Page 1

HARTING

04 2E

Solutions for Industrial Ethernet

Page 2

HARTING was founded in 1945 by

the family that still owns the company.

Today, HARTING employs around

2,300 people worldwide, including

150 qualified engineers. The sales

team, including more than 100 sales

engineers is in daily contact with our

customers.

The company is one of the world’s

leading manufacturers of connectors,

and currently have 33 subsidiary

companies in Europe, the United States

and Asia. In several product ares,

HARTING is a market leader.

Great emphasis is placed on close links

with customers, including the provision

of a ‘Just-in-Time’-Service to ensure

rapid delivery to key customers.

HARTING products are designed and

manufactured using the latest

automated techniques, from CAD

systems in the research and

development department to automatic

production techniques on the assembly

lines.

Production and quality control is based

on a ‘zero-error’ philosophy which can

only be reached by the continuous

successful implementation of fully

automated production techniques.

The organisation and procedures for

quality assurance are based on the

EN ISO 9001 standard. A total of

60 engineers and other employees,

most of whom are trained and qualified

to standards laid down by the DGQ

(German Association of Quality) or the

SAQ (Swiss Association of Quality), are

employed solely on quality-assurance

activities.

Quality Connections

Worldwide

People | Power | Partnership

Page 3

00

.

01

Chapter

Directory

Solutions for Industrial Ethernet

Industrial Ethernet – General information 00

Connectors 02

Active and passive

network components

01

System cables 03

List of part numbers 10

Company addresses 20

Page 4

00

.

02

Solutions for Industrial Ethernet

General information

It is the user's responsibility to check

whether the components illustrated in

this catalogue comply with different

regulations from those stated in special

fields of application which we are unable

to foresee.

We reserve the right to modify designs

in order to improve quality, keep pace

with technological advancement or meet

particular requirements in production.

This catalogue must not be used in any

form or manner without our prior

approval in writing (Copyright Law,

Fair Trading Law, Civil Code).

We are bound by the German version

only.

General

information

Page 5

00

.

03

What is Ethernet?

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00.04

Ethernet principles

Classic Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00.04

Ethernet transmission media in common use . . . . . . . . . . . . . . . . . . . . . . 00.04

Fast Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00.05

Switched Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00.05

The Industrial Ethernet network

General requirements for Industrial Ethernet networks . . . . . . . . . . . . . . . 00.08

PROFInet

®

transmission system and wiring . . . . . . . . . . . . . . . . . . . . . . . 00.09

Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00.12

Industrial Ethernet – General information

Page

Directory chapter 00

General

information

Page 6

00

.

04

Industrial Ethernet – General information

What is Ethernet?

Ethernet is a well established specification for serial

data transmission, originally published by Xerox in

1975. In 1985 Ethernet was standardised in IEEE

802.3, since when it has been extended a number of

times. "Classic" Ethernet operates at a data transmission rate of 10 Mbit/s.

Since the 1990s, Ethernet has developed in the

following areas:

– Transmission media

– Data transmission rates

l

Fast Ethernet at 100 Mbit/s (1995)

l

Gigabit Ethernet at 1 Gbit/s (1999)

l

There are plans for Ethernet running at 10 gigabits

– Networked topologies

l

Switched Ethernet

– Industrial Ethernet

Nowadays Ethernet is the most widespread base

technology in the world in commercial DP systems,

and is also gaining importance in industrial automation. The use of Ethernet creates a homogenous

and standardised communication infrastructure,

extending seamlessly from the office environment to

the machine.

Classic Ethernet (Shared Ethernet)

All network users have the same rights under Ethernet.

Any user can exchange data of any size with another

user at any time.

Because Ethernet was conceived as a logical bus system, any network device that is transmitting is heard by

all other users. Each Ethernet user filters the data

packets that are intended for it out from the stream, ignoring all the others.Telegrams that are intended for all

devices are an exception to this rule.These are known

as broadcast or multicast telegrams.

The CSMA/CD network access procedure

In Classic Ethernet, also frequently called shared

Ethernet, all the network users share one collision

domain. In Ethernet, network access is controlled by

the CSMA/CD procedure (Carrier Sense Multiple

Access with Collision Detection).

If a network user wishes to transmit data, it first checks

whether the network is free (carrier sense). If so, it

starts to transmit data. At the same time it checks

whether other users have also begun to transmit

(collision detection). If that is the case, a collision

occurs. All the network users concerned now stop their

transmission, wait for a period of time determined

according to a randomising principle, and then start

transmission again.

The result of this is that the time required to transmit

data packets depends heavily on the network loading,

and cannot be determined in advance. The more

collisions occur, the "slower" the entire network

becomes. Shared Ethernet therefore only has limited

suitability for industrial automation.

The physical size of the network is also limited. It

depends on the data rate being used and on the

maximum permissible transmission time of data

packets.

Approaches to improved performance

A number of approaches have been tried to improve

performance:

Segmentation: -> subdividing the collision domains

Higher

bandwidths: -> Fast Ethernet, Gigabit Ethernet

Switching: -> Switched Ethernet

and combinations of these.

Only with the implementation of these approaches

does Ethernet become interesting and useful for

industrial automation. For this reason, only Switched

Ethernet and Fast Ethernet will be considered further

in the following chapters.

Ethernet installations are primarily characterised by

two parameters: the Category of the cable (Category)

and the Class of the channel (Class).

General

information

Ethernet transmission media in common use

Description Meaning Distance

10 Mbit/s system

10 Base T [FD] 2 conductor pairs, min. Category 3, UTP and STP >100 m

10 Base FX [FD] Fibre-optic cable Depends on fibre type

100 Mbit/s system (Fast Ethernet)

100 Base TX [FD] 2 conductor pairs, Category 5, UTP and STP 100 m

100 Base FX [FD] Fibre-optic cable Depends on fibre type

[FD] = Full-duplex operation possible

Page 7

00

.

05

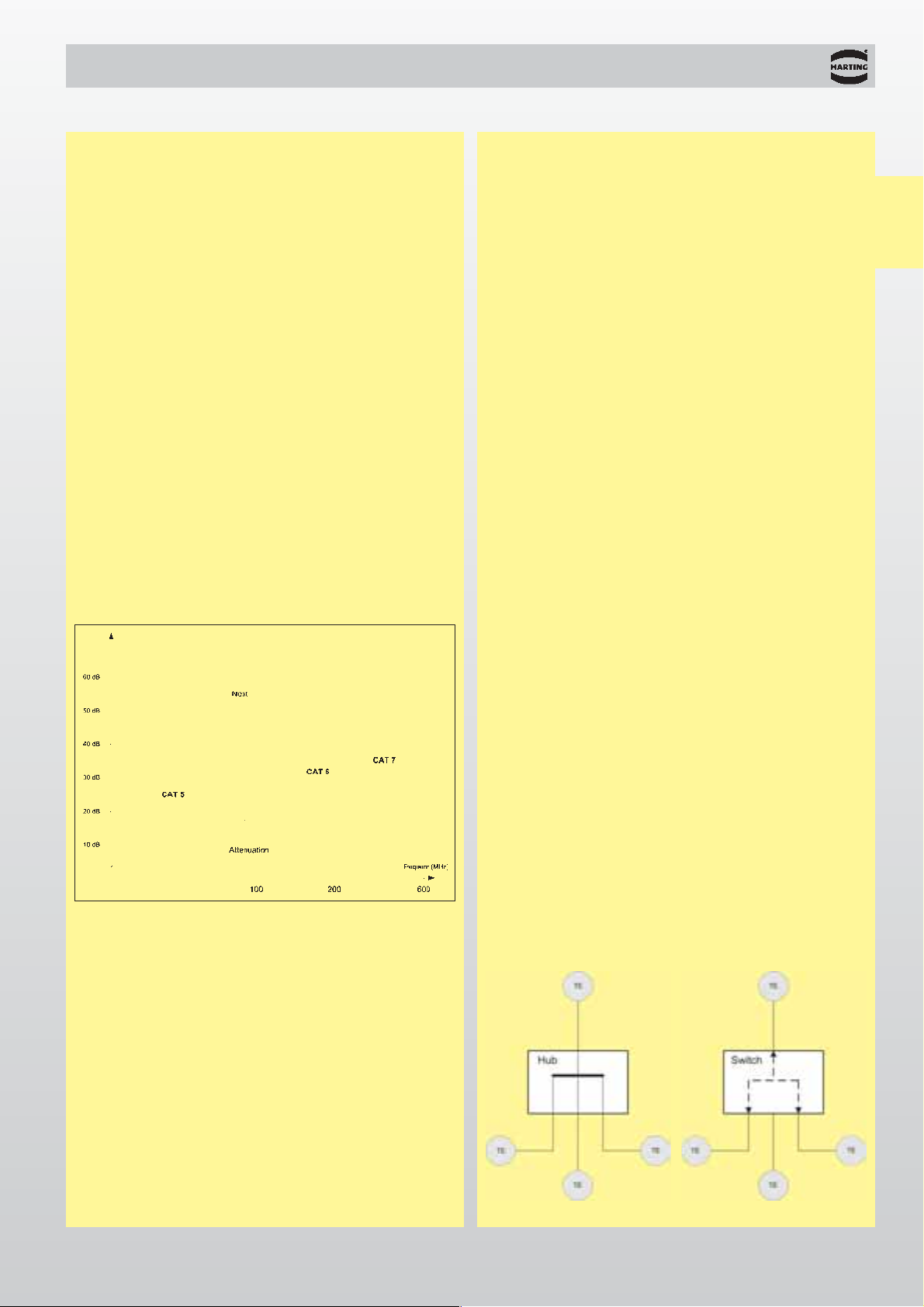

Next = Near end crosstalk

Industrial Ethernet – General information

The cable is identified by its Category in accordance

with its electrical transmission and high-frequency

properties, as follows:

Category 1: not specified

Category 2: up to 1 MHz

Category 3: up to 16 MHz

Category 4: up to 20 MHz

Category 5: up to 100 MHz

Category 6: up to 250 MHz

Category 7: up to 600 MHz

The channel is the point-to-point part of the transmission process, and is specified as follows:

Class A: up to 100 kHz

Class B: up to 1 MHz

Class C: up to 16 MHz

Class D: up to 100 MHz

Class E: up to 250 MHz

Class F: up to 600 MHz

The higher the alphabetical sequence of the letter, the

tougher are the requirements on the transmission

channel, and therefore also on the cable. If, for

instance, only Category 5 components are used in a

system, the capacity of a Class D cable is required.

The same applies to Category 6 and Class E, as to

Category 7 and Class F.

General

information

TE = Terminal Equipment

Switched Ethernet

Definition

Switched Ethernet refers to a network in which each

Ethernet user is assigned a port in a switch.

Switches separate former collision domains into

individual point-to-point connections between the

network components and the relevant user equipment.

Preventing collisions makes the full network bandwidth

available to each point-to-point connection. The second

pair of conductors in the Ethernet cable, which otherwise is necessary for the detection of collisions, can

now be used as an additional transmission medium, so

providing a significant increase in data transfer rate.

The use of switches allows any desired network

configuration, such as star, ring, tree or linear, to be

implemented.

Switched Ethernet offers the following important

advantages:

l

The possibility of scaling the collision regions to

match the needs of the application, going as far as

fully collision-free networks in which only one user is

assigned to each port

l

Very fast packet transfer between the collision

regions

l

A considerable increase in data transfer rate through

"true" full duplex operation

l

Preventing collisions allows deterministic operation

Network size

There is no theoretical limit to the physical extent of a

Switched Ethernet network. The maximum length of

conductor between the ends of a point-to-point

connection is only determined by the physical

transmission properties and is, according to the

specification, 100 m. In practice, the connectors and

cables used have a decisive effect on the transmission

length that can actually be achieved.

Fast Ethernet

Fast Ethernet, according to IEEE 802.3, is not a new

standard, but an extension of Classic Ethernet to

include the following new properties:

l

A data rate of 100 Mbit/s

l

Switching

l

Full duplex operation

These form the basis of industrially useful Ethernet

networks. Autonegotiation provides compatibility with

Classic Ethernet in accordance with IEEE 802.3.

Page 8

00

.

