Page 1

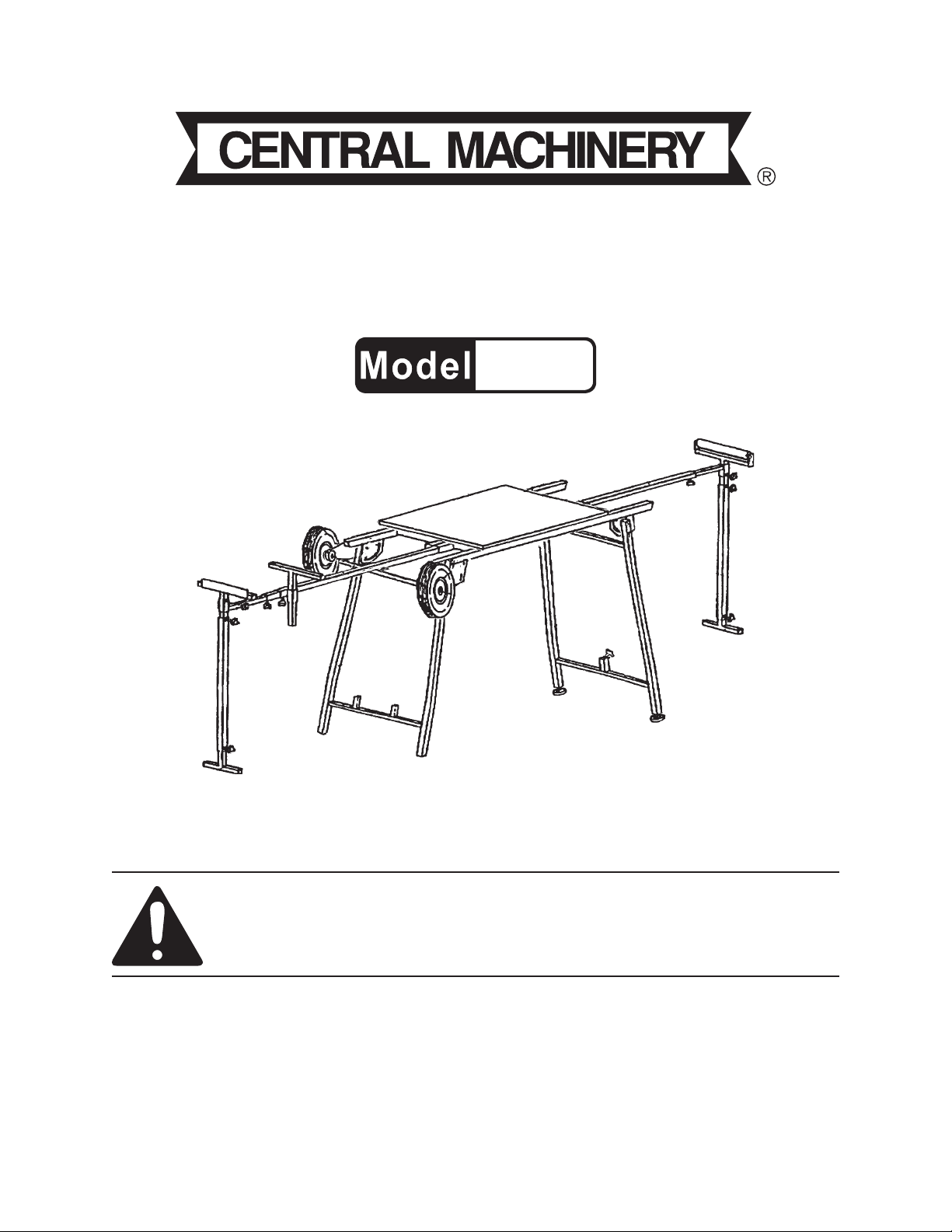

Mobile / Folding

Power Tool Stand

40612

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 1999 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Cover Revised 05e, 09c

