S-45

STPCW (Four tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-27 . . . . . . .C-45 . . . . . .S-27 . . . . . .S-45

STPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30 . . . . . . .C-54 . . . . . .S-27 . . . . . .S-54

STPCW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-36 . . . . . .(2)C-30 . . . . .S-36 . . . . .(2)S-30

SD-2RA, SDRA, SDRA-PACK . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-18 . . . . . .S-12 . . . . . .S-18

U-31-A, U-31-AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . . .S-24 . . . . . .S-45

U-31-A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .--- . . . . . . . . .--- . . . . . .(2)S-24 . . . .(2)S-45

STBUW-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-45 . . . . . .(2)C-36 . . . . .S-45 . . . . .(2)S-36

SC-2-3-4, SC-5-2-3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30 . . . . . . .C-45 . . . . . .S-30 . . . . . .S-45

SC20-1 (low temp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . . .--- . . . . . . .S-12 . . . . . . .---

SC20-2 (low temp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12 . . . . . . .C-24 . . . . . .S-12 . . . . . .S-24

SC-2-8, SC-2-9, SC-1-2-8, SC-5-6-8, SC-6-8, SC-6-9, SC-1-6-8

SC-5-6-9, SC-5-2-9, SC-1-6-9, SC-5-2-8 (low temp) . . . . . . .C-18 . . . . . . .C-36 . . . . . .S-18 . . . . . .S-36

This selector chart is based on 40°F (22°C) and 70°F (39°C) temperature rises, 20 psi flow pressure, and minimum rinse cycle timer

setting in NSF listing.

All booster heaters are rated at 100% of the capacity of the dish machines as recommended by the National Sanitation Foundation.

Where make-up water for wash tank is provided from final rinse supply, chart recommendations are based upon this additional

demand (not over 2 GPM) as required by NSF.

NOTE: All sizings shown are that of the dish machine manufacturers. Hatco Corporation is not responsible for incorrect sizing

applications.

