Page 1

2008 Softail Models Service

Manual

©2008 H-D.

ALL RIGHTS RESERVED

99482-08A

Printed in the U.S.A.

VISIT THE HARLEY-DAVIDSON WEB SITE

http://www.harley-davidson.com

Page 2

ABOUT THIS MANUAL

GENERAL

This Service Manual has been prepared with two purposes in

mind. First, it will acquaint the user with the construction of the

Harley-Davidson product and assist in the performance of basic

maintenance and repair. Secondly, it will introduce to the professional Harley-Davidson Technician the latest field-tested

and factory-approved major repair methods. We sincerely

believe that this Service Manual will make your association

with Harley-Davidson products more pleasant and profitable.

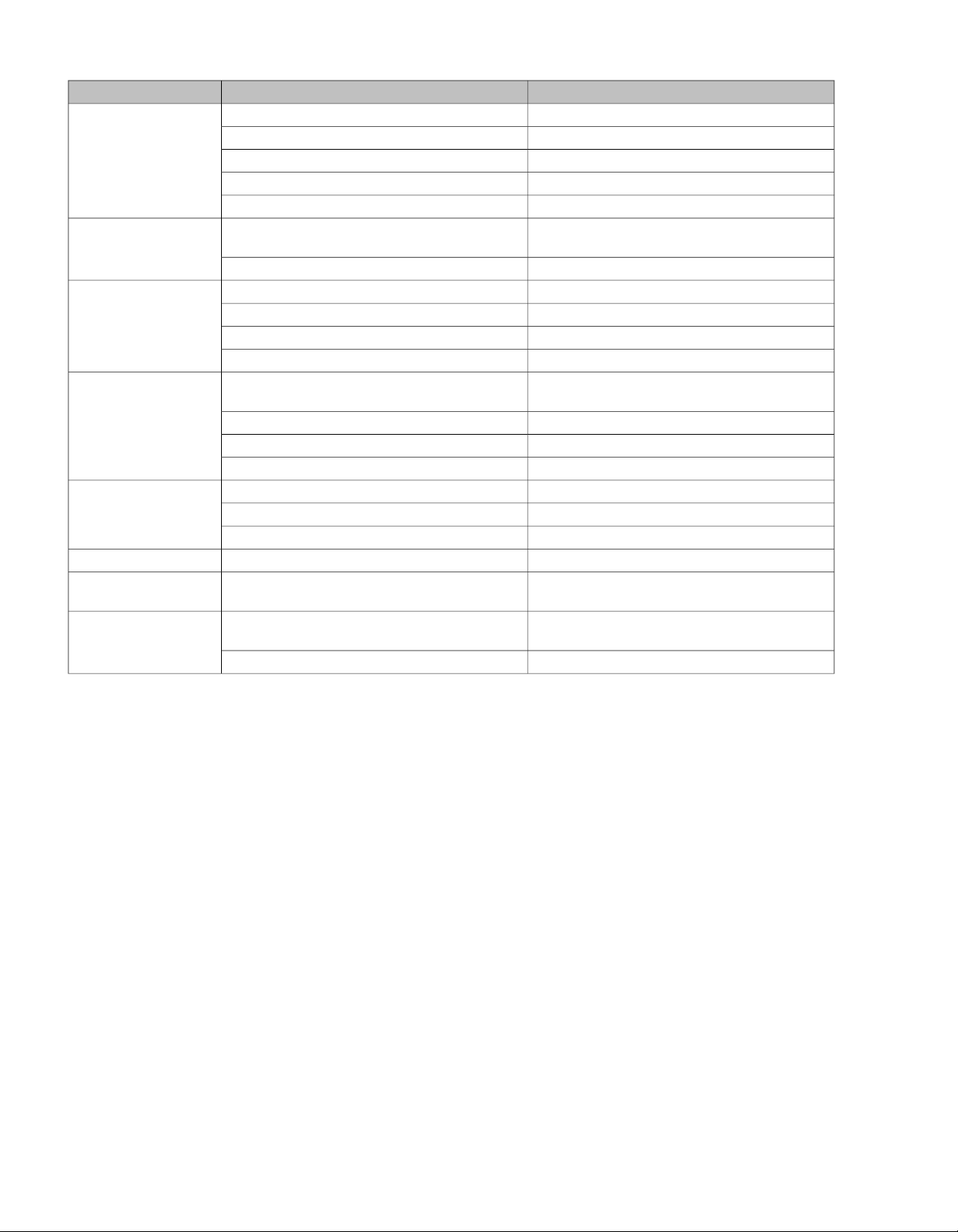

HOW TO USE YOUR SERVICE MANUAL

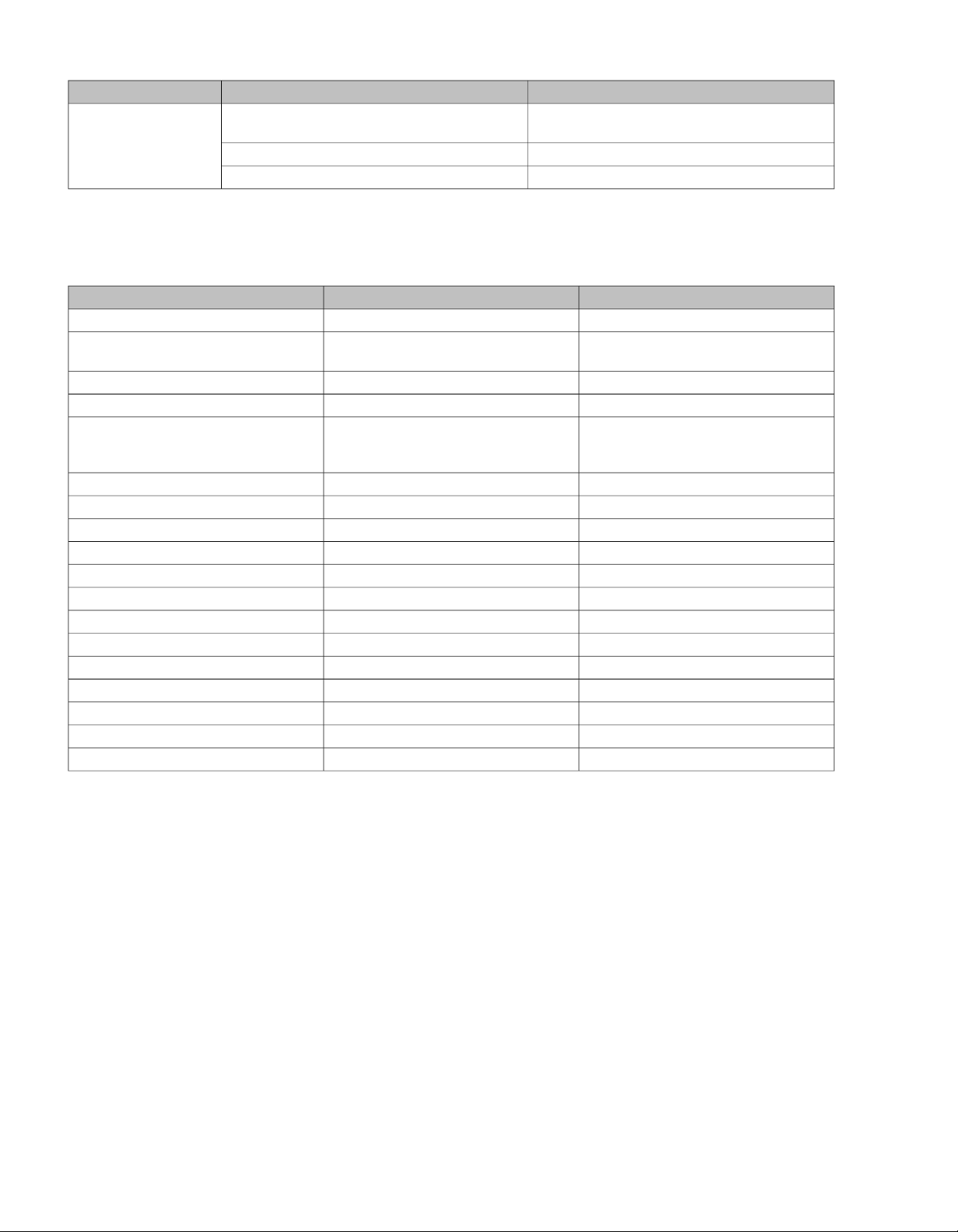

Refer to the table below for the content layout of this manual.

CHAPTERNO.