06

Industrial Ethernet – General information

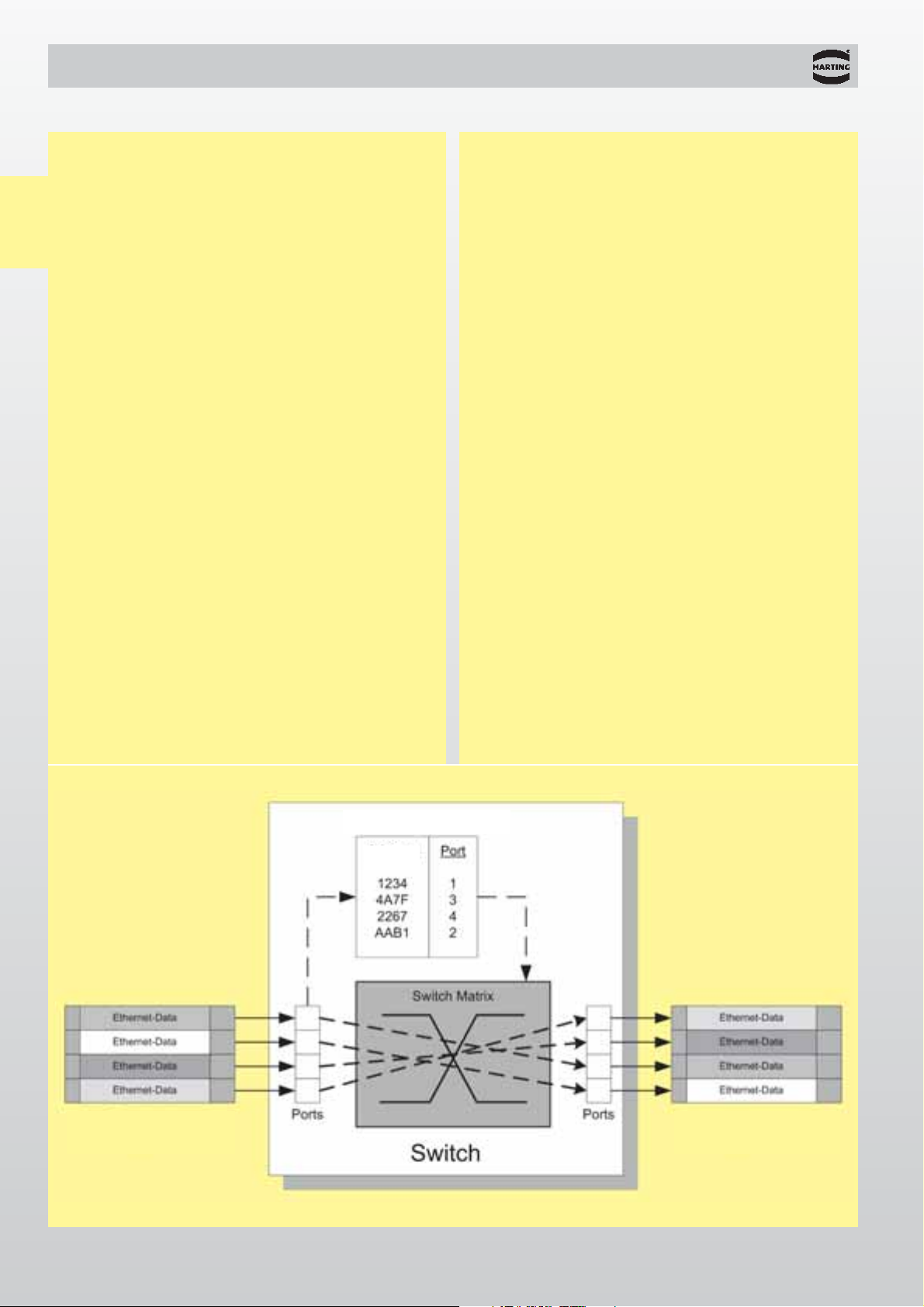

The switch – the central network

component in Switched Ethernet

Switches are active infrastructure components that

operate according to IEEE 801.3 on layer 2 of the OSI

reference model. Switches analyse all the data

packets as they arrive, directing them on to the port

where the corresponding user is located. Only multicast and broadcast telegrams are an exception to

this. They are passed on to all the active ports and

switches.

Each switch requires an address/port assignment

table in order to correctly redirect the telegrams. The

assignment of a destination address to a specific port

in the switch is stored in this table. The destination

address of an incoming data packet is analysed with

the aid of this table, and the data packet is passed on

immediately to the corresponding port. The

address/port assignment table is usually generated

and maintained automatically by the switch in a selflearning process. One switch can learn several

thousand addresses. This is necessary when more

than one item of user equipment is connected to one

or more ports. This allows a number of independent

subnets to be connected to one switch.

In this way, each of the ports in a switch generates its

own collision region. This prevents data collision with

users attached through other ports. In Switched

Ethernet, only one user is assigned to any port. In this

way collisions are avoided altogether. Guaranteed

freedom from collisions provides a significant

increase in the effective data transfer rate. Additional-

ly, full duplex operation is now possible, since one pair

of conductors in the Ethernet cable, otherwise

required to detect collisions, can be used as an

additional data transfer medium. With Fast Ethernet

operating in full duplex mode (100 Base TX), 100

Mbit/s can be transferred simultaneously in the two

directions.This corresponds to doubling the data rate.

Thanks to the switching technology it is possible to

construct Industrial Ethernet networks that satisfy the

requirements both for reliability and for real-time

performance.

Different types of switches

Switches are chiefly distinguished according to the

following features:

Modes of operation: Store and forward

Cut-through

Modified cut-through

Blocking: Blocking

Non-blocking

Management: Managed

Unmanaged

Principle of a switch

Incoming

telegrams

Outgoing

telegrams

Assignment table

General

information

Address

Page 9

00

.

07

Industrial Ethernet – General information

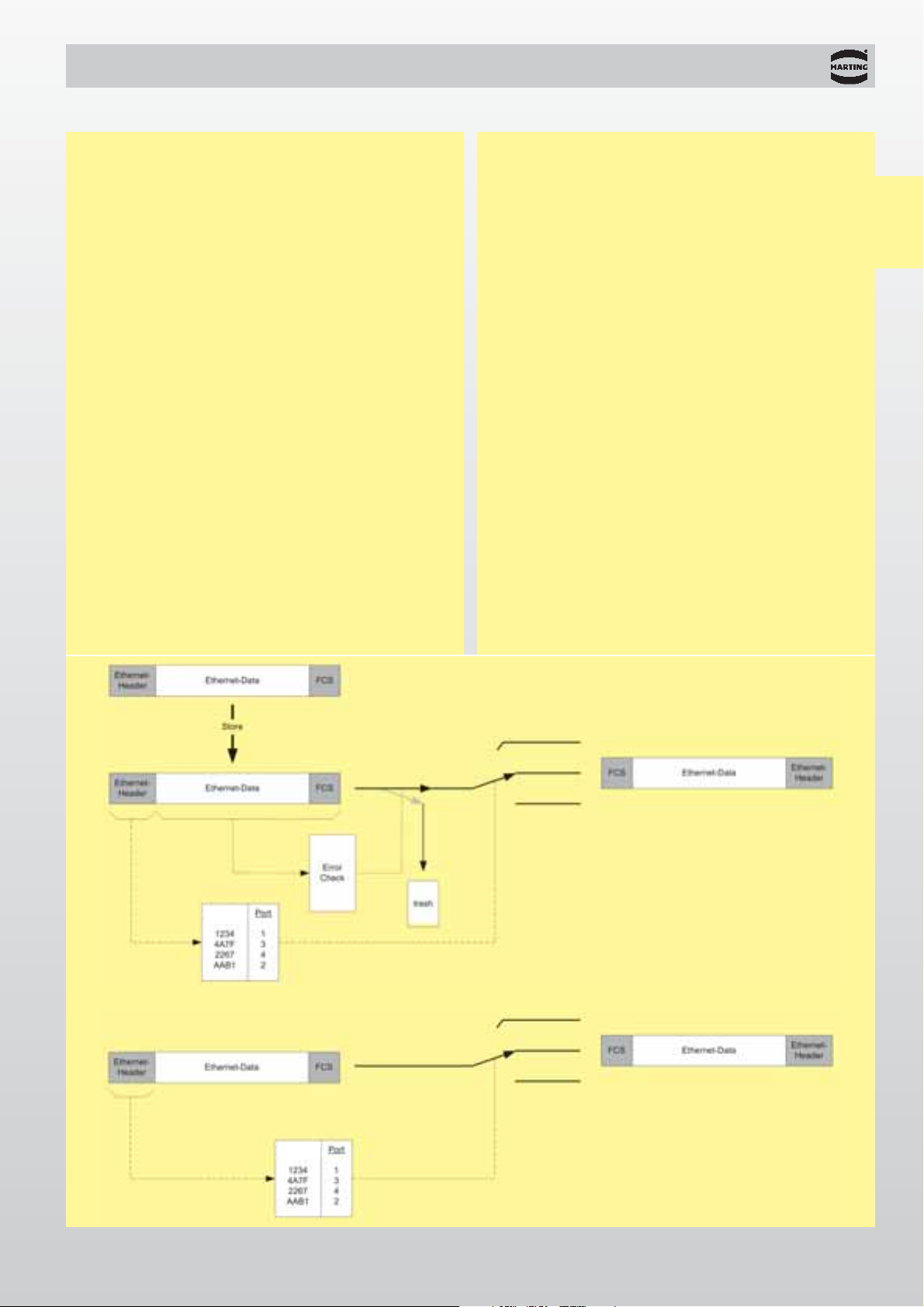

A comparison of the operating modes

Store and forward (Figure 1)

In this mode of operation, the switch temporarily

stores the entire data packet, checks it for errors and,

if it is free of errors, passes it on to the appropriate

port.

Cut-through / Modified cut-through (Figure 2)

In this mode of operation only enough bytes from the

data packet are placed into temporary storage as are

necessary for the evaluation in the address/port

assignment table.

Once this has been done, all the incoming bytes from

the data packet are passed on immediately to the

corresponding port without any intermediate storage.

In modified cut-through, the switch waits for precisely

64 bytes before making a decision according to the

address/port assignment table.

Blocking

A switch has a certain number of ports available to

it, and these are connected through the switch matrix.

If the switch matrix is capable of handling all

the connections without delay at full data rate

immediately, then it is called a non-blocking switch. If

the number of simultaneous connections at full data

rate is limited, the switch is said to be blocking.

Management

An unmanaged switch handles all the data traffic on

the basis of the address/port assignment table. The

user has no options for manipulating this.

A managed switch controls the data flow in

accordance with certain parameters or rules. The

basis for this activity is provided by the switch

management software. Modern switches support

SNMP management and web-based management.

These provide a variety of options for manipulation by

the user. The capabilities of the management

software differ from one switch to another.

Time behaviour

In Switched Ethernet, all the uncertainties of time

that result from Ethernet's collision management

algorithm (CSMA/CD) are eliminated. If correctly

dimensioned, Switched Ethernet thus becomes a

deterministic system. For the purposes of industrial

automation it is necessary to select the switches and

to dimension the network in such a way that the

switches operate within their deterministic range

under all operating conditions.

General

information

Figure 1

Figure 2

Address

Address

Page 10

00

.