Form No. EBOOSTERM-0816

13

Page 14

SPECIFICATIONS

English

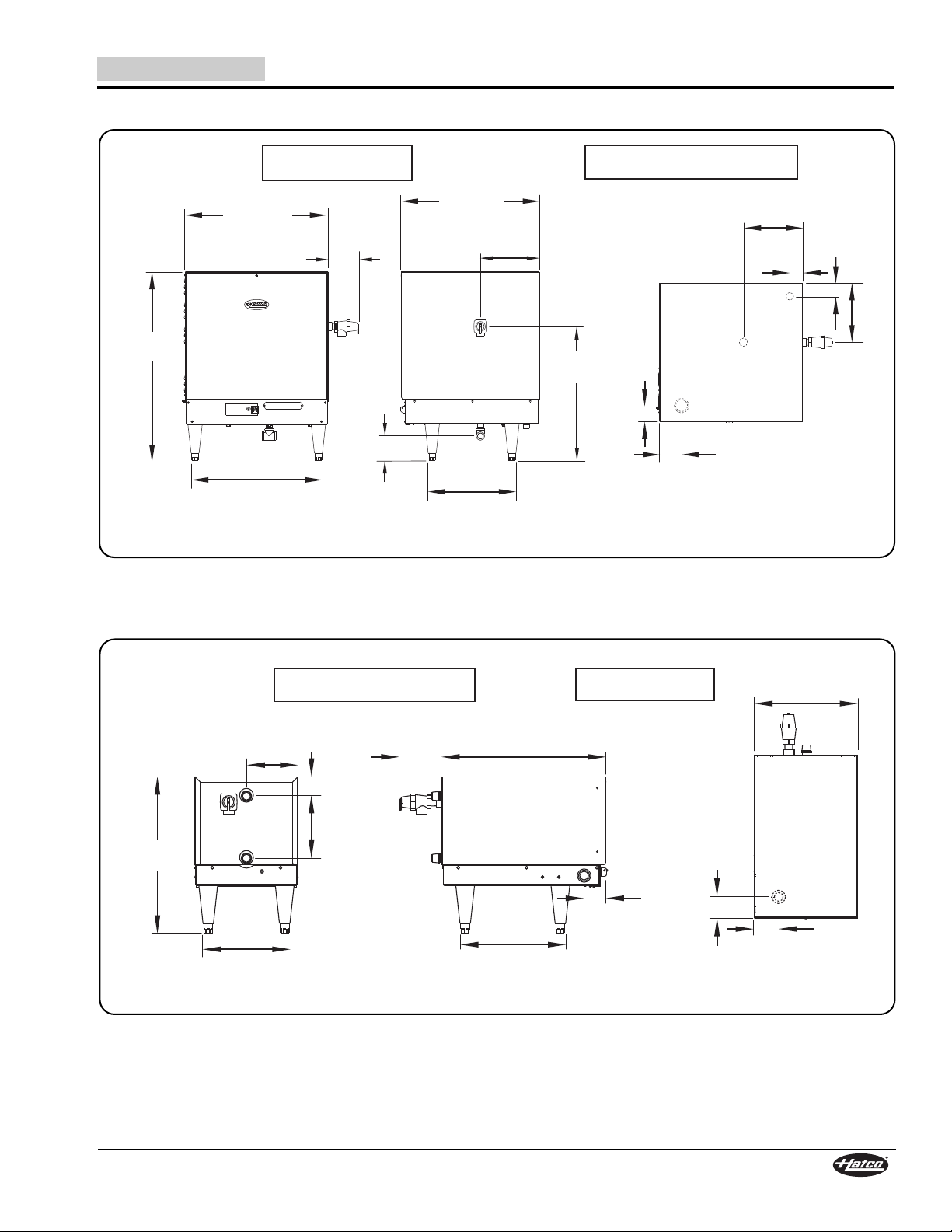

Capacity — Imperial “S” Series

Model kW 40°F (22°C) Rise 70°F (39°C) Rise Storage Capacity Shipping Weight

S-6

S-7

S-9

S-12

S-13

S-15

S-17

S-18

S-24

S-27

S-30

S-36

S-39

S-40

S-45

S-54

S-57

6

7

9

12

13.5

15

17.2

18

24

27

30

36

39

40.5

45

54

57

60 gph (227 lph)

70 gph (265 lph)

90 gph (341 lph)

120 gph (454 lph)

135 gph (511 lph)

151 gph (572 lph)

173 gph (655 lph)

181 gph (685 lph)

241 gph (912 lph)

271 gph (1026 lph)

301 gph (1139 lph)

361 gph (1367 lph)

391 gph (1480 lph)

407 gph (1541 lph)

452 gph (1711 lph)

542 gph (2052 lph)

573 gph (2169 lph)

34 gph (129 lph)

40 gph (151 lph)

52 gph (197 lph)

69 gph (261 lph)

77 gph (292 lph)

86 gph (326 lph)

99 gph (375 lph)

103 gph (390 lph)

138 gph (522 lph)

155 gph (587 lph)

172 gph (651 lph)

206 gph (780 lph)

224 gph (848 lph)

232 gph (878 lph)

258 gph (977 lph)

310 gph (1174 lph)

326 gph (1234 lph)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

16 gallons (61 liters)

200 lbs. (91 kg)

200 lbs. (91 kg)

200 lbs. (91 kg)

200 lbs. (91 kg)

200 lbs. (91 kg)

200 lbs. (91 kg)

200 lbs. (91 kg)

200 lbs. (91 kg)

214 lbs. (97 kg)

214 lbs. (97 kg)

214 lbs. (97 kg)

214 lbs. (97 kg)

214 lbs. (97 kg)

224 lbs. (102 kg)

224 lbs. (102 kg)

224 lbs. (102 kg)

224 lbs. (102 kg)

Capacity — Compact “C” Series

Model kW 40°F (22°C) Rise 70°F (39°C) Rise Storage Capacity Shipping Weight

C-4

C-5

C-6

C-7

C-9

C-12

C-13

C-15

C-17

C-18

C-24

C-27

C-30

C-36

C-39

C-45

C-54

C-57

12

13

15

17

18

24

27

30

36

39

45

54

57

4

5

6

7

9

40 gph (151 lph)

50 gph (189 lph)

60 gph (227 lph)

70 gph (265 lph)

90 gph (341 lph)

120 gph (454 lph)

135 gph (511 lph)

151 gph (572 lph)

173 gph (655 lph)

181 gph (685 lph)

241 gph (912 lph)

271 gph (1026 lph)

301 gph (1139 lph)

361 gph (1367 lph)

391 gph (1480 lph)

