Page 1

Service Manual

COPYRIGHT ' 2000 ANDERS ENGSTR M

ANDERS ENGSTR M, ILLUSTRAT R

stra v gen 46

430 91 H N

tel/fax 031-96 84 64

anders.968464@telia.com

903SWCOM.EPS

001027

January 2001

Victor Hasselblad AB

Göteborg Sweden

Copyright © 2001 by Victor Hasselblad AB. All rights reserved. No parts of this material may be reproduced, stored

in retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopy, recording, or

otherwise, without the prior written permission of the Company.

Page 2

903SWC

1.

General description

2.

Tools

3.

Disassembly

4.

Reassembly

5.

Exploded view: Shell

6.

Exploded view: Mechanism plate

7.

Exploded view: Viewfinder SWC

Contents list

Revision 0 January 2001

Page 3

903SWC

Related Service Infos

12/96

05/97

20/97

04/01

Tripod foot adapter/kits

New tripod foot

New camera shell

New CD-ROM - Version 2.0

Revision 0 January 2001

Page 4

1

903SWC

Camera type: Mechanical wide-angle camera with a permanently attached 38

mm Biogon lens, and detachable optical viewfinder and

optional interchangeable film magazines.

Film format and film 6x6 cm and 6x4.5 cm with different magazines; 120 and 220

choices: with roll films, 70 mm perforated long rolls and Polaroid film

with different magazines.

Lens: Zeiss Biogon CF 4.5/38 mm T*. True wide-angle lens with

91º diagonal (72º horizontal) angle of view and Ø60 front

bayonet mount.

Viewfinder: Detachable optical viewfinder with built-in spirit level and

built-in magnifier for reading lens scales through the viewfinder.

Focusing: Focusing range of lens: 0.3 m to infinity. Depth-of-field range:

3 m to infinity at f/4.5 and 0.65 m to infinity at f/22.

General description

Shutter: Leaf shutter in lens, 1-1/500 s and flash synchronisation at all

shutter speeds.

Film advance: Simultaneous manual shutter winding and film advance.

Foldable winding crank.

Camera body: One-piece cast aluminium alloy shell with 1/4" and 3/8"

threads and plate for Tripod quick-coupling attachment.

System compatibility: The 903SWC accepts all film magazines in the Hasselblad

system. The Biogon lens will accept Ø60 filters and Softars as

well as lens shades, fixed or professional.

Dimensions: Camera body with lens and film magazine A12 (LxWxH):

147x112x153 mm (5.8"x4.4"x6.0").

Weight: Camera body with lens and film magazine A12: 1340 g

(2 lb 15 oz.)

Revision 0

January 2001

Page 5

2

903SWC

Tool No. Description Used for

902 894 Focusing gauge SWC Focus the Biogon lens in the same way

as other Hasselblad lenses. Can be used

with all horizontal collimators.

109950 0747 000 Biogon adapter for V-2223 Adaption between the shutter function

gauge V-2223 and the Biogon lens.

The shutter can consequently be

repaired and the lens can be completed

before the assembly to the camera

body.

102165 0000 901 Wrench Engraved ring

104867 8005 906 Wrench Front lens group

Tools

104117 0064 903 Wrench Rear lens group

Additional tools for the lens shutter, please see the Service Manual CF lenses.

Revision 0

January 2001

Page 6

3:1

90303.EPS

001026

903SWC

Tripod Foot, rear plate and cone

Remove the viewfinder. Unscrew the four

screws, two (829790) and two (829760)

and remove the tripod foot (30735).

Unscrew the three screws, two (823783)

and one (823780).

Remove the intermediate foot (22821).

Unscrew the four screws (823640) and

remove the rear plate.

Fig. 1

Lift out the cone (13435-1).

Fig. 2

823640

22821

823783

829790

90301.EPS

001026

Disassembly

823780

30735

829760

Fig. 1

Unscrew the rear lens group with the help

of wrench 104117 0064 903.

Fig. 3

90302.EPS

001026

13435-1

Fig. 2

Fig. 3

Revision 0

January 2001

Page 7

3:2

903SWC

Make sure the camera is released, then

remove the release lever (13332-1).

Unscrew the screw (822002) and remove

the catch (21165).

Fig. 4

The driving ring (21081-1) consists of two

rings, mark their relative position.

Unhook the spring (814707) from the

washer (810928).

