Page 1

150 LB. DRYWALL PANEL HOIST

Model

95852

®

ASSEMBLY AND OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this manual

or any artwork contained herein may be reproduced in any shape or form without the

express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

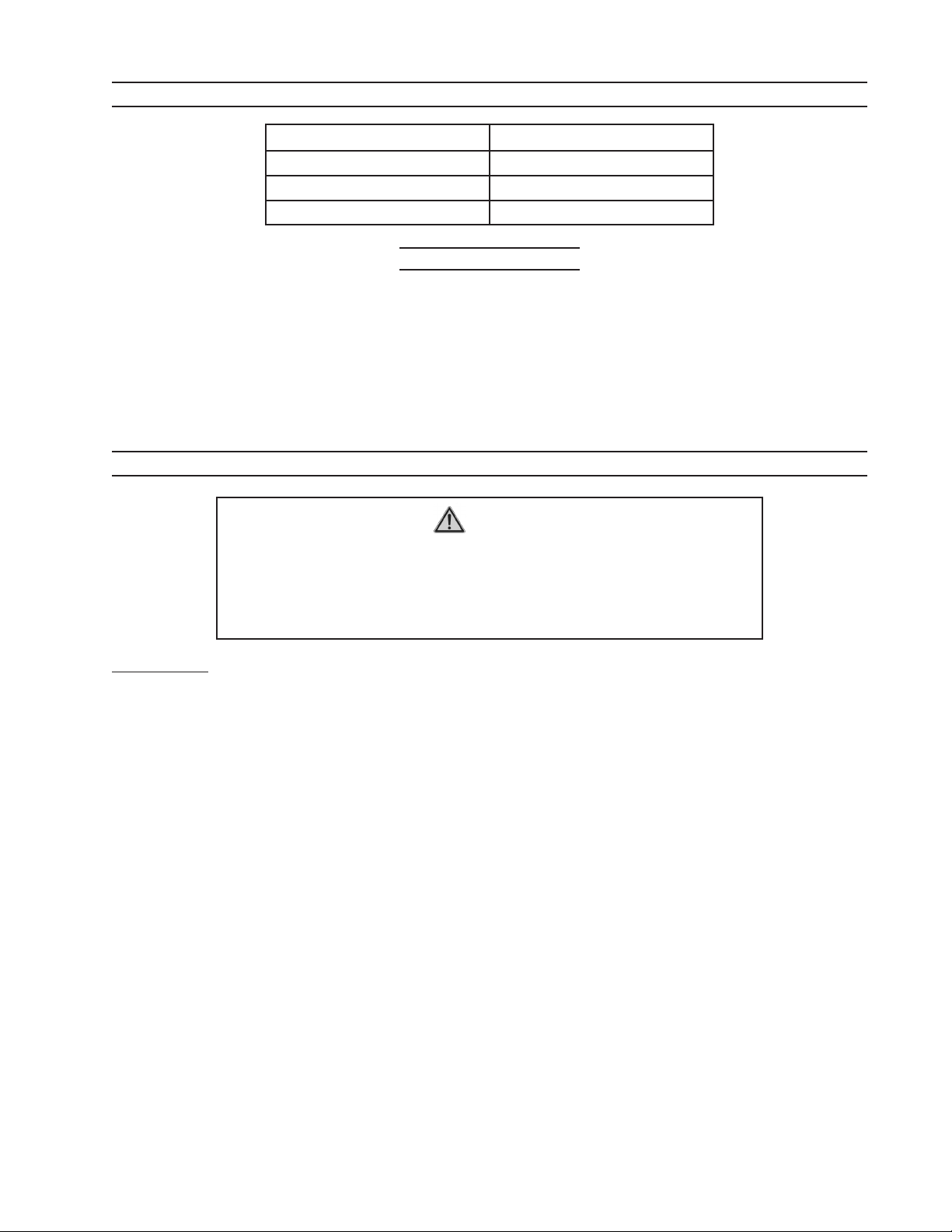

SPECIFICATIONS

Capacity 150 lb.