Maintenance1

Chassis2

Engine3

Fuel System4

Starter5

Drive6

Transmission7

Electrical8

Appendix A Connector RepairA

Appendix B WiringB

Appendix C ConversionsC

Appendix D GlossaryD

Use the TABLE OF CONTENTS (which follows this FOREWORD) and the INDEX (at the back of this manual) to quickly

locate subjects. Sections and topics in this manual are

sequentially numbered for easy navigation.

For example, a cross-reference shown as 2.1 SPECIFICA-

TIONS refers to chapter 2 CHASSIS, heading 2.1 SPECIFICATIONS.

For quick and easy reference, all pages contain a section

number followed by a page number. For example, page 3-5

refers to page 5 in section 3.

A number of acronyms and abbreviations are used in this

document. See the D.1 GLOSSARY for a list of acronyms,

abbreviations and definitions.

gathered before work is started. Interrupting a job to locate

tools or parts is a distraction and causes needless delay.

NOTES

• To avoid unnecessary disassembly, carefully read all relative service information before repair work is started.

• In figure legends, the number which follows the name of

a part indicates the quantity necessary for one complete

assembly.

• When servicing a vehicle equipped with the HarleyDavidson Smart Security System (H-DSSS), you must

first disarm the security system. Either keep the fob in

close proximity to the vehicle, or use Digital Technician to

disable the security system while the vehicle is being serviced and re-enable the system after service is completed.

SERVICE BULLETINS

In addition to the information presented in this Service Manual,

Harley-Davidson Motor Company will periodically issue Service

Bulletins to Harley-Davidson dealers. Service Bulletins cover

interim engineering changes and supplementary information.

Consult the Service Bulletins to keep your product knowledge

current and complete.

USE GENUINE REPLACEMENT PARTS

Do not use aftermarket parts and custom made front forks

which can adversely affect performance and handling.

Removing or altering factory installed parts can adversely

affect performance and could result in death or serious

injury. (00001a)

To ensure satisfactory and lasting repairs, carefully follow the

Service Manual instructions and use only genuine HarleyDavidson replacement parts. Behind the emblem bearing the

words GENUINE HARLEY-DAVIDSON stand more than 100

years of design, research, manufacturing, testing and inspecting

experience.This is your assurance that the parts you are using

will fit right, operate properly and last longer.

WARNINGS AND CAUTIONS

Statements in this service manual preceded by the following

words are of special significance.

FOREWORD

PREPARATION FOR SERVICE

Stop the engine when refueling or servicing the fuel

system. Do not smoke or allow open flame or sparks near

gasoline. Gasoline is extremely flammable and highly

explosive, which could result in death or serious injury.

(00002a)

Good preparation is very important for efficient service work.

A clean work area at the start of each job will allow you to

perform the repair as easily and quickly as possible, and will

reduce the incidence of misplaced tools and parts. A motorcycle

that is excessively dirty should be cleaned before work starts.

Cleaning will occasionally uncover sources of trouble. Tools,

instruments and any parts needed for the job should be

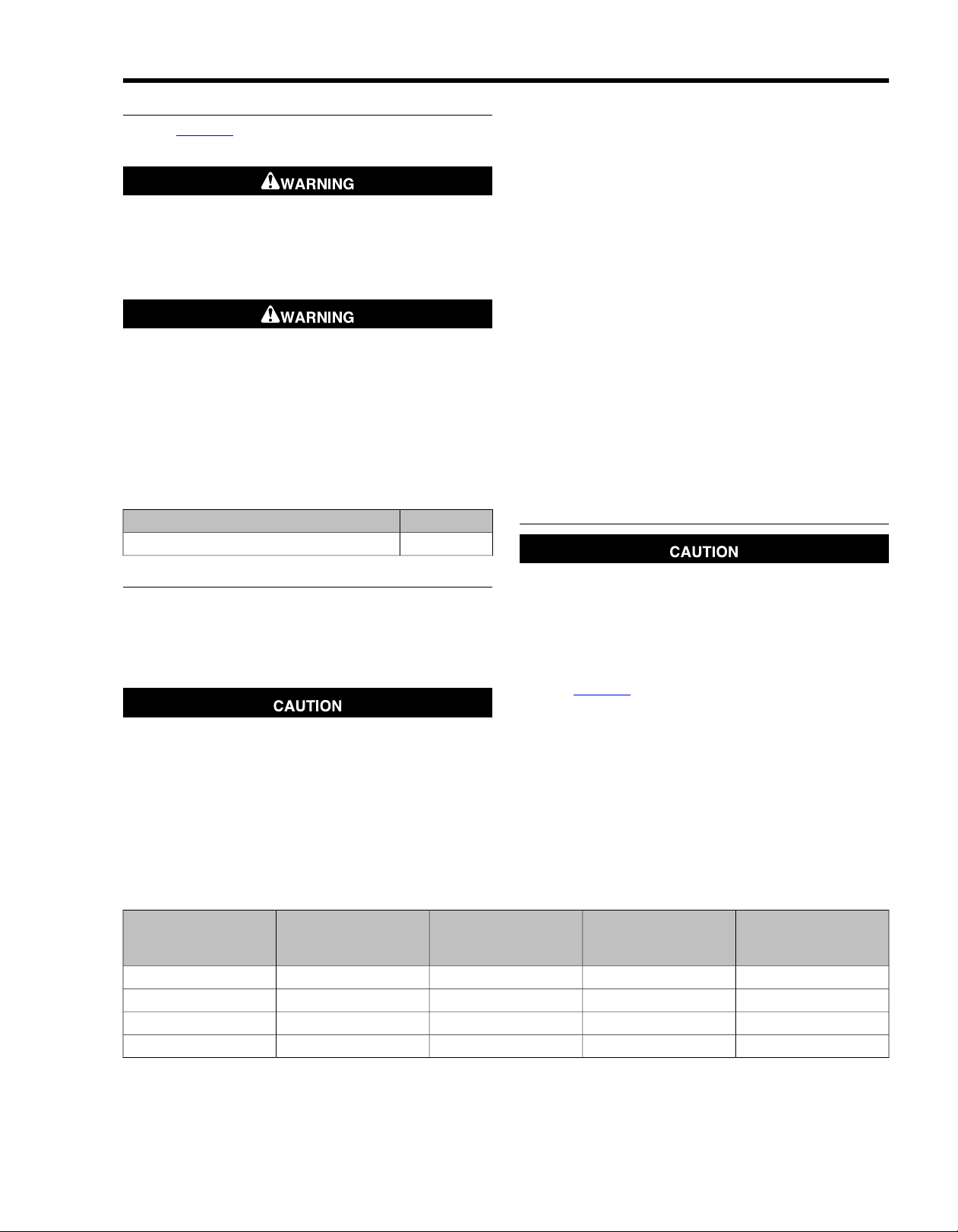

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury. (00119a)

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. (00139a)

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage. (00140a)

I

Page 3

NOTE

Refers to important information, and is placed in italic type. It

is recommended that you take special notice of these items.

Proper service and repair is important for the safe, reliable

operation of all mechanical products.The service procedures

recommended and described in this service manual are

effective methods for performing service operations.

information or product returns, warranty or otherwise, visit

www.spx.com.

Loctite Sealing and Threadlocking Pr oducts

Some procedures in this manual call for the use of Loctite

products. If you have any questions regarding Loctite product

usage or retailer/wholesaler locations, please contact Loctite

Corp. at www.loctite.com.

PRODUCT REGISTERED MARKS

Always wear proper ey e protection when using hammer s,

arbor or hydraulic presses, gear pullers, spring compressors, slide hammers and similar tools. Flying parts

could result in death or serious injury. (00496b)

Some of these service operations require the use of tools

specially designed for the purpose.These special tools should

be used when and as recommended. It is important to note

that some warnings against the use of specific service methods,

which could damage the motorcycle or render it unsafe, are

stated in this service manual. Howe v er, please remember that

these warnings are not all-inclusive. Inadequate safety precautions could result in death or serious injury.

Since Harley-Davidson could not possibly know, evaluate or

advise the service trade of all possible ways in which service

might be performed, or of the possible hazardous consequences of each method, we have not undertaken any such

broad evaluation. Accordingly, anyone who uses a service

procedure or tool which is not recommended by HarleyDavidson must first thoroughly satisfy himself that neither his

nor the operator's safety will be jeopardized as a result. F ailure

to do so could result in death or serious injury.

