Page 1

Polyester Web Slings

FAILURE TO READ, UNDERSTAND AND FOLLOW THE USE AND

WEB SLINGS CAN BE CUT BY CONTACT WITH SHARP OR UNPROTECTED

USE, CARE AND INSPECTION REQUIREMENTS

WARNING

INSPECTION INSTRUCTIONS FURNISHED WITH EACH SLING

MAY RESULT IN SEVERE PERSONAL INJURY OR DEATH.

INSPECTION

ALWAYS INSPECT SLINGS BEFORE EACH USE

Upon receipt of each new sling, make certain that it meets the

requirements of your Purchase Order and that it has not been damaged in shipment.

Remove Web Slings from service if any of the following are visible:

A. A rated capacity tag is missing or illegible.

B. Exposure of red core warning yarn. (For slings containing red core warning yarn.)

C. Broken or worn threads in the stitch patterns.

D. Knots in any part of the sling.

E. Any evidence of heat or chemical damage, including melting or charring.

F. Metal fittings that are cracked, deformed, witted, corroded or excessively worn.

G. Hooks with throat openings increased by more than 15 percent

or twisted out of plane more than 10 degrees.

H. Any other visible damage which causes doubt as to the sling strength.

OPERATING PRACTICES

WARNING

LOAD EDGES. PROPER PADDING MUST BE USED TO PROTECT THE SLINGS.

DO NOT EXCEED RATED CAPACITIES.

A. Slings shall not be loaded in excess of the rated capacity. Consideration shall be

given to the effect of angles. (See Effect of Angle Chart shown on reverse side.)

B. Select slings having suitable characteristics for the type of load, hitch and environment.

C. Slings shall not be shortened by twisting, knotting, or other unapproved methods.

D. Slings shall not be lengthened by knotting, choking or basketing slings together,

or by any other unapproved method. Suitable fittings must interconnect slings.

E. Slings shall be hitched in a manner providing control of the load.

F. Web slings shall always be protected from being cut or damaged

by corners, edges, protrusions, or abrasive surfaces.

G. Keep all portions of the human body from between the sling and the load,

and from between the sling and the lifting hook.

H. Personnel should stand clear of the suspended load.

I. Personnel shall not ride the sling or a load suspended by a sling.

J. Shock loading shall be avoided.

K. Slings should not be pulled from under a load when the load is resting on them.

Where practicable, use blocking to allow for easy sling removal.

L. Twisting and kinking slings shall be avoided.

M. Loads applied to a hook should be centered in the base of

the hook to prevent point loading on the hook.

Page 2

N. Before lifting, make certain that the sling, attachments, or load shall not snag.

Personnel shall be continuously alert to avoid snagging or bumping.

O. In a basket hitch, proper slings must be selected to balance the load and

restrict slippage in order to prevent the load from falling out of the sling.

P. In a choker hitch, slings shall be long enough so that the choker fitting

chokes onto the sling eye or body and never onto any fittings.

Q. Slings should be stored in an area where they will not be subject to

mechanical damage, moisture, extreme heat or ultraviolet light.

R. Do not expose slings to chemicals that are not compatible

with all of the sling materials.

S. Polyester slings shall not be used in temperatures in excess of 200° F.

T. Exposure to sunlight or ultraviolet light will degrade the strength of synthetic web.

U. Slings should not be used at angles of less than 30 degrees from horizontal.

V. Slings should not be dragged on the floor or over an abrasive surface.

W. When lifting points are below the center of gravity, loads tend to be unstable.

Proper rigging must restrict load rotation to avoid tipping and loss of load control.

X. For lifts of nonsymmetrical loads using multiple sling legs, an analysis should

be performed by a qualified person to prevent the overloading of any leg.

