Page 1

GENERAL

1

is02720

-J04167 REV. 2006-05-02

CRUISE CONTROL KIT FOR FLHR/S MODELS

Kit Number

77197-07, 77198-07

Models

These kits fit 2007 and later FLHR (77197-07) and FLHRS

(77198-07) (Road King) model motorcycles.

Additional Parts Required

The rider's safety depends upon the correct installation

of this kit. Use the appropriate service manual pr ocedures.

If the procedure is not within your capabilities or you do

not have the correct tools, have a Harle y-Da vidson dealer

perform the installation. Improper installation of this kit

could result in death or serious injury. (00333a)

NOTE

This Instruction Sheet refers the installer to the appropriate

FLT Service Manual for many procedures.Therefore, HarleyDavidson recommends that you do not attempt to install this

kit without having a copy of the FLT Service Manual applicable

to your vehicle.

NOTE

A Service Manual for your vehicle is a vailable from any Harle yDavidson dealer.

Kit Contents

See Figure 10 and Table 1.

INSTALLATION

1. Remove seat, left saddlebag, left side cover and air

cleaner assembly following instructions in applicable Service Manual.

2. Review the "CR UISE CONTR OL-Ultra MODELS" section

in the applicable FLT Service Manual before attempting

to install this kit.

Install Cruise Control Module

T o prevent accidental vehic le start-up, whic h could cause

death or serious injury, disconnect battery cables (negative

(-) cable first) before proceeding. (00307a)

Disconnect negative (-) battery cable first. If positive (+)

cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion,

which could result in death or serious injury. (00049a)

