Page 1

Geo-Trio™ High Efficiency Geothermal/Water Source

Step-Capacity Heat Pump — R-410A

Ground Water Application: Water Temp 40° to 100°

Ground Loop Application: Temp Range 25° to 110°

The Bard Geo-Trio™ Geothermal/Water Source

Heat Pump delivers economical year-round

comfort by utilizing nature’s most abundant and

efficient solar energy collector – the earth. The

Geo-Trio™ Series heat pumps are designed for

low water flow rates and offer cooling efficiencies

up to 29.1 EER and heating efficiencies up to 4.8

COP on ground water, and cooling efficiencies up

to 24.9 EER and heating efficiencies up to 4.4

COP on ground loop.

All units are shipped prewired for fast, easy

installation in residential or commercial buildings.

Engineered Features

Steel Cabinet:

Galvanized 20 gauge zinc coated steel

cabinet with baked-on, textured enamel

which allows it to withstand 1000 hours of

salt spray exposure.

Multi-Capacity Two-Stage:

Simple thermostatic control seamlessly

stages the compressor and indoor airflow

rate between full and part load capacity

operation without cycling the compressor.

This helps to maximize comfort, humidity

control, energy efficiency and overall

reduction in compressor cycling for

improved system life.

Step Capacity Compressor:

Copeland step-capacity (2-stage) scroll

compressors are designed for increased

efficiency, quieter operation and improved

reliability for longer life.

R-410A Refrigerant:

Designed with R-410A (HFC) non-ozone

depleting refrigerant in compliance with the

Montreal protocol and 2010 EPA requirements.

Liquid Line Drier:

Protects system against moisture.

Thermostatic Expansion Valve:

For wide range refrigerant control

(2-way operation).

High Pressure Switch:

Provides additional protection for the system.

Low Pressure Switch:

Two switches provided. Factory wired

switch is for ground water applications,

alternate switch is field connected for

ground loop applications.

Control Panel:

Mid-level for easy access. Blower section

includes transformer and blower control.

High Efficiency Coaxial Water Coil in

either Copper or Cupronickel

Water to refrigerant coil is completely

insulated to prevent frost build-up at low

temperature operation.

TYPICAL INSTALLATION APPLICATIONS

Compressor, Blower and A Coil Sections stack

vertically for upflow and counterflow

installations. Blower and A Coil Sections can

be remotely mounted in attics or crawl spaces

providing horizontal right or left opportunities.

Indoor Air Coil:

Grooved copper tubing and enhanced

louvered aluminum fin for maximum heat

transfer and energy efficiency.

Coil coating is black E-Coat electrostatic

coating on complete coil.

Cased Indoor Air Coils for Fossil Fuel

(Dual Fuel):

Insulated cased coils to fit standard 17.5"

and 21" width furnaces.

Lockout Circuit:

Built-in lockout circuit resets from the room

thermostat. Provides commercial quality

protection to the compressor.

Variable Speed ECM Blower Motor:

• High Efficiency

• Soft starting - low noise on start up

• Continuous fan - will operate at 50%

of rated Stage 2 airflow

Mild Weather Operation:

Part Load Cooling Operation will operate at

20% reduced airflow for the first 5 minutes

of operation. This results in 32% increased

applied moisture removal during this 5minute period, and helps humidity control

during short-run conditions. This is

seamlessly controlled internal of the unit

controls with no required user intervention.

Water Connections:

All water connections on outside of

cabinet. Brass full swivel double o-ring

connection with 1" full flow ports.

Refrigerant Connections:

Special self-sealing fittings are used with 3'

line set for stacked upflow or downflow

applications, and line sets up to 50'

available for horizontal or dual-fuel

applications.

Service Access Ports:

Permits service pressure check of

discharge and suction pressures.

Filter Rack (Optional):

Accessory kit with 1" filter (reversible for left or

right side access for upflow installations).

Accessory Electric Duct Heater Option:

5, 10, 15 and 20KW nominal size. Field

installed external to unit. For upflow and

horizontal duct installation only.

Optional Accessories:

Room thermostat - Water accessory kit Waterflow controls.

Domestic Hot Water Heat Exchanger System:

Double wall vented heat exchanger and pump

with ECM motor and operating controls,

factory installed on all 1-phase models.

Hot Water Heating Performance and

Operating Cost Savings: The actual amount

of hot water (gallons of hot water per day)

generated and resultant operating cost

savings can vary greatly because of several

factors: heat pump system size, hours per day

of operation of the heat pump, mode of

operation (cooling vs. heating), hot water

usage patterns, heat pump water supply

system (ground water, ground or pond loop,

etc.), and climatic conditions. The gallons of

hot water per day are dependent upon the

above variables, and in general can range up

to 125 gallons per day for a nominal 24,000

BTU heat pump system, and up to 375

gallons per day for a nominal 60,000 BTU

heat pump system in the cooling mode,

offering a 100% energy savings over

conventional electric water heaters. During

the winter months when the heat pump is

operating in the heating mode, less hot water

is available, but at the same time, the electric

water heater will consume less electricity.

Form No. S3423-1112

Supersedes S3423-912

Page 1 of 28

Page 2

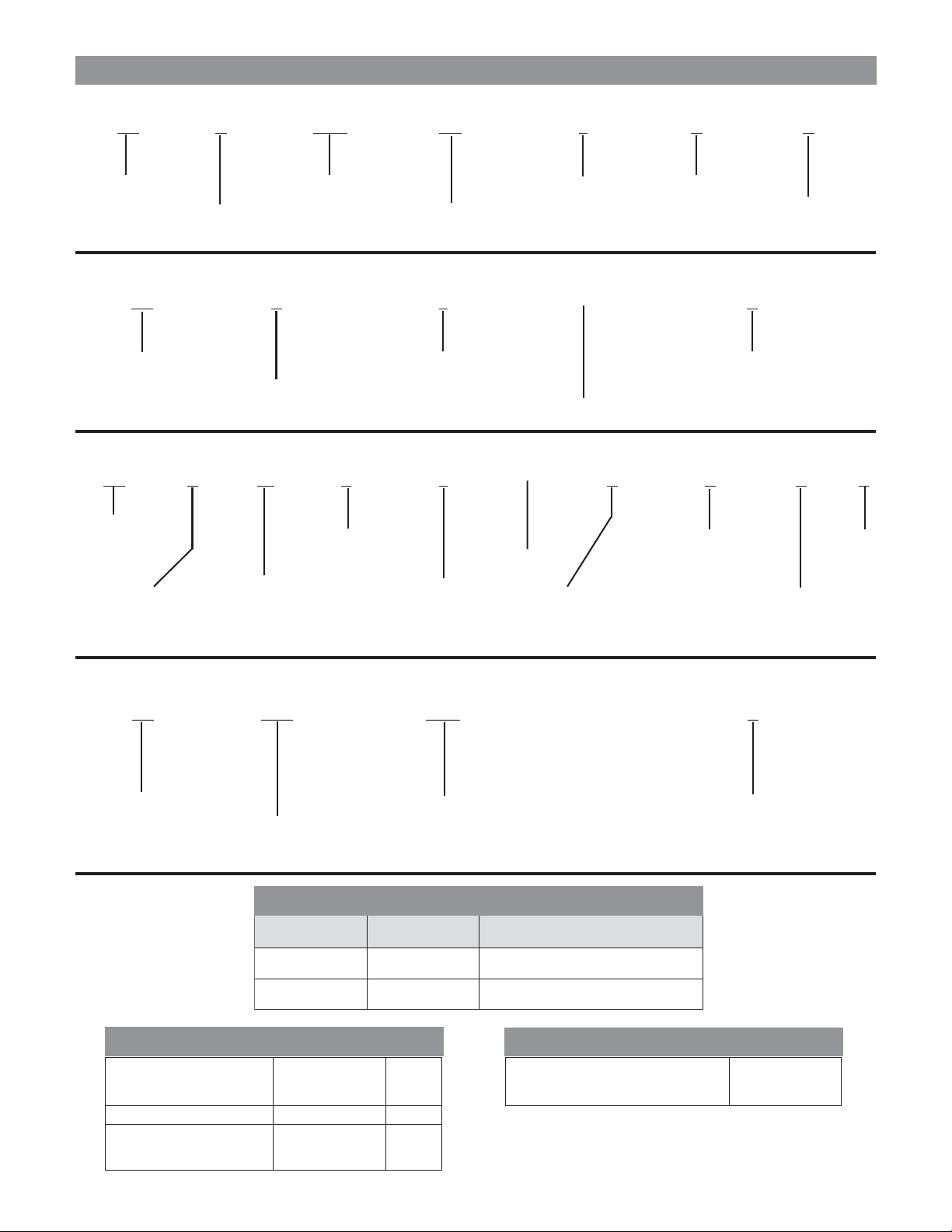

Geo-Trio™ GT*-Series Geothermal / Water Source Heat Pump Nomenclature

.

"A" Coil Section

GT A 3600 UD 1 A A

Geo-Trio

"A" = Coil Section

3600 (3 Ton)

4860 (4 & 5 Ton)

Series

Revision

Level

A = Black ECoated Coils

Option

Blower Section

GT B 1– A

Geo-Trio

B = Blower

Section

Revision

Level

Option

A = 230 Volt 1-Phase

Compressor Section

GT C 36 S 1–A D C X

Geo-Trio

C = Compressor

Section

Nominal Capacity

36 = 36K

48 = 48K

60 = 60K

S = Step Capacity

Revision

Level

Option

A = 230 Volt 1-Phase

D = Desuperheater

C = Copper Coil

N = Cupronickel Coil

X = Future

Use

Fossil Fuel “A” Coil Section (For Use on Hi-Boy, Lo-Boy & Counterflow Gas or Oil Furnaces in place of GTA Coil)

GT ADP – 3642 – B

Geo-Trio

A = Coil Manufactuer

ADP = Advanced Distributor Products

3642 (3 Ton)

4860 (4 & 5 Ton)

B = 17.50" Wide Furnace

C = 21.00" Wide Furnace

Cross-Reference Table

Shipping Weights - GT Series

noitceSlioC"A"

noitceSrewolB"B"A-1BTG.sbl59

noitceSrosserpmoC"C"

