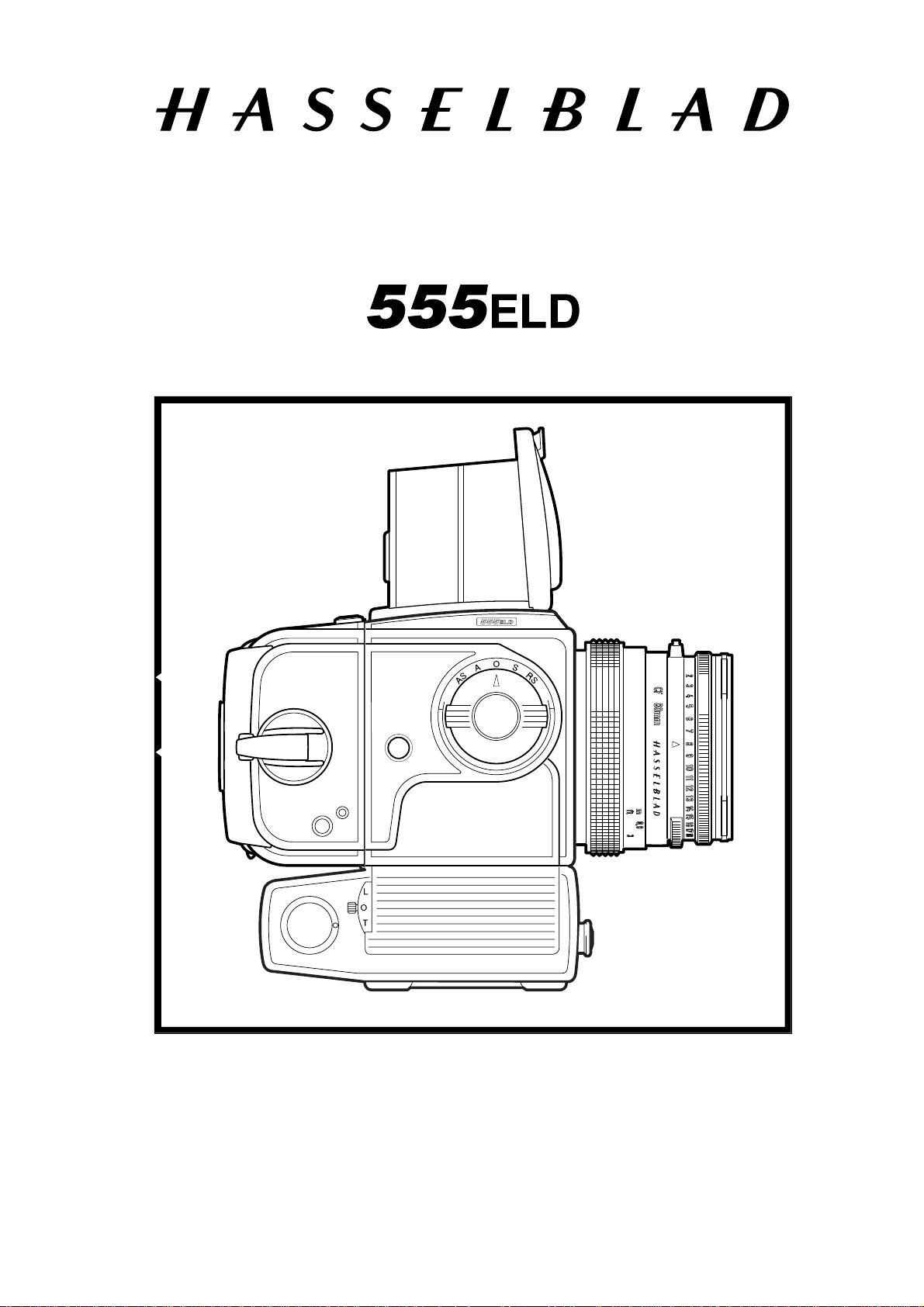

Hasselblad 555ELD Service Manual

Service Manual

COPYRIGHT © 1999 ANDERS ENGSTRÖM

ANDERS ENGSTRÖM, ILLUSTRATÖR

Östra vägen 46

430 91 HÖNÖ

tel/fax 031-96 84 64

anders@aeillustr.se

555ELDOM.EPS

990215

Victor Hasselblad AB

Göteborg Sweden

May 1999

Contents list

Camera body 555ELD

1.

General

2.

Tools

3.

Disassembly

4.

Reassembly

5.

Adjustment, final assembly and calibration of the flash meter

6.

Sub-assembly: Front bayonet plate and auxiliary shutter

7.