Panel Size Capacity 4’ x 16’ Maximum

Maximum Lift Height 11 Feet

Net Weight 124 lb.

Save This Manual

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep your

invoice with this manual. Write the invoice number on the inside of the front cover. Write the

product’s serial number in the back of the manual near the assembly diagram, or write month

and year of purchase if product has no number. Keep this manual and invoice in a safe and

dry place for future reference.

SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WARNING: When using tool, basic safety precautions should always be followed to reduce

the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1.

2.

3.

4.

5.

Keep work area clean. Cluttered areas invite injuries.

Observe work area conditions. Do not use machines or tools in damp or wet loca-

tions. Don’t expose to rain. Keep work area well lit.

Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools or let them climb on or play with the product.

Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this tool

was designed. It will do the job better and more safely at the rate for which it was in-

tended. Do not modify this tool and do not use this tool for a purpose for which it was

not intended.

6.

Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically nonconductive clothes and nonskid footwear are recom-

mended when working. Wear restrictive hair covering to contain long hair.

For technical questions, please call 1-800-444-3353

Page 2SKU 95852

Page 3

7.

Use eye protection. Always wear ANSI-approved impact safety goggles.

8.

9.

10.

11.

12.

13.

Do not overreach. Keep proper footing and balance at all times. Do not reach over

or across a Panel Lift while in operation. Do not walk or stand under Panel Lift while

in operation.

Maintain tools with care. Keep tools clean for better and safer performance. Follow

instructions for lubricating and changing accessories. The Brake Hub lining must be

kept clean, dry, and free from oil and grease at all times.

Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician. Do

not use the tool if any switch does not operate properly.

Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

Do not operate tool if under the influence of alcohol or drugs. Read warning labels

if taking prescription medicine to determine if your judgment or reflexes are impaired

while taking drugs. If there is any doubt, do not operate the tool.

14.

15.

16.

17.

18.

19.

20.

21.

Maintenance. For your safety, service and maintenance should be performed regularly

by a qualified technician.

Stand clear of the Panel Lift when raising or lowering a panel. Never reach through

the winch wheel.

Lift Capacity. Never exceed the Lift’s capacity of 150 lb. Check the manufacturer’s docu-

mentation to determine the actual weight of panels before attempting to lift them.

Never ride on the Panel Lift. Never ride on the Panel Lift, and never have people or

pets in the area while operating lift.

Only use the Lift to raise/lower panels. After raising the panel, immediately fix in

place using the recommended type, number and pattern of nails, adhesive or screws.

Do not use this lift to store panels.

Place Panel Lift on correct surface. Only use this Lift on a stable, level, clean and

dry surface that is capable of sustaining the load.

Stabilize the load. Ensure that the load remains stable at all times. Do not move the

load while it is on the Lift.

Center load. Center the load on the Panel Lift. Off-center loads can topple over caus-

ing property damage or injury.

For technical questions, please call 1-800-444-3353

Page 3SKU 95852

Page 4

22.

Warning: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur. It

must be understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

UNPACKING

When unpacking, check to make sure the item is intact and undamaged. If any parts are

missing or broken, please call Harbor Freight Tools at the number on the cover of this manual

as soon as possible. Please refer to Parts List and Assembly Diagram on pages 14-15.

This tool has several sub assemblies which must be assembled before use. These

are:

* Tripod Base

* Frame Assembly including Winch and Telescoping Lift sections

* Cradle Assembly

* Two Cradle Crossarm Assemblies

For technical questions, please call 1-800-444-3353

Page 4SKU 95852

Page 5

ASSEMBLY

Please note: It is recommended that two or

more able workers assemble this product.

Setting up the Tripod Base

1.

2.

3.

Place the Tripod Base Assembly (1) on the floor

with the Casters (4) down.

Press down on the Slide Yoke Ring (5) while swing-

ing the two Outer Legs (3) out and back into place.

The Yoke Ring will snap into the hole in the bottom

of the Center Leg (2).