3. Remove battery.

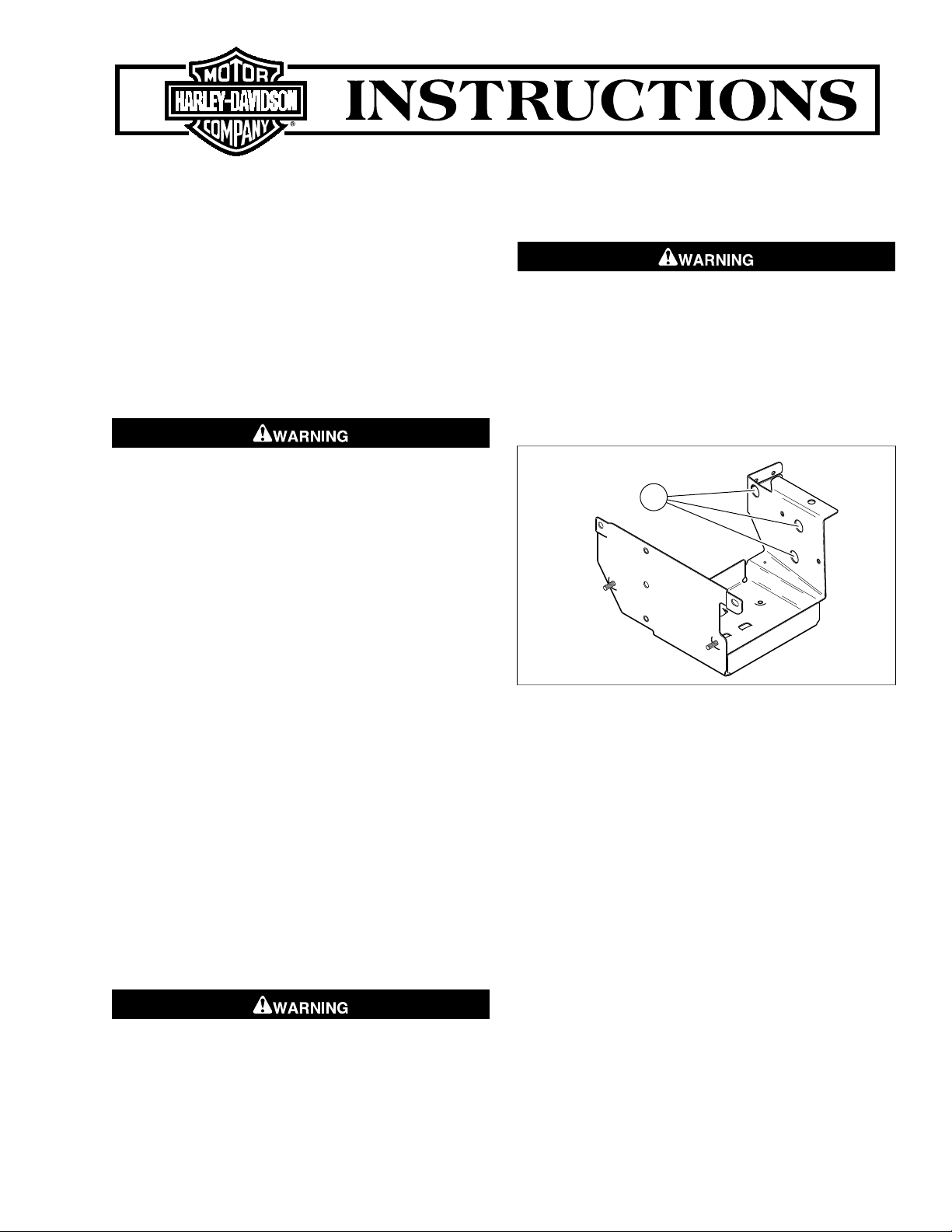

4. See Figure 1. In battery box, identify the location of the

three mounting holes (on left side of panel) for mounting

the cruise control module.

Figure 1. Battery Box (right side view)

5. See Figure 10. Obtain the Cruise Control Module (1) with

cruise cable attached and three Grommets (5) from kit.

Install the grommets on studs of cruise control module

with small diameters outward.

6. See Figure 2.While holding cruise control module in place

near its mounting location, feed the cruise control cable

through the hole in frame crossmember plate and route

under rear spark plug wire staying on inner side of fuel

line components. Carefully cur ve cable toward the right

and continue routing up under the fuel tank and over the

top of the engine stabilizer bracket, then down between

cylinder heads. Leave in place temporarily. See Figure

10. Obtain a harness retainer (4) from kit and secure the

cruise cable to crossmember plate with barb as shown in

Figure 2. On California models, remove the EVAP hose

from cable clip and secure hose with one of the cable ties

(6).

-J04167 1 of 6

Page 2

2

4

3

1

is02721

1. Cruise control cable

5

3

4

2

1

is02722

1

is02723

2. Harness retainer

3. Rear cylinder head

4. From hole in frame crossmember plate

Figure 2. Routing Cruise Cable from Cruise Contr ol Module

to Carburetor or Induction module (left side view)

NOTE

Prior to performing the next step, it may be necessar y to cut

the wire ties securing the main harness to the frame tube

(above mounting area) and temporarily move har ness aside

to allow adequate room for cruise module installation. It may

also be necessary to move the charcoal canister hose to the

side and secure to frame tube with cable tie (8).

