Page 1

AUTO A/C RECOVERY /

Model

95951

RECHARGE MACHINE

SET UP AND OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SPECIFICATIONS

Sheet Steel Housing, Reinforced Braided Rubber

Construction

Electrical Requirements 110 V~, 60 Hz

Compressor 1/3 HP Input Power

Vacuum Maximum Capacity 60 Liters per Minute (15.9 Gallons per minute)

Suitable for R134A Refrigerant

Refrigerant Tank Capacity 14 kg (30.8 lb)

Maximum Scale Weight 30 kg (66 lb)

Recovery Speed 250 Grams/Min (8.82 Ounces per Minute)

Relling Speed 800 G/Min (28 Ounces per Minute)

Overall Dimensions 18-1/8” W x 22” D x 43-1/8” H

Net Weight 160.8 lb.

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Write the product’s serial number in the back of the manual near the assembly

diagram, or write month and year of purchase if product has no number. Keep this manual

and invoice in a safe and dry place for future reference.

Hoses with Brass Fittings, Polypropylene Valves,

Copper Tubing, Thermoplastic Oil Bottle and

Carbon Steel Hardware

Save This Manual

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, re, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. 1. Cluttered benches and dark areas invite

accidents.

Do not operate powered machines in explosive atmospheres, such as in the 2.

presence of ammable liquids, gases, or dust. Power machines create sparks

which may ignite the dust or fumes.

Page 2SKU 95951 For technical questions, please call 1-800-444-3353.

Page 3

Keep bystanders, children, and visitors away while operating a powered ma-3.

chine. Distractions can cause you to lose control. Protect others in the work area

from debris fumes and oil. Provide barriers or shields as needed.

ELECTRICAL SAFETY

Grounded machines must be plugged into an outlet properly installed and 1.

grounded in accordance with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do not use any adapter plugs.

Check with a qualied electrician if you are in doubt as to whether the outlet is

properly grounded. If the machines should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity away from the user.

Double insulated machines are equipped with a polarized plug (one blade is 2.

wider than the other). This plug will t in a polarized outlet only one way. If

the plug does not t fully in the outlet, reverse the plug. If it still does not

t, contact a qualied electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for the three wire

grounded power cord and grounded power supply system.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges, 3.

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

Do not expose powered machines to rain or wet conditions. 4. Water entering a

powered machine will increase the risk of electric shock.

Do not abuse the Power Cord. Never use the Power Cord to carry the machines 5.

or pull the Plug from an outlet. Keep the Power Cord away from heat, oil,

sharp edges, or moving parts. Replace damaged Power Cords immediately.

Damaged Power Cords increase the risk of electric shock.

When operating a powered machine outside, use an outdoor extension cord 6.

marked “W-A” or “W”. These extension cords are rated for outdoor use, and

reduce the risk of electric shock.

PERSONAL SAFETY

Stay alert. Watch what you are doing, and use common sense when operat-1.

ing a powered machine. Do not use a powered machine while tired or under

the inuence of drugs, alcohol, or medication. A moment of inattention while

operating powered machines may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep 2.

your hair, clothing, and gloves away from moving parts in engine compartment.

Loose clothes, jewelry, or long hair can be caught in moving parts in the machine.

Page 3SKU 95951 For technical questions, please call 1-800-444-3353.

Page 4

Avoid accidental starting. Be sure the Power Switch is off before plugging in. 3.

Leaving the Power Switch on while the machine is unattended invites accidents.

Remove adjusting keys or wrenches before turning the powered machine on. 4.

A wrench or a key that is left attached to a rotating part of the powered machine

may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. 5. Proper foot-

ing and balance enables better control of the powered machine in unexpected

situations.

Use safety equipment. Always wear eye protection. 6. Dust mask, nonskid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions. Al-

ways wear ANSI-approved safety goggles and a dust mask/respirator when using

or performing maintenance on this machine. Keep the work area well ventilated.

TOOL USE AND CARE

Do not force the machine. Use the correct machine for your application. 1. The

correct machine will do the job better and safer at the rate for which it is designed.

Do not force the machine and do not use the machine for a purpose for which it is

not intended.

Do not use the powered machine if the Power Switch does not turn it on or 2.

off. Any machine that cannot be controlled with the Power Switch is dangerous

and must be replaced.

Disconnect the Power Cord Plug from the power source before making any 3.

adjustments, changing accessories, or storing the machine. Such preventive

safety measures reduce the risk of starting the machine accidentally. Always un-

plug the machine from its electrical outlet before performing any inspection,

maintenance, or cleaning procedures.

Store idle machines out of reach of children and other untrained persons. 4.

Tools are dangerous in the hands of untrained users.

Maintain machines with care. 5. Properly maintained machines are less likely to fail

and are easier to control. Do not use a damaged machine. Tag damaged machines

“Do not use” until repaired.

Check for misalignment or binding of moving parts, breakage of parts, and 6.

any other condition that may affect the machine’s operation. If damaged,

have the machine serviced before using. Many accidents are caused by poorly

maintained machines.

Use only accessories that are recommended by the manufacturer for your 7.

model. Accessories that may be suitable for one machine may become hazardous

when used on another machine.