Form No. S3423-1112

Supersedes S3423-912

Page 2 of 28

rosserpmoC

noitceStinU

1S63CTG

1S84CTG

1S06CTG

AA1DU0063ATG

AA1DU0684ATG

1S63CTG

1S84CTG

1S06CTG

draB

.oNledoM

B-2463-PDATG

C-2463-PDATG

C-0684-PDATGWA5072B012D84994EH

.sbl39

sbl201

.sbl842

.sbl062

.sbl392

.oNtraPPDA

WA5052B571D24973EH

WA5052B012D24973EH

Shipping Weights - Fossil Fuel Coils

B-2463-PDATG

C-2463-PDATG

C-0684-PDATG

.sbl55

.sbl95

.sbl66

Page 3

M

B

F

D

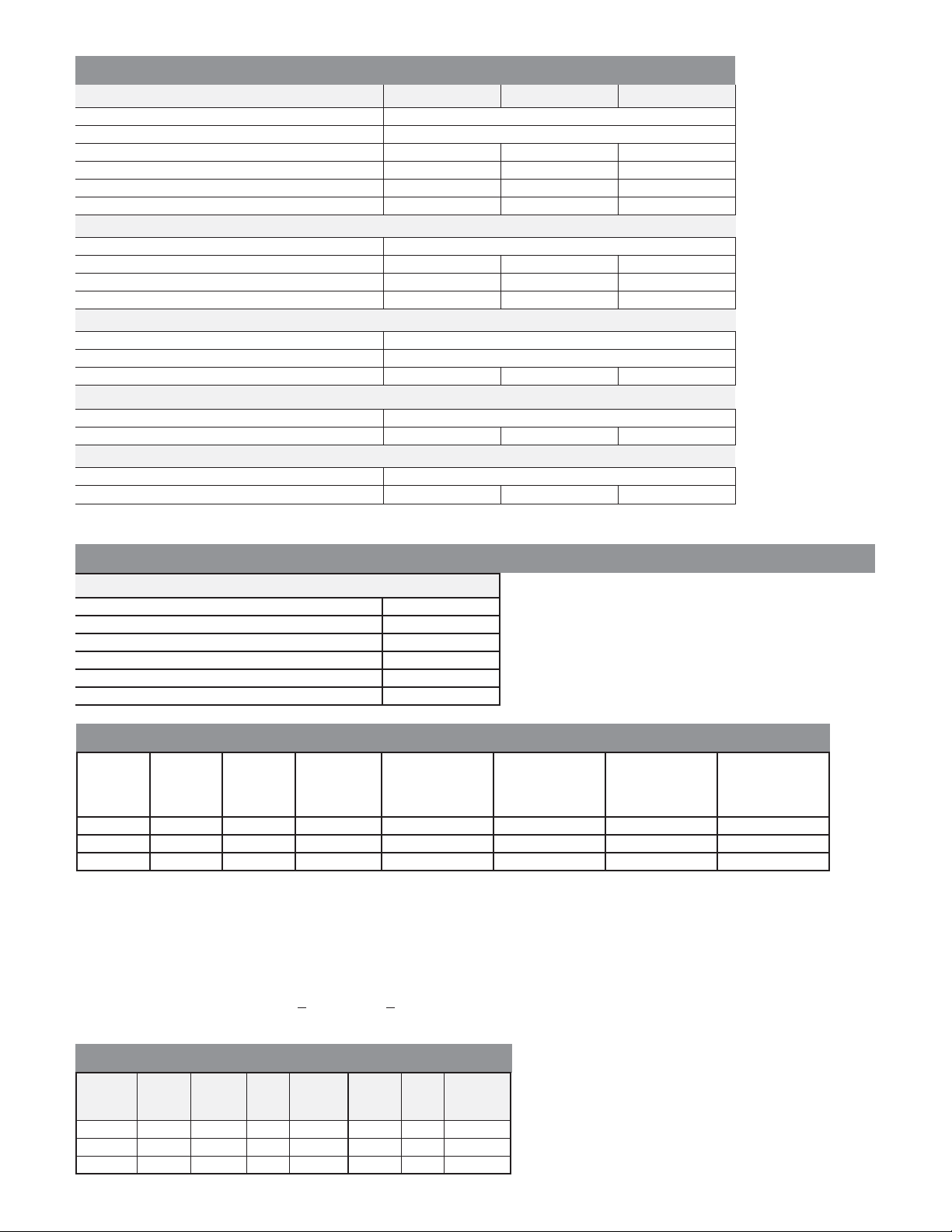

Specifications (Compressor & Blower Sections Stacked Together)

n

B

M

H

M

M

+

+

LEDO

)HP1/ZH06(gnitaRlacirtcelE 1-06-802/032

egnaRegatloVgnitarepO CAV791-352

yticapmAtiucriCmuminiM 0.620.430.83

eziSeriWdleiF+ 8#6#4#

eziSeriWdnuorG 01#8#6#

.xaMrekaerBtiucriCroesuFyaleD++ 040506

ROSSERPMOC

stloV 1-06-802/032

)802/032(spmAdaoLdetaR 0.31/2.116.91/4.616.32/2.91

tnerruCnoitceleStiucriChcnarB 7.612.126.52

)802/032(spmArotoRdekcoL 28/2869/69811/811

ROTOMREWOL

)rotoMMCE(rewopesroH deepSelbairaV4/3

stloV 1-06-802/032

)MFCdetaR@2#egatS(spmArotoM 4.33.44.4

)2-CFRODnodesaB(RETNECWOL

stloV 1-06-802/032

spmA 41.241.241.2

ROTOMPMUPRETAEHREPUSE

stloV 1-06-802/032

spmA 51.051.051.0

+75°C copper wire ++ HACR type circuit breaker

1S63CTG 1S84CTG 1S06CTG

Specifications (for Blower Section Only when Remote Mounted from Compressor)

)detnuoMyletomeRfI(NOITCESREWOL

ledo

epyT/P

)ALR(spmAroto

yticapmAtiucriCmumini

eziSeriWdleiF

rekaerBtiucriCro.xaMesuFyaleD+

A-1BTG

1.6

8

41

51

Indoor Blower Performance (Rated CFM)

22222

LEDOM

detaR

PSE

1S63CTG51.006.000600705800210031

1S84CTG02.006.0057578051100510061

1S06CTG02.006.00090501003100810081

33333

XAM

PSE

44444

suounitnoC

wolfriA

1 Motor will automatically step through the various airflows with thermostatic control

2 ESP = External Static Pressure (inches of water)

3 Maximum allowable duct static

4 Continuous airflow is the CFM being circulated with manual fan operation without any additional function occurring.

5 Will occur automatically for first 5 minutes of Part Load Cooling Operation.

6 Will occur automatically after five minutes of Part Load Cooling Operation.

7 Will occur automatically with control signal input.

NOTE: All values can be changed + 10% via the + adjustment dip switches on the tap select control inclusive in the GTB1-A

Blower Section (see Airflow Corrections for performance impact).

55555

NOTE: This applies only if blower section is remote mounted

from compressor section. When blower section is coupled

deepSelbairaV4/3

directly to compressor section, the blower is powered from the

compressor section.