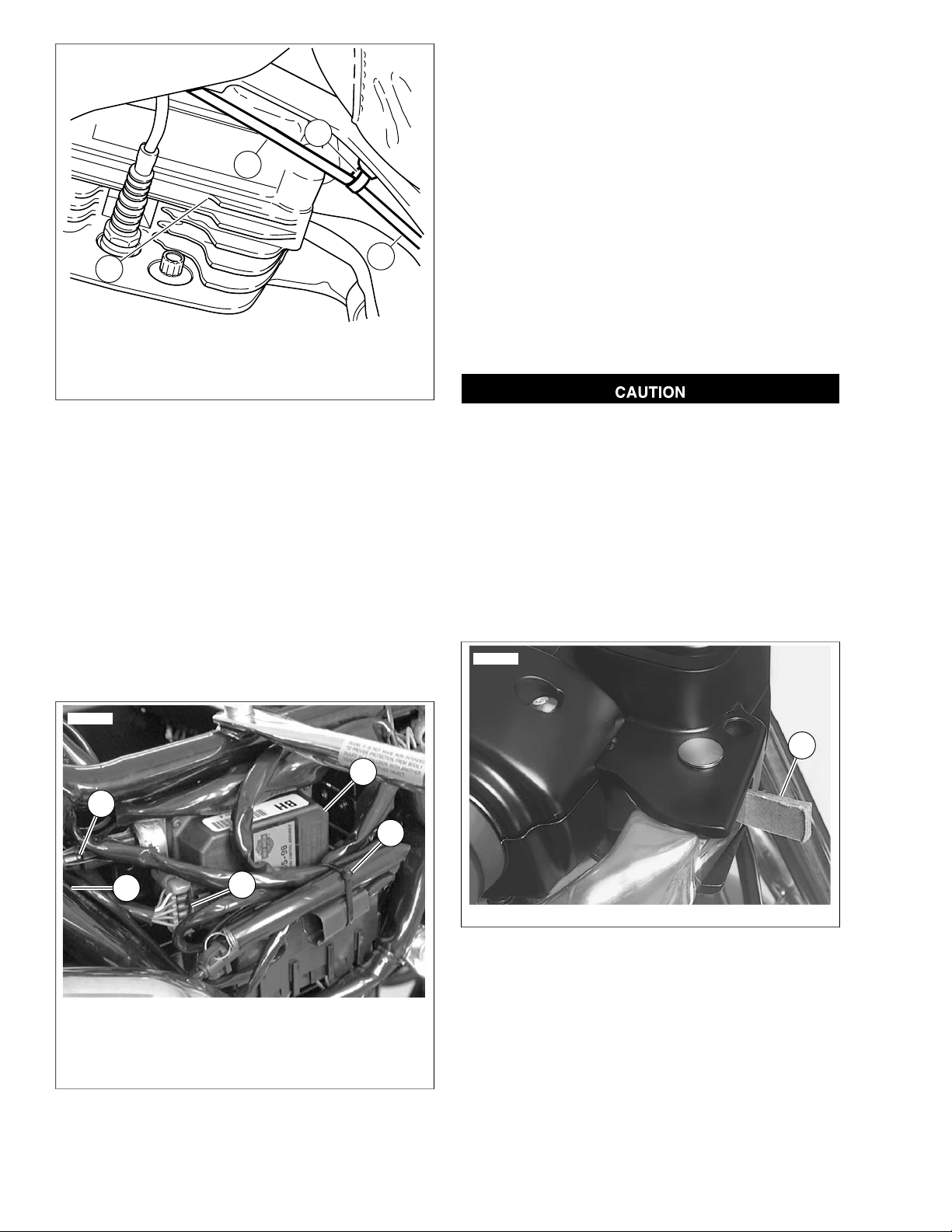

7. See Figure 3. Remove the fuse block cover panel by

pulling straight out from mounts and temporarily position

the cover away from the mounting area. Align the cruise

module studs (and grommets) with mounting holes in

battery box and push module firmly into position. Make

sure grommets enter mounting holes in battery box.

8. See Figure 10. Obtain the three flange locknuts (7) and

install to cruise control module studs (inside battery box).

Tighten nuts 9-11 ft-lbs (12.2-15 Nm). Locate the 10-place

connector harness (normally wire tied to frame tube next

to battery box) and cut the tie. Route downward and install

the 10-place connector into cruise module.

9. Reinstall the fuse block cover panel by sliding (side

channels) back onto mounts. See Figure 10. Obtain cable

tie/s (8) from kit. Bundle wire harnesses (mov ed to install

cruise module) along side of cruise module to allow the

side cover to be reinstalled.

10. Return to cruise cable end near carburetor or induction

module. Follow instructions in applicable Service Manual

to connect cruise cable to carburetor or induction module.