PRODUCT REFERENCES

Allen, Amp Multilock, Bluetooth, Brembo, Delphi, Deutsch,

Dunlop, Dynojet, Fluke, G.E. Versilube, Gunk, Hydroseal,

Hylomar, Kevlar, Lexan, Loctite, Lubriplate, Keps, K&N, Magnaflux, Marson Thread-Setter Tool Kit, MAXI fuse, Molex, MPZ,

Mulitilock, Novus, Packard, Pirelli, Permatex, Philips, PJ1,

Pozidriv , Robinair , S100, Sems, Snap-on, Teflon, Threadlocker ,

Torca, Torco, TORX, Tufoil, Tyco, Ultratorch, Velcro, X-Acto,

and XM Satellite Radio are among the trademarks of their

respective owners.

H-D MICHIGAN, INC.TRADEMARK

INFORMATION

Harley, Harley-Davidson, H-D, Bar & Shield, Digital Tech,

Digital Technician, Destroyer, Deuce, Dyna, Electra Glide,

Evolution, F at Boy, Glaze, Gloss, H-D, H-Dnet.com, HD , Harley,

Heritage Softail, Heritage Springer, Low Rider, Night Rod, Night

Train, Profile, Revolution, Road Glide, Road King, Rocker,

Softail, Sportster, Sun Ray, Sunwash, Tech Link, Twin Cam

88, Twin Cam 88B, Twin Cam 96, Twin Cam 96B, Twin Cam

103, Twin Cam 103B, Twin Cam 110, Twin Cam 110B, TourPak, Screamin' Eagle, Softail, Super Guide, Super Premium,

SYN3, Ultra Glide, V-Rod, VRSC, Wide Glide, and HarleyDavidson Genuine Motor Parts and Genuine Motor Accessories

are among the trademarks of H-D Michigan, Inc.

CONTENTS

Read and follow warnings and directions on all products.

Failure to follow warnings and directions can result in

death or serious injury. (00470b)

When reference is made in this manual to a specific brand

name product, tool or instrument, an equivalent product, tool

or instrument may be substituted.

Kent-Moore Products

All tools mentioned in this manual with an "HD", "J" or "B"

preface must be ordered through SPX K ent-Moore. For ordering

All photographs, illustrations and procedures may not necessarily depict the most current model or component, but are

based on the latest production information available at the time

of publication.

Since product improvement is our continual goal, HarleyDavidson reserves the right to change specifications, equipment

or designs at any time without notice and without incurring

obligation.

II FOREWORD

Page 4

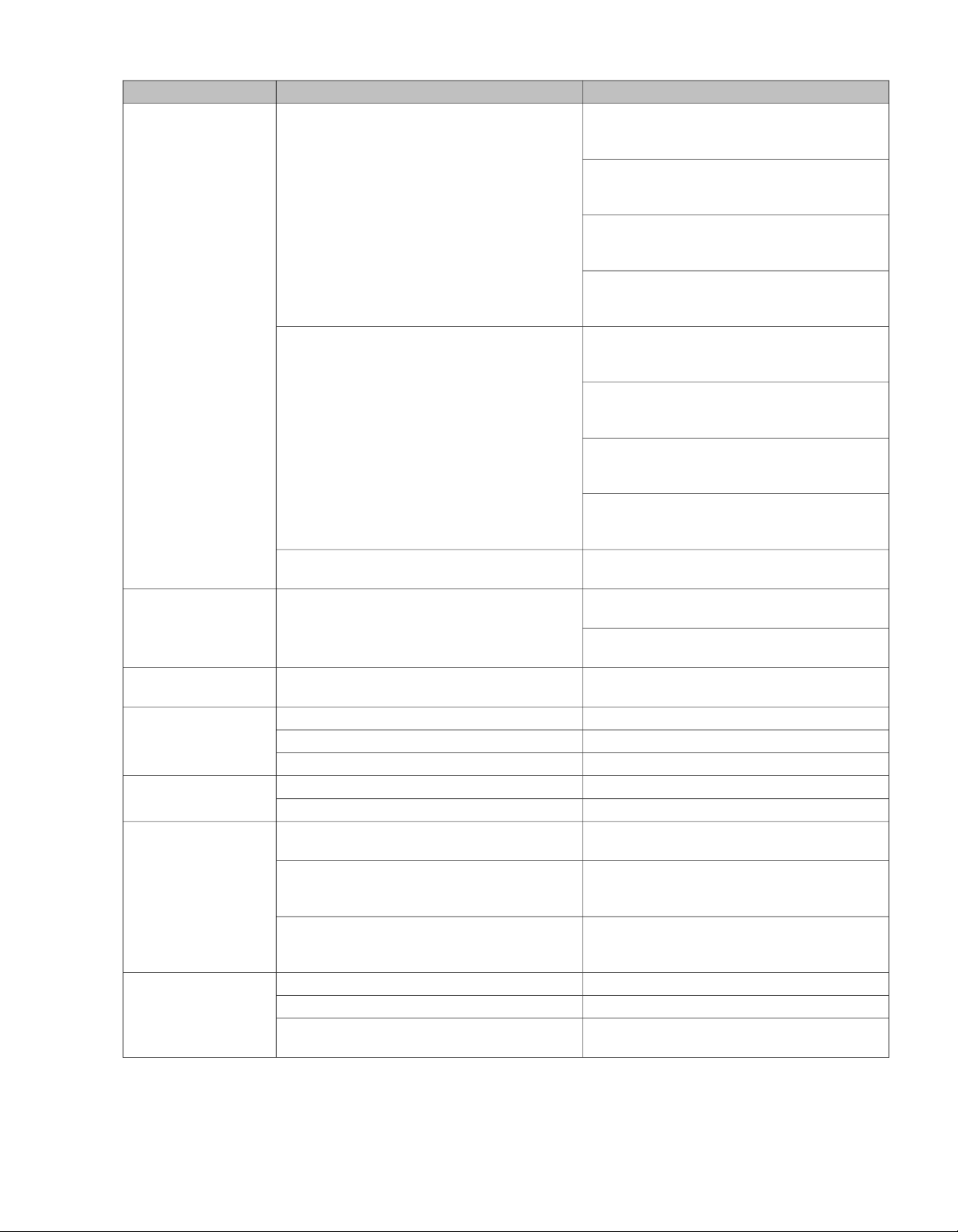

MAINTENANCE

Pedal Lubrication.......................................................1-14

Pedal Pad..................................................................1-14

1.1 GENERAL

Servicing a New Motorcycle...............................................1-1

Safe Operating Maintenance..............................................1-1

Shop Practices...................................................................1-1

Repair Notes...............................................................1-1

Safety..........................................................................1-1

Removing Parts...........................................................1-1

Cleaning......................................................................1-1

Disassembly and Assembly........................................1-2

Checking Torques on Fasteners with Lock Patches.....1-2

Magnetic Parts Trays...................................................1-2

Repair and Replacement Procedures................................1-2

Hardware and Threaded Parts....................................1-2

Threadlocking Agents..................................................1-2

Wiring, Hoses and Lines.............................................1-2

Instruments and Gauges.............................................1-2

Bearings......................................................................1-2

Bushings.....................................................................1-2

Gaskets.......................................................................1-2

Lip Type Seals.............................................................1-2

O-Rings (Preformed Packings)....................................1-3

Gears..........................................................................1-3

Shafts..........................................................................1-3

Part Replacement........................................................1-3

Exhaust System Leakage............................................1-3

Cleaning.............................................................................1-3

Part Protection............................................................1-3

Cleaning Process........................................................1-3

Rust or Corrosion Removal.........................................1-3

Bearings......................................................................1-3

Tool Safety..........................................................................1-3

Air Tools.......................................................................1-3

Wrenches....................................................................1-3

Pliers/Cutters/Pry bars................................................1-3

Hammers.....................................................................1-4

Punches/Chisels..........................................................1-4

Screwdrivers................................................................1-4

Ratchets and Handles.................................................1-4

Sockets........................................................................1-4

Storage Units...............................................................1-4

1.2 MAINTENANCE SCHEDULE

General...............................................................................1-5

1.3 FUEL AND OIL

Fuel....................................................................................1-9

Gasoline Blends.................................................................1-9

Engine Lubrication..............................................................1-9

Winter Lubrication............................................................1-10

1.4 BULB REQUIREMENTS

General.............................................................................1-11