452 gph (1711 lph)

542 gph (2052 lph)

573 gph (2169 lph)

23 gph (87 lph)

29 gph (110 lph)

34 gph (129 lph)

40 gph (151 lph)

52 gph (197 lph)

69 gph (261 lph)

77 gph (292 lph)

86 gph (326 lph)

99 gph (375 lph)

103 gph (390 lph)

138 gph (522 lph)

155 gph (587 lph)

172 gph (651 lph)

206 gph (780 lph)

224 gph (848 lph)

258 gph (977 lph)

310 gph (1174 lph)

326 gph (1234 lph)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

6 gallons (23 liters)

105 lbs. (48 kg)

105 lbs. (48 kg)

118 lbs. (54 kg)

118 lbs. (54 kg)

118 lbs. (54 kg)

120 lbs. (54 kg)

120 lbs. (54 kg)

120 lbs. (54 kg)

120 lbs. (54 kg)

120 lbs. (54 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

142 lbs. (64 kg)

Capacity — Mini-Compact “MC” Series

Model kW 40°F (22°C) Rise 70°F (39°C) Rise Storage Capacity Shipping Weight

MC-10 9.9 99 gph (375 lph) 57 gph (216 lph) 3.2 gallons (12 liters) 48 lbs. (22 kg)

MC-10.5 10.4 104 gph (393 lph) 60 gph (227 lph) 3.2 gallons (12 liters) 48 lbs. (22 kg)

MC-11 11.4 114 gph (432 lph) 65 gph (248 lph) 3.2 gallons (12 liters) 48 lbs. (22 kg)

MC-15 15 150 gph (568 lph) 86 gph (326 lph) 3.2 gallons (12 liters) 48 lbs. (22 kg)

MC-17 17.25 173 gph (655 lph) 99 gph (375 lph) 3.2 gallons (12 liters) 48 lbs. (22 kg)