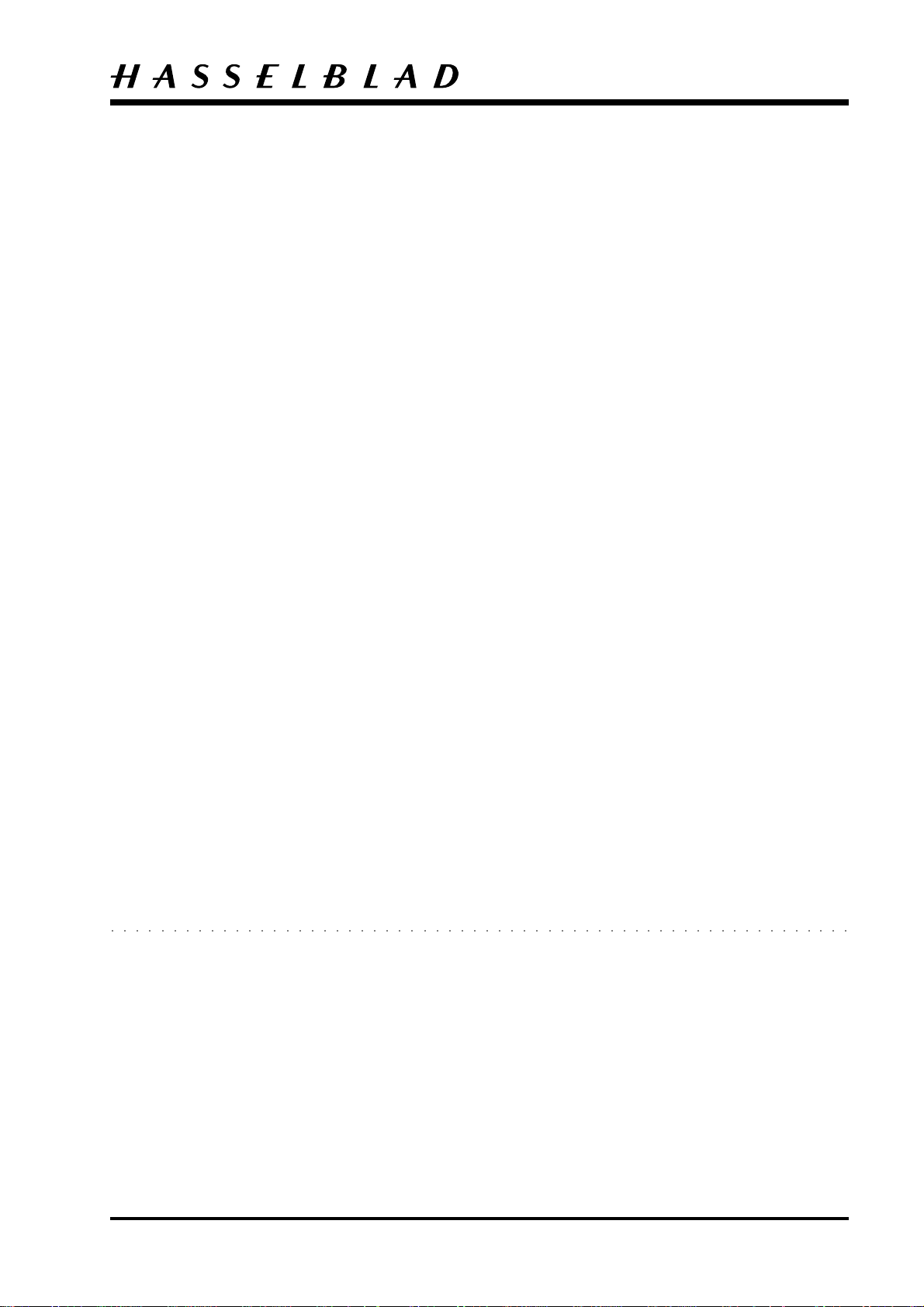

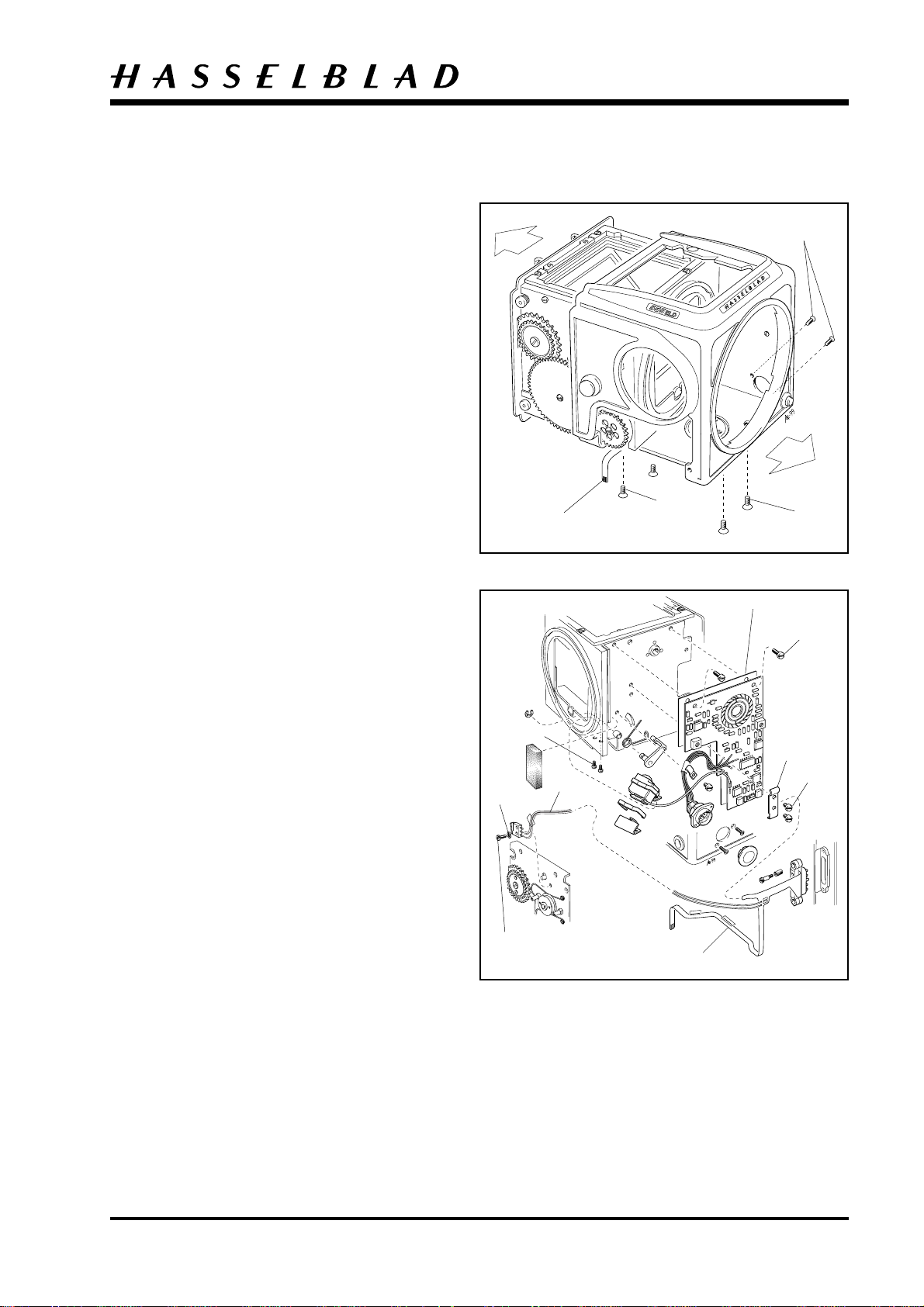

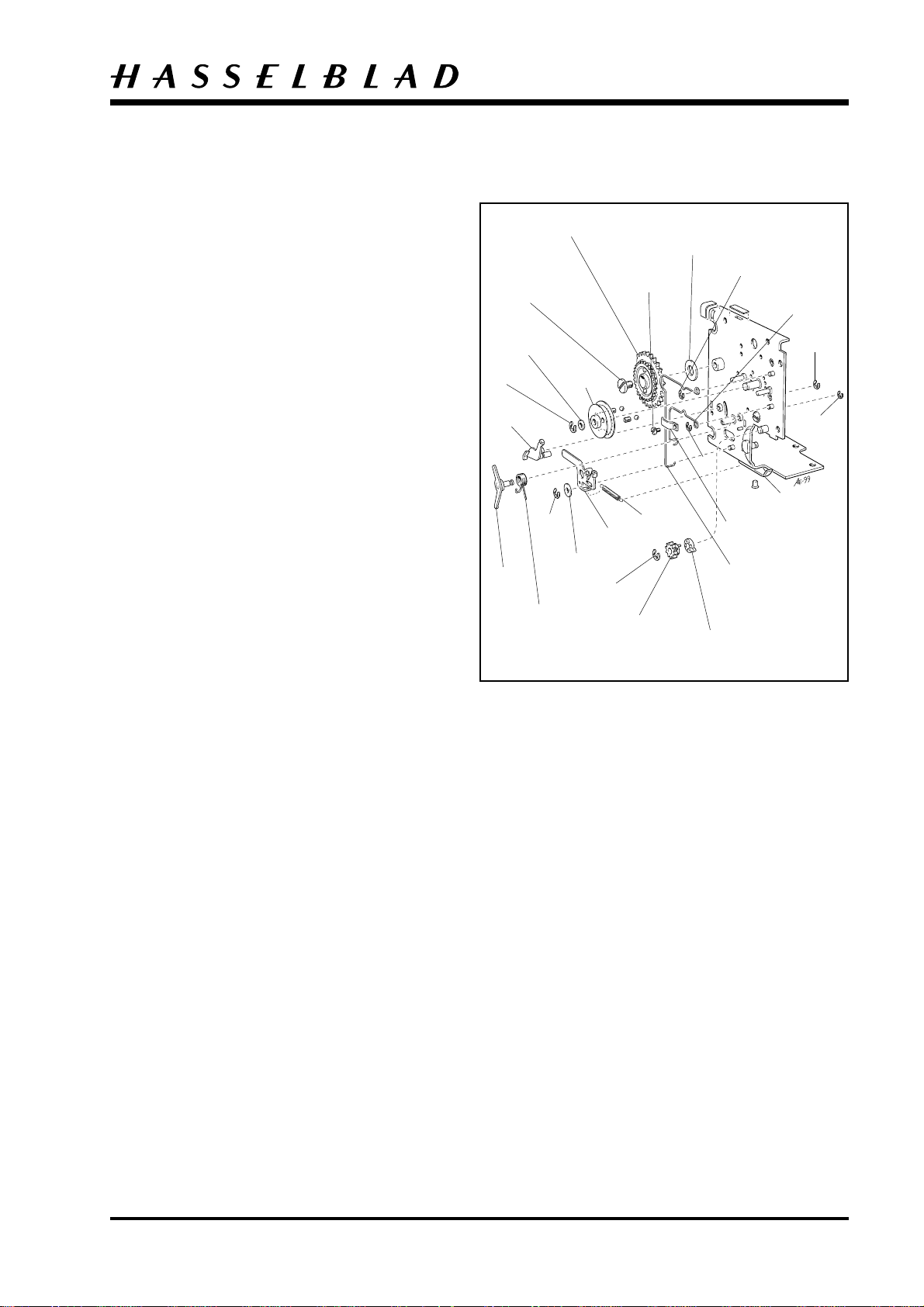

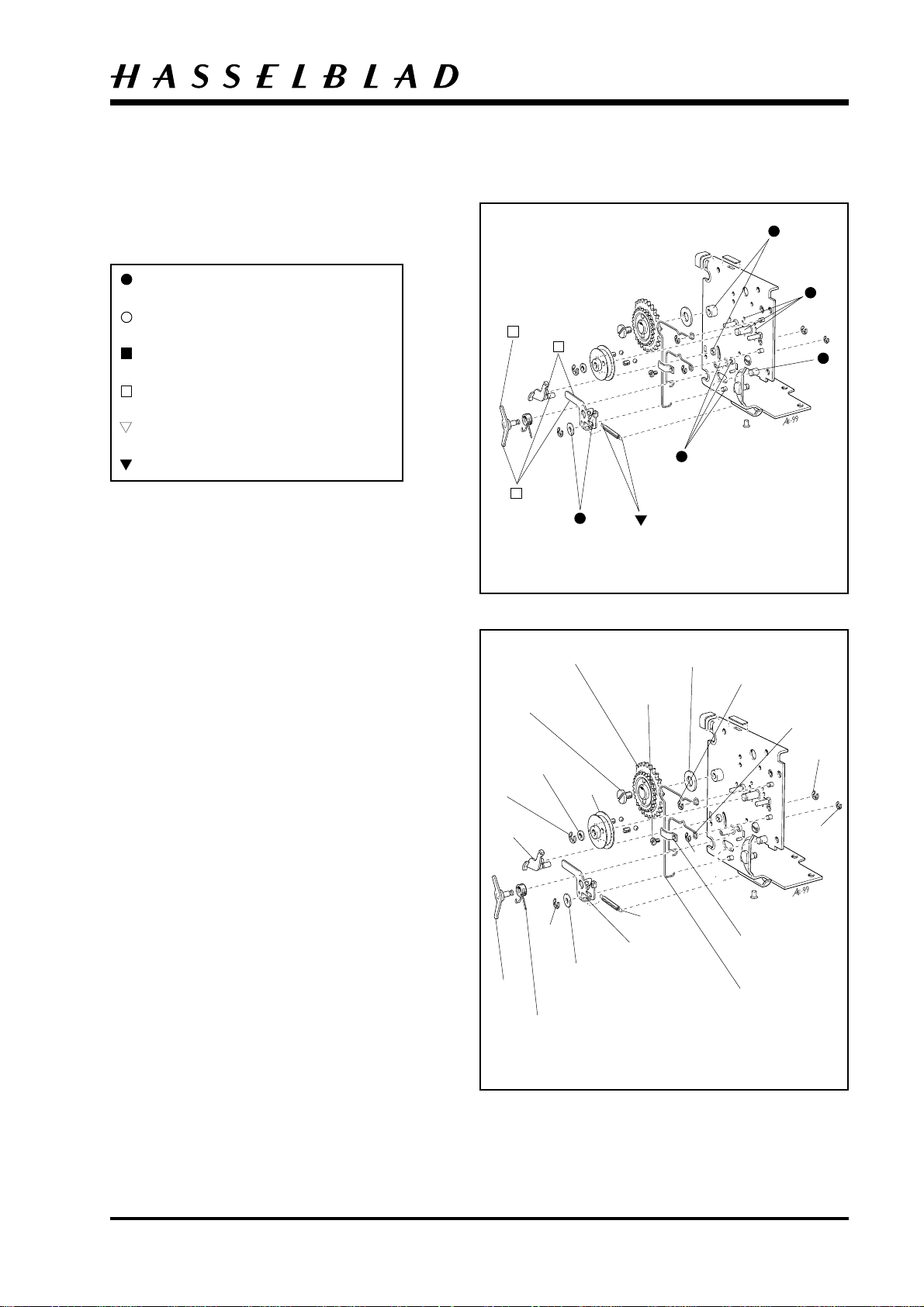

Exploded view: Shell

8.

