Page 1

®

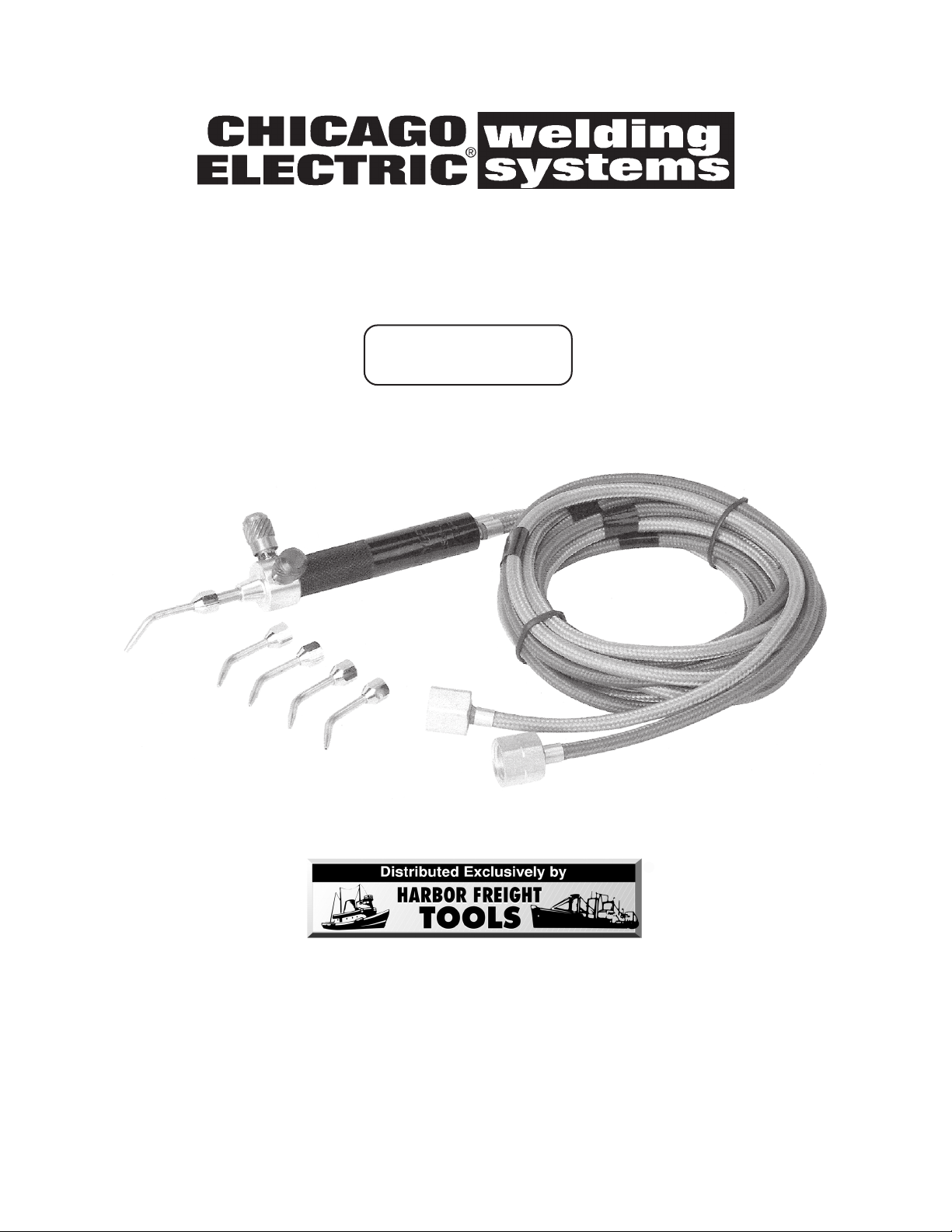

WELDING TORCH MINI-KIT

Model 95671

ASSEMBLY AND OPERATING INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

Item Description

Product

Applications

Required Gas

Pressure

Hose Assembly 6 Ft. Long / Color-Coded (Red & Green)

Additional

Features

Accessories 0.2mm Tip (Qty. 1) / 0.3mm Tip (Qty. 1)

Weight 0.35 Pound

Used for jewelry, hobby crafts, metal sculptures, electronics, etc.