14

Form No. EBOOSTERM-0816

Page 15

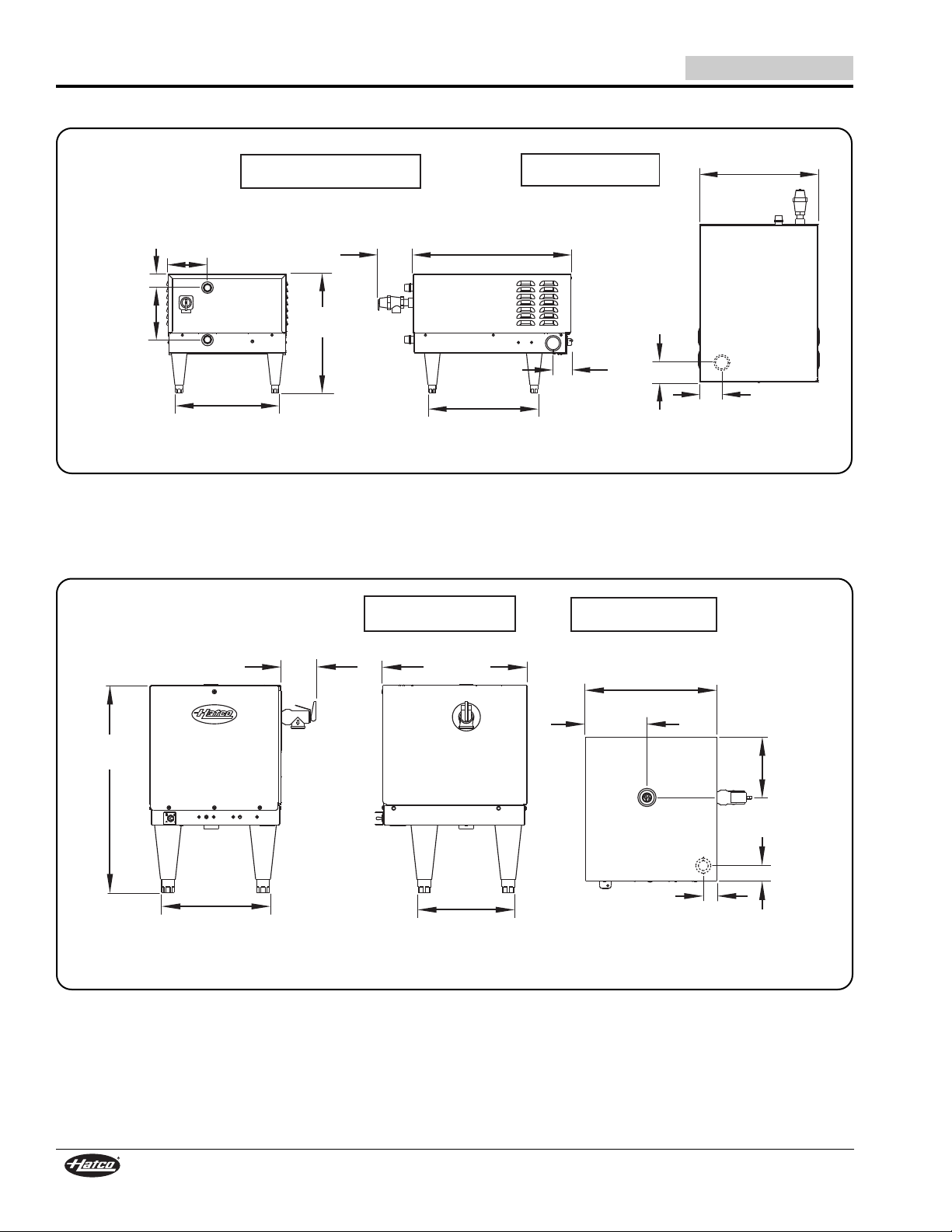

English

[

9-3/4"

(247 mm)

22-1/16"

(560 mm)

31-1/16"

(788 mm)

4" (102 mm)

20-7/8"

(532 mm)

13-3/4"

(349 mm)

9-3/4"

(247 mm)

2"

(53 mm)

5"

(126 mm)

3/4

" Inlet Tee3/4" Inlet Tee

2-1/8"

(55 mm)

23-9/16"

(598 mm)

Knockout*

Side View

Front View

Top View

Inlet*

Outlet*

22-3/4"

(578 mm)

9-3/4"

(247 mm)

3-5/8"

(92 mm)

2-5/8"

(66 mm)

* Outlet, Inlet, and Knockout are

located on the bottom of unit.

Front Side

E

lectrical Knockouts

bottom—1-1/2

" and 2"

13-1/16"

(332 mm)

20-11/16"

(525 mm)

Knockout*

3-1/8"

(79 mm)

2-3/4" (69 mm)

19-13/16"

(502 mm)

10-3/8"

(262 mm)

12-3/4"

(322 mm)

2-3/4"

(69 mm)

Inlet

Outlet

7-7/8"

(200 mm)

6-1/2"

(166 mm)

2-1/2"

(70 mm)

T/P Relief

Valve

Electrical Knockouts left side

and bottom—3/4", 1", and 1-1/4"

5-5/16"

(134 mm)

Top View

Side View

Rear View

* Knockout is located

on the bottom of unit.