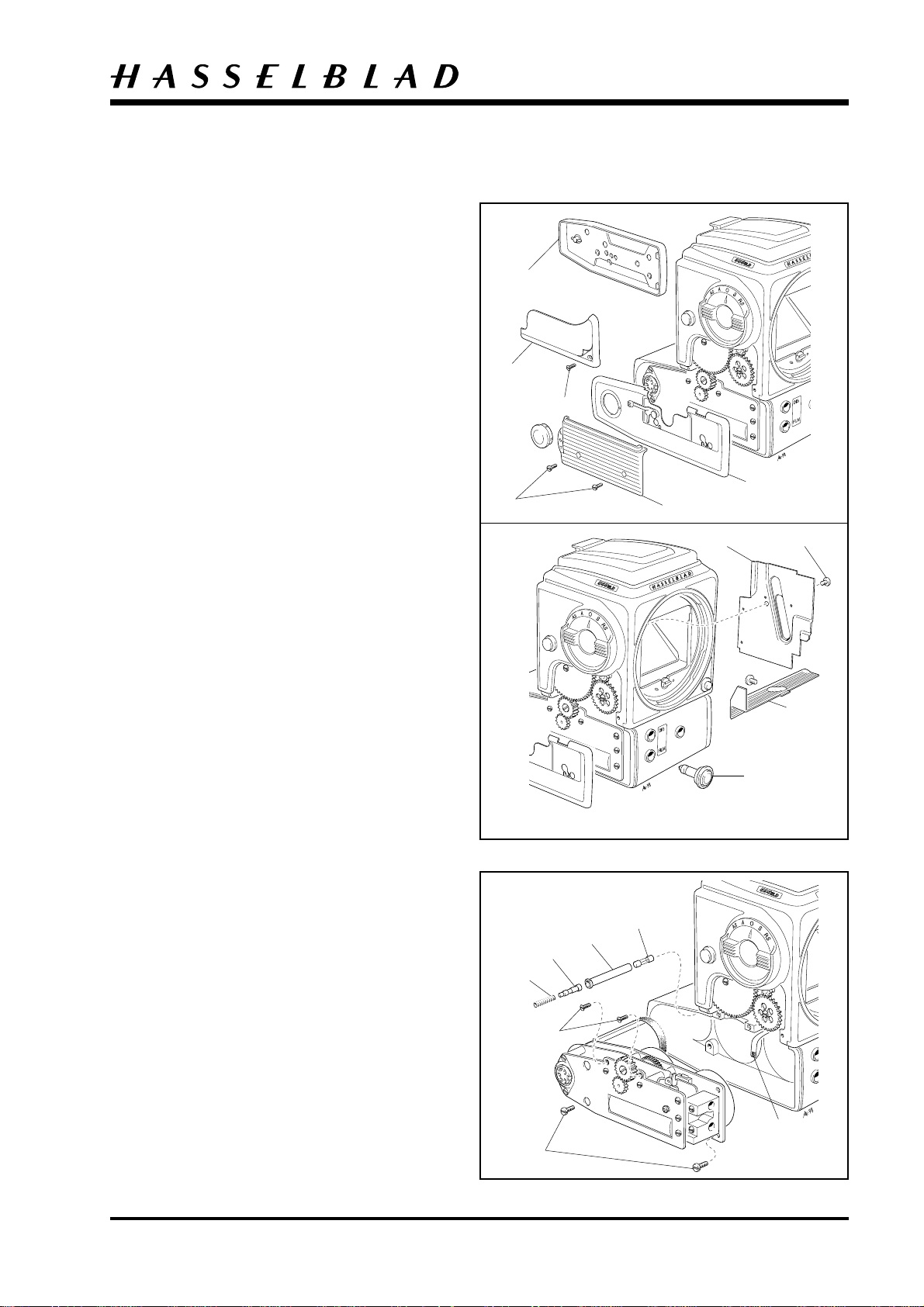

Exploded view: Motor housing

1.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

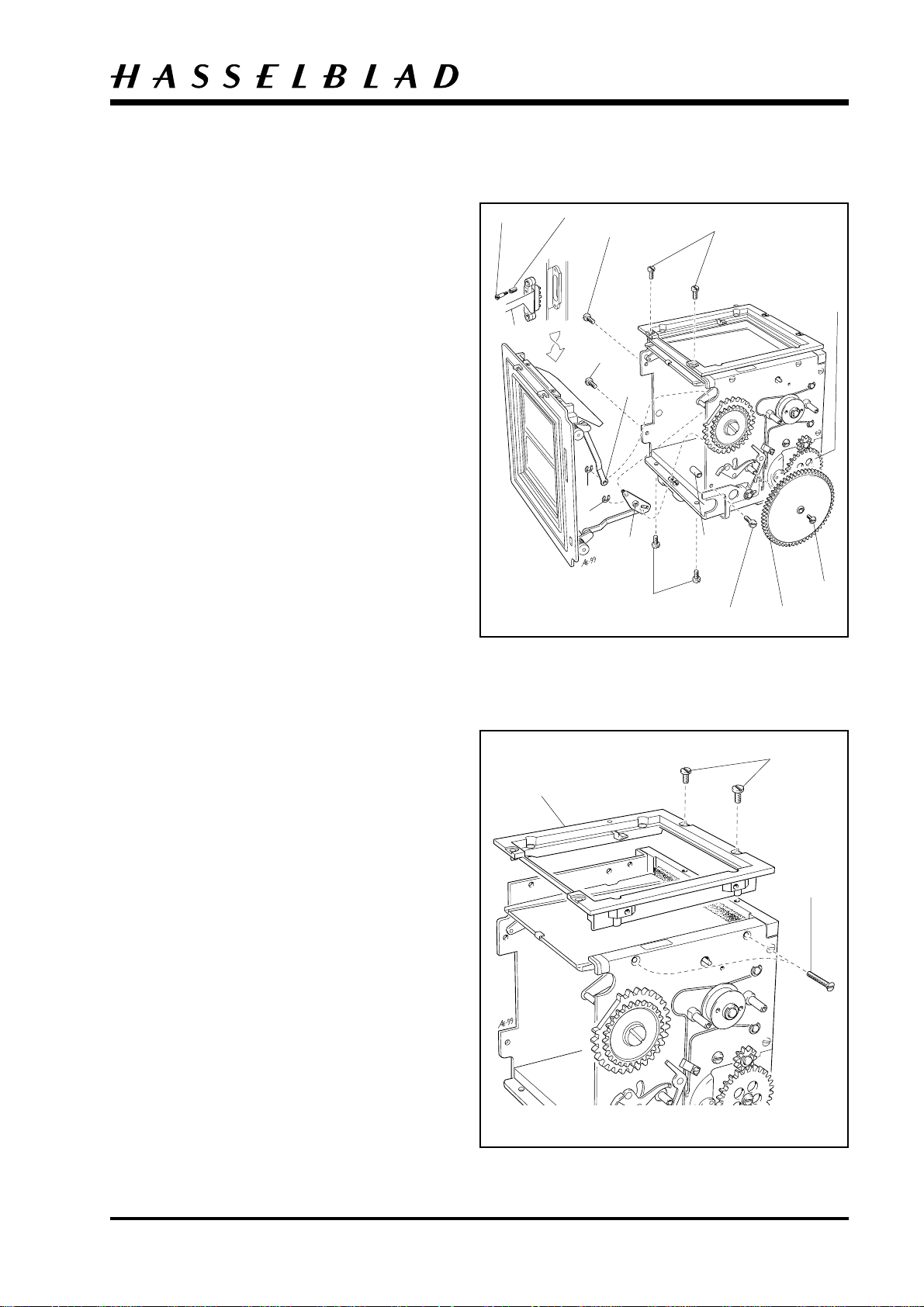

Exploded view: Right hand wall & main components

Exploded view: Left hand wall & electronics

Exploded view: Rear plate & auxiliary shutter

Exploded view: Front bayonet plate, mirror assembly & screen frame

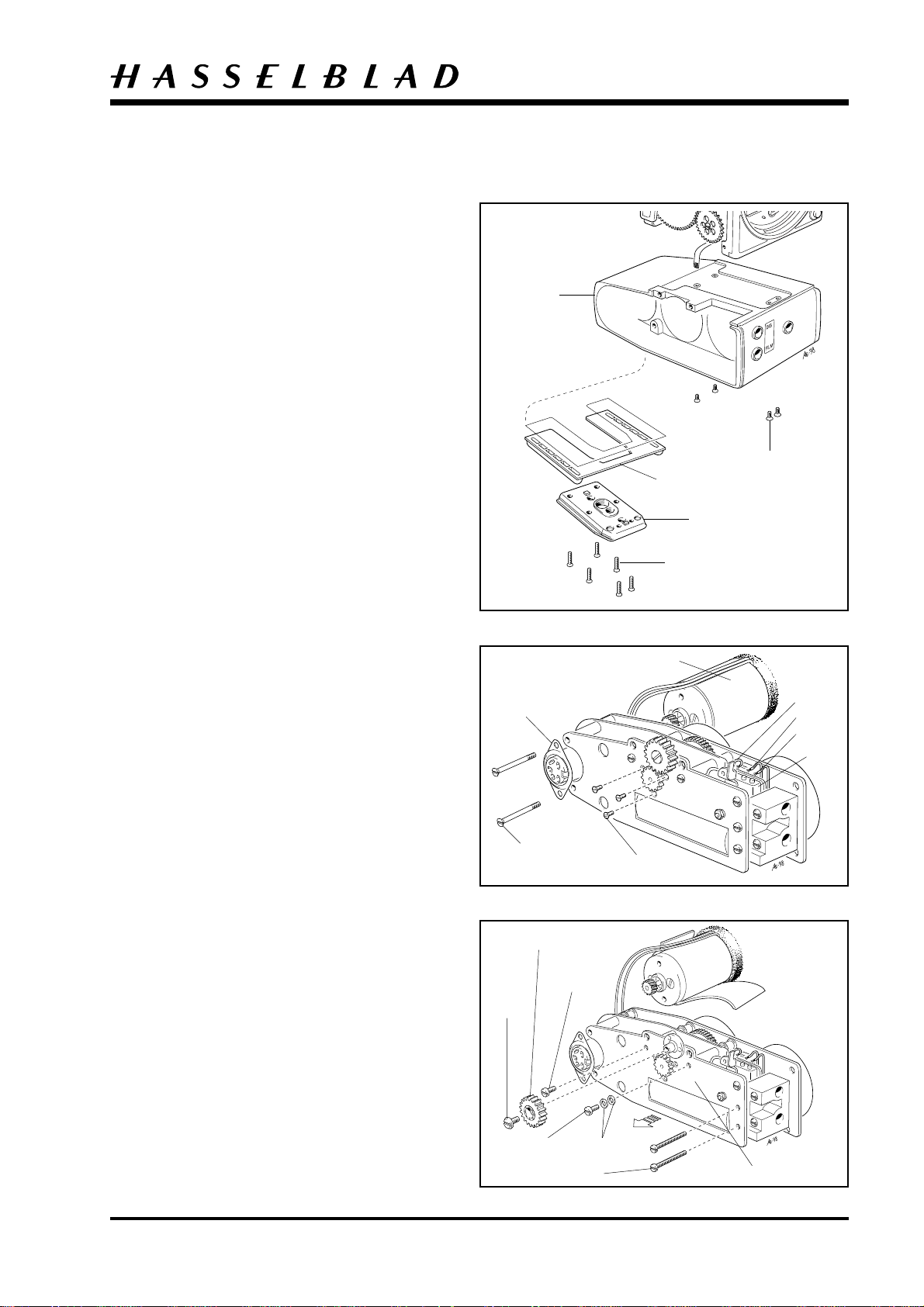

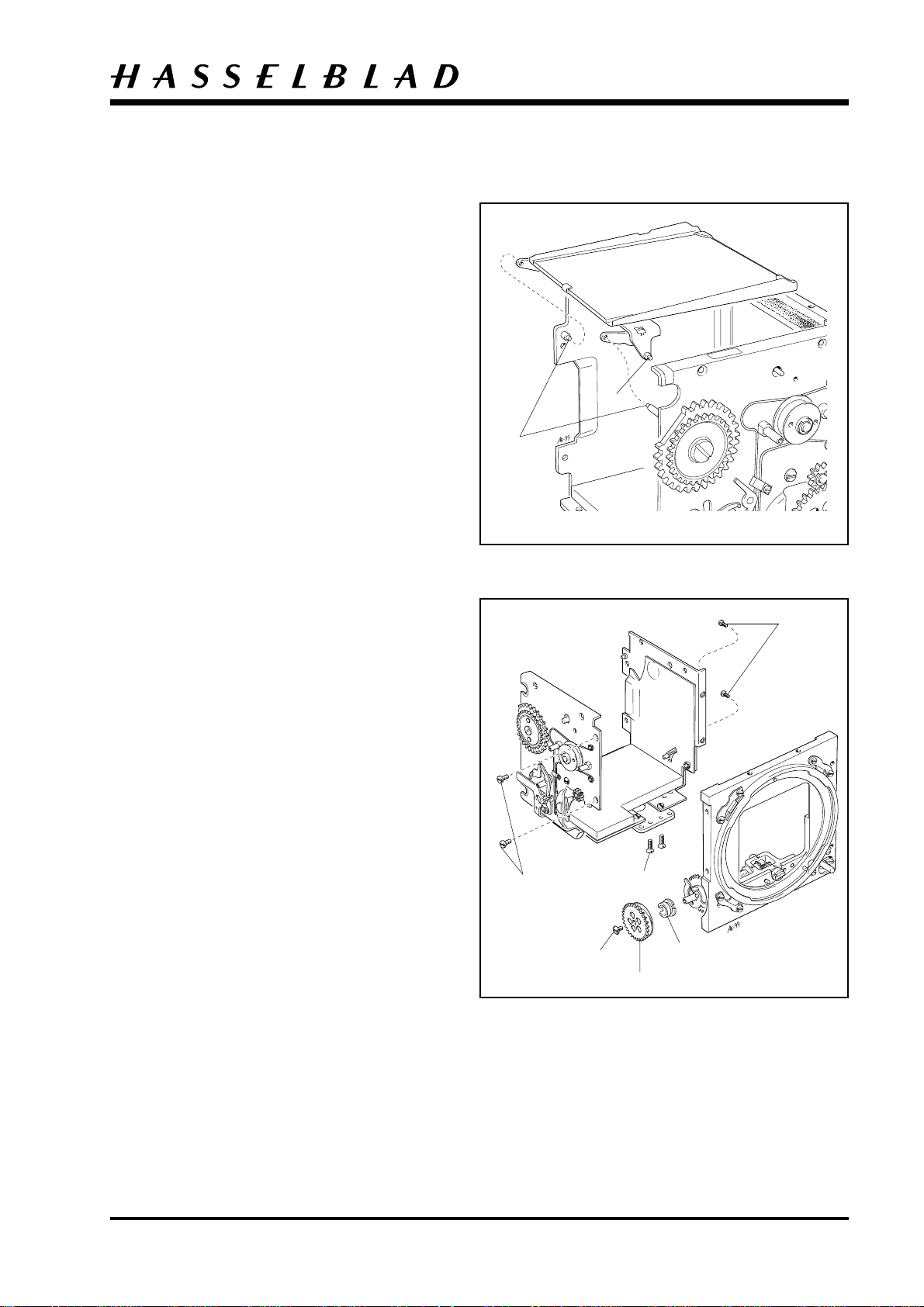

Exploded view: Motor & electrical connections

Exploded view: Motor drive gear box

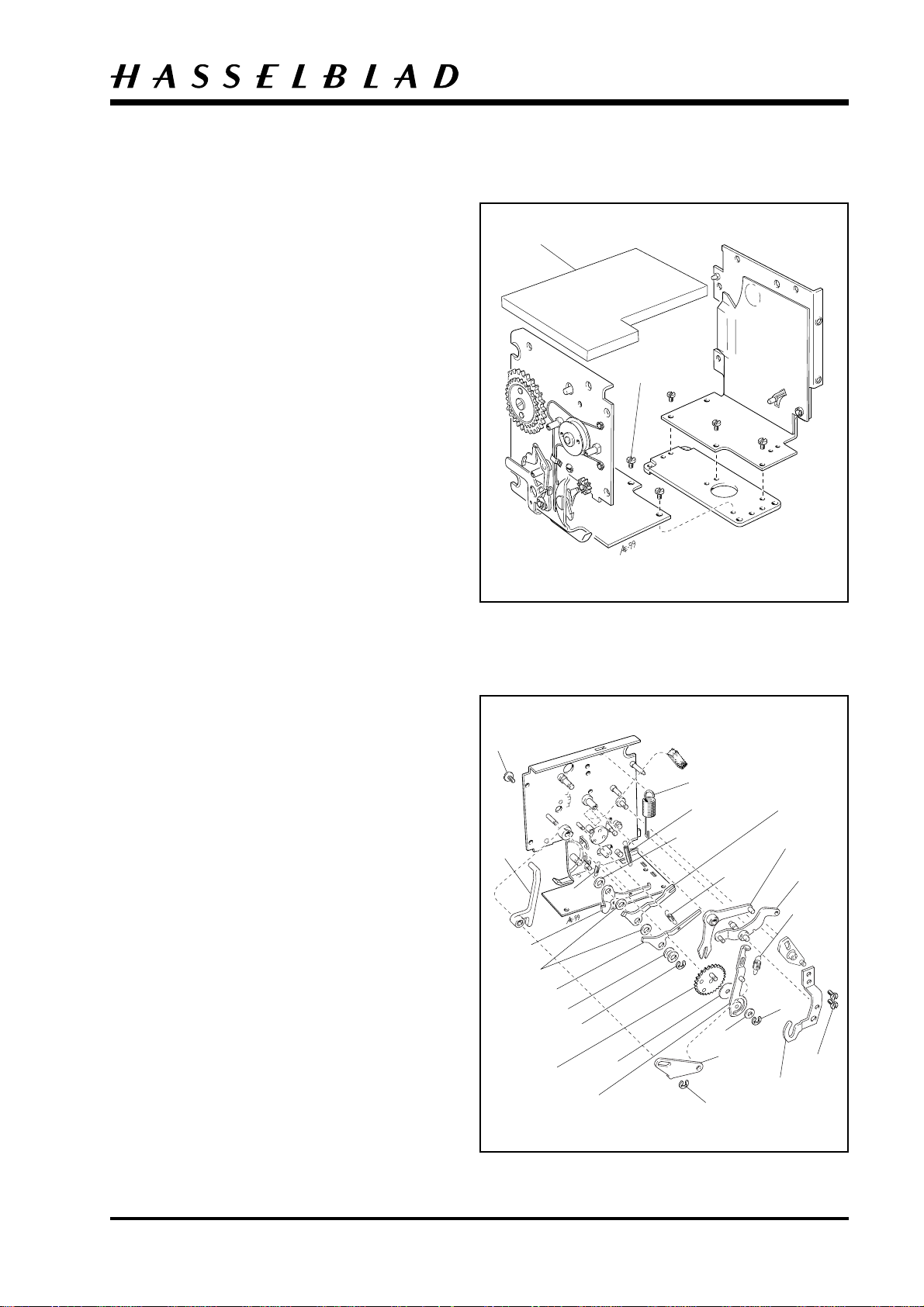

Exploded view: Shell 553ELX/500ELX

Exploded view: Motor housing 553ELX

Exploded view: Motor housing 500ELX

Exploded view: Right hand wall & main components 553ELX/500ELX

Exploded view: Left hand wall & electronics 553ELX/500ELX

20.

21.

22.

23.

Revision 0

Exploded view: Rear plate & auxiliary shutter 553ELX/500ELX

Exploded view: Front bayonet plate & screen frame 553ELX/500500ELX

Exploded view: Motor & electrical connections 553ELX

Exploded view: Motor & electrical connections 500ELX

May 1999

Contents list

Camera body 555ELD

24.

25.

Exploded view: Motor drive gear box 553ELX/500ELX

Exploded view: IR Release unit

2.

Revision 0

May 1999

555ELD - 553ELX - 500ELX

Related Service Infos

01/93

17/93

20/93

23/95

12/96

01/97

06/97

03/99

04/99

05/99

07/99

New screw holding the side cover - 553ELX and 500ELX

Fitted with wrong spacers - 553ELX

Redesigned flash metering circuit - 553ELX and 500ELX

New motor - 553ELX

Tripod foot adapter/kits

Rechargeable batteries discontinued - 500ELX

New tripod foot - 553ELX

Battery compartment - 553ELX

Release and S-arm redesigned - 553ELX and 500ELX

Preliminary spare part catalogue - 555ELD

New Service Manual - 555ELD

09/99

14/99

01/00

09/00

14/00

01/01

02/01

04/01

Mounting plate in motor housing modified - 555ELD

Battery compartment for AA batteries - 500ELX

New CD-ROM - Version 1.2

New CD-ROM - Version 1.3

Discontinued parts - 500 series cameras

Modified magazine hook - 555ELD

Modified motor unit - 555ELD

New CD-ROM - Version 2.0

Revision 3 January 2001

1:1

Camera body 555ELD

Camera type: Medium format single lens reflex camera with a built-in motor,

TTL/OTF flash metering and two release systems, one adapted

for conventional photography, the other one for digital

photography including integrated connections for digital

camera backs.

Camera body: One-piece, cast aluminium alloy shell with permanently

attached motor housing in lightweight magnesium. Tripod

socket threads 1/4" and 3/8", and tripod plate for rapid

mounting.

Film format and film 6x6 cm and 6x4.5 cm with different film magazines; 120 and

types: 220 rollfilm, 70 mm perforated long rolls and Polaroid film.

General description

Film advance: Automatic motorized film advance with simultaneous shutter

winding and mirror return; maximum speed 1.3 frames/s.

Remote shutter release via optional cord or IR control.

Lenses: All CF/CFi/CFE/CB lenses from 30 to 500 mm, Teleconverter

1.4XE, Converter 2XE, Converter 2XE, Teleconverter APO

1.4XE and PC-Mutar 1.4X Shift Converter.

Shutter: Lens leaf shutter. Speeds from 1 to 1/500 s and B. Time

exposure lever on camera body.

Shutter / Mirror modes: Five different shutter/mirror modes; single exposure with

normal mirror function, sequential exposures with normal

mirror function, pre-release of mirror for one single exposure,

repeated pre-release for single exposures and pre-release for

sequential exposures.

Flash control: TTL centre-weighted dedicated system with OTF metering.

Measured area Ø40 mm. Film speed range ISO 64 - 4000.