Page 4SKU 95951 For technical questions, please call 1-800-444-3353.

Page 5

SERVICE

Tool service must be performed only by qualied repair personnel. 1. Service or

maintenance performed by unqualied personnel could result in a risk of injury.

When servicing a machine, use only identical replacement parts. Follow 2.

instructions in the “Inspection, Maintenance, And Cleaning” section of this

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

Maintain labels and nameplates on the machine. 1. These carry important informa-

tion. If unreadable or missing, contact Harbor Freight Tools for a replacement.

Maintain a safe working environment. 2. Make sure there is adequate surround-

ing workspace. Do not use this product in a damp or wet location. Be sure there is

adequate ventilation. Do not operate machine or vehicle in enclosed space.

When using a handheld powered machine, always maintain a rm grip on the 3.

machine with both hands to resist starting torque.

Avoid unintentional starting. 4. Make sure you are prepared to begin work before

turning on the machine.

Always keep the extension cord away from moving parts on the machine or 5.

the vehicle.

People with pacemakers should consult their physician(s) before using this 6.

product. Electromagnetic elds in close proximity to a heart pacemaker could cause

interference to or failure of the pacemaker. In addition, people with pacemakers

should adhere to the following:

• Avoid operating powered machines alone.

• Don’t use a powered machine with the power switch locked on.

• If powered via a power cord be certain that the machine is properly grounded. A

ground fault interrupt (GFCI) system is also a good precaution. This inexpensive de-

vice is a good safety measure because it prevents a sustained electrical shock.

• Properly maintain and inspect all machines before use to avoid electrical

shock.

Only use R134A refrigerant with this machine. 7. Do not use other refrigerants.

Please see refrigerant discussion on page 12 of this manual for more information.

Before servicing, check vehicle owner’s manual to conrm that A/C system will

operate on R134A refrigerant.

Before starting service, check to see that the recovery tank has space for ad-8.

ditional coolant, there is replacement refrigerant in the coolant tank, and there

REV 08k

Page 5SKU 95951 For technical questions, please call 1-800-444-3353.

Page 6

is cooling oil in the cooling oil bottle. Check compressor oil level to determine

it is within safe limits before starting service.

Do not expose this machine to direct sunlight or rain. 9. Keep it in a well ventilated

sheltered area.

The refrigerant tank may only be lled to 80% capacity during the recovery 10.

operation. Check tank level before starting service to ensure that there is sufcient

recovery space.

There must be at least 1 kg (2.2 lb) of refrigerant in the coolant tank to perform 11.

the relling operation. Do not attempt the relling operation if there is less than 1

kg (2.2 lb) of refrigerant in the coolant tank.

The HP and LP Valves on the Control Panel must be in the CLOSED position 12.

when attaching the machine to the auto A/C system.

When servicing, keep all hoses away from hot parts and moving components 13.

of vehicle engine area to prevent hose damage.

When running the vehicle, be sure it is in PARK or NEUTRAL with parking 14.

brakes locked and wheels chocked.

Never start the vehicle or operate the vehicle A/C system if the hose is con-15.

nected to the HP system and the HP Valve on the Control Panel is open.

WARNING: The brass components of this product contain lead, a chemical 16.

known to the State of California to cause birth defects (or other reproductive

harm). (California Health & Safety code § 25249.5, et seq.)

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualied electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool.

Never remove the grounding prong from the plug. Do not use the tool if the

power cord or plug is damaged. If damaged, have it repaired by a service facil-

ity before use. If the plug will not t the outlet, have a proper outlet installed by

a qualied electrician.