+75°C copper wire ++ HACR type circuit breaker

1

etamilCdliM

traPninoitarepO

gnilooCdaoL

66666

wolfriAdaoLtraPwolfriAdaoLlluF

77777

taeHcirtcelE

wolfriA

Airflow Corrections

fo%

detaR

wolfriA

%09589.0448.0879.0389.0889.0030.1879.0

DETAR000.1000.1000.1000.1000.1000.1000.1

%011010.1050.1520.1310.1010.1889.0510.1

latoT

yticapaC

)HutBM(

elbisneS

rewoP

yticapaC

tupnI

)HutBM(

)WK(

fotaeH

noitcejeR

)HutBM(

latoT

rewoP

yticapaC

tupnI

)HutBM(

)WK(

fotaeH

oitprosbA

)HutBM(

Form No. S3423-1112

Supersedes S3423-912

Page 3 of 28

Page 4

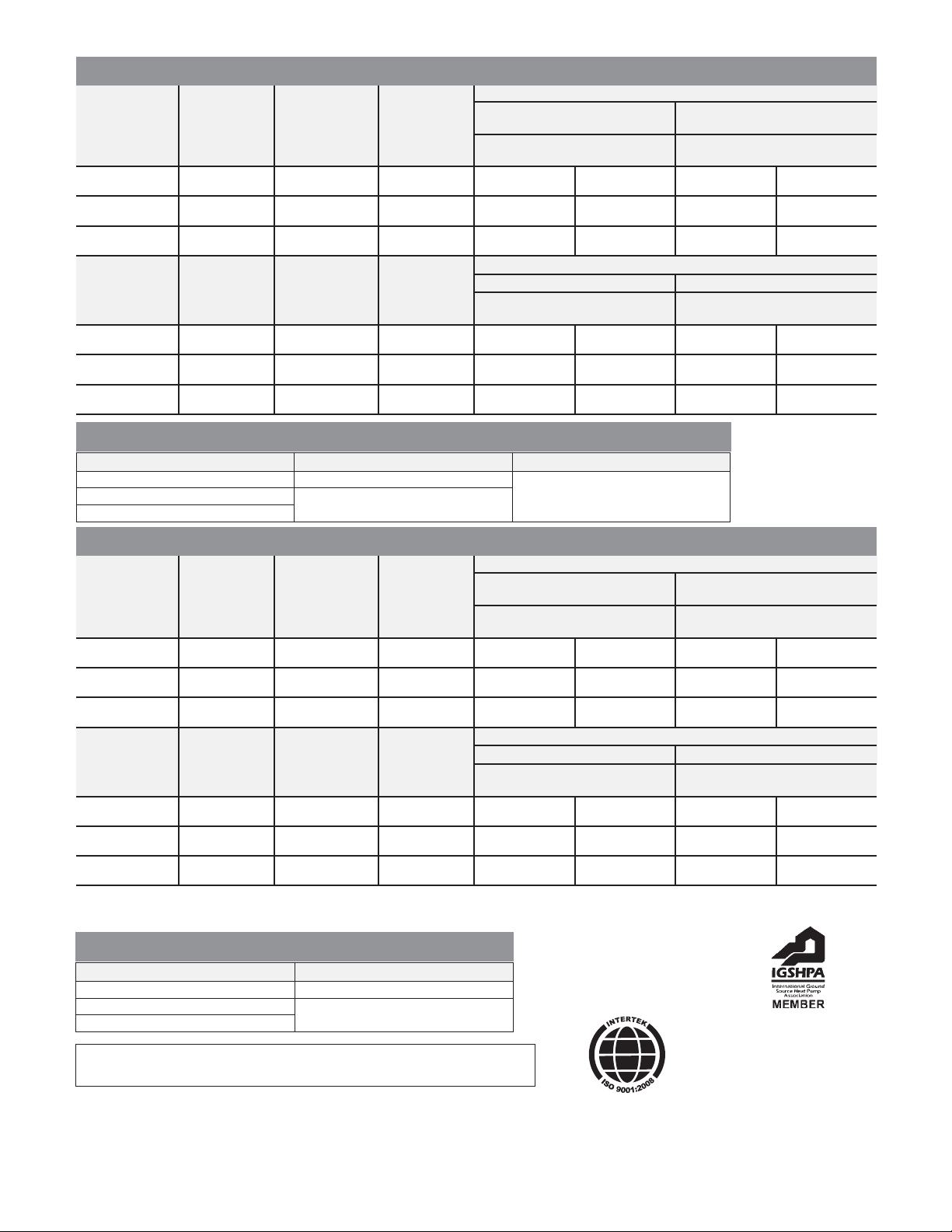

Ratings Based on Approved Compressor, GTA-Coil & Blower Combinations

—pmuPtaeHpooLdnuorG 8991:1-65231OSIotdeifitreC&detseT

enirBgnilooC

metsyS

LEDOM

1S63CTG

1S84CTG

1S06CTG

noitaludoM

lluF

traP

lluF

traP

lluF

traP

yticapaC

8

21

51

wolFdiulF

MPGetaR MFCwolfriA

0021

058

0051

0511

0081

0031

yticapaC

HUTB

008,83

000,82

000,15

000,83

005,16

005,74

F°86daoLtraP/F°77daoLlluF

REE

W/UTB

5.71

9.42

0.61

5.12

5.51

7.02

HUTB

—pmuPtaeHretaWdnuorG 8991:1-65231OSIotdeifitreC&detseT

metsyS

LEDOM

1S63CTG

1S84CTG

1S06CTG

noitaludoM

lluF

traP

lluF

traP

lluF

traP

yticapaC

6

7

9

wolFdiulF

MPGetaR MFCwolfriA

0021

058

0051

0511

0081

0031

yticapaC

HUTB

000,24

006,92

000,45

000,04

005,36

000,94

F°95TWE—gnilooC F°05TWE—gnitaeH

REE

W/UTB

8.12

4.92

0.91

5.42

8.81

7.42

HUTB

Approved Compressor, GTA-Coil & Blower Section Combinations

noitceStinUrosserpmoC noitceSlioC noitceSrewolB

1S63CTGAA1DU0063ATG,A-1DU0063ATG

1S06CTG

AA1DU0684ATG,A-1DU0684ATG

A-1BTG1S84CTG

enirBgnitaeH

F°14daoLtraP/F°23daoLlluF

yticapaC

008,82

008,22

005,73

000,13

000,94

005,93

yticapaC

000,43

000,52

000,64

000,43

000,85

000,24

POC

09.3

04.4

06.3

50.4

05.3

09.3

POC

05.4

08.4

02.4

54.4

50.4

52.4

Ratings Based on Approved Compressor & GTA-Coil Only

—pmuPtaeHpooLdnuorG 8991:1-65231OSIotdeifitreC&detseT

enirBgnilooC

metsyS

LEDOM

1S63CTG

1S84CTG

1S06CTG

noitaludoM

lluF

traP

lluF

traP

lluF

traP

yticapaC

8

21

51

wolFdiulF

MPGetaR MFCwolfriA

yticapaC

HUTB

0021

058

0051

0511

0081

0031

000,93

008,72

000,15

000,83

000,26

000,84

F°86daoLtraP/F°77daoLlluF

REE

W/UTB

2.81

0.52

6.61

6.12

4.61

2.32

—pmuPtaeHretaWdnuorG 8991:1-65231OSIotdeifitreC&detseT

gnilooC

TWE—

metsyS

LEDOM

1S63CTG

1S84CTG

1S06CTG

ISO Standard 13256-1:1998, “Water to Air and Brine to Air Heat Pumps”, which includes watt allowance for water pumping.

Cooling capacity based on 80.6°F DB, 66.2°F WB entering air temperature. Heating capacity based on 68°F DB entering air temperature.

noitaludoM

lluF

traP

lluF

traP

lluF

traP

yticapaC

6

7

9

wolFdiulF

MPGetaR MFCwolfriA

0021

058

0051

0511

0081

0031

yticapaC

HUTB

000,24

006,92

005,45

000,04

000,46

000,94

F°95 gnitaeH

REE

W/UTB

8.22

5.92

1.02

7.42

0.02

4.72

Approved Compressor and GTA-Coil

noitceStinUrosserpmoC noitceSlioC

1S63CTGA-1DU0063ATG

1S84CTG

1S06CTG

A-1DU0684ATG

enirBgnitaeH

F°14daoLtraP/F°23daoLlluF

yticapaC

HUTB

006,72

002,22

004,63

004,03

000,74

005,73

yticapaC

HUTB

002,33

002,42

005,44

004,33

000,65

000,04

POC

09.3

03.4

06.3

59.3

04.3

09.3

TWE—

F°05

POC

54.4

07.4

02.4

53.4

01.4

53.4

• Intertek ETL Listed to Standard for Safety Heating and Cooling Equipment

ANSI/UL 1995/CSA 22.2 No. 236-05, Third Edition.

PATENT PENDING

See Page 5 for alternate Fossil Fuel A-coil Ratings.

Form No. S3423-1112

Supersedes S3423-912

Page 4 of 28

Page 5

I

C

For Use with Gas or Oil Furnace as Dual Fuel Installation

The GTC Compressor Unit Sections are approved for use with certain 3rd Party A-Coils.

See Below.

All Models are Energy Star qualified for Ground Loop and Ground Water Applications.

Ratings Based on Approved Compressor and Fossil Fuel A-Coil

lissoF

leuF

ROSSERPMOC

NOITCES

LEDOM

1S63CTG

1S84CTG

1S06CTG

lioC-A

.oNdraB

11111

1

1

1

metsyS

yticapaC

noitaludoM

lluF

traP

lluF

traP

lluF

traP

wolFdiulF

MPGetaR

8

21

51

MFCwolfriA

0021

058

0051

0511

0081

0031

yticapaC

HUTB

000,93

003,82

000,84

000,73

000,95

005,44

metsyS

yticapaC

LEDOM

1S63CTG

1S84CTG

1S06CTG

1 See Cross-Reference Chart (Page 2) for approved Bard/ADP Coil part numbers.

Charge must be adjusted when using a Fossil Fuel A-Coil. See Installation Manual.

A coil spacer with a minimum height of 6" must be used on all Oil Furnaces to protect the coil drain pan and ensure even airflow across the coil.

GTLS-SK2-1 Line Set Stub Kit is required for installation to make connections to the GTC Compressor Section.

1

1

1

noitaludoM

lluF

traP

lluF

traP

lluF

traP

wolFdiulF

MPGetaR

6

7

9

MFCwolfriA

0021

058

0051

0511

0081

0031

yticapaC

HUTB

000,24

006,92

000,35

005,73

000,36

005,54

—pmuPtaeHpooLdnuorG 8991:1-65231OSIotdeifitreC&detseT

enirBgnilooC

F°86daoLtraP/F°77daoLlluF

REE

W/UTB

02.81

05.62

05.71

06.22

05.61

00.12

—pmuPtaeHretaWdnuorG 8991:1-65231OSIotdeifitreC&detseT

F°95TWE—gnilooC F°05TWE—gnitaeH

REE

W/UTB

04.32

08.13

00.22

00.62

08.02

52.52

.gnipmupretawrofecnawollattawsedulcni)spmuPtaeHriA-ot-enirBdnariA-ot-retaW(1-65231dradnatSOS

yticapaC

HUTB

002,72

004,12

000,53

000,82

000,54

000,73

yticapaC

HUTB

005,43

007,42

000,44

000,33

000,45

005,93

.erutarepmetriagniretneBDF86nodesabyticapacgnitaeH.erutarepmetriagniretneBWF2.66,BDF6.08nodesabyticapacgniloo

enirBgnitaeH

F°14daoLtraP/F°23daoLlluF

POC

00.4

05.4

08.3

00.4

06.3

57.3

POC

09.4

00.5

05.4

07.4

02.4

03.4

Correction Factors @ Increased Water Flows

wolFdetaR

sulP

MPG2500.1889.0600.1200.1

MPG3700.1489.0900.1300.1

MPG4800.1979.0110.1300.1

HutB sttaW HutB sttaW

gnilooC gnitaeH

Loop Pump Modules and Pump Outputs for Ground Loop Installations 1

sledoMpmuP spmuPfo.oN

7 9 21 51 61

1-CFROD15.825.72525.2222

2-CFROD27555055444

1 Pump output (feet of head) @ GPM at top of column.

MPGNIDERIUQERETARWOLFRETAW

Antifreeze Percentages by Volume for Ground Loop Installations 1

epyT

)C°2.21-(F°01 )C°4.9-(F°51 )C°7.6-(F°02 )C°9.3-(F°52

lonahteM%52%12%61%01

lonahtE 2 %92%52%02%41

locylGenelyporPedarGdooFPSU%001%72%42%02%31

1 Loop antifreeze protection must be determined based on loop design and geographic location.

2 Must not be denatured with any petroleum based product.

noitcetorPezeerFroferutarepmeTmuminiM

Form No. S3423-1112

Supersedes S3423-912

Page 5 of 28

Page 6

Refrigerant Connections (Self-Sealing Fittings)

rebmuNtraPnoitpircseD.D.OeziSeniL

1-4KS-SLTGsdnEriaPowThtiwtiKbutSteSeniL 1 "8/7&"8/3

1-2KS-SLTGsdnEriaPelgniShtiwtiKbutSteSeniL 1 "8/7&"8/3

1-30-SLTGsgnittiFhtiwteSeniL'3"8/7&"8/3

1-51-SLTGsgnittiFhtiwteSeniL'51"8/7&"8/3

1-52-SLTGsgnittiFhtiwteSeniL'52"8/7&"8/3

1-53-SLTGsgnittiFhtiwteSeniL'53"8/7&"8/3

1-05-SLTGsgnittiFhtiwteSeniL'05"8/7&"8/3

Horizontal Drain Pan Kit

1ZHTG

snoitceS"lioC-A"ATGroftiKnaPniarDlatnoziroH

Remote Condenser Cover

DILTG

1 One pair consists of one each of 3/8" liquid and 7/8"

vapor self-sealing fittings with short section of tube with

90° bend and each has 1/4" service port.

GTLS-SK2-1 (Shown)

metsyS-tilpSsadellatsnInehwsnoitceSgnisnednoCCTGrofrevoCpoT

Side Filter Rack – For Upflow Installations

32RF

retliF2VREMhtiw1x52x61kcaRretliF

)MPF056yticolevmumixam,elbahsawhsemmunimulA(

Coil Spacers for GTADP Fossil Fuel Coils

0222PDASC

0252PDASC

sledoM041,031RLFsecanruFliOdraBstiF

sledoM011,001,580,570RLF/FLFsecanruFliOdraBstiF

Optional Field Installed Start Kits for 1-Phase Models 1

sledoMtinU rebmuNtraPdellatsnIdleiF

A-1S63CTG 411KS

A-1S84CTG 111KS

A-1S06CTG 511KS

1 Start capacitor and potential relay start kit can be used with all -A single phase models only. Increases starting torque 9x.

Do not use if CMC-15 is used.

Optional Field Installed Start Kit for 1-Phase Models 2

sledoMtinU rebmuNtraPdellatsnIdleiF

esahP-1llA 51-CMC

2 PTCR start kit can be used with all -A single phase models. Increases starting torque 2-3x.

Do not use if SK111, SK114 or SK115 is used.

