Page 1

harman/kardon

Model

FL8550

5 Disc Compact Disc Changer

Service Manual

CONTENTS

LASER BEAM/SAFETY PRECAUTIONS ......…....... 2

SPECIFICATIONS ..………………. …………..…...... 4

CONTROLS.....……………………………….............. 5

REAR PANEL CONNECTIONS…………………....... 6

REMOTE CONTROL.........…………………….. ….... 7

TROUBLE SHOOTING GUIDE .................……........ 8

SERVICE BULLETIN H/K9901...................……........ 9

SERVICE BULLETIN H/K2000-09.............……....... 10

TECH TIP HKTT2003-06..........…….......……...….... 11

DISASSEMBLY INSTRUCTIONS ...............……..... 12

EXPLODED VIEWS...............………………...…….. 17

harman/kardon, Inc.

250 Crossways Park Dr.

Woodbury, New York 11797 Rev1 11/2003

ADJUSTMENT PROCEDURES……….……...21

AUDIO TEST PROCEDURE…………………..25

CIRCUIT DESCRIPTIONS ...............…….......27

I.C. SPECIFICATIONS ....……...………......... 35

ELECTRICAL PARTS LIST ..………………... 61

MECHANICAL PARTS LIST ......…………..... 67

TROUBLESHOOTING FLOW CHARTS……. 68

BLOCK DIAGRAM .…………………………... 73

PCB LAYOUTS .…………………………….....74

SCHEMATIC DIAGRAMS .......... ……........... 78

PACKING………….........…….....…………..... 83

Page 2

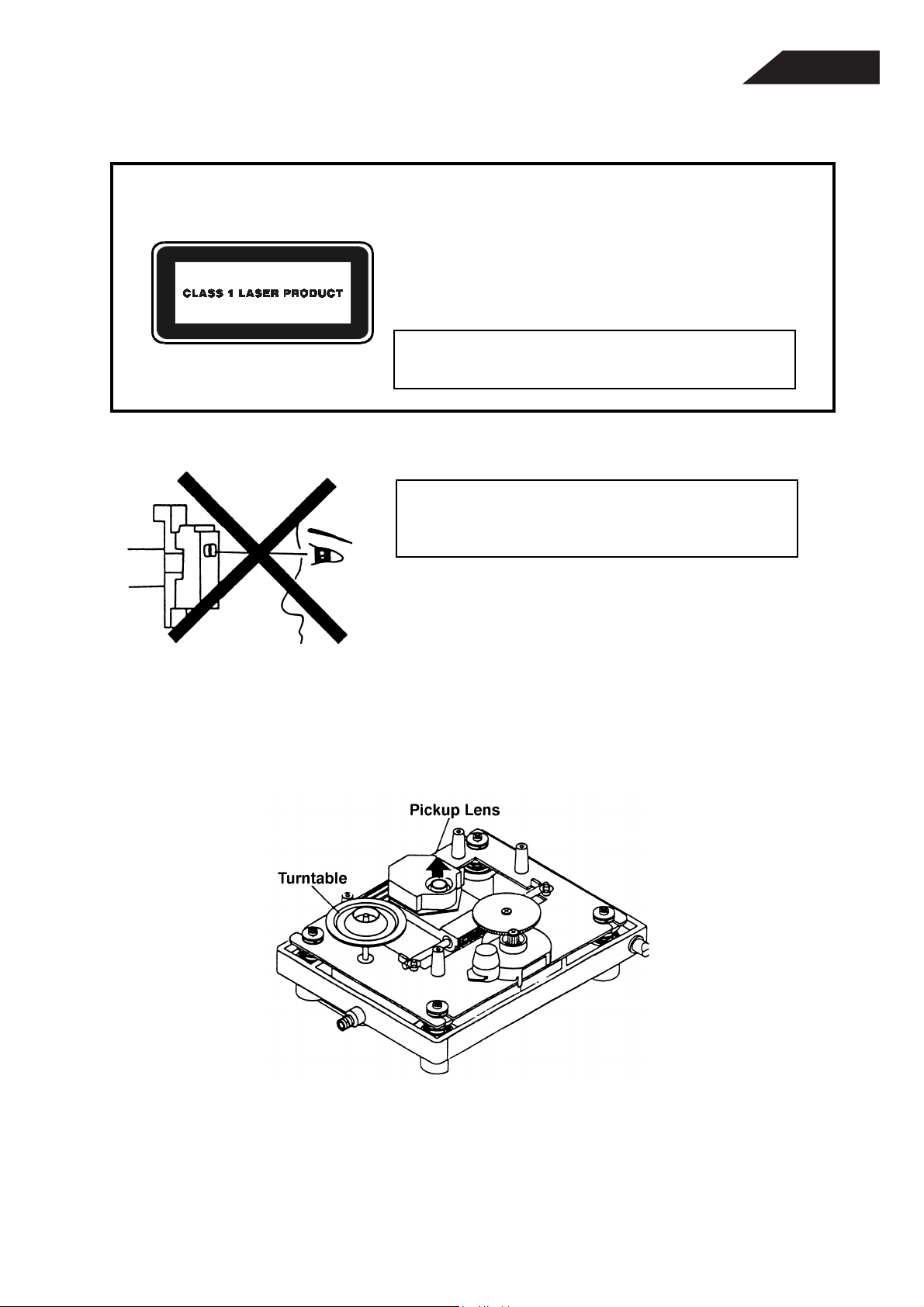

LASER BEAM SAFETY PRECAUTIONS

CLASS 1 LASER PRODUCT

CAUTION

Invisible laser radiation when the unit is open.

Do not stare into beam.

CAUTION: USE OF ANY CONTROLS, ADJUSTMENT, OR

PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

Do not look directly at the laser beam

coming from the pickup or allow it to

FL8550

strike against your skin.

This compact disc player uses a pickup that emits a laser beam. The laser beam is emitted from the

location shown in the figure. When checking the laser diode, be sure to keep your eyes at least 1 foot away

from the pickup lens when the diode is turned on. Do not look directly at the laser beam.

CAUTION:

Using controls and adjustment, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

2

Page 3

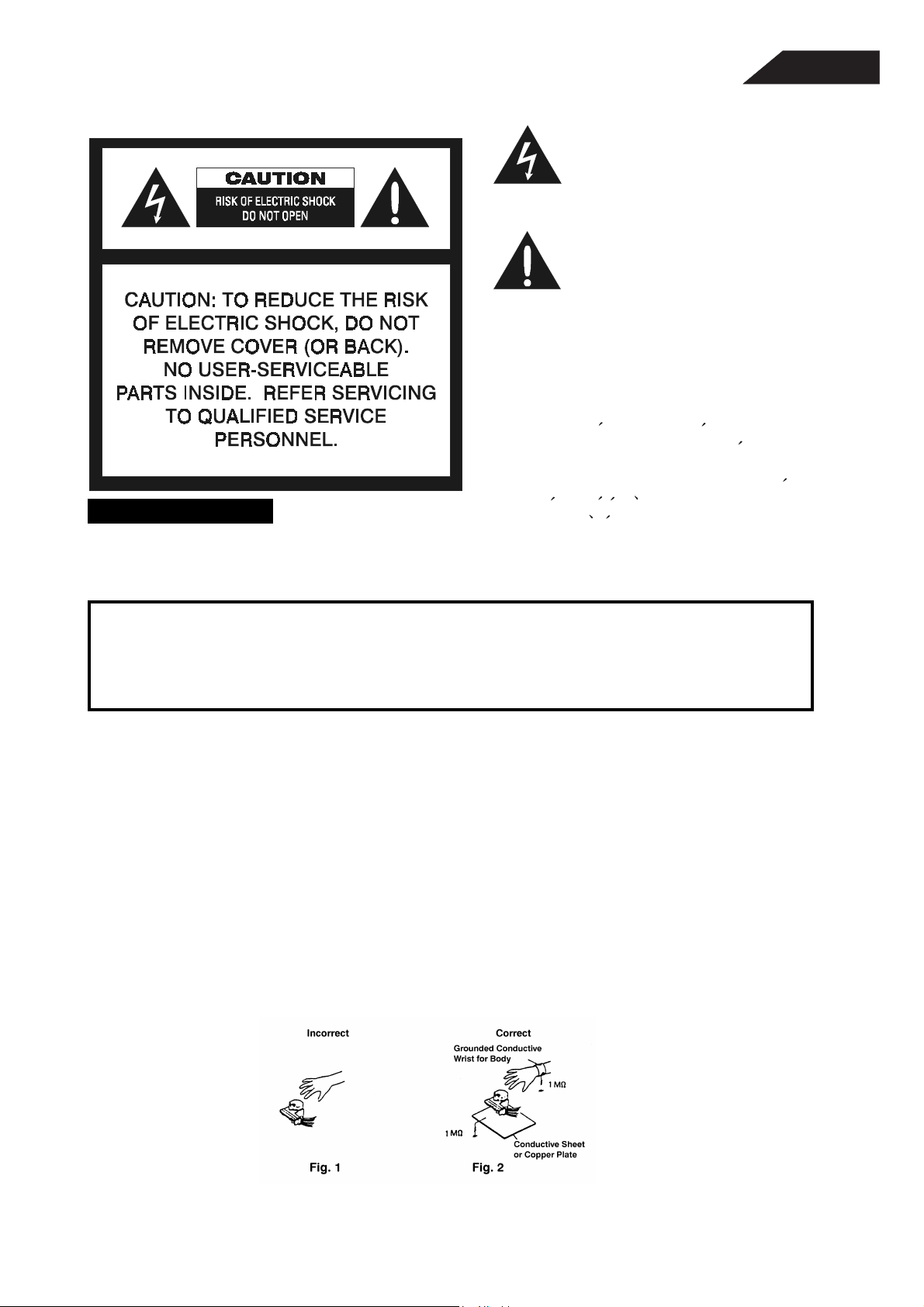

SAFETY PRECAUTIONS

WARNING

To prevent fire or shock hazard, do not

FL8550

This symbol is intended to alert the user to

the presence of uninsulated "dangerous

voltage" within the product's enclosure that

may be of sufficient magnitude to constitute a risk of electric shock to persons.

This symbol is intended to alert the user to

the presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

Caution: To p re v e nt e l e ct r i c s h o ck d o not use this

(polarized) plug with an extension cord, receptacle or other outlet unless the blades can be

fully inserted to prevent blade exposure.

Attention: Pour prevenir les chocs electriques ne pas

utiliser cetre fiche polarisee avec un

prolongateur, une prise de courant ou une autre sortie de courant, sauf si les lames prevent

etre inserees a fond-sans en laisser aucune

partie a decouvert.

expose the unit to rain or moisture.

HANDLING LASER PICKUP

The laser diode in the optical system of this player can be damaged by electrostatic discharge from

your clothes or your body. Proper electrostatic grounding for service personal is required during servicing.

BEFORE REPAIRING THE COMPACT DISC PLAYER

Preparation

Human Body Grounding:

Many of the components used in this compact disc player, including the laser pickup, are sensitive to

electrostatic discharge. Service personal should be grounded with an electrostatic armband (1 Mohm).

Caution:

Static charge on clothing does not escape through a body grounding wrist band.

Be careful not to contact the pickup or electrical components with your clothing.

Workbench and Tool Grounding:

A properly-grounded electroconductive plate (1Mohm) or metal sheet should be fitted to the workbench

surface. Tools and instruments (such as soldering irons and scopes) should be grounded to prevent AC

leakage.

Note: Laser diodes are so susceptible to damage from static electricity that, even if a static discharge does

not ruin a diode, it can shorten its life or cause it to work improperly.