08

Industrial Ethernet – General information

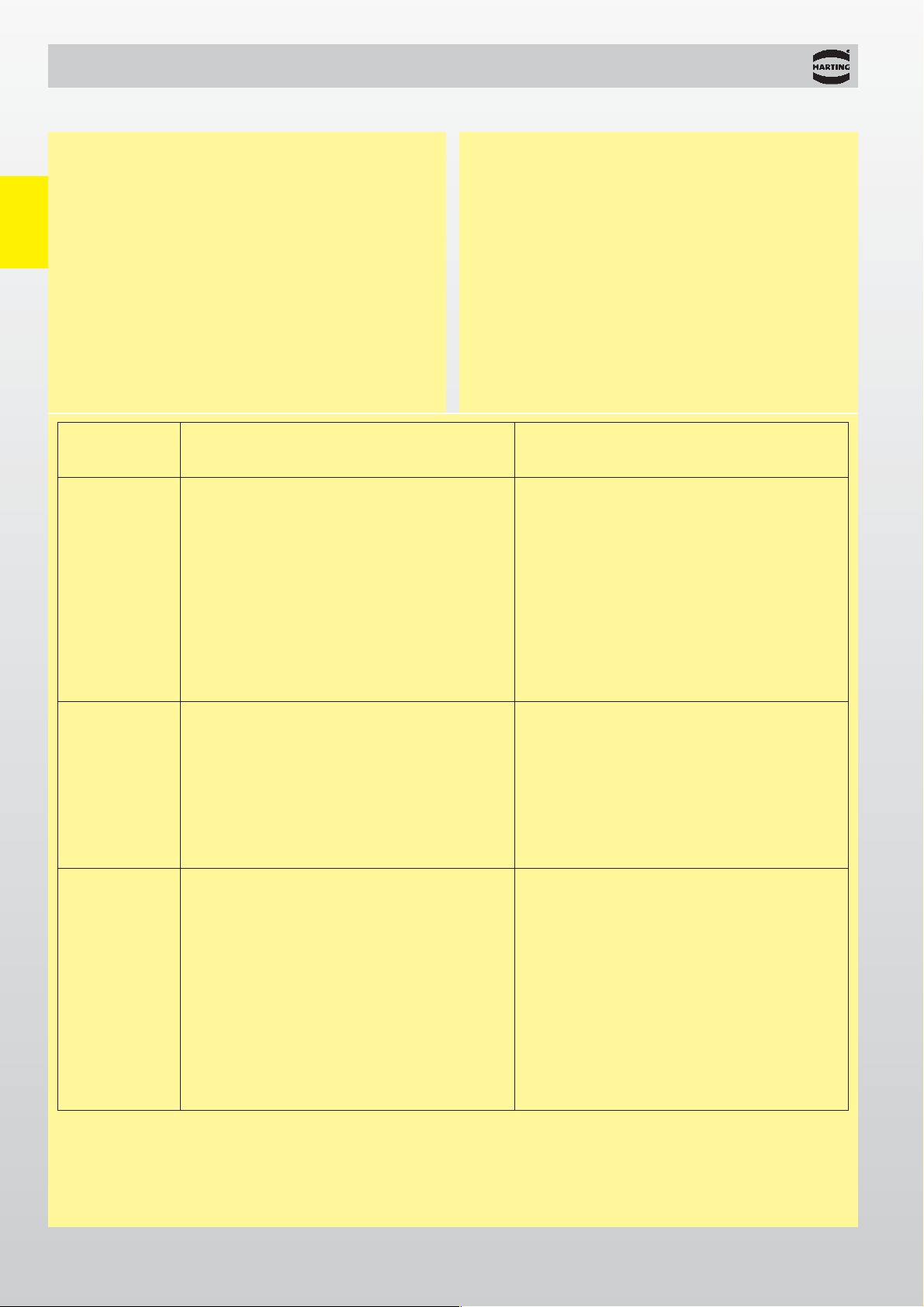

The Industrial Ethernet network

General requirements for Industrial Ethernet

networks

The international standard ISO/IEC 11801 and its

European equivalent, EN 50173, define an

application-neutral standard form of information

networking for a building complex. The contents of the

two standards are largely identical. Both standards

assume that the buildings are used in a way similar to

an office, and aim to be neutral towards particular

applications. The specific requirements for Ethernet

networks in industrial environments, such as

l

equipment-specific cabling

l

individually adapted levels of networking for each

machine/plant

l

linear network structures

l

robust, industrial cables and connectors meeting

special requirements for EMC, temperature,

humidity, dust and vibration

are not considered in either of these standards.

General

information

Office areas Production and other industrial areas

Installation

conditions

Transmission

capacity

Environmental

requirements

l

Fixed basic installation in the building

l

Cables laid in false floor

l

Devices connected at workstation vary

frequently

l

Prefabricated connecting cables

l

Largely standard work places

(desk with PC, …)

l

Tree network structures

l

Wiring depends heavily on the equipment

l

Equipment-specific cabling

l

Connection points are rarely modified

l

Device connections may be assembled on

site

l

Each machine/plant requires individual

levels of networking

l

Linear or (redundant) ring network

structures are common

l

Large data packets (e.g. images)

l

Medium network availability

l

Transmission time on the scale of

seconds

l

Predominantly acyclic transmission

l

No isochronism

l

Moderate temperatures

l

Low dust levels

l

No humidity

l

Little shock or vibration

l

Low EMI exposure

l

Low mechanical hazard

l

Low UV radiation

l

Very little chemical hazard

l

Small data packets (measurement data)

l

Very high network availability

l

Transmission time on the scale of

microseconds

l

High proportion of cyclic transmission

l

Isochronism

l

Extreme temperatures

l

High dust levels

l

Humidity possible

l

Vibrating machines

l

High EMI exposure

l

Risk of mechanical damage

l

UV exposure out of doors

l

Chemical hazard from oily or aggressive

atmospheres

Table: Differing requirements of office and industrial areas

Page 11

00

.

09

Industrial Ethernet – General information

Network topologies

The topologies of Industrial Ethernet networks are

oriented toward the requirements of the equipment

that must be connected. Star, linear, tree and ring

structures are amongst the most common. In practice,

a real installation often consists of a mixture of the

individual structures considered below.

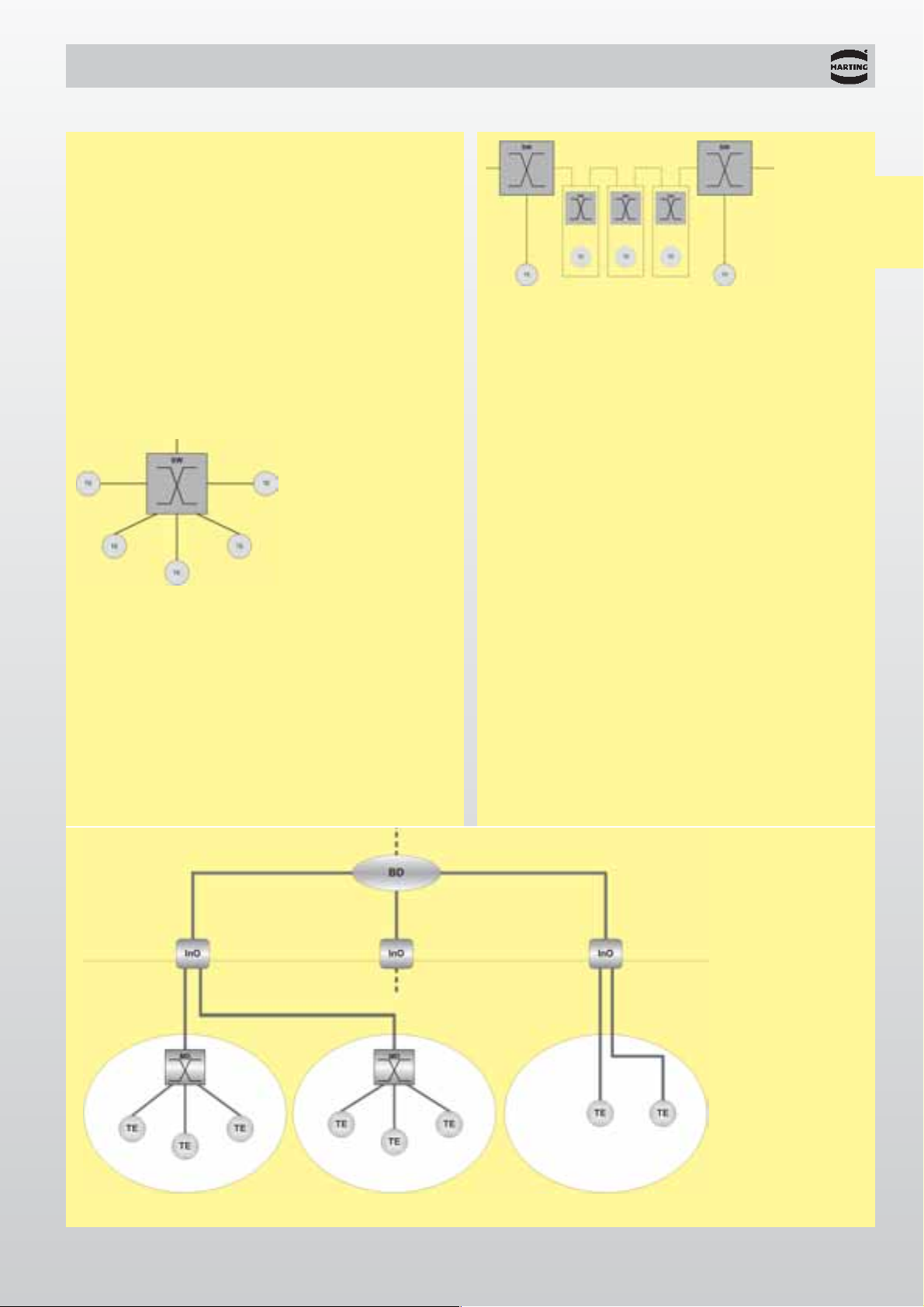

Star

A star structure is characterised by a central signal

distributor (switch) with single connections to all the

network's end devices. Star network structures are

best applied to areas where the density of devices is

high and the physical distances between them is

small, such as small production cells or an individual

production machine.

Tree

A tree topology is formed when a number of stars are

combined into one network. It is used when a complex

installation is divided into smaller regions.

Linear

A linear structure can be implemented by a switch

close to the end device requiring connection, or by a

switch integrated into the end device. Linear

structures are most often used in installations that

are physically extensive, such as conveyor systems,

and for the connection of manufacturing cells.

General

information

Ring (redundancy)

If the ends of a line are closed by an additional

connection, a ring structure results. Ring topologies

are used to protect against line breaks or the failure

of one network component in installations with high

requirements for availability.

PROFInet®transmission system and wiring

The "PROFInet®transmission system and wiring"

guideline defines a method of cabling for Industrial

Ethernet, suitable for industrial application, on the

basis of the fundamental requirements of ISO/IEC

11801.

The PROFInet

®

guideline sets new standards,

because:

l

The component manufacturer is provided with

unambiguous interface specifications

l

The user is provided with simple rules for the

installation

l

He is therefore able to implement networks without

additional Ethernet-specific planning, as with a field

bus.

The PROFInet

®

guideline specifies cables and

connectors with which the user can create an

installation without special calculations relating to the

transmission routes.

Detailed information can be found on the internet

under www.profibus.com

SW = Switch

TE = Terminal Equipment

Star structure

SW = Switch

TE = Terminal

Equipment

Linear structure

ISO / IEC 11801

Structured building network

Structured

machine

network

Manufacturing plant

BD = Building Distributor

MD = Machine Distributor

InO = Industrial Outlet

TE = Terminal Equipment

Page 12

00

.

10

2 100 m

2 100 m

2 100 m

4 100 m

4 100 m

6 100 m

6 100 m

Industrial Ethernet – General information

Cabling

Cables in an industrial environment may be exposed

to extreme mechanical stresses. To ensure adequate

mechanical protection special industrialised cable

may be required, and this can have an effect on

the transmission properties, which may mean that

only relatively short transmission routes can be

implemented. Signal transmission along symmetric

copper cables (twisted pair) must be in accordance

with 100 BASE-TX at 100 Mbit/s (Fast Ethernet). The

transmission medium contains two pairs of twisted,

screened copper cables (twisted pair or star quad)

with a characteristic impedance of 100 Ohms. Only

screened cables and connectors are permitted. The

individual components must satisfy the requirements

for Category 5 in accordance with ISO/IEC 11801.

The entire transmission route must satisfy the

requirements for Class D in accordance with ISO/IEC

11801. Removable connections on the cable side are

made using either RJ 45 or M12 male connectors. On

the device connections are in the form of female

mating connectors. Connecting cables (device

connecting cables and routing cables) accordingly

have male connectors at both ends. Each device is

connected through an active network component.The

transmission cable therefore has identical connectors

at both ends which simplifies installation as the

connecting cable fulfils the function of a patch lead.

The maximum cable length is 100 metres.

As long as the cable and the connectors meet with the

above specifications a maximum cabling length of

100 m can be achieved with up to six connector pairs.

The combination of a male and female connector is

regarded as one pair.

General

information

Table: Transmission route lengths

Wiring example Number of Maximum

connector pairs cabling length

TE = Terminal

Equipment

PMD = PROFInet

®

Machine Distributor

Area

"inside"

Connector

Connector

coupling

Page 13

00

.