Controls a wide variety of flash units using appropriate adapters

(SCA-system).

Revision 0

May 1999

1:2

Camera body 555ELD

General description

Viewfinder and focusing Foldable focusing hood with 5x magnification, interchangeable

screen: with 90º or 45º prism viewfinders or magnifying hoods.

Bright Acute-Matte D* screen interchangeable for other types.

Full viewfinder image with all lenses and accessories.

Adaption to digital backs: Integrated databus connections interface directly to leading

digital backs. A unique release system with separate front

release port on camera activates the digital back.

Camera operation: Electronic front release. Alternatively, the camera can be

released remotely by optional cord or IR control. Selector dial

for shutter/mirror release modes. Film speed selector for

TTL/OTF flash metering. Battery check for alkaline batteries.

Battery/Capacity: Five standard 1.5 V AA size alkaline batteries (LR-6 or AM-3)

or rechargeable NiCd types. Up to 4000 exposures with

alkaline batteries, less than 2000 exposures with fully charged

NiCd.

Fuse: 5x20 mm 1.5 A medium slow-blow instrument fuse.

Dimensions: Length 120 mm (4.7"), width 100 mm (3.9"), height 150 mm

(5.9").

Weight: 1125 g (2 lb 8 oz).

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

IR Release unit: Unit for infrared remote release of the Hasselblad 555ELD.

Attaches to the front release ports of the camera and powered

by the camera batteries. Can be set for normal or digital

photography. Supplied with the Hasselblad IR Remote control

44113, which in normal conditions provides an operating range

of approx. 10 m (33').

Dimensions: Length 26 mm (1.0"), width 86 mm (3.4"), height 36 mm

(1.4"), weight approx. 70g (2.5oz).

*Acute-Matte D designed by Minolta

Revision 0 May 1999

2

Camera body 555ELD

Tools

Tool No. Description Used for

V-2211 Pin driver Fitting the locating pin in the front plate

and the front gear bracket

V-2229 Focal length gauge Adjustment of the focal length,

mirror 45ºangle and focusing screen

V-2236 Microscope Focusing screen adjustment

V-4151/52 Focusing tester Focusing screen adjustment

V-4705 Focusing screen adapter Focusing screen adjustment

V-5423 Riveting jig Replacement of aux. shutter flaps

902474 Test box ELX/CX Calibration of the TTL flash meter

902658 Key angle gauge Adjustment of the front key angle

(V-2075)

903202 Power supply adapter Running the camera without batteries

970600 Service Test System Calibration of the TTL flash meter

Revision 0

May 1999

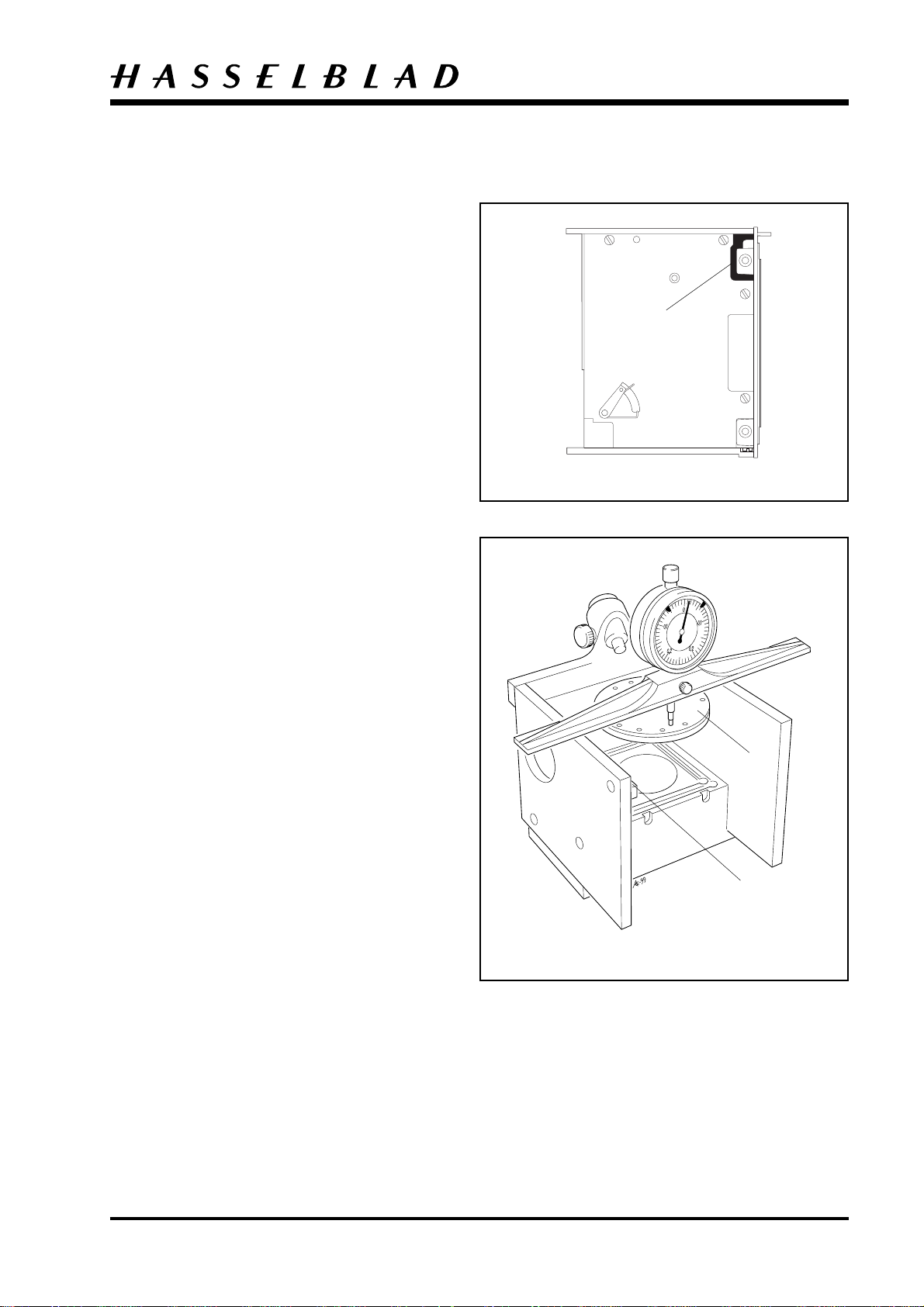

DIS01.EPS

990316

3:1

Camera body 555ELD

Motor Housing

Remove the lens, film magazine, viewfinder and

focusing screen.

Unlock the battery cover, operate the release button

and disconnect the battery cover at the exact moment

when the auxiliary shutter is closed and mirror is in

the upper position.

Peel back the small palpas cover hiding the screw

(821033). Use the short screwdriver V-2245.

Remove the inner side cover (22709).

Remove the cover (22928).

Fully wind the camera.

Remove the batteries and battery cover (30737

chrome or 30742 black).

30737, (30742)

30424-1,

(30631-1)

823017

820019

40202

Disassembly

21292, (22117)

22709

821033

Remove the socket cap (22470) from the side contact.

Remove the two screws (820019) from the right hand

plastic grip (40202). Peel back the leather on the side

cover (chrome 30424 -1, black 30631-1) and remove

the screw (823017) underneath. The side cover and

the plastic grip can now be removed.

Remove the cover (Chrome 21292, black 22117)

from the motor housing.

Unplug the release button (46120) from the release

socket

Fig. 1.

Remove the four screws, two (820042), two (823017)

and loosen the contact flex (22915) from the motor

unit and pull it clear of the motor housing. At this

point the fuse assembly (815855, 21305, 22342 and

13593) can also be removed. Finally, push out the

battery compartment (50178).

Fig. 2.

815855

DIS02.EPS

990316

21305

823017

22928

46120

Fig. 1

13593

22342

Revision 0

820042

DIS03.EPS

990316

22915

Fig. 2

May 1999

3:2

Camera body 555ELD

Remove the tripod foot (30763) by removing the six

screws (829790) and the rubber support (30778) held

by double-sided tape. When the tripod foot and the

rubber support have been removed, four holes are

exposed allowing access to the four screws (823745)

holding the motor housing (30801) to the main

camera body. Insert a screwdriver through the access

holes and remove all four screws. The motor housing

can now be removed from the main body of the

camera.

Fig. 3.

Disassembly

30801

823745

30778

30763

829790

Motor unit

Remove the to long screws (823049) from the side

contact (13604). The contact will now pull clear but

will still be connected to the motor (22827) and the

wiring. If no further disassembly is to take place, then

care should be taken that this wiring is not broken.

Unsolder the brown, red, and blue wire from the

micro switch (13605). Remove the three screws

(824205).

Fig. 4.

Remove the screw (821012) and the gear (13566).

Remove the two long screws (820048), that pass

through the outer mounting plate, then through the

connecting terminal and into the inner mounting

plate. Remove the two short screws (820041 and

820042) located on both sides of the gear (13566) and

the two washers (810613). Gently remove the outer

mounting plate (21290).

Fig. 5.