3

Page 4

GENERAL INFORMATION

4

1. Power Consumption Operating < 18W; Standby < 5W

2. Power Supply 230VAC 50Hz or 120VAC 60Hz

3. Dimensions 440 x 130 x 386 mm

4. Product Outlook Refer to attached diagram

5. Remote Unit RT03, harman/kardon remote code

6. Compliance Requirement CE LVD EN60065

CE EMC EN55013, EN61000-3-2, EN61000-3-3

NRTL/C

FCC

HDCD

7. Disc Changer Mechanism 5 disc carousel; Play 1 change 4

FL8550

8. Sound Processor HDCD

9. CD Servo System Auto Alignment

AUDIO SPECIFICATION

Typical Limit

Output Level 1KHz 0 dB(no HDCD) 2.0 Vrms ± 1 dB

Frequency Response 20Hz~20KHz reference 1KHz +0-0.5 dB +0.5-1 dB

THD 1KHz 0 dB 30KHz LPF 0.004% 0.01%

THD 20Hz~20KHz 0 dB 30KHz LPF 0.015%

S/N 1KHz 0 dB A-weighted 105 dB 100 dB

Dynamic Range 100 dB 95 dB

Channel Seperation 1KHz 0 dB 95 dB 90 dB

Channel Balance ± 0.5 dB ± 1 dB

De-emphasis ± 0.5 dB ± 1 dB

Maximum Headphones Level 1KHz 0 dB 32 ohm Load 1.5 Vp-p ± 2 dB

Black Dot TCD725A 1000 µm 600 µm

Interruption MCD-131 900 µm 600 µm

Finger Print TCD725A 75 µm 65 µm

Vertical Deviation MCD-151 1.00 mm 0.92 mm

Eccentricity TCD712 140 µm 140 µm

8 cm disc TCD783 Last Track Last Track

Access Time 1st to last track YEDS18 4 sec 10 sec

7

Page 5

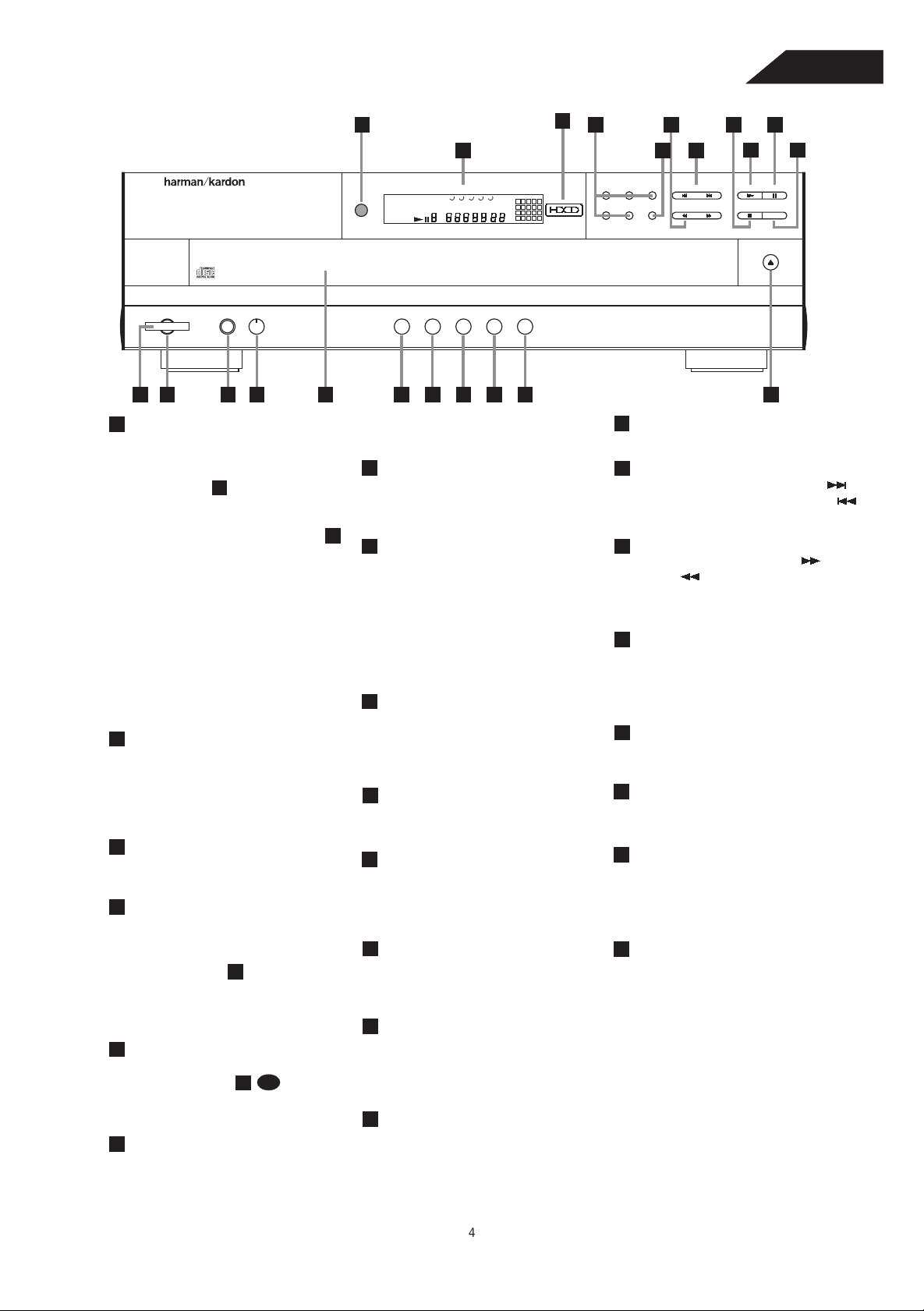

Front Panel Controls

5

21

20

22

18

FL8550

16

15

14

13

12

1719

FL 8550

Power Phones Phones Level

1

2

Power Switch

1

3

4

: Press this switch

5

to change the FL8550 from STANDBY

to ON. When the unit is first

connected to AC power, the

Mode Indicator

2

Status

will turn Amber

(STANDBY mode). Press this switch

to turn the unit ON; indicator will

Green and the

Information Display

20

will illuminate. Press the switch again

to turn the unit off, in STANDBY mode.

When the FL8550 is connected to a

switched AC outlet, such as those

found on the back of many audio

products, when power is applied it will

return to whatever state it was left in

previously, whether ON or STANDBY.

In this case, when always left ON,

further use of the power switch is not

needed.

Status Mode Indicator

2

: When the

FL8550 is in the ON mode, this

indicator will glow green. When the

unit is off, the indicator will glow

amber, indicating that the unit is still

connected to the AC mains supply.

3

Headphones Jack

: Connect a set

of standard headphones to this jack

for private listening.

4

Headphones Level

: Turn this

knob to increase or decrease the

volume level for headphones

connected to the FL8550's

Headphones Jack

3

. Note that

changing this level will not change the

sound level for the unit's main output,

as that remains constant.

CD Drawer

5

: This drawer holds the

discs that will be played. Press the

Open/ Close

button to open

11

1

the drawer so that discs may be

inserted.

Time Button

: In normal operation,

this display will show the running time

of the track being played. Press the

button once to check the time

remaining for the track in play. Press

321

Disc Skip54

DISC TRACK

1 32 4 5

INTRO

MIN

SEC

PROGRAM

RANDOM

ALL 1 DISCS

REPEAT 1A-B

Time Repeat Intro Clear Program

3

1

2

4

5

6

7

8

9

10

11

13

12

14

15

16

18

17

19

20

667 8 9 10 11

this button again to view the total play

time remaining for the disc in play.

7

Repeat Button

: Press this button

once to constantly repeat the track

currently being played. Press it a

second time to repeat the entire disc.

Intro Button

8

: Press this button to

put the FL8550 in the Intro Scan

mode. When you press the button,

the unit will play the first 10 seconds

of each track on the disc, and then

Stop Button

15

stop the disc currently being played.

16

Skip Button

this button to move to the next track ,

or to move back to the previous track

on the disc being played.

Search Button

17

of this button to search forward or

backwards through a disc to

locate a particular portion of the

selection of the disc being played.

move to the next track. Press the

Disc Skip Button

button again to defeat the function

and continue full play of the current

track.

18

button to change to the next disc. If a

disc position is empty, the FL8550 will

automatically search for the next

9

Clear Button

: Press this button to

position that contains a disc.

remove tracks from a programmed

Disc Select Buttons

sequence. Each press of the button

will remove one track, starting with

the last track programmed to play.

Program Button

10

: This button is

used to program the playback of a

disc in a particular order.

Open/ Close

11

open or close the disc drawer. DO

: Press this button to

NOT push the drawer to close it, or

damage to the transport mechanism

may result.

Random Button

12

: Press this

button to put a disc into play, and to

have all of the tracks played in a

19

of these buttons to select the disc in a

specific position in the CD drawer.

20

Information Display

provides details about the operation

of the FL8550.

Remote Sensor

21

behind this window receives

commands from the remote control.

Keep this area clear if you wish to use

the FL8550 with a remote control.

22

HDCD Indicator: This LED will light

automatically when a CD with HDCD

encoding is playing.

random order.

Pause Button

13

: Press this button

once to momentarily pause a disc.

When the button is pressed again, the

disc will resume play at the point it

was paused.

Play Button

14

: Press this button to

start the playback of a CD. If the CD

drawer is open, pressing this button

will automatically close the drawer.

PausePlaySkip

Stop RandomSearch

Open/Close

: Press this button to

: Press either side of

: Press either side

: Press this

: Press one

: This display

: The sensor

4

Page 6

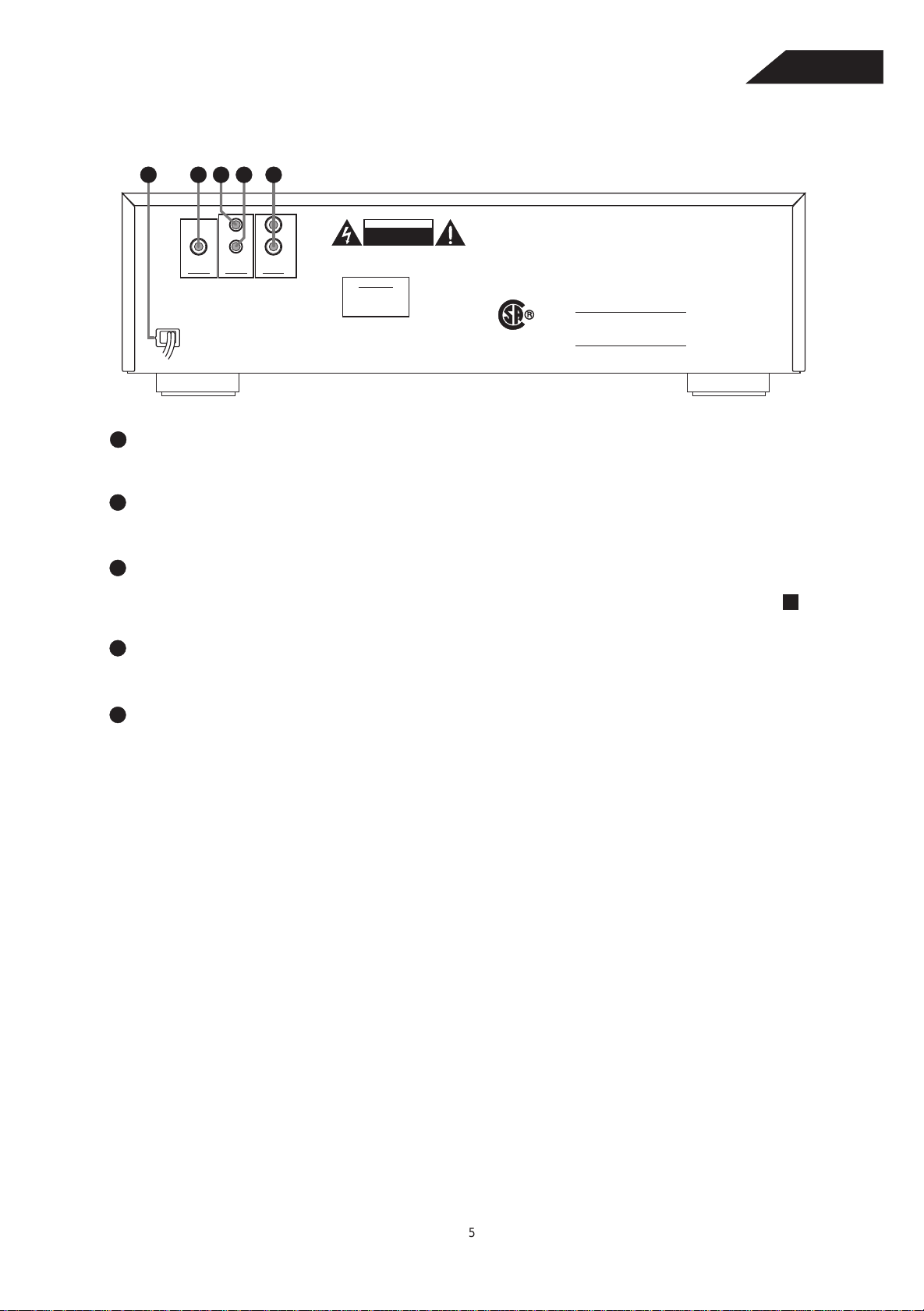

Rear Panel Connections

6

2 4 531

FL8550

(YCL).

MODEL NO: FL8550

HARMAN KARDON

NORTHRIDGE

CALIFORNIA, U.S.A.

MADE IN CHINA

LEFT

IN

RIGHT

OUT

DIGITAL

OUTPUT

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference,

AC INPUT

AC 117V / 60Hz

1

and (2) this device must accept any interference

received, including interference that may cause

20W

undesired operation.

AC Power Cord

OUTPUTREMOTE

AUDIO

CAUTION

RISK OF ELECTRIC SHOCK

RISK OF ELECTRIC SHOCK

DO NOT OPEN

SHOCK HAZARD : DO NOT OPEN.

SHOCK HAZARD : DO NOT OPEN.

AVIS:RISQUE DE CHOC ELECTRIQUE-NE PAS OUVRIR.

AVIS:RISQUE DE CHOC ELECTRIQUE-NE PAS OUVRIR.

WARNING: "TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE

TO RAIN OR MOISTURE."

DO NOT OPEN

SERIAL NO.

NRTL/C

LR46800

CSA 22.2

UL 1270

PRODUCT COMPLIES WITH DHHS

RULES 21CFR SUBCHAPTER J,

APPLICABLE AT DATE MANUFACTURED:

Connect this plug to an AC outlet. If the outlet is switch is controlled, make certain that the switch is in the ON

position.

2

Coaxial Digital Output

Connect this jack to the coaxial digital input of an external digital-to-analog converter for direct access to the digital

signals of the FL8550. DO NOT connect this jack to the standard audio inputs of any device.

3

Remote Control Input

Connect the output of a remote infrared sensor or the remote control output of another compatible Harman Kardon

product. This will enable the remote control system to operate even when the front panel is

Remote Sensor

21

blocked. It will also allow use of the FL8550 with optional, external control systems.

4

Remote Control Output

Connect this jack to the input of another compatible Harman Kardon remote controlled device to have the remote

sensor on the FL8550 provide signals to other products.

5

Fixed Audio Outputs

Connect these jacks to the CD audio inputs of your receiver, surround processor or preamplifier.

5

Page 7

Remote Control Functions

7

1

FL8550

. Press this button to open or close

Open/ Close Button:

1

the disc drawer. The drawer may also be closed by

pressing the button . DO NOT push the

drawer, as damage to the transport mechanism may

result.

Play

14

8

Disc Select Buttons:

2

DISC NO.

1 2 3

2

4 5

DISC

SKIP

OPEN/

CLOSE

REPEAT

16

15

PROGRAM321

14

4 5 6 CLEAR

13

3

TIME987

12

+10 INTRO

10

11

4

RANDOMSEARCH

10

5

SKIP

9

8

6

7

select the disc in a specific position in the CD drawer.

Numeric Buttons:

3

specific track on a disc. The FL8550 will immediately

search for the track and begin to play it. For tracks 1

through 10 on a disc, you need only press the desired

number. For tracks 10 and above, press the button

to select the first digit of the track number, and then

press the second digit from these numeric buttons.

These buttons are also used to enter track numbers into

the memory for pre-programmed play lists.

+10 Button:

4

track number above 10. Each press of the button

increases the first digit one increment. Press it once to

start accessing tracks 10 through 19 twice to start

accessing tracks 20 through 29, and so forth. For

example, to select track 22, press the button twice,

and then press the button .

Search Buttons:

5

or backwards through a disc to locate a particular

portion of the selection being played.

Skip Buttons:

6

next track , or to move back to the previous track

on the disc being played.

Press this button to select the first digit of a

Press one of these buttons to

Press these buttons to select a

10+

+10

2

Press these buttons to search forward

Press one of these buttons to move to the

3

4

7

FL 8550

11

Intro Button:

play the first 10 seconds of each track on the disc, and then move to the next track. Press the button again to defeat

the function and continue full play of the current track.

Time Button:

12

of the track being played. Press the button once to check the time remaining for the track in play. Press the button a

third time to view the total play time remaining for the disc in play.

Clear Button:

13

remove one track, starting with the last track programmed to play.

Program Button:

14

Repeat Button:

15

to repeat the entire disc.

Press this button to put the FL8550 into the Intro Scan mode. When you press this button, the unit will

Press this button to select the time display. In normal operation, the display will show the running time

Press this button to remove tracks from a programmed sequence. Each press of the button will

This button is used to program the playback of a disc in a particular order.

Press this button once to constantly repeat the track currently being played. Press it a second time

Stop Button:

being played.

Play Button:

8

CD. If the CD drawer is open, pressing this button will

automatically close the drawer.

Random Button:

9

and to have all of the tracks played in a random order.

Pause Button:

10

stop a disc. When the button is pressed again, the disc

will resume play at the point it was stopped.

Press this button to stop the disc currently

Press this button to start the playback of a

Press this button to put a disc into play,

Press this button once to momentarily

Disc Skip Button:

16

automatically search for the next position that contains a disc.

Press this button to change to the next disc. If a disc position is empty, the FL8350 will

6

Page 8

Troubleshooting Guide

8

SYMPTOM

CAUSE

FL8550

SOLUTION

No lights on front panel

Remote does not appear

to operate

Front panel lights, but CD

does not play

Play indicator lights, but

no sound is heard

Sound skips or stutters

during play

Sound is continually distorted

• No AC power

• Main Power Switch turned off

• Weak batteries

• Blocked sensor

• Disc upside down

• Moisture inside unit

•Poor connections

• Wrong source selected

• Disc may be damaged

• Surface vibrations

• Incorrect input

• Make certain that the AC power cord is plugged into

a live outlet.

