Page 1

AIR COMPRESSOR PUMP

®

3 HORSEPOWER

Model 09592

ASSEMBLY AND

OPERATING INSTRUCTIONS

®

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright 2003 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor F reight T ools.

For technical questions, please call 1-800-444-3353.

Page 2

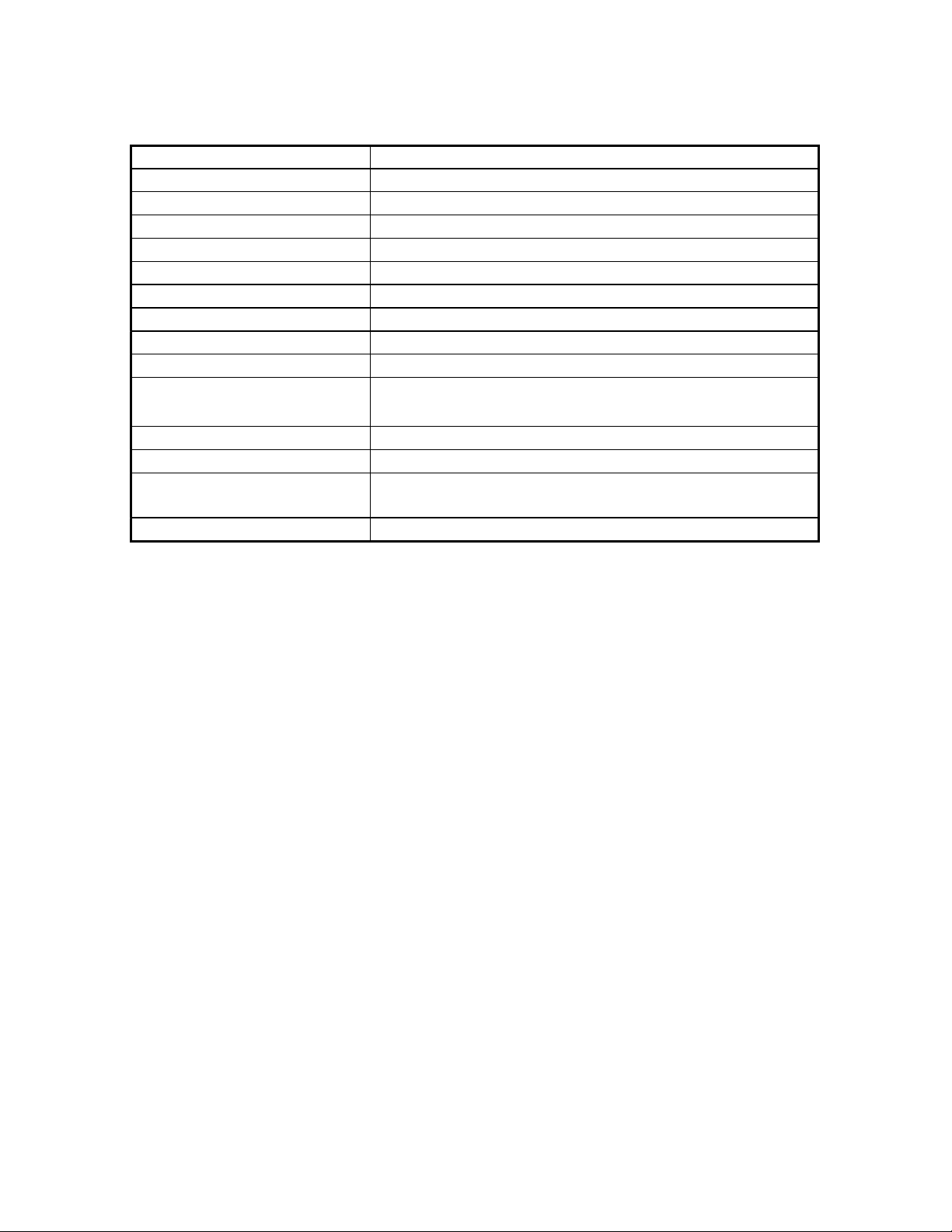

PRODUCT SPECIFICATIONS

Item Description

Product Capability For u s e with 3 HP, 3400 RPM (not included)

Pump Stage Single

Maximum Pressure 140 PSI

Maximum Intake Capacity 8.05 CFM

Pump RPM 1,200 RPM

Cylinder Design Twin

Stroke 1.57”