Form No. S3423-1112

Supersedes S3423-912

Page 6 of 28

Page 7

Ground Loop Accessories

pmuPtaeH

ledoM

llA1-CFROD1 sgnittifgnir-oelbuod,MPG61@.dH.tF22,pmup1,hP1-zH06-V032,tenibaChtiwretneCwolFpooL

llA2-CFROD1 sgnittifgnir-oelbuod,MPG61@.dH.tF44,pmup2,hP1-zH06-V032,tenibaChtiwretneCwolFpooL

llA1-KCFLROD1

llACH4-S-1BROD1 spmalcesohSS"1)4(htiwsgnittifgnir-oelbuodthgiartsdebrab"1)2(

llAS-521FROD1

rebmuNtraPdraB

52-1KHhcaEesohISP051DI"1fonoitces'52)1(

deriuqeR

ytitnauQ

:elbaliavasmetiyrosseccalanoitiddA

noitpircseD

:poolrofderiuqerdaehfoteefdnapmuptaehrofMPGderiuqernodesabretnecwolfpool1redrO:ETON

:gniniatnoctiKretneCwolFpooL

tseterutarepmet/erusserp620-3068dnastropTPF"4/1htiwswoblegnir-oelbuod°09debrab"1)2(

ecnereferrofCH4-09-1BRODeeS.)noitcennocpmuptaehrof(sgulp

)edispmuptaehnonoitcennocretnecwolfpoolrof(sgnittifgnir-oelbuodthgiartsdebrab"1)2(

ecnereferrofCH4-S-1BRODeeS

esohISP051DI"1fonoitces'21)1(

spmalcesohSS"1)8(

:retnecwolfpoolotsnoitcennocedis-poolrofgniwollofehtfo1redrO:ETON

sgnittifgnir-oelbuodthgiartsnoisuf"52.1)2(

DORFC-2

Elbow, 1" Hose Barb X Double

O-ring with 1/4" Port and

Pressure/Temperature Test Plugs

DORB1-90-4HC

Ground Loop Service Accessories

pmuPtaeH

ledoM

S-1BLChcaE evobasgnittif09-1LCRODottcennocotsgnittifelamefrevel-mactcennoc-kciuqdebrabthgiarts"1)2(

1-KGGhcaE eborp'8/1gnittifT/P,noitcennocesohnedrag,eguagISP001-0,evlavffo-tuhs/wresooG-oeG)1(

1" Cam Lever Male X

Double O-ring

DORCL1-90

rebmuNtraPdraB

09-1LCRODhcaE retnecwolfpoolottnemhcattahsulfrofsgnittifelamrevel-mactcennoc-kciuqgnir-oelbuod°09)2(

TMHGRODhcaE )pooltsoob/prubot(retnecwolfpoolrofgnittifretpadaesohnedragelamxgnir-oelbuoD)1(

deriuqeR

ytitnauQ

CLB1-S

1" Hose Barb X

Double O-ring

DORB1-S-4HC

noitpircseD

Garden Hose Male X O-ring

(single) Adapter

DORGHMT

1-1/4" Socket Fusion X

Double O-ring

DORF125-S

GGK-1

Form No. S3423-1112

Supersedes S3423-912

Page 7 of 28

Page 8

Ground Water/Water Loop Accessories

pmuPtaeH

ledoM

llA1-KWG1

63CTG6-VFC1

84CTG7-VFC1

06CTG9-VFC1 TPF"4/3,MPG9,evlavwolftnatsnoC

rebmuNtraPdraB

Elbow, 1" MPT X Double

O-ring with 1/4" Port and

Pressure/Temperature Test Plugs

DORMP1-90

sevlaVylppuSretaW

330-3068hcaEhctiwsdnehtiwevlavllabesolc/nepowolsssarbV42TPF"4/3

600-3068hcaE reveldeelblaunamlanretnidnalortnocwolfhtiwevlavdionelosCVPV42TPF"1

deriuqeR

ytitnauQ

:gniniatnoctiKretaWdnuorG

TPF"4/3,MPG6,evlavwolftnatsnoC

TPF"4/3,MPG7,evlavwolftnatsnoC

8603-033

noitpircseD

sgulptseterutarepmet/erusserp620-3068dnastropTPF"4/1htiwswoblegnir-oelbuod°09TPM"1)2(

ecnereferrof09-1PMRODeeS.)noitcennocpmuptaehrof(

.ecnereferrof330-3068eeS–hctiwsdne/wevlavllabesolc/nepowolsdezirotomssarbV42TPF"4/3)1(

tinurepderiuqer1,pmuptaehfoMPGdetarrofevlavwolftnatsnoctcerrocredrO:ETON

8603-006

)kcaprep2ytQ(skcaPgnittiFgniR-OelbuoDlaudividnI

CH4-09-1BROD

CH4-S-1BROD spmalcesohSS"1)4(htiwsgnittifgnir-oelbuodthgiartsdebrab"1)2(

09-1PMROD sgulptseterutarepmet/erusserp620-3068dnastropTPF"4/1htiwswoblegnir-oelbuod°09TPM"1)2(

S-1PMRODsgnittifgnir-oelbuodthgiartsTPM"1)2(

S-1PFRODsgnittifgnir-oelbuodthgiartsTPF"1)2(

S-1SROD sgulptseterutarepmet/erusserp620-3068dnastropTPF"4/1htiwsgnittifgnir-oelbuodthgiartstaewsreppoc"1)2(

1" MPT X Double O-ring

DORMP1-S

1" FPT X Double O-ring

spmalcesoh"1SS)4(dna

DORFP1-S

Ground Water/Water Loop Service Accessories

llA710-3068hcaETPF"1,MPG71-1,reteMwolF

llA620-3068hcaEgulptseterutarepmet/erusserp"4/1

llA720-3068hcaEeborpytudyvaeh"8/1/wretpadaeguagTPF"4/1

llA820-3068hcaEeguagISP001-0TPM"4/1

llA920-3068hcaEF022+ot0,eborp"8/1,retemomrehttekcoP

,sgulptseterutarepmet/erusserp620-3068,stropTPF"4/1htiwswoblegnir-oelbuod°09debrab"1)2(

1" Copper Sweat X Double O-ring with 1/4"

FPT Port & Pressure/Temperature Test Plugs

DORS1-S

8603-017

Form No. S3423-1112

Supersedes S3423-912

Page 8 of 28

8603-026

8603-027

8603-028

8603-029

Page 9

NOTE:

Requires

horizontal

drain pan kit

Model GTHZ-1

24"

15"

Opening

"

1

8

17

MIS-2824 A

Right Side View

Horiz. S uppor t Bracket

(Remote Compr essor Section)

Evaporator and Blower in Horizontal Position

Top View

Blower

Section

30"

High Voltage

3

Entrance

"31

8

1

Low Voltage

Evaporator

"

4

1

Entrance

Section

"

3

4

2

1

3 "

18

Entrance

Low Voltage

"

3

4

1

8"

21"

"

5

8

42

Refrigerant

Connections

Outlet

Overflow Drain

Outlet

Main Drain

"

1

22"

2

1

19 7/8"

"

3

4

"28

1

8

8

7

31 "

"

5

8

36

"

1

2

38

Front View

"

2

1

3

"

1

8

2

30"

"

7

8

27

Evaporator O pening Blower

GTHZ1

(Req'd)

Drain Pan

Horizontal

Form No. S3423-1112

Supersedes S3423-912

Page 9 of 28

Left Side View

Page 10

Position

Counterflow

MIS-2826

Model GTLID

Return

Upflow

Supply

Position

Return

Refrigerant

Connections

Evap. Coil

Drain

Secondary

Main Drain

Evap. Coil

Drain

Secondary

Main Drain

Blower Air

Return

Blower Air

Return

Blower in

Alternate Position

Blower in

Shipped Position

Supply

Return

Supply

Optional Top

Water Out

Cond. Coil

Desuper.

Water Out

Refrigerant

Connections

Water In

Desuper.

snoitallatsnIllArofediSriAnruteRnoderiuqeRretliFriA

Water In

Cond. Coil

notnelaviuqedeilppusdleifro)1x52x61(32RF)1(esunacsnoitallatsniwolfpU

.deilppusdleifebtsumwolfnwodrofnruterpotdnawolfpurofnrutermottoB

.lanoitposisedishtobno)2(foesU.noitcesrewolbehtfoedisrehtie

Remote Condenser Section

dleifebtsumtnemegnarraretlifsnoitallatsniecapslwarcrocittalatnozirohroF

.resuehtrofnoitacolelbisseccaylidaernidetacolebdluohs&deilppus

Return

Evap. Coil

Horizontal, Left Discharge

Form No. S3423-1112

Supersedes S3423-912

Page 10 of 28

Supply

Blower Air

Blower in

Shipped Position

Refrigerant

Connections

Secondary Drain

< >

Main Drain

Blower Air

Evap. Coil

NOTE: Requires horizontal

drain pan kit Model GTHZ-1

Horizontal, Right Discharge

Return

Blower in

Alternate Position

Refrigerant

Connections

Secondary Drain

Main Drain

.41&31segaPnonoitamrofnilanoitiddaeeS

Page 11

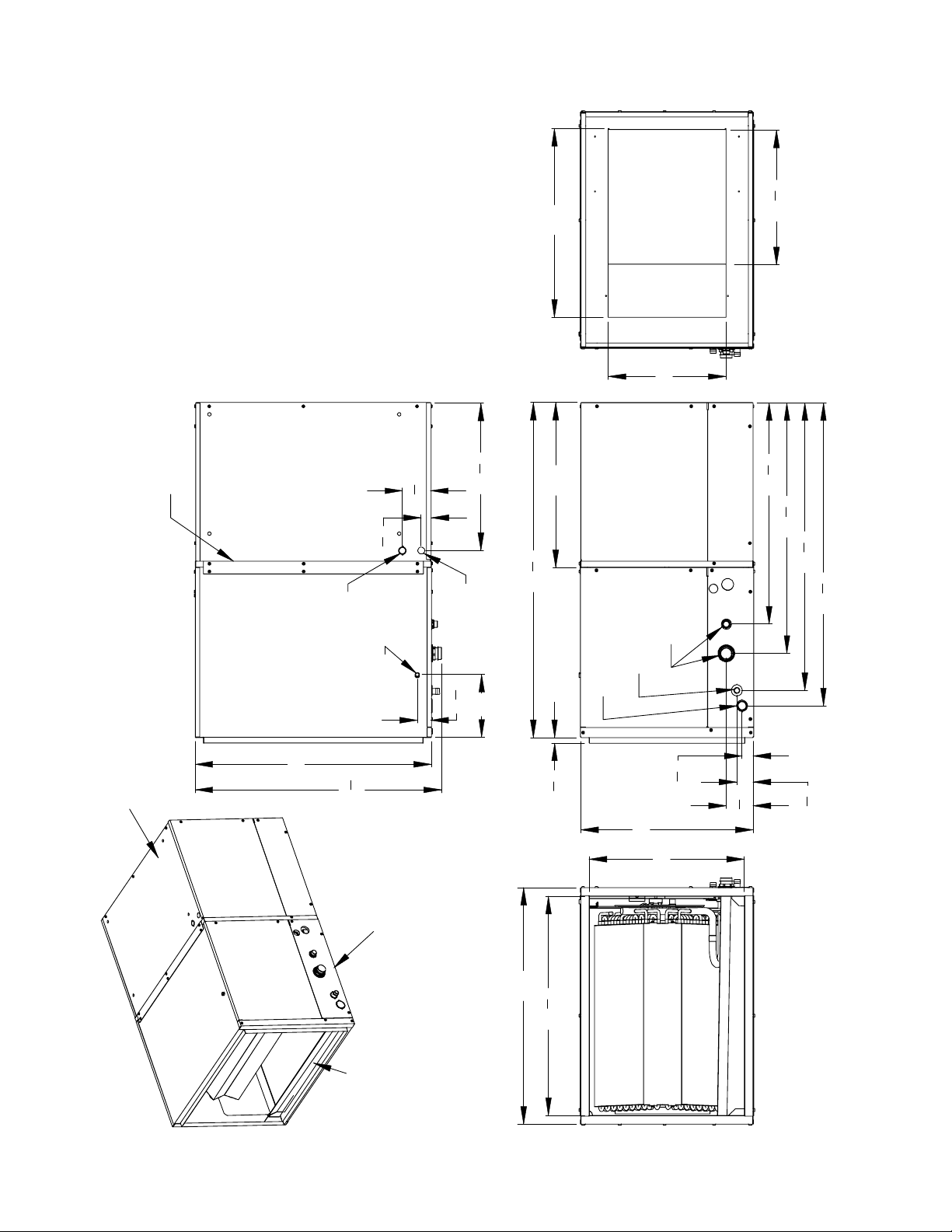

19 13/16"