• Turn on Main Power Switch.

• Install fresh batteries, observing polarity indications.

• Remove obstructions from the front panel sensor or

connect a remote sensor to the

on the rear panel.

• Reload disc with label side facing up.

• Leave the unit turned ON for 30 minutes to allow

moisture to evaporate.

• Make certain connections are secure and made

to the correct (e.g.,

• Select CD source on receiver or preamp.

• Try another disc.

• Isolate the unit from vibration by placing it on a

firm surface or move it further away from speakers.

• Make certain that the FL8550 is connected to a linelevel audio input, NOT a digital audio or phono input.

CD) input.

Remote In jack

Page 9

9

harman/kardon

Service Bulletin

Service bulletin # H/K9901 Rev1 November 2002

Warranty Labor Rate: Major Repair

To: All harman/kardon Service Centers

Models: FL8350/FL8550

Subject: “No disc” reading in display

When a CD is in the carousel at the play position, Infra red light emitted by IR LED D3 is reflected onto IR Photo

sensor D2. D3 and D2 are on the PCB located underneath the carousel. When the amount of IR light received

by D2 is insufficient, D2 will not saturate and the display will read “No disc”.

In the event you receive an FL8350 or FL8550 with the complaint: Display reads “No disc” but a disc is in

the tray, perform the modification as listed below:

Lay the unit on a padded surface.

1)

2)

Remove the (7) Black Philips screws holding the Top Cover on; remove cover.

3)

Lay unit on its side and remove (5) Black screws on bottom which hold front panel to chassis.

4)

Lay unit upright, remove (2) Black screws at top front section holding front panel to the front tray retainer brackets.

5)

Pull front panel away, cut plastic cable ties if necessary, and lay the front panel face down on the table.

6)

Remove (4) tray retainer brackets, (1) Plated screw each. (Bracket on left side may have a ground terminal).

7)

Pull the carousel tray up and out of the unit; turn upside-down to expose the sensor board.

8)

Remove the (2) Plated screws holding the sensor board to tray.

9)

Lift the board and unplug either molex connector CN1 or CN2 to be able to turn board upside-down.

10)

Locate R1 and change from a 470Ω to a 750Ω resistor - h/k part# 1007-501316-000.

11)

Locate R2 and change from a 750Ω to a 470Ω resistor - h/k part# 1004-701316-000.

Alternately, the two above parts may just be “swapped”, as this will result in the correct values.

12) Locate D3 and replace with new infra-red LED - h/k part# 3100-204000-002.

REASSEMBLY:

13) Replace sensor board, screws, and CN1 or CN2 connectors.

14) Turn the carousel tray over and replace back in the track; tray must be positioned all the way at the rear of the unit.

When placed correctly, tray should not glide back & forth on the track.

15) Replace and attach the (4) tray retainer brackets with single screws - ground wire (if present) is re-attached to left

front bracket.

16) Replace the front panel, both with the (5) bottom screws and the (2) screws at the top. Note: Make sure any

washers that were present between the various brackets and the chassis are reinstalled. Replace cable ties as

necessary.

17) Test the player by inserting one or more compact discs, assure unit reads discs in all slots.

18) Locate MCU board, which is mounted vertically on right side of unit. Connect DC Multimeter to Pin 8 (gray wire) of

CN705 (10 pin plug, labeled 'DSNS'), and Pin 2 (red wire) of CN701 (2 pin plug). While playing a disc, DC Multimeter

reading must be between 4.7 V and 5.0 V.

19) Replace top cover and screws.

Model Serial number (120V) Serial number (230V) Status Action

FL8350

FL8550

FL8350

FL8550

YC0001-01001

to

YC0001-37014

YC0003-01001

to

YC0003-08666

YC0001-37015

and above

YC0003-08667

and above

YC0002-01001

to

YC0002-16673

YC0004-01001

to

YC0004-04884

YC0002-16674

and above

YC0004-04885

and above

Needs Modification

Changed by factory

R1 with

R2 with 470 Ω

NONE REQUIRED

Replace:

750 Ω

D3

Page 10

harman/kardon

10

Service bulletin # H/K2000-09 November 2000 This is considered a Minor Repair

To: All harman/kardon Service Centers

Models: FL8350/FL8550

Subject: Carousel does not stop

In the event you receive an FL8350 or FL8550 with the complaint: “The carousel does not stop at a given

disc position, …or passes disc positions intermittently”, perform the modification listed below:

1) Lay the unit on a padded surface.

2) Remove the (7) Black Philips screws holding the Top Cover on; remove cover.

3) In the center of the carousel are a single screw and plated washer; remove these.

4) Underneath the larger plated washer are two smaller fiber washers. These are to be removed permanently.

5) Examine the larger plated washer carefully. Upon replacement of the larger plated washer and screw, make

sure the slightly sharper, stamped edge of the washer is facing upwards.

6) Test the player by inserting one or more compact discs, assure the unit reads discs in all slots, and stops at

all positions.

IF THIS MODIFICATION DOES NOT CORRECT THE PROBLEM

7) Lay unit on its side and remove (5) Black screws on the bottom, which hold the front panel to the chassis.

8) Lay unit upright, remove (2) Black screws at top front section holding front panel to the front tray retainer

brackets.

9) Pull front panel away, cut plastic cable ties if necessary, and lay the front panel face down on the table.

10) In the center of the carousel, once again remove the single screw and plated washer.

11) Lift the carousel up and off the chassis, towards the front of the unit.

12) Turn the carousel upside-down; in the center is a hollow plastic post. Remove any excess lubricant with a

clean dry cloth or paper towel, saving it for re-application. The end of this post must be filed down

approximately 0.020” (0.5mm) with a file, Dremel tool, or similar tool. Be sure not to remove too much

material and keep the surface even (flat). Remove any debris or shavings when finished.

13) Spread and replace the saved lubricant on the new surface of the center post.

Service Bulletin

REASSEMBLY:

14) Replace the carousel and mounting screw + washer.

15) Replace the front panel, both with the (5) bottom screws and the (2) screws at the top. Note: Make sure any

washers that were present between the various brackets and the chassis are reinstalled. Replace cable ties

as necessary. Replace the top cover.

16) Test the player by inserting one or more compact discs, assure unit reads discs in all slots, and stops at all

positions.

Model Serial number (120V) Serial number (230V) Status Action

Remove small fiber washers

FL8350

FL8550

All Serial numbers

affected

All Serial numbers

affected

May need modification

in center screw of carousel; if

necessary file center post

down 0.020” (0.5mm)

harman/kardon Incorporated 250 Crossways Park Drive, Woodbury New York 11797 (516) 496-3400

Page 11

11

harman/kardon

Troubleshooting tips and solutions to common service problems

For models: FL8350/FL8550/FL8380 TIP# HKTT2003-06

Complaint: Unit Will Not Play or Recognize a Disc, “Skipping”.

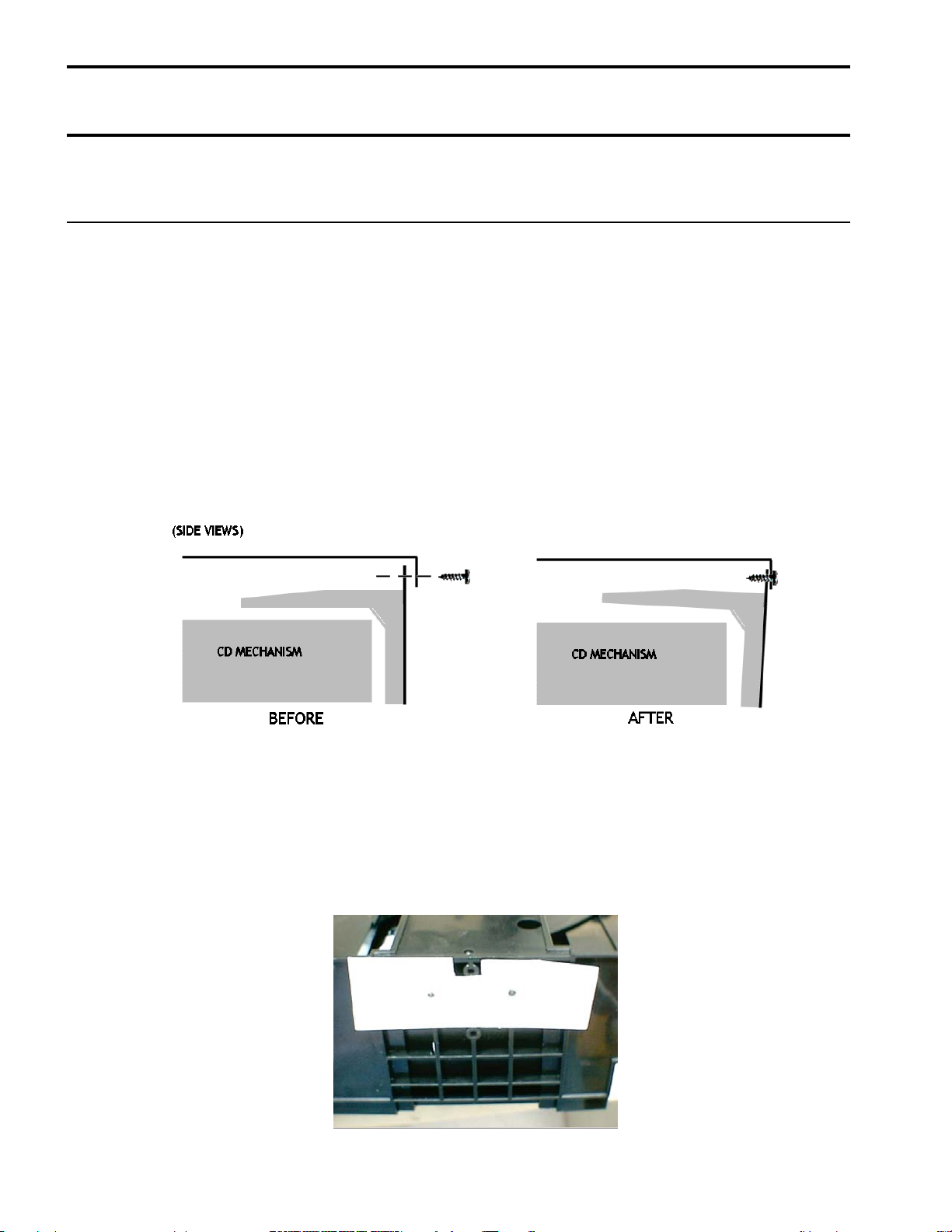

Possible Problem: Misalignment of the top cover and rear panel.

To test, attempt to play the unit with the top cover OFF. If symptoms persist, troubleshoot further. If the

unit will play with the cover OFF, the problem is caused by a misalignment of the top cover and the rear

panel. When the screws are tightened on the top cover, at the rear of the unit, the CD mechanism may

“warp” upward in the area of the clamper arm, which causes a “Will not Play” symptom, which shows up as

an unusual delay, with the word “Disc” in the display, after the “Play” button is pressed.

TECH TIPS

Solutions:

Washers can be added to the top rear screws to fill the gap between the top cover “lip” and rear panel.

Alternately, a spacer can be constructed of fish paper, plastic sheet, or similar material, that will fit

between the Disc Clamper and the inside of the rear panel. Choose thickness as necessary.