SPECIFICATIONS

Dimensions — Imperial “S” Series

Form No. EBOOSTERM-0816

Dimensions — Compact “C” Series 4 to 18 kW

15

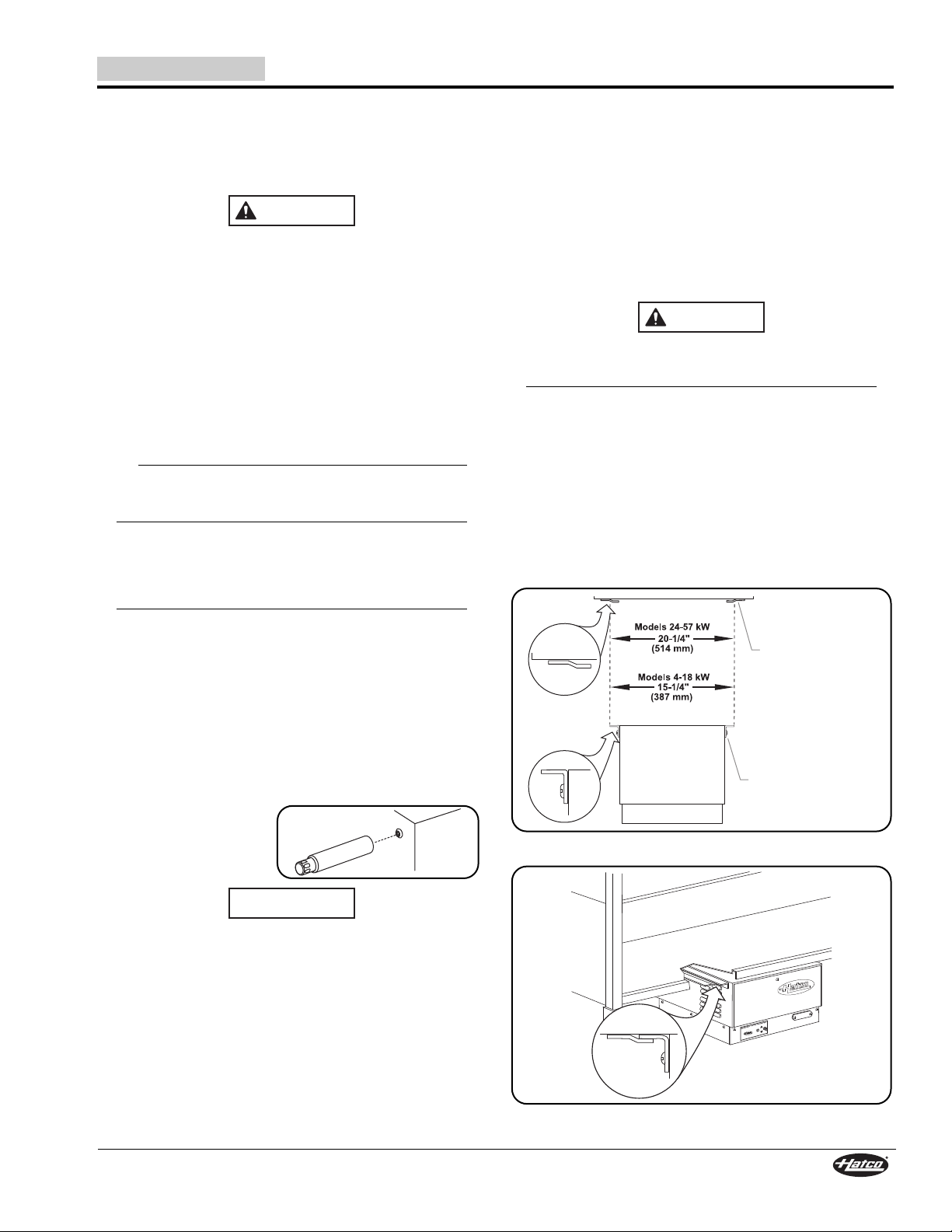

Page 16

SPECIFICATIONS

Side View

Top ViewFront View

11-3/4"

(298 mm)

1-1/4"

(31 mm)

1-3/8"

(34 mm)

Knockout*

Inlet

Outlet

T/P

Relief

Valve

18-1/2"

(469 mm)

9-1/8"

(232 mm)

8-1/8"

(206 mm)

12-7/8"

(327 mm)

5-1/2"

(139 mm)

4-3/8"

(138 mm)

3-1/8"

(79 mm)

T/P

Relief

Valve

Electrical Knockouts—

1/2", 3/4", and 1"

Front Side

* Knockout is located

on the bottom of unit.

Side View

Top View

Rear View

Knockout*

I

nlet

Outlet

T

/P Relief

Valve

1

8"

(

457 mm)

3-3/8"

(85 mm)

3" (75 mm)

18-1/16"

(458 mm)

6"

(152 mm)

7-7/8"

(200 mm)

2-1/16"

(54 mm)

15-3/16"

(387 mm)

24"

(610 mm)

16-1/8"

(410 mm)

2-3/4"

(69 mm)

Electrical Knockouts left side

and bottom—1-1/2" and 2"

5-5/16”

(134 mm)

* Knockout is located

on the bottom of unit.

English

Dimensions — Compact “C” Series 24 to 57 kW

Dimensions — Mini-Compact “MC” Series

16

Form No. EBOOSTERM-0816

Page 17

English

NOTICE

WARNING

Weld slide rail

to bottom of

dish table

Fasten slide

brackets to booster

heater sides

WARNING

INSTALLATION

General

Booster Heaters are shipped with most components preassembled. Care should be taken when unpacking shipping

carton to avoid damage to unit and components enclosed.

Components are shipped with the heater unit.