1.5 ENGINE OIL AND FILTER

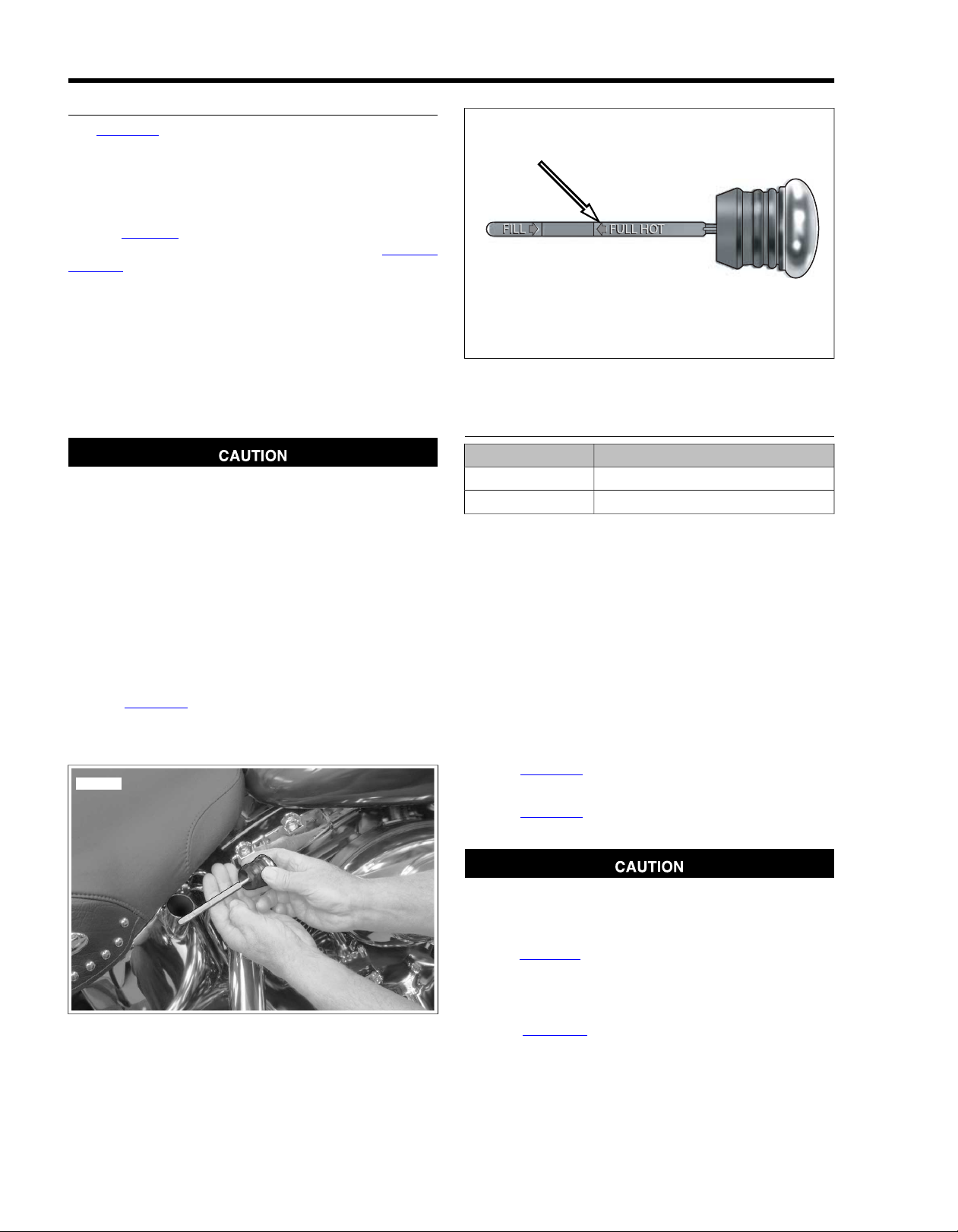

Checking and Adding Oil..................................................1-12

Type of Oil.................................................................1-12

Checking Oil Level.....................................................1-12

Changing Oil and Filter.....................................................1-12

1.6 BRAKES

Fluid Inspection................................................................1-14

Rear Brake Pedal.............................................................1-14

Pedal Height..............................................................1-14

1.7 AIR CLEANER AND EXHAUST SYSTEM

Removal...........................................................................1-16

Installation........................................................................1-17

Exhaust System Leak Check............................................1-18

1.8 TIRES AND WHEELS

Tires.................................................................................1-19

Tire Replacement.............................................................1-19

Inspection..................................................................1-19

When To Replace Tires.............................................1-19

Wheel Bearings................................................................1-20

Wheel Spokes..................................................................1-20

1.9 PRIMARY CHAIN

General.............................................................................1-21

Changing Primary Chaincase Lubricant...........................1-21

1.10 TRANSMISSION LUBRICANT

Changing Transmission Lubricant.....................................1-23

1.11 CLUTCH

Adjustment.......................................................................1-25

1.12 REAR BELT AND SPROCKETS

General.............................................................................1-27

Cleaning...........................................................................1-27

Inspection.........................................................................1-27

Sprockets..................................................................1-27

Rear Belt...................................................................1-27

1.13 REAR BELT DEFLECTION

Inspection.........................................................................1-29

Adjustment.......................................................................1-29

1.14 THROTTLE CABLES

Cable Inspection, Lubrication and Adjustment.................1-31

Inspection and Lubrication........................................1-31

Adjustment................................................................1-31

1.15 BLEEDING BRAKES

General.............................................................................1-32

Procedure.........................................................................1-32

1.16 BRAKE PADS AND DISCS

Inspection.........................................................................1-33

Brake Pads................................................................1-33

Brake Disc.................................................................1-33

Brake Pad Replacement...................................................1-33

Rear Brake Caliper....................................................1-33

Front Brake Caliper...................................................1-35

1.17 BATTERY MAINTENANCE

General.............................................................................1-37

Cleaning and Inspection...................................................1-38

Voltmeter Test...................................................................1-38

Voltmeter Test............................................................1-38

Charging Battery..............................................................1-38

Safety Precautions....................................................1-38

Using a Battery Charger............................................1-38

Disconnection and Removal.............................................1-39

Storage.............................................................................1-40

Installation and Connection..............................................1-41

TABLE OF CONTENTS

III

Page 5

TABLE OF CONTENTS

1.18 SUSPENSION ADJUSTMENTS

Shock Absorbers: Softail Models......................................1-43

Adjustment................................................................1-43

1.19 SPARK PLUGS

Inspection.........................................................................1-44

Spark Plug Cable Inspection............................................1-44

1.20 STEERING HEAD BEARINGS: ALL BUT

FLSTSB

Adjustment: FLST, FLSTC, FLSTF, FLSTN......................1-46

Bearing Adjustment (Fall-away)................................1-46

Adjustment: FXST, FXSTB, FXSTC, FXCW/C..................1-47

Bearing Adjustment (Fall-away)................................1-47

Lubrication........................................................................1-48

1.21 STEERING HEAD BEARINGS: FLSTSB

General.............................................................................1-49

Lubrication.................................................................1-49

Adjustment: FLSTSB........................................................1-49

Bearing Adjustment (Fall-away)................................1-49

1.22 ROCKER BEARINGS: FLSTSB

Inspection.........................................................................1-51

1.23 FRONT FORK OIL

Replacing Fork Oil............................................................1-53

1.24 CABLE AND CHASSIS LUBRICATION

General.............................................................................1-54

Cables and Hand Levers..................................................1-54

Jiffy Stand.........................................................................1-54

Steering Head Bearings...................................................1-54

1.25 HEADLAMP ALIGNMENT

Inspection.........................................................................1-55

Adjustment.......................................................................1-56

1.26 CRITICAL FASTENERS

Inspection.........................................................................1-57

1.27 ENGINE MOUNTS

Inspection.........................................................................1-58

1.28 STORAGE

General.............................................................................1-59

Placing in Storage............................................................1-59

Removal from Storage......................................................1-59

1.29 TROUBLESHOOTING

General.............................................................................1-61

Engine..............................................................................1-61

Starter Motor Does Not Operate or Does Not Turn Engine

Over ..........................................................................1-61

Engine Turns Over But Does Not Start .....................1-61

Starts Hard................................................................1-61

Starts But Runs Irregularly or Misses .......................1-61

A Spark Plug Fouls Repeatedly................................1-62

Pre-Ignition or Detonation (Knocks or Pings)............1-62

Overheating...............................................................1-62

Valve Train Noise.......................................................1-62

Excessive Vibration...................................................1-62

Check Engine Light Illuminates During Operation.....1-62

Lubrication System...........................................................1-62

Oil Does Not Return To Oil Tank................................1-62

Engine Uses Too Much Oil Or Smokes Excessively...1-62

Engine Leaks Oil From Cases, Push Rods, Hoses,

Etc.............................................................................1-62

Low Oil Pressure.......................................................1-63

High Oil Pressure......................................................1-63

Electrical System..............................................................1-63

Alternator Does Not Charge......................................1-63

Alternator Charge Rate Is Below Normal..................1-63

Speedometer Operates Erratically............................1-63

Transmission.....................................................................1-63

Shifts Hard................................................................1-63

Jumps Out Of Gear...................................................1-63

Clutch Slips...............................................................1-63

Clutch Drags Or Does Not Release..........................1-63

Clutch Chatters..........................................................1-63

Handling...........................................................................1-63

Irregularities..............................................................1-63

Brakes..............................................................................1-63

Brake Does Not Hold Normally.................................1-63

CHASSIS

2.1 SPECIFICATIONS

Specifications.....................................................................2-1

Chassis Specifications................................................2-1

Tire Specifications.......................................................2-2

2.2 VEHICLE IDENTIFICATION NUMBER

(V.I.N.)

