Page 1

®

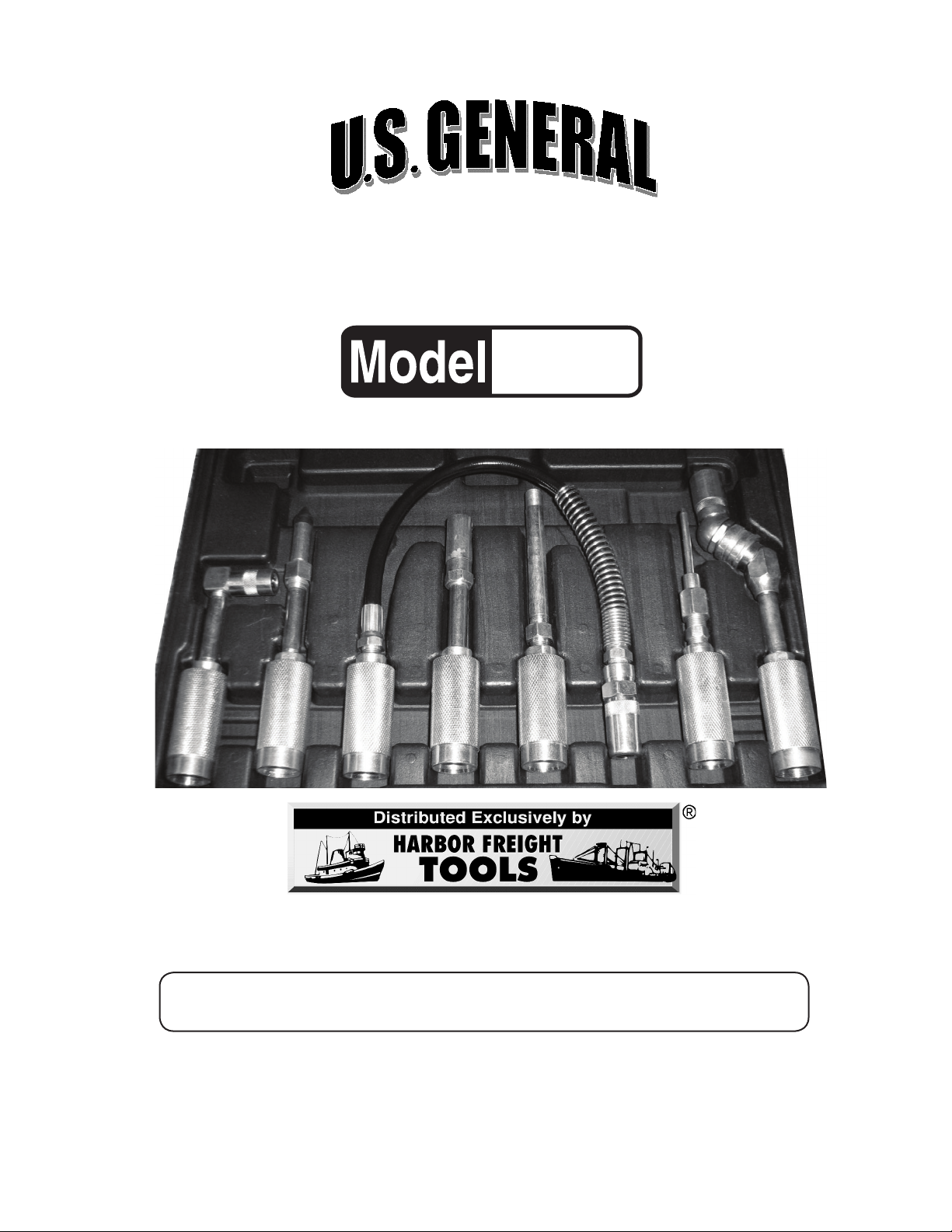

QUICK-CONNECT LUBE

ACCESSORY KIT, 7 PIECES

95904

OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright © 2007 by Harbor Freight Tools®. All rights reserved. No portion

of this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

Kit Contents (shown page 4)

Tools Low Carbon Steel

Hose Nylon

Dimensions 11-1/4” L X 13-7/16” W X 2-3/8” H

Working Pressure Do not exceed 10,000 PSI

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep your

invoice with this manual. Write the invoice number on the inside of the front cover. Write the

product’s serial number in the back of the manual near the assembly diagram, or write month

and year of purchase if product has no number. Keep this manual and invoice in a safe and

dry place for future reference.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

1.