To keep the Tripod in position during assembly, rotate

the Backstop (7) down to lock onto the floor.

The Frame Assembly with Winch and Lift

1.

Set the Frame Assembly (10) into the Tripod Base (1),

fitting the end into the V-shaped opening. Insert the

Frame Assembly about 1 inch to seat it in the base.

Be sure the Frame Assembly is firmly seated before

continuing.

2.

3.

4.

Attach the Handle (34) to the Winch Wheel (27). Leave the

Nut loose enough for the Handle to rotate when in use.

Move the Winch Assembly (20) into its working position.

a. Rotate the Winch Wheel (27) forward slightly while lift-

ing the Brake Arm (30) to release the Brake.

b. Raise the Brake Arm all the way up with your left hand

and hold in place by gripping the Winch Post

c. Place your right hand on top of the Frame. Continuing

to hold the Brake Arm, pull the Winch Assembly toward

you as far as it will go.

d. Release the Brake Arm and move the Retaining Hook

(26) away to release the telescoping sections inside the

Frame Housing (11).

Push the Winch Assembly slightly back toward the

Frame to engage the Slide Bar Lock (23). Be sure that

Slide Bar Lock is engaged before continuing.

1.

For technical questions, please call 1-800-444-3353

Page 5SKU 95852

Page 6

Attach the Cradle to the Frame

1.

2.

Insert the Cradle Post, which is part of Cradle (42) into the opening in the top of the

Frame (11).

Attach the Cradle to the Frame by rotating the Tilt

Latch (47) over the stud on the Cradle.

Attach the Crossarms to the Cradle

1.

2.

The Crossarms are interchangeable. Slide the

tapered plates on both of the Crossarms (61) into

the receiving sockets on the Cradle (42).

Press each Crossarm into its socket until the spring

tab locks into place.

Testing the Assembly

With assembly completed, check the Panel Lift tool

to be sure all fasteners are tight, the cable is in place and

is undamaged, and the tool is safe to use.

1.

2.

3.

4.

tion before using this tool.

Check the Tripod Base to be sure it is firmly attached to the Frame. Be sure the legs

are firmly extended and locked in place.

Check the Frame Assembly and Winch Assembly

to be sure they are properly installed and function-

ing properly.

Check to be sure the Cradle is properly attached

to the Frame.

Check to be sure the Crossarms are firmly attached

to the Cradle.

CAUTION: Be sure the assembly is properly completed and checked for proper func-

For technical questions, please call 1-800-444-3353

Page 6SKU 95852

Page 7

Set Up Legs and Extend the Backstop

1.

2.

3.

4.

1.

2.

3.

Unlatch the two Outer Legs (3) by pressing down on the Slide Yoke Ring (5).

Rotate the Outer Legs into position.

Be sure the Slide Yoke Ring snaps into the hole on the under-

side of the Slide Tube, locking the Outer Legs into position.

Rotate the Backstop (7) downward. Be sure the Backstop

wedges against the floor, holding the Lift in place.

Extend the Outriggers

The Outriggers (44) can be extended to support the ends of panels. For safe use,

both outriggers should be extended the same amount to support the panel equally.

Warning! Failure to properly extend the outriggers could cause the Hoist to tip over,

resulting in personal injury and/or property damage.

To extend an Outrigger, pull out the Lock Pin (43) to release it,

and pull the Outrigger straight out the end of the Body Cradle

(42).

The Lock Pin (43) will lock the Outrigger in three positions,

while fully retracted, while extended 21” or fully extended

at 33”. Be sure the Lock Pin is engaged in one of these

positions whenever using the Lift.

4.

5.

1.

2.

1.

2.

3.

Extend both Outriggers equally, and ensure that both are locked in place using the Lock Pin.

To avoid damage, always retract the outriggers before transporting or storing the Lift.

Open the Panel Support Hooks

Rotate the Panel Support Hooks (62) on the lower ends of the Crossarms (61) outward.