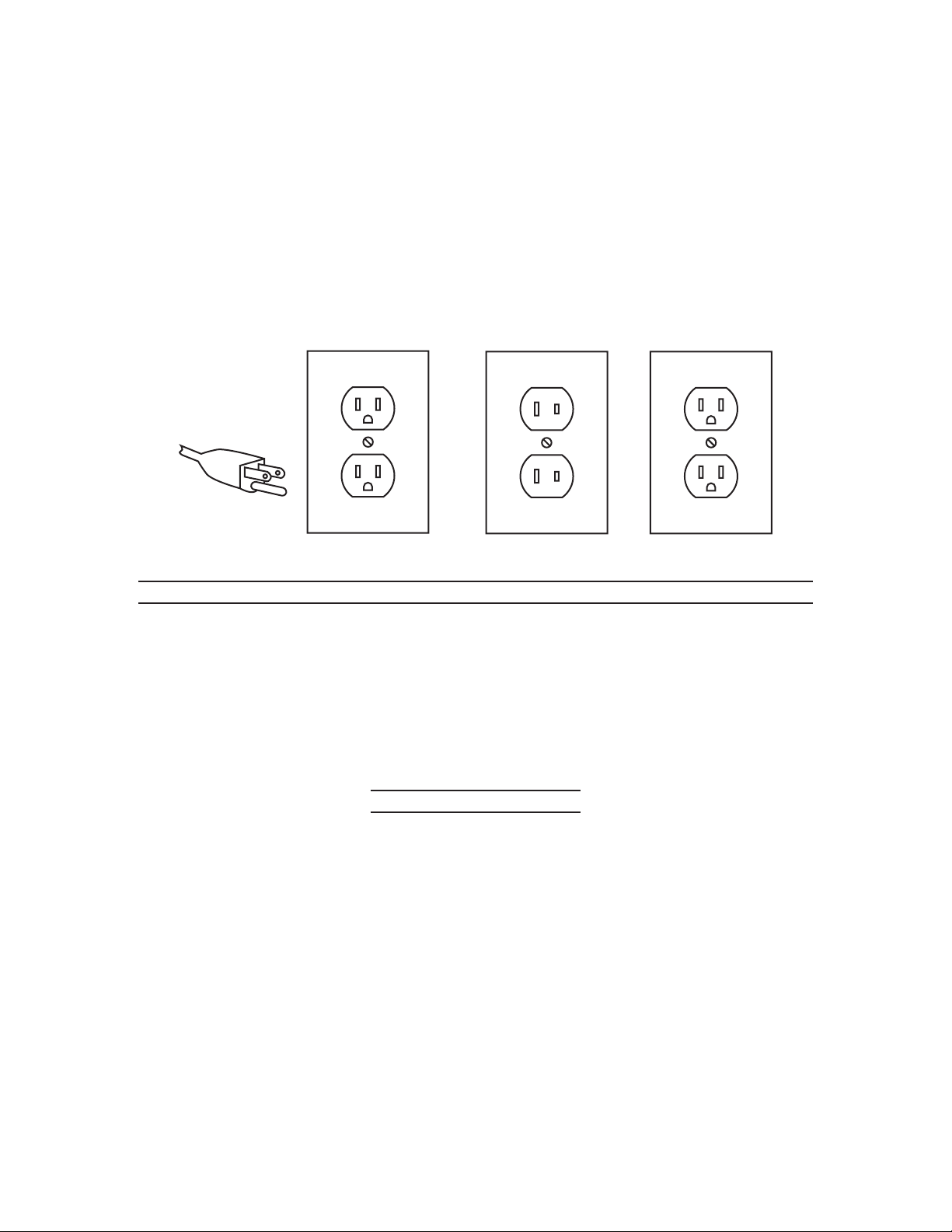

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

Tools marked with “Grounding Required” have a three wire cord and three prong 1.

grounding plug. The plug must be connected to a properly grounded outlet. If the

machine should electrically malfunction or break down, grounding provides a low

REV 08a

Page 6SKU 95951 For technical questions, please call 1-800-444-3353.

Page 7

resistance path to carry electricity away from the user, reducing the risk of electric

shock. (See 3-Prong Plug and Outlet.)

The grounding prong in the plug is connected through the green wire inside the 2.

cord to the grounding system in the machine. The green wire in the cord must be

the only wire connected to the machine’s grounding system and must never be at-

tached to an electrically “live” terminal. (See 3-Prong Plug and Outlet.)

Your machine must be plugged into an appropriate outlet, properly installed and 3.

grounded in accordance with all codes and ordinances. The plug and outlet should

look like those in the following illustration. (See 3-Prong Plug and Outlet.)

3-Prong Plug and Outlet Outlets for 2-Prong Plug

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

Tools marked “Double Insulated” do not require grounding. They have a special 1.

double insulation system which satises OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Outlets for 2-Prong Plug.)

Double insulated machines may be used in either of the 120 volt outlets shown in 2.

the preceding illustration. (See Outlets for 2-Prong Plug.)

EXTENSION CORDS

Grounded1. machines require a three wire extension cord. Double Insulated ma-

chines can use either a two or three wire extension cord.

As the distance from the supply outlet increases, you must use a heavier gauge 2.

extension cord. Using extension cords with inadequately sized wire causes a seri-

ous drop in voltage, resulting in loss of power and possible machine damage.

(See Table A.)

The smaller the gauge number of the wire, the greater the capacity of the cord. For 3.

example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Table A.)

When using more than one extension cord to make up the total length, make sure 4.

each cord contains at least the minimum wire size required. (See Table A.)

Page 7SKU 95951 For technical questions, please call 1-800-444-3353.

Page 8

If you are using one extension cord for more than one machine, add the nameplate5.

amperes and use the sum to determine the required minimum cord size.

(See Table A.)

If you are using an extension cord outdoors, make sure it is marked with the sufx 6.

“W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

Make sure your extension cord is properly wired and in good electrical condition. 7.

Always replace a damaged extension cord or have it repaired by a qualied electri-

cian before using it.

Protect your extension cords from sharp objects, excessive heat, and damp or wet 8.

areas.