Vehicle Identification Number.............................................2-4

2.3 FRONT WHEEL: ALL BUT FLSTSB

Removal.............................................................................2-6

Disassembly.......................................................................2-6

Disc Wheel..................................................................2-6

Laced Wheel...............................................................2-6

Cleaning and Inspection.....................................................2-8

Assembly............................................................................2-8

Disc Wheel..................................................................2-8

Laced Wheel...............................................................2-8

Installation..........................................................................2-9

2.4 FRONT WHEEL: FLSTSB

Removal...........................................................................2-10

Disassembly.....................................................................2-10

Cleaning and Inspection...................................................2-10

Assembly..........................................................................2-10

Installation........................................................................2-11

2.5 REAR WHEEL

Removal...........................................................................2-12

Disassembly.....................................................................2-12

Cleaning and Inspection...................................................2-13

Assembly..........................................................................2-13

Installation........................................................................2-14

IV TABLE OF CONTENTS

Page 6

TABLE OF CONTENTS

2.6 SEALED WHEEL BEARINGS

Inspection.........................................................................2-15

Removal...........................................................................2-15

Installation........................................................................2-16

2.7 WHEEL LACING: 16 INCH RIM

General.............................................................................2-18

Procedure.........................................................................2-18

2.8 WHEEL LACING: 17 INCH RIM

General.............................................................................2-21

Procedure.........................................................................2-21

2.9 WHEEL LACING: 21 INCH RIM

General.............................................................................2-24

Procedure.........................................................................2-24

2.10 TRUING LACED WHEELS

General.............................................................................2-27

Lateral Truing....................................................................2-27

Radial Truing.....................................................................2-28

2.11 CHECKING CAST WHEEL RUNOUT

General.............................................................................2-30

Lateral Runout..................................................................2-30

Radial Runout...................................................................2-30

2.12 VEHICLE ALIGNMENT

Inspection.........................................................................2-31

2.13 FRONT BRAKE MASTER CYLINDER

General.............................................................................2-32

Removal and Disassembly...............................................2-32

Cleaning and Inspection...................................................2-34

Assembly and Installation.................................................2-34

2.14 FRONT BRAKE CALIPER: ALL BUT

FLSTSB

Removal...........................................................................2-36

Disassembly.....................................................................2-36

Cleaning, Inspection and Repair......................................2-38

Assembly..........................................................................2-39

Installation........................................................................2-39

2.15 FRONT BRAKE CALIPER: FLSTSB

Removal...........................................................................2-41

Disassembly.....................................................................2-42

Cleaning and Inspection...................................................2-43

Assembly..........................................................................2-44

Installation........................................................................2-45

2.16 REAR BRAKE MASTER CYLINDER

General.............................................................................2-47

Removal...........................................................................2-47

Installation........................................................................2-47

Disassembly.....................................................................2-49

Cleaning and Inspection...................................................2-50

Assembly..........................................................................2-50

2.17 REAR BRAKE CALIPER

Removal...........................................................................2-52

Disassembly.....................................................................2-52

Cleaning, Inspection and Repair......................................2-54

Assembly..........................................................................2-55

Installation........................................................................2-55

2.18 TIRES

General.............................................................................2-57

Removal...........................................................................2-57

Cleaning, Inspection and Repair......................................2-58

Installation........................................................................2-58

Tube Type Tires.........................................................2-58

Tubeless Tires...........................................................2-59

2.19 FRONT FORK:TELESCOPIC

General.............................................................................2-60

Removal...........................................................................2-60

Disassembly.....................................................................2-60

Cleaning and Inspection...................................................2-60

Assembly..........................................................................2-64

Installation........................................................................2-64

2.20 FRONT FORK: SPRINGER

General.............................................................................2-65

Front Shock Absorber.......................................................2-65

Removal....................................................................2-65

Installation.................................................................2-65

Rigid Fork.........................................................................2-65

Removal....................................................................2-65

Installation.................................................................2-66

Spring Fork.......................................................................2-66

Disassembly..............................................................2-66

Assembly...................................................................2-68

Fork Rockers....................................................................2-70

Removal....................................................................2-70

Installation.................................................................2-70

Fork Stem Bearings..........................................................2-71

Removal and Installation...........................................2-71

2.21 STEERING HEAD

Removal...........................................................................2-72

FLST, FLSTC, FLSTF, FLSTN Models......................2-72

FXST, FXSTC, FXSTB Models..................................2-72

FXCW/C Models........................................................2-72

FLSTSB Models........................................................2-73

Inspection.........................................................................2-73

All Models..................................................................2-73

Disassembly.....................................................................2-73

Removing Lower Bearings From Fork Stem.............2-73

Steering Head Bearing Race Removal.....................2-74

Assembly..........................................................................2-74

Installation........................................................................2-75

FLST, FLSTC, FLSTF, FLSTN Models......................2-75

FXST, FXSTC, FXSTB Models..................................2-75

FXCW/C Models........................................................2-75

FLSTSB Models........................................................2-75

2.22 BELT GUARD AND DEBRIS

DEFLECTOR

Removal...........................................................................2-76

TABLE OF CONTENTS V

Page 7

TABLE OF CONTENTS

Belt Guard.................................................................2-76

Debris Deflector........................................................2-76

Installation........................................................................2-76

Belt Guard.................................................................2-76

Debris Deflector........................................................2-76

2.23 REAR SHOCK ABSORBERS

General.............................................................................2-77

Removal...........................................................................2-77

Installation........................................................................2-77

2.24 REAR FORK

Removal...........................................................................2-79

Cleaning and Inspection...................................................2-80

Installation........................................................................2-80

2.25 THROTTLE CONTROL

Removal/Disassembly......................................................2-82

Cleaning and Inspection...................................................2-82

Assembly/Installation........................................................2-82

Cable Routing...................................................................2-83

2.26 CLUTCH CONTROL

Removal...........................................................................2-84

Installation........................................................................2-84

2.27 HANDLEBARS: ALL BUT

FLSTF/FLSTSB/FXCW/FXCWC

Removal...........................................................................2-86

Installation........................................................................2-87

2.28 HANDLEBARS: FLSTF

Removal...........................................................................2-88

Installation........................................................................2-89

2.29 HANDLEBARS: FLSTSB

Removal...........................................................................2-91

Installation........................................................................2-91

2.30 HANDLEBARS: FXCW/FXCWC

Removal...........................................................................2-93

Installation........................................................................2-94

2.31 FRONT FENDER: ALL BUT FLSTSB

Removal...........................................................................2-97

Installation........................................................................2-97

2.32 FRONT FENDER: FLSTSB

Removal...........................................................................2-98

Installation........................................................................2-99

2.33 REAR FENDER: FLST/FLSTC

Removal.........................................................................2-100

Installation......................................................................2-100

2.34 REAR FENDER: FLSTF

Removal.........................................................................2-102

Installation......................................................................2-102

2.35 REAR FENDER:

FXST/FXSTB/FXSTC/FLSTSB

Removal.........................................................................2-104

Installation......................................................................2-104

2.36 REAR FENDER: FXCW/FXCWC

Removal.........................................................................2-106

Installation......................................................................2-106

2.37 REAR FENDER: FLSTN

Removal.........................................................................2-108

Disassembly...................................................................2-108

Assembly........................................................................2-110

Installation......................................................................2-110

2.38 REAR FENDER WIRE CONDUIT

Installation......................................................................2-111

2.39 JIFFY STAND

Cleaning.........................................................................2-113

Sensor (HDI Models)......................................................2-113

Removal.........................................................................2-114

Installation......................................................................2-114

2.40 FORK LOCK

Removal.........................................................................2-115

Installation......................................................................2-115

2.41 SEAT AND STRAP RETENTION NUT

Replacement..................................................................2-116

2.42 SEAT: FXST/FXSTB

Removal and Installation................................................2-117

Seat Strap...............................................................2-117

Seat.........................................................................2-117