Oil Capacity 28.73 ounces

Shaft Diameter 15/16”

Mounting Holes Qty. 4 / 3/8” Diameter /

Bolt Pattern: 5-1/2” L x 7-1/2” W

Lubrication System Design Splash

Construction Aluminum Head, Pump, Flywheel / Cast Iron Sleeve

Pu lle y Design / Size Be lt Driven

10-5/8” Dia. X 1/2” Belt, CCW Rotation

Weight 23.25 Pounds

SAVE THIS MANU AL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and

assembly diagram. Keep your invoice with this manual. Write the invoice

number on the inside of the front cover. Keep this manual and invoice in a safe

and dry place for future reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp, or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be

stored in a dry location to inhibit rust. Always lock up tools and equipment, and

keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgement or

reflexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this product.

SKU 09592 PAGE 2 REV 04/04

Page 3

5. USE EYE AND HAND PROTECTION. Wear ANSI approved safety impact eye

goggles and heavy-duty work gloves when using this product. ANSI

approved safety impact eye goggles and heavy-duty work gloves are available

from Harbor Freight Tools.

6. DRESS SAFELY. Do not wear loose clothing or jewelry, as they can become

caught in moving parts. Wear a protective hair covering to prevent long hair from

becoming caught in moving parts. If wearing a long-sleeve shirt, roll sleeves up

above elbows.

7. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. INDUSTRIAL APPLICATIONS MUST FOLLO W OSHA REQUIREMENTS.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do

not use this product when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product. Replace or repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES: When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this product clean and dry for

better and safer performance.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualified technician.

14. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. It will do the job better and more

safely at the rate for which it was intended. Do not modify this tool, and do not

use this tool for a purpose for which it was not intended.

15. WARNING: The warnings, precautions, and instructions discussed in this manual

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied by the operator.

SKU 09592 PAGE 3

Page 4

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. THIS AIR COMPRESSOR PUMP IS DESIGNED FOR USE ONLY WITH A

3 HORSEPO WER MO TOR 3,400 RPM (not included).

2. WARNING! Make sure to fill the Air Compressor Pump with a premium quality,

30-weight, non-detergent oil before each use. Running the Air Compressor

Pump with no oil or low oil will cause damage to the equipment.

3. WHEN FILLING WITH OIL: Make sure to unscrew (do not pull) the Oil Fill Plug

(part #20) out. (See Figure D.)

4. MAKE SURE ALL TOOLS AND EQUIPMENT USED WITH THE AIR

COMPRESSOR PUMP ARE RATED TO THE APPROPRIATE CAPACITY. Do

not use any tool or equipment that does not operate from 0 to 140 PSI.

5. MAINTAIN A SAFE WORKING ENVIRONMENT. Keep the work area well lit.

Make sure there is adequate surrounding workspace. Always keep the work

area free of obstructions, grease, oil, trash, and other debris. Do not use the Air

Compressor Pump in areas near flammable chemicals, dusts, and vapors.

6. AVOID INJURY: Never direct the Exhaust Elbow (par t #3) at people or animals.

(See Figure D.)

7. AVOID BURNS: The Air Compressor Pump becomes very hot during use and for

a while after its use. Do not touch the Air Compressor Pump until it has completely cooled.

8. WARNING! DO NOT USE THE AIR COMPRESSOR PUMP UNTIL A PROP-

ERLY FUNCTIONING PULLEY/BELT GUARD (not included) HAS BEEN

INSTALLED. (See Figure C.)

9. BEFORE PERFORMING ANY INSPECTION, MAINTENANCE, OR CLEANING

PROCEDURES, MAKE SURE ALL AIR PRESSURE HAS BEEN RELEASED

FROM THE AIR COMPRESSOR’S T ANK (not included) AND THA T THE

EQUIPMENT IS UNPLUGGED FROM ITS ELECTRICAL OUTLET, and ALL

COMPONENTS HVAE COLLED.

10. WARNING! This product contains or produces a chemical known to the State of

California to cause cancer and birth defects (or other reproductive harm).

(California Health & Safety Code 25249.5 et seq.)

SKU 09592 PAGE 4

Page 5

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List on page 9 are

included. If an y parts are missing or broken, please call Harbor Freight Tools at the number shown on the cover of this manual as soon as possible.

ASSEMBLY INSTRUCTIONS

NOTE: For additional references to the parts mentioned in the following pages, refer to

the Assembly Diagram on page 10.