Fig. 5

822002

90304.EPS

001026

Disassembly

21165

820046

13332-1

Fig. 4

Unscrew the three screws (820046) to free

the driving ring (21081-1) from the lens.

Fig. 4

The camera body can now be lifted from the

lens. Do not loose the gear (13320) and the

ring (13322) from the rear part of the lens!

Lift out the driving ring (21081-1) from the

camera body.

Fig. 5

Crank

Unscrew the two screws (821662) and

remove the spring (22328).

Unscrew the two screws (823640) and

remove the outer part of the crank (22331).

Remove the nylon string (22327) and lift

out the inner part of the crank (A).

Remove the tooth wheel (22335) and the

washer (810944).

Unscrew the four screws (820013 and

820015)

Remove the housing (22323).

Fig. 6

"Mark"

21081-1

90305.EPS

001026

22323

810928

814707

820015

820013

810944

22335

22327

13320

13322

Fig. 5

823640

22331

A

22328

821662

Fig. 6

Revision 0

90306.EPS

001211

January 2001

Page 8

3:3

903SWC

Unscrew the screw (820047) and lift out

the complete mechanism plate (30367-1).

Fig. 7

Take out the spacer (810721) and the

washer (810928) from the shell (circular

area fig. 8).

Mechanism plate (30367-1)

Unhook the spring (814705) from the

bracket (12873).

Lift of the catch (13427-1) incl. the signal

(20737) and the spring (814705). Remove

the clip (817112) and disconnect the signal

incl. the spring (814705) from the catch.

90307.EPS

001026

822001

13340

816709

12873

820047

816751

30367-1

13337

Disassembly

810721

810928

816702

810542

13343-1

814705

817112

Fig. 7

Unscrew the screw (822031) and remove

the signal release mechanism (13429).

Unscrew the screw (825002), which is

secured with loctite, and separate the

driving gear (13343-1) and the driving

ratchet wheel (13340).

Unscrew the screw (822001), remove the

spring (816709) and the bracket (12873).

Remove the release mechanism (13337).

Remove the spring (816751), the washer

(810542) and the spring (816702) from the

release mechanism.

Fig. 8

Revision 0

30361-1

90308.EPS

001026

822031

825002

13427-1

13429

20737

Fig. 8

January 2001

Page 9

90308.EPS

001026

4:1

90308.EPS

001026

903SWC

Lubricate the camera as detailed in the

appropriate lubrication chart. Use the

lubricants listed below:

= Isoflex Topas L32

= Isoflex PDP-48

= Loctite, e.g. Loctite 243

= Safety lacquer

Mechanism plate (30367-1)

Lubricate according to fig. 9.

Reassembly

Attach the spring (816702), the washer

(810542) and the spring (816751) to the

release mechanism (13337).

Mount the release mechanism to the

mechanism plate (30361-1) and place the

two springs according to Fig. 10 A.

Fit the bracket (12873) and the spring

(816709) into position and secure them

with the screw (822001).

Reassemble the driving gear (13343-1) and

the driving ratchet wheel (13340) according

to fig. 10 B and secure them with the screw

(825002). Make sure that the pawl and the

spring (816506) are in correct position (in

relation to the driving ratchet wheel).

Refit the signal release mechanism (13429)

and secure it with the screw (822031).

Fit the signal (20737) incl. the spring

(814705) to the catch (13427-1) and secure

it with the clip (817112).

822001

13340

816506

30361-1

816751

90311.EPS

001030

816709

816702

12873

Fig. 9

A

13337

816751

816702

810542

13343-1

814705

817112

822031

825002

Connect the spring (814705) to the bracket

(12873) and then fit the complete catch to

the mechanism plate.

Revision 0

13429

13427-1

20737

B

Fig. 10

January 2001

Page 10

4:2

90306.EPS

001211

903SWC

Fitting the mechanism plate into the shell

Place the signal (20737) according to fig. 11.

Fit the mechanism plate (30367-1) into the

shell. Fit the washer (810928) and the

spacer (810721) and secure them into

position using screw (820047).

Fig. 12

90310.EPS

001023

Reassembly

20737

Fig. 11

30367-1

Crank

Lubricate according to fig. 13.

90307.EPS

001026

810928

810721

820047

Fig. 12

Fig. 13

Revision 0

January 2001

Page 11

90306.EPS

001211

4:3

903SWC

Mount the housing (22323) on the camera

body with the four screws (820015) and

(820013). Check the axle so it turns freely.