Can be used with acetylene, hydrogen, propane, or natural gas.

0.2mm Tip = 2 PSI Oxygen / 2 PSI Fuel

0.3mm Tip = 3 PSI Oxygen / 3 PSI Fuel

0.4mm Tip = 4 PSI Oxygen / 4 PSI Fuel

0.5mm Tip = 6 PSI Oxygen / 5 PSI Fuel

0.6mm Tip = 6 PSI Oxygen / 6 PSI Fuel

9/16” x 18 NPT Brass Connectors Braided

Aluminum Alloy Body / Copper Tips with Rubber O-Rings

Oxygen Adjustment Knob / Fuel Gas Adjustment Knob

0.4mm Tip (Qty. 1) / 0.5mm Tip (Qty. 1) / 0.6mm Tip (Qty. 1)

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the

inside of the front cover. Keep this manual and invoice in a safe and dry place for

future reference.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dark areas

invite accidents.

2. Do not operate welding equipment in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Welding equipment

create sparks which may ignite the dust or fumes.

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 2

Page 3

3. Keep bystanders, children, and visitors away while operating welding

equipment. Distractions can cause you to lose control. Protect others in the

work area from debris such as chips and sparks. Provide barriers or shields as

needed. Children should not be allowed in the work area.

PERSONAL SAFETY

4. Stay alert. Watch what you are doing, and use common sense when operating welding equipment. Do not use welding equipment while tired or

under the influence of drugs, alcohol, or medication. A moment of inatten-

tion while operating welding equipment may result in serious personal injury.

5. Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

6. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool in unexpected situations.

TOOL USE AND CARE

7. Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

8. Do not force the tool. Use the correct tool for your application. The correct

tool will do the job better and safer at the rate for which it is designed.

9. Store idle tools out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

10. Maintain tools with care. Keep the welding equipment clean. Properly

maintained tools are less likely to malfunction and are easier to control. Do not use

a damaged tool. Tag damaged tools “Do not use” until repaired.

11. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tool’s operation. If damaged, have the

tool serviced before using. Many accidents are caused by poorly maintained

tools.

12. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous

when used on another tool.

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 3

Page 4

SERVICE

13. Tool service must be performed only by qualified repair personnel. Service

or maintenance performed by unqualified personnel could result in a risk of injury.

14. When servicing a tool, use only identical replacement parts. Follow

instructions in the

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of electric shock or injury.

“Inspection, Maintenance, And Cleaning”

section of this

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on the Welding Torch Mini-Kit. These carry

important information. If unreadable or missing, contact Harbor Freight Tools for

a replacement.

2. Maintain a safe working environment. Keep the work area well lit. Make sure

there is adequate surrounding workspace. Always keep the work area free of

obstructions, grease, oil, trash, and other debris.

3. Prevent eye injury and burns. Wearing and using personal safety clothing and

safety devices reduce the risk for injury. Wear ANSI approved welding goggles (not

included) featuring at least a number 10 shade lens rating. Leather leggings, fire

resistant shoes or boots should be worn when using this product. Do not wear

pants with cuffs, shirts with open pockets, or any clothing that can catch and hold

molten metal or sparks. Keep clothing free of grease, oil, solvents, or any flammable

substances. Wear dry, insulating gloves and protective clothing. Wear an approved

head covering to protect the head and neck. Use aprons, cape, sleeves, shoulder

covers, and bibs designed and approved for welding and cutting procedures. When

welding or cutting overhead or in confined spaces, wear flame resistant ear plugs or

ear muffs to keep sparks out of ears.

4. Prevent accidental fires. Remove any combustible material from the work area.

When possible, move the work to a location well away from combustible materials.