2.

3.

4.

5.

6.

7.

Keep work area clean. Dark and cluttered areas invite injuries.

Keep children away. Children must never be allowed in the work area. Do not let

them handle tools.

Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock tools up and keep out of reach of children.

Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. Use tool only for applications for which it was

designed.

Use safety equipment. Always wear ANSI approved eye protection. Dust mask,

nonskid safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

Do not overreach. Keep proper footing and balance at all times. Do not reach over

or across running machines.

Check for damaged parts. Before using any tool, all parts should be carefully checked

to determine if they operate properly and perform the intended function. Check for

alignment and binding of moving parts, grease leaks, cracks or bulges in the 12” Hose

Extension (1), any broken parts or mounting fixtures, and any other condition that may

SKU 95904 For technical questions, please call 1-800-444-3353. Page 2

Page 3

affect proper operation. Any part that is damaged should be replaced or properly repaired by a qualified technician.

8.

9.

10.

11.

12.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built

into this product, but must be supplied by the operator.

Replacement parts. When servicing, use only identical replacement parts. Use of

any other parts will void the warranty.

Do not operate tool if under the influence of alcohol or drugs. Read warning labels if taking prescription medicine to determine whether judgment or reflexes might

be impaired. If there is any doubt, do not operate the tool.

This Accessory Kit is for handheld grease guns only.

Grease is extremely flammable. Do not use grease around hot engines, mufflers,

flames, or any other heat source.

Don’t use a grease gun on moving or operating components. Do not use the

grease gun on tools that are plugged into a power source.

Unpacking

When unpacking, check to make sure all parts are included. If any parts are missing

or broken, please call Harbor Freight Tools at the number on the cover of this manual as soon

as possible.

OPERATION

Note: Each of the accessories below are used with a grease gun that accepts Zerk fittings.

1.

2.

3.

4.

5.

6.

7.

To attach any accessory to a grease gun, slide the cover back and snap the Zerk fitting

into the coupling.

The 12” Hose Extension (1) provides additional reach when needed.

The 90 Degree Attachment (2) makes it easy to contact hard-to-reach fittings.

Straight Extension is used (3) to lubricate recessed fittings.

The 90 Degree Coupler (4) locks onto fittings that traditional couplers can not access.

The Rubber Tripod Nozzle (5) is used to lubricate grease plugs, spindles, and capped

lube ports.

The Needle Injector (6) is used to inject grease into hydraulic fittings and CV-Joint

Boots.

SKU 95904 For technical questions, please call 1-800-444-3353. Page 3

Page 4

8.

The 360 Degree Coupler (7) swivels, and has a 2” steel extension tube and locking

sleeve.

Maintenance

1.

Thoroughly clean each piece after use. Make sure they are dry and free of grease

before storing in the Carrying Case.

PARTS DIAGRAM

Part Description

1 12” Hose Extension

2 90 Degree Attachment

3 Straight Extension

4 90 Degree Coupler

5 Rubber Tripod Nozzle

6 Needle Nozzle

7 360 Degree Coupler

8 Carrying Case (not pictured)

1

2

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE

ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS

AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS

AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

3

PLEASE READ THE FOLLOWING CAREFULLY

4

5

6

7

Record Product’s Serial Number Here:______________________

Note: If product has no serial number, record month and year of purchase instead.

SKU 95904 For technical questions, please call 1-800-444-3353. Page 4

Loading...

Loading...