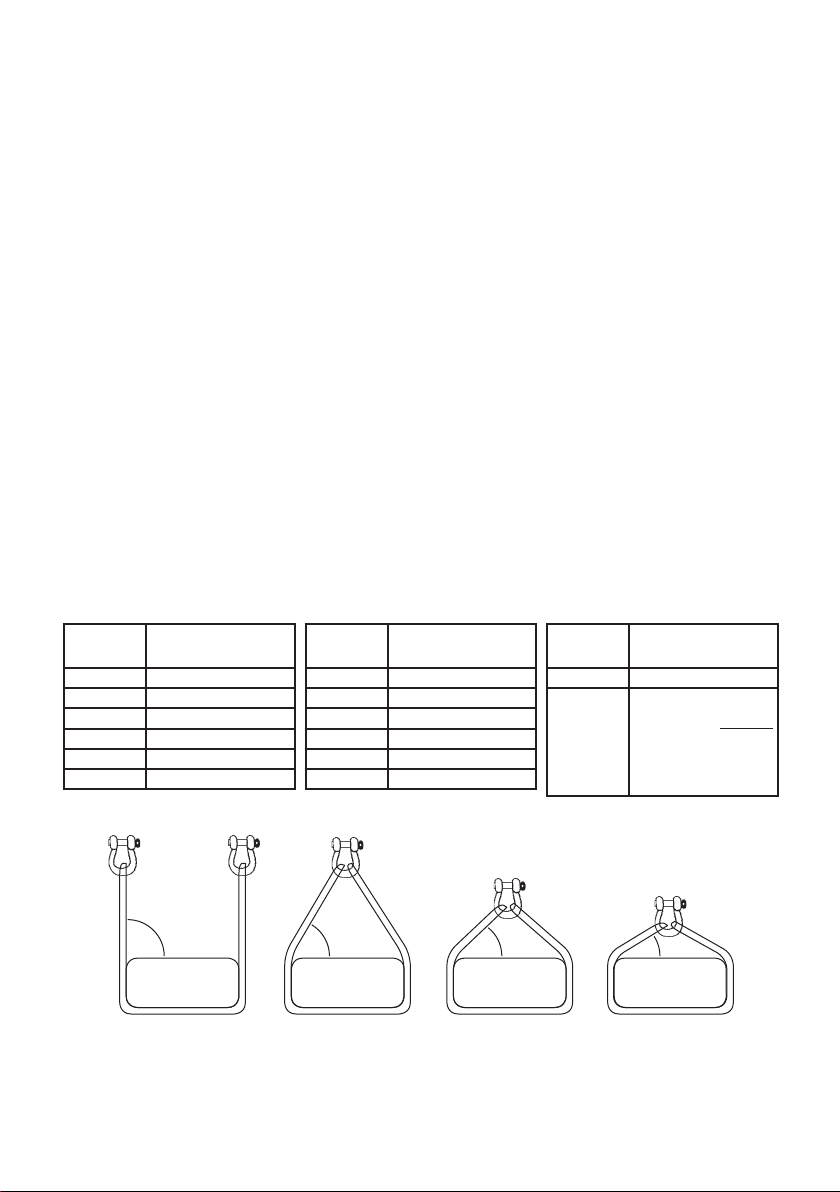

EFFECT OF ANGLE

When slings are used at an angle (i.e., two slings, or one sling in a basket hitch,

attached to only one crane hook), sling capacity is reduced. How much it is

reduced depends on the degree of the angle. You can determine whether a

sling will be rated high enough if you know the angle between the sling leg

and the horizontal. Once you know this angle, multiply the sling’s rating by the

appropriate factor in the table. This will give you the sling’s reduced rating.

ANGLE

DEGREES

90 1.00

85 .996

80 .986

75 .966

70 .940

65 .906

FACTOR

ANGLE

DEGREES

60 .866

55 .819

50 .766

45 .707

40 .643

35 .574

FACTOR

ANGLE

DEGREES

30 .500

Capacity

decreases rapidly

<30

under 30°.

DO NOT USE

UNDER 30°.

FACTOR

SLING CAPACITY DECREASES AS THE ANGLE DECREASES

90°

1,000 lb.

A sling capable of lifting 1,000 lb. in a 90° vertical basket hitch can only lift

866 lb. at a 60° angle, 707 lb. at a 45° angle, and 500 lb. at a 30° angle.

Refer to other regulations, codes and standards for additional information and

safe operating practices. See OSHA CFR 1910.184 Regulations,

ANSI/ASME 830.9, and the Web Sling and Tie Down Association Standards.

60°

866 lb.

45°

707 lb.

30°

500 lb.

Loading...

Loading...