Put on the washer (810944) and the tooth

wheel (22335).

Place the inner part of the crank (A) in the

housing and secure it with the nylon string

(22327).

Mount the crank (22321) with the two

screws (823640) and the spring (22328)

secured with the two screws 821662).

Fig. 14

Reassembling the lens and camera

body

22323

820015

Axle

820013

810944

Reassembly

22335

823640

22331

A

22328

821662

22327

Fig. 14

Lubricate and then put the driving ring

(21081-1) in the camera with its index mark

aligned. Hold it in place by using two screws

(820046).

Fig. 15

If a new driving ring (21081-1) is used, align

the inner and outer driving rings according

to fig. 16. Mark their relative position

according to fig. 15.

Place the gear (13320) and the ring (13322)

on the lens and turn it clockwise to take up

the play.

Fig. 15

Fit the camera body, with the driving ring

aligned, on to the lens. Check that the gear

and coggsector mesh properly and press

down the body firmly.

"Mark"

21081-1

820046

810928

814707

Driving ring alignment

13320

13322

Fig. 15

Tighten the two screws (820046) and check

the function.

Fig. 15

Revision 0

90309.EPS

001023

Fig. 16

January 2001

Page 12

4:4

90309.EPS

001023

903SWC

Check the release sequence:

Cock the camera and move the outer driving

ring slowly towards the release mechanism

(13337). Free the release mechanism by

hand and the shutter should release at a

point just before the release mechanism

leaves the nylon stop (13295).

Fig. 17

If the shutter releases too early, or not at all,

it is adjusted by changing the mesh between

the gear (13320) and the toothed segment

(13346). For a small adjustment, turn the

gear (13320) 180º.

Fig. 18

90312.EPS

010130

Reassembly

13295

13337

Fig. 17

13346

Lens

Fit the catch (21165) and tighten the screw

(822002) and one screw (820046).

Install the release lever (13332-1) and

engage the spring (816709). Connect the

spring (814707) to the washer (810928)

according to the circular area and check the

release sequence again.

Fig. 19

Revision 0

822002

90304.EPS

001026

13320

Fig. 18

21165

816709

820046

13332-1

Fig. 19

January 2001

Page 13

4:5

90303.EPS

001026

903SWC

Re-install the rear lens group with the help

of wrench 104117 0064 903.

Fig. 20

Install the cone (13435-1).

Fig. 21

Reassembly

Fig. 20

Fit the rear plate (22603). Secure with the

four screws (823640). Check that the rear

plate is aligned with the rear edge of the

camera shell. If necessary adjust with

washers.

Note! The rear plate must not protrude over

the shell at any point.

Fit the intermediate foot (22821).

Secure with the two screws (823783) and

one (823780).

Fit the tripod foot (30735) with the four

screws, two (829790) and two (829760).

Fig. 22

Mount the viewfinder.