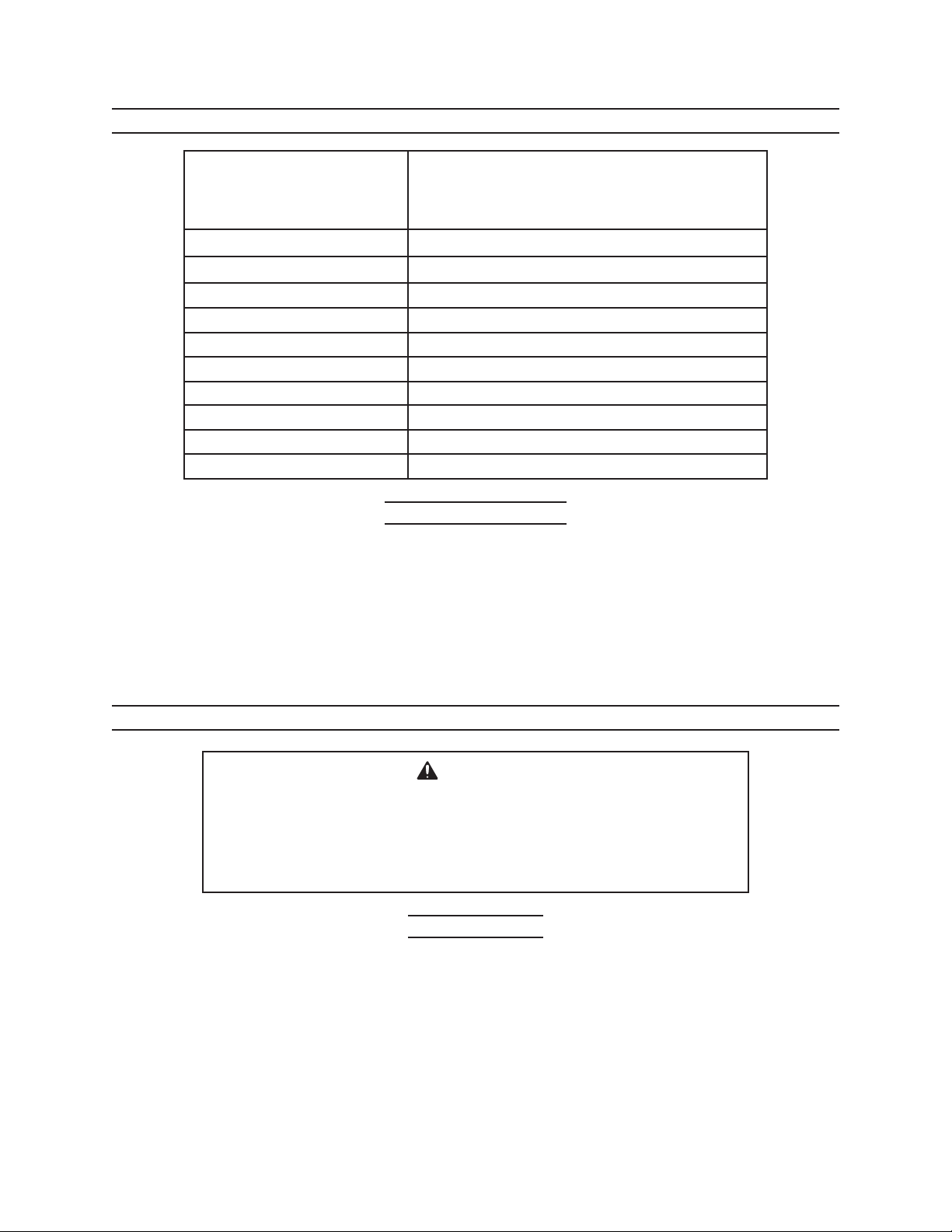

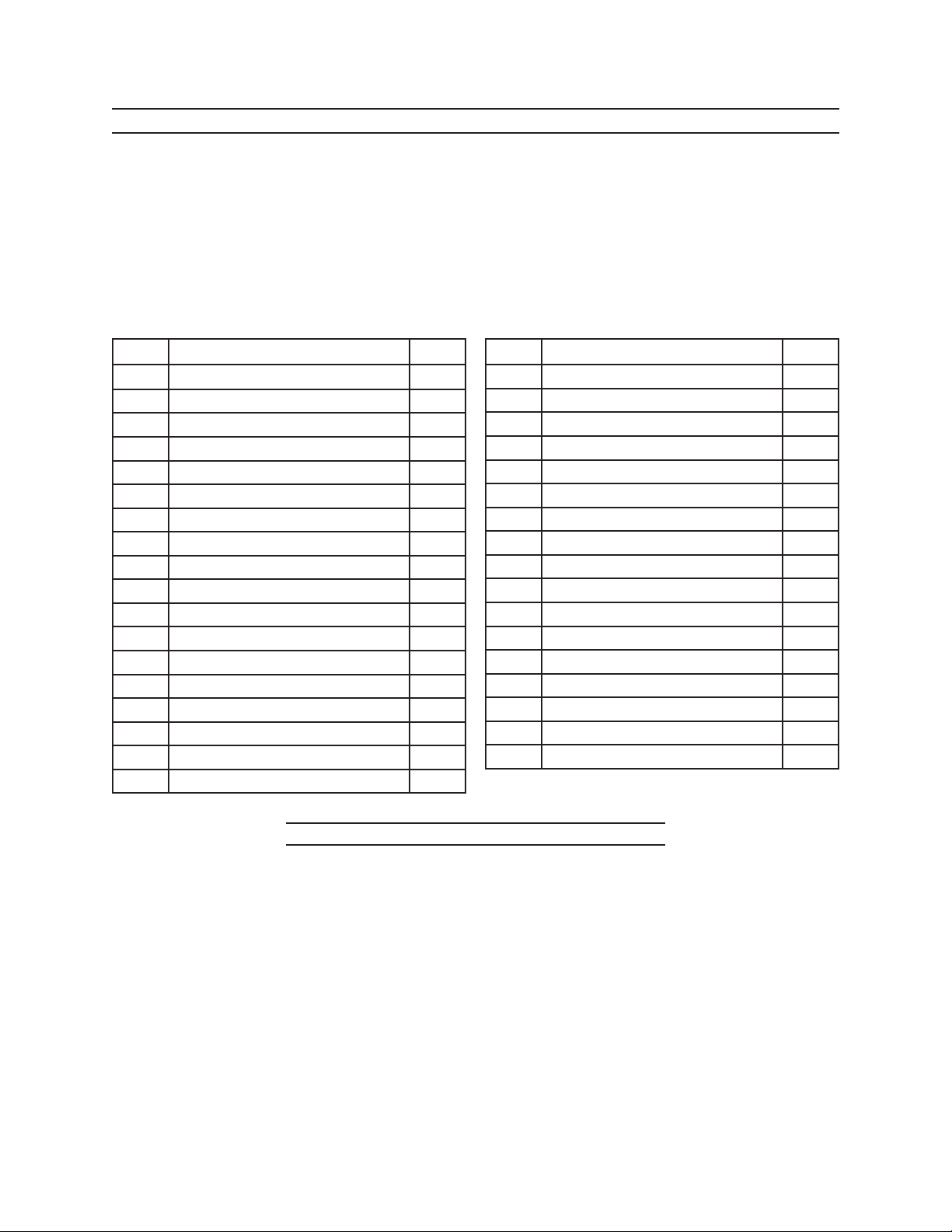

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS*

(120 OR 240 VOLT)

NAMEPLATE

EXTENSION CORD LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

TABLE A

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

* Based on limiting the line voltage drop to ve volts at 150% of the rated amperes.

SYMBOLOGY

Double Insulated

Canadian Standards Association

V~

A

n0 xxxx/min.

Underwriters Laboratories, Inc.

Volts Alternating Current

Amperes

No Load Revolutions per Minute (RPM)

Page 8SKU 95951 For technical questions, please call 1-800-444-3353.

Page 9

UNPACKING

When unpacking, check to make sure that the item is intact and undamaged. If any

parts are missing or broken, please call Harbor Freight Tools at the number shown on the

cover of this manual as soon as possible.

ASSEMBLY INSTRUCTIONS

Note: For additional information regarding the parts listed in the following pages, refer to

the Assembly Diagrams near the end of this manual.

1. WARNING! Make sure the Power Switch of the tool is in its “OFF” position and

that the tool is unplugged from the electrical outlet before making any adjustments

to the tool.

Remove the (4) Protection Bolts from the Electronic Scale before using this machine 2.

for the rst time. The four Protection Bolts (see photo below) are fastened to the

bottom of the machine. To do this:

Use a 6mm wrench to remove the bolts. Turn them counterclockwise to loosen. a.

Store the bolts in a safe place for future use.

Use the Power ON/OFF Switch to turn on the machine. b.

Press the “Recovering” and “Circulate” keys at the same time to reset the scale. c.

The word “Good” will appear in the LED display if the scale is working properly.

Protection Bolts

Prior to shipping this machine, replace the Protection Bolts to lock the scale in place 3.

to prevent damage.