ELECTRIC SHOCK HAZARD:

• Unit must be installed by qualified, trained installers.

Installation must conform to all local electrical and

plumbing codes. Installation by unqualified personnel

will void the unit warranty and may lead to electric

shock or burn, as well as damage to unit and/or its

surroundings. Check with local plumbing and electrical

inspectors for proper procedures and codes.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• Do not place aftermarket covers on or over booster

heater. Doing so can cause temperature and moisture

build-up resulting in premature failure and electrical

shock.

EXPLOSION HAZARD: Do not store or use gasoline or

other flammable vapors or liquids in the vicinity of this or

any other appliance.

Install booster water heater as close as possible to a

commercial dish machine. Employ re-circulation if distance

between water heater and dish machine exceeds National

Sanitation Foundation (NSF) specifications of five (5) linear

feet (1524 mm).

Install booster water heater in a horizontal position with the

base parallel to the floor and the inlet connection at the

lowest point. Improper installation could create an unsafe

condition.

1. Remove the unit from the box.

NOTE: To prevent delay in obtaining warranty coverage,

complete online warranty registration. See the

IMPORTANT OWNER INFORMATION section for

details.

2. Remove tape and protective packaging from all surfaces

of unit.

3. If unit is equipped with

legs, carefully lay unit

on its side and install

the four legs.

4. Place the unit in the appropriate location.

• The location must have a solid foundation along with

being clean and dry.

• Adequate front clearance is required to allow for

accessibility to the control compartment. Hatco

recommends the side clearance be at least 2" (51 mm).

• Location must have adequate clearance to allow for

inspection, testing or replacement of pressure and/or

temperature relief valve.

• Install the booster heater as close as possible to the

commercial dish machine for efficient operation.

Make sure the dishtable is strong enough to support the

weight of the booster heater and water when installing with

slide mounting brackets.

Follow standard welding safety and operational procedures

when attaching sliderails to bottom of dishtable.

5. Install unit under dishtable using mounting slide brackets,

if applicable (Compact Series only).

a. Weld slide rails to bottom of dishtable.

b. Using Hatco slide brackets as a template, drill 1/8"

(3 mm) holes into the sides of the heater jacket.

c. Attach slide brackets to sides of heater with supplied

screws.

d. Slide heater onto slide rails under dishtable.

Hanging Support

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

NOTE: If unit is not level, use an adjustable wrench to adjust the

Form No. EBOOSTERM-0816

foot of each leg until unit is level. Each leg is adjustable

from 6" (152 mm) to 7" (178 mm).

Compact Series Heater Mounted to Dishtable

17

Page 18

INSTALLATION

WARNING

CAUTION

NOTICE

CAUTION

English

Plumbing Installation

Do not connect booster water heaters to domestic

(consumer) dish machines or other domestic utilized

equipment. This booster may damage domestic equipment.

Do not connect an expansion tank of any type to booster

heater water lines.

Use only copper plumbing material. Non-copper plumbing

material may create an unsafe condition.

Refer to the BOOSTER HEATER SIZING CHART in this

manual to ensure proper sizing and avoid personal injury

and/or damage to the booster heater.

Do not connect booster heater directly to a boiler or

furnace coil or any other uncontrolled temperature source.

The booster heater thermostat could be damaged causing

unit to overheat.

Use dielectric couplings when connecting dissimilar

metals, such as galvanized to copper. This will prevent

electrolysis or premature plumbing damage.

DO NOT turn or adjust inlet water connection on Compact

Series Booster Heaters. Doing so will change the internal

water flow.

Do not back out or loosen any pipe fittings. Doing so may

cause leaks.

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

Incoming water in excess of 3 grains of hardness per

gallon (GPG) (0.75 grains of hardness per liter [GPL]) must

be treated and softened before being supplied to booster

heater(s). Water containing over 3 GPG (0.75 GPL) will

decrease efficiency, increase energy use, and reduce the

operating life of the unit through increased lime build-up.

Product failure caused by liming or sediment buildup is not

covered under warranty.

Do not use deionized water. Deionized water will shorten

the life of water reservoir and heating element.

NOTE: Product failure caused by liming or sediment buildup is

not covered under warranty.

NOTE: A 3/4" union and a drain valve are required for easy

servicing.

NOTE: An optional flow restrictor (P/N 03.02.074.00) is

available for installation on the water inlet line.