See Figure 10. Use new retaining ring (6) from kit when

installing cable end to carburetor/Induction module.

Install New Right Handlebar Control with Harness

Do not remove or install the master cylinder assembly

without first positioning a 5/32-inch (4 mm) thick insert

between the brake lever and lever bracket. Removing or

installing the master cylinder assembly without the insert

in place may result in damage to the rubber boot and

plunger on the front stoplight switch. (00324a)

NOTE

Use the eyelet of an ordinary cable strap if the cardboard insert

is not available.

1. See Figure 4. Place a 5/32 inch cardboard insert between

the brake lever and lever bracket.

1. 5/32 inch cardboard insert

1. Cruise control

2. 10-Place connector

3. Cable tie

4. Cruise control cable

5. To frame crossmember hole

Figure 3. Mount Cruise Control Module

2. Using a T27 TORX® drive head, remove two screws with

flat washers securing the handlebar clamp to the master

cylinder housing. Remove brake lever/master cylinder

assembly and clamp from the handlebar. Use a cable tie

or other means to keep the assembly out of the way.

3. Using T25 T ORX driv e head, remov e the upper and lower

switch housing screws.

4. Remove the friction shoe from the end of the tension

adjuster screw. Save friction shoe for reinstallation.

Figure 4. Install Cardboard Insert

-J04167 2 of 6

Page 3

3

4

5

2

1

is02724

1

3

2

4

is02725

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the lower switch housing is turned upside down or

shaken.

5. See Figure 5. Remo ve the brass f errules from the notches

on the inboard side of the throttle control grip, then remove

ferrules from the cable end fittings. Save ferrules for reinstallation.

1. Lower cable housing

2. Idle cable insert (gold)

3. Tension adjuster screw

4. Throttle cable insert (silver)

Figure 6. Upper Right Handlebar Switch Housing

9. Trace the right handlebar wiring harness to the 6-place

Molex connector and disconnect connector halves. Note

the existing harness routing and cable ties securing harness to handlebars. Remove and discard the right hand

control and harness assembly.

10. See Figure 10. Obtain the new Right Handlebar Control

1. Throttle cable

2. Idle cable

3. Groove

4. Notch

5. Ferrule

Figure 5. Remove Throttle and Idle Control Cables

NOTE

It is not necessary to remove the throttle control grip.

6. See Figure 6. Pull the crimped inserts at the end of the

throttle and idle control cable housings from the lower

switch housing. For best results, use a rocking motion

while pulling. Place a drop of light oil on the retaining rings,

if necessary. Save inserts for re-installation.

7. Remove the cables from the s witch housing, then separate

the upper and lower switch halves.

8. Follow the instructions in applicable Service Manual and

remove windshield and nacelle.

NOTE

When performing the next Step, the right side Mole x Electrical

Connectors are Black; the left side Mole x Electrical Connectors

are Grey.

and Harness Assembly (2) from kit. Install the ne w harness

6-place connector in same place as connector removed

in Step 9. Locate the unused 3-place connector half (next

to the 6-place) and install the 4-Place connector from the

new harness to the 4-place connector in headlamp

assembly.

11. At new handlebar control assembly, hold the lower switch

housing with concave side facing upward. Install the tension adjuster screw and spring with the friction shoe (saved

from Step 4) so that pin hole is over the point of the Tension adjuster screw. Adjust the tension adjuster two or

three turns to hold assembly in place.

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the switch housing is turned upside down or shaken.

12. Refer to Figure 6. Push the throttle and idle control cables

into the lower switch housing until they snap into place.

Perform the following:

a. Obtain the crimped inserts removed in Step 6. Note

the different diameter inserts crimped into the end of

the throttle and idle control cable housings.

b. Push the larger diameter insert (silver) on the throttle

cable housing into the larger hole in front of the tension adjuster screw.

c. Push the smaller diameter inser t (gold) on the idle

cable housing into the smaller hole at the rear of the

tension adjuster screw.