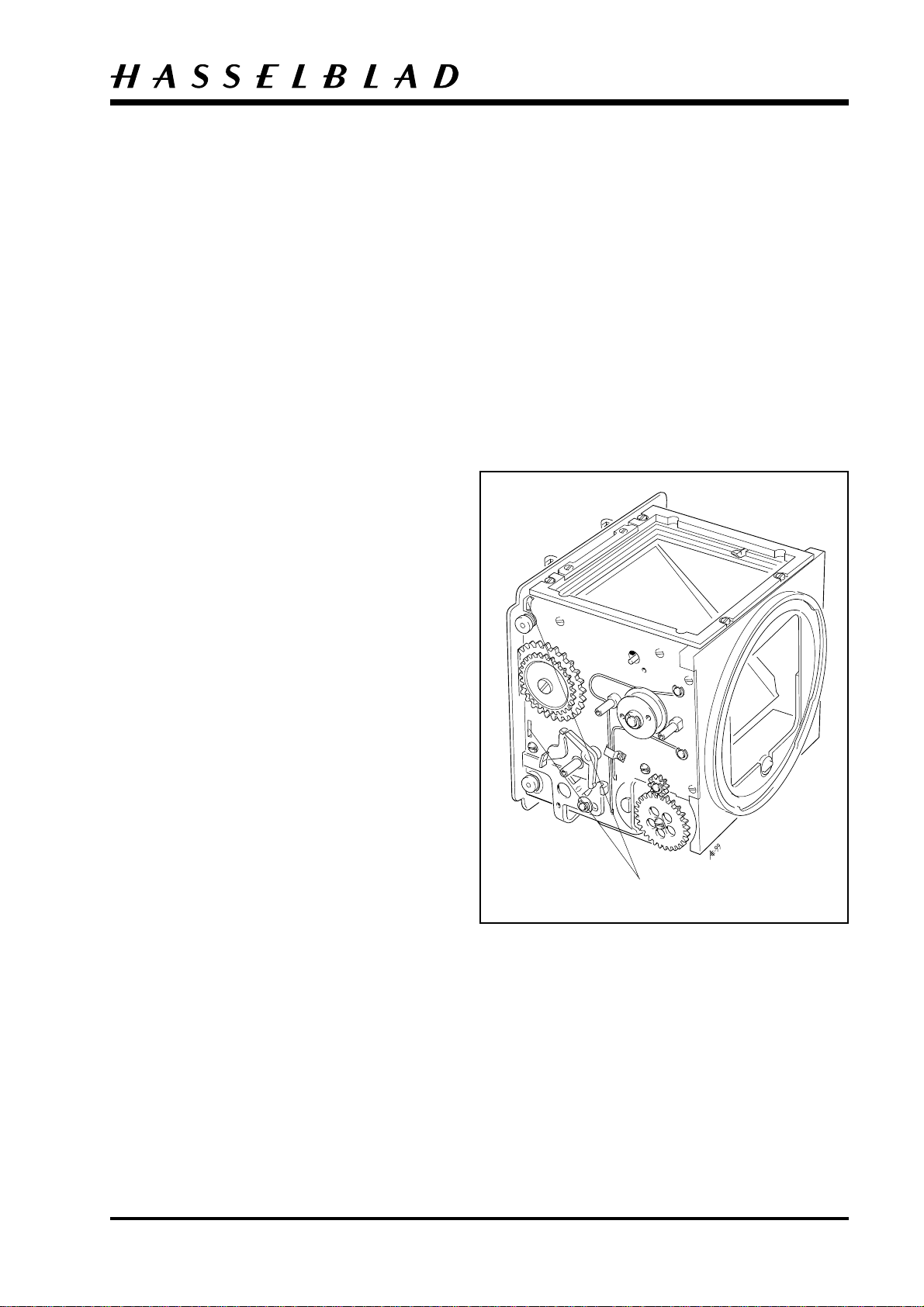

DIS04.EPS

990316

13604

DIS05.EPS

990406

821012

Fig. 3

22827

Brown

Red

Blue

13605

823049

824205

Fig. 4

13566

820041

Revision 0

820042

DIS06.EPS

990406

810613

820048

21290

Fig. 5

May 1999

3:3

Camera body 555ELD

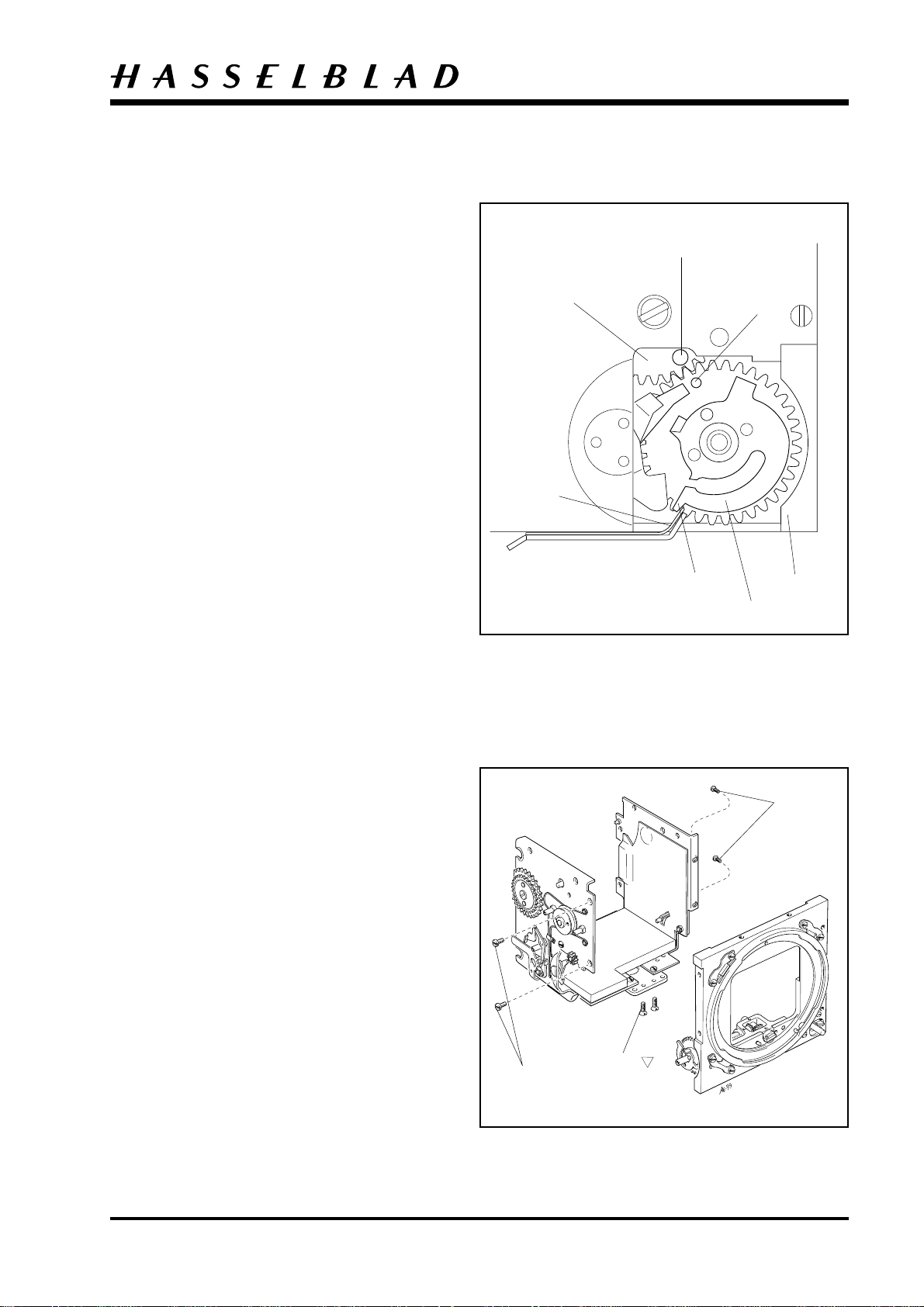

To remove the parts from the outer and inner

mounting plates proceed as follows (see the exploded

views 13 and 14):

Remove the small nut (828001), eccentric (22352)

and bearing pin (14100). Remove the screw (821033)

and washer (810532) and the micro switch (13605)

can be separated from the outer mounting plate.

Remove the link (22351), clip (817112) and stop arm

(13571). Disconnect the spring (814601), remove clip

(817115). Separate the magnet arm (13561) and the

clutch arm (14099) from the outer mounting plate.

Remove the two bearings (13528).

Remove the three plastic tubes (13606) from the

inner mounting plate. Remove the four screws

(821033) and disconnect the green, black, blue and

red wires from the connecting terminal (30435).

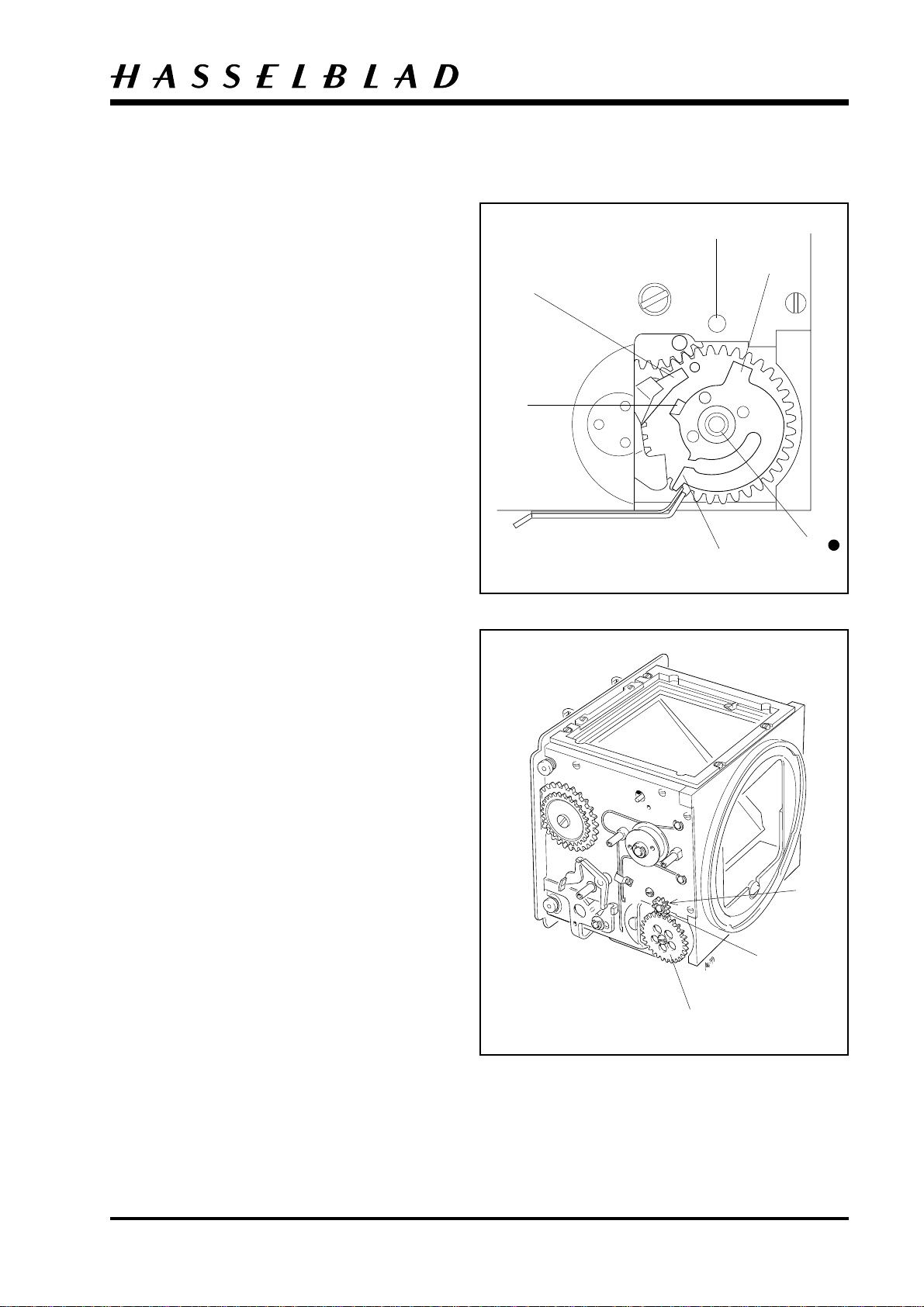

Fig. 6.

814601

14099

22351

13561

13528

817112

DIS08.EPS

990316

Disassembly

13605

13571

14100

30435

821033

810532

821033

22352

Remove the foam pad (22823). Unsolder the blue

wire from the sheet metal shield marked "+" of the

motor, the white wirer right opposite and the

capacitor (853549). The motor can now be separated

from the remainder of the motor unit.

Fig. 7.

Unloosen the screw (820020) and disconnect the blue

wire connected to the inner mounting plate (ground).

Lift carefully the PC board (22913) a bit and remove

the gears (13565, 13563 and 13564).

Unsolder the red wire from the contact spring

(22646) and separate the PC board from inner

mounting plate. Unsolder the solenoid (30421).

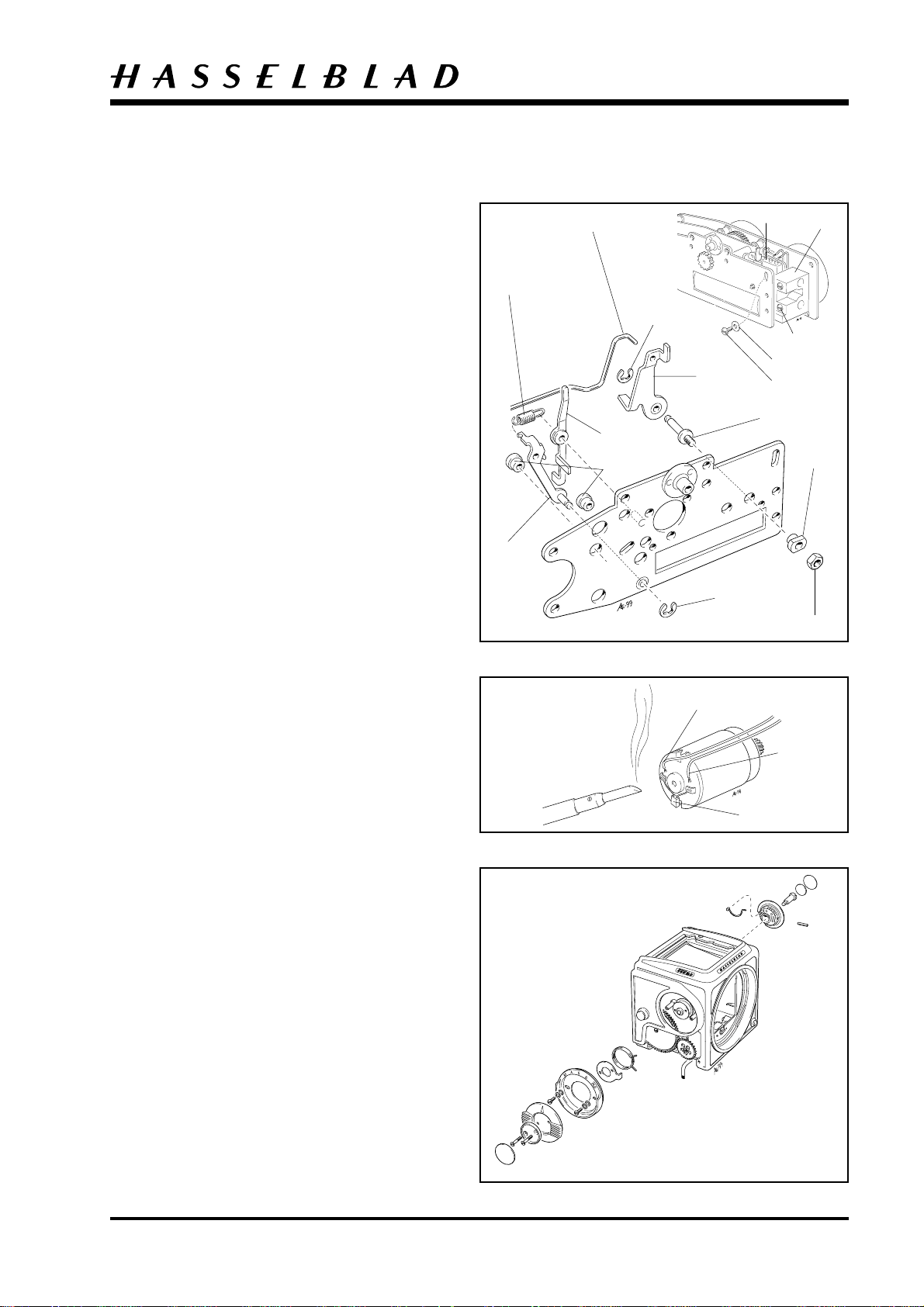

Camera shell

Remove the circular piece of leather (13374) from the

centre of the mode selector and then remove the two

screws (823023) beneath it. Withdraw the selector

knob (30429), thus exposing a further two screws.

Remove these two screws (820014) together with

their washers (810613) and (810607), and then

withdraw the symbol plate (30682), together with

the washer (13541) and spring (816906). Remove the

circular piece of leather (13374) on the ISO selector

(22495) and remove the set screw beneath it. When

withdrawing the selector care must be taken that the

spring loaded dog (22533) does not spring

free.

Fig. 8.

DIS20.EPS

990401

DIS07.EPS

990316

817115

828001

Fig. 6

Blue (+)

White (-)

853549

Fig. 7

Revision 0

DIS09.EPS

990316

Fig. 8

May 1999

3:4

DIS10.EPS

990505

DIS11.EPS

990316

Camera body 555ELD

Remove the two long screws (823781) located

towards the front of the camera shell. Remove the

two short screws (823755) located towards the rear of

the camera shell.

Remove the cap (22470) from the chassis connector

and peel back the leather (22455) covering the two

screws (823335). Remove these screws and push the

chassis connector into the body of the camera. The

shell can now be separated from the body.

Note: Care must be taken so that the flex (22915)

will not become damaged during the separation.

To accomplish this separation requires manipulation

of the shell and body in order that the gearing, on the

right hand wall of the camera shell, does not snag on

the camera shell. When the shell and body have been

separated the teflon button (103773) can also be

removed if required.

Fig. 9.

22915

823755

Disassembly

823335

823781

Fig. 9

Circuit board and contact flex

CAUTION! When handling the circuit board a

grounded bench mat and a wrist strap must be used to

prevent ESD damage.

Remove the screw (820019) and the washer (810407)

that secures the micro switch (852589). Loosen

carefully the cables (22931) from the chassis. Remove

the two screws (820011) from the grounding

attachment (22918). Remove the screw (820011) that

secure the cable holder (12453). Remove the two

screws (820325) that secure the photodiode and the

two screws (820015) that secure the PC board.

Loosen carefully the contact flex (22915) from the

bottom side of the chassis. The circuit board, also

secured by double-sided tape, can now carefully be

separated from the assembly.

Fig. 10.