If relocation is not possible, protect the combustibles with a cover made of fire

resistant material. Remove or make safe all combustible materials for a radius of 35

feet (10 meters) around the work area. Use a fire resistant material to cover or

block all open doorways, windows, cracks, and other openings. Enclose the work

area with portable fire resistant screens. Protect combustible walls, ceilings, floors,

etc., from sparks and heat with fire resistant covers. If working on a metal wall,

ceiling, etc., prevent ignition of combustibles on the other side by moving the

combustibles to a safe location. If relocation of combustibles is not possible, designate

someone to serve as a fire watch, equipped with a fire extinguisher, during the

welding process and for at least one half hour after the welding is completed. Do

not weld or cut on materials having a combustible coating or combustible internal

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 4

Page 5

structure, as in walls or ceilings, without an approved method for eliminating the

hazard. Do not dispose of hot slag in containers holding combustible materials.

Keep a fire extinguisher nearby and know how to use it. After welding or cutting,

make a thorough examination for evidence of fire. Be aware that easily visible

smoke or flame may not be present for some time after the fire has started. Do not

weld or cut in atmospheres containing dangerously reactive or flammable gases,

vapors, liquids, and dust. Provide adequate ventilation in work areas to prevent

accumulation of flammable gases, vapors, and dust. Do not apply heat to a container

that has held an unknown substance or a combustible material whose contents,

when heated, can produce flammable or explosive vapors. Clean and purge

containers before applying heat. Vent closed containers, including castings, before

preheating, welding, or cutting.

5. Avoid overexposure to fumes and gases. Always keep your head out of the

fumes. Do not breathe the fumes. Use enough ventilation or exhaust, or both, to

keep fumes and gases from your breathing zone and general area. Where ventilation

is questionable, have a qualified technician take an air sampling to determine the

need for corrective measures. Use mechanical ventilation to improve air quality. If

engineering controls are not feasible, use an approved respirator. Work in a confined

area only if it is well ventilated, or while wearing an air-supplied respirator. Follow

OSHA guidelines for Permissible Exposure Limits (PEL’s) for various fumes and

gases. Follow the American Conference of Governmental Industrial Hygienists

recommendations for Threshold Limit Values (TLV’s) for fumes and gases. Have a

recognized specialist in Industrial Hygiene or Environmental Services check the

operation and air quality and make recommendations for the specific welding or

cutting situation.

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 5

Page 6

6. Always keep the Welding Hoses (7, 8) away from moving parts on the tool.

Examine the Welding Hoses for cuts, burns, or worn areas before each use. If any

damaged areas are found, replace the Welding Hoses immediately.

7. Read and understand all instructions and safety precautions as outlined in

the manufacturer’s manual for the material you will weld or cut.

8. Proper cylinder care. Secure cylinders to a cart, wall, or post, to prevent them

from falling. All cylinders should be used and stored in an upright position.

Never drop or strike a cylinder. Do not use cylinders that have been dented.

Cylinder caps should be used when moving or storing cylinders. Empty cylinders

should be kept in specified areas and clearly marked “empty”.

9. Never use oil or grease on any inlet connector, outlet connector, or cylin-

der valves.

10. Always use reverse-flow check valves (not included) on the torch and

regulator. This greatly reduces the possibility of mixing gases in the regulator or

hose.

11. Working pressure on the Acetylene Regulator should NEVER be set above

6 PSI.

12. For the Cutting Attachment, inspect the tapered seating surfaces on the

Tip and in the Torch Head. Have a qualified technician resurface the seat area

if it has dents, burrs, or is burned. A poor seating surface may result in

or

flashback

13. Backfire and flashback. When the flame goes out with a loud “pop”, it is called

a

backfire

than required for the Tip used, (2) touching the Tip against the workpiece, (3)

overheating the Tip, or (4) an obstruction in the Tip. If backfire occurs, shut off

the Torch Handle Valves (oxygen first) and after remedying the cause, relight the

Torch. A

the Torch and burns inside with a shrill hissing or squealing noise. If flashback

occurs, close the Torch Handle Valves (oxygen first), IMMEDIATELY. Flashback

generally indicates a problem that should be repaired. A clogged Tip, improper

functioning of the Valves, or incorrect acetylene/oxygen pressure could lead to

flashback. Make sure to find the cause before relighting the Torch.