11

Industrial Ethernet – General information

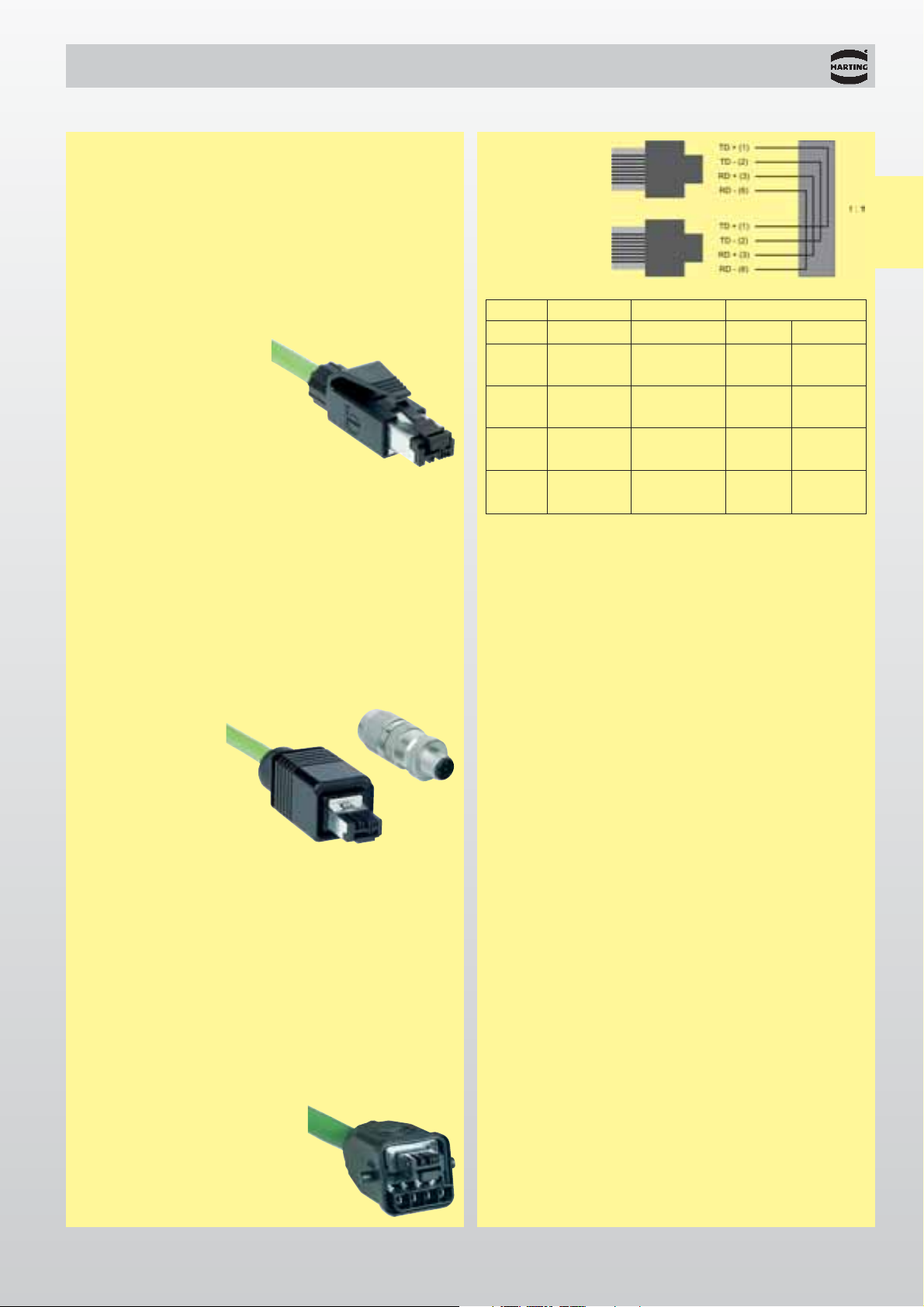

Connectors

An important criterion for industrial applications is the

ease with which connection equipment can be

handled on site. Connectors for M12 and for RJ 45

are available for this purpose. They can easily be

assembled on site using standard tools.

In the control cabinet area, PROFInet

®

uses RJ45 in

an IP 20 implementation. It is compatible with office

connectors.

HARTING RJ Industrial®IP 20 Data

Connectors outside the control cabinet must be capable of withstanding the stresses of industrial applications. RJ 45 or M12 connectors with protection to

IP 65 or IP 67 are used in this environment.The RJ 45

in IP 65 / IP 67 implementation has a robust housing

with push pull locking. Special versions allow a level

of protection up to IP 68 to be achieved. The M12

connectors use the screened, D-coded, 4-pin version,

as included by DKE for Industrial Ethernet in the IEC

standard.

HARTING RJ Industrial

®

IP 67 Push Pull

and

HARAX

®

M12-L shielded

Hybrid connectors can be used where distributed field

devices require connection to both the data network

and to a low voltage power supply. A fully contactprotected connector allows the connectors to be

identical at both ends, since the integrated contact

protection means that it is not necessary to alternate

between male and female contact.An RJ 45 providing

IP 67 protection is used to connect twin-pair,

screened data lines for communication and four

electrical contacts provide connection to the power

supply.

HARTING RJ Industrial®IP 67 Hybrid

Connector

assignment

RJ 45

Signal Function

Conductor colour

Pin assignment

RJ 45 M12

TD+

Transmission

Data + Yellow 1 1

TD-

Transmission

Data - Orange 2 3

RD+ Receiver

Data + White 3 2

RD- Receiver

Data - Blue 6 4

Switches

Switches are devices located in the transmission path

between end devices, and which regenerate signals they

receive before passing them on to their destinations.

They are used to construct networks, and permit data

communication over long distances. Switches suitable

for PROFInet

®

are designed for Fast Ethernet (100

Mbit/s, IEEE 802.3u) and for full duplex transmission. In

full duplex operation, a switch simultaneously sends and

receives data at the same port. Collisions do not occur.

No bandwidth is therefore lost through the Ethernet

collision process. Network planning is made significantly

more straightforward, because it is not necessary to

examine route lengths within a collision domain.

Industrialised switches are used for applications in the

industrial environments. Switches designed for the office

environment can only be used under certain conditions.

One reason for this is that they are not suitable for harsh

industrial surroundings. Secondly, large numbers of

ports can become expensive.

Industrial Outlets

The interface between the structured building network in

accordance with ISO/IEC 11801 and the PROFInet

®

plant cabling is provided by the Industrial Outlet, or InO.

Its function corresponds to the socket outlet used in the

office environment. The InO is manufactured to meet

protection levels IP 65 / IP 67 and is suitable for the

harsh conditions found in the industrial environment.

Source:

PROFInet®Technologie und Anwendung

(PROFInet

®

Technology and Application),

November 2002

PROFInet®transmission system and wiring,

November 2002

General

information

Page 14

00

.

12

Industrial Ethernet – General information

Glossary

10 Base T

The standard for data transmission of 10 Mbit/s

Ethernet through unscreened twisted pair cables

(Category 3, 4 or 5). Each connection is made using

two pairs of wires, one pair being used for data

transmission and the other for data reception.

10 Base FX

The standard for data transmission of 10 Mbit/s

Ethernet through optical fibres. Each connection is

made using two fibres, one fibre being used for data

transmission and the other for data reception.

100 Base TX

The standard for data transmission of 100 Mbit/s

Ethernet through twisted pair cables (Category 5).

Each connection is made using two pairs of wires,

one pair being used for data transmission and the

other for data reception.

100 Base FX

The standard for data transmission of 100 Mbit/s

Ethernet through optical fibres. Each connection is

made using two fibres, one fibre being used for data

transmission and the other for data reception.

Autonegotiation

A procedure defined in Fast Ethernet in which the

devices agree a transmission mode with one another

before the actual data transmission begins (100

Mbit/s or 10 Mbit/s, full or half duplex).

Autocrossing (1:1 cable; cross-over cable)

This function makes it possible to cross the send and

receive lines of twisted pair interfaces automatically.

Devices such as switches that support this function

can be joined through a cable that is wired 1:1 instead

of a cross-over cable.

AWG (American Wire Gauge)

The AWG value describes a cable in terms of the wire

thickness and the permissible attenuation.

Depending on the structure of the cable:

AWG 22 corresponds to a conductor

wire gauge of 0.33 - 0.38 mm²

AWG 24 corresponds to a conductor

wire gauge of 0.21 - 0.25 mm²

AWG 26 corresponds to a conductor

wire gauge of 0.13 - 0.15 mm²

Broadcast telegram

A broadcast telegram is defined as a call to all

network devices ("one to all").

CSMA/CD procedure

Carrier Sense Multiple Access/Collision Detection

Access procedure in Ethernet according to IEEE

802.3. Before sending a message, each network user

first checks whether the transmission medium is free

(Carrier Sense). It then begins to transmit, checking at

the same time whether other devices (Multiple

Access) have also begun to transmit data. If two or

more devices transmit at the same time, a collision

takes place. The devices stop transmitting their data

(Collision Detection). After a randomly chosen time

the next attempt is made when the line is free. In the

CSMA/CD procedure the physical size of the network

is limited by the maximum permissible transmission

time of the data signals across the network, and this

depends on the data rate.

Ethernet

The name of a data network that has been

standardised in IEEE 802.3 since 1985. The term

"Ethernet" is often used as a general term, without

distinguishing between the different versions

(Ethernet, Fast Ethernet etc.).

Fast Ethernet

A fast data network specified in IEEE 802.3 in 1995.

Important parameters: transmission speed 100

Mbit/s, variable packet length 64 - 1522 bytes

(with optional 4 byte tag field).

FEXT (Far End Cross Talk)

A form of crosstalk in which the signals from devices

located at the opposite ends of a twisted pair cable

are superimposed on one another.

Full Duplex

A mode of operation in which one device can

simultaneously send and receive data.

General

information

Page 15

00

.

13

Industrial Ethernet – General information

Gigabit Ethernet

A fast data network specified in IEEE 802.3 in 1999.

Important parameters: transmission speed 1000

Mbit/s, variable packet length 64 – 1518 bytes.

Half Duplex

A mode of operation in which a device either sends or

receives data at any one time. Collision detection is

active in Ethernet for half duplex operation. The

physical size of the network is limited by the

transmission time delays in the devices and the

transmission media.

Hub

The central point in a star arrangement.

A hub – often also called a star coupler – can be used

to connect a number of devices in a star arrangement.

In this arrangement, data packets must take turns to

pass through the hub one after another. Data packets

received at one port are immediately transmitted

again on all the other ports.

Industrial Ethernet

A name for the form of Ethernet used in automation

engineering. Because of the conditions encountered

in industrial applications, the network components

must withstand greater ranges of temperature and

satisfy tougher requirements in terms of availability

and reliability of the network.

Collision Domain

The CSMA/CD access procedure restricts the

transmission time of a data packet from one network

device to another. In accordance with the data rate,

this yields a spatially limited network referred to as a

collision domain. The maximum size of a collision

domain is 4250 m at 10 Mbit/s (Ethernet) and 412 m

at 100 Mbit/s (Fast Ethernet).If a connection operates

in full duplex mode, the physical size can exceed

these limits, because collisions do not then occur.

This requires bridges or switches to be used.

LAN (Local Area Network)

A name for local networks extending up to 10 km.

Multicast Telegram

A multicast telegram is sent to a group of defined

receivers. This group can be reached through one

address (cf. Broadcast Telegram).

NEXT (Near End Cross Talk)

A form of crosstalk in which the signals from devices

located at the same end of a twisted pair cable are

superimposed on one another.

POF (Plastic Optical Fibre)

A name for an optical fibre whose core and sheath are

formed of plastic. POF fibres have a typical core

diameter of 0.98 mm.

PROFInet

®

A network concept that defines the communication

from the field level to the control level utilising Profibus and Ethernet, along with a model for the

network engineering of the entire plant. See also:

www.profibus.com

Queue / Queuing

Queue is a general term for a series of elements or

tasks awaiting sequential processing. In a data

transmission system, a queue is a number of

messages or data packets that are waiting for further

processing or to be transmitted elsewhere. They are

temporarily sorted, and are processed one after

another under the control of appropriate queueing

procedures.