820325

810407

820019

22931

Double-sided tape

820015

22918

820011

22915

Fig. 10

Revision 1

February 2000

3:5

Camera body 555ELD

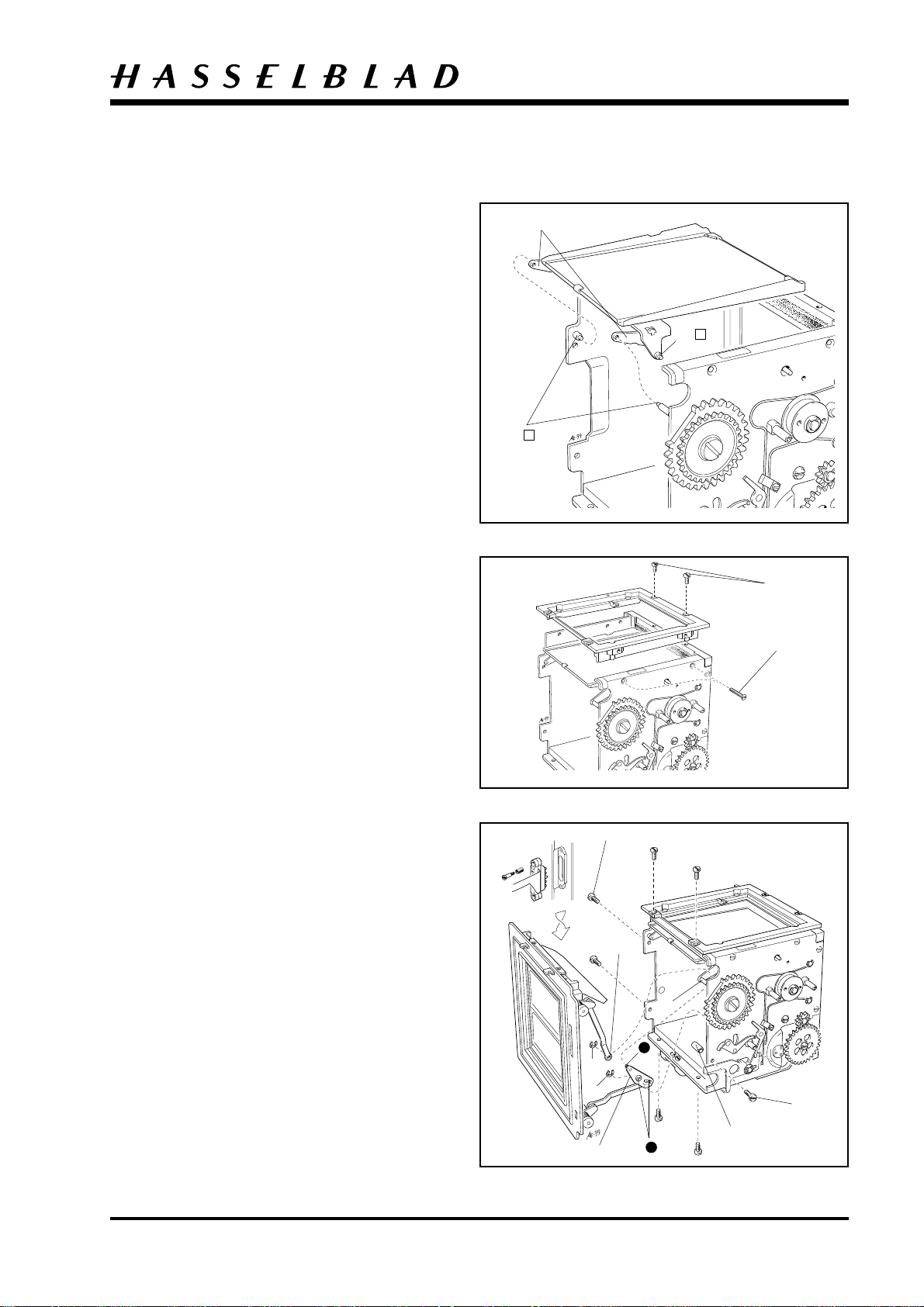

Rear plate

Remove the screw (821033) from the centre of the

large gear (13557) and lift the gear clear. With the

gear removed an additional screw is exposed which

must also be removed (820025). Remove the screws

(820013 and 820015) securing the rear plate to the

left hand wall, the two screws (820015) on the

underside and the screws (821017) on the upper side.

Release the camera.

Remove the clip "A" (817115) located in the centre of

the actuating part (13551). Tension the camera

somewhat by turning the gear (13556) clockwise and

pull out the rear plate approximately 10 mm. Remove

the clip "B" (817115) that secure the upper actuating

arm (13580) and disconnect it from the actuating

part. Lift the actuating part clear of its stud. Keeping

track of the spacer (13547), the rear plate can now be

separated completely from the remainder of the

assembly.

Remove the two screws (105412) and the two springs

(815511). The contact flex (22915) can now be

separated from the rear plate.

Fig. 11.

105412

22915

DIS13.EPS

990505

815511

820013

820015

"B"

"A"

13551

13580

820015

Disassembly

821017

13547

820025

13557

13556

821033

Fig. 11

Focusing screen frame

Remove the two long screws (823028) that secure the

frame to the side walls. Remove the screws (821017)

that secure the frame to the top of the camera body.

The frame (22980) can now be separated from the

remainder of the assembly.

Fig. 12.

DIS14.EPS

990316

821017

22980

823028

Fig. 12

Revision 0

May 1999

3:6

Camera body 555ELD

Mirror

Disconnect the mirror hinge (30754) from the two

pins "A" and release the pin "B" on the mirror frame,

from the mirror lever (22460). The complete mirror

(30716) can now be separated from the remainder of

the assembly.

Fig. 13.

Disassembly

"B"

"A"

DIS15.EPS

990316

Fig. 13

Front bayonet plate

Remove the two screws (820015) located at the rear

of the bayonet plate. Remove the two screws

(823655) that secure the bottom of the bayonet plate

to the main camera body. Remove the two screws

(823015) that secure the bayonet plate to right hand

wall of the camera body (i.e. the side upon which the

mode selector is mounted).

When separating the bayonet plate from the rest of

the camera body a firm grip should be maintained on

the gear (13556), thus ensuring that tension on the

spring behind it is not quickly relieved.

When the bayonet plate has been separated from the

rest of the camera body the gear should be gradually

released allowing the tension on the spring to be

gradually relieved. Remove gear (13556) and disc

(21324)) with screw (821033) from bayonet plate.

Fig. 14.

823015

DIS16.EPS

990505

821033

820015

823655

21324

13556

Fig. 14

Revision 0

May 1999

3:7

DIS18.EPS

990316

Camera body 555ELD

Right and left hand wall

Remove (or cut) the foam plastic pad (22513) to get

access to the screws (820014). remove the right hand

wall.

Fig. 15.

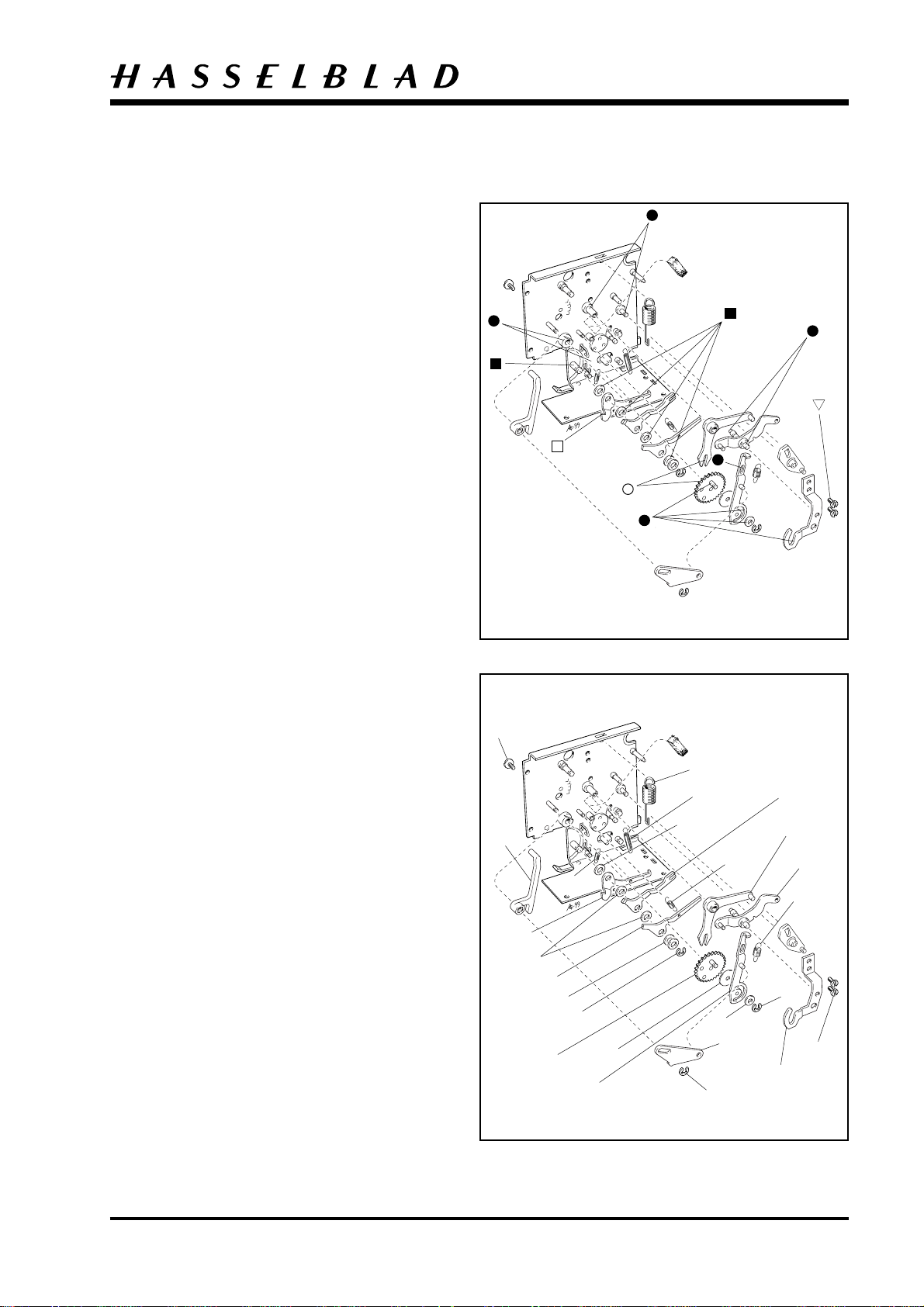

Mechanism plate

To dismantle the right and left hand wall proceed

using the following sequence:

Disassembly

22513

820014

Inner wall right

Remove the spring (814862). Remove the two screws

(820013) that secure the support (30701).

Remove the clip "A" (817115) and lift the plate

(22714).

Lift the arm (22896).

Remove the spring (814861), clip "B" (817115) and

washer (810532). Lift the mirror actuating arm

(22458) and the mirror lever (22460). Remove the

teflon washer (810761).

Remove the screw "C" (821033) that secures the gear

(22476) to the inside wall, then lift the gear clear.

Lift the auxiliary shutter arm (13554) clear.

Disconnect the springs "D", "E" and "F" (814302,

814706 and 814509).

Remove the clip (817123) and two washers (810702/

705). Lift the locking arm (21219) clear, together

with the washer (810702) underneath. Lift the S-arm

(22923) clear together with the washer (810702). Lift

the B-arm (21221) clear together with the washer

(810703).

Fig.16.

DIS17.EPS

990505

"C"

22896

21221

810702

21219

810702/705

22476

"D"

817123

22458

810761

814862

"E"

810703

810532

"A"

"F"

22714

Fig.15

22923

13554

22460

814861

"B"

820013

30701

Fig. 16

Revision 0

May 1999

3:8

Camera body 555ELD

Outer wall right

Remove the screw (821012) and lift the gear (13558)

clear, together with the washer (810854).

Remove the clip "A" (817119) from the inside wall.

The release arm (22922) can now be lifted clear of

the outside wall.

Remove the clip (817112) from the inside wall.

The release catch (13570) and the torsion spring

(816608) underneath can be lifted clear of the outside

wall. Remove the draw spring (814309) that connects

the release lever (30793) to the stop (22317).

Remove the clip "B" (817115) and washer (810538),

then lift the release lever clear. Remove the clip "C"

(817119) and lift the gear (13567) clear, together

with the dog (13525).

Remove the clip (817123), the washer (810702/705)

and the selector (13559). Remove the screw

(820011) and cable holder (12453).

Remove the two clips "D" (817115), then remove the

S-wire (21223) and the A-wire (21224).

Fig. 17.

821012

810702/705

817123

22922

13570

816608

DIS19.EPS

990316

13558

"B"

13559

810538

"C"

820011

30793

13567

810854

814309

Disassembly

"D"

21223

"A"

817112

"D"

22317

12453

21224

13525

Fig. 17

The dismantling procedure for the Hasselblad

555ELD is now completed.

Revision 0

May 1999

4:1

Camera body 555ELD

Lubricate the camera as detailed in the appropriate

lubrication chart. Use the lubricants listed below:

= Isoflex Topas L32

= Mollykote - X

= Isoflex PDP-48

= Gleitmo 805-K

= Loctite, e.g. Loctite 243

= Safety lacquer

Mechanism plate

To reassembly the right and left hand walls

proceed using the following sequence:

Outer wall right

DIS19.EPS

990316

Reassembly

Fig. 18

Lubricate according to Fig. 18.

Locate the A-wire (21224) and the S-wire (21223)

and secure them into place with the two clips "D"

(817115).

Fit the cable holder (12453) over the A and Swires and fit the screw (820011). Fit the selector

(13559) and secure it into position with the

washer (810702/705) and the clip (817123).

Fit the release lever (30793) and secure it into

position with the clip "B" (817115) and washer

(810538). Refit the draw spring (814309) securing

both ends of the spring.

Fit the torsion spring (816608) and the release

catch (13570) and secure them into position using

clip (817112). Note: This clip is fitted on the

inside wall.

Fit the release arm (22922) and secure it with the

clip (817119) which clips on from the inside wall.

Fit the gear (13558) and washer (810854) and then

fit the screw (821012).

Fig. 19.