To Attach The Air Compressor Pump To A Mounting Surface:

1. NOTE: Depending on your level of assembly expertise, you may wish to have a

qualified technician perform the assembly procedures.

2. CAUTION: Make sure the mounting surface (air compressor stand, workbench, etc.) to which the Air Compressor Pump will be attached is flat, level, and

sturdy enough to withstand the weight of the Air Compressor Pump and all other

necessary equipment and accessories.

3. At the base of the Air Compressor Pump are

pattern of 5-1/2” long by 7-1/2” wide. If

four

3/8” mounting holes with a hole

four

3/8” mounting holes with a hole

pattern of 5-1/2” long by 7-1/2” wide do not already exist in the mounting surface,

it will be necessary to drill the

four

3/8” mounting holes through the mounting

surface. IMPORTANT: Prior to drilling, make sure there are no electrical cables,

wires or other obstructions in the drilling path. (See Figure A.)

4. To do so, temporarily position the Air Compressor Pump in the desired location

on the mounting surface. Use the base of the Air Compressor Pump, with its four

3/8” mounting holes, as a template by which to mark the four 3/8” mounting holes

that are to be drilled through the mounting surface. Then, remove the Air Compressor Pump from the mounting surface. NOTE: You may also follow the illus-

tration below by which to measure where each of the four 3/8” mounting holes

should be drilled. (See Figure A.)

5-1/2”

BOTTOM VIEW

7-1/2”

PULLEY

(#38)

FIGURE A

SKU 09592 PAGE 5

BASE OF AIR COMPRESSOR PUMP

Page 6

5. Once the four 3/8” mounting holes are drilled through the mounting surface,

place the Air Compressor Pump on the mounting surface and align its four

mounting holes with the four drilled mounting holes on the mounting surface.

Then, secure the Air Compressor Pump to the mounting surface, using four 3/8”

Bolts of appropriate length, four Lockwashers, and four Nuts (all not included).

6. The Air Compressor Pump requires the use of a “V” Pulley Belt (not included).

The “V” Pulley Belt should be no wider than 1-5/16” wide at its widest point and

of appropriate length depending on the distance between the Air Compressor

Pump’s Pulley (part #38) and the 3 HP Motor’s Pulley (not included). Once the

“V” Belt Pulley is installed, its proper length is indicated by pushing down with

your finger midway on the “V” Belt Pulley. The “V” Belt Pulley should not depress more than 1/2”. (See Figure B.)

“V” BELT PULLEY

(NOT INCLUDED)

3 HP MOTOR PULLEY

(NOT INCLUDED)

PULLEY

(#38)

FIGURE B

7. WARNING! To avoid personal injury and/or property damage, it is recommended

that a properly functioning Pulley/Belt Guard (not included) be installed. The

Pulley/Belt Guard should

fully

enclose (front, back, top, bottom) the Air Compressor Pump’s Pulley (par t #38), the “V” Belt, and the Motor’s Pulley. NOTE: Make

sure to allow for about 1” clearance, on all sides, between the Pulley/Belt Guard

and the Air Compressor Pump’s Pulley, the “V” Belt, and the Motor’s Pulley.

(See Figure C.)

CONVENTIONAL PULLEY/BELT GUARD

(NOT INCLUDED)

SKU 09592 PAGE 6

FIGURE C

Page 7

8. Attach the Air Compressor Tank’s Inlet Hose (not included) to the 1/2” by 14-TPI

Exhaust Elbow (part #3). NOTE: Make sure to wrap the male threads of Tank’s

Inlet Hose

Connector

with pipe seal tape (not included). Then, screw the Con-

nector firmly into the Exhaust Elbow. (See Figure D.)

EXHAUST ELBOW

ATTACH

AIR T ANK INLET HOSE

(NOT INCLUDED)

HERE.

(#3)

AIR FILTER

(#4)

OIL FILL PLUG

(#20)

OIL WINDOW

(#25)

FIGURE D

OPERATING INSTRUCTIONS

NOTE: For additional references to the parts mentioned in the following pages, refer to

the Assembly Diagram on page 10.

To Check The Oil Level:

1. The Oil Window (par t #25) is used to determine if oil is needed. To check the oil,

observe the Oil Window. The oil should appear at the midway point (horizontally) in the circle of the Oil Windo w. (See Figure D.)

Note: The optimal capacity of the oil tank is 28.73 ounces .