These must be in place during use to safely support the

panel.

Always rotate the Support Hooks into their closed position

when transporting or storing the Lift, to avoid damaging

the Hooks.

Slide Bar Lock

The Slide Bar Lock (23) holds the Winch Assembly (20) in

its fully extended operating position.

Follow instructions on Page 5, item 4 of this manual for

engaging and releasing the Slide Bar Lock.

NOTE: Do not tighten the nut on the Slide Bar Lock. You will

not be able to fold up the unit for transport or storage.

For technical questions, please call 1-800-444-3353

Page 7SKU 95852

Page 8

Tilt Latch

1.

2.

3.

1.

2.

3.

The Tilt Latch (47) allows the Cradle (41) to tilt to adjust

the panel as needed for installation on sloped ceilings

or walls.

To lock the Cradle in a level position, rotate the Latch

up to engage the stud in the Cradle.

NOTE: When in the locked position, the cradle will tilt

up to 10° side-to-side.

Brake Arm

The spring-loaded Brake Arm (30) will automatically

hold the Cradle at any height you raise it.

To lower the Cradle, grasp the Winch Wheel (27) to

prevent it rotating in an uncontrolled manner.

Raise the Brake Arm to release the Cradle, and lower

it carefully with the Winch Wheel.

Winch Wheel, Handle and Post

1.

2.

3.

1.

The Winch Wheel (27) is used to raise and lower the

Cradle, which holds the panel. This is done by means of

a Cable (24) which wraps around a spool in the Winch

Wheel Assembly.

If necessary, you can grasp the top of the Winch Post

(21) for leverage when raising a panel.

CAUTION: Pay attention to the action of the Cable when

operating this tool. Do not allow your hands, clothing,

hair or jewelry to come near the Cable. If these become

caught in the cable, you can be injured. Do not allow the

cable to become tangled or jammed during operation.

Retaining Hook

Catch the Retaining Hook (26) on the end of the Frame

housing (11) to prevent the telescoping portions of the

tool from shifting during storage or transport.

For technical questions, please call 1-800-444-3353

Page 8SKU 95852

Page 9

OPERATION

Safety Checks Before Operation

1.

2.

3.

4.

1.

2.

3.

Carefully inspect the lift before operating the tool each time.

Inspect the tool for wear or damage. Pay special attention to any wear or damage to

the cable.

Allow the lift to reach room temperature before operation.

Be sure the Winch Brake Hub (33) is clean and dry before operation.

Loading a Drywall Panel

Please note: Drywall panels are very heavy; it is recommended that they be handled

by two able workers. Set the Backstop (7) to prevent the Lift from moving or rolling

while you are loading a panel on it.

Rotate the Cradle (41) so the Support Hooks

(62) are on the opposite side of the tool from

the Winch Wheel (27). Fold the Support Hooks

down.

Extend the Outriggers (44) as needed to support

the panel size you are working with

4.

5.

6.

7.

Release the Tilt Latch (47) and tilt the Cradle.

Place the drywall panel on the Cradle, with the

face side of the panel facing the cradle. Care-

fully lean the panel on the Crossarms, being careful not to damage the edges of the

panel.

If the panel will be installed on a flat ceiling, tilt the Cradle back to its level position and

lock the Tilt latch. If the panel will be installed on a side wall or sloped ceiling, leave

the Cradle tilted.

Raise the Backstop, and carefully roll the Lift near to the position where the panel will

be installed.

For technical questions, please call 1-800-444-3353

Page 9SKU 95852

Page 10

Raising the Panel

1.

2.

3.

CAUTION: Always lower the Backstop (7) to prevent

the Lift from rolling whenever raising a panel.

Crank the Winch Wheel (27) forward as shown to raise

the panel to the desired level. You may wish to grasp

the Winch Post (21) for leverage while doing this.

The Brake Hub (33) is spring loaded to hold the panel

in place after cranking.

1.

2.

Lowering the Panel

Grasp the Winch Wheel (27) with your right hand to prevent it turning backwards when

the brake is released.