14. WARNING! This product, when used for welding and similar applica-

tions, contains or produces a chemical known to the State of California to

cause cancer and birth defects (or other reproductive harm).

.

. Backfire can be caused by (1) operating the Torch at lower pressures

flashback

is a condition that results when the flame flashes back into

backfire

(California Health & Safety Code 25249.5 et seq.)

15. WARNING! The brass components of this product contain lead, a

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 6

Page 7

chemical known to the State of California to cause birth defects (or other

reproductive harm).

(California Health & Safety Code 25249.5 et seq.)

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List on page 11 are

included. If any parts are missing or broken, please call Harbor Freight Tools at the number

shown on the cover of this manual as soon as possible.

ASSEMBLY AND OPERATING INSTRUCTIONS

NOTE:

For additional information regarding the parts listed in the

following pages, refer to the Assembly Diagram on page 11.

1. IMPORTANT! The following instructions are for

acetylene

gas use only.

Contact your gas supplier for instructions on the use of other fuel gases.

2. Make sure to secure the cylinders (as noted in the

Specific Safety Rules

sec-

tion).

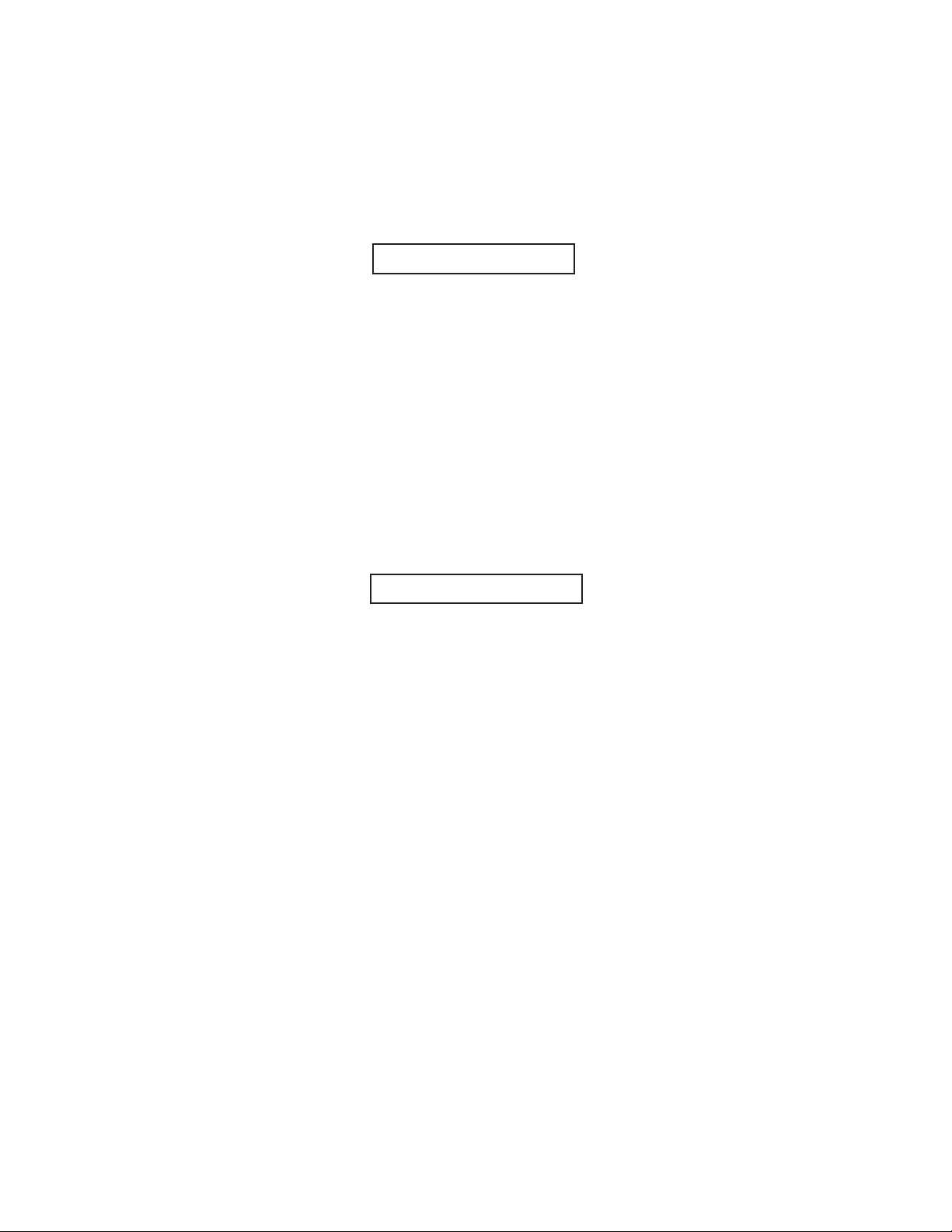

3. While standing to one side, “crack” each cylinder valve. “Cracking” is to quickly

open and close the valve, allowing gas to escape and clearing the valve of any

foreign material. WARNING! If oil or grease is found, discontinue using

cylinder and immediately contact your supplier. (See Figure A.)

QUICKLY

OPEN/CLOSE

VALVE TO

“CRACK”

ACETYLENE

OR

OXYGEN

CYLINDER

(NOT INCLUDED)