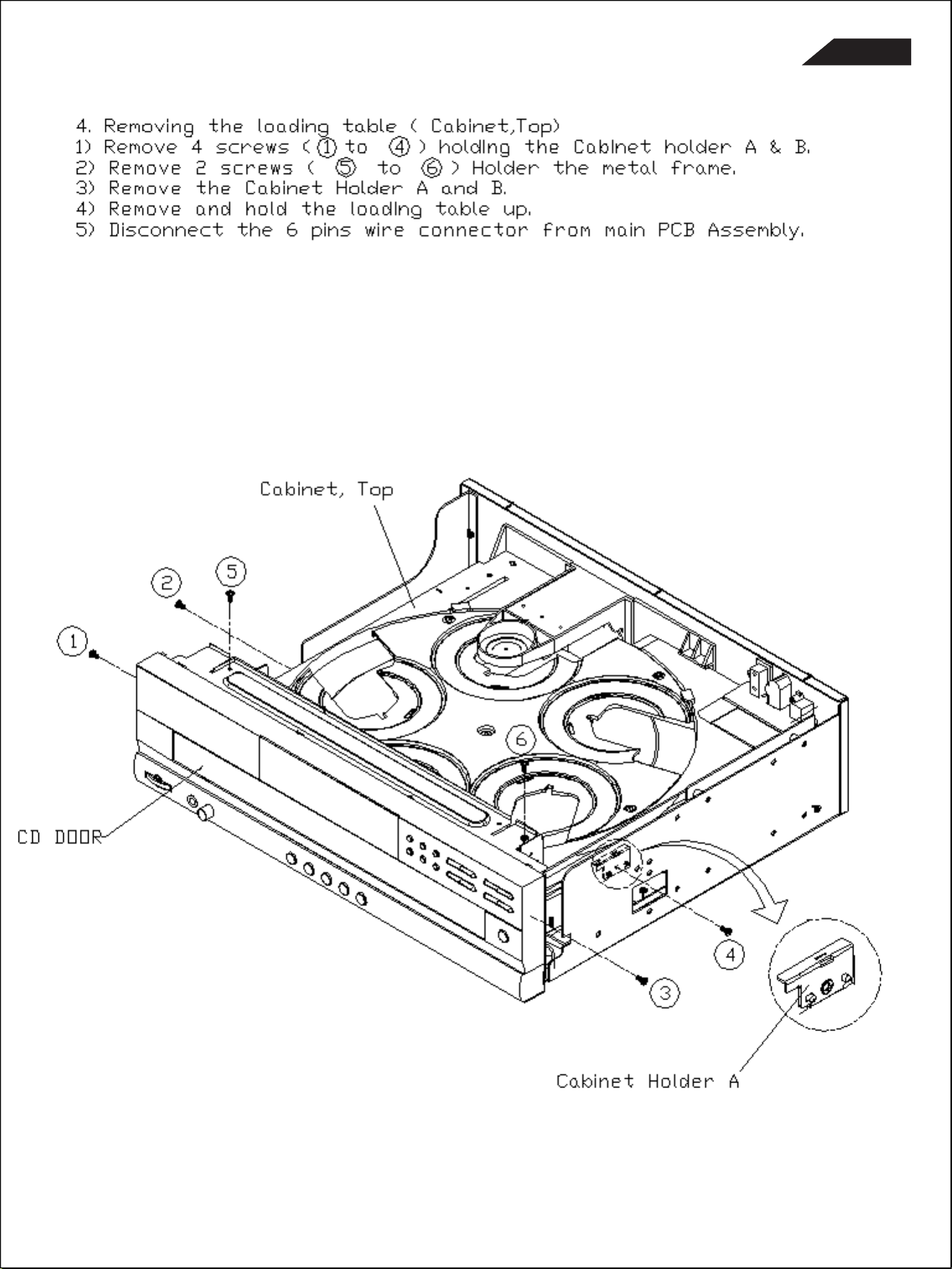

Page 12

FL8550

12

Page 13

FL8550

13

Page 14

FL8550

14

Page 15

15

FL8550

Page 16

FL8550

16

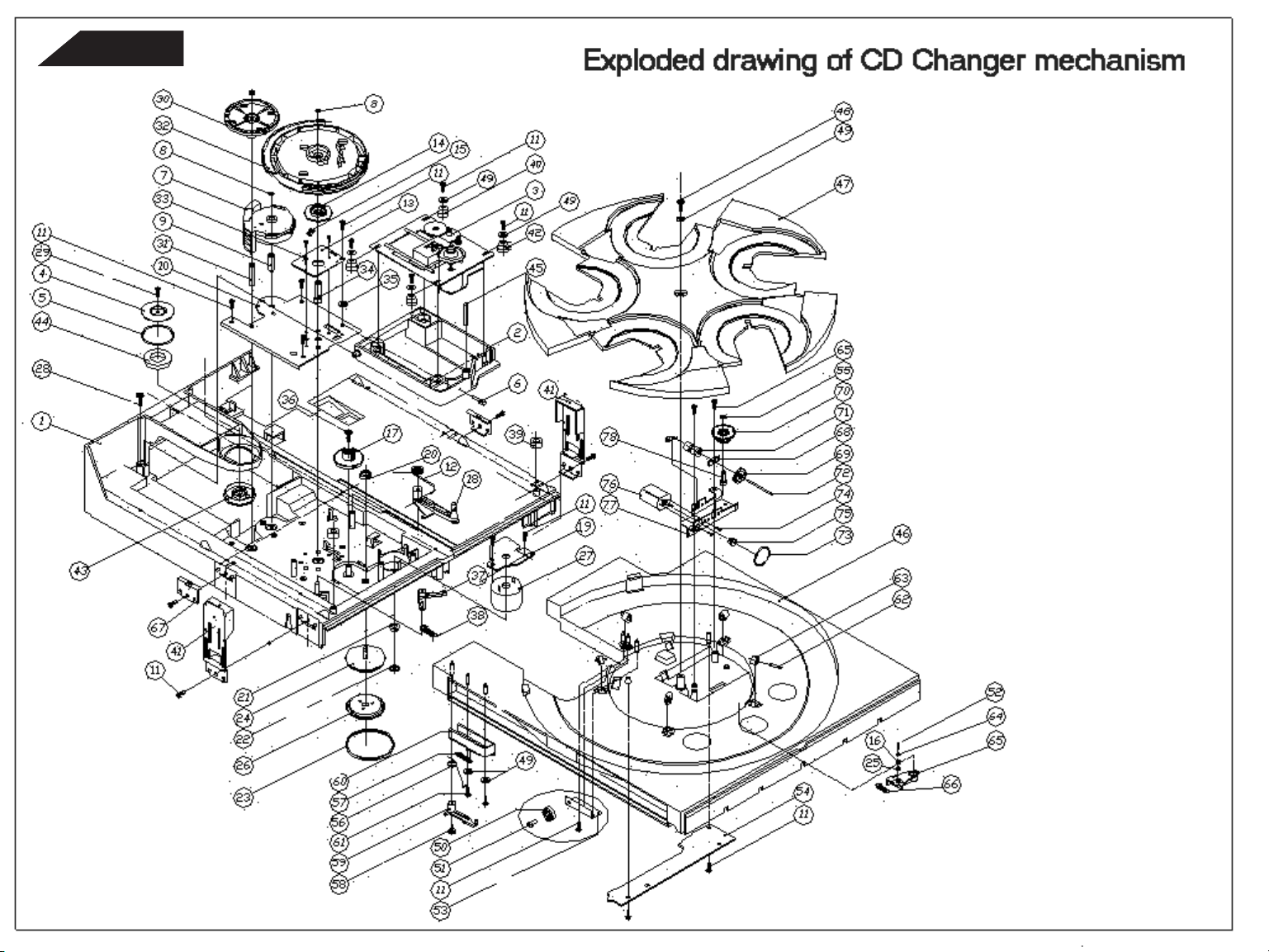

Page 17

FL8550

17

Page 18

FL8550 Exploded Drawing List

18

Seq. No. Part Number Description Qty

1 6583-510002-000-01 TOP CABINET, PAINTED 1.0

2 6583-510004-001 BRACKET, FRONT PANEL 1.0

3 6083-510002-000-01 HARMAN/KARDON FL8350&FL8550 TRAY DOOR(WSILKSCREEN) 1.0

4 9483-501000-111 FL8350 POWER CONTROL BOARD ASSY REV A 1.0

5 6600-010293-000 SPRING, POWER SWITCH 1.0

6 6083-510008-000 *LENS, POWER KNOB 1.0

7 6083-5100015-000 LIGHT SHEET BLACK 1.0

8 6083-510007-000-01 KNOB, POWER PAINTED 1.0

10 6583-510006-000 BRACKET, PHONES (MIC) 1.0

11 7107-212005-022 WASHER M7 1.0

12 7112-517506-022 WASHER M12 1.0

13 6600-120120-000 NUTS M12 1.0

14 6600-120070-000 NUTS M7 1.0

15 6083-510006-000-01 KNOB VR PAINTED 1.0

16 6083-510005-000-01 KNOB, PROGRAM PAINTED 1.0

17 6083-510001-002-02 HARMAN/KARONT FRONT PANEL W/SILKCREEN&P 1.0

18 6083-510003-000-01 HARMAN/KARDON FL8550 DISPLAY LENS (W SILKSCREEN) 1.0

19 6083-510004-000-01 KNOB, DISC PAINTED 1.0

20 9485-801000-261 FL8550 DISPLAY BOARD (VFD) ASSY REV A 1.0

21 6083-510010-000-01 HARMAN/KARDON FUNCTION KNOB (W SILKSCREEN&PAINTED) 1.0

22 6083-510009-000-01 HARMAN/KARDON 'EJECT' KNOB (W SILKSCREEN&PAINTED) 1.0

23 6583-510001-001 BOTTOM CABINET 1.0

24 6029-010012-000-01 PLASTIC FOOT (HOT STAMPING) 4.0

25 6600-070003-000 CD90R05 RUBBER PAD,LEG 4.0

26 6083-510014-000 *BRACKET, 5CD-SIDE 2 1.0

27 9483-501000-232 FL8350 MCU BOARD 1.0

28 6600-020010-000 CD420L01 PCB MOUNT. 4.0

29 9485-501000-291 FL8550 DIGITAL OUTPUT BOARD 1.0

30 6600-180007-000 AC CORD BUSHING (PG5RF-5B) 1.0

31 6600-120040-000 SCREW NUT M4X7X3 2.0

32 7104-010010-022 WASHER M4X10X1MM 3.0

33 3200-480140-401 TRANSFORMER EI48 117V CUL #4801Y44T-1 (WINBOND) 1.0

34 9485-501000-013 FL8550 CD MAIN BOARD ASSY 1.0

35 9600-505004-002 5CD MECHA ASSY FOR FL8350 REV B 1.0

36 6083-510013-000 *BRACKET, 5CD-SIDE 1 1.0

37 6083-510011-000 STAND, FRONT-5CD 2.0

38 6083-510012-000 STAND, REAR-5CD 1.0

39 2610-218300-002 AC POWER CORD NON-INTEGRAL SPT-2 UL/CSA 1.0

40 6583-510003-001-03 HARMAN/KARDON FL8550 R/P (117V FCC&CSA VR) 1.0

A 7003-006001-111 SCREW M3X6 S.T.P. B/H (BLACK) 22.0

B 7003-006002-112 SCREW M3X6 P.T.P. B/H 23.0

C 7003-008002-112 SCREW M3X8 P.T.P. B/H 16.0

D 7002-606010-062 SCREW M2.6X6 W/H 8.0

E 7004-010010-112 SCREW M4X10 B/H 2.0

F 7003-016002-112 SCREW M3X16 PTP B/H ZN 3.0

FL8550

Page 19

5CD EXPLODED DRAWING LIST

DC MOTOR MABUCHI RF-500TB-14415 (DC002VT00003)

19

SEQ NO.

1 6005-050050-007 BASE, 5CD 1.0

2 6005-050010-004 BRACKET, CD MECHA 1.0

3 3009-901000-000 SANYO CD MECHANISM CD90V1 1.0

4 6590-050001-001 CD90 CHUCKING METAL PLATE 1.0

5 6600-140001-000 CD90F01 CHUCKING METAL PLATE FELT RING 1.0

6 6600-020200-002 PIN, ROUND 1.0

7 6005-050008-001 CONTROL CAM 1.0

8 7105-010005-030 WASHER LOCK 5X10X0.5MM 3.0

9 6600-020198-000 5CD PIN, CONTROL CAM 1.0

10 6505-050001-001 BRACKET GEAR 1.0

11 7003-008002-112 SCREW M3X8 B TYPE B/H ZN 12.0

12 6600-010211-000 5CD SPRING, LEVER LOCK, OUTER 1.0

13 4841-010700-006 TURNTABLE PCB REV. F 1.0

14 6005-050025-002 SWITCH COVER 1.0

15 6505-050007-001 CONTACT PLATE 1.0

17 6005-050009-000 INTERMEDIATE GEAR 1.0

18 6005-050014-004 LEVER LOCK, OUTER 1.0

19 4800-310210-001 LOADER BOARD VER A 1.0

20 6005-050011-000 IDLER GEAR 1.0

21 6005-050023-001 PULLEY MOTOR 1.0

22 6005-050024-000 PULLEY DISC 1.0

23 6600-090053-000 5CD BELT MOTOR LOADING 1.0

24 6005-050013-001 DRIVEN PULLEY (WHITE) 1.0

25 6005-050027-000 BUSH, ROLLER 1.0

26 6005-050012-000 DRIVEN PULLEY PLATE 1.0

27 RF-500TB-14415

28 7003-012002-062 SCREW M3X12 P.T.P. W/H 1.0

29 7002-605005-112 SCREW M2.6X5 CLASSI B/H ZN 1.0

30 6005-050007-000 GEAR, CABINET TOP 1.0

31 6600-020197-001 PIN CABINET TOP 1.0

32 6005-050006-004 CONTROL CAM 1.0

33 7002-006001-022 SCREW M2*6 S.T.P. P/H 2.0

34 6600-020196-002 PIN, CAM CABINET 1.0

35 7103-012010-022 WASHER M3X12X1MM 1.0

36 7003-008002-062 SCREWM3X8 P TYPE W/H ZN 1.0

37 6005-050015-000 LEVER LOCK 1.0

38 6600-010210-000 SPRING LEVER LOCK 1.0

39 6600-170021-000 5CD CUSHION RING 2.0

40 6600-170019-000 5CD CUSHION B 2.0

41 6600-020181-000 5CD SCREW, SPECIAL 4.0

42 6600-170018-000 5CD CUSHION A 2.0

43 6090-050002-004 CD90 CHUCKING PULLEY 1.0

44 6600-150006-001 CHUCKING MAGNET 1.0

45 6600-020199-001 PIN, LOCK 1.0

46 6005-050002-011 CABINET TOP 1.0

47 6005-050001-006 TRUNTABLE 1.0

48 7003-012002-062 SCREW M3X12 P.T.P. W/H 1.0

49 7103-012010-022 WASHER M3X12X1MM 1.0

50 6005-050017-000 ROLLER 1.0

51 6600-020202-000 5CD PIN, ROLLER 1.0

PART NO. DESCRUPTION QTY.

1.0

FL8550

Page 20

52 6600-020297-000 PIN ROLLER LOCK 1.0

20

53 6505-050005-001 BRACKET ROLLER 1.0

54 9400-501000-132 5CD SENSOR BOARD ASSY REV B 1.0

55 7103-006005-130 WASHER 3X6X0.5MM CUT 1.0

56 6600-010213-000 5CD SPRING, GEAR BLOCK ARM 1.0

57 6600-010212-002 5CD SPRING, GEAR BLOCK 1.0

58 7002-620002-062 SCREW M2.6X20 P TYPE W/H ZN 1.0

59 6005-050005-001 GEAR BLOCK ARM 1.0

60 6005-050004-003 GEAR BLOCK 1.0

61 7002-608002-002 SCREW M2.6X8 P.T.P W/H D6.5 2.0

62 6600-020203-000 5CD SHAFT, T.T. ROLLER 5.0

63 6600-080001-000 YN21R D03/04 PINCH ROLLER 5.0

64 6005-050028-000 WASHER, BUSH 1.0

65 6005-050026-002 LEVER LOCK, T.T. 1.0

66 6600-010290-001 SPRING LEVER LOCK 1.0

67 6505-050002-001 CABINET HOLDER A 2.0

68 6005-050019-000 SHAFT BUSHING 2.0

69 6005-050020-000 PULLEY ROTARY 1.0

70 6005-050021-000 GEAR ROTARY 1.0

71 6005-050022-000 GEAR WORM 1.0

72 6600-020268-000 SHAFT DIA. 2X34MM 1.0

73 6600-090052-000 5CD BELT ROTARY 1.0

74 7002-003010-111 SCREW M2X3 B/H (BLACK) 2.0

75 6005-050018-000 MOTOR PULLEY 1.0

76 FF130SH11340-2684A MOTOR FF-130SH-11340-02684A (MABUCHI) 1.0

77 6505-050004-004 MOTOR BRACKET 1.0

78 6600-020201-001 SHAFT GEAR ROTARY 1.0

79 6505-050003-001 5CD CABINET HOLDER B 2.0

FL8550

Page 21

ADJUSTMENT PROCEDURES

21

Reference Disk for adjustments: Sony YEDS - 18

Mode: FL8550

Testing Equipment:

i. 5020 Frequency Response Analyzer

ii. Oscilloscope

iii. Frequency Counter

iv. Frequency Generator (Kenwood AG-203A)