57 3/4"

15 5/8"

MIS-2821 A

TOP DUCT OUTLET FLANGE

MODEL DIM. A

GTC36S1 39 7/16"

GTC48S1 40 15/16"

GTC60S1 41 15/16"

27 15/16"

TOP

MAIN DRAIN OUTLET

OVERFLOW DRAIN OUTLET

LOW VOLTA G E

WATER OUT

OUTLET

DESUPERHEATER

DESUPERHEATER

HIGH

LOW

WATER IN

INLET

VOLTAGE

VOLTAGE

LOW VOLTA G E

37 7/8"

AIR

ENTRANCE

(UPFLOW ONLY)

18 13/16"

25 3/4"

28 15/16"

33 1/4"

30 9/16"

30"

24 9/16"

RIGHT SIDEFRONT

22"

SECURE SECTIONS TOGETHER

USING BOLT PART #1012-015

AND WAS HER PAR T #1012-109

23 7/16"

"A"

46 3/16"

46 3/4"

REFRIGERANT

CONNECTIONS

31 1/4"

3/4"

21 5/8"

55"

51 1/4"

37 1/16"

27 7/8"

30"

AIR

ENTRANCE

(UPFLOW ONLY)

15 5/8"

23"

65 5/8"

21"

24 9/16"

LEFT SIDE

Form No. S3423-1112

Supersedes S3423-912

Page 11 of 28

Page 12

Counterflow

NOTE:

MIS-2828

See Page 20 for physical

dimensions of GTA coil

if removed from casing

for installation on a

fossil-fuel furnace.

Position

Control Panel

Blower in

Alternate Position

Return

Drain

Secondary

Upflow

Position

Evap. Coi l

Water In

Desuper.

Desuper.

Water Out

Main Drain

Cond. Coil

7/8" Line S et

3/8" Line S et

Water Out

Control Panel

Water In

Cond. Coil

Return

Blower Air

Air F ilter Required

One FR23 (16 x 25 x 1) or

field suppl ied equivalent

required for upflow side

return installation

Blower in

Shipped Position

Supply

Bottom return upflow and

top return count erflow filter

provision must be field

supplied

tnelaviuqedeilppusdleifro)1x52x61(32RF)1(esunacsnoitallatsniwolfpU

.deilppusdleifebtsumwolfnwodrofnruterpotdnawolfpurofnrutermottoB

.lanoitposisedishtobno)2(foesU.noitcesrewolbehtfoedisrehtieno

snoitallatsnIllArofediSriAnruteRnoderiuqeRretliFriA

.41&31segaPnonoitamrofnilanoitiddaeeS

Supply

Form No. S3423-1112

Supersedes S3423-912

Page 12 of 28

Evap. Coi l

Drain

Water In

Water Out

Secondary

Main Drain

Cond. Coil

7/8" Line S et

Desuper.

3/8" Line S et

Desuper.

Water Out

Cond. Coil

Blower Air

Return

Water In

Return

Page 13

Filter Application Table

Many standard size filters are represented below since there can be a wide variety of possibilities depending upon application

position of the heat pump system and the return air duct installation.

eziSlanimoNretliF2TFaerAecafruSepyTretliF

003@ytilibapaC

yticoleVMPF

MFCwolfriA

"1X"02X"0193.1

"1X"02X"2176.1005

"1X"02X"4149.1085

"1X"52X"4134.2037

"1X"02X"6122.2076

"1X"52X"6187.2048

"1X"02X"0287.2048

"1X"52X"0274.30501

"1X"42X"4200.40021

"2X"02X"0193.1

"2X"42X"2100.20060001

"2X"02X"4149.1085579

"2X"52X"4134.20375121

"2X"02X"6122.20760211

"2X"52X"6187.20480041

"2X"02X"0287.20480041

"2X"52X"0274.305010571

"2X"42X"420.400210002

"1X"02X"0193.1

"1X"42X"2100.20060001

"1X"02X"4149.1095089

"1X"52X"4134.20375121

"1X"02X"6122.20765111

"1X"52X"6187.20480041

"1X"02X"0287.20480041

"1X"52X"0274.305010471

"1X"42X"4200.400210002

"2X"02X"0193.1

"2X"42X"2100.200600010521

"2X"02X"4149.10950895121

"2X"52X"4134.203751210251

"2X"02X"6122.207651110041

"2X"52X"6187.204800410471

"2X"02X"0287.204800410471

"2X"52X"0274.3050104710712

"2X"42X"4200.4002100020052

"4X"42X"212

"4X"02X"6122.207651110041

"4X"02X"0287.204800410471

"4X"52X"0274.3050104710712

"4X"42X"424

elbasopsiDssalgrebiF"1

elbasopsiDssalgrebiF.dtS"2

retliFdetaelP"1

retliFdetaelP"2

retliFdetaelP"4

514

514007

524007

524007078

00600010521

002100020052

MFCwolfriA

yticoleVMPF

005@ytilibapaC

dednemmoceRtoN dednemmoceRtoN

MFCwolfriA

526@ytilibapaC

yticoleVMPF

dednemmoceRtoN

dednemmoceRtoN

NOTE: FR23 16x25x1 side filter rack has a washable multi-layer aluminum mesh filter that is rated at 650 FPM maximum.

Form No. S3423-1112

Supersedes S3423-912

Page 13 of 28

Page 14

Filter Application for All Installation Positions

AIR FILTER

AIR FILTER

AIR FILTER

AIR FILTER

AIR FILTER

AIR FILTER

AIRFLOW

*NOTE: SINGLE FILTER MAY REQUIRE

A TRANSITION FOR ADEQUATE FILTER

SIZING. SEE FILTER APPLICATION

INFORMATION.

*

AIRFLOW

CONFIGURATION

"V" FILTER CONFIGURATION

*

AIRFLOW

"A" FILTER

CONFIGURATION

AIRFLOW AIRFLOW

SINGLE FILTER

MIS-2882

AIR FILTER

CENTRAL RETURN GRILLE(S)

(ONE OR MULTIPLE)

AIR FILTER

*

AIR FILTER

AIR FILTER

AIR FILTER

AIR FILTE

R

AIR FILTER

*

AIR FILTER

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

MIS-2884

AIRFLOW

CONFIGURATION

SINGLE FILTE R

"A"/"V" FILTER

CONFIGURATION

CENTRAL RETURN

(ONE OR MULTIPLE)

INFORMATION.

*NOTE: SINGLE FILTER MAY REQUIRE

A TRANSITION FOR ADEQUATE FILTER

SIZING. SEE FILTER APPLICATION

AIRFLOW

CENTRAL RETURN GRILLE(S)

(ONE OR MULTIPLE)

*

AIR FILTER

AIRFLOW

AIR FILTER

SIDE INLET(S); ONE OR

BOTH SIDES OR IN COMBINATION

WITH BOTTOM INLET

*

UPFLOW

AIRFLOW

*

AIR FILTER

AIRFLOW

*

*NOTE: SINGLE FILTER MAY REQUIRE

A TRANSITION FOR ADEQUATE FILTER

SIZING. SEE FILTER APPLICATION

INFORMATION.

AIRFLOW

AIR FILTER

MIS-2881

COUNTERFLOW

FILTERS SHOULD ALWAYS BE APPLIED IN A MANNER THAT MAKES THEM EASY TO ACCESS & CHANGE.

HORIZONTAL LEFT DISCHARGE

CENTRAL RETURN GRILLE(S)

(ONE OR MULTIPLE)

*

AIR FILTER

AIRFLOW

SIDE INLET(S); ONE OR

BOTH SIDES OR IN COMBINATION

WITH BOTTOM INLET

*NOTE: SINGLE FILTER MAY REQUIRE

A TRANSITION FOR ADEQUATE FILTER

SIZING. SEE FILTER APPLICATION

INFORMATION.

AIRFLOW

AIR FILTER

*

*

AIR FILTER

*

AIR FILTER

AIRFLOW

HORIZONTAL FRONT DISCHARGE

AIRFLOW

MIS-2883

Form No. S3423-1112

Supersedes S3423-912

Page 14 of 28

Page 15

GTC36S1 Matched with GTA3600UD1-A Coil

6

8

2

4

1

2

7

4

2

3

3

9

9

2

0

6

5

3

7

6

9

7

0

6

3

6

3

5

7

9

3

8

1

4

8

5

7

1

5

8

2

5

1

3

7

1

4

7

9

0

1

7

2

9

3

3

6

9

0

2

6

9

8

1

2

3

4

5

6

7

0

2

6

3

3

3

9

7

9

5

1

6

1

6

5

7

3

8

3

8

3

1

4

9

3

8

2

7

Full Load Capacities based upon rated flow of 8 GPM of 15% methanol/mass at 1200 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°05

°061.831.8247.047.10.44

°072.634.7267.099.10.34

°083.436.6287.032.29.14

°094.239.5208.074.28.04

°0015.031.5228.027.28.93

°0116.823.4258.069.27.83

°05

°060.143.9227.067.10.74

°079.835.8237.010.28.54

°089.637.7257.062.26.44

°099.439.6277.015.24.34

°0018.231.6208.067.22.24

°0118.033.5228.010.31.14

°05

°060.444.0396.097.11.05

°078.146.9217.040.28.84

°086.938.8237.092.24.74

°094.739.7257.045.21.64

°0012.531.7277.097.28.44

°0110.333.6208.040.34.34

°05

°061.745.1376.028.13.35

°078.446.0386.070.29.15

°085.248.9207.023.24.05

°091.049.8227.085.29.84

°0018.731.8247.038.24.74

°0114.532.7277.080.39.54

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

0.049.8227.005.11.54

0.341.0307.015.12.84

2.642.1386.045.14.15

5.943.2356.065.18.45

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.62

.12

.81

.51

.31

.11

.9

.82

.32

.91

.61

.31

.11

.01

.03

.42

.02

.71

.41

.21

.01

.13

.62

.12

.81

.51

.31

.11

gniretnE

diulF

)F°(.pmeT

°52

°033.623.5889.13.91

°044.133.9821.20.42

°056.632.3962.27.82

°068.142.7993.24.33

°079.642.10135.21.83

°081.252.50176.28.24

°52

°037.528.9840.27.81

°047.037.3981.23.32

°058.536.7923.29.72

°068.045.10164.24.23

°079.544.50106.20.73

°089.053.90147.26.14

°52

°030.620.5992.22.81

°041.130.9944.26.22

°052.639.20106.20.72

°063.148.60167.25.13

°074.648.01129.29.53

°085.157.41170.33.04

Part Load Capacities based upon rated flow of 8 GPM of 15% methanol/mass at 850 CFM airflow.