Page 2

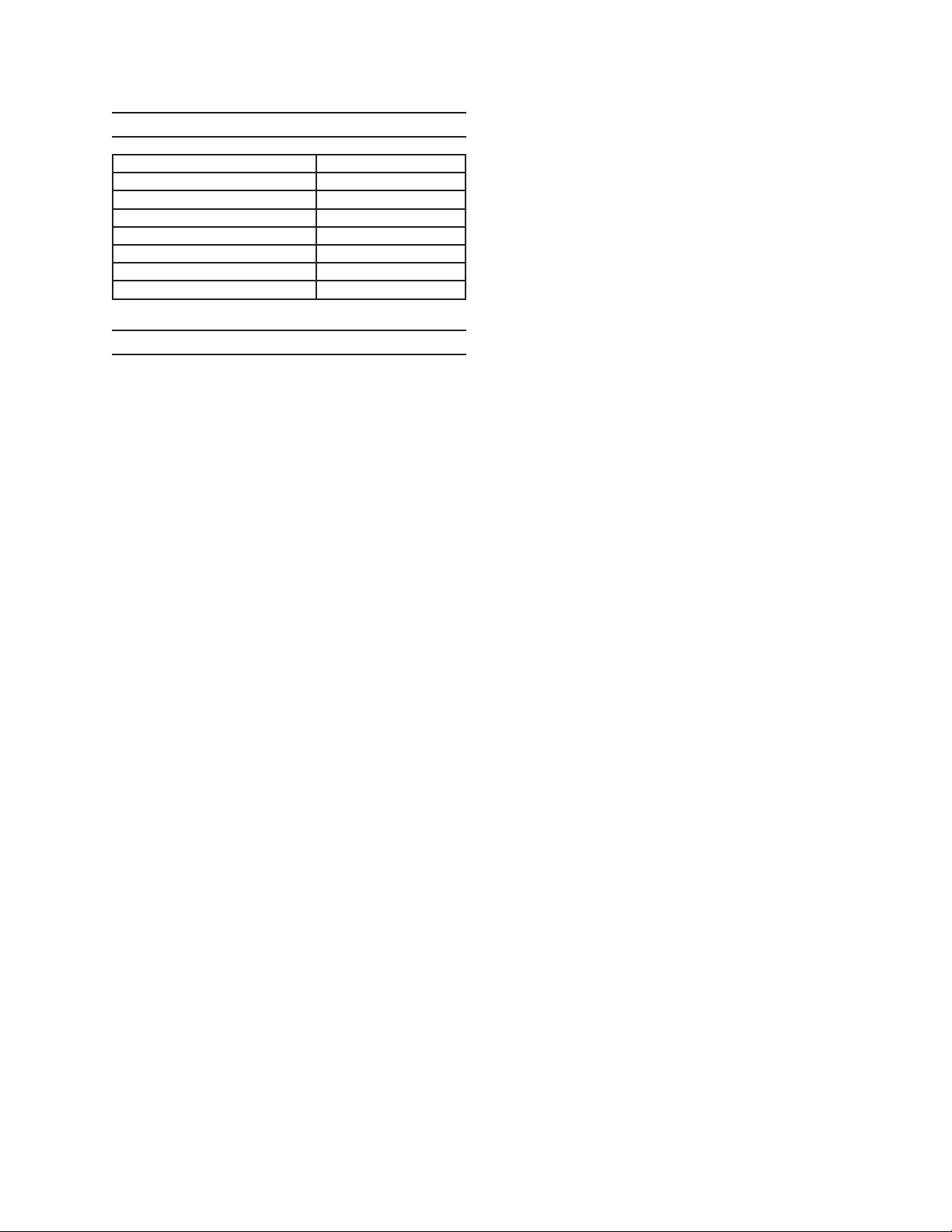

SPECIFICATIONS

This bolt goes through the curved slot

in the pivot bracket. Note how the

Maximum Extension Length 13’ x 10”

Table Top Dimensions 28” x 19-1/2”

Extension Wings Max. Width 57”

Overall Dimensions 22” x 52” x 37-3/4”

Wheel Diameter 7-3/4”

Roller Diameter 1-1/4”

Material Square Steel Tubing

Net Weight 71 lb.

Latch Pin (#18) is meant to engage

the holes adjacent to either end of the

curved slot.

Repeat steps 1 and 2 on the other 3.

side of the table. Install the Leveling Guides (#21) to the bottom of the

legs. Tighten the fasteners on both

sides of the leg assembly.

ASSEMBLY INSTRUCTIONS

Please refer to the Parts Diagram

to conrm identication of the parts discussed below. The Mobile/Folding Tool

Stand comes partially assembled. All that

remains is to attach the legs and wheels to

one end. It is best to have someone help

align the parts as you work. Lay the table

upside down at a comfortable working

height, and proceed as follows.

Slide one Latch Spring (#19) over 1.

one Latch Pin (#18) until the spring

stops. Insert the spring end through

the large diameter hole on one side

of the leg assembly. The handle of

the Latch Pin should be toward the

outside of the square tubing.

Place the narrow end of the legs over 2.

the outside of the pivot brackets that

are welded to the table frame -here

Insert Axle (#6) through one of the 4.

Axle Plates (#5), then slide both Axle

Collars (#23) over the axle. Leave

loose for now. Slide end of axle

through the other Axle Plate. Install

Wheels (#8) on each side of axle,

and fasten with a Flat Washer (#26)

and Axle Bolt (#22). Slide each axle

collar next to the axle plates, and

tighten the Hex Bolt (#29).