FL8550

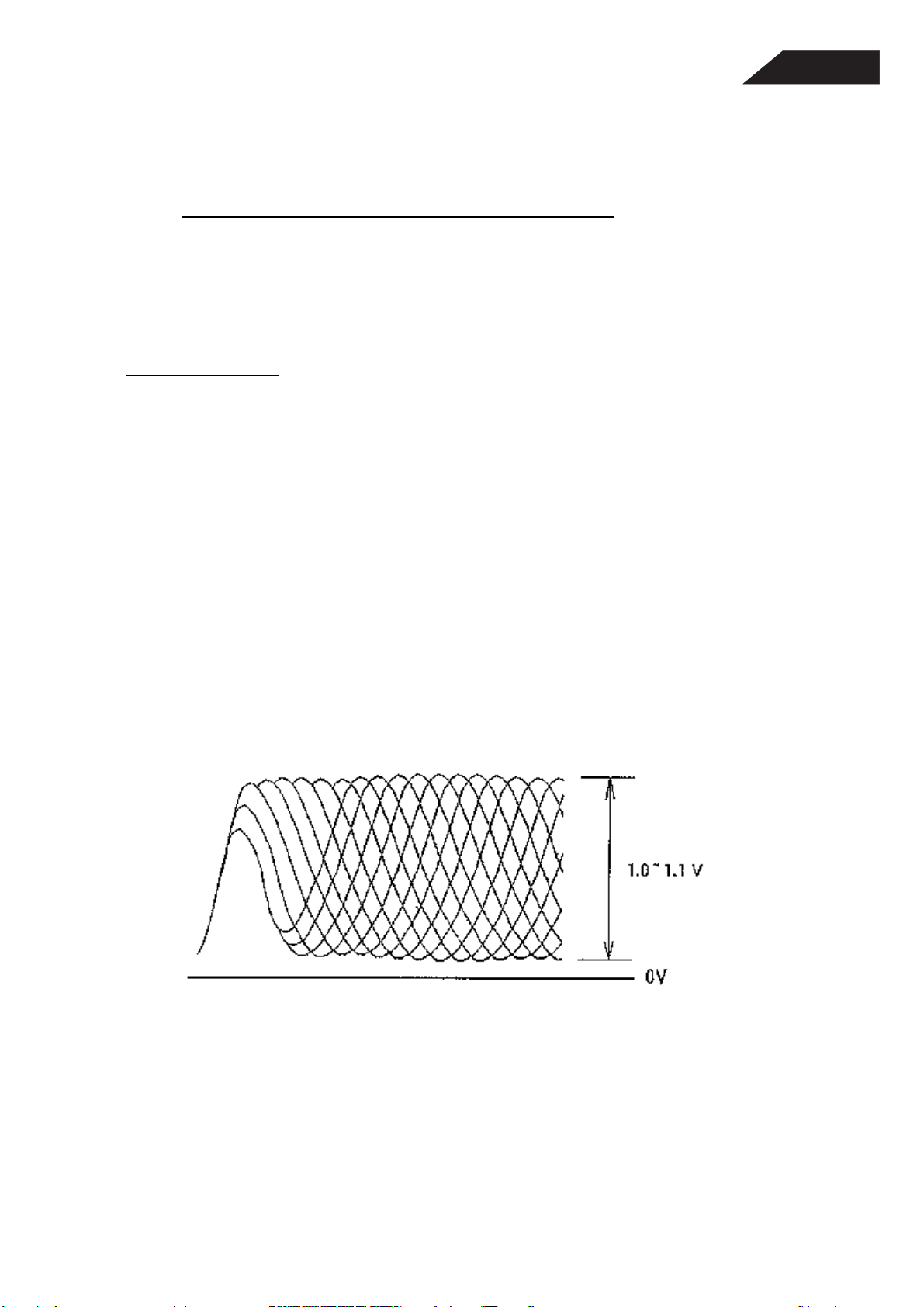

Adjustment Procedure

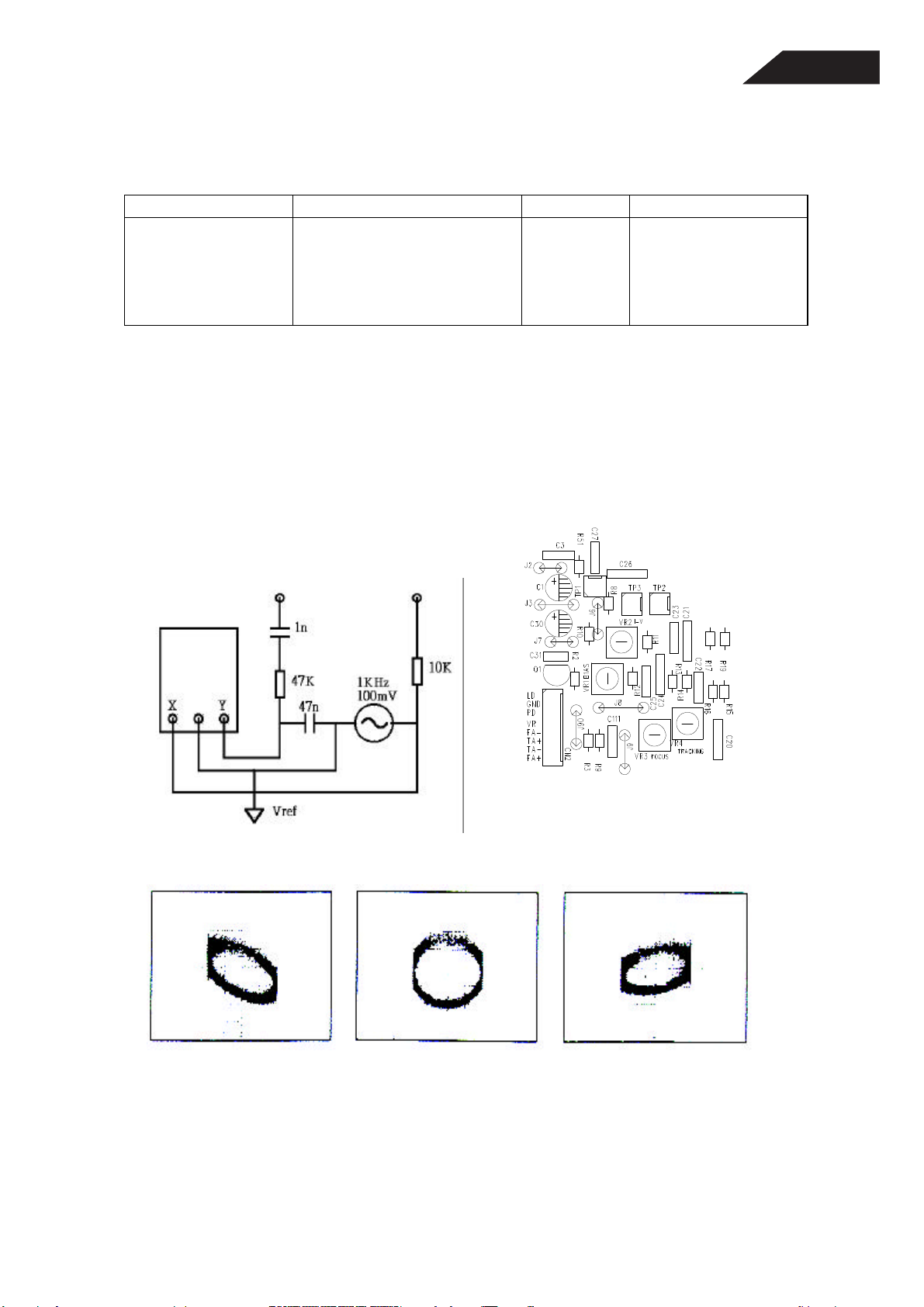

(A) Focus Adjustment

i. Connect Jitter Meter between TP1 (R51) and Vref (J6), then play a CD disc.

ii. Adjust VR1 until Jitter Meter get the minimum point.

iii. Connect Oscilloscope as the same as the last step. Waveform will be read as

diamond shape and voltage is about 1.1v as perfect. (see the figure 1)

Fig. 1

Page 22

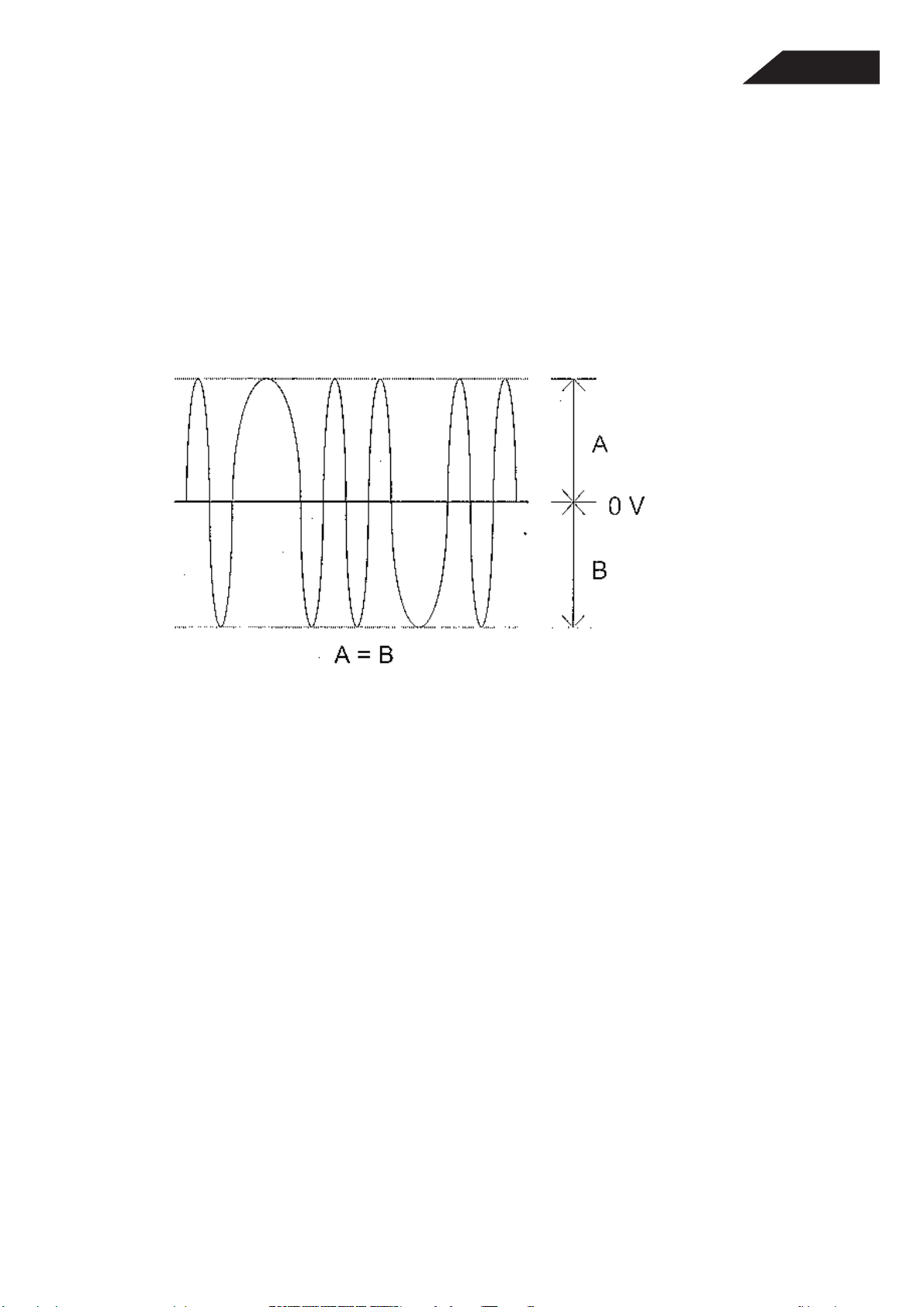

(B) Tracking Adjustment

22

i. Connect oscilloscope to the test point TP3 (KA9220C) and Vref (J6).

ii. Press PLAY button and adjust VR4 to maximum and press SKIP DOWN button to

make it Tracking off.

iii. Adjust VR2 to get symmetrical waveform height. After adjust VR4 to center.

iv. The result is show as below fig. 2

FL8550

Fig. 2

Page 23

(C) Focus Servo Loop Gain Adjustment

23

Connection point Settings State Adjustment Location

U1 (KA9220C)

Pin 57 (R11)

Pin 56 (R12)

See fig 3

i. Set the frequency generator output to 1KHz and 100mv.

ii. Press the play key and press skip key to move the pickup to halfway across the disk

(R=35mm).

iii. Adjustment VR3(focus gain) so that the Lissajous waveform is symmetrical

above the X axis and the Y axis.

1. Oscilloscope Probe: x 10

2. Oscilloscope setting

CH1: 20mV/division

CH2: 10mV/division

Remark: X-Y mode

Play State Adjustment VR3

FL8550

Focus Gain Adjustment

Fig. 3

Higher gain Optimum gain Lower gain

Page 24

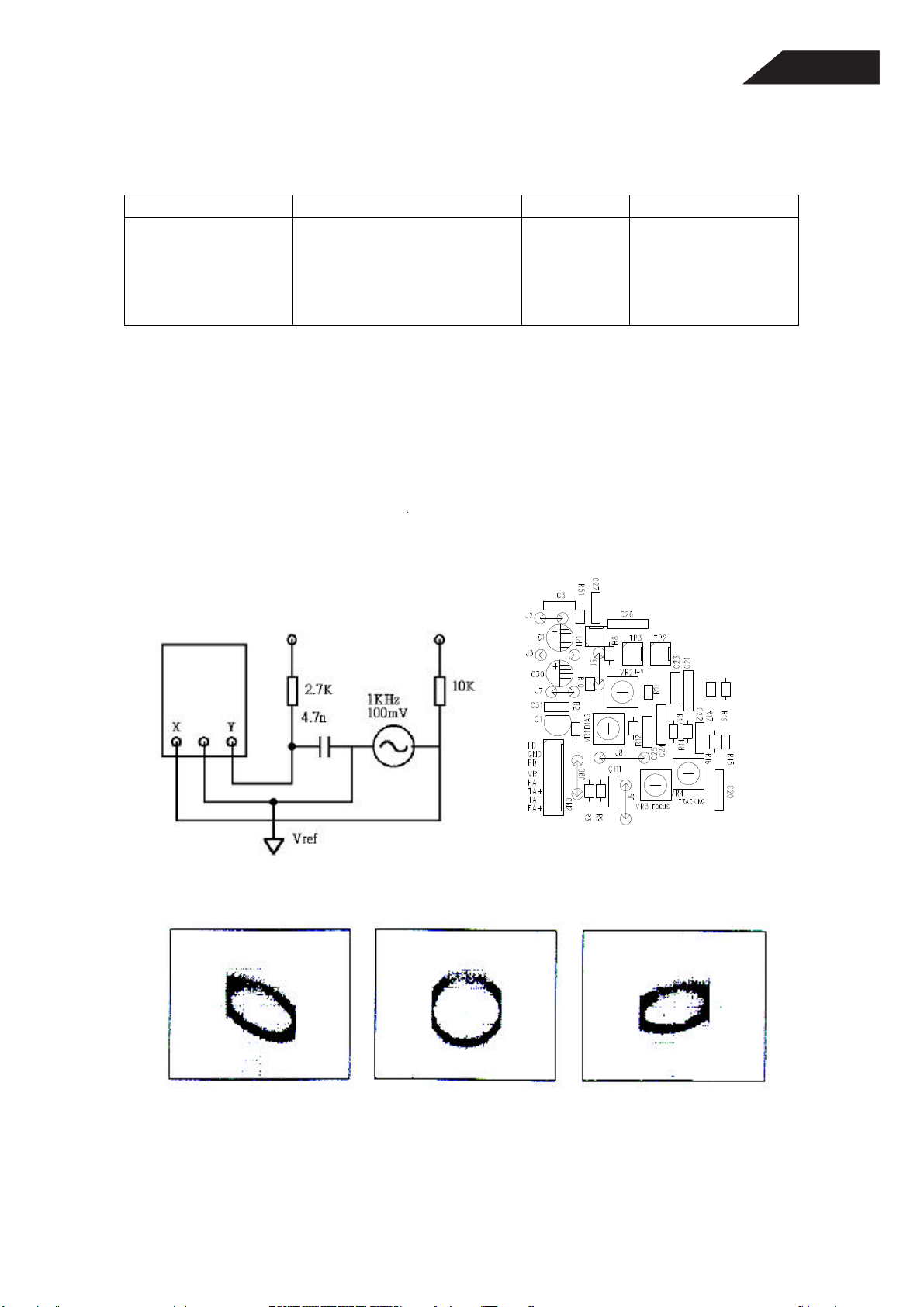

(D) Tracking Servo Loop Gain Adjustment

Vref

24

Connections point Settings State Adjustment location

U1 (KA9220C)

Pin 53 (R13)

Pin 52 (R14)

See fig.4

1. Oscilloscope probe: X10

3. Oscilloscope setting

CH1: 50mV/division

CH2: 20mV/division

Play State Adjustment VR4

Remark: X-Y mode

i. Set the frequency generator output to 1KHz and 100mV.

ii. Press the play key and press skip key to move the pickup to halfway across the disk

(R=35mm).

iii. Adjustment VR4(track gain) so that the Lissajous waveform is symmetrical above

the X axis Y axis.