COOLING PART LOAD HEATING PART LOAD

gniretnE

diulF

)F°(.pmeT

°05

°061.528.0238.039.03.82

°073.326.9148.021.11.72

°084.124.8168.023.10.62

°096.912.7188.025.18.42

°0018.710.6109.027.17.32

°0110.618.4139.029.15.22

°05

°060.726.1208.049.02.03

°070.524.0218.041.19.82

°081.322.9138.043.17.72

°091.129.7158.055.14.62

°0011.917.6178.057.11.52

°0112.714.5109.059.19.32

°05

°060.925.2277.059.02.23

°079.622.1297.051.18.03

°088.429.9118.063.14.92

°097.226.8128.065.10.82

°0016.023.7148.077.16.62

°0114.810.6168.079.12.52

°05

°061.132.3257.069.04.43

°078.829.1267.071.18.23

°086.626.0277.083.13.13

°093.422.9197.095.17.92

°0010.229.7118.097.11.82

°0118.916.6148.000.26.62

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

9.620.2228.037.04.92

0.929.2297.037.05.13

1.137.3257.057.06.33

3.336.4247.067.09.53

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.73

.72

.02

.61

.21

.01

.8

.93

.82

.22

.71

.31

.01

.8

.13

.72

.32

.91

.51

.11

.7

.44

.23

.42

.91

.51

.21

.9

gniretnE

diulF

)F°(.pmeT

°52

°030.028.6894.18.41

°044.324.0925.10.81

°057.621.4955.13.12

°061.037.7975.16.42

°074.334.10106.19.72

°088.630.50136.11.13

°52

°036.913.1935.13.41

°048.229.4965.15.71

°051.624.8995.17.02

°064.920.20126.19.32

°077.236.50146.10.72

°089.531.90176.12.03

°52

°038.915.6927.19.31

°041.321.00157.10.71

°054.628.30187.11.02

°067.924.70118.12.32

°070.330.11158.12.62

°083.636.41188.13.92

gniretnE

riA

latoT

.pmeT

)F°(

°56

°07

°57

gniretnE

riA

latoT

.pmeT

)F°(

°56

°07

°57

gnivaeL

riA

yticapaC

)HutBM(

)F°(

rewoP

tupnI

.pmeT

)WK(

7.323.3829.10.71

2.329.7879.15.61

4.321.3912.20.61

gnivaeL

riA

yticapaC

)HutBM(

)F°(

rewoP

tupnI

.pmeT

)WK(

3.810.5884.11.31

9.715.9825.17.21

1.817.4907.14.21

Form No. S3423-1112

Supersedes S3423-912

Page 15 of 28

fotaeH

noitprosbA

POC

)HutBM(

.3

.3

.4

.4

.5

.5

.5

.3

.3

.4

.4

.4

.5

.5

.3

.3

.3

.4

.4

.4

.4

fotaeH

noitprosbA

POC

)HutBM(

.3

.3

.4

.5

.5

.6

.6

.3

.3

.4

.4

.5

.5

.6

.3

.3

.3

.4

.4

.5

.5

Page 16

GTC36S1 Matched with GTA3600UD1-A Coil

0

9

2

7

2

9

0

4

2

4

8

4

2

4

9

6

6

9

6

6

9

4

9

8

1

8

9

4

2

5

7

0

4

6

9

0

2

4

8

1

4

8

6

8

0

3

6

8

0

3

2

9

9

7

1

9

7

2

6

3

9

1

8

2

2

7

7

7

8

8

7

2

0

2

4

3

7

3

6

9

5

0

5

0

1

4

7

9

2

5

8

7

9

2

7

2

6

0

Full Load Capacities based upon rated flow of 6 GPM water at 1200 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°04

°058.532.6237.017.16.14

°067.537.6257.068.11.24

°077.531.7267.010.26.24

°087.537.6257.068.11.24

°098.532.6237.017.16.14

°0018.537.5227.065.11.14

°04

°055.833.7267.037.14.44

°064.838.7257.088.18.44

°074.832.8247.040.23.54

°084.838.7227.088.18.44

°095.833.7217.037.14.44

°0015.838.6207.085.19.34

°04

°053.143.8247.057.12.94

°062.148.8227.019.17.84

°072.143.9217.070.23.84

°082.148.8207.019.18.74

°093.143.8296.057.13.74

°0013.148.7276.006.18.64

°04

°053.443.9266.087.13.05

°062.448.9276.049.18.05

°072.443.0396.001.23.15

°082.448.9276.049.18.05

°093.443.9266.087.13.05

°0013.448.8256.026.18.94

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

8.537.5227.065.11.14

5.838.6207.085.19.34

3.148.7257.006.18.64

3.448.8256.026.18.94

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.32

.02

.91

.71

.91

.02

.32

.42

.22

.02

.81

.02

.22

.42

.52

.32

.12

.91

.12

.32

.52

.72

.42

.22

.12

.22

.42

.72

gniretnE

diulF

)F°(.pmeT

°04

°541.130.9840.21.42

°050.432.1931.27.62

°067.937.5913.28.13

°075.541.00194.20.73

°082.155.40166.22.24

°090.750.90148.23.74

°04

°544.034.3901.22.32

°052.336.5991.27.52

°068.830.00173.27.03

°075.443.40155.27.53

°081.056.80137.28.04

°097.550.31119.28.54

°04

°547.037.8963.27.22

°056.339.00164.22.52

°063.933.50166.22.03

°079.447.90178.22.53

°086.051.41170.32.04

°093.655.81172.32.54

Part Load Capacities based upon rated flow of 6 GPM water at 850 CFM airflow.

COOLING PART LOAD HEATING PART LOAD

gniretnE

diulF

)F°(.pmeT

°04

°056.721.0237.068.06.03

°066.626.9147.099.00.03

°075.521.9157.021.13.92

°085.427.8167.052.17.82

°094.322.8187.073.11.82

°0014.227.7197.005.15.72

°04

°057.929.0207.078.07.23

°066.824.0217.000.10.23

°075.729.9137.031.13.13

°083.624.9147.062.16.03

°092.529.8157.093.10.03

°0011.425.8177.025.13.92

°04

°059.137.1286.088.09.43

°067.032.1296.010.12.43

°075.927.0207.051.14.33

°083.822.0217.082.16.23

°091.727.9137.014.19.13

°0019.522.9147.045.11.13

°04

°052.434.2266.098.03.73

°069.239.1276.030.14.63

°076.134.1286.061.16.53

°083.039.0296.003.17.43

°090.924.0207.034.19.33

°0017.728.9127.065.11.33

Form No. S3423-1112

Supersedes S3423-912

Page 16 of 28

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

7.825.0227.037.02.13

8.034.1296.047.04.33

1.332.2276.057.07.53

5.530.3256.067.01.83

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.93

.23

.62

.22

.91

.71

.41

.14

.43

.82

.42

.02

.81

.51

.44

.63

.82

.52

.22

.91

.61

.64

.83

.23

.72

.32

.02

.71

gniretnE

diulF

)F°(.pmeT

°04

°549.229.9864.19.71

°058.420.2984.17.91

°065.821.6935.13.32

°073.232.00185.19.62

°081.633.40126.15.03

°099.934.80176.12.43

°04

°544.224.4905.12.71

°052.424.6925.10.91

°069.724.00175.15.22

°076.134.40126.11.62

°083.534.80176.16.92

°090.934.21117.11.33

°04

°546.226.9986.19.61

°055.427.10117.16.81

°062.827.50167.12.22

°079.138.90128.17.52

°087.538.31178.13.92

°094.939.71139.18.23

gniretnE

riA

.pmeT

)F°(

°56

°07

°57

gniretnE

riA

.pmeT

)F°(

°56

°07

°57

latoT

yticapaC

)HutBM(

gnivaeL

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

2.828.6869.15.12

6.723.1910.27.02

9.725.6962.22.02

latoT

yticapaC

)HutBM(

gnivaeL

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

0.129.7834.11.61

5.023.2974.15.51

7.026.7956.11.51

fotaeH

noitprosbA

POC

)HutBM(

.4

.4

.4

.5

.5

.5

.5

.4

.4

.4

.4

.5

.5

.5

.3

.3

.4

.4

.4

.4

.5

fotaeH

noitprosbA

POC

)HutBM(

.4

.4

.4

.5

.6

.6

.7

.4

.4

.4

.4

.5

.5

.5

.3

.3

.4

.4

.5

.5

.6

Page 17

GTC48S1 Matched with GTA4860UD1-A Coil

3

1

5

4

6

1

8

7

2

5

2

3

7

3

9

3

4

1

1

4

0

3

5

4

9

8

0

5

4

6

9

2

5

7

0

3

4

7

0

3

5

8

9

1

4

6

8

1

3

0

2

9

7

1

1

4

0

7

1

6

9

7

9

1

2

3

3

4

5

6

5

5

5

6

6

2

2

2

5

0

5

0

4

9

1

3

8

3

7

2

6

8

0

4

9

3

7

0

Full Load Capacities based upon rated flow of 12 GPM of 15% methanol/mass at 1500 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°05

°060.941.5317.017.23.85

°077.640.4337.010.39.65

°083.440.3347.013.36.55

°099.149.1367.016.32.45

°0015.939.0387.009.38.25

°0111.738.9208.002.45.15

°05

°068.255.6396.047.21.26

°072.054.5317.050.36.06

°086.743.4327.053.31.95

°091.542.3347.066.36.75

°0015.242.2367.079.30.65

°0119.931.1387.072.45.45

°05

°066.659.7376.097.21.66

°079.358.6386.090.34.46

°081.156.5307.093.37.26

°094.845.4317.007.30.16

°0016.544.3337.000.43.95

°0119.242.2357.013.46.75

°05

°067.062.9356.038.24.07

°078.750.8366.031.35.86

°088.459.6376.044.36.66

°099.157.5396.057.37.46

°0019.845.4317.060.48.26

°0110.644.3337.073.49.06

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

4.151.6307.024.27.95

3.556.7386.044.26.36

4.950.9366.084.29.76

7.364.0436.025.22.27

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.12

.81

.51

.31

.11

.01

.8

.22

.91

.61

.41

.21

.01

.9

.32

.02

.71

.51

.31

.11

.01

.52

.12

.81

.51

.31

.21

.01

gniretnE

diulF

°52

°032.730.8840.35.62

°045.348.1942.31.23

°057.947.5944.36.73

°060.655.9946.32.34

°072.264.30158.37.84

°084.862.70150.43.45

°52

°034.635.2921.38.52

°045.242.6933.32.13

°056.840.00135.35.63

°067.458.30147.39.14

°078.065.70159.33.74

°089.663.11161.47.25

°52

°038.637.7905.30.52

°040.345.10137.32.03

°051.943.50179.34.53

°063.551.90102.47.04

°075.169.21134.49.54

°086.768.61176.41.15

Part Load Capacities based upon rated flow of 12 GPM of 15% methanol/mass at 1150 CFM airflow.