Revision 0

90302.EPS

001026

823640

22821

90301.EPS

001026

823783

829790

13435-1

Fig. 21

823780

30735

829760

Fig. 22

January 2001

Page 14

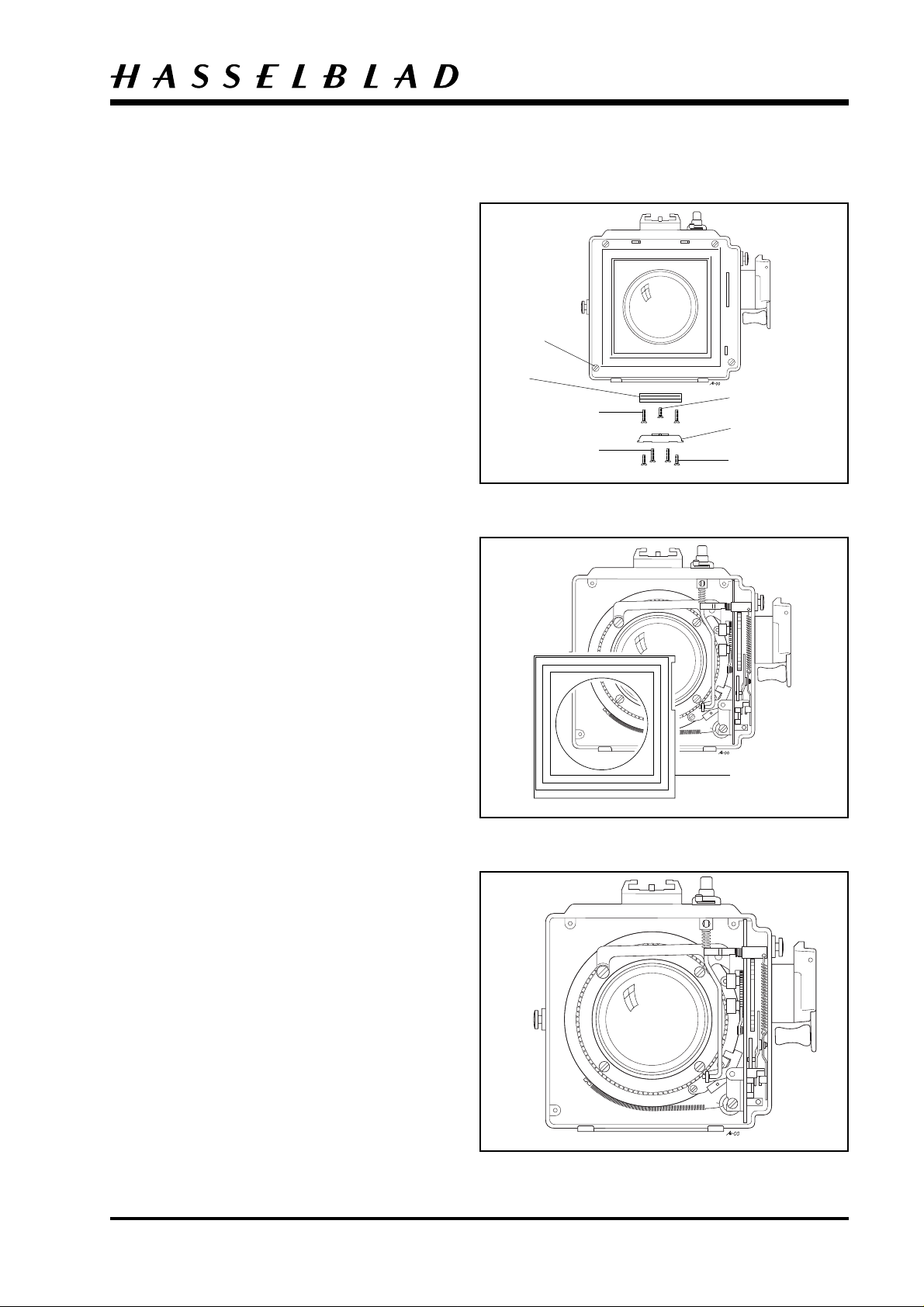

903SWC01.EPS

001023

COPYRIGHT ' 2000 ANDERS ENGSTR M

ANDERS ENGSTR M, ILLUSTRATR

stra v gen 46

430 91 H N

tel/fax 031-96 84 64

anders.968464@telia.com

903SWC

5

1

55

41

34

35

42

39

36

40

2

3

4

5

6

7

8

9

10

11

12

38

37

13

14

15

16

17

18

21

19

20

24

22

62

54

56

53

50

61

60

49

52

51

59

58

57

48

47

33

43

46

45

44

32

31

25

23

26

27

28

29

30

63

64

29

30

65

66

65

Revision 0

January 2001

Page 15

903SWC

5

Pos

Pcs Spare

No.

1 1 40 356 Shell, complete Chrome

1 40 357 Shell, complete Black

2 2 824 607 Screw

3 1 821 608 Screw

4 1 22 274 Shoe

5 1 414 434 Plate spring

6 1 20 948 Socket

7 1 13 417 T-arm

8 1 22 597 Leather

9 1 13 418 Plate spring

10 1 22 599 Cover

11 1 816 759 Spring

12 1 821 206 Screw

13 1 13 134 Release button

14 1 13 137 Screw

15 1 812 501 Pin

16 1 22 595 Leather

17 1 812 201 Pin

18 1 22 594 Leather

19 1 22 591 Leather

20 1 22 589 Leather

21 1 13 633 Foam plastic strip

22 1 22 588 Leather

23 1 22 590 Leather

24 2 13 466 Strap button

25 1 22 592 Leather

26 1 22 585 Magazine support

27 2 831 502 Rivet

28 1 22 821 Intermediate foot

29 1 823 780 Screw

30 2 823 783 Screw

Part No.