Optional external coolant tank is discussed in this manual. This accessory is NOT 4.

INCLUDED with this machine and must be purchased separately. It is discussed

here for your convenience.

REV 09h

Page 9SKU 95951 For technical questions, please call 1-800-444-3353.

Page 10

BP Gauge

OPERATING INFORMATION

LP Gauge HP Gauge

LP Valve HP Valve

Indicators

Recovering

Vacuumize

Control Panel Gauges

Please refer to the drawing on page 9 for Control Panel items.

LED Display

Circulate

+

Start/Stop

Relling

HP Gauge:1. Displays pressure of the high pressure end of the auto A/C system.

LP Gauge:2. Displays pressure of the low pressure end of the auto A/C system.

BP Gauge:3. Displays pressure of the refrigerant tank of this machine.

Indicator Lights

Recovering:1. When lighted, indicates that the machine is performing the recovery

operation.

Vacuumize:2. When lighted, indicates that the machine is generating vacuum.

Relling:3. When lighted, indicates that the machine is relling the auto system. New

refrigerant is being added.

Drain:4. When lighted, indicates that the machine is draining used cooling oil from

the auto A/C system.

HP / Bottle Full:5. During the Recovery process when the light is on, it indicates either

that the HP pressure has reached or exceeded 240 PSI. The Recovery process

will halt until the pressure has automatically lowered to 180 PSI or less. If the pres-

sure is within safe bounds and this light comes on, it indicates that the Refrigerant

Tank is full, weighing over 14 kg. The Refrigerant Tank must be partially emptied to

continue the recovery process.

REV 09h

Page 10SKU 95951 For technical questions, please call 1-800-444-3353.

Page 11

Bottle Empty:6. During the Relling Process, if the Refrigerant Tank contains less

than 1 kg of uid, the process will stop and the indicator light will come on. The

bottle must be relled before continuing the Relling Process.