Segmentation / Network Segmentation

Network segmentation is used to set limits to collision

domains, allowing Ethernet networks to achieve

higher performance. A network can be segmented

with the aid, for instance, of switches.

Switched Network

A name for an Ethernet network constructed using

switches.

General

information

Page 16

00

.

14

Notes

General

information

Page 17

01

.

01

Ethernet switches for industrial applications

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.02

Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.03

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.03

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.04

Industrial Outlets

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.06

Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.07

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.07

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01.08

Active and passive network components

Page

Directory chapter 01

Network

components

Page 18

01

.

02

General description

Advantages

General information

Application fields

Switches divide former collision domains into

point-to-point connections between the network

components and the user equipment involved.

Constructing the network this way prevents

collisions.

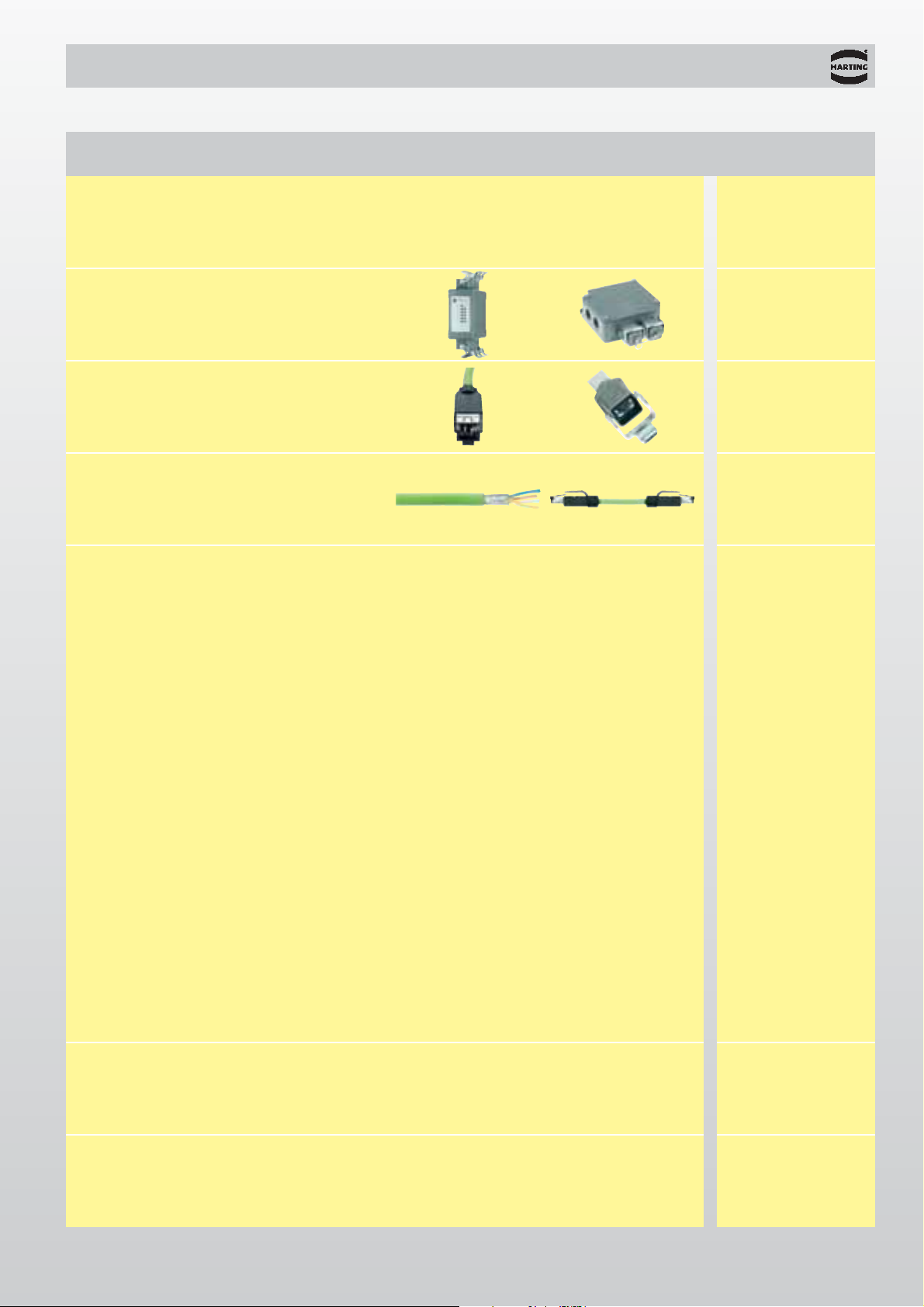

The ESC 67-10 TP05U Fast Ethernet Switch

allows up five items of user equipment to be

connected through shielded twisted pair cable in

accordance with IEC 802.3. The protection level,

temperature range and mechanical stability

satisfy the toughest demands. The Fast Ethernet

Switch can therefore be directly used in industrial

environments.

It allows the amount of cabling needed to

construct industrial networks to be reduced. The

ESC 67-10 TP05U facilitates any kind of network

configuration. All connections are plugged, which

means that assembly is fast and reliable. All

Ethernet interfaces are protected against overvoltage.

l

High IP 65 / IP 67 protection level

l

Robust metal housing

l

Can be used directly in industrial environments

l

EMI, temperature range and mechanical

stability for the toughest demands

l

PROFInet®compatible

l

Industrial automation

l

Automotive industry

l

Wind power

l

Power distribution systems

ESC 67-10 TP05U

Fast Ethernet Switch for industrial applications

Network

components

Page 19

01

.

03

Technical characteristics

Network

components

Function Ethernet Switch in accordance with IEEE 802.3, store and forward switching mode non-blocking,

5 ports unmanaged, autocrossing, autonegotiation, Ethernet (10 Mbit/s) and Fast Ethernet

(100 Mbit/s) diagnostic LEDs (link status, data)

Mechanical data

Hood type Robust metal hood of zinc die-cast

Dimensions 45 x 120 x 87 (W x D x H in mm, without connectors)

Mounting 35 mm top-hat rail according to DIN EN 60715, vertical wall

mounting, horizontal wall mounting

Protection level IP 65 / IP 67

Power supply

Input voltage 24 V DC (18 ... 30 V DC)

Current consumption 100 mA at 24 V DC

Connections Compatible with Han

®

4A connector, redundant power supply

Ethernet Interface

Ports 5 x 10/100 Base-TX, twisted pair, data transmission rate 10 or 100

Mbit/s

Cable Shielded twisted pair (STP) and unshielded twisted pair (UTP),

Category 5

Cascade depth

Linear / star structure Any

Maximum cable length 100 m (with Category 5 cable) in accordance with EN 50 173-1

Available device HARTING RJ Industrial

®

IP 67 Data 3A,

HARTING RJ Industrial

®

IP 67 Push Pull,

HARAX

®

M12-L with D-coding

Environmental conditions

Operating temperature range -40 °C … +70 °C

Relative humidity for operation

30% to 95%, non-condensing

Mechanical stability

Shock / vibration IEC 68-2-27-Ea / IEC 68-2-6-Fc

EMI Interference immunity EN 61000-4-2 … EN 61000-4-6

Interference emission EN 50011, Class A

Ordering information

Switch type Part No. Specification

ESC 67-10 TP05U

20 70 305 3921

HARTING RJ Industrial®IP 67 Data 3A

ESC 67-10 TP05U

20 70 305 3931

HARTING RJ Industrial®IP 67 Push Pull

ESC 67-10 TP05U

20 70 305 3941

M12 D-coding

Page 20

01

.

04

Accessories

Part No.

Switch type Identification Power termination Ethernet termination

Network

components

Further connectors can be found in our catalogue “Heavy Duty Han®connectors”.

1)

Order insert fixing screw 09 20 000 9918 separately

ESC 67-10 TP05U

HARTING RJ Industrial

®

IP 67 Data 3A

Straight metal hood, metric

1)

19 20 003 1440

1)

Protection cover Han®3A 09 20 003 5422 09 20 003 5425

Han

®

4A female insert 09 20 004 2711

Metal cable gland IP 65,

metric M20, cable diameter: 5 - 9 mm 19 00 000 5080

Connector set HARTING RJ Industrial

®

IP 67 Data 3A, metal 09 45 115 1100

Coding pin set 09 45 820 0000

ESC 67-10 TP05U

HARTING RJ Industrial

®

IP 67 Push Pull

HARAX

®

M12-L circular connector 21 03 212 2305

Connector set HARTING RJ Industrial

®

IP 67 Push Pull 09 45 145 1100

ESC 67-10 TP05U

M12 D-coding

HARAX

®

M12-L circular connector 21 03 212 2305

HARAX

®

M12-L circular connector, shielded 21 03 281 1405

Protection cover M12 21 01 000 0003 21 01 000 0003

Page 21

01

.

05

Accessories

Identification Part No. Drawing

Set for top-hat rail mounting

in accordance with DIN EN 60715

20 80 000 0003

Set for vertical wall mounting

20 80 010 0001

Set for horizontal wall mounting

20 80 010 0002

Network

components

Page 22

01

.

06

General description

General information

Advantages

The Industrial Outlet permits a structured building

cable link in accordance with ISO/IEC 11801 for

industrial areas.

The Industrial Outlet INO 67-30 TP02 can be

mounted very simply on walls or beams internally

or externally. The proven LSA+ cable termination

technology means that the cables can be installed

quickly and easily. Lockable, plug-in RJ 45 cables

make the work of extending the Ethernet network

into the production level simple.

In the version with HARTING RJ Industrial

®

IP 67 Data 3A, the Industrial Outlet provides the

interface to the Ethernet cabling as specified for

PROFInet

®

.

l

High IP 65 / IP 67 protection level

l

Robust metal housing

l

Can be used directly in industrial environments

l

Easy mounting on walls or beams

l

LSA+ connection technology makes installation

straightforward

l

Optimum connector technology with high data

security

l

PROFInet®compatible

Industrial Outlet INO 67-30 TP02

Network

components

Field

installation cable

Industrial Outlet for PROFInet

®

(left hand cable entry selected)

Machinery

installation cable

Page 23

01

.

07

Technical characteristics

Mechanical data

Hood type Robust metal hood of aluminium die-cast

Dimensions 105 x 120 x 42 (W x D x H in mm,

without covers; without cable gland)

Mounting Wall mounting

Weight app. 0.6 kg

Protection level IP 65 / IP 67

Ethernet Interface

Suitable for Ethernet, Fast Ethernet

Transmission characteristics In accordance to Category 5, ISO/IEC 11801:2002

and EN 50 173-1

Cable termination 2 x LSA+ connection technology

2 x mateable exit (RJ 45, fit for industrial use)

Available mating interfaces HARTING RJ Industrial

®

IP 67 Data 3A

HARAX

®

M12 with D-coding

Environmental conditions

Operating temperature range 0 °C … +55 °C

Relative humidity for operation

30% to 95%, non-condensing

Mechanical stability

Shock / vibration IEC 68-2-27-Ea / IEC 68-2-6-Fc

EMI Interference immunity EN 61000-4-2 … EN 61000-4-6

INO 67-30 TP02

HARTING RJ Industrial

®

IP 67 Data 3A

with four cable entries

20 70 302 4921

Ordering information

Industrial Outlet type Part No. Specification

Network

components

INO 67-30 TP02

M12 D-coding

with four cable entries

20 70 302 4941

Page 24

01

.

08

Accessories

INO 67-30 TP02

HARTING RJ Industrial

®

IP 67 Data 3A

Metal cable gland IP 65,

metric M20, cable diameter: 5 - 9 mm 19 00 000 5080

Metal blanking piece IP 65, metric M20 19 00 000 5070

Connector set HARTING RJ Industrial

®

IP 67 Data 3A, metal 09 45 115 1100

Coding pin set 09 45 820 0000

INO 67-30 TP02

M12 D-coding

Metal cable gland IP 65,

metric M20, cable diameter: 5 - 9 mm 19 00 000 5080

Metal blanking piece IP 65, metric M20 19 00 000 5070

HARAX

®

M12-L circular connector, shielded 21 03 281 1405

Industrial Outlet type Identification Part No.

Network

components

Page 25

02

.