NOTE

To aid assembly, place a drop of light oil on the retaining rings

of the crimped inserts. Always replace the retaining rings if

damaged or distorted.

13. Slide the throttle control grip towards motorcycle until it

bottoms against the closed end of the handlebar. Rotate

-J04167 3 of 6

Page 4

the grip so that the ferrule notches are at the top.To pre-

3

4

2

1

is02726

2

3

5

6

4

1

is02727

vent binding, pull the grip back about 1/8 inch (3.2 mm).

14. Refer to Figure 5. Position the new lower switch housing

beneath the throttle control grip. Install the brass ferrules

onto the cables so that the end fittings seat in the ferrule

recess. Seat the ferrules in their respective notches on

the throttle control grip.V erify that the cables are captured

in the grooves molded into the grip.

15. Position the upper s witch housing ov er the handlebar and

lower switch housing.

16. V erify that wire harness conduit runs in the depression at

the bottom of the handlebar. Be sure that the upper s witch

housing harness will not be pinched under the handlebar

when the switch housing screws are tightened.

NOTE

Do not remove the 5/32 inch cardboard insert wedged between

the brake lever and lever bracket. Removal will result in

damage to the rubber boot and plunger of the Front Stoplight

Switch during installation of the master cylinder assembly.

17. Start the upper and lower switch housing screws, but do

not tighten.

18. See Figure 7. Position the brake lever/master cylinder

assembly inboard of the switch housing assembly

engaging the tab on the lower switch housing in the groo ve

at the top of the brake lever bracket.

19. Align the holes in the handlebar clamp with those in the

master cylinder housing and start the two screws (with flat

washers). Position the assembly for rider comfort. Beginning with the top screw , tighten the screws to 60-80 in-lbs

(6-9 Nm) using a T27 TORX® drive head.

21. Remove the cardboard insert between the brake lev er and

lever bracket.

22. See Figure 10. Obtain two harness retainers (4) from kit.

Adjust the harness so it runs under the handlebar and

secure harness conduit to holes in lower side of handlebar

by inserting barbed ends of retainers.

Install New Left Handlebar Control with Harness

NOTE

Prior to performing the next step, cut all cab le ties securing left

control switch harness to handlebars and discard.

1. Trace the left control switch harness wiring to the headlamp area (with nacelle removed) and locate the Grey 8place Molex Connector. Disconnect the handlebar switch

half from the connector.

2. Using a T27 TORX® drive head, remove the two screws

with flat washers securing the handlebar clamp to the

clutch lever bracket. Remove the clutch hand lever

assembly and clamp from the handlebar. Save all hardware for reinstallation.

3. Using a T25 TORX® drive head, remove the upper and

lower switch housing scre ws. Sav e switch housing screws

for reinstallation. Remove the left handlebar control and

harness and discard.

NOTE

It is not necessary to remove the left handlebar grip. Leave

grip in place.

4. See Figure 10. Obtain the new Left Handlebar Control

with Harness (3) from kit.

5. See Figure 8. P osition the left s witch control upper (1) and

lower (2) housings onto the handlebar (3). Be sure that

rib (4) on outboard side of switch housings fits in groove

(5) molded into the grip.

1. Brake lever bracket

2. Groove

3. Tab

4. New switch assembly with cruise Set/Resume

Figure 7. Installing Brake Lever/Master Cylinder Assembl y

to Right Switch Housing Assemblies

When performing the following Step, tighten the lower switch

housing screw first so that any gap between the upper and

lower housings is at the front of the switch.

20. Using a T25 TORX® drive head, tighten the lower then

upper switch housing screws to 35-45 in-lbs (4-5 Nm).