821012

810702/705

817123

22922

13570

816608

DIS19.EPS

990316

"B"

13558

13559

810538

820011

814309

30793

810854

"D"

21223

817119

817112

"D"

12453

21224

Fig. 19

Revision 0

May 1999

DIS18.EPS

990316

4:2

DIS18.EPS

990316

Camera body 555ELD

Outer wall right

Lubricate according to Fig. 20.

Fit the washer (810703) followed by the B-arm

(21221), then fit the washer (810702) followed by

the S-arm (22923).

Fit the washer (810702) followed by the locking arm

(21219) and the two washers (810702/705) and

secure them into place with the clip (817123).

Fit the auxiliary shutter arm (13554).

Reassembly

Fit the gear (22476) and secure it into position with

the screw "C" (821031) from the outside wall.

Check the function.

Fit the mirror lever (22460).

Fit the teflon washer (810761) on the top of gear

(22476).

Fit the mirror actuating arm (22458) followed by the

washer (810532) and secure with the clip "B"

(817115).

Fit the arm (22896) and the plate (22714). Secure

them into position with the clip "A" (817115).

Check for easy of operation.

Fit the support (30701) and secure it in position

with the two screws (820013).

Fit the spring (814862).

Fit the spring (814861).

Fit the spring "F" (814509).

Fit the spring "E"(814706).

Fit the spring "D" (814302) Note: Secure the spring

with safety lacquer.

Fig. 21.

"C"

22896

21221

810702

21219

810702/705

22476

"D"

817123

22458

810761

814862

"E"

810703

810532

"A"

"F"

22714

Fig. 20

22923

13554

22460

814861

"B"

820013

30701

Revision 0

Fig. 21

May 1999

4:3

Camera body 555ELD

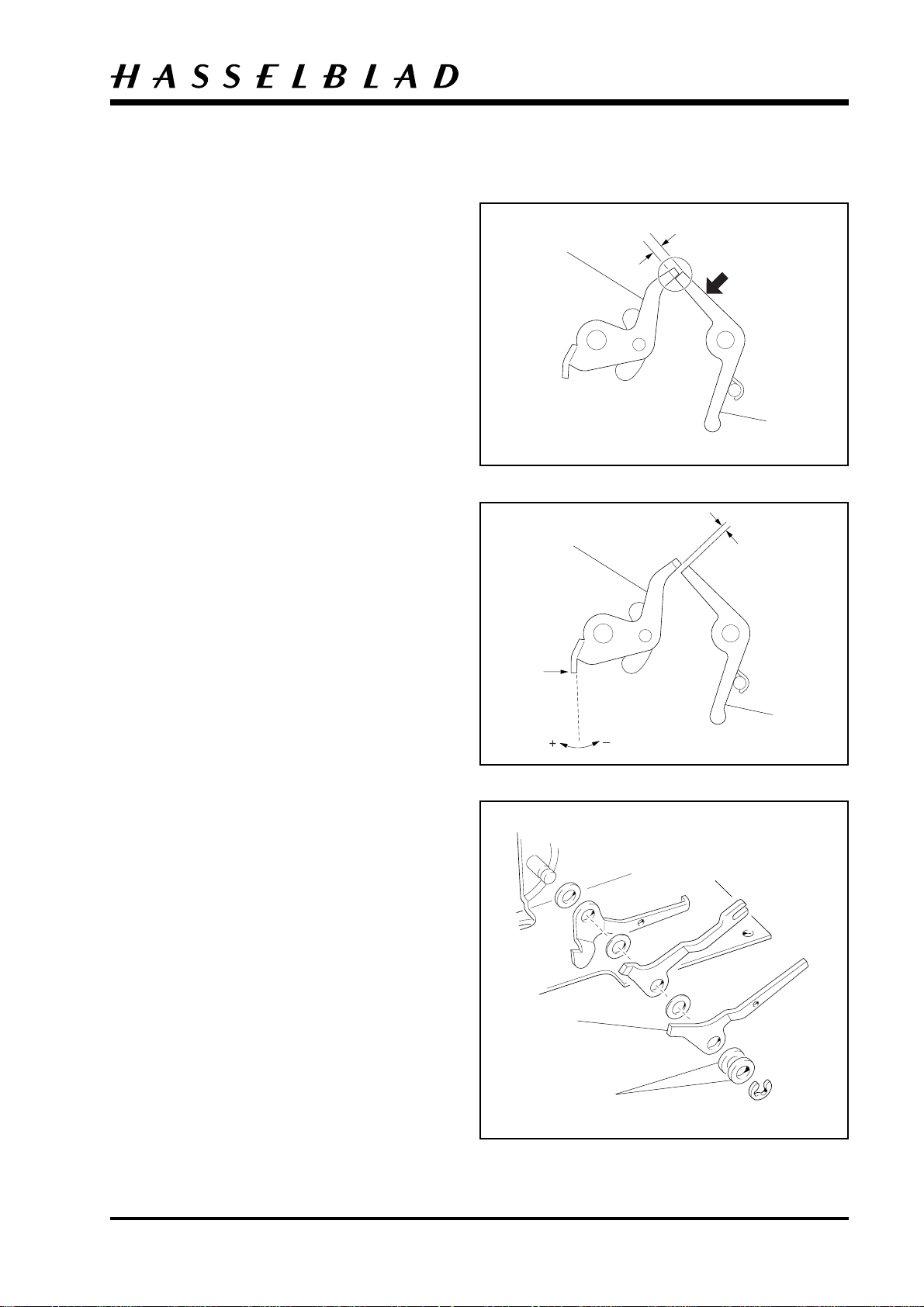

Release catch/arm adjustment

Check and if necessary bend the release catch (13570)

at the arrow so that it is engaged by approximately

1mm.

Fig. 22.

Refit the gearwheel (13557) temporarily. Rotate the

gear anticlockwise and check that the overtravel on

the release arm (22922) is approximately 1mm with

respect to the release catch (13570).

22922

REA02.EPS

990316

22922

Reassembly

13570

Fig. 22

If adjustment is required, bend the angle on the

release arm (22922) see arrow.

Fig. 23.

Locking arm adjustment

Check that the arms move easily without axial play.

If there is play on the locking arm (21219) then fit a

further washer (810702/705) in addition to the two

already fitted. If the arms are sluggish then try a

thinner washer.

Fig. 24.

REA03.EPS

990316

21219

13570

Fig. 23

Revision 0

810702/705

REA04.EPS

990316

Fig. 24

May 1999

4:4

Camera body 555ELD

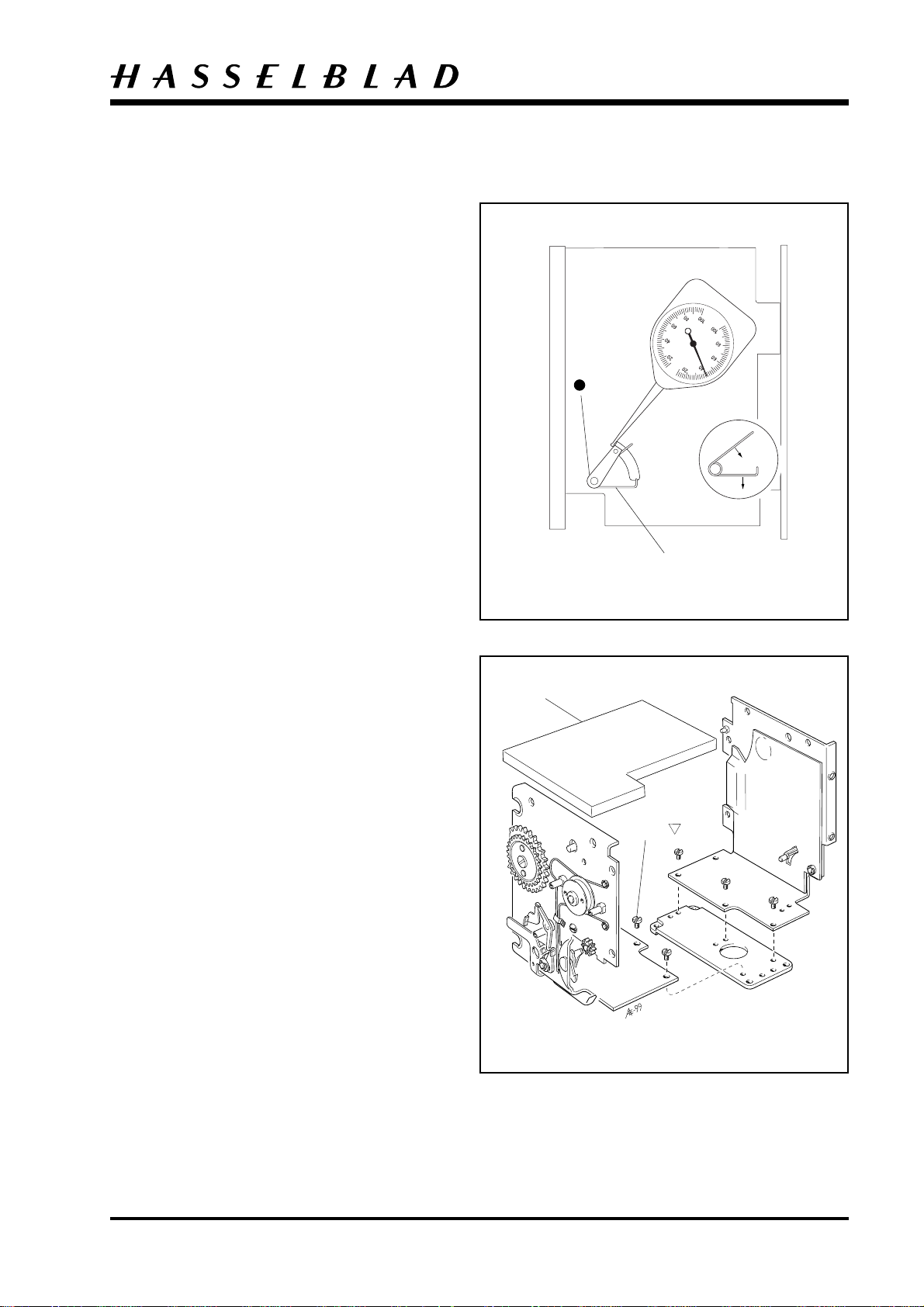

Left hand wall

Check the tension of the spring (816864). This should

be between 40 and 60 grams.

Adjust by bending the spring (816864) as indicated in

Fig. 25.

REA05.EPS

990505

Reassembly

816864

Fit the left and right hand walls together and secure

with the screws (820014). Fit the foam plastic pad

(22513).

Fig. 26.

Fig. 25

22513

820014

Revision 0

DIS17.EPS

990505

Fig. 26

May 1999

DIS16.EPS

990505

4:5

Camera body 555ELD

Front bayonet plate

Before fitting the bayonet plate (30706-1) make sure

the camera is released. This is done by turning gear

(22476). Note that the pin "A" should be visible from

the outside.

Fig. 27.

Fitting the front bayonet plate to the camera body:

Tension the drive spring by turning the front gear

wheel (30413) clockwise 3 turns.

Fit in the lower part of the bayonet plate so that the

check "C" on the front gear cam plate is stopped by

the spring (22317). Ensure that the two indexes "A"

and "B" are aligned opposite each other and that the

upper part of the bayonet plate is put into position.

Fig. 27.

22476

22317

Reassembly

"A"

"B"

Secure the bayonet plate to the right hand wall using

two screws (823015). Secure the bayonet plate to the

REA06.EPS

990316

bottom of the main camera body using two screws

(823655). Refit the two screws (820015) to the rear

of the bayonet plate.

Fig. 28.

"C"

30706-1

30413

Fig. 27

820015

Revision 0

823015

823655

Fig. 28

May 1999

4:6

Camera body 555ELD

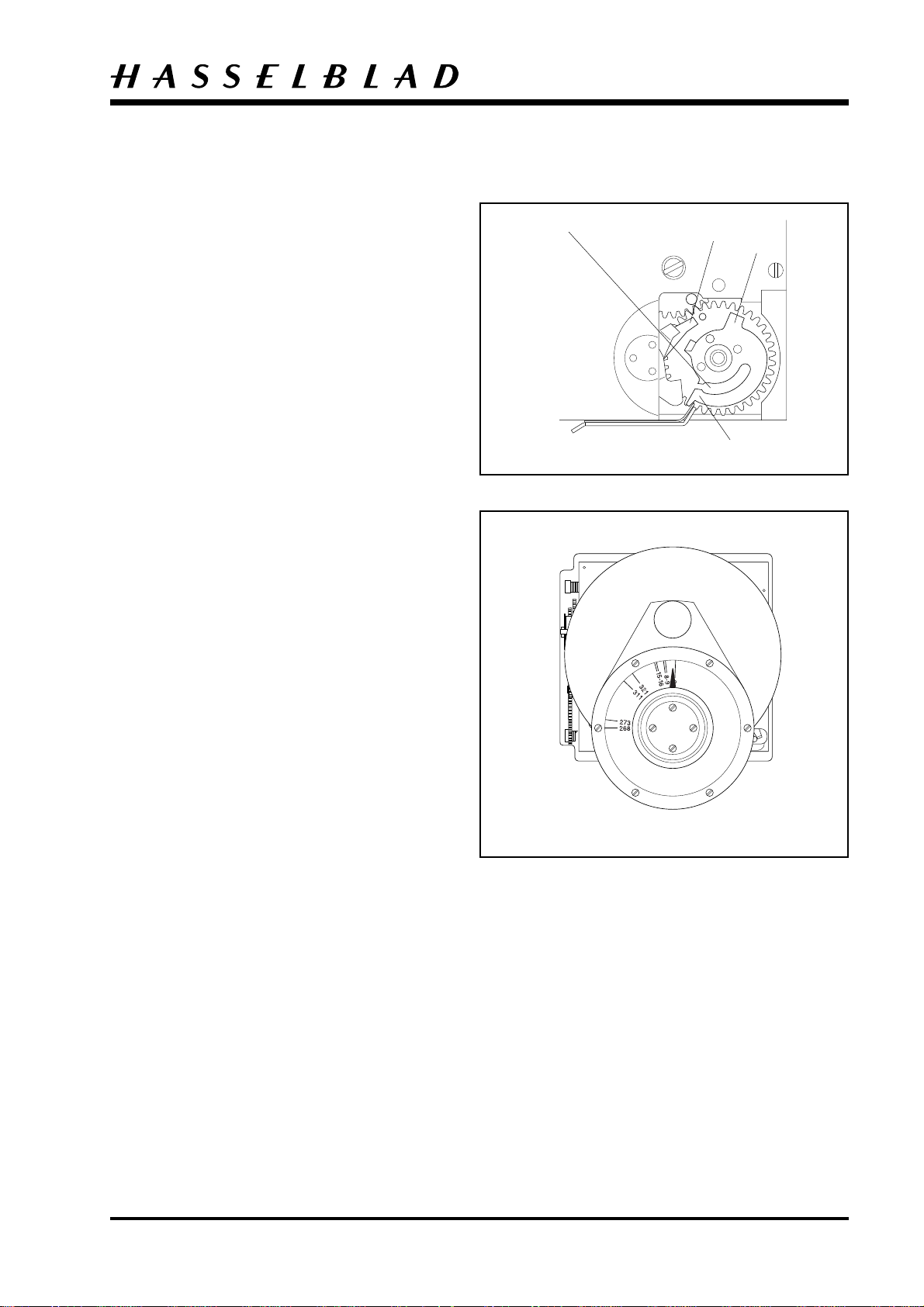

The key position of the front gear is checked with the

camera cocked. This is carried out as follows:

Fit the blade of a screwdriver in the slot on the front

gear wheel (30413). Turn the gear in a clockwise

direction until the check "C" has passed the locking

arm (21219). In this position it is now possible to

cock the release arm (22922) against the release catch

(13570). Continue the cocking action until the

locking arm (21219) operates and is blocked against

the check "D".