CYLINDER

VALVE

HANDLE

FIGURE A

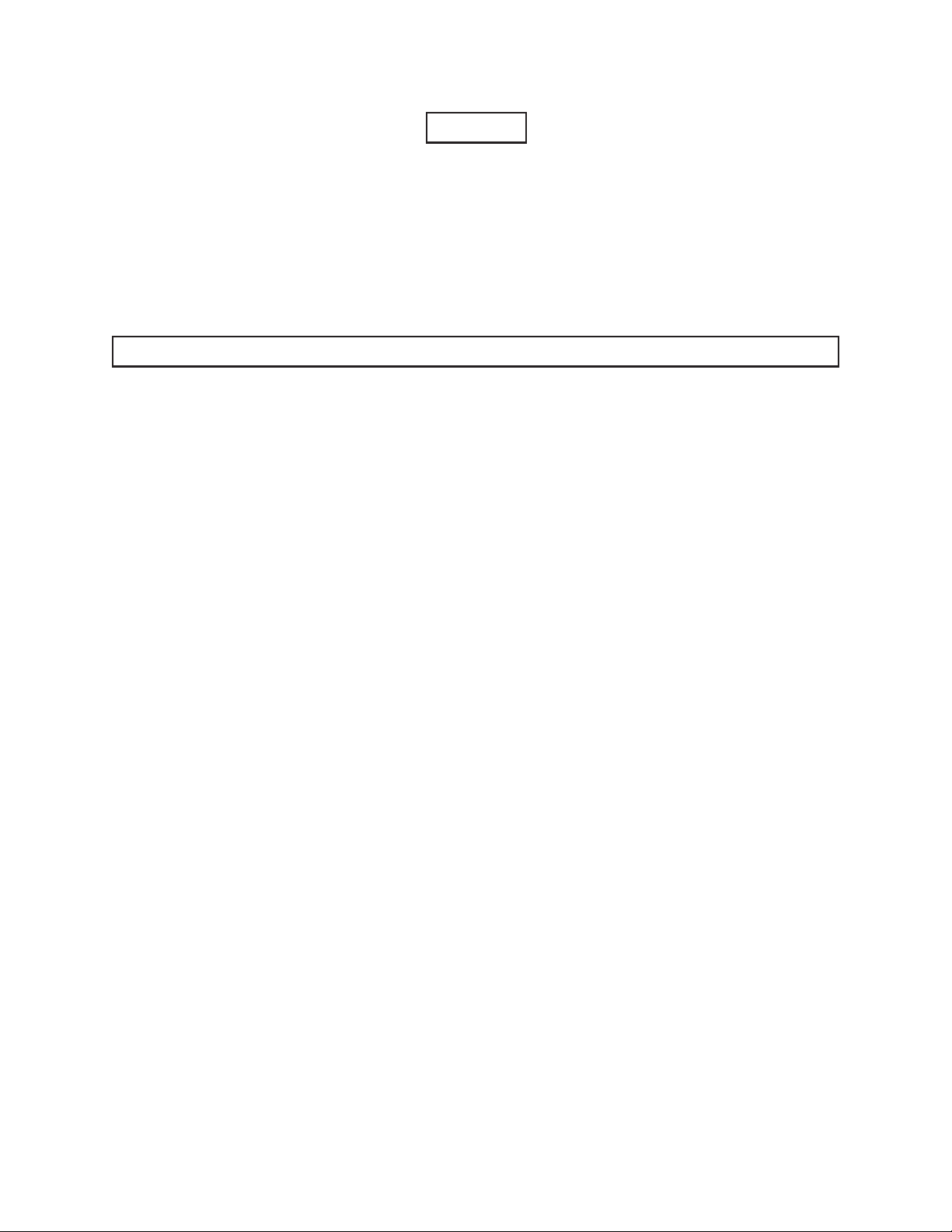

4. Attach the GREEN Oxygen Hose (7) to the oxygen cylinder. Then, attach the RED

Acetylene Hose (8) to the acetylene cylinder. Make sure they are tightened in the

correct directions (normally, clockwise for oxygen and counterclockwise for acetylene.) (See Figure B, next page.)

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 7

Page 8

5. IMPORTANT! The Pressure Adjusting Screw on the Acetylene Regulator (not

included) and the Pressure Adjusting Screw on the Oxygen Regulator (not included)

should be opened slightly by turning counterclockwise to relieve pressure on the

regulator diaphragms before opening the cylinder valves. If this is not done, pressure from the cylinders may damage the diaphragms and render the regulators

inoperable. (See Figure B.)

CYLINDER VALVE

OXYGEN REGULATOR

PRESSURE ADJUSTING SCREW

ACETYLENE REGULATOR

PRESSURE ADJUSTING SCREW

CYLINDER VALVE

VALVE STEM

(ACETYLENE)

(10)

RED

(ACETYLENE)

HOSE

(8)

TIP (1, 12, 13,14,15)

MIXER (2)

VALVE STEM (OXYGEN) (9)

TORCH HANDLE (5)

GREEN

(OXYGEN)

HOSE

(7)