01

HARTING RJ Industrial®– RJ 45 connectors

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02.02

IP 20 Data

connectors . . . . . . . . . . . . . . . . . . . . . . . . . 02.05

IP 67 Push Pull

connectors / panel feed through . . . . . . . . 02.06

IP 67 Data 3A

connectors / panel feed through . . . . . . . . 02.08

IP 67 Hybrid

connectors / panel feed through . . . . . . . . 02.10

HARAX®M12 connectors

Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02.12

HARAX

®

circular connector M12-L, shielded . . . . . . . . . . . . . . . . . . . . . 02.13

Customer specific connectors

Han-Brid®Quintax 3A . . . . . . . . . . . . . . . . 02.14

Accessories

. . . . . . . . . . . . . . . . . . . . . . . . 02.16

Connectors Page

Directory chapter 02

Connectors

Page 26

02

.

02

RJ Industrial General information

HARTING RJ Industrial

®

Ethernet connector family

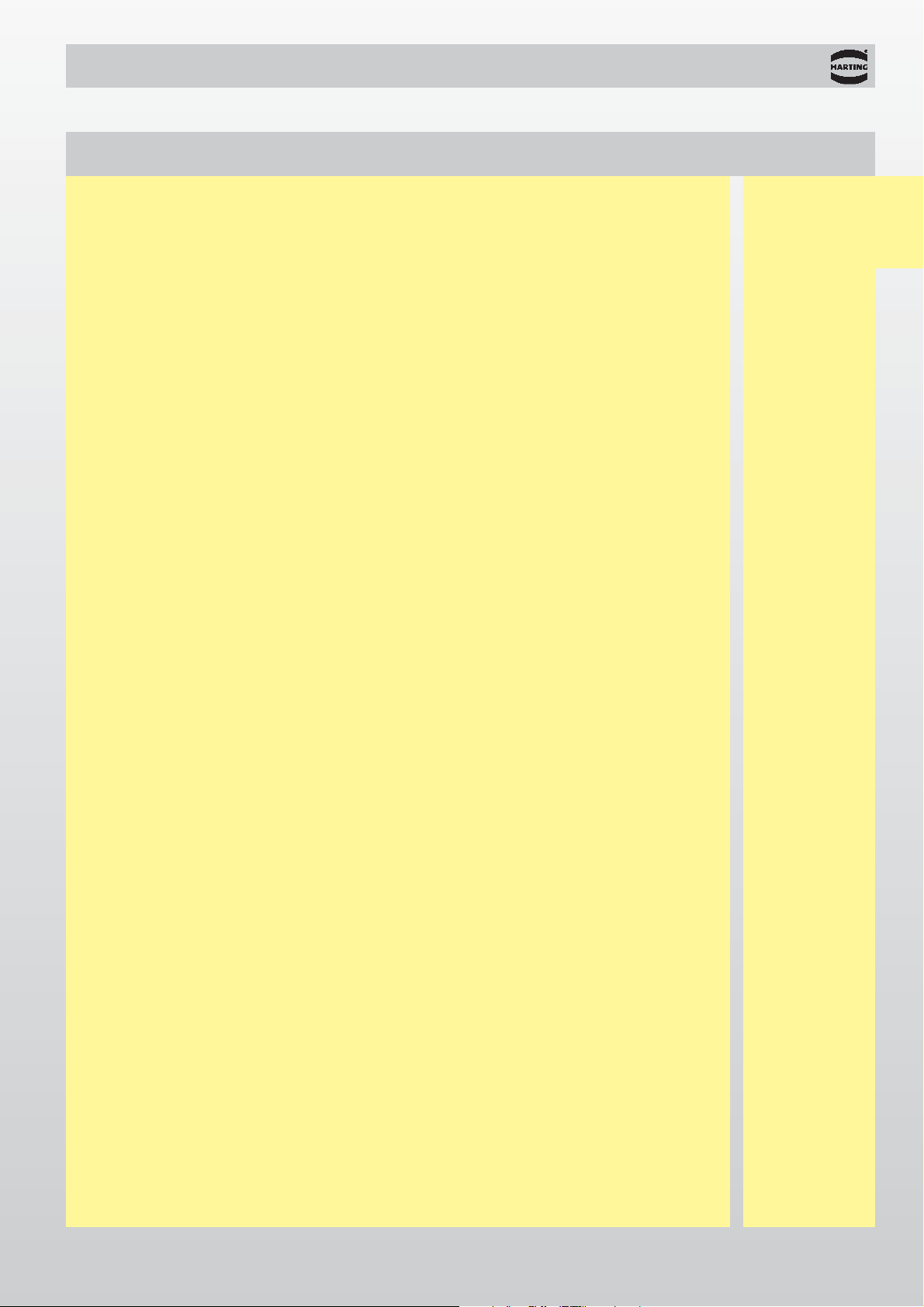

The modular HARTING RJ Industrial®family of

connectors is based on the standard RJ 45 connector

pattern, and is specifically developed for use in harsh

industrial environments. It points the way forward

in connecting Ethernet devices in industrial

applications. In many circumstances it is necessary

for connectors to be assembled on site, regardless of

whether they are being used for power or

communication. HARTING are making consistent use

of their

HARAX

®

rapid termination technology, which

has been proven in many industrial applications.With

HARAX

®

the user can terminate the cable at the

connectors without the need for special tools. The

design of the HARTING RJ Industrial

®

family of

connectors allows for quick and easy termination and

connection to Ethernet devices in either data only or

hybrid networks.

HARTING RJ Industrial

®

is the only RJ 45 connector

in the world that allows robust Ethernet cables with a

solid and stranded AWG 22 cross section to be

connected using IDC technology. The heart of each of

these connectors is the RJ 45 data module with fast

termination technology. This functions without

needing to strip insulation from the cores and without

special tools, creating a gas-tight connection, secure

against vibration. The data module has four

HARAX

®

fast termination contacts.These make reliable contact

with stranded, industry-standard Category 5 cables

with dimensions from AWG 22 to 24, and solid cables

with conductor cross-sections from AWG 22 to 23.

HARTING have developed a

complete family of connectors

around this innovative data

module, meeting all the needs

of industrial environments.

Solutions for IP 20 and IP 67

protection levels, standard,

push pull and latching clip-locks

are available.

Data and hybrid cables can be used. The user can fit

stranded cores with a cross section of 1.5 mm² for the

IDC power contacts on the Hybrid version, and these

can be loaded with up to 16 A.

At the device end, panel feed throughs or

couplings integrated directly into the device can

be accomodated. Consistent application of SMD

components for both data and power at the device

end keeps manufacturing costs low, and permits high

packing density within the assembly.

Field assembly of Industrial Ethernet

connectors

The facility of on-site assembly was given high

priority in the development of the new HARTING RJ

Industrial

®

family of connectors. As a result, the

connector is not just quicker to terminate, but is also

easier to handle due to the reduced number of

individual parts.

All of the HARTING RJ Industrial

®

range can be reterminated up to ten times. An electrician can carry

out assembly of the IP 20 Data version on site in less

than one minute, while the IP 67 Hybrid version

requires less than three minutes. Dismantling is just

as quick. New operatives can also learn the individual

steps involved very quickly and carry them out

reliably.

Another advantage of the quick-connection technology is provided by the industrial-quality screening of

the data module in the connector. Termination of the

screen which in the past has been achieved by

crimping is no longer necessary. In the

RJ Industrial connection technology,

a pair of screening plates are

simply pushed over the data

module, and pressed together

with an audible "click". With

this, complete, 360 degree

connection of the screen

and the sheath is

achieved.

Various special tools for handling the RJ 45 data

module and the power leads are unnecessary.

HARTING supplies all the components in a complete

set.

Connectors

Page 27

02

.

03

RJ Industrial

!!!!

!

!

!!

IP 20 Data

IP 67 Push Pull

IP 67 Hybrid

IP 67 Data 3A

IP 67 Push Pull IP 67 Hybrid IP 67 Data 3A

Specified for PROFInet

®

From the very beginning, HARTING saw it as their

task to set a broad standard for Ethernet in industrial

environments through a uniform connector solution.

Through its involvement in the PNO (PROFIBUS

Nutzerorganisation e.V.), the IAONA (Industrial

Automation Open Networking Alliance e.V.), the

DKE (Deutsche Kommission Elektrotechnik

Elektronik Informationstechnik) and also with the

IEC (International Electrotechnical Committee),

HARTING contributed to advancing the specification

of industry-standard Ethernet connectors. At the

beginning of 2003, the PNO decided to use the

HARTING solution of the RJ Industrial family as the

general concept for PROFInet

®

.

In addition to this an international standardisation

process was initiated, because the HARTING

approach is not a proprietary system, but an open

solution for Industrial Ethernet interfaces.

General information

Connectors

Device side

IP 20 Data

Standard

RJ 45 jack

Cable side

Mating compatibility of the HARTING RJ Industrial®family

Page 28

02

.

04

RJ Industrial

1 2 3

6 5 4

7 8 9

12 11 10

6 Place the data module and the splicing piece into

the supplied IDC assembly tool

7 Press the data module and the IDC assembly tool

together, to make the insulation displacement

contact

8 Remove the assembled data module from the

IDC assembly tool

9 Put on the upper screen plate, and push it over

the cable screen

10 Put the lower screen plate in place, and latch it

to the upper screen plate with an audible

click

11 Push the housing over the assembled data

module, latching it into place with an audible click

12 Tighten the cable gland

Assembly operations

HARTING RJ Industrial

®

IP 20 Data

Only a few steps are necessary to quickly and reliably

connect an Industrial Ethernet cable to a HARTING

RJ Industrial

®

connector with IDC connection

technology.

1 Push the housing complete with cable gland over

the cable outer insulation

2 Strip the correct length of outer insulation and

screening braid

3 Prepare the cores to match the splicing piece in

accordance with the colour code

4 Insert the cores into the splicing piece to the

required depth

5 Place the splicing piece on the RJ 45 data

module and engage it

General information

Connectors

Page 29

02

.

05

RJ Industrial

09 45 151 1100

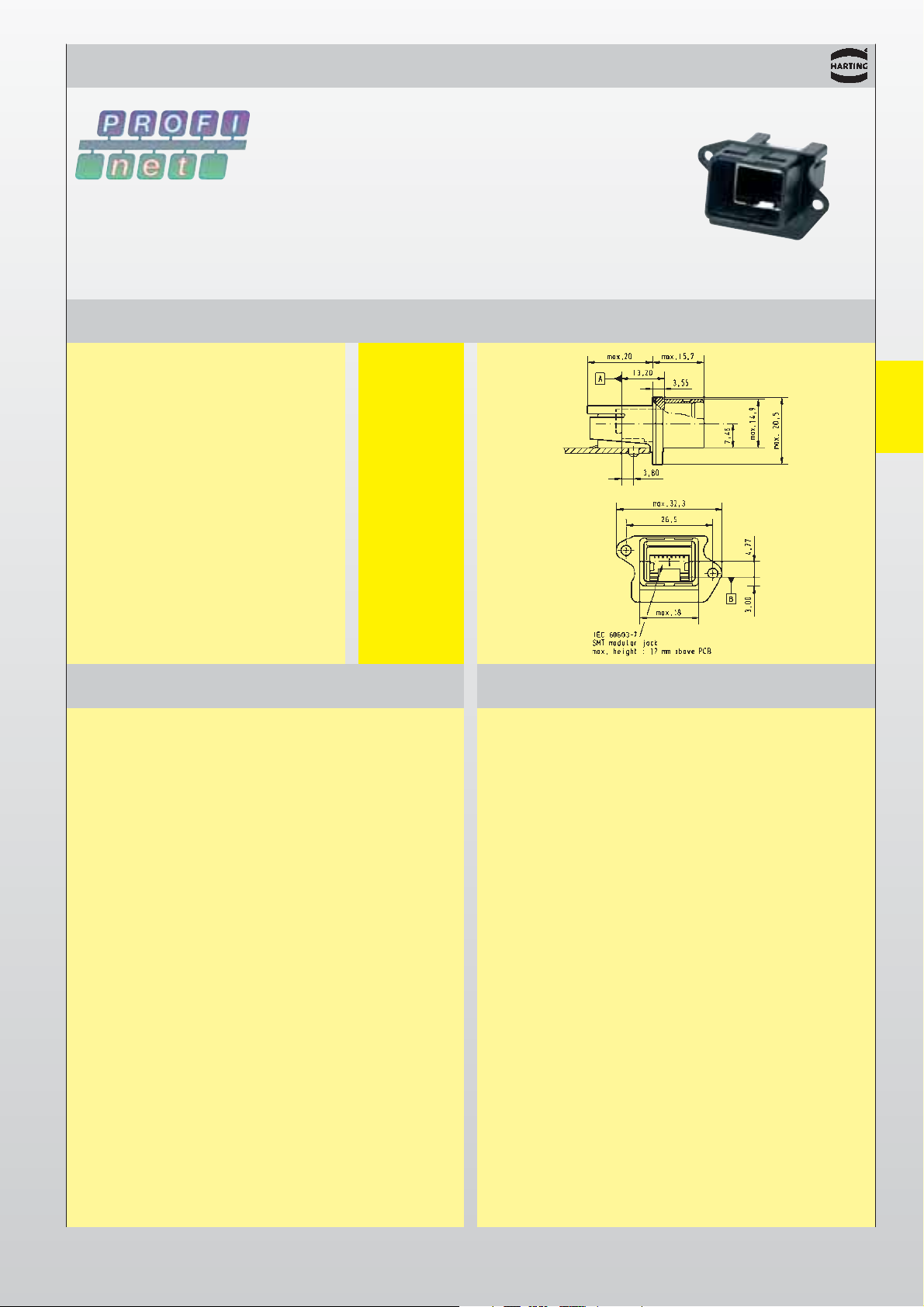

Technical characteristics General information

Connectors

IP 20 Data connectors

Connector set

incl. housing, cable gland

and instruction manual

Identification Part No. Drawing Dimensions in mm

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 20

Mating interface: RJ 45 in accordance with

IEC 60603-7

Wire gauge data

1)