Fig. 29.

Mount the key inspection tool 902658 (V-2075) to

the camera's front bayonet plate. Ensure the indicator

is pointing upwards when the camera is cocked.

Fig. 30.

With the tool 902658 (V-2075) fitted to the front of

the camera, the key position should have a minimum

of 3º with a load of 1400 gram-centimetres and a

maximum of 9º with 300 gram-centimetres. Remove

the tool.

Fig. 30.

Position for screw driver

REA06.EPS

990316

Reassembly

21219

"D"

"C"

Fig. 29

1. If the measured value is less than 3º, replace the

ordinary locking arm (21219-2) by a locking arm

which is 0.2 mm longer. This arm is designated

(21219-1).

2. If the measured value is more than 9º, replace the

ordinary locking arm (21219-2) by a locking arm

which is 0.2 mm shorter. This arm is designated

(21219-3).

3. If the above-mentioned adjustment is insufficient,

a new front gear (30413) must be fitted on the

bayonet plate.

REA07.EPS

990316

Fig. 30

Revision 0

May 1999

4:7

Camera body 555ELD

Mirror

Lubricate according to Fig. 31.

Make sure the camera is released. Locate the mirror

(30716) into position. Connect the mirror hinge

(30754) to the two pins "A".

Relocate the pin "B" on the mirror frame to the

mirror lever (22460).

Fig. 31.

Test the function of the mirror by fitting the blade of

a screwdriver in the slot on the front gear wheel and

cock the camera. Release by moving the release catch

(13570) to the rear.

Fig. 29

Focusing screen frame

30754

"A"

DIS15.EPS

990316

Reassembly

"B"

Fig. 31

Refit the focusing screen frame and secure it as

follows:

Refit the two long screws (823028) to the right hand

side wall and two short screws (821017) to the top of

the frame.

Fig. 32.

Rear plate

Fit the springs (815511) to the screws (105412).

Fit the contact flex (22915) to the rear plate and

secure it into position with the above mentioned

screws.

Lubricate according to Fig. 33.

Release the camera. Fit in the actuating part (13551)

and secure it in the position with the clip "C"

(817115).

Locate the upper actuating part (13580) around the

pin "D" and fasten it to actuating part (13551).

Secure it in position with the clip "E" (817115).

DIS14.EPS

990316

821017

823028

Fig. 32

820013 (short)

13580

"D"

Locate the spacer (13547). Note: Turn the front gear

(30413) somewhat in a clockwise direction.

Locate the rear plate into position and secure it with

seven screws, note the long screw (820025) is fitted

on the right hand wall and the short one (820013) at

the top of the left hand wall.

Fig. 33.

Revision 0

REA21.EPS

990505

"E"

"C"

13551

820025

13547

Fig. 33

May 1999

4:8

Camera body 555ELD

Seal between the rear plate and the left side wall

using black silicone or similar as shown in Fig. 34

to ensure a tight light seal.

Preliminary adjustment of the focal length

REA09.EPS

990316

Reassembly

Seal here

Fig. 34

71.40 ± 0.03 mm

Mount the front plate "A" in the front of the camera

body and place the camera with the rear section in

control tool V-2229.

Check that the rear section is flat.

If the rear section is warped, the first procedure is to

ensure that both the inner walls of the camera are in

good contact with the inside of the rear section. This

is carried out by knocking carefully on the front plate

with a plastic-faced hammer.

If this operation is insufficient, it is possible to adjust

the warp at the corners which may be too low.

Loosen the two nearest screws and push the rear

section backwards until it is flat. Then tighten the

screws.

Place the camera body in control tool V-2229

without tensioning it. Set the ruler with the indicator

clock to zero by placing it on surface "B".

Fig. 35.

"A"

"B"

REA14.EPS

990316

Fig. 35

Revision 0

May 1999

4:9

Camera body 555ELD

Place the ruler with indicator clock onto the gauge

and move the indicator around the periphery on the

front plate and check that the length is within the

tolerance.

If the camera body is too short, on the left-hand side,

then the front must be moved forward on this side.

This is carried out by knocking on the angle on the

left wall which provides the support for the bayonet

plate. A solid fibre rod and a suitable hammer are

used for this operation.

Re-check as described above.

If the camera is too short on the right hand side, it

must extended. This is carried out by moving the rear

section to the rear. Loosen the screw (820025) on the

right wall (30748), the screw (820015) on the bottom

of the camera and the screw (820017) on top of the

camera. Insert the blade of the screwdriver first in one

and then in the other of the two rectangular recesses

in the rear edge of the right wall close to the rear

section and turn carefully. Then tighten the screws

and check on control tool V-2229 that the rear

section has not become distorted during adjustment.

Fig. 36.

Reassembly

Check the length measurement above.

If the total length measurement of the camera body is

too long, adjust the bayonet front plate downwards

by knocking on the front plate "A" at the points

where necessary.

Re-tighten all screws retaining the rear section, the

front plate and the frame.

Note! The focal length is checked once more when

the camera is fully reassembled.

REA20A.EPS

990505

Adjust here

Fig. 36

Revision 0

May 1999

REA20.EPS

990505

REA06.EPS

990316

4:10

Camera body 555ELD

Dog (13525), gear (13567) and gear

(13556)

Cock the camera as follows:

Fit the blade of a screwdriver in the curved slot on

the front gear (30413). Turn the gear in a clockwise

direction until the check "C" has passed the locking

arm (21219). In this position it is now possible to

cock the release arm (22922) against the release catch

(13570). Continue the cocking action until the

locking arm (21219) operates and stops against the

check "D".

Fig. 37.

Lubricate the front gear journal "F". Locate the dog

(13525) onto the pin "E" with the bent lug upwards.

Place the disk (21324) with the large flange

downwards on the front gear journal. The recess in

the disk fits against the pin on the front gear cam

disk.

Check that both catches on the gear (13556) move

easily and that the spring-loaded setting hook returns

under the influence of its own spring. If the

movement of the catches should be doubtful, this can

possibly be adjusted by carefully bending the ring

which is riveted on.

Reassembly

"E"

"D"

21219

"G"

"F"

"C"

Fig. 37

The gear (13556) is fitted so that the point of the

hook which is not spring-loaded comes into contact

with the recess in the disk (21324). Turn the gear in a

clockwise direction until the spring-loaded setting

hook stops against the check "G" as shown in Fig. 37.

The dog (13525) is backed off in an anti-clockwise

direction so that the bent lug rests against the

periphery of the spring-loaded setting hook in gear

(13556).

Fit gear (13567) with the pin pointing downwards

from "E".

Fig. 37.

Note that the gear (13556) and the dog (13525) must

be retained in the positions previously described. This

facilitates adjustment. Ensure that the pin on gear

(13567) is placed in the hole on the dog (13525) in a

12 o'clock position.

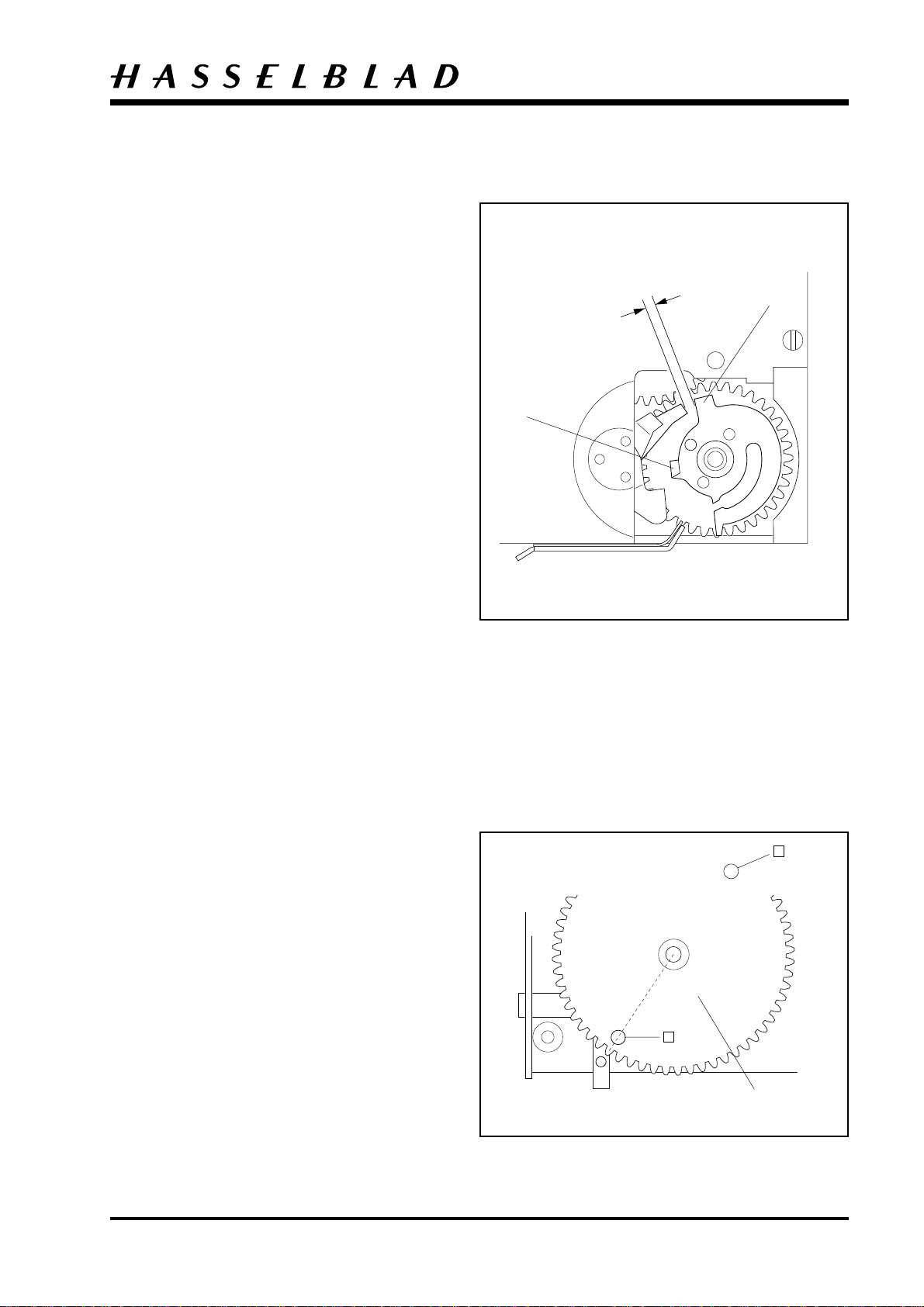

Fig. 38.

13525

13567

13556

Fig. 38

Revision 0

May 1999

4:11

Camera body 555ELD

When the gear (13556) is turned in a clockwise

direction the dog (13525) should release the setting

hook from the check "G".

Fig. 39.

Adjustment: Disengagement should occur when the

check "D" has passed the locking arm (21219) and

moved a further 1 - 2 mm. (this is a safety margin to

ensure that the lens is fully cocked).

Fig. 39.

If a further movement is needed, then the

relationship between the dog (13525) and the gear

(13567) must be altered.

Adjustment: If smaller movement is required, lift the

gear (13567) out of engagement with gear (13556).

Turn gear (13567) one (1) tooth segment in an anticlockwise direction. Re-check as specified above.

Reassembly

1 - 2mm

"D"

"G"

Adjustment: In the case of excessively large further

movement, carry out the same operation in the

reverse direction.

Tighten gear (13556) with screw (821033) and secure

gear (13567) with clip (817119).

Note that the front gear (30413) must be held when

the screw for gear (13556) is tightened. This can be

done in a convenient way by inserting the blade of a

screwdriver on the underside of the camera between

the spring stop (22317) and the fixed gear on the

front gear.

Gear (13557)

The initial position for fitting gear (13557) is as

follows. The dog (13525) has just operated the springloaded setting hook on gear (13556) and further

movement has been checked as described previously.

Gear (13556) is backed in an anti-clockwise direction

until the spring-loaded setting hook stops against the

upper point "G" on the front cam disk.

Fig. 39.

REA10.EPS

990316

Fig. 39

The straight side of gear (13558) is placed parallel

with the rear section of the camera. Lubricate and fit

the gear wheel (13557) on its pin. The position of

both the pins on the underside of the gear is shown in

Fig. 40.

Tighten gear (13557) with one screw (821033).

Revision 0

REA11.EPS

990316

13557

Fig. 40

May 1999

Loading...

Loading...