-J04167 4 of 6

NOTE

1. Left switch control upper

2. Left switch control lower

3. Handlebar

4. Rib

5. Groove

6. Wire harness conduit

Figure 8. Installing Left Handlebar Switch Housing

Page 5

6. V erify that the wire harness conduit (6) runs in the groove

3

2

1

4

is02728

at the bottom of the handlebar. Be sure that the upper

switch housing harness will not be pinched under the

handlebar when the switch housing screws are tightened.

7. Start the upper and lower switch housing screws saved

in Step 3, but do not completely tighten at this time.

8. See Figure 9. Position the clutch hand lever assembly

inboard of the switch housing assembly engaging the tab

on the lower switch housing in the groove at the bottom

of the clutch lever bracket. Be sure that harness will not

be pinched when installing handlebar clamp. Harness

should reside in recess between handlebar clamp and

clutch lever bracket.

1. Clutch lever bracket

2. Switch housing assembly

3. Groove

4. Tab

Figure 9. Positioning Clutch Lever Bracket with Left

handlebar Switch Housings

9. Align the holes in the handlebar clamp with those in the

clutch lever bracket and start the two screws (with flat

washers) saved from Step 2. Position the assembly for

rider comfort. Beginning with the top screw, tighten the

screws to 60-80 in-lbs (7-9 Nm) using a T27 T ORX® drive

head.

10. Using a T25 TORX® drive head, tighten the lower and

upper switch housing screws to 35-45 in-lbs (4-5 Nm).

NOTE

Always tighten the lower s witch housing scre w first so that any

gap between the upper and lower housings is at the front of

the switch.

11. Route left hand control harness under handlebar and down

to headlamp area (with nacelle removed). Locate the 8place Molex Connector and connect the 6-place control

harness connector.

12. Locate the unused 3-place Molex Connector and connect

the 3-place control harness connector.

13. See Figure 10. Obtain two wire harness retainers (4) from

kit and secure harness to handlebar in two places by

installing barbs on retainers into holes in handlebar.

14. Follow instructions in applicable Service Manual and install

fairing nacelle and windshield.

15. Follow instructions in Service Manual and install left sad-

dlebag, left side cover and air cleaner assembly.

Connect positive (+) battery cable first. If positive (+) cable

should contact ground with negative (-) cable connected,

the resulting sparks can cause a battery explosion, which

could result in death or serious injury. (00068a)

16. Reconnect battery, positive (+) cable first.

17. Install seat.

After installing seat, pull upward on seat to be sure it is

locked in position. While riding, a loose seat can shift

causing loss of control, which could result in death or

serious injury. (00070b)

Cruise Cable Adjustment and Final Test

1. Perf orm cruise cable adjustment. See "Cable Lash Initial-

ization" in applicable Service Manual.

2. Refer to cruise control section in Owner's Manual for cruise

control operating instructions.

3. Test ride motorcycle and verify cruise control is operating

properly.

-J04167 5 of 6

Page 6

SERVICE PARTS

1

6

2

7

3

8

5

4

A

is02729

Figure 10. Service Parts: FLHR/I and FLHRS/I Cruise Control Kit

Table 1. Service Parts Table

Model FLHRS/I, Kit 77198-07Model FLHR/I, Kit 77197-07

1

ness

170955-04Assembly, cruise control w/har-

ness

Items mentioned in text, but not included in kit:Items mentioned in text, but not included in kit:

Cruise control cableACruise control cableA

Part NumberDescription (Quantity)ItemPart NumberDescription (Quantity)Item

70955-04Assembly, cruise control w/har-

70437-07Assembly, hand control (right)270419-07Assembly, hand control (right)2

70438-07Assembly, hand control (left)370434-07Assembly, hand control (left)3

70345-84Retainer, wire harness (5)470345-84Retainer, wire harness (5)4

11497Grommet (3)511497Grommet (3)5

11193Ring, retaining611193Ring, retaining6

7499Nut, flange locking (3)77499Nut, flange locking (3)7

10065Ties, wire (2)810065Ties, wire (2)8

-J04167 6 of 6

Loading...

Loading...