ACETYLENE CYLINDER

OXYGEN CYLINDER

FIGURE B

6. Check connections for leaks. Adjust the Acetylene Regulator and Oxygen Regulator

operating pressure to coincide with the Tip used (1, 12, 13, 14, 15). Use an approved

leak detection solution to check for leaks at the Welding Hoses (7, 8) and cylinder

valve connections. If leaks are found, tighten the nuts more securely. If a leak still

persists, discontinue use and call your gas supplier. (See Figures B and C.)

7. WARNING! NEVER set the Acetylene Regulator to a delivery pressure

above that of which is required for a specific Tip (1, 12, 13, 14, 15) used.

(See Figures B and C.)

FIGURE C

Tip #1 (0.2mm) Oxygen

Tip #12 (0.3mm) Oxygen

Tip #13 (0.4mm) Oxygen

Tip #14 (0.5mm) Oxygen

Tip #15 (0.6mm) Oxygen

Oxygen/Acetylene Gas Pressure Required

Acetylene

Acetylene

Acetylene

Acetylene

Acetylene

2 P.S.I.

2 P.S.I.

3 P.S.I.

3 P.S.I.

4 P.S.I.

4 P.S.I.

6 P.S.I.

5 P.S.I.

6 P.S.I.

6 P.S.I.

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 8

Page 9

8. Depending on use, attach a Tip (1, 12, 13, 14, 15) to the Mixer (2) on the Torch

Handle (5). (See Figure B.)