: AWG 22 - 24 stranded

AWG 22 - 23 solid

Temperature range: -40 °C … +70 °C

Cable sheath diameter: 6.5 mm - 6.9 mm

Mating cycles: min. 750

Housing material: Thermoplastic, black

The IP 20 Data connector is the smallest and only

RJ 45 Ethernet connector in the world to which

AWG-22 cables can be connected with IDC technology.

The connector is designed with a standard grid of just

14 mm, which guarantees maximum packing density in

the application. An additional latching clip on the

housing makes its significantly easier to unlock the

connector.

This connector can be assembled on site, permitting

Industrial Ethernet installation cable to be connected

directly to IP 20 devices located inside a control

cabinet. Special panel feed through to provide the

transition between protection level IP 67 and IP 20 is

therefore not necessary. This lessens the installation

work required from the customer, while the reduced

number of contact points offers increased reliability.

Connectors

1)

Details see technical data sheet

Page 30

02

.

06

09 45 145 1100

RJ Industrial

Technical characteristics General information

IP 67 Push Pull connectors

Connector set

incl. housing, cable gland

and instruction manual

Identification Part No. Drawing Dimensions in mm

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 67

Mating interface: RJ 45 in accordance with

IEC 60603-7

Wire gauge data

1)

: AWG 22 - 24 stranded

AWG 22 - 23 solid

Temperature range: -40 °C … +70 °C

Cable sheath diameter: 6.5 mm - 7.2 mm

Mating cycles: min. 750

Housing material: Thermoplastic, black

The IP 67 Data version in a push pull housing is an

entirely new development with innovative housing

locking technology. The housing of the connector is

locked tightly to the hood by means of a locking sleeve

that surrounds it. The connector can be locked and

unlocked using one hand and only minimal force. In

spite of its high degree of protection, the housing is

very compact, and is ideally suited for compact

industrial applications.

The HARTING RJ Industrial

®

Push-Pull is thus the

smallest IP 67 Industrial Ethernet connector based on

RJ 45 with IDC connection technology in the world.

Connectors

Connectors

1)

Details see technical data sheet

Page 31

02

.

07

09 45 245 1100

RJ Industrial

Technical characteristics General information

IP 67 Push Pull panel feed through

Identification Part No. Drawing Dimensions in mm

Connectors

Panel feed through set

incl. housing

and instruction manual

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 67

Mating interface

internal and external: RJ 45 jack in accordance

with IEC 60603-7

Temperature range: -40 °C … +70 °C

Panel cut out: 21 x 27 mm

Mating cycles: min. 750

Housing material: Thermoplastic, black

The IP 67 Data version in a push pull housing is an

entirely new development with innovative housing

locking technology. The housing of the connector is

locked securely to the hood by means of a surrounding

locking sleeve. In spite of the high degree of protection,

the panel feed through is very compact, having a space

requirement of just 21 x 27 mm, the same space as for

a M12 connector.

The Push Pull panel feed through is compatible with

RJ 45 connectors, which means that standard patch

cables for service and test purposes can also be used

here.

The data lines are connected at the rear via an RJ 45

jack meeting IP 20.

Connectors

Page 32

02

.

08

09 45 125 1100

09 45 115 1100

09 45 820 0000

RJ Industrial

Technical characteristics General information

IP 67 Data 3A connectors

Plastic version

Metal version

Coding pin set

Identification Part No. Drawing Dimensions in mm

Connectors

Connector set

incl. housing, cable gland

and instruction manual

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 67/65

Mating interface: RJ 45 in accordance with

IEC 60603-7

Wire gauge data

1)

: AWG 22 - 24 stranded

AWG 22 - 23 solid

Temperature range: -40 °C … +70 °C

Cable sheath diameter: 6.5 mm - 6.9 mm

Mating cycles: min. 750

Housing material: Thermoplastic, black

Zinc die cast, grey

The IP 67 Data version of the RJ Industrial is based on

the RJ 45 Data module, integrated into a standard

Han

®

3A industry housing that can be used for most

industrial applications. The housing is optionally

available in plastic or metal, and offers protection level

IP 67/65.

Implementing a uniform pattern for all the connectors

based on the Han

®

3A contour for data and hybrid

solutions means that all versions are plug-compatible

for data signals. Optional coding prevents incorrect

mating up to four different connectors.

1)

Details see technical data sheet

Connectors

Page 33

02

.

09

09 45 225 1100

09 45 215 1100

09 45 820 0000

RJ Industrial

Technical characteristics General information

IP 67 Data 3A panel feed through

Identification Part No. Drawing Dimensions in mm

Plastic version

Metal version

Coding pin set

Connectors

Panel feed through set

incl. housing

and instruction manual

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 67/65

Mating interface

internal and external: RJ 45 jack in accordance

with IEC 60603-7

Panel cut out: 22 x 22 mm

Temperature range: -40 °C … +70 °C

Mating cycles: min. 750

Housing material: Thermoplastic, black

Zinc die cast, grey

The IP 67 panel feed through data version of the

RJ Industrial is based on an RJ 45 jack, integrated into

a Han

®

3A housing that can be used for most industrial

applications. The housing is optionally available in

plastic or metal, and offers protection level IP 67/65.

Implementing a uniform plug pattern for all the

connectors based on the 3A contour for data and hybrid

solutions means that all versions are plug-compatible

for data signals. Optional coding prevents incorrect

mating up to four different connectors. The panel feed

through is compatible with RJ 45 connectors, which

means that standard patch cables for service and test

purposes can be used. The data lines are connected at

the rear via an RJ 45 jack meeting IP 20.

Connectors

Page 34

02

.

10

09 45 125 1300

RJ Industrial

Technical characteristics General information

IP 67 Hybrid connectors

Identification Part No. Drawing Dimensions in mm

Connectors

Connector set

incl. housing, cable gland

and instruction manual

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 67

Mating interface: RJ 45 in accordance

with IEC 60603-7

plus 4 x power supply

Wire gauge data: AWG 22 - 24 stranded

AWG 22 - 23 solid

Wire gauge

power supply: 1.5 mm² stranded

Working voltage

power supply: 24 V

Working current

power supply: 16 A

Temperature range: -40 °C … +70 °C

Cable sheath diameter: 10 mm - 11 mm

Mating cycles: min. 500

Housing material: Thermoplastic, black

In the RJ Industrial Hybrid connector, HARTING has

developed an interface solution that integrates the

data lines and the power supply into one connector for

hybrid Ethernet networks. The connector's geometry

nevertheless maintains a clear separation between

the data and the power contacts. This brings a

significant reduction in the costs of installation and of

field devices suitable for industrial application with

hybrid cabling.

The four power contacts of the hybrid module have also been designed with

HARAX

®

rapid termination

technology, allowing stranded cables of up to 1.5 mm²

to be connected.

The physical length of the hybrid IP 67 version of the

industry standard Han

®

3A housing has been

reduced by 30 per cent, making it significantly

easier to handle and to use in compact industrial

applications.

Connectors

Page 35

02

.

11

09 45 225 1300

RJ Industrial

09 45 820 0000

Technical characteristics General information

IP 67 Hybrid panel feed through

Identification Part No. Drawing Dimensions in mm

Connectors

Panel feed through set

incl. housing

and instruction manual

Coding pin set

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level: IP 67

Mating interface external: RJ 45 jack in accordance

with IEC 60603-7

plus 4 x power supply

Mating interface internal: RJ 45 jack in accordance

with IEC 60603-7

plus 4 x power supply

with cage clamp 1.5 mm²

Working voltage

power supply: 24 V

Working current

power supply: 16 A

Panel cut out: 22 x 22 mm

Temperature range: -40 °C … +70 °C

Mating cycles: min. 500

Housing material: Thermoplastic, black

In the RJ Industrial Hybrid connector, HARTING has

developed an interface solution that integrates the

data lines and the power supply into one connector for

hybrid Ethernet networks. The connector’s geometry

nevertheless maintains a clear separation between

the data and the power contacts. This brings a

significant reduction in the costs of installation and of

field devices suitable for industrial application with

hybrid cabling.

The panel feed through is compatible with RJ 45

connectors, which means that the standard patch

cables for service and test purposes can be used. The

data lines are connected at the rear via an RJ 45 jack,

while the power lines use a cage clamp terminal.

Connectors

Page 36

02

.

12

À

Á

Â

Å

M12-L, shielded

HARAX

®

circular connector M12-L Technical characteristics

Assembly details General information

Transmission characteristics in accordance with DIN 50 173-1

Working voltage 32 V

Working current 4 A

(see current carrying capacity)

Coding D

Wire gauge 0.25 mm² - 0.34 mm²

AWG 24 - AWG 22 stranded

Diameter of individual strands > 0.1 mm

Conductor insulation material PVC

Conductor diameter 1.2 mm - 1.6 mm

Cable diameter 5.5 mm - 7.2 mm

Working temperature -25 °C ... +85 °C

Temperature during connection -5 °C ... +50 °C

Protection level IP 67

Number of terminations with

same cable cross section 10

Current carrying capacity

The current carrying capacity is limited by maximum temperature

of materials for inserts and contacts including terminals. The

current capacity-curve is valid for continuous, not interrupted

current-loaded contacts of connectors when simultaneous power

on all contacts is given, without exceeding the maximum

temperature.

Control and test procedures according to DIN IEC 60 512-3.

1. Remove cable sheath

2. Put screening braid in place, and fix with sliding

ring

3. Assemble

HARAX

®

elements

4. Cut off the ends of the cables at the splicing ring

and the screening braid at the sliding ring

5. Screw tight

6. The coupling ring must be screwed as far as the

stop on the contact carrier.

Attention!

For reconnection cut off the used cable end and

repeat steps 1 to 6.

The

HARAX

®

principle

l

The cores are terminated automatically by screwing

the coupling ring onto the contact carrier. This

guides the cores through ducts in the splicing ring,

positioning them accurately. A new design of

insulation displacement contact blade, guided by

contact ducts permits the individual cores to be

terminated reliably.

l

The screening braid is passed laterally through the

slotted seal, and is fixed by a sliding ring.The sliding

ring provides a transition between the screen and

the housing.

l

After tightening the coupling ring, the sealing ring

provides cable strain relief and protection to IP 67

against dust and water spray.

Working current [A]

Ambient temperature [°C]

1 = Wire gauge

0.34 mm²

M12-L, shielded

Frequency [Hz]

Near end crosstalk [dB]

Limit acc. ISO/IEC 11801

M12-L, shielded

Connectors

Screening attenuation diagram

Page 37

02

.