LCD Display

When the “kg” indicator light is on, the value shown in the LCD Display is the re-1.

covered or relled refrigerant weight.

When the “MIN” indicator light is on the LCD Display shows the Vacuuming Time 2.

in Minutes.

Valve Controls

LP Valve: 1. Low Pressure Control Valve.

HP Valve:2. High Pressure Control Valve.

Function Keys

“+” Key:1. Press this Key to adjust the setup value. Each press of the Key increases

the set value by 1.

“Circulate”:2. Press this Key to lock in the value set using the + Key.

“Recovering”:3. Press this Key to initiate the refrigerant recovery operation. Dur-

ing the Recovery operation, pressing this Key will toggle the LCD display between

“Setup Value” and “Actual Recovery Value.”

“Vacuumize”: 4. Press this Key to initiate the vacuum generation operation.

“Relling”:5. Press this Key to initiate the Relling operation.

“Start / Stop” :6. Press this Key to start or stop the current operation.

WARNING: Do not use any refrigerant other than factory specied R134A (also

identied as 134A, Forane 134a or HFC-134a) in an automotive A/C system.

Use of Freon or other Fluorocarbons is prohibited by US law.

WARNING: DO NOT INHALE or HANDLE REFRIGERANT. Inhalation of high concen-

trations of refrigerant is harmful and may cause heart irregularities, dizziness,

central nervous effects, unconsciousness or death. Intentional misuse or

deliberate inhalation may cause death without warning. Vapor reduces oxy-

gen available for breathing and is heavier than air. Decomposition products

of refrigerant are also hazardous. Contact with liquid refrigerant can cause

injury including frostbite.

REV 09h

Page 11SKU 95951 For technical questions, please call 1-800-444-3353.

Page 12

OPERATION

Preparation

Before operation, check the Vacuum Pump oil level. Do this by looking through 1.

the opening on the lower right side of the back panel. You will be able to see the

vacuum pump oil reservoir. The level must be between the MIN and MAX mark-

ings. If the oil level is low, open the back of the machine, remove the cap of the oil

reservoir and ll to the MAX line with good quality compressor oil. Replace the oil

cap and back of machine before beginning operation. DO NOT OPERATE THIS

MACHINE WITHOUT ADEQUATE OIL IN THE VACUUM PUMP, SEVERE DAM-

AGE WILL RESULT.

WARNING: The A/C (air conditioning) system is under high pressure. Do not loosen 2.

any hose ttings or remove any components until after the system has been com-

pletely discharged and depressurized. Removal or loosening of a component while

the system is under pressure can cause severe personal and property damage or

injury.

Checking the Vehicle A/C System

Check the vehicle compressor drive belt. If it is worn or cracked, it should be re-1.

placed before any other service is performed.

Check the vehicle system hoses. Look for cracks, bubbles, hard spots and dete-2.

rioration. Inspect all hoses and ttings for leaks and refrigerant seepage. If there

is any evidence of wear, replace the damaged parts before performing any other

service.

Note: Use of a leak detector kit (not included) is recommended.

Inspect the compressor ns for debris that may be impeding heat dispersion of the 3.

compressor. Clean between the ns with a tool or compressed air.

Attaching the Recovery / Recharge Machine

Operate the vehicle A/C system on “High” for a few minutes to pressurize the sys-1.

tem. Turn the vehicle OFF. WARNING: Opening the HP valve while the vehicle

is running with the A/C system on can cause the refrigerant tank to break or

explode.

Close the LP and HP valves on the Control Panel of the machine.2.

WARNING: Check vehicle service manual to identify with certainty the correct system

connections.

Connect the High Pressure hose to the high pressure connector of the machine and 3.

high pressure connector of the vehicle A/C system, and the Low Pressure hose to

REV 09h

Page 12SKU 95951 For technical questions, please call 1-800-444-3353.

Page 13

the low pressure connector of the machine and the low pressure connector of the

vehicle A/C system.

Turn the Power Switch to the ON position. The Power Switch is located on the up-4.

per left side of the machine.

The “kg” Indicator light will come on, and the LCD Display will show the net weight 5.

of refrigerant in the tank. If the tank is nearly full, (capacity 14 kg) you may not be

able to recover the refrigerant in the vehicle A/C system.

Open the HP and LP Valves located on the Control Panel of the machine.6.

Read pressure shown on the HP and LP Pressure Gauges on the Control Panel.7.

Note: If the pressure on either gauge is less than 22 PSI, it indicates that the system

needs repair. There is probably a leak which does not allow the automotive system

to maintain pressure.

Clearing the Hoses

With the vehicle turned OFF, and the hoses connected, it is necessary to remove 1.

air from the hoses and machine before beginning the recovery process. To do this,

run the Vacuuming process.

Press the “Vacuumize” Key on the control panel. The LED Display will show the 2.

default time setting for the Vacuuming process.

Press “+” to set Vacuuming time. 3-5 minutes is recommended. 3.

Close the HP and LP Valves on the Control Panel. 4.

Press the “Start / Stop” Key to begin the vacuuming process.5.

Recovery

Once the hoses have been cleared, you can run the “Recovery” process.1.

Open the HP and LP valves on the Control Panel.2.