While holding the Winch Wheel, release the Brake Arm (30) and allow the Winch Wheel

to rotate backward at a controlled rate, to lower the panel.

For technical questions, please call 1-800-444-3353

Page 10SKU 95852

Page 11

DISASSEMBLY

1.

2.

3.

4.

5.

6.

7.

Remove any panel which might be on the Lift. Release

the Brake Arm (30) and crank the Winch Handle (34)

to lower the Cradle (41) all the way down.

Slide the Cradle Outriggers (44) all the way in until they

latch. Fold up the Panel Support Hooks (62).

Press the Spring Tab on the underside, and remove the

crossarms by sliding them out of the tapered socket.

Unlock the Cradle Latch (47). Raise the Cradle to re-

move it from the Frame.

Rotate the Winch Wheel one full revolution forward to

raise the inner telescoping section.

Unlock the Winch Assembly by lifting the Slide Bar (22)

with one hand, and rotating the Slide Bar Lock coun-

terclockwise with your other hand.

Hold the Slide Bar Lock (23) in this disengaged posi-

tion, and press down on the telescoping sections of the

frame with your other hand. The Winch Assembly (20)

will rotate toward the Frame Housing (11).

8.

9.

10.

11.

Crank the telescoping sections all the way down. Swing

up the Retaining Hook (26) and crank the telescoping

sections back up until they are secured by the hook.

Hold the Retaining Hook in position while rotating the

Winch Forward. The Winch Assembly will fold up against

the Frame. When the Slide Bar contacts the Frame, tighten the

cable by turning the wheel further to hold the Winch Assembly in

this position.

Lift the Frame and Winch Assembly to remove it from the Base.

To fold the Base, press down on the Slide Yoke Ring (5) and pivot

the Outer Legs (3) forward until they lock into place in closed

position.

For technical questions, please call 1-800-444-3353

Page 11SKU 95852

Page 12

MAINTENANCE

1.

2.

3.

4.

1.

2.

Inspect the Cable before beginning work each day. Replace the Cable immediately as

soon as wear is detected. CAUTION: A cable breaking while under load can cause

severe personal and property injury. Broken cable strands are sharp and can cause

puncture injury.

Occasionally oil the Cable Pulleys and telescoping sections. CAUTION: Never allow oil

or grease to contact the surface of the Winch Brake Hub (33). Keep the Winch Brake

Hub clean and dry to prevent brake slipping or failure.

Occasionally oil the Caster Wheel (4) bearings.

If the telescoping sections do not slide freely, apply paraffin or candle wax to the sides

as a lubricant.

CABLE SAFETY INFORMATION

Woven or twisted Steel Cables are also known as Wire Ropes.

Since the safe operation of this lift depends on safe maintenance of the steel cable, it

is important that you carefully monitor and maintain the included cable. Replace the

cable as soon as it appears to have any fault, defect or noticeable wear.

3.

4.

The American Society of Mechanical Engineers has promulgated standards for the

safe use of Wire Rope in its standard numbered ASME B30 19-2000. This standard is

available to the public, and we strongly suggest you become familiar with it.

The following does not replace the information found in ASME B30 19-2000, but

paraphrases some of the important information contained therein.

a. Inspection should be made at least once every work day. Inspection should look

for damage to the cable, such as crushing, kinking, broken strands, corrosion etc.

Particular attention should be paid to wear and stress points, such as near pulleys,

crimped ends, hooks, etc.

b. Cables should be taken out of service if discovered to be damaged, and must be

replaced before resuming use of the affected tool.

c. The cable must be replaced with one of comparable size and material quality,

suited to the purpose. The cable provided with this Lift is suited to the purpose, and

any replacement must be at least to the original standard.

d. Cables must be maintained in a manner that prevents unneeded wear or damage,

such as corrosion, kinking, crushing or cutting.

For technical questions, please call 1-800-444-3353

Page 12SKU 95852

Page 13

OPTIONAL EXTENSION ACCESSORY (NOT INCLUDED)

1.