FL8550

Tracking Gain Adjustment

Fig 4

Higher gain Optimum gain Lower gain

Page 25

Audio Characteristics Test Procedure

25

Test Equipment

1. 3346 CD Player Evaluating Filter x 2 (NF Electronic Instrument)

2. VP7722 Panasonic Audio Analyzer

3. Sony YEDS18 Test CD disc

Procedure

Equipment Setup

1. The audio output of the CD player under test is connected to the CD filter L

& R inputs.

2. The outputs from the filter are connected to the Audio Analyzer.

Check the output Voltage

1. Set the mode of the filter to ‘ THRU’

FL8550

2. Set the mode of Audio Analyzer to ‘ LEVEL’ mode

3. Select track 2 of the test disc and play the CD disc

4. The output voltage and gain of the R & L channels are taken by pressing

the respective buttons on the control board of Audio Analyzer.

Frequency Response

1. Set the mode of the filter to reference level mode.

2. Select the track 3, 4, 5, and 6 of the test disc and run it under ‘ Play’ mode.

3. Check the output of the R & L Channels

Total Harmonic Distortion

1. Set the mode of the filter to ‘ DIST/CH-SP’ mode

2. Set the audio analyzer to ‘ DIST’ mode.

3. Set the unit of the audio analyzer to ‘ %’ mode

4. Select the track 2, 4, and 5 on the test disc and run them under ‘ PLAY’

mode

5. Check the % of each R & L channels

9

Page 26

Signal to Noise Ratio

26

1. Set the mode of the filter to ‘ S/N’ mode

2. Play track 2 of the test disc

3. The unit of the audio analyzer is set to dB mode

4. Press the S/N key on the control panel of the audio analyzer

5. Play track 7

6. Measure the data of S/N ratio

Dynamic Range

1. Set the mode of the filter to ‘ D-Range’ mode

2. Set the audio analyzer to ‘ DIST’ Mode

3. Set the unit of the audio analyzer to ‘ dB’ mode

4. Play track 17of the test disc

5. The dynamic range should be |A| + 60dB

FL8550

Channel Separation

1. Set the mode of the filter to ‘ DIST/CH-SP’ mode

2. Set the audio analyzer to ‘ LEVEL’ mode

3. Play the tracks 8, 9, 10 & 11

4. The measured results is the difference between L & R channel

De-emphasis

1. Press the ‘ THRU’ button of the CD filter

2. Play the track 2 of the test disc

3. Press the ‘ Relative Level’ and make it ‘ ON’

4. Select the track 12 and 13 and measure the L & R channels value

Page 27

FL8550

27

Circuit Description

1. RF AMP BLOCK

The KA9220 is designed for 3-spot type optical pick-up assembly. The photo detector is composed of 6

light sensor (A through F). The photo detector A, B, C and D detect audio modulation signal on the disc

and generate focus error signal.

RF I-V AMP (1) and RF I-V AMP (2) are converted current of PD1 (A + C) and PD2 (B + D) through the

58 Kohm Internal resistor into Voltage.

Furthermore, they are added to RF Summing amplifier.

This signal (A + B + C + D) is outputted from RFO (Pin66).

The output Voltage is as follow.

BA

10K

BA

)

V

) V V ( X2.2 -

) iPD2 iPD1 ( XR3 V

BA

)

RFO

( XR3

V

R1

( 22K X -

10K

V

+−=

V

+−=

R2

+=

+=

Page 28

2. TRACKING ERROR AMPLIFIER

28

FL8550

The output of photo detector F is directed to the (-) Input of F I – V AMP and out of photo detector E is

directed to the (-) input of E I – V AMP.

These input signals are current.

E I – V AMP and F I – V AMP are converted into voltage from the current signal. When correct tracking,

two input (V

AMP output and E I – V AMP output.

=

accordingly,

, VE) signals are equal. The occurrence of tracking error is due to difference between F I – V

F

26K

R

+

=

13K 260K X

A

22K R

1290K X) I - I ( V

FE1TE

=+=

FFF

+++

A

]403K XI 273K )

]260K R 260K

( [ XI V

[ XI V

EE

B

Page 29

FL8550

29

3. FOCUS ERROR AMPLIFIER

The focus error amp is the difference between RF I – V AMP (1) output VA and RF I – V AMP (2) output

V

. This two (VA, VB) signals are each applied to the (-) and (+) input of focus error amp. As the result of

B

differential voltage, Focus error signal is appeared at FE1 Pin (Pin57). This FE1 Output Voltage (low

frequency) becomes (A + C) – (B + D), as follow V

The focus error voltage is directed to the focus servo Block, to maintain optimum focusing at all times.

= R1/R3 (VB – VA)

FE1

4. FOCUS OK GENERATION CIRCUIT

The focus OK circuit generates a timing window to monitor focus search status of focus servo. When

RFO (Pin 66) Voltage is more than –0.37V, the focus OK circuit is inverted. Time constant of HPF in EFM

comparator and in mirror circuit and that of LPF in focus OK circuit are determined bu capacitor (0.01µF)

between RFI and RFO.

Page 30

5. MIRROR CIRCUIT

30

FL8550

After RF input signal is amplified by Mirror amp, it is held in Bottom and Peak hold circuit. Such a hold is

determined by the time constant. Envelope signal A (demodulated to DC) is two-thirds of the peak value

of this signal. The time constant of A signal is held when it is larger than that of B signal. Therefore,

mirror output is; Low at track on disc, High at between tracks on disc, High when defect is detected.

6. DEFECT CIRCUIT

Page 31

FL8550

31

The bottom hold has had two time constant of long and short, after than the RFI signal inverted. The

short time constant of bottom hold is generated shorter than 0.1m sec of disc mirror defect, and long time

constant is generated by previous mirror level. Mirror defect detection signals are generated by

differentiation on Capacitor Coupling, and then transfer level.

7. EFM COMPARATOR

The EFM Comparator converts a RF signal into a binary signal. A processing of disc production is

occurred disproportion because of modification of disc. That is not reduced by only AC coupling. The

reference voltage of EFM comparator is controlled utilizing the fact that the generation-probability 1, 0 is

50% (duty) in the binary EFM signal.

8. APC (AUTOMATIC POWER CONTROL) CIRCUIT

As the Laser diode has had large negative temperature characteristic when it does something for

regularly supply current on laser diode. Therefore, the output on processing monitor photo diode must be

controlled current for getting regularly output power.

Page 32

SERVO BLOCK

32

FL8550

1. FOCUS SERVO

When the defect signal is detected, the focus servo Loop is isolated. At this time, the focus servo error

output is outputted through low pass filter formed by connecting a capacitor (0.1µF) between the built-in

470KΩ resistor and FDFCT Pin (Pin58). Accordingly, the focus error output is held as just before error

value during the defect.

The peak frequency of the focus phase compensation is at about 1.2KHz when the resistor connected to

PFSET(Pin7) is 510KΩ. It is inversely proportional to the resistor connected to the Pin 7.

Page 33

FL8550

33

While the focus search is operating, the FS4 switch is ON and then focus error signal is isolated,

accordingly it is outputted by FSEO Pin (Pin48). When the FS2 switch is ON, the focus servo Loop is on

and then focus error is outputted through the focus servo Loop.

2. TRACKING AND SLED SERVO LOOP

The capacitor across RTG (Pin16) and TGSW (Pin15) reduces high frequency gain when the TG2 switch

is OFF. The Peak frequency of the tracking phase compensation is at about 1.2KHz when the resistor

connected to PFSET (Pin7) is 510KΩ. It is inversely proportional to the resistor connected to the Pin 7.

The tracking error signal is switched into low pass filter route formed by connecting a capacitor between

the built-in resistor at DFCT (470KΩ) and TDFCT (Pin54) as for tracking error signal.

Page 34

3. SPINDLE SERVO AND LOW PASS FILTER

34

FL8550

The 0.033nF and 20KΩ connected to SMEF (Pin 25) form the 200Hz low Pass filter. And the carrier

component of spindle servo error signals is eliminated. In the CLV – S mode, SMEF becomes L and

Pin25 LPF fc lowers, strengthening the filter further.

Page 35

KA9258D

35

4-Channel Motor Driver

FL8550

Features

• 1-phase, full-wave, linear DC motor driver

• Output gain adjustable

• Built in OP-amp

• Built in mute function

• Built in level shift circuit

• Built in thermal shutdown circuit (TSD)

• Operating range 6~13.2V

Description

The KA9258D is a monolithic integrated circuit, suitable for

4-CH motor driver which drives tracking actuator, focus

actuator, sled motor and loading motor of CD/CD-ROM/

DVD system, and can also drive spindle motor of CD

system.

28-SSOPH-375

Typical Applications

• Compact disk player (CDP)

• Video compact disk player (VCD)

• Automotive compact disk player

• Other compact disk media

Ordering Information

Device Package Operating Temp.

KA9258BD 28-SSOPH-375 −40°C ~ +85°C

KA9258BDTF 28-SSOPH-375 −40°C ~ +85°C

Page 36

Pin Definitions

36

Pin Number Pin Name I/O Pin Function Description

1 DO1.1 O Drive output

2 DO1.2 O Drive output

3 DI1.1 I Drive input

4 DI1.2 I Drive input

5 REG - Regulator

6 REO O Regulator output

7MUTEIMute

8 GND1 - Ground 1

9 DI2.1 I Drive input

10 DI2.2 I Drive input

11 DO2.1 O Drive output

12 DO2.2 O Drive output

13 GND2 - Ground 2

14 OPOUT O Op-amp output

15 OPIN(−) I Op-amp input (−)

16 OPIN(+) I Op-amp input (+)

17 DO3.1 O Drive output

18 DO3.2 O Drive output

19 DI3.1 I Drive input

20 DI3.2 I Drive input

21 V

22 V

23 VREF I 2.5V bias voltage

24 DI4.1 I Drive input

25 DI4.2 I Drive input

26 DO4.1 O Drive output

27 DO4.2 O Drive output

28GND3-Ground 3

CC1

CC2

- Supply voltage

- Supply voltage

FL8550

Page 37

Internal Block Diagram

37

GND3

DO4.2

DO4.1

+

−

Level

shift

−

+

+

−

Level

shift

−

12 345 6 8 9 10 11 12 13714

10k

+

10k

10k

FL8550

OPIN (−)

DI4.2

DI4.1

VREF

10k

TSD

Regulator

−

+

10k

VCC2

10k

+

Mute

50k

−

50k

VCC1

DI3.2

DI3.1

DO3.2

DO3.1

10k

+

−

Level

10k

10k

10k

shift

−

+

−

+

Level

shift

+

−

OPIN(+)

1516171819202122232425262728

+

−

DO1.1

DO1.2

Pin Assignments

GND3

DO4.2

1234567 891011121314

DO1.1

DO1.2

REG

DI1.1

DI1.2

DO4.2

DI4.2

REO

MUTE

FIN

(GND)

DI4.1

CC2

VREF

V

GND1

CC1

V

DI2.1

DI2.2

DO2.1

DI3.2

DI3.1

GND2

DO2.2

DO3.2

OPOUT

)

−

DO3.1

OPIN (+)

OPIN (

1516171819202122232425262728

KA9258D

REG

DI1.1

DI1.2

REO

MUTE

FIN

(GND)

GND1

DI2.1

DI2.2

DO2.1

GND2

DO2.2

OPOUT

Page 38

KA9220C

38

FL8550

Page 39

FL8550

39

Page 40

FL8550

40

Page 41

FL8550

41

Page 42

FL8550

42

Page 43

FL8550

43

Page 44

KS9284

44

FL8550

Page 45

FL8550

45

Page 46

FL8550

46

Page 47

FL8550

47

Page 48

FL8550

48

Page 49

FL8550

49

Page 50

KA8301

50

Bi-Directional DC Motor Driver

FL8550

Features

• Built-in brake function.

• Built-in element to absorb a surge current derived from

changing motor direction and braking motor drive.

• External motor speed control pin

• Motor direction change circuit.

• Interfaces with CMOS devices.

Description

The KA8301 is a monolithic integrated circuit designed for

driving bi-directional DC motor with braking and speed control, and it is suitable for the loading motor driver of VCR

systems. The speed control can be achieved by adjusting the

external voltage of the speed control pin.

10-SIPH-B

Typical Application

• Video cassette recorder (VCR) loading motor

• Low current DC motor such audio or video equipment

• General DC motor

Ordering Information

Device Package Operating Temp.

KA8301-L 10-SIPH-B −25°C ~ +75°C

Page 51

Pin Assignments

51

FL8550

KA8301

GND V

OUT1VZ1

12345678910

V

F

R

R

IN

V

IN

CC1

V

CC2VZ2

Pin Definitions

Pin Number Pin Name I/O Pin Function Description

1 GND - Ground

2V

3V

4V

5F

6R

7V

8V

9V

10 V

OUT1

Z1

R

IN

IN

CC1

CC2

Z2

OUT2

O Output 1

- Phase compensation

I Motor speed control

I Input 1

I Input 2

- Supply voltage (Signal)

I Supply voltage (Power)

I Phase compensation

O Output 2

V

OUT2

Page 52

FL8550

52

®

49%

PCM1702P

FPO

PCM1702U

BiCMOS Advanced Sign Magnitude 20-Bit

DIGITAL-TO-ANALOG CONVERTER

DESCRIPTIONFEATURES

● ULTRA LOW –96dB max THD+N

(No External Adjustment Required)

● NEAR-IDEAL LOW LEVEL OPERATION

● GLITCH-FREE OUTPUT

● 120dB SNR TYP (A-Weight Method)

● INDUSTRY STD SERIAL INPUT FORMAT

● FAST (200ns) CURRENT OUTPUT

±1.2mA)

(

● CAPABLE OF 16X OVERSAMPLING

● COMPLETE WITH REFERENCE

● LOW POWER (150mW typ)

The PCM1702 is a precision 20-bit digital-to-analog

converter with ultra-low distortion (–96dB typ with a

full scale output). Incorporated into the PCM1702 is

an advanced sign magnitude architecture that eliminates unwanted glitches and other nonlinearities around

bipolar zero. The PCM1702 also features a very low

noise (120dB typ SNR: A-weighted method) and fast

settling current output (200ns typ, 1.2mA step) which

is capable of 16X oversampling rates.