COOLING PART LOAD HEATING PART LOAD

gniretnE

diulF

)F°(.pmeT

°05

°061.735.7247.006.16.24

°071.536.6267.068.14.14

°081.338.5287.011.23.04

°091.130.5208.073.22.93

°0011.922.4238.026.20.83

°0111.723.3268.088.29.63

°05

°069.936.8227.026.14.54

°077.737.7237.088.12.44

°086.539.6267.041.29.24

°094.330.6287.014.27.14

°0013.132.5208.076.24.04

°0111.923.4238.039.21.93

°05

°068.247.9296.046.15.84

°075.048.8217.019.10.74

°082.839.7237.071.26.54

°099.530.7257.034.22.44

°0016.331.6287.096.28.24

°0113.132.5208.059.24.14

°05

°069.547.0376.076.16.15

°074.348.9296.039.10.05

°080.149.8207.002.25.84

°095.839.7237.074.29.64

°0010.630.7257.037.23.54

°0115.331.6287.000.38.34

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

1.933.8227.053.17.34

1.245.9207.063.17.64

2.546.0376.083.19.94

4.847.1356.004.12.35

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.92

.32

.81

.51

.31

.11

.9

.13

.42

.02

.61

.31

.11

.9

.72

.42

.12

.81

.51

.21

.9

.43

.72

.22

.81

.51

.31

.11

gniretnE

diulF

°52

°033.627.7812.25.81

°043.130.2982.23.32

°053.633.6953.21.82

°064.146.00134.29.23

°074.649.40105.27.73

°084.152.90175.24.24

°52

°037.522.2972.20.81

°046.034.6943.26.22

°055.536.00124.23.72

°064.048.40194.29.13

°073.540.90175.26.63

°082.053.31146.22.14

°52

°030.624.7955.24.71

°040.137.10136.20.22

°059.539.50117.25.62

°069.042.01108.20.13

°078.545.41188.25.53

°088.057.81179.20.04

gniretnE

riA

.pmeT

)F°(.pmeT

)F°(

latoT

yticapaC

)HutBM(

1.431.6839.28.32

°56

4.336.0910.31.32

°07

7.338.5983.34.22

°57

gniretnE

riA

.pmeT

)F°(.pmeT

)F°(

latoT

yticapaC

)HutBM(

8.325.5871.21.61

°56

3.320.0932.27.51

°07

5.323.5915.22.51

°57

gnivaeL

riA

)F°(

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

gnivaeL

rewoP

tupnI

.pmeT

)WK(

Form No. S3423-1112

Supersedes S3423-912

Page 17 of 28

fotaeH

noitprosbA

POC

)HutBM(

.3

.3

.3

.4

.4

.4

.5

.3

.3

.3

.4

.4

.4

.4

.2

.3

.3

.3

.3

.4

.4

fotaeH

noitprosbA

POC

)HutBM(

.3

.3

.4

.4

.5

.5

.5

.3

.3

.3

.4

.4

.5

.5

.2

.3

.3

.3

.4

.4

.5

Page 18

GTC48S1 Matched with GTA4860UD1-A Coil

9

2

7

4

7

2

9

1

3

7

3

7

3

1

4

4

8

3

8

4

4

7

6

8

3

8

6

7

2

3

4

6

7

9

9

0

1

2

4

5

7

8

6

7

8

9

1

2

2

9

9

9

5

5

9

6

7

5

2

7

6

9

5

5

1

8

9

1

2

4

4

6

0

2

8

9

3

0

3

6

1

6

0

5

8

1

3

6

9

1

4

4

7

9

4

8

2

5

Full Load Capacities based upon rated flow of 7 GPM water at 1500 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°04

°057.747.3317.036.27.65

°060.744.3317.028.26.65

°072.640.3317.010.35.65

°080.744.3317.028.26.65

°097.747.3317.036.27.65

°0015.841.4307.044.28.65

°04

°054.151.5307.066.24.06

°065.057.4396.058.23.06

°077.944.4396.050.31.06

°085.057.4396.058.23.06

°094.151.5386.066.24.06

°0012.255.5386.074.26.06

°04

°051.554.6376.007.26.36

°063.450.6376.098.28.36

°074.357.5376.090.39.36

°083.450.6366.098.21.46

°091.554.6366.007.23.46

°0010.658.6366.005.25.46

°04

°051.957.7346.047.24.86

°062.853.7346.039.22.86

°072.759.6346.031.39.76

°082.853.7346.039.22.86

°091.957.7346.047.24.86

°0010.061.8336.045.27.86

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

5.841.4307.044.28.65

2.255.5386.074.26.06

0.658.6386.005.25.46

0.061.8336.045.27.86

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.91

.81

.61

.51

.61

.81

.91

.12

.91

.71

.61

.71

.91

.12

.22

.02

.81

.71

.81

.02

.22

.32

.12

.91

.81

.91

.12

.32

gniretnE

diulF

)F°(.pmeT

°04

°543.145.0918.27.13

°055.541.3920.32.53

°069.353.8934.32.24

°072.264.30158.31.94

°086.076.80162.40.65

°099.877.31176.40.36

°04

°544.049.4998.26.03

°055.445.7901.39.33

°067.255.20125.36.04

°078.066.70159.34.74

°080.966.21173.41.45

°092.776.71108.48.06

°04

°549.042.01142.38.92

°050.548.31184.31.33

°062.359.02169.37.93

°075.160.82134.44.64

°088.961.53119.40.35

°090.872.24193.56.95

Part Load Capacities based upon rated flow of 5 GPM water at 1150 CFM airflow.

COOLING PART LOAD HEATING PART LOAD

gniretnE

diulF

)F°(.pmeT

°04

°059.530.7257.044.18.04

°067.537.6257.036.13.14

°075.535.6257.028.17.14

°083.532.6247.010.21.24

°090.539.5247.002.25.24

°0018.437.5247.093.20.34

°04

°056.831.8237.064.16.34

°064.838.7227.056.10.44

°072.835.7227.048.15.44

°089.733.7227.040.29.44

°097.730.7227.032.23.54

°0014.737.6217.024.27.54

°04

°055.142.9207.084.15.64

°062.149.8207.076.19.64

°070.146.8207.078.13.74

°087.043.8296.060.28.74

°095.040.8296.062.22.84

°0012.047.7296.054.26.84

°04

°055.442.0386.005.16.94

°062.449.9286.007.10.05

°079.346.9276.009.14.05

°086.343.9276.090.28.05

°094.340.9276.092.22.15

°0011.347.8276.094.26.15

Form No. S3423-1112

Supersedes S3423-912

Page 18 of 28

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

1.632.7257.052.14.04

9.834.8237.072.12.34

7.144.9217.082.11.64

7.445.0386.003.12.94

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.82

.42

.12

.91

.71

.51

.41

.03

.62

.32

.02

.81

.61

.51

.23

.82

.32

.12

.02

.81

.61

.43

.92

.62

.32

.02

.81

.71

gniretnE

diulF

)F°(.pmeT

°04

°547.136.4861.23.42

°052.431.6891.27.62

°061.931.9852.24.13

°070.442.2923.21.63

°080.942.5983.29.04

°099.353.8944.26.54

°04

°540.137.6922.24.32

°054.338.8952.27.52

°062.839.20113.23.03

°071.341.70183.29.43

°089.742.11144.25.93

°097.254.51115.22.44

°04

°543.130.20194.28.22

°058.331.40135.21.52

°066.833.80106.28.92

°075.345.21176.24.43

°084.847.61147.20.93

°093.359.02118.27.34

gniretnE

riA

.pmeT

)F°(

°56

°07

°57

gniretnE

riA

.pmeT

)F°(

°56

°07

°57

latoT

yticapaC

)HutBM(

gnivaeL

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

2.739.7816.23.82

3.634.2986.22.72

7.636.60100.35.62

latoT

yticapaC

)HutBM(

gnivaeL

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

2.920.3831.20.22

6.826.4991.21.12

9.829.9954.25.02

fotaeH

noitprosbA

POC

)HutBM(

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.3

.3

.3

.3

.4

.4

.4

fotaeH

noitprosbA

POC

)HutBM(

.4

.4

.4

.5

.5

.6

.6

.3

.4

.4

.4

.4

.5

.5

.3

.3

.3

.4

.4

.5

.5

Page 19

GTC60S1 Matched with GTA4860UD1-A Coil

4

9

2

0

2

7

5

8

0

1

8

9

3

0

0

1

1

6

6

0

6

4

3

0

5

3

6

1

5

7

9

2

4

6

9

4

5

8

0

2

4

6

0

2

4

6

8

0

2

8

2

6

3

7

7

1

8

7

8

2

5

3

6

9

9

0

0

0

0

1

4

6

1

2

1

7

8

2

4

8

2

6

0

3

1

3

7

0

4

7

1

8

9

3

6

9

3

6

Full Load Capacities based upon rated flow of 15 GPM of 15% methanol/mass at 1800 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°05

°061.758.1437.091.30.86

°075.458.0457.095.37.66

°089.158.9377.099.35.56

°092.948.8397.093.42.46

°0016.648.7318.087.40.36

°0110.448.6348.081.57.16

°05

°064.166.3417.032.34.27

°076.855.2437.036.30.17

°088.555.1447.040.46.96

°090.354.0467.054.42.86

°0011.054.9397.068.47.66

°0113.744.8318.072.53.56

°05

°069.562.5496.082.31.77

°079.261.4407.086.35.57

°089.950.3427.090.49.37

°099.650.2447.005.42.27

°0018.359.0467.019.46.07

°0118.058.9387.023.50.96

°05

°067.078.6466.023.30.28

°074.767.5486.047.32.08

°082.465.4496.051.44.87

°099.064.3417.075.45.67

°0017.753.2437.089.47.47

°0115.452.1467.093.59.27

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

7.958.2427.097.22.96

2.466.4496.028.28.37

9.863.6476.078.27.87

9.379.7456.019.28.38

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.12

.71

.51

.31

.11

.9

.8

.22

.91

.61

.31

.11

.01

.9

.42

.02

.71

.41

.21

.11

.9

.52

.12

.81

.51

.31

.11

.01

gniretnE

diulF

°52

°036.945.0959.37.53

°048.557.3941.43.14

°051.269.6933.49.64

°064.862.00125.45.25

°076.474.30127.41.85

°089.086.60119.47.36

°52

°035.849.4950.46.43

°046.451.8952.41.04

°057.062.10154.45.54

°068.664.40156.40.15

°070.375.70148.44.65

°081.977.01140.59.16

°52

°030.942.00155.46.33

°042.554.30177.49.83

°054.166.60100.52.44

°066.768.90122.54.94

°078.379.21144.57.45

°089.971.61166.50.06

Part Load Capacities based upon rated flow of 15 GPM of 15% methanol/mass at 1300 CFM airflow.