2.43 SEAT: FXSTC

Removal and Installation................................................2-118

Seat Strap...............................................................2-118

Seat.........................................................................2-118

2.44 SEAT: FXCW/FXCWC

Removal and Installation................................................2-119

Solo Seat: FXCW....................................................2-119

Rider Seat: FXCWC................................................2-119

Passenger Seat Support: FXCWC..........................2-119

2.45 SEAT: FLSTN/FLSTF/FLST/FLSTC

Removal and Installation................................................2-121

2.46 SEAT: FLSTSB

Seat: FLSTSB.................................................................2-122

Removal..................................................................2-122

Installation...............................................................2-122

Adjusting Seat Position...........................................2-122

2.47 LUGGAGE RACK: FLSTN

Removal and Installation................................................2-124

VI TABLE OF CONTENTS

Page 8

TABLE OF CONTENTS

2.48 SADDLEBAGS: FLSTC

Removal.........................................................................2-125

Installation......................................................................2-125

2.49 WINDSHIELD: FLSTC

Removal.........................................................................2-126

Installation......................................................................2-126

ENGINE

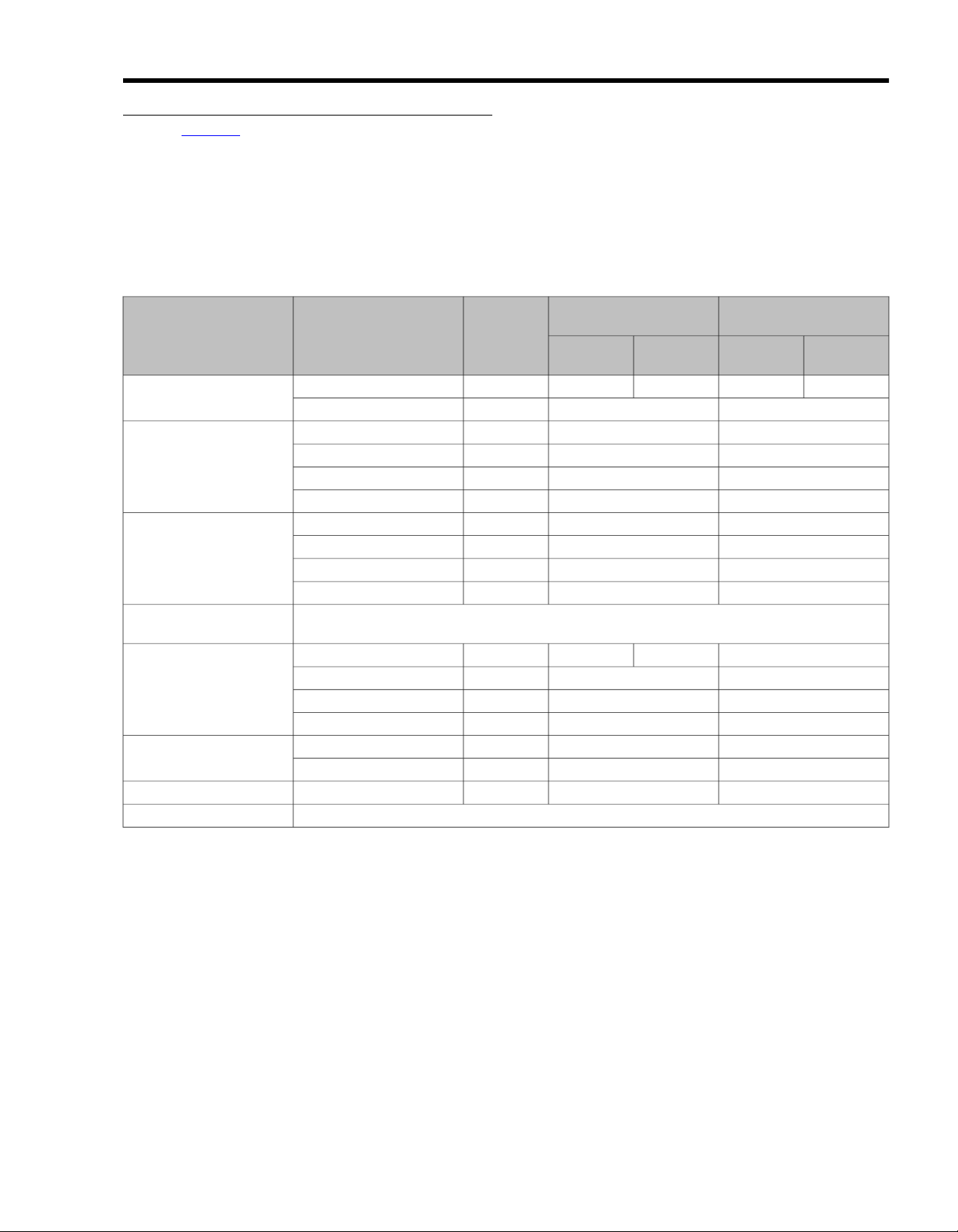

3.1 SPECIFICATIONS

Specifications.....................................................................3-1

3.2 SERVICE WEAR LIMITS

General...............................................................................3-3

3.3 ENGINE OIL FLOW

Oil Feed..............................................................................3-5

Top End..............................................................................3-6

Bottom End.........................................................................3-7

Chain Guide Bracket..........................................................3-9

Oil Return...........................................................................3-9

3.4 OIL PUMP OPERATION

General.............................................................................3-10

Operation..........................................................................3-10

3.5 BREATHER OPERATION

General.............................................................................3-12

3.6 OIL PRESSURE

Oil Pressure Indicator Lamp.............................................3-13

Checking Oil Pressure......................................................3-13

3.7 TROUBLESHOOTING

Diagnosing Valve Train Noise...........................................3-14

Compression Test.............................................................3-14

Cylinder Leakdown Test....................................................3-14

Diagnosing Smoking Engine or High Oil Consumption.....3-15

Check Prior To Cylinder Head Removal....................3-15

Check After Cylinder Head Removal.........................3-15

3.8 HOW TO USE THIS SECTION

Top End Repair.................................................................3-16

Bottom End Repair...........................................................3-16

Typical Symptoms.............................................................3-16

3.9 TOP END SERVICE

Engine in Chassis.............................................................3-17

Engine Removed from Chassis........................................3-18

3.10 BOTTOM END SERVICE

Engine in Chassis.............................................................3-19

Engine Removed From Chassis.......................................3-20

3.11 STRIPPING MOTORCYCLE FOR

SERVICE

Procedure.........................................................................3-21

3.12 ASSEMBLING MOTORCYCLE AFTER

SERVICE

Procedure.........................................................................3-22

3.13 REMOVING ENGINE FROM CHASSIS

Procedure.........................................................................3-23

3.14 INSTALLING ENGINE IN CHASSIS

Procedure.........................................................................3-24

3.15 TOP END OVERHAUL: DISASSEMBLY

General.............................................................................3-26

Rocker Covers..................................................................3-26

Rocker Arm Support Plate................................................3-26

Push Rods, Lifters and Covers.........................................3-28

Cylinder Head...................................................................3-29

Cylinder............................................................................3-30

Piston...............................................................................3-30

3.16 TOP END OVERHAUL: ASSEMBLY

General.............................................................................3-32

Piston...............................................................................3-32

Cylinder............................................................................3-33

Cylinder Head...................................................................3-35

Push Rods, Lifters and Covers.........................................3-38

Rocker Arm Support Plate................................................3-39

Breather Assembly...........................................................3-40

3.17 BOTTOM END OVERHAUL:

DISASSEMBLY

General.............................................................................3-42

Cover and Cam Support Plate..........................................3-42

Prepare Engine.........................................................3-42

Cam Chain and Sprockets........................................3-42

Cam Support Plate....................................................3-43

Crankcase........................................................................3-44

Counterbalancer Assembly..............................................3-45

3.18 BOTT OM END OVERHA UL: ASSEMBL Y

General.............................................................................3-48

Counterbalancer Assembly..............................................3-48

Crankcase........................................................................3-51

Cover and Cam Support Plate..........................................3-55

3.19 BREATHER ASSEMBLY

Removal Overview............................................................3-59

Disassembly.....................................................................3-59

Cleaning and Inspection...................................................3-59

Assembly..........................................................................3-59

Installation Overview........................................................3-59

3.20 ROCKER ARM SUPPORT PLATE

Removal Overview............................................................3-60

Disassembly.....................................................................3-60