Applications include very low distortion frequency

synthesis and high-end consumer and professional

digital audio applications.

Clock

Data

LE

DCOM

ACOM

+V

CC

–V

CC

International Airport Industrial Park • Mailing Address: PO Box 11400 • Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd. • Tucson, AZ 85706

Tel: (520) 746-1111 • Twx: 910-952-1111 • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

© 1993 Burr-Brown Corporation PDS-1175B Printed in U.S.A. June, 1995

Input Shift Register

and Control Logic

Reference

and

Servo

SERV DCRF DC

Balanced Current

Segment DAC A

Balanced Current

Segment DAC B

Bipolar Offset

BPO DC

1

I

OUT

PCM1702

®

Page 53

FL8550

53

SPECIFICATIONS

All specifications at 25°C, ±VCC and +V

PARAMETER CONDITIONS MIN TYP MAX UNITS

RESOLUTION 20 Bits

DYNAMIC RANGE, THD + N at –60dB Referred to Full Scale, with A-weight 110 dB

DIGITAL INPUT

Logic Family TTL/CMOS Compatible

Logic Level: V

Data Format Serial, MSB First, BTC

IH

V

IL

I

IH

I

IL

Input Clock Frequency 12.5 20.0 MHz

TOTAL HARMONIC DISTORTION + N

P/U VO = 0dB fS = 352.8kHz

V

= –20dB fS = 352.8kHz

O

V

= –60dB fS = 352.8kHz

P/U, -J V

P/U, -K V

O

= 0dB fS = 352.8kHz

O

V

= –20dB fS = 352.8kHz

O

V

= –60dB fS = 352.8kHz

O

= 0dB fS = 352.8kHz

O

V

= –20dB fS = 352.8kHz

O

V

= –60dB fS = 352.8kHz

O

ACCURACY

Level Linearity At –90dB Signal Level ±0.5 dB

Gain Error ±0.5 ±3%

Bipolar Zero Error

(5)

Gain Drift 0°C to 70°C ±25 ppm of FSR/°C

Bipolar Zero Drift 0°C to 70°C ±5 ppm of FSR/°C

Warm-up Time 1 minute

IDLE CHANNEL SNR

(6)

ANALOG OUTPUT

Output Range ±1.2 mA

Output Impedance 1.0 kΩ

Settling Time (±0.003% of FSR, 1.2mA Step) 200 ns

Glitch Energy No Glitch Around Zero

POWER SUPPLY REQUIREMENTS

Supply Voltage Range: +V

Combined Supply Current: +I

Combined Supply Current: –I

Power Dissipation ±V

= +V

CC

–V

= –V

CC

CC

CC

TEMPERATURE RANGE

Operating –25 +85 °C

Storage –55 +125 °C

NOTES: (1) Binary Two’s Complement coding. (2) Ratio of (Distortion

(4) D/A converter output frequency (signal level). (5) Offset error at bipolar zero. (6) Measured using an OPA627 and 5kΩ feedback and an A-weighted filter.

= ±5V unless otherwise noted.

DD

(2)

DD

DD

PCM1702P/U, -J, -K

+2.4 +V

0 0.8 V

VIH = +V

DD

VIL = 0V ±10 µA

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(3)

, f = 1002Hz

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

–92 –88 dB

–82 –74 dB

–46 –40 dB

–96 –92 dB

–83 –76 dB

–48 –42 dB

–100 –96 dB

–84 –80 dB

–50 –44 dB

DD

±10 µA

(1)

±0.25 %

Bipolar Zero, A-weighted Filter 110 120 dB

+4.75 +5.00 +5.25 V

–4.75 –5.00 –5.25 V

+VCC = +VDD = +5V +5.00 +9.0 mA

–V

= –V

= –5V –25.00 –41.0 mA

CC

DD

= ±VDD = ±5V 150 250 mW

CC

RMS

+ Noise

) / Signal

RMS

. (3) D/A converter sample frequency (8 x 44.1kHz; 8x oversampling).

RMS

V

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

®

PCM1702

Page 54

FL8550

54

ABSOLUTE MAXIMUM RATINGS (DIP Package)

Power Supply Voltage .................................................................. ±6.5VDC

Input Logic Voltage ........................................... DGND—0.3V~+V

Operating Temperature..................................................... –25 °C to +85°C

DD

+0.3V

Storage Temperature ...................................................... –55°C to +125°C

Power Dissipation ..........................................................................500mW

Lead Temperature (soldering, 10s).................................................. 260°C

PIN ASSIGNMENTS (DIP Package)

PIN MNEMONIC PIN MNEMONIC

1 DATA 9 +V

2 CLOCK 10 BPO DC

3+V

4 DCOM 12 ACOM

5–V

6 LE 14 SERV DC

DD

DD

11 I

13 ACOM

7 NC 15 REF DC

8NC16–V

PACKAGE INFORMATION

(1)

PACKAGE DRAWING

MODEL PACKAGE NUMBER

PCM1702P 16-Pin Plastic DIP 180

PCM1702U 20-Pin Plastic SOP 248

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix D of Burr-Brown IC Data Book.

CC

OUT

CC

ABSOLUTE MAXIMUM RATINGS (SOP Package)

Power Supply Voltage .................................................................. ±6.5VDC

Input Logic Voltage ........................................... DGND—0.3V~+V

Operating Temperature..................................................... –25°C to +85°C

DD

+0.3V

Storage Temperature ...................................................... –55°C to +125°C

Power Dissipation ..........................................................................300mW

Lead Temperature (soldering, 5s).................................................... 260°C

PIN ASSIGNMENTS (SOP Package)

PIN MNEMONIC PIN MNEMONIC

1 DATA 11 +V

2 CLOCK 12 BPO DC

CC

3NC13NC

4+V

5 DCOM 15 ACOM

6–V

7 LE 17 SERV DC

DD

DD

14 I

OUT

16 ACOM

8NC18NC

9 NC 19 RFE DC

10 NC 20 –V

CC

GRADE MARKING (SOP Package)

MODEL PACKAGE

PCM1702U Marked PCM1702.

PCM1702U-J Marked with white dot by pin 10.

PCM1702U-K Marked with red dot by pin 10.

CONNECTION DIAGRAM

CLOCK

DATA

LE

+5V V

DD

47µF

47µF

–5V V

DD

+

+

= SOP

= DIP

47µF

+

47µF

+

–5V V

CC

R

NF

V

OUT

2

2

1

1

6

7

3

4

4

5

5

6

16

20

15

19

14

17

11

14

10

12

9

11

13

16

12

15

22µF

+

+

47µF

+

+5V V

100µF

CC

®

PCM1702

Page 55

FL8550

55

®

PMD-100

PMD-100 Process Decoder

General Description

The PMD-100 HDCD® Process Decoder is a sophisticated

0.6 micron CMOS Integrated Circuit that performs precise decoding of HDCD encoded recordings. The D ecoder

also functions as a state-of-the-art digital filter when fed

data from non-HDCD recordings. It is designed to interface directly with popular data receivers and DAC’s, eliminates the need for conventional monolithic digital filters.

The PMD-100 has been carefully designed to maximize performance and ease of use in a wide variety of applications.

HDCD Process Information

Data encoded with HDCD process information carries precisely encrypted signals, hidden within the LSB of the 16bit data word. Over time, only 1 to 5% of the LSB is used

for this hidden code. The encoded information is inaudible and causes no perceptible loss of information. The

PMD-100 recognizes the encrypted signals as HDCD process information, and directs the decoding function to precisely reconstruct the high resolution signal in a form appropriate for output to the D-A converter being used.

Note: To preserve HDCD process information, no alteration

of the encoded data is allowed prior to processing by the PMD-

100. Digital data processing including phase inversion prior to

the PMD-100 input will result in the loss of HDCD process

information encoded in the data.

SPECIAL FEATURES

Automatic HDCD Process Decoding

When the PMD-100 detects HDCD® process information in the input data, it automatically switches to

®

HDCD

an LED indicator. When non-HDCD

data is received, the decoder automatically operates

as a high performance digital filter.

Excellent Filter Characteristics

When operating as a digital filter, the PMD-100 exhibits passband characteristics that have been carefully optimized to provide extremely accurate sound

quality. Passband ripple from 0 to 20 kHz is within

±.0001 dB and stopband attenuation is greater than

120 dB.

Two Operating Modes

Stand-Alone

In Stand-Alone Mode, the PMD-100 requires no

external controller, allowing for the most cost

effective designs.

Program

In Program mode, an external processor controls

the PMD-100’s many advanced operating modes

and features.

decode mode, and provides an output to drive

®

process input

9300-0005

Rev A1

HDCD

HDCD® and High Definition Compatible Digital®

are registered trademarks of Pacific Microsonics, Inc

Page 56

PMD-100

56

PMD-100 Process Decoder

FL8550

®

SPECIAL FEATURES (Cont.)

DAC Optimize Operating Modes

To achieve the best possible performance from a variety of

different DAC types, adjustable parameters are provided including eight different levels of dither and Patented “Silent

Conversion” variable clock timing.

Constant Clock Output

The PMD-100 constantly provides output clocking to the DAC,

even if input data and master clocks are lost. This feature eliminates the possiblility of spikes or DC offsets at the DAC’s output.

Additional Features

•

24 bit or greater accuracy provided for all opera-

tions.

•

Up to 24 bit input data passed without truncation.

•

32 kHz to 55 kHz input data rates.

•

Output digital attenuation over a 96 dB range in

0.188 dB steps.

•

Output soft mute and hard mute functions.

•

16, 18, 20 or 24 bit output data.

•

8 Fs, 4 Fs or 2 Fs output data rates. (Multiple

output data rates are provided to allow flexible DAC

operation and ease of use in designs that employ

custom DSP based filters for non-HDCD

recordings.)

•

Digital domain deemphasis.

•

256 Fs or 384 Fs system clock.

®

process

Digital Characterisitcs

= 4.75V to 5.25V, VSS = OV, TA = 0°C to +70°C unless otherwise specified.

V

DD

Page 57

PMD-100

57

PMD-100 Process Decoder

Pin Description (Stand-Alone Mode) Pin 9 Low

( I = Input, O = Output. All input levels TTL compatible

except XTI which must be CMOS level. No inputs have

pull-ups. All outputs are full CMOS levels. )

1: DIN (I) Serial data input.

2: BCKI (I) Bit clock input.

3: XTIM(I) Select system clock frequency.

Low = 256 Fs, High = 384 Fs.

4: DITH(I) Dither select.

Low = dither disabled,

High = dither added.

5: GAIN (O) Analog output stage gain.

Use only if Pin 19 is High (see page

14).

Low = low gain,

High = high gain (+6 dB).

(See pin 19 description).

6: XTI (I) System clock input.

7: VDD1 +5 volt power for filter.

8: VSS1 Ground

9: PROG(I) Select Program mode.

Low = Stand-Alone,

High = Program.

Note: Pins 10 through 14 perform different functions

depending on whether Stand-Alone or Program mode is

selected.

Stand-Alone Mode:

10: OSIZ0 (I)

11: OSIZ1 (I)

These two pins determine the output word size, as well as

the number of pulses on BCKO.

12: COB (I) Output data format.

Low = complementary offset binary,

High = 2’s complement.

13: JUST (I) Input data justification.

Low = data assumed to be left justi

fied up to 24 bits in length,

High = data right justified 16 bits.

14: BCPL (I) Input data latching.

Low = input data latched on rising

edge of BCKI. High = input data

latched on falling edge of BCKI.

15: SMUTE (I) Soft mute. Low = off, High = on.

16: DEEMPH(I)De-emphasis filter.

FL8550

®

Low = off, High = on.

17: HMUTE (I) Hard mute. Low = off, High = on.

18: FSEL (I) De-emphasis filter Fs.

Low = 44.1 kHz, High = 48 kHz.

19: SCAL (I) Gain scaling.

Low = 6dB gain scaling is performed

internally in the digital domain,

High = analog output gain stage is set

by pin 5 GAIN. (See page 14.)

20: DG (O) DAC sample and hold deglitch signal.

21: VSS2 Ground. (Common with VSS1)

22: VDD2 +5 volt power for output interface.

23: DOR (O) Right channel serial data output.

24: DOL (O) Left channel serial data output.

25: WCKO(O) Word clock output.

26: BCKO (O) Bit clock output.

27: HDCD (O) HDCD encoding detect.

Low = no encoding. High = HDCD

encoded input data. (Output current

rated at 12mA.)

28: LRCI (I) Word clock input.

Page 58

HD6433724E93F MICROPROCESSOR

58

Overview

The H8/300L Series is a single-chip microcomputer (MCU: microcomputer unit),

built around the high-speed H8/300L CPU and equipped with peripheral system

functions on chip.

The H8/3724 and H8/3754 Series are single-chip microcomputers in the H8/300L

Series equipped with high-voltage pins. Their on-chip peripheral functions include a

vacuum fluorescent display (VFD) controller/driver, timers, a 14-bit PWM (pulse

width modulator), two serial communication interface channels, and an analog-todigital converter. Together these functions make this chip ideally suited to use as a

microcontroller in embedded systems requiring a VFD display.

The H8/3724 and H8/3754 Series come in the following memory configurations for

FL8550

various system scale needs.

H8/3723: 24-kbyte ROM, 384-byte RAM

H8/3724: 32-kbyte ROM, 512-byte RAM

H8/3725: 40-kbyte ROM, 640-byte RAM

H8/3726: 48-kbyte ROM, 1,024-byte RAM

H8/3753: 24-kbyte ROM, 1,024-byte RAM

H8/3754: 32-kbyte ROM, 1,024-byte RAM

In addition to masked ROM versions available for the H8/3724 Series, H8/3724 and

H8/3726 are also available in ZTATTM versions which allow the user to freely

program the on-chip PROM.

Note: * ZTAT (zero turn around time) is a trademark of Hitachi, Ltd.

Page 59

Internal Block Diagram

59

FL8550

Page 60

Pin Arrangement

60

FL8550

Page 61

REF. NO. PART NO. DESCRIPTION QTY.

61

FL8550 MAIN BOARD

RESISTOR

R32/33/35-37/52/5963/79/80.