Description

Remark

31 2 829 790 Screw

32 2 829 760 Screw

33 1 30 735 Tripod foot

34 1 22 583 Spacer

35 1 22 593 Leather

36 2 22 612 Name plate

37 1 22 596 Leather

38 1 22 562 Name plate

39 4 823 640 Screw

40 1 22 321 Spacer

41 1 21 081 Driving ring

42 1 13 322 Guide ring

43 1 13 320 Gear

44 1 13 346 Toothed segment

45 3 820 046 Screw

46 1 810 928 Washer

47 1 13 295 Nylon stop

48 1 814 707 Spring

49 2 823 017 Screw

50 1 820 013 Screw

51 2 810 408 Washer

52 2 820 019 Screw

53 1 822 002 Screw

Revision 0

-1

-1

January 2001

Page 16

903SWC

5

Pos

Pcs Spare

No.

54 1 22 997 Magazine hook

55 2 830 435 Screw

56 1 13 435 Cone, complete

57 1 13 394 Cone

58 1 20 769 Frame

59 1 12 871 Foam strip

60 4 810 549 Washer 0,10 mm

4 810 542 Washer 0,15 mm

4 810 543 Washer 0,20 mm

4 810 545 Washer 0,30 mm

61 4 823 640 Screw

62 1 22 603 Rear plate Please state serial No.

63 1 22 566 Foot Previous type tripod foot

64 1 22 584 Tripod socket Standard 1/4"

1 22 667 Tripod socket Optional 3/8"

65 8 823 735 Screw

66 1 103 349 Slide

Part No.

-1

-1

-1

-1

Description

Remark

Revision 0

January 2001

Page 17

903SWC02.EPS

001120

COPYRIGHT ' 2000 ANDERS ENGSTR M

ANDERS ENGSTR M, ILLUSTRATR

stra v gen 46

430 91 H N

tel/fax 031-96 84 64

anders.968464@telia.com

6

36

35

12

11

1

2

10

9

3

4

5

6

8

7

34

33

32

30

29

31

28

27

26

25

17

24

16

18

15

14

13

23

19

20

21

22

Revision 0

January 2001

Page 18

903SWC

6

Pos

Pcs Spare

No.

1 1 22 323 Housing

2 2 820 015 Screw

3 1 810 944 Washer

4 1 22 335 Tooth wheel

5 1 22 331 Crank

6 2 821 662 Screw

7 1 22 328 Spring

8 2 823 640 Screw

9 1 22 327 Nylon string

10 2 820 013 Screw

11 1 810 721 Spacer

12 1 30 367 Mechanism plate, complete

13 1 13 337 Release mechanism

14 1 816 702 Spring

15 1 810 542 Washer

16 1 816 751 Spring

17 1 13 343 Driving gear

18 1 13 429 Signal release mechanism

19 1 822 031 Screw

20 1 13 427 Catch

21 1 814 705 Spring

22 1 817 112 Clip

23 1 20 737 Signal

24 1 814 505 Spring

25 1 816 606 Spring

Part No.

-1

-1

-1

Description

Remark

26 1 825 002 Screw

27 2 811 106 Pin

28 1 820 047 Screw

29 1 30 361 Mechanism plate

30 1 816 506 Spring

31 1 12 873 Bracket

32 1 816 709 Spring

33 1 822 001 Screw

34 1 13 340 Driving ratchet wheel

35 1 13 332 Release lever

36 1 21 165 Catch

-1

-1

Revision 0 January 2001

Page 19

430 91 HN

tel/fax 031-96 84 64

anders.968464@telia.com

Viewfinder SWC

7

1

3

2

4

18

17

19

5

6

16

7

15

8

9

13

10

12

14

Revision 0

11

January 2001

Page 20

Viewfinder SWC

7

Pos

Pcs Spare

No.

1 1 52 036/01 Libell

2 2 52 036/02 Cushion

3 1 52 036/03 Housing, upper

4 1 52 036/04 Glass plate

5 2 52 036/05 String

6 1 52 036/06 Housing, lower

7 2 52 036/07 Screw

8 1 52 036/08 Catch

9 1 52 036/09 Foot

10 4 52 036/10 Screw

11 1 52 036/11 Screw

12 1 52 036/12 Plate spring

13 2 52 036/13 Steel ball

14 1 52 036/14 Plate spring

15 1 52 036/15 Name plate

16 2 52 036/16 Screw

17 1 52 036/17 Lens element

18 1 52 036/18 Eye piece

19 1 52 036/19 Rubber eye cup

Part No.

Description

Remark

Revision 0 January 2001

Loading...

Loading...