9. Open the Oxygen Valve Stem (9) on the Torch Handle (5). Adjust the Oxygen

Regulator to the desired working pressure. Then, close the Oxygen Valve Stem on

the Torch Handle. (See Figure B.)

10. Open the Acetylene Valve Stem (10) on the Torch Handle. Adjust the Acetylene

Regulator to the desired working pressure. Then, close the Acetylene Valve Stem

on the Torch Handle. (See Figure B.)

11. Hold the Torch Handle (5) in one hand and a flint lighter (not included) in the other

hand. (See Figure B.)

12. WARNING! Always point the Tip (1, 12, 13, 14, 15) away from other people

when lighting.

13. Open the Acetylene Valve Stem (10) about 1/4 turn, and ignite the acetylene gas

coming out of the Tip (1, 12, 13, 14, 15). (See Figure B.)

14. Slowly open the Acetylene Valve Stem (10) further until the smoke subsides and the

flame jumps away from the end of the Tip (1, 12, 13, 14, 15) slightly.

(See Figure B.)

15. Slowly open the Oxygen Valve Stem (9) until a brilliant neutral flame is reached. (If

the flame has a smooth inner cone, the flame is called

(See Figure B.)

16. WARNING! Always use appropriate welding goggles or welding

helmet (with at least a #10 shade lens rating) when welding or cutting.

17. Once the welding or cutting job is competed, turn off the Oxygen Valve Stem (9).

Then, turn off the Acetylene Valve Stem (10). (See Figure B.)

NOTE: Reversal of this procedure may cause damage to the Torch Handle (5).

(See Figure B.)

18. Shut off both cylinder valves. (See Figure B.)

19. Drain the gas from the Oxygen Regulator by opening the Oxygen Valve Stem (9).

Complete this Step on the acetylene side. (See Figure B.)

20. Release the pressure on the Acetylene and Oxygen Regulators by turning their

Pressure Adjusting Screws counterclockwise. (See Figure B.)

neutral.

)

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 9

Page 10

INSPECTION, MAINTENANCE, AND CLEANING

1. WARNING! Make sure the Welding Torch Mini-Kit is cool to the touch

and disconnected from its oxygen and acetylene cylinders before

performing any inspection, maintenance, or cleaning procedures.

2. BEFORE EACH USE, inspect the general condition of the Welding Torch Mini-Kit.

Check for loose screws, misalignment or binding of moving parts, cracked or broken

parts, damaged Welding Hoses (7, 8), and any other condition that may affect its

safe operation. If a problem occurs, have the problem corrected before further use.

Do not use damaged equipment.

3. PERIODICALLY, use a Tip Cleaner (not included) to clean out dirt and debris from

the Tips (1, 12, 13, 14, 15). Make sure to use the correct size Tip Cleaner for each

individual Tip.

4. TO CLEAN, use a clean cloth. If necessary, a mild detergent may be used.

Do not immerse any part of the Welding Torch Mini-Kit in liquid.

Do not use solvents or other flammable agents to clean the Welding Torch

Mini-Kit.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER

THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR

WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE

ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT

BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF

HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT

PARTS THERETO.

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 10

Page 11

PARTS LIST AND ASSEMBLY DIAGRAM

Part # Description Qty. Part # Description Qty.

1 Welding Tip (0.2mm) 1 9 Valve Stem Assy. (Oxygen) 1

2 Mixer 1 10 Valve Stem Assy. (Acetylene) 1

3 Body 1 11 Retainer 5

4 Inner Tube 2 12 Tip (0.3mm) 1

5 Handle 1 13 Tip (0.4mm) 1

6 Retainer 1 14 Tip (0.5mm) 1

7 Hose (Green) 1 15 Tip (0.6mm) 1

8 Hose (Red) 1

15

14

13

NOTE:

Some parts are listed and shown for illustration purposes only, and are not available individually as replacement parts.

12

SKU 95671 For technical questions, please call 1-800-444-3353 PAGE 11

Loading...

Loading...