Cleaning and Inspection...................................................3-60

Inspection..................................................................3-60

Rocker Shaft Fit.........................................................3-60

Rocker Arm Shaft to Bushing....................................3-61

Replace Rocker Arm Bushings.................................3-61

Assembly..........................................................................3-62

TABLE OF CONTENTS VII

Page 9

TABLE OF CONTENTS

Installation Overview........................................................3-62

3.21 PUSH RODS, LIFTERS AND COVERS

Removal Overview............................................................3-64

Disassembly.....................................................................3-64

Cleaning and Inspection...................................................3-64

Lifter Inspection................................................................3-65

Assembly..........................................................................3-65

Installation Overview........................................................3-66

3.22 CYLINDER HEAD

Removal Overview............................................................3-67

Disassembly.....................................................................3-67

Cleaning...........................................................................3-68

Inspection.........................................................................3-69

Cylinder Head............................................................3-69

Valve Guides.............................................................3-69

Valves........................................................................3-69

Valve Springs............................................................3-69

Tapered Keepers.......................................................3-70

Valve Seats...............................................................3-70

Valve Guide Replacement................................................3-70

Removal....................................................................3-70

Installation.................................................................3-71

Valve and Seat Refacing..................................................3-74

Assembly..........................................................................3-76

Installation Overview........................................................3-77

3.23 CYLINDER

Removal Overview............................................................3-78

Cleaning...........................................................................3-78

Inspection.........................................................................3-79

Deglazing Cylinder...........................................................3-80

Boring and Honing Cylinder.............................................3-81

Installation Overview........................................................3-81

3.24 PISTON

Removal Overview............................................................3-82

Disassembly.....................................................................3-82

Piston Rings..............................................................3-82

Cleaning...........................................................................3-82

Inspection.........................................................................3-83

Assembly..........................................................................3-84

Checking Piston Ring Gap........................................3-84

Installing Piston Rings...............................................3-85

Installation Overview........................................................3-86

3.25 COVER AND CAM SUPPORT PLATE

Removal Overview............................................................3-87

Camshafts........................................................................3-87

Removal....................................................................3-87

Assembly...................................................................3-87

Oil Pressure Relief Valve..................................................3-89

Removal....................................................................3-89

Installation.................................................................3-89

Inspection..................................................................3-89

Cam Needle Bearings......................................................3-89

Removal....................................................................3-89

Installation.................................................................3-91

Cleaning and Inspection...................................................3-92

Oil Pressure Valve.....................................................3-92

Cam Support Plate....................................................3-93

Installation Overview........................................................3-93

3.26 OIL PUMP

Removal Overview............................................................3-94

Cleaning and Inspection...................................................3-94

Installation Overview........................................................3-94

3.27 CRANKCASE

Removal Overview............................................................3-95

Right Crankcase Half........................................................3-95

Chain Guide Screen..................................................3-95

Crankshaft (Roller) Bearing Removal........................3-95

Crankshaft (Roller) Bearing Installation.....................3-96

Piston Jets Removal..................................................3-96

Piston Jets Installation...............................................3-96

Left Crankcase Half..........................................................3-97

Main Bearing Removal..............................................3-97

Main Bearing Installation...........................................3-98

Sprocket Shaft Bearing Inner Race..................................3-99

Removal....................................................................3-99

Installation...............................................................3-100

Cylinder Studs................................................................3-101

Removal..................................................................3-101

Installation...............................................................3-101

Pipe Plugs and Oil Fittings.............................................3-101

Removal/Installation................................................3-101

Cleaning and Inspection.................................................3-102

Installation Overview......................................................3-102

3.28 FLYWHEEL AND CONNECTING RODS

Removal Overview..........................................................3-103

Inspection.......................................................................3-103

Installation Overview......................................................3-103

3.29 COUNTERBALANCER ASSEMBLY

Removal Overview..........................................................3-104

Cleaning, Inspection, and Repair...................................3-104

General....................................................................3-104

Balance Shaft Removal...........................................3-104

Balance Shaft Installation........................................3-105

Balance Shaft Support Bearings Removal..............3-105

Balance Shaft Support Bearings Installation...........3-105

Front and Rear Balance Sprockets.........................3-106

Hydraulic Tensioners...............................................3-106

Chain Tensioner Guides..........................................3-107

Chain Guide Bracket...............................................3-107

Balance Chain.........................................................3-107

Installation Overview......................................................3-107

3.30 OIL TANK: ALL BUT FXCW/C

Removal and Disassembly.............................................3-108

Oil Tank....................................................................3-108

Oil Line Fittings/Retainers.......................................3-110

Installation......................................................................3-111

3.31 OIL TANK: FXCW/C

Removal and Disassembly.............................................3-112

Oil Tank....................................................................3-112

Oil Line Fittings/Retainers.......................................3-114

Installation......................................................................3-115

VIII TABLE OF CONTENTS

Page 10

TABLE OF CONTENTS

FUEL SYSTEM

4.1 SPECIFICATIONS: FUEL SYSTEM

Specifications.....................................................................4-1

4.2 ELECTRONIC FUEL INJECTION (EFI)

Troubleshooting..................................................................4-2

4.3 IDLE SPEED

General...............................................................................4-3

4.4 AIR CLEANER ASSEMBLY

Removal.............................................................................4-4

Installation..........................................................................4-4

Backplate Assembly: HDI Models.......................................4-5

4.5 FUEL TANK

General...............................................................................4-6

Removal.............................................................................4-6

Cleaning and Inspection...................................................4-10

Installation........................................................................4-10

All But FXCW/C.........................................................4-10

FXCW/C....................................................................4-10

4.6 THROTTLE POSITION SENSOR (TPS)

General.............................................................................4-12

Removal...........................................................................4-12

Installation........................................................................4-12

4.7 INTAKE AIR TEMPERATURE SENSOR

(IAT)

General.............................................................................4-13

Removal...........................................................................4-13

Installation........................................................................4-13

4.8 ENGINE TEMPERATURE SENSOR (ET)

General.............................................................................4-14

Removal...........................................................................4-14

Installation........................................................................4-14

4.9 INDUCTION MODULE

Removal...........................................................................4-16

Installation........................................................................4-17

4.10 IDLE AIR CONTROL (IAC)

General.............................................................................4-18

Removal...........................................................................4-18

Installation........................................................................4-18

4.11 MANIFOLD ABSOLUTE PRESSURE

SENSOR (MAP)

General.............................................................................4-19

Removal...........................................................................4-19

Installation........................................................................4-19

Installation........................................................................4-20

4.13 FUEL INJECTORS

General.............................................................................4-22

Removal...........................................................................4-22

Installation........................................................................4-22

4.14 FUEL PUMP AND FUEL GAUGE

SENDING UNIT

General.............................................................................4-24

Removal...........................................................................4-24

Disassembly/Assembly.....................................................4-26

Fuel Filter..................................................................4-26

Regulator...................................................................4-26

Inlet sock...................................................................4-27

Fuel Pump.................................................................4-28

Installation........................................................................4-28

4.15 FUEL PRESSURE TEST

General.............................................................................4-30

Testing..............................................................................4-30

4.16 EXHAUST SYSTEM: ALL BUT

FLSTF/FLSTN/FLSTSB

Mufflers.............................................................................4-33

Removal....................................................................4-33

Assembly...................................................................4-33

System.............................................................................4-33

Removal....................................................................4-33

Installation.................................................................4-33

4.17 EXHAUST SYSTEM:

FLSTF/FLSTN/FLSTSB

Mufflers.............................................................................4-35

Removal....................................................................4-35

Assembly...................................................................4-35

System.............................................................................4-35

Removal....................................................................4-35

Installation.................................................................4-35

4.18 INTAKE LEAK TEST

General.............................................................................4-37

Leak Tester.......................................................................4-37

Parts List...................................................................4-37

Tester Assembly........................................................4-37

Tester Adjustment......................................................4-37

Procedure.........................................................................4-37

4.19 EVAPORATIVE EMISSIONS CONTROL

(CA MODELS)

General.............................................................................4-39

Charcoal Canister.............................................................4-39

Removal....................................................................4-39

Installation.................................................................4-40

Hose Routing/Replacement..............................................4-40

4.12 OXYGEN SENSOR

General.............................................................................4-20

Removal...........................................................................4-20

TABLE OF CONTENTS IX

Page 11

TABLE OF CONTENTS

STARTER

5.1 SPECIFICATIONS: STARTER

Specifications.....................................................................5-1

5.2 STARTER

General...............................................................................5-3

Wiring Diagrams..........................................................5-3

Removal.............................................................................5-3

Installation..........................................................................5-3

Testing................................................................................5-3