2. If the oil level is below the midway point in the Oil Window (part #25) then it is

necessary to add a

oil reaches the midway point in the Oil Window. Do not overfill. NOTE: Make

sure to unscrew the Oil Fill Plug and remove it from its Oil Fill Hole. Add the

new oil. Then screw the Oil Fill Plug back into the Oil Fill Hole, being careful not

to strip the threads. (See Figure D.)

premium quality, 30-weight, non-detergent oil

until the level of

SKU 09592 PAGE 7 REV 02/04

Page 8

3. Start the Air Compressor, and visually check the “V” Belt for proper tension. Also

check for air leaks in the system, abnormal noise or vibration. If a problem occurs immediately disconnect the Air Compressor from its electrical supply source,

release all air pressure from the system, and have the problem corrected before

further use.

4.

IMPORTANT: After starting the Air Compressor Pump, it should run for about 30

minutes without a load in order for it to build up sufficient air pressure.

INSPECTION, MAINTENANCE, AND CLEANING

1.

2. BEFORE EACH USE, inspect the general condition of the Air Compressor

Do not use damaged equipment.

3. DAILY: Check the Air Compressor Pump’s oil level. If necessary, fill with a pre-

(See Figure D.)

WARNING! Before performing any inspection, maintenance, and cleaning procedures, make sure all air pressure has been released from the Air Compressor’s

Tank and that the Air Compressor is unplugged from its electrical outlet.

Pump. Check all air fittings for leaks. Check for loose screws, misalignment or

binding of moving parts, cracked or broken parts, and any other condition that

may affect the safe operation of this equipment. If abnormal noise or vibration

occurs, immediately disconnect the Air Compressor from its electrical supply

source and have the problem corrected before further use.

mium quality, 30-weight, non-detergent oil. NOTE: When checking the oil level,

make sure to unscrew (do not pull) the Oil Fill Plug (part #20).

4. EVERY 100 HOURS OF USE: Clean the Air Filter Element (part #4) with a mild

solvent. Then, dry and re-attach the Air Filter Element. NOTE: Replace the Air

Filter Element if it is too dirty to properly clean. (See Assy. Diagram.)

5. EVERY 500 HOURS OR 12 MONTHS: Replace the old oil with new, premium

quality, 30-weight, non-detergent oil.

6. TO CLEAN: wipe with a damp cloth, using a mild detergent or mild solvent.

7. WHEN STORING: Keep the Air Compressor Pump in a clean, dry location.

SKU 09592 PAGE 8

Page 9

PLEASE READ THE FOLLOWING CAREFULLY

#

#

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTA TION OR WARRANTY OF ANY KIND T O THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTUER AND/OR

DISTRIBUTOR EXPRESSLY STATES THA T ALL REPAIRS AND P A RTS REPLA CEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NO T BY THE B UYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERET O , OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO .

PARTS LIST

Part

1 Screw 6 21 Bolt 3

2 Cylinder Head 1 22 Crankcase Front Cover 1

3 Exhaust Elbow 1 23 Crankcase Front Washer 1

4 Air Filter 1 24 O-Ring 1

5 Spring Washer 2 25 Oil Window 1

6 Screw 2 26 Oil Drain Plug 1

7 Cylinder Head Washer 1 27 O-Ring 1

8 Valve Plate Seat 2 28 Crankcase Seal 1

9 Valve Plate 4 29 Crankcase Down Cover 1

10 Aluminum Washer 1 30 Bolt 8

11 Cylinder Up Washer 2 31 Crankcase 1

12 Piston Ring Assembly 2 32 Bearing 2

13 Piston 2 33 Crankshaft 1

14 Piston Pin 2 34 Crankcase Back Washer 1

15 Retaining Ring In Hole 4 35 Oil Seal 1

16 Connect Rod Assembly 2 36 Crankcase Back Cover 1

17 Bolt 6 37 Bolt 3

18 Cylinder 1 38 Pulley 1

19 Cylinder Down Washer 1 39 Large Washer 1

20 Oil Fill Plug 1 40 Bolt 1

Description Qty. Part

Description Qty.

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

SKU 09592 PAGE 9

Page 10

ASSEMBLY DIAGRAM

6

5

4

7

8

9

10

8

11

12

14

15

16

1

2

3

13

20

21

25

22

20

23

26

17

18

19

24

29

27

30

32

31

28

33

32

34

37

35

36

38

40

39

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

SKU 09592 PAGE 10

Loading...

Loading...