Page 1

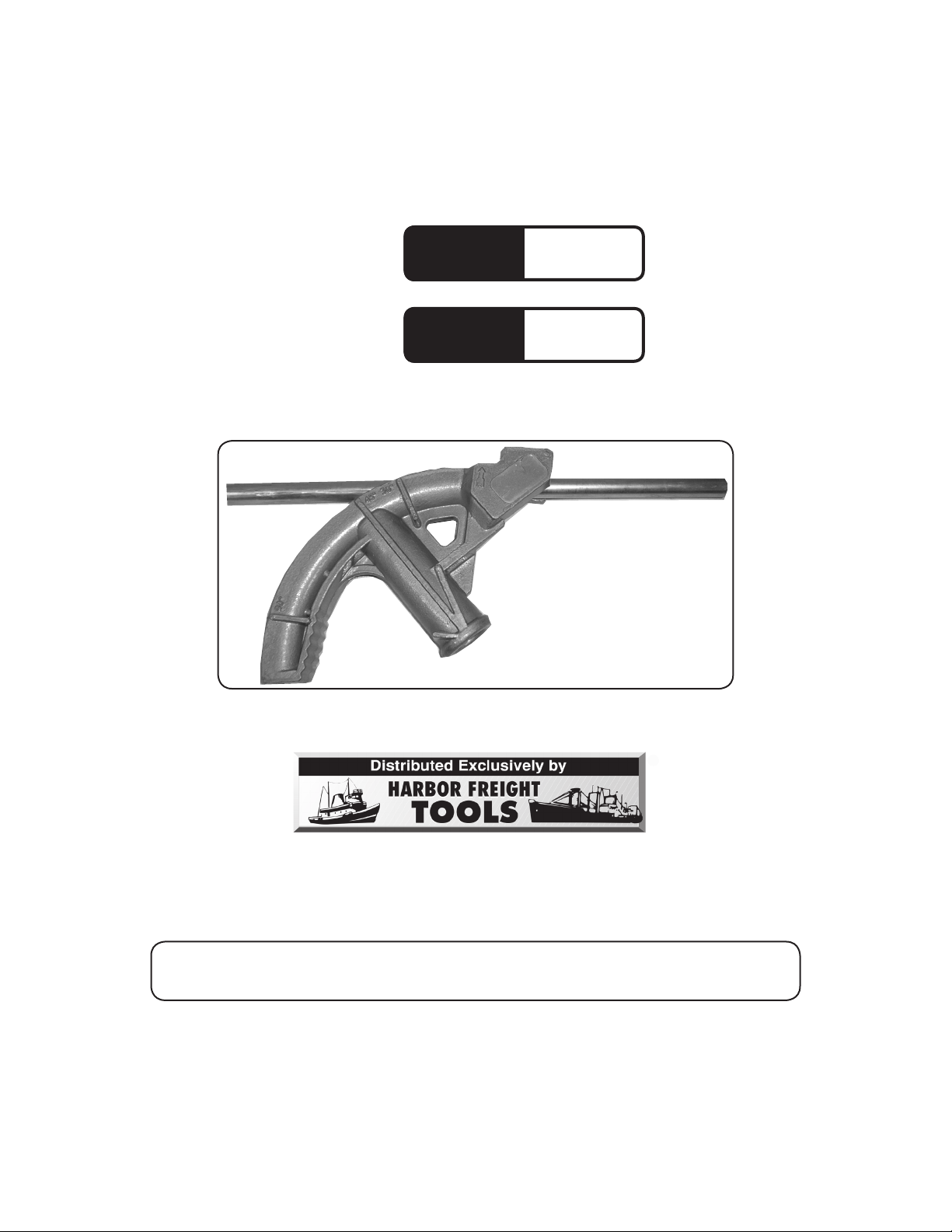

CONDUIT BENDER

Model

95805

Model

95806

®

1/2”

3/4”