2.

1.

2.

An optional Extension Accessory is available that in-

creases the maximum lift height to 15’, instead of the

standard 11’.

The Accessory includes two 6’ telescoping sections

that replace the standard 4’ sections in the frame. A

longer Cable is included, which must be attached to

the Winch Drum.

To Install the Extension Accessory

Release the cable tension, loosen the cable from the mooring tab

on the side of the Winch. Pull the Cable out through the hole in

the Winch Hub.

Provide some slack in the Cable, and with a large pliers, grasp the

top of the two telescoping units (12, 13) and pull them straight out

of the Frame.

3.

4.

5.

6.

7.

Feed the crimped end of the longer Accessory Cable

into the opening near the top of the Frame Housing.

IMPORTANT: The Cable must be routed over the TOP

of the pulley.

Pull the Cable through the opening, and feed the new

Telescoping Sections down into the Frame.

Feed the free end of the new Cable under and around

the Winch Hub, then through the hole in the Winch

Drum.

Secure the crimped end of the Cable firmly behind the

mooring tab inside the drum.

Rotate the Winch Wheel forward to take up the slack

in the cable.

For technical questions, please call 1-800-444-3353

Page 13SKU 95852

Page 14

PARTS LIST

Part Description Q’ty

Tripod Base Assembly

1

Tripod Base Assembly, Complete

2 Center Leg with Fasteners 1

3 Outer Legs with Fasteners 2

4 Caster, 5 in. 3

5 Slide Yoke Ring 1

6 Tie Arm with Fasteners 2

7 Backstop with Rubber Tips 1

Frame Assembly

10 Complete Frame Assembly including

Winch Assembly

11 Frame Housing 1

12 Inner Telescoping Frame Section ,

4 ft.

13 Outer Telescoping Frame Section , 4

ft. with Pulley

Winch Assembly

20 Complete Winch Assembly 1

21 Winch Post with Pin and Fastener 1

22 Slide Bar with Axle and Cotter Pin 1

23 Slide Bar Lock with Fasteners 1

24 Cable, 13-½’ 1

25 Cable Pulley with Axle and Cotter

Pin

26 Retaining Hook 1

27 Winch Wheel with Flange Bearings 1

28 Bushing, 7/8” 1

29 Bolt, ½” x 5” with Nut and Washer 1

30 Brake Arm Assembly 1

31 Brake Lining with Fasteners 1

1

1

1

1

3

Part Description Q’ty

32 Brake Arm Tension Spring 1

33 Brake Hub with Bolts 1

34 Winch Wheel Handle 1

Cradle Assembly

41 Complete Cradle Assembly 1

42 Cradle Body 1

43 Outrigger Lock Pin with Spring and

Clip

44 Outrigger with End Caps 2

45 Complete Cradle Mounting Head

Assembly

46 Mounting Head Body 1

47 Cradle Tilt Latch with Fasteners 1

48 Tension Spring 1

49 Compression Spring 2

50 Hinge Pin with Bolts 1

Cradle Crossarms

60 Complete Crossarm Assembly 2

61 Crossarm Body 2

62 Panel Support Hook with Fasteners 2

63 Crossarm End Cap 2

Extension Accessory (NOT

INCLUDED)

70 Complete Extension Accessory 1

71 Inner Telescoping Section, 6’ 1

72 Outer Telescoping Section, 6’ with

Pulley

73 Cable, 17-½’ 1

2

1

1

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF

THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL

REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS

OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF

HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

For technical questions, please call 1-800-444-3353

Page 14SKU 95852

Page 15

ASSEMBLY DIAGRAM

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

For technical questions, please call 1-800-444-3353

Page 15SKU 95852

Page 16

WARRANTY

Limited 90 day

warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for

the period of ninety days from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, or to lack of

maintenance. We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid.

Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection

verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of

our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

For technical questions, please call 1-800-444-3353

Page 16SKU 95852

Loading...

Loading...