By loosening the Locking Knobs 5.

(#20) and pulling outward on the

Latch Pins, the legs can either be extended for use or folded for storage.

When folded, the table can be moved

about on the Wheels.

The table can be congured in mul-6.

tiple ways by moving and adjusting

the stops and rollers to suit the application.

is where help is needed. Take one

Axle Plate (#5) and slide the small

round hole over the handle of Latch

Pin (#18). Note that the long straight

edge of the axle plate should be facing down, toward the table top. Hold

together tightly, and insert one Bolt

(#24) through the lower square hole

in the plate, the leg, and pivot bracket. Fasten loosely with one Washer

(#27) and one Locking Nut (#28).

Repeat this with the upper square

hole, but use a Locking Knob (#20)

on the thread in place of the lock nut.

Rev 00k

SKU 40612 For technical questions, please call 1-800-444-3353. Page 2

Page 3

WARNING

Read All Instructions and warnings be-

fore using this product.

COMMON SENSE AND CAUTION ARE

FACTORS WHICH CANNOT BE BUILT

INTO ANY PRODUCT; THESE SAFETY

FACTORS MUST BE SUPPLIED BY THE

OPERATOR.

Select a level surface, free from ob-1.

structions, when working with power

tools.

Properly anchor tools to the table 2.

work surface before starting work.

Power tools must be bolted securely to the Power Tool Stand

before using.

When folding or unfolding the stand, 3.

be careful not to pinch ngers.

Align all work supports with work 4.

surfaces.

Wear ANSI-approved safety gog-5.

gles during assembly.

Work supports must be within safe 6.

operating limits, and locked into place

before starting power tools.

When working with long or heavy 7.

workpieces (over 50 lb.) use additional supports.

Test your work set-up for stability 8.

before beginning work.

Always unplug your power tool when 9.

making adjustments or repairs to the

work set-up area.

Keep Work area Clean and unclut-10.

tered. Clutter, grease and debris can

cause accidents.

Keep children away while tools are 11.

being set up or in use.

Never leave power tools unattended 12.

where children or unauthorized persons can use them.

Do not exceed 550 lb. capacity. Be 13.

aware of dynamic loading! Sudden

load movement may briey create

excess load causing product failure.

Do not operate power tools, or use 14.

this product if over-tired or under the

inuence of drugs, alcohol or medicines.

Do not wear loose clothing or jewelry 15.

when operating power equipment.

Never reach over or across running 16.

power tools.

Always check that adjusting wrench-17.

es or keys are removed from any

machine before starting.

Check for alignment and binding 18.

of all moving parts, broken parts or

other conditions that may affect safe

operation. Any damaged part should

be repaired or replaced by a qualied

technician.

Never force any tool or xture beyond 19.

its design limits. This will damage the

tool, and may cause injury or property

damage.

When repairing this table or any tool, 20.

use only factory original parts.

For replacement parts, contact

Harbor Freight Tools.

MAINTENANCE

Your Mobile / Folding Power Tool

Stand requires very little maintenance.

Keep it clean and dry, and occasionally

put a small amount of machine oil on the

threaded parts.

REV 09c

SKU 40612 For technical questions, please call 1-800-444-3353. Page 3

Page 4

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE

IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES

ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR

REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

30

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

Rev 01a

SKU 40612 For technical questions, please call 1-800-444-3353. Page 4

Page 5

PARTS LIST

Part Description Qty

1 Top Frame 1

2 Left Leg Assembly 1

3 Right Leg Assembly 1

4 Table Top 1

5 Axle Plate 2

6 Axle Shaft 1

7 Leg Plate 2

8 Wheel 2

9 Outrigger - 1” sq. 2

10 Outer Extension 2

11 Support Leg 2

12 Adjustable Foot 2

13 Adaptor Tee 1

14 Posi-stop Tee 1

15 Support Tee 1

Part Description Qty

16 Support Roller Tee 1

17 Roller 1-3/8” x 10” 1

18 Latch Pin 2

19 Latch Spring 2

20 Locking Knob 4

21 Leveling Glide 2

22 Axle Bolt 1/2” x 20 2

23 Axle Collar 2

24 Carriage Bolt 1/4” x 20 x 1.75” 8

25 Locking Knob 5/16” male 12

26 Flat Washer 1/2” 2

27 Flat Washer 1/4” 14

28 Self Locking Nut 1/4” 8

29 Hex Bolt 1/4” x 20 x 2

30 Locking Pin for Roller 2

Rev 01a

SKU 40612 For technical questions, please call 1-800-444-3353. Page 5

Loading...

Loading...