ASSEMBLY AND OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

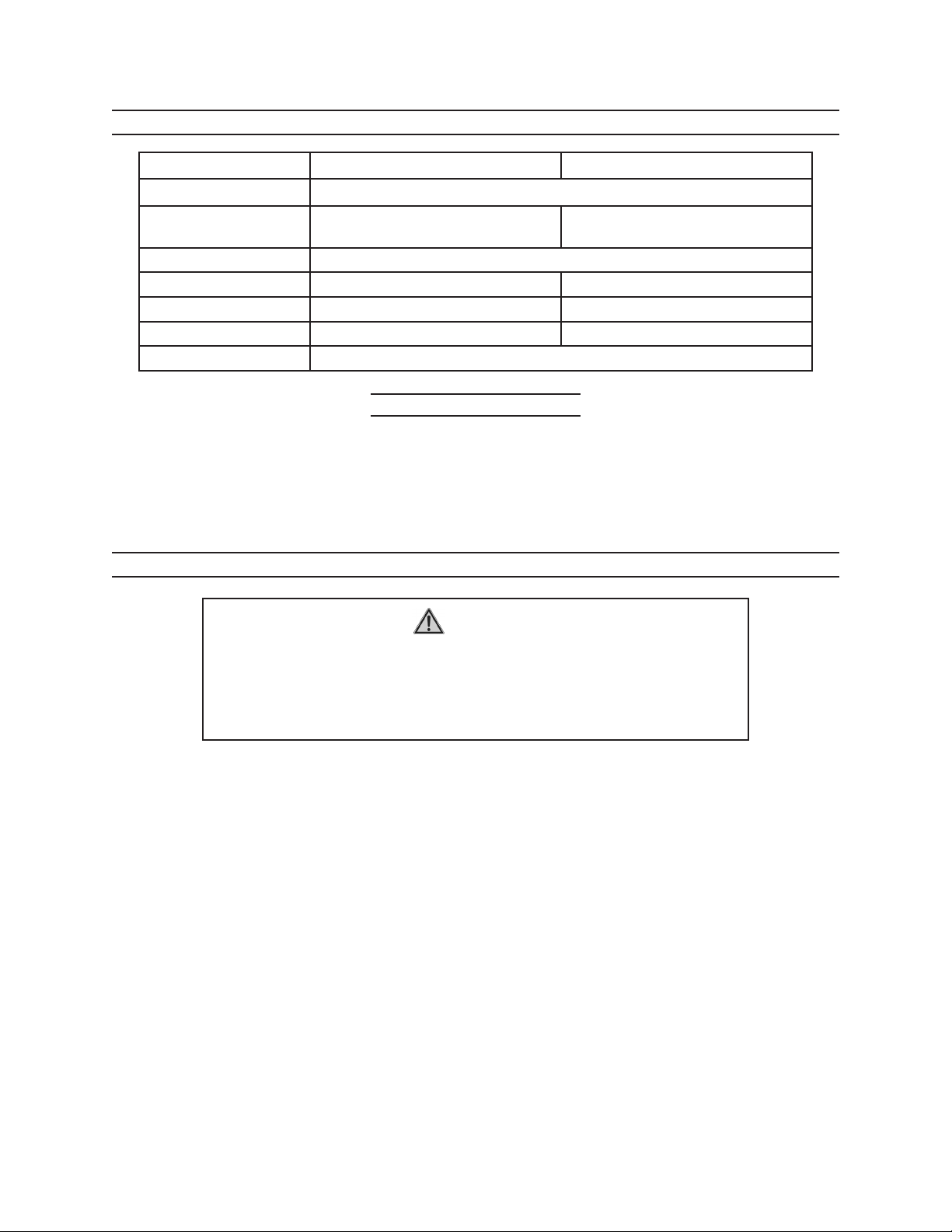

SPECIFICATIONS

Model 95805 95806

Construction Die cast aluminum

Overall Dimensions 8-1/2” L X 4-5/8” H X 1-5/8” W

Markings 30°, 45°, 90°

Handle Input 3/4” NPT 3/4” NPT

Weight 1 lb. 1.85 lb.