13

M12 4 21 03 281 1405

M12 21 01 010 2003

HARAX

®

circular connector M12-L

No. of

Identification Series contacts Part No. Drawing Dimensions in mm

Circular connector

M12-L, shielded

male

D-coding for Ethernet

straight version

Seal

M12-L

Connectors

View:

Mating side

Page 38

02

.

14

Han-Brid®Quintax 3A

Description Data interface

General information

Power supply

The Han-Brid®series combines a data and power

interface for industrial communication in the

smallest possible space.

The components in this hybrid connector family

all contain the facility to load power contacts rated

at 50 V 10 A to provide a power supply for

distributed devices. This means that a power

supply can be provided to all devices in a bus

structure via a single connector.

l

Han-Brid®Quintax 3A for 4-wire bus systems

and Ethernet networks with continuous screen

connection.

The contact inserts can be used either in the

standard plastic housing or the metal housing

from the Han

®

3A series. The protection level of

the housings corresponds to DIN EN 60 529,

IP 65.

l

Can be connected to screened 4-wire cables

l

Can be used for all 4-wire bus systems

l

Accepts screened cable with a diameter from

3 to 9.5 mm

l

Continuity of screen is independent of housing

potential

l

Cable connection in accordance with DIN EN

50 173, Category 5

l

Standard Han D®male and female crimp

contacts

l

Rated current: 10 A

l

Rated voltage: 50 V

l

Connection range: 0.14 to 2.5 mm² stranded

l

Approval: UL

4 contacts + screening

+ 2 power contacts

For use in Han

®

3A hoods with metric cable gland

Connectors

Technical characteristics

Transmission properties in accordance with

Category 5 ISO/IEC 11 801:2002 and EN 50173-1

Protection level IP 65

Wire gauge data: 0.14 - 2.5 mm² stranded

AWG 26 - 14

Wire gauge

power supply: 0.14 - 2.5 mm² stranded

AWG 26 - 14

Temperature range: -40 °C … +70 °C

Cable sheath diameter: 3 mm - 9.5 mm

Mating cycles: ≥ 500

Page 39

02

.

15

Han-Brid®Quintax 3A

– 09 15 003 3001 09 15 003 3101

3 - 9,5 09 15 004 3013 09 15 004 3113

M

M

F

F

Cable-Ø

Part No.

Identification mm Male insert (M) Female insert (F) Drawing Dimensions in mm

4 contacts + screening

+ 2 power contacts

For use in Han

®

3A hoods with metric cable gland

Quintax insert

Quintax Z contact

Zinc alloy

Order crimp contacts

separately

see page 02.16

Cable clamp for cable

diameter 3 - 6 and

6 - 9.5 mm is supplied

with the inserts

Connectors

Page 40

02

.

16

Accessories

Wire gauge

Part No.

Identification (mm2) Male contacts Female contacts Drawing Dimensions in mm

Crimp contacts

silver plated

0.14-0.37

09 15 000 6104 09 15 000 6204

0.5 09 15 000 6103 09 15 000 6203

0.75 09 15 000 6105 09 15 000 6205

1.0 09 15 000 6102 09 15 000 6202

1.5 09 15 000 6101 09 15 000 6201

2.5 09 15 000 6106 09 15 000 6206

gold plated

0.14-0.37

09 15 000 6124 09 15 000 6224

0.5 09 15 000 6123 09 15 000 6223

0.75 09 15 000 6125 09 15 000 6225

1.0 09 15 000 6122 09 15 000 6222

1.5 09 15 000 6121 09 15 000 6221

2.5 09 15 000 6126 09 15 000 6226

Connectors

0.14-0.37 mm2AWG 26-22 0.90 mm 8 mm

0.5 mm

2

AWG 20 1.10 mm 8 mm

0.75 mm

2

AWG 18 1.30 mm 8 mm

1. mm

2

AWG 18 1.45 mm 8 mm

1.5 mm

2

AWG 16 1.75 mm 8 mm

2.5 mm

2

AWG 14 2.25 mm 6 mm

Wire gauge

Identification (mm2) Part No.

HARTINGcrimping tool

with locators

for all Han D

®

contacts

0.14 - 1.5 mm² 09 99 000 0021

BUCHANANcrimping tool

for all Han D®contacts

0.14 - 4.0 mm² 09 99 000 0001

Removal tool

for Han D®contacts 09 99 000 0012

Locator

09 99 000 0311

Plug gauge

0.14-0.25

09 99 000 0203

0.37 09 99 000 0125

0.5-1.0

09 99 000 0007

1.5 09 99 000 0008

2.5 09 99 000 0007

Wire gauge Stripping

ø

(stranded) length

Page 41

02

.

17

Accessories

Identification Part No. Drawing Dimensions in mm

Hoods

l

Han®3A hood with integral sealing – Protection level: IP 65

IP 67 under preparation

l

Plastic versions

l

Metal versions

l

EMC versions

l

Han®HPR (pressure tight and EMI protected)

l

Han-Brid®Quintax can be fitted exclusively in hoods with metric threads

Further information can be found in our catalogue “Heavy Duty Han®connectors”

Hood

straight, metric Plastic grey

1)

19 20 003 0423

1)

Plastic black

1)

19 20 003 0426

1)

Metal

1)

19 20 003 1443

1)

HPR 19 40 003 0400

Hood

right angled, metric Plastic grey

1)

19 20 003 0623

1)

Plastic black

1)

19 20 003 0626

1)

Metal

1)

19 20 003 1643

1)

Housing

Plastic grey 09 20 003 0320

Plastic black 09 20 003 0327

Metal 09 20 003 0301

HPR 09 40 003 0301

Cable to cable hood

metric Plastic grey 19 20 003 0720

Plastic black 19 20 003 0727

Metal 19 20 003 1750

Cable gland

metric, M20,

cable-Ø 5 - 9 mm Plastic grey, IP 65 19 00 000 5180

cable-Ø 5 - 9 mm Metal, IP 65 19 00 000 5080

cable-Ø 6 - 12 mm Plastic black, IP 65 19 00 000 5132

1)

with integral sealing

Protection cover Han®3A

Plastic black

1)

09 20 003 5409

1)

Metal

1)

09 20 003 5425

1)

Connectors

Page 42

02

.

18

Notes

Connectors

Page 43

03

.

01

Cables for Industrial Ethernet . . . . . . . . . 03.02

Cable assemblies for Industrial Ethernet 03.04

System cables

Page

Directory chapter 03

System

cables

Page 44

03

.

02

09 45 600 0100

System cables

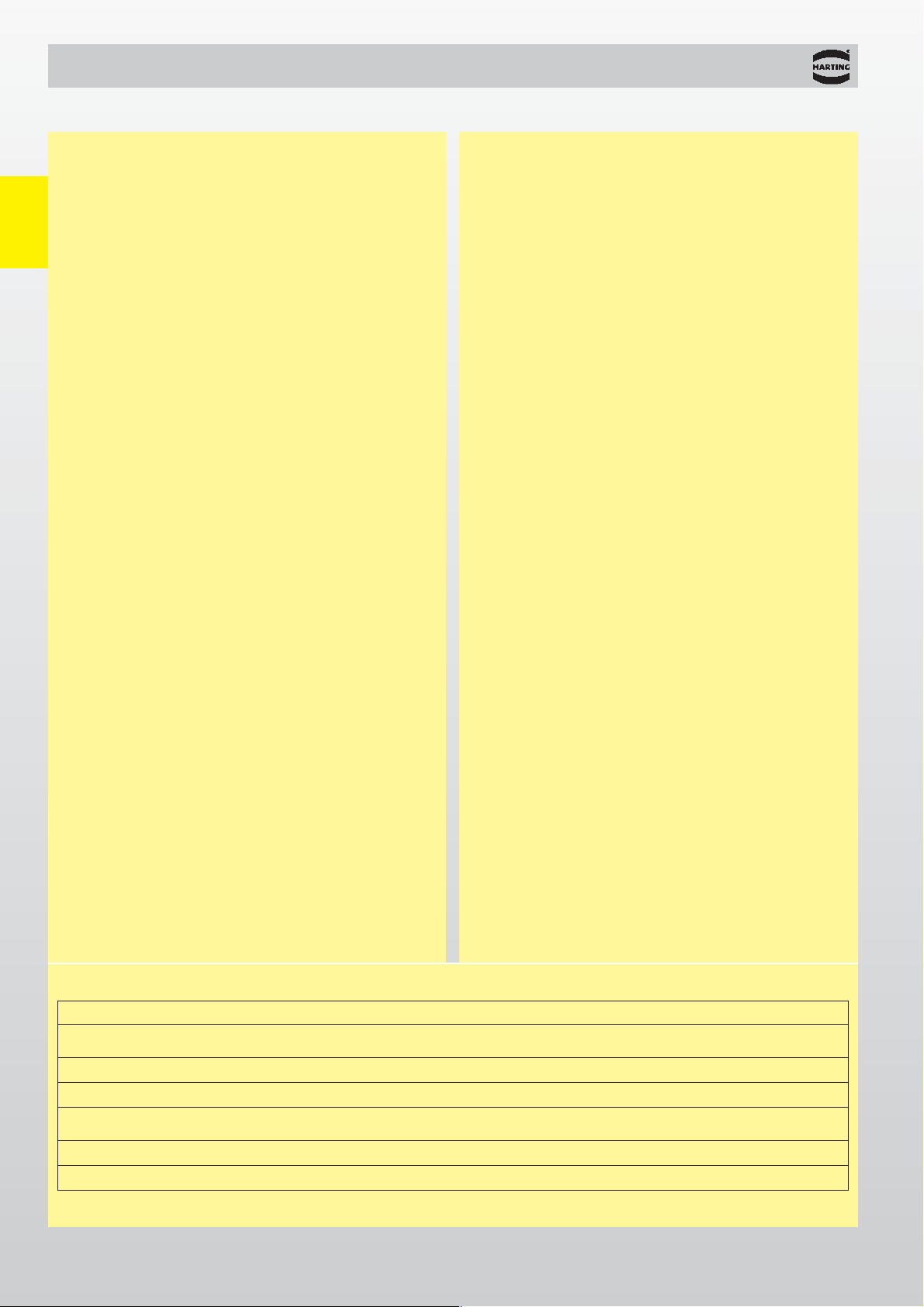

Cable for Industrial Ethernet

Industrial Ethernet Shielded

Twisted Pair Standard Cable

meeting the Category 5 cabling standard.

Specially for industrial applications in

structured cabling of Ethernet networks.

Radially symmetrical structure, with four

solid AWG 22/1 cores arranged as star

quad. Particularly good immunity to electromagnetic interference through double

screening.

The cable is specially designed for

assembly to the HARTING RJ Industrial

®

family of connectors.

Length: 100 m reel

Electrical properties

Cabling standard in accordance

with ISO/IEC 11801:2002: Category 5

Loop resistance: max. 124 Ohm / km

Insulation resistance: min. 500 MOhm x km

Characteristic impedance

at 1 MHz .... 100 MHz: (100 ± 15) Ohm

Near end crosstalk attenuation

at 100 MHz (typical): 50 dB / 100 m

Far end crosstalk attenuation

at 100 MHz (typical): 45 dB / 100 m

Attenuation coefficient

at 100 MHz (typical): 19.5 dB / 100 m

Mechanical properties

Wire type: 2YY(ST)CY 2X2X0.64/1.5-100 GN

Sheath: PVC green dia. (6.5 ± 0.2) mm

Cores: solid, AWG 22/1 (dia. 0.64 mm)

Core colour sequence: white - yellow - blue - orange

Service temperature: -40 °C … +70 °C

Installation temperature: -20 °C … +60 °C

Storage/transport

temperature: -40 °C … +70 °C

Minimum bending radius: Multiple bending 15 x diameter

One time 10 x diameter

Max. permissible tension: 150 N

Description Part No. Technical characteristics

System

cables

Page 45

03

.

03

09 45 600 0101

System cables

Cable for Industrial Ethernet

Industrial Ethernet Shielded

Twisted Pair Trailing Cable

meeting the Category 5 cabling standard.

Specially designed for industrial application

of Ethernet cables in power chains and

moving machine parts. Radially

symmetrical structure, with four stranded

AWG 22/7 cores arranged in star quad

format. Particularly good immunity to

electromagnetic interference through

double screening.

This cable is specially designed for

assembly to the HARTING RJ Industrial

®