Harbor Freight Tools 90153 Owner's Manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the manual

near the assembly diagram (or month and year of purchase if product has no number). Keep this manual and

the receipt in a safe and dry place for future reference.

ITEM 90153

WARNING!

IMPORTANT INFORMATION

This trailer’s Hitch Coupler MUST be

properly secured to the hitch ball of the towing

vehicle. After assembly and attachment, pull

up and down on the Hitch Coupler to make

sure the hitch ball is tting snugly in the Hitch

Coupler. There must be no play between the

hitch ball and the Hitch Coupler. If there is

play, tighten the Adjustment Nut until no play is

present. If the Adjustment Nut is too tight, the

Handle will not lock. Carefully read and fol-

low the complete instructions in this manual

BEFORE setup or use.

If the coupler is not secured

properly, the ball could come loose

while the trailer is in motion, possibly

causing property damage, SERIOUS

PERSONAL INJURY, or DEATH.

Visit our website at: http://www.harborfreight.com

REV 12j

Email our technical support at: tech@harborfreight.com

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-800-444-3353 as soon as possible.

No portion of this manual or any artwork contained herein may be reproduced in

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Copyright© 2003 by Harbor Freight Tools®. All rights reserved.

any shape or form without the express written consent of Harbor Freight Tools.

Tools required for assembly and service may not be included.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

CONTENTS

SPECIFICATIONS .................................................................................... 3

GENERAL SAFETY WARNINGS AND PRECAUTIONS ........................ 3