NOTE: Some dish machines require two booster heaters to be

plumbed in series (not parallel) to meet the demand. To

ensure proper operation, a 30°F (17°C) temperature

differential must be maintained between the inlet and

outlet of each booster heater.

Inlet

Use the following procedure to install the inlet assembly. Refer

to the appropriate “Plumbing Connections” diagram in this

section for more information.

1. Connect the booster water inlet to a copper hot water

supply line from a normal water heater.

• Water temperature from the water heater should be

115°–145°F (46°–63°C) and should not exceed 155°F

(68°C). Minimum temperature differential between inlet

and outlet should never be less than 30°F (17°C).

NOTE: Refer to BOOSTER HEATER SIZING CHART for

application information.

NOTE: The red mark on the inlet and outlet water pipes of

Compact series units must remain in the top most

position.

2. Install a shut-off valve (a full opening gate or ball type).

3. Install one of the temperature/pressure gauges.

• When installing the temperature/pressure gauge, the

temperature sensing element must be in the water

stream and the gauge must be mounted upright.

NOTE: Tighten gauge during installation by turning the 1/2"

brass nut only. DO NOT turn the face of the gauge.

Turning the face will cause inaccurate measurements.

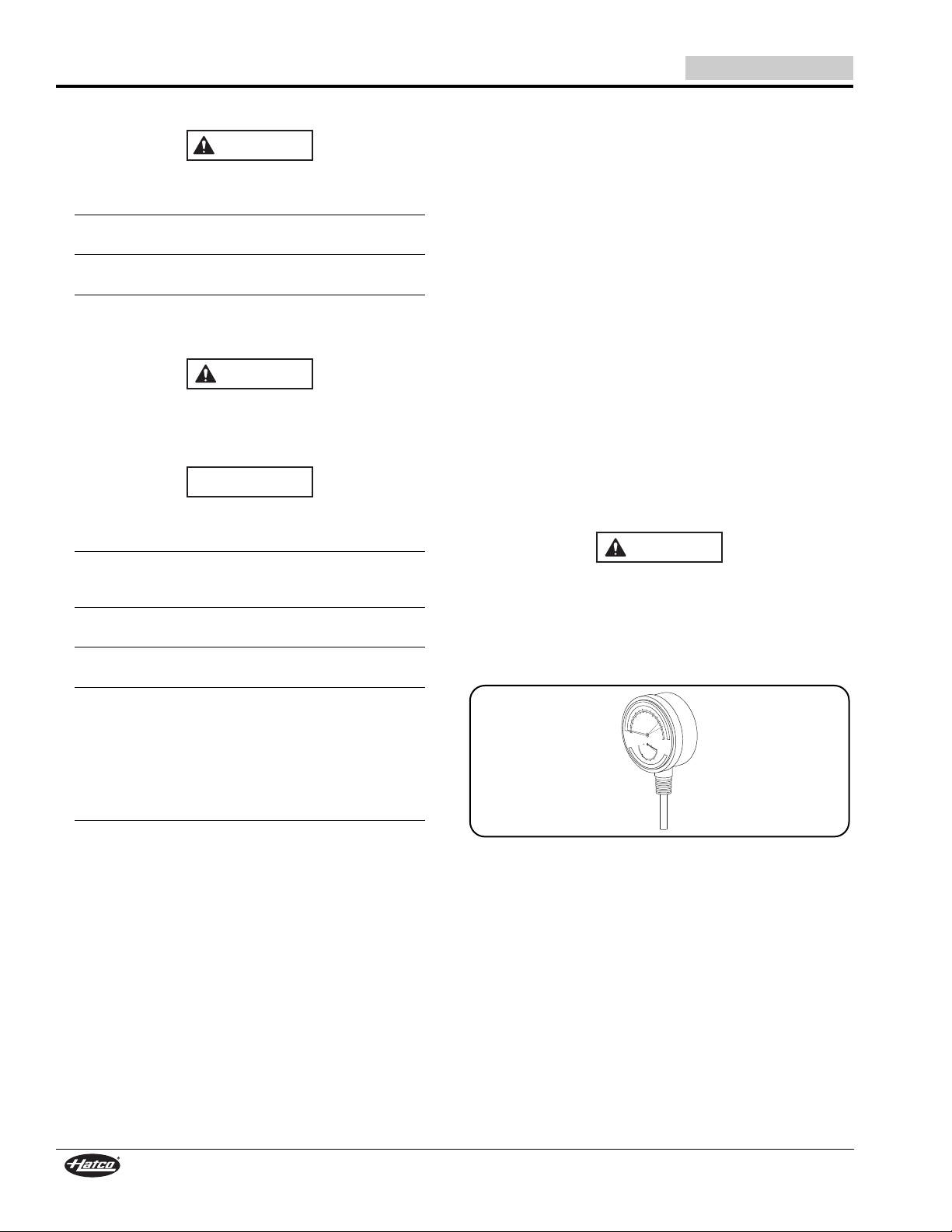

Hatco requires that two temperature/pressure gauges

(Hatco P/N 03.01.003.00) be installed to ensure proper

operation. Install one in the supply line before the pressure

reducing valve and one in the outlet line as close to the

booster heater as possible. This provides a visual check

of the water temperature and pressure before and after the

water heater.

Temperature/Pressure Gauge

NOTE: If a check valve is installed and cannot be removed, install

a back pressure relief valve (P/N 03.02.039.00) set at

125 psi (862 kPa) on the incoming line between the

pressure reducing valve and the inlet to the booster

heater. Discharge must be to open site drain.

18

Form No. EBOOSTERM-0816

Page 19

CAUTION

CAUTION

WARNING

English

4. Install the pressure reducing valve if water pressure

available to the booster heater inlet is over 25 psi (172 kPa).

• Set pressure reducing valve at 20 psi (138 kPa) flow

pressure.

NOTE: Be sure water flows through the pressure reducing

valve in the proper direction. Check directional arrow.

Valve will reduce pressure only during flow conditions.

If water supply pressure to the booster inlet is over 20 psi

(138 kPa) during flow, install standard pressure reducing

valve with built-in bypass (Hatco P/N 03.02.004.00) for