R1/11/13/27/48/49/50. 1001-002316-000 CARBON FILM RESISTOR 1K OHM 1/6W ±5% 7

R20/21/26/42/110. 1001-003316-000 CARBON FILM RESISTOR 10K OHM 1/6W ±5% 5

R5/15/18/24/25. 1001-004316-000 CARBON FILM RESISTOR 100K OHM 1/6W ±5% 5

R7/64. 1001-005316-000 CARBON FILM RESISTOR 1M OHM 1/6W ±5% 2

R111. 1001-501312-000 CARBON FILM RESISTOR 150 OHM 1/2W ±5% 1

R14/22. 1001-504316-000 CARBON FILM RESISTOR 150K OHM 1/6W ±5% 2

R9/10. 1001-803316-000 CARBON FILM RESISTOR 18K OHM 1/6W ±5% 2

R6. 1001-804316-000 CARBON FILM RESISTOR 180K OHM 1/6W ±5% 1

J101. 1002-200312-000 CARBON FILM RESISTOR 22 OHM 1/2W ±5% 1

R2. 1002-200316-000 CARBON FILM RESISTOR 22 OHM 1/6W ±5% 1

R44. 1002-201316-000 CARBON FILM RESISTOR 220 OHM 1/6W ±5% 1

R34. 1002-202316-000 CARBON FILM RESISTOR 2.2K OHM 1/6W ±5% 1

R8/12. 1002-203316-000 CARBON FILM RESISTOR 22K OHM 1/6W ±5% 2

R38. 1002-701316-000 CARBON FILM RESISTOR 270 OHM 1/6W ±5% 1

R29/51/84. 1002-703316-000 CARBON FILM RESISTOR 27K OHM 1/6W ±5% 3

R30/31/39/40/41. 1003-302316-000 CARBON FILM RESISTOR 3.3K OHM 1/6W ±5% 5

R16/45/85. 1003-303316-000 CARBON FILM RESISTOR 33K OHM 1/6W ±5% 3

R3. 1004-700316-000 CARBON FILM RESISTOR 47 OHM 1/6W ±5% 1

R46. 1004-701316-000 CARBON FILM RESISTOR 470 OHM 1/6W ±5% 1

R53-57/109. 1004-702316-000 CARBON FILM RESISTOR 4.7K OHM 1/6W ±5% 6

R4. 1005-104316-000 CARBON FILM RESISTOR 510K OHM 1/6W ±5% 1

R23. 1005-602316-000 CARBON FILM RESISTOR 5.6K OHM 1/6W ±5% 1

R19. 1005-603316-000 CARBON FILM RESISTOR 56K OHM 1/6W ±5% 1

R58. 1006-801316-000 CARBON FILM RESISTOR 680 OHM 1/6W ±5% 1

R17. 1006-803316-000 CARBON FILM RESISTOR 68K OHM 1/6W ±5% 1

R83. 1008-200316-000 CARBON FILM RESISTOR 82 OHM 1/6W ±5% 1

R28. 1008-202316-000 CARBON FILM RESISTOR 8.2K OHM 1/6W ±5% 1

R47. 1009-100316-000 CARBON FILM RESISTOR 91 OHM 1/6W ±5% 1

R105-108. 1011-002014-000 METAL FILM RESISTOR 1K OHM 1/4W ±1% 4

R77/78. 1011-104016-000 METAL FILM RESISTOR 100K 1/6W ±1% 2

R71-76 1011-502016-000 METAL FILM RESISTOR 1.5K OHM 1/4W ±1% 6

R67/68 1011-802014-000 METAL FILM RESISTOR 1.8K OHM 1/4W ±1% 2

R69/70 1014-701014-000 METAL FILM RESISTOR 470K OHM 1/4W ±1% 2

R65/66 1015-102016-000 METAL FILM RESISTOR 5.1K OHM 1/6W ±1% 2

VR1 1051-003500-001 VARIABLE RESISTOR 10K OHM ±30% 1

VR2-4 1052-003600-110 VARIABLE RESISTOR 20K OHM ±30% 3

CAPACITOR

C50/51 1100-100042-001 CERAMIC CAP. 10pF/50V ±5% NPO 2

C44/114/122 1100-102044-000 CERAMIC CAP. 1000pF/50V ±20% 3

C97/98/104108/121/128

C38/45-47/49/7780/85/86/91-94/99/111

C67/68 1100-221043-000 CERAMIC CAP. 220pF/50V ±10% 2

C31 1101-102063-000 POLYESTER/MYLAR CAP. 0.001uF/100V ±10% 1

C6/12/18/27/32 1101-103063-000 POLYESTER/MYLAR CAP. 0.01uF/100V ±10% 5

C8/9/16/19/20/24/26 1101-104063-000 POLYESTER/MYLAR CAP. 0.1uF/100V ±10% 7

C37 1101-152063-000 POLYESTER/MYLAR CAP. 0.0015uF/100V ±10% 1

C3/4/23/34/35 1101-223063-000 POLYESTER/MYLAR CAP. 0.022uF/100V ±10% 5

C5 1101-332063-000 POLYESTER/MYLAR CAP. 3300pF/100V ±10% 1

C7/13/29 1101-333063-000 POLYESTER/MYLAR CAP.0.033uF/100V ±10% 3

C21/25/36 1101-473063-000 POLYESTER/MYLAR CAP. 0.047uF/100V ±10% 3

C22 1101-682063-000 POLYESTER/MYLAR CAP. 0.0068uF/100V ±10% 1

C1/2/30/33/102/103 1102-101014-000 ELECT. CAP. 100uF/16V ±20% 6

C61-66 1102-101024-000 ELECT. CAP. 100uF/25V ±20% 6

C17 1102-220014-000 ELECT. CAP. 22uF/16V ±20% 1

1001-001316-000 CARBON FILM RESISTOR 100 OHM 1/6W ±5% 13

1100-103044-000 CREAMIC CAP. 0.01uF/50V ±20% 9

1100-104044-000 CERAMIC CAP. 0.1uF/50V ±20% 17

1101-222062-000 POLYESTER/ MYLAR CAP. 2200pF/100V ±5% 6

FL8550

Page 62

C39/-39/42/75/76/100 1102-221014-000 ELECT. CAP. 220uF/16V ±20% 6

62

C95/96/101 1102-222014-000 ELECT. CAP. 2200uF/16V ±20% 3

C53-60 1102-337024-000 ELECT. CAP. 3.3uF/25V ±20% 8

C11/28/43 1102-470014-000 ELECT. CAP. 47uF/16V ±20% 3

C41/48/87-90 1102-471014-000 ELECT. CAP. 470uF/16V ±20% 6

C10 1102-477044-000 ELECT. CAP. 4.7uF/50V ±20% 1

C14/15 1102-478044-000 ELECT. CAP. 0.47UF/50V ±20% 2

TRANSISTOR

Q4/6/7 1300-805000-100 TRANSISTOR NPN 8050D TO92 (SAMSUNG) 3

Q5 1300-945000-100 TRANSISTOR NPN KSC945-Y (SAMSUNG) 1

Q1 1301-733000-100 TRANSISTOR PNP A733 1

Q2 1301-928000-100 TRANSISTOR PNP KS928A TO-92 (SAMSUNG) 1

DIODE

D1-5/7-10 1401-140020-000 DIODE RECTIFIER 1N4002 9

D6/11 1401-141480-000 DIODE 1N4148 2

ZD3 1402-510001-200 ZENER DIODE 5.1V 1/2W 1

ZD2 1402-560000-000 ZENER DIODE 5.6V 1/2W 1

ZD1 1402-620001-200 ZENER DIODE 6.2V1/2W 1

MISCELLANEOUS

J20 1503-353400-100 FERRITE COILS B3534 1

XTAL 1600-169343-000 CRYSTAL 16.9344 ± 30PPM 49U3H TYPE 1

CN19 2300-002000-001 STRAIGHT CONN. WAFER 2PINS 2mmP JST 1

CN20 2300-003000-001 STRAIGHT CONN. WAFER 3PINS 2mmP JST 1

CN1 2300-005000-000 STRAIGHT CONN. WAFER 5PINS 2mmP 1

CN3/5/6/17/18 2300-006000-001 STRAIGHT CONN. WAFER 6PINS 2mmP JST 5

CN2 2300-008000-000 STRAIGHT CONN. WAFER 8PINS 2mmP 1

CN11 2300-010000-000 STRAIGHT CONN. WAFER 10PINS 2mmP 1

CN10 2300-012000-000 STRAIGHT CONN. WAFER 12PINS 2mmP 1

CN4/14 2500-023001-040 2PINS 300MM 1CONN.(JST) CABLE AWG#26 2mmP 2

CN21 TO CN502 2500-037001-050 3PINS 700MM 1CONN. CABLE AWG#28 2mmP 1

CN3 2501-062801-150 6PINS 280MM 2CONN. RIBBON CABLE AWG#28 2mmP 1

CN2 2501-084001-150 8PINS 400MM 2CONN. CABLE AWG#28 2mmP 1

CN5 TO CN17 2506-062201-150 6PINS 220MM 2CONN. RIBBON CABLE AWG#28 2mmP 1

CN13 TO CN713 2510-024501-050 2PINS 450MM 1CONN. SHIELD CABLE AWG#28 2mmP 1

CN15 TO CN712 2510-044501-050 4PINS 450MM 1CONN. SHIELD CABLE AWG#28 2mmP 1

CN16 2510-047001-050 4PINS 700MM 1CONN. SHIELD CABLE AWG#28 2mmP 1

CN1 2510-052501-060

2600-100654-200 65MM JUMPER WIRE AWG#26 UL1007 RED 1

2600-102004-000 200MM JUMPER WIRE AWG#26 UL1007 BLACK 1

4002-311975-000 TOROID COILS “T31X19X7.5MM” 2

F101 4030-100000-000 MICRO FUSE 1A 1

RLY 1/2 4050-520000-000 RELAY DS2Y-SDC5V (NATIONAL) 2

5PINS 250MM 1 CONN. SHIELD CABLE AWG#30 2mmP 1

INTEGRATED CIRCUIT

U9 4100-100056-200 I.C. PMD100 HDCD DIP (PACIFIC MICROSONICS)

HDCD DECODER

U10/11 4117-020104-600 I.C. PCM1702U SOP (BURR-BROWN) DAC 2

U12-15 4155-320052-100 I.C. NE5532N 8P DIP (PHILIPS) OP-AMP 4

U8 4174-040012-100 I.C. 74HC04 DIP (PHILIPS) CMOS 1

U7 4174-740052-100 I.C. 74HC74 DIP (PHILIPS) CMOS 1

U16 4178-050304-100 I.C. 7805 3PINS TO-220 (JRC) REGULATOR 1

U19 4178-050310-000 I.C. LM78L05 TO92 REGULATOR 1

U6 4178-080301-400 I.C. MC7808AC 3PINS TO-220 (MOTOROLA)

REGULATOR

U17 4178-080310-000 I.C. 78L08 TO92 (MIRCO) REGULATOR 1

U20 4179-050310-000 I.C. LM79L05 TO92 REGULATOR 1

U18 4179-080311-600 I.C. 79L08 TO92 (NJRC) OP-AMP 1

U4/5 4183-010020-400 I.C. KA8301 10PINS SIL MOTOR DRIVER 2

U1 4192-200122-400 I.C. KA9220C QFP SAMSUNG SSP 1

U2 4192-580122-400 I.C. KA9258D SMT SAMSUNG MOTOR DRIVE 1

U3 4192-840122-400 I.C. KS9284 QFP SAMSUNG DSP 1

FL8550

1

1

Page 63

FL8350/8550 HEADPHONE BOARD

63

RESISTOR

R511-514 1001-003316-000 CARBON FILM RESISTOR 10K OHM 1/6W +-5% 4

R507-510 1001-004316-000 CARBON FILM RESISTOR 100K OHM 1/6W +-5% 4

R503/504 1001-503316-000 CARBON FILM RESISTOR 15K OHM 1/6W +-5% 2

R501/502 1004-701316-000 CARBON FILM RESISTOR 470 OHM 1/6W +-5% 2

R515/516 1005-600314-000 CARBON FILM RESISTOR 56 OHM 1/6W +-5% 2

R505 1065-003500-130 VAR. RESISTOR 50K 1/4W +-20% ROTARY B-TYPE 1

CAPACITOR

C509/510 1100-102044-000 CERAMIC CAP. 1000pF/50V +-20% 2

C511 1100-103044-000 CERAMIC CAP. 0.01uF/50V +-20% 1

C503/504/511 1100-104044-000 CERAMIC CAP. 0.1uF/50V +-20% 3

C505-508 1102-100044-000 ELECT. CAP. 10uF/50V +-20% 4

C501/502 1102-101044-000 ELECT. CAP. 100uF/50V +-20% 2

MISCELLANEOUS

CN501-502 2300-003000-001 STRAIGHT CONN. WAFER 3PINS 2mmP JST 2

U502 2320-009911-003 6.4MM HEADPHONE JACK (JY-6303-02-030) GD

PLT

2605-100902-000 90MM GND WIRE 1RING (M3) AWG#22 BLK 1

INTEGRATED CIRCUIT

U501 4145-580051-600 I.C. NJM 4558L (NJRC) OP-AMP 1

FL8550

1

FL8350/8550 CONTROL BOARD

RESISTOR

R831-832 1001-201316-000 CARBON FILM RESISTOR 120 OHM 1/6W +-5% 2

R833 1001-801316-000 CARBON FILM RESISTOR 180 OHM 1/6W +-5% 2

R834 1001-201316-000 CARBON FILM RESISTOR 120 OHM 1/6W +-5% 1

R835 1002-201316-000 CARBON FILM RESISTOR 330 OHM 1/6W +-5% 1

MISCELLANEOUS

S831-835 2400-020200-000 TACT SW 2P2T KPT-1105A (5MM) 5

CN831 2500-022001-040 2PIN 200MM 1 CONN CABLE AWG#26 2MMP 1

FL8350/8550 POWER BOARD

2610-221000-000 2100MM POWER CORD W/POLARZED PLUG UL

SPT-2 AWG#18

3200-480140-401 TRANSFORMER EI48 118V CUL #4801Y44T-1

(WINBOND)

4002-311975-000 TOROID COILS “T31X19X7.5MM” 1

FL8350/8550 POWER CONTROL BOARD

RESISTOR

R841 1001-501316-000 CARBON FILM RESISTOR 150 OHM 1/6W ±5% 1

MISCELLANEOUS

S841 2400-020200-003 PUSH SWITCH 2P2T ESB64801 (MATSUSHITA) 1

CN841 2500-032201-050 3PIN 220MM 1CONN CABLE AWG#28 UL1571 1

D841 3100-204000-001 LED 5MM BI-COLOR A/G #BL-BAG204 1

1

1

FL8550 MCU BOARD

RESISTOR

R701 1001-000320-000 CARBON FILM RESISTOR 10 OHM 2W ±5% 1

R704-705 1001-001314-000 CARBON FILM RESISTOR 100 OHM 1/4W ±5% 2

R703/722-725 1001-002316-000 CARBON FILM RESISTOR 1K OHM 1/6W ±5% 5

R731 1001-004316-000 CARBON FILM RESISTOR 100K OHM 1/6W ±5% 1

Page 64

R708 1001-005316-000 CARBON FILM RESISTOR 1M OHM 1/6W ±5% 1

64

R706 1002-203316-000 CARBON FILM RESISTOR 22K OHM 1/6W ±5% 1

R730 1002-403316-000 CARBON FILM RESISTOR 24K OHM 1/6W ±5% 1

R702 1008-202316-000 CARBON FILM RESISTOR 8.2K OHM 1/6W ±5% 1

R733 1041-003318-331 RESISTOR ARRAY 10K x 4 1/8W TYPE A 1

CAPACITOR

C701 1100-102044-000 CERAMIC CAP. 0.01UF/50V ±20% 1

C703 1100-103044-000 CERAMIC CAP. 0.1UF/50V ±20% 1

C710/711 1100-104044-000 CERAMIC CAP. 22PF ±5% ‘NPO’ 2

C707 1102-100004-000 ELECT. CAP. 10UF/10V ±20% 1

C705 1102-100044-000 ELECT. CAP. 10UF/50V ±20% 1