COOLING PART LOAD HEATING PART LOAD

gniretnE

diulF

)F°(.pmeT

°05

°066.241.0317.048.18.84

°074.045.9237.071.28.74

°082.839.8267.005.28.64

°091.633.8287.048.27.54

°0019.337.7228.071.37.44

°0117.130.7258.005.37.34

°05

°068.544.1386.068.11.25

°075.347.0317.002.20.15

°081.141.0337.045.28.94

°098.834.9267.088.26.84

°0014.638.8297.022.34.74

°0111.432.8238.065.33.64

°05

°062.945.2366.088.16.55

°077.649.1386.032.23.45

°082.442.1317.075.29.25

°096.145.0347.019.26.15

°0011.939.9267.052.32.05

°0116.632.9297.095.39.84

°05

°067.257.3346.019.12.95

°070.050.3366.062.27.75

°083.743.2386.016.22.65

°096.446.1317.059.27.45

°0019.149.0347.003.32.35

°0112.932.0377.056.37.15

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

8.447.0396.005.19.94

1.840.2366.015.13.35

7.152.3336.045.10.75

4.554.4326.075.17.06

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.92

.32

.81

.51

.21

.01

.9

.13

.42

.91

.61

.31

.11

.9

.62

.32

.12

.81

.51

.21

.9

.53

.72

.22

.81

.51

.21

.01

gniretnE

diulF

°52

°031.336.8838.21.32

°044.834.2929.21.82

°058.342.6920.32.33

°061.940.00111.32.83

°074.457.30112.32.34

°087.955.70103.32.84

°52

°034.231.3919.25.22

°046.738.6900.33.72

°058.245.00101.32.23

°060.842.40102.31.73

°072.359.70192.39.14

°084.856.11193.38.64

°52

°037.233.8962.38.12

°040.831.20173.35.62

°052.348.50184.32.13

°065.845.90195.30.63

°078.353.31107.37.04

°080.950.71118.34.54

gniretnE

riA

.pmeT

)F°(.pmeT

)F°(

latoT

yticapaC

)HutBM(

4.649.8858.38.23

°56

4.544.3969.39.13

°07

9.546.8944.49.03

°57

gniretnE

riA

.pmeT

)F°(.pmeT

)F°(

latoT

yticapaC

)HutBM(

5.037.6887.26.02

°56

8.922.1968.20.02

°07

1.034.6912.34.91

°57

gnivaeL

riA

)F°(

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

gnivaeL

rewoP

tupnI

.pmeT

)WK(

Form No. S3423-1112

Supersedes S3423-912

Page 19 of 28

fotaeH

noitprosbA

POC

)HutBM(

.3

.3

.3

.4

.4

.4

.4

.3

.3

.3

.4

.4

.4

.4

.3

.3

.3

.3

.3

.4

.4

fotaeH

noitprosbA

POC

)HutBM(

.3

.3

.3

.4

.4

.5

.5

.3

.3

.3

.4

.4

.4

.5

.2

.2

.3

.3

.3

.4

.4

Page 20

GTC60S1 Matched with GTA4860UD1-A Coil

9

9

3

0

3

9

9

1

0

3

9

3

0

1

4

2

4

9

4

2

4

6

3

4

8

4

3

6

0

1

2

5

6

8

0

8

9

0

2

4

6

8

4

5

6

8

0

1

3

4

8

5

3

7

6

8

4

4

9

4

7

4

6

4

0

0

6

2

7

3

4

6

6

7

7

2

1

4

5

6

6

6

7

7

7

7

3

4

4

5

5

8

9

9

9

0

0

0

Full Load Capacities based upon rated flow of 9 GPM water at 1800 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°04

°058.354.0457.000.30.46

°067.357.0467.092.39.46

°076.351.1477.085.38.56

°087.357.0467.092.39.46

°098.354.0457.000.30.46

°0019.350.0447.017.21.36

°04

°059.750.2467.040.32.86

°068.754.2457.033.31.96

°077.758.2447.026.30.07

°088.754.2437.033.31.96

°099.750.2437.040.32.86

°0019.756.1427.057.23.76

°04

°051.266.3407.080.36.27

°060.260.4427.04.35.37

°079.164.4427.076.35.47

°080.260.4417.083.35.37

°091.266.3407.080.36.27

°0012.262.3496.087.27.17

°04

°056.661.5486.021.32.77

°065.665.5486.024.32.87

°074.669.5496.037.31.97

°085.665.5486.024.32.87

°096.661.5486.021.32.77

°0017.667.4476.028.23.67

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

9.350.0447.017.21.36

9.756.1427.057.23.76

2.262.3486.08.27.17

7.667.4476.028.23.67

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.91

.71

.61

.51

.61

.71

.91

.12

.91

.71

.51

.71

.91

.12

.22

.02

.81

.61

.81

.02

.22

.32

.12

.91

.71

.91

.12

.32

gniretnE

diulF

)F°(.pmeT

°04

°543.459.2958.32.14

°053.755.4959.38.34

°063.366.7961.41.94

°073.966.00173.43.45

°083.577.30195.46.95

°093.188.60108.49.46

°04

°541.353.7959.36.93

°050.658.8960.41.24

°069.168.10182.43.74

°077.768.40194.44.25

°086.378.70117.45.75

°094.979.01129.46.26

°04

°547.356.20144.45.83

°056.651.40165.41.14

°065.262.70108.41.64

°075.862.01140.52.15

°084.473.31192.53.65

°093.083.61135.54.16

Part Load Capacities based upon rated flow of 9 GPM water at 1300 CFM airflow.

COOLING PART LOAD HEATING PART LOAD

gniretnE

diulF

)F°(.pmeT

°04

°059.244.1337.076.16.84

°062.146.0347.019.17.74

°075.938.9257.061.28.64

°087.730.9277.004.20.64

°090.632.8287.056.21.54

°0013.434.7208.009.22.44

°04

°051.647.2307.096.19.15

°063.448.1327.049.19.05

°074.240.1337.091.29.94

°086.042.0347.034.29.84

°098.833.9267.086.29.74

°0019.635.8277.039.29.64

°04

°055.949.3386.017.14.55

°065.740.3396.069.12.45

°076.542.2317.012.21.35

°086.343.1327.074.20.25

°096.144.0337.027.29.05

°0016.936.9257.079.28.94

°04

°051.351.5366.037.10.95

°060.152.4376.099.17.75

°078.843.3386.052.25.65

°087.644.2396.005.23.55

°096.445.1317.067.20.45

°0015.246.0327.020.38.25

Form No. S3423-1112

Supersedes S3423-912

Page 20 of 28

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

6.442.2327.024.14.94

0.845.3307.044.19.25

5.158.4386.064.15.65

2.550.6356.084.12.06

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

REE

)HutBM(

.13

.52

.12

.81

.51

.31

.11

.33

.72

.22

.91

.61

.41

.21

.53

.92

.32

.02

.81

.51

.31

.73

.03

.52

.12

.81

.61

.41

gniretnE

diulF

)F°(.pmeT

°04

°548.331.9802.23.62

°059.041.4936.29.13

°061.552.40105.31.34

°073.963.41173.43.45

°084.384.42142.55.56

°096.795.43111.67.67

°04

°541.330.7862.24.52

°050.046.0917.28.03

°069.357.7906.36.14

°077.768.40194.44.25

°086.180.21183.52.36

°094.591.91182.60.47

°04

°544.338.8945.28.42

°054.048.30140.31.03

°064.458.31140.47.04

°075.868.32140.52.15

°085.287.33150.68.16

°095.697.34150.74.27

gniretnE

riA

.pmeT

)F°(

°56

°07

°57

gniretnE

riA

.pmeT

)F°(

°56

°07

°57

latoT

yticapaC

)HutBM(

gnivaeL

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

3.154.1947.35.83

1.058.5948.30.73

7.051.10123.40.63

latoT

yticapaC

)HutBM(

gnivaeL

riA

)F°(

rewoP

tupnI

.pmeT

)WK(

7.620.4867.17.02

1.624.3818.10.02

4.628.3930.25.91

fotaeH

noitprosbA

POC

)HutBM(

.4

.4

.4

.4

.4

.4

.5

.3

.3

.4

.4

.4

.4

.4

.3

.3

.3

.3

.4

.4

.4

fotaeH

noitprosbA

POC

)HutBM(

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.4

.3

.3

.3

.3

.4

.4

.4

Page 21

1

1

1

1

1

1

7

9

3

8

1

4

8

5

7

1

5

8

2

5

1

3

7

1

4

7

9

9

1

7

2

7

1

5

7

9

4

0

4

8

2

3

5

0

5

8

2

6

GTC36S1 Matched with GTADP-3642-B (HE37942D175B2505AW) and GTADP-3642-C (HE37942D210B2505AW) -A Coils

Full Load Capacities based upon rated flow of 8 GPM of 15% methanol/mass at 1200 CFM airflow.

COOLING FULL LOAD HEATING FULL LOAD

gniretnE

diulF

)F°(.pmeT

°05

°060.830.9267.076.17.348.22

°071.630.8287.039.17.247.81

°082.431.7297.091.27.146.51

°092.231.6218.064.26.04

°0013.031.5238.027.26.93

°0114.821.4258.089.26.835.9

°05

°069.042.0347.086.17.643.42

°078.832.9257.059.15.549.91

°088.632.8277.022.23.445.61

°097.432.7287.094.22.349.31

°0016.231.6208.067.20.248.11

°0115.031.5228.030.39.04

°05

°069.344.1317.017.18.947.52

°077.143.0337.089.15.84

°085.932.9247.052.21.745.71

°092.732.8267.025.28.548.41

°0010.531.7277.097.25.445.21

°0118.231.6208.060.32.347.01

°05

°061.745.2396.037.10.35

°077.444.1307.010.25.153.22

°083.243.0327.082.21.055.81

°099.932.9237.065.26.846.51

°0015.731.8257.038.22.743.31

°0111.530.7277.001.37.543.11

gniretnE

)F°(

BD°07

BW°95

BD°57

BW°36

BD°08

BW°76

BD°58

BW°17

latoT

.pmeTriA

yticapaC

)HutBM(

0.040.0357.004.18.445.82

0.342.1337.014.18.744.03

2.644.2307.044.11.15

5.946.3386.064.15.459.33

elbisneS

yticapaC

)HutBM(

elbisneS

rewoP

latoTot

oitaR

tupnI

)WK(

fotaeH

noitcejeR

)HutBM(

REE

gniretnE

diulF

)F°(.pmeT

°52

gniretnE

riA

.pmeT

)F°(

latoT

yticapaC

)HutBM(

7.323.3829.10.71

°033.623.5889.13.91

°044.133.9821.20.42

.31

.11

°056.632.3962.27.82

°068.142.7993.24.33

°56

°079.642.10135.21.83

°081.252.50176.28.24

°52

2.329.7879.15.61

°037.528.9840.27.81

°047.037.3981.23.32

°058.536.7923.29.72

.01

.23

.12

°068.045.10164.24.23

°079.544.50106.20.73