Armature.....................................................................5-3

Brushes and Brush Holder..........................................5-5

Field Coil Assembly............................................................5-6

Disassembly................................................................5-6

Inspection....................................................................5-6

Assembly.....................................................................5-6

Drive Assembly...................................................................5-7

Disassembly................................................................5-7

Inspection....................................................................5-7

Assembly.....................................................................5-7

5.3 STARTER SOLENOID

Solenoid Assembly.............................................................5-8

Disassembly................................................................5-8

Assembly.....................................................................5-8

Solenoid Plunger................................................................5-8

Disassembly................................................................5-8

Assembly.....................................................................5-8

Solenoid Contacts..............................................................5-8

Disassembly................................................................5-8

Assembly.....................................................................5-9

DRIVE

6.1 SPECIFICATIONS: DRIVE

Specifications.....................................................................6-1

6.2 PRIMARY CHAINCASE COVER

General...............................................................................6-2

Removal.............................................................................6-2

Installation..........................................................................6-2

6.3 DRIVE COMPONENTS

Removal.............................................................................6-3

Installation..........................................................................6-5

6.4 PRIMARY CHAINCASE HOUSING

Removal.............................................................................6-9

Inspection...........................................................................6-9

Mainshaft Bearing and Lip Seal.........................................6-9

Removal......................................................................6-9

Installation...................................................................6-9

Mainshaft Bearing Inner Race..........................................6-10

Removal....................................................................6-10

Installation.................................................................6-10

Installation........................................................................6-11

6.5 CLUTCH

Removal and Installation..................................................6-13

Clutch Pack Only..............................................................6-13

Partial Disassembly...................................................6-13

Cleaning And Inspection...........................................6-13

Assembly...................................................................6-14

Clutch Pack and Bearing..................................................6-15

Complete Disassembly..............................................6-15

Assembly...................................................................6-16

6.6 TRANSMISSION SPROCKET

Removal...........................................................................6-18

Cleaning and Inspection...................................................6-19

Installation........................................................................6-19

6.7 DRIVE BELT

Removal...........................................................................6-21

Inspection.........................................................................6-21

Installation........................................................................6-21

TRANSMISSION

7.1 SPECIFICATIONS:TRANSMISSION

Specifications.....................................................................7-1

Service Wear Limits............................................................7-1

7.2 TRANSMISSION

Power Flow.........................................................................7-2

Neutral.........................................................................7-2

1st Gear......................................................................7-2

2nd Gear.....................................................................7-2

3rd Gear......................................................................7-2

4th Gear......................................................................7-2

5th Gear......................................................................7-2

6th Gear......................................................................7-2

7.3 SHIFTER LINKAGE

Adjustment.........................................................................7-4

Shifter Rod.........................................................................7-4

7.4 CLUTCH RELEASE COVER

Removal and Disassembly.................................................7-5

Cleaning and Inspection.....................................................7-5

Assembly and Installation...................................................7-6

7.5 TRANSMISSION ASSEMBLY

Removal.............................................................................7-7

Disassembly.......................................................................7-8

Shifter Cam/Shifter Forks............................................7-8

Mainshaft...................................................................7-10

Countershaft..............................................................7-13

Replacing Side Door Bearings..................................7-14

Cleaning and Inspection...................................................7-15

Assembly..........................................................................7-15

Installing Side Door Bearings....................................7-15

Countershaft..............................................................7-15

Mainshaft...................................................................7-16

Shifter Cam/Shifter Forks..........................................7-16

Installation........................................................................7-18

7.6 MAIN DRIVE GEAR AND BEARING

Removal...........................................................................7-20

X TABLE OF CONTENTS

Page 12

TABLE OF CONTENTS

Cleaning and Inspection...................................................7-21

Needle Bearing Replacement...................................7-22

Installation........................................................................7-23

Installing Main Drive Gear Bearing...........................7-23

Installing Main Drive Gear.........................................7-24

Installing Main Drive Gear Large Seal.......................7-24

7.7 TRANSMISSION CASE

Removal...........................................................................7-27

Installation........................................................................7-27

Disassembly.....................................................................7-28

Shifter Arm Assembly................................................7-28

Cleaning and Inspection...................................................7-28

Assembly..........................................................................7-29

Countershaft Needle Bearing Replacement..............7-29

Shifter Pawl Lever Assembly.....................................7-29

ELECTRICAL

8.1 SPECIFICATIONS: ELECTRICAL

Specifications.....................................................................8-1

8.2 ELECTRICAL PANEL

General...............................................................................8-2

Removal: All But FXCW/C..................................................8-2

Installation: All But FXCW/C...............................................8-2

Removal: FXCW/C.............................................................8-2

Installation: FXCW/C..........................................................8-3

8.3 ELECTRONIC CONTROL MODULE (ECM)

General...............................................................................8-4

Removal: All But FXCW/C..................................................8-4

Installation: All But FXCW/C...............................................8-4

Removal: FXCW/FXCWC...................................................8-4

Installation: FXCW/FXCWC................................................8-5

8.4 VOLTAGE REGULATOR

General...............................................................................8-6

8.5 FRONT ELECTRICAL CADDY

General...............................................................................8-7

Disassembly.......................................................................8-7

Assembly............................................................................8-7

8.6 FUSES

General...............................................................................8-8

Removal.............................................................................8-8

Installation..........................................................................8-8

8.7 RELAYS

General...............................................................................8-9

Removal.............................................................................8-9

Installation..........................................................................8-9

8.8 MAIN FUSE

Removal...........................................................................8-10

Installation........................................................................8-10

Removal and Installation: All But FXCW/C.......................8-11

Removal and Installation: FXCW/C..................................8-12

8.10 BATTERY CABLES

Routing Procedure...........................................................8-13

8.11 HEADLAMP

General.............................................................................8-15

Removal and Installation..................................................8-15

FXSTC Models..........................................................8-15

FXCW/C Models........................................................8-15

FXST, FXSTB, and FLSTSB Models.........................8-15

FLST, FLSTC, FLSTF, and FLSTN Models...............8-15

8.12 TAIL LAMP: ALL BUT FLSTN

General.............................................................................8-19

Bulb Replacement............................................................8-19

Base Replacement...........................................................8-19

8.13 TAIL LAMP: FLSTN

Bulb Replacement............................................................8-21

Tail Lamp Replacement....................................................8-21

8.14 AUXILIARY LAMPS:

FLST/FLSTC/FLSTN

Auxiliary Lamp Bulb..........................................................8-23

Removal....................................................................8-23

Installation.................................................................8-23

FLST and FLSTC Models.................................................8-23

Auxiliary Lamp Bracket Removal...............................8-23

Auxiliary Lamp Bracket Installation...........................8-24

Auxiliary Lamp Housing Removal.............................8-24

Auxiliary Lamp Housing Installation..........................8-24

FLSTN Models.................................................................8-26

Auxiliary Lamp Bracket Removal...............................8-26

Auxiliary Lamp Bracket Installation...........................8-26

Auxiliary Lamp Housing Removal.............................8-27

Auxiliary Lamp Housing Installation..........................8-27

Adjustment: FLST/FLSTC/FLSTN Models.......................8-28

8.15 TURN SIGNALS AND RUNNING LIGHTS

Bulb Replacement: Bullet Style........................................8-30

Bulb Replacement: Flat Lens Style..................................8-30

Lamp Replacement..........................................................8-30

All Models..................................................................8-30

Front Turn Signals: All But FLST, FLSTC, FLSTN.....8-31

Front Turn Signals: FLST, FLSTC, FLSTN.................8-32

Rear Turn Signals: All But FXCW/C, FLSTN.............8-32

Rear Turn Signals: FXCW/C......................................8-32

Rear Turn Signals: FLSTN.........................................8-34

8.16 TURN SIGNAL AND SECURITY

MODULE (TSM/TSSM/HFSM)

General.............................................................................8-35

TSM/HFSM/TSSM Configuration.....................................8-35

Removal...........................................................................8-35

Installation........................................................................8-35

8.9 IGNITION AND LIGHT SWITCH

General.............................................................................8-11

8.17 CRANK POSITION SENSOR (CKP)

General.............................................................................8-36

TABLE OF CONTENTS XI

Page 13

TABLE OF CONTENTS

Removal...........................................................................8-36

Installation........................................................................8-36

8.18 IGNITION COIL

Removal...........................................................................8-37

All Except FXCW/C...................................................8-37

FXCW/C Only............................................................8-37

Installation........................................................................8-37

All Except FXCW/C...................................................8-37

FXCW/C Only............................................................8-37

8.19 SPARK PLUG CABLES

General.............................................................................8-39