Press the “Recovering” Key on the Control Panel.3.

The LCD Display will show the default number of kilograms of refrigerant to be re-4.

covered. Check the vehicle specications to determine the correct amount for that

vehicle. Press the “+” Key repeatedly to set the correct value.

Press the “Start / Stop” Key to begin the recovery process.5.

During the recovery process, you can monitor progress by pressing the “Recover-6.

ing” Key. The LCD Display will toggle between the preset recovery target value and

the current recovery value.

REV 09h

Page 13SKU 95951 For technical questions, please call 1-800-444-3353.

Page 14

Machine will run automatically until correct amount of refrigerant is removed. 7.

When the pressure of both the HP and LP system are near “0”, the system will 8.

automatically reset to run approximately 1 minute longer. After that, there is a 20

second oil drain period. The machine will then automatically shut off.

Machine will shut off and alarm will sound to signal process is completed.9.

Understanding and resolving problems during the recovery process

If during the recovery process the pressure exceeds safe limits, the refrigerant bottle be-1.

comes full, or no refrigerant is recovered for a minute, the system will stop automatically.

Depending on the reason for shut down, an alarm may sound, and the “HP/Bottle Full”

indicator may light. If this happens, resolve the problem before restarting the process.

If the system pressure exceeds 240 PSI, the machine will shut down an alarm will 2.

sound, and the “HP / Bottle Full” light will come on. Reduce the pressure to below

180 PSI, then press the “Start / Stop” Key to restart the process.

If the Refrigerant Bottle becomes full during the recovery process, the operation 3.

will shut down, an alarm will sound, and the “HP / Bottle Full” light will come on.

Remove some refrigerant from the bottle before restarting the process.

If weight of refrigerant tank does not increase for a minute, it indicates that no refrig-4.

erant is being recovered. This may mean the auto A/C system is empty, the HP or

LP valve is closed, a hose is blocked, or other problem. The process will shut down,

and an alarm will sound. Resolve the problem before restarting the process.

Do not operate machine more than 10 times in an hour. Doing so may overheat 5.

compressor. If overheated, machine will automatically shut down and alarm will

sound. Allow machine to rest for at least 5 minutes before attempting restart.

Vacuuming the System

After recovering the refrigerant in the auto A/C system, you must vacuum the system 1.

to remove all remaining contaminants.

The LP and HP hoses are still connected from running the Recovery Process. The 2.

HP and LP Valves are open on the Control Panel. NOTE: The Vacuuming Process

will not run if the system pressure is above 35 PSI. The recovery process must be

run to reduce system pressure.

Press “Vacuumize” Key on the Control Panel. The LCD Display will show the default 3.

time preset for the vacuum process. Using the “+” Key adjust the time as required.

Typically, vacuuming should proceed for 20-30 minutes. Newer or more regularly

serviced systems can run 20 minutes. Dirtier systems should run 30 minutes.

Press “Start / Stop” Key on the Control Panel to begin the Vacuuming Process. 4.

REV 09h

Page 14SKU 95951 For technical questions, please call 1-800-444-3353.

Page 15

The LCD Display will count down the time remaining in the process. When the time 5.

reaches “0” the process will automatically stop.

Relling the Automotive System with Oil and Refrigerant

Vehicle manufacturers design for and specify a specic amount of refrigerant for 1.

best operation of your vehicle A/C system. This amount is specied in weight. Too

much or too little refrigerant will adversely effect the operation of the A/C system.

Some newer vehicles will shut down the A/C system if too much refrigerant is in

the system.

After recovery, check the amount of used oil separated from the automotive sys-2.

tem, and be sure there is at least 20 ml more new oil in the New Oil bottle than the

amount removed. If there is not enough oil in the bottle, close the Oil Charge Valve

(I-9) and add oil to the new oil bottle.

Check to be sure the HP and LP valves on the Control Panel are open.3.

Slowly open the Oil Charge Valve (I-9) allowing new oil to be sucked into the au-4.

tomotive A/C system. Do not open the valve all the way, rather, use it carefully to

control the ow of oil. Allow oil to ow into the system until 10 ml more than the

amount removed has been added back.

When sufcient oil has owed back into system, close Oil Charge Valve.5.

Press the “Relling” Key on the Control Panel. The machine will begin to replace 6.

refrigerant in the vehicle A/C system. The Relling Indicator light will be on.

NOTE: If the relling process is taking too long, you can speed the process by using 7.

the vehicle A/C compressor. Turn off the HP valve on the machine Control Panel.

WARNING! Never turn the vehicle A/C system on if the HP valve is open. Turn the

vehicle A/C system on. The relling process will go faster.

After system has been completely relled, the machine will stop automatically.8.

Close both the HP and LP valves on the Control Panel. Move the Power Switch to 9.

the OFF position. If the vehicle A/C system is running, turn it off.

Slightly loosen the hose connector, allow a few seconds to stabilize any existing pres-10.

sure in the hoses, and then back off the hose connectors and remove the hoses.

Always test the vehicle A/C system before returning the vehicle to the customer.11.

Relling Using an External Refrigerant Tank (Not Included)

Note: For more accurate relling, use the internal tank process as discussed pages 15 - 16.