Conduit Capacity 1/2” 3/4”

Conduit Types EMT, RMC, or IMC

10-13/16” L X 5-1/5” H

X 1-15/16” W

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

SAFETY RULES

1.

2.

3.

4.

5.

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below

may result in serious injury.

SAVE THESE INSTRUCTIONS

Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

Stay alert. Watch what you are doing, use common sense. Do not use while

tired or under the influence of drugs, alcohol, or medication. A moment of

inattention may result in serious personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control in unexpected situations.

Use safety equipment. Always wear eye protection. Nonskid safety shoes must

be used for appropriate conditions. Always wear ANSI-approved safety goggles

when using or performing maintenance on this tool.

Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

For technical questions, please call 1-800-444-3353.

Page 295805 -95806

Page 3

6.

Do not force the tool. Use the correct tool for your application. The correct

tool will do the job better and safer at the rate for which it is designed. Do not force

the tool and do not use the tool for a purpose for which it is not intended.

7.

8.

9.

10.

11.

12.

Check for any condition that may affect the tool’s operation. If damaged, have

the tool serviced before using. Many accidents are caused by poorly maintained

tools.

Make a test bend in scrap material before working on the workpiece. Make

sure you understand how and where the exact bend you want will happen.

Work on electrical conduit must meet all local, state and federal regulations.

Never attempt to bend pipe with wires or cables inside.

Be aware of both ends of conduit at all times. Be careful that the free ends of

conduit do not cause hazards to others or create a hazard to yourself, such as by

getting near electrical wiring.

WARNING! The warnings and cautions discussed in this manual cannot cover

all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this

product, but must be supplied the operator.

UNPACKING

When unpacking, check to make sure that the item is intact and undamaged. If

any parts are broken, please call Harbor Freight Tools at the number shown on the cover

of this manual as soon as possible.

ASSEMBLY INSTRUCTIONS

1.

2.

This Conduit Bender comes as one piece. The only additional piece needed is a

threaded 3/4” pipe handle (between 30” and 36” long) not included.

Insert the handle into the proper end of the bender and thread in place securely.

The bender is now ready for use.

OPERATION INSTRUCTIONS

Note: Always test your desired bend on a piece of scrap material before attempting on a

workpiece. Bending properly takes a measure of experience. Techniques such as

offset bends and unbending take an exceptional degree of skill and are not covered

in this manual.

For technical questions, please call 1-800-444-3353.

Page 395805 -95806

Page 4

1.

For a 90° bend, measure the distance from the object that you start from to the point

you want the radius to end at. Subtract 5” (for 1/2” conduit bender) or 6” (for 3/4”

conduit bender) “take up” distance from this and make the Bend Mark.

2.

FIGURE 1

Measured End

3.

For 45° or 30° bend, make the Bend Mark where you want the bend to start. Prac-

tice bends can help you determine how much take up distance different bends

require.

Foot

Pedal

Line up Bend Mark

with this arrow.

Slide the Conduit Bender onto the piece of conduit you wish to bend and line up

the arrow on the Bender with the Bend mark you made in step 1 or 2, above. Ap-

ply light pressure to the handle and foot pedal and verify that the arrow still aligns

with the Bend Mark.

4.

Apply constant, simultaneous pressure to both the handle and the foot pedal to bend

the conduit. Cast into the surface on the Conduit Bender you will see three different

lines: 30°, 45°, and 90°. When the bend is complete, the line beside the desired

degree of angle will be exactly perpendicular to the piece of conduit on the floor.

Note: If simultaneous force is not applied to the handle and the foot pedal, then the conduit

may kink. Do not use a conduit that is kinked or bent too sharply.

INSPECTION, MAINTENANCE, AND CLEANING

BEFORE EACH USE, inspect the general condition of the tool.

Do not use damaged equipment. Discard tool if damaged.

Note: Replacement parts are not available for this item.

Tool service must be performed only by qualified repair personnel. Service or main-

tenance performed by unqualified personnel could result in a risk of injury.

For technical questions, please call 1-800-444-3353.

Page 495805 -95806

Loading...

Loading...