proper operation of dish machine rinse nozzles.

NOTE: The pressure reducing valve must be the type equipped

with a high pressure bypass, as supplied by Hatco.

NOTE: Optional brass pressure reducing valve with built-in

bypass (Hatco P/N 03.02.015.00) also available.

Pressure Reducing Valve

5. Install the temperature/pressure relief valve.

• Mini-Compact Series: P/N 03.02.020.00

• Compact and Imperial Series: P/N 03.02.022.00

INSTALLATION

Temperature/pressure protective equipment should not be

less than a combination temperature/pressure relief valve

certified by a nationally recognized testing laboratory that

maintains periodic inspection of the production of this

equipment and meets the requirements for Relief Valves

and Automatic Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22-1979. The temperature/pressure

relief valve must be marked with a minimum set pressure

not to exceed the marked hydrostatic test pressure of the

booster heater as noted on the unit specifications.

FOR INSTALLING PRESSURE AND TEMPERATURE

RELIEF VALVES IN ACCORDANCE WITH AMERICAN

NATIONAL STD. Z21.22-1979. Combination pressure and

temperature relief valves with extension thermostats must

be installed so that the temperature-sensing element is

immersed in the water within the top 6" (152 mm) of the

tank. They must be installed directly in a tank tapping.

Combination pressure and temperature relief valves that

do not have extension elements must be mounted directly

in a tank tapping located within the top 6" (152 mm) of the

tank, and shall be adequately insulated and located so as

to assure isolation from ambient conditions that are not

indicative of stored water temperature. TO AVOID WATER

DAMAGE OR SCALDING DUE TO VALVE OPERATION,

DRAIN PIPE MUST BE CONNECTED TO VALVE OUTLET

AND RUN TO A SAFE PLACE OF DISPOSAL. Discharge line

must be as short as possible and be the same size as the

valve discharge connection throughout its entire length.

Drain line must pitch downward from the valve and must

terminate between 1-1/2" (38 mm) and 6" (152 mm) above

the floor drain where any discharge will be clearly visible.

The drain line shall terminate plain, not threaded, with

material serviceable for temperatures up to 250°F (121°C)

or greater. Excessive length, over 30' (9.1 m), or use of

more than four elbows can cause a restriction and reduce

the discharge capacity of the valve. No shut-off valve shall

be installed between the relief valve and tank, or in the

drain line. Valve lever must be tripped periodically to

assure that waterways are clear. This device is designated