Note: Make sure the LP and HP Valves on the control panel on the machine are closed.

REV 09h

Page 15SKU 95951 For technical questions, please call 1-800-444-3353.

Page 16

Connect the Low Pressure hose to the vehicle A/C system.1.

Disconnect the High Pressure (HP) hose from the auto A/C system.2.

Disconnect HP hose from the High Pressure Connector on the Left Side Panel.3.

Using the High Pressure Hose, connect the Oil Drain Valve (I-13) to the valve of 4.

the External Tank (not included).

Open the HP and LP Valves on the Control Panel. If the gauges show more than 29 5.

PSI, perform the recovery operation discussed on page 14 before proceeding.

Close Oil Drain Valve and Tank Filling Valve. Run Vacuuming Process for the HP and 6.

LP Hoses and auto A/C system as discussed on page 13 “Clearing the Hoses”.

Add new cooling oil by opening the oil valve as discussed on page 15 “Relling the 7.

Automotive System with Oil and Refrigerant”. NOTE: Always add cooling oil before

adding refrigerant.

Open the Oil Drain Valve (I-13). Gradually open the External Tank Valve.8.

The new refrigerant will be drawn into the vehicle A/C system due to the vacuum 9.

created in step 6 above.

If the relling process is slow, you may speed things up by starting the vehicle and 10.

turning on the A/C system.

INSPECTION, MAINTENANCE, AND CLEANING

1. WARNING! Make sure the Power Switch of the tool is in its “OFF” position and

that the tool is unplugged from the electrical outlet before performing any inspec-

tion, maintenance, or cleaning procedures.

BEFORE EACH USE,2. inspect the general condition of the tool. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, damaged

electrical wiring, leaking valves, damaged hoses, and any other condition that may

affect its safe operation. If abnormal noise, leaking or vibration occurs, have the

problem corrected before further use. Do not use damaged equipment.

MAINTENANCE CHART

Maintenance Type

Inspect tool for damage

(see #2, above)

Wipe off with clean, moist

cloth

Check Refrigerant and

Cooling Oil level

Check Compressor Oil Level

Before

Use

X

X

X

After

Use

X

REV 09h

Page 16SKU 95951 For technical questions, please call 1-800-444-3353.

Page 17

PARTS LIST

For ease of understanding, the components of this machine are displayed in groups.

Each group is identied with a Roman Numeral. Components within each group are identied with the group numeral plus a part number. For example “IV-3” is Part 3 in Group IV.

Group I : Left Panel Assembly Group II : Bottom Panel Assembly

Group III : Front Panel Assembly Group IV : Right Panel Assembly

Group V : Control Panel Assembly Group VI : Back Panel Assembly

Part Description Q’ty

I-1 Left Side Panel 1

I-2 Load Cell Controller 1

I-3 Pressure Controller A 1

I-4 Mounting Bracket 1 1

I-5 Transformer 1

I-6 Pressure Controller B 1

I-7 Mounting Bracket 2 1

I-8 Hose Connector 4

I-9 Oil Charge Valve 1

I-10 Quick Coupler 1

I-11 Oil Bottle 1

I-12 Separator 1

I-13 Oil Drain Valve 1

II-1 Bottom Panel 1

II-2 Vacuum Pump 1

II-3 Caster Wheel 4

II-4 Compressor 1

II-5 Scale Weight Sensor 1

Part Description Q’ty

II-6 Mat 1

II-7 Scale Tray 1

II-8 Refrigerant Cylinder 1

III-1 Front Panel 1

III-2 Dryer and Filter 1

III-3 Separator 1

III-4 Solenoid 1

IV Right Side Panel 1

V-1 Control Panel 1

V-2 Main Control Board with LCD 1

V-3 Key Pad 1

V-4 High Pressure (HP) Gauge 1

V-5 Low Pressure (LP) Gauge 1

V-6 Cylinder Gauge 1

V-7 Low Pressure (LP) Valve 1

V-8 High Pressure (HP) Valve 1

VI-1 Back Panel 1

Please Read The Following Carefully

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

Page 17SKU 95951 For technical questions, please call 1-800-444-3353.

Page 18

Auto A/C Recovery / Recharge Machine Component Groups

Page 18SKU 95951 For technical questions, please call 1-800-444-3353.

Page 19

Group I Left Side Panel Assembly

Page 19SKU 95951 For technical questions, please call 1-800-444-3353.

Page 20

Group II Bottom Panel Assembly

Page 20SKU 95951 For technical questions, please call 1-800-444-3353.

Page 21

Group III Front Panel Assembly and Group V Control Panel Assembly

Page 21SKU 95951 For technical questions, please call 1-800-444-3353.

Page 22

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product

is free from defects in materials and workmanship for the period of 90 days from the date

of purchase. This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity,

improper installation, normal wear and tear, or to lack of maintenance. We shall in no event

be liable for death, injuries to persons or property, or for incidental, contingent, special

or consequential damages arising from the use of our product. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation

of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the com-

plaint must accompany the merchandise. If our inspection veries the defect, we will either

repair or replace the product at our election or we may elect to refund the purchase price

if we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

Page 22SKU 95951 For technical questions, please call 1-800-444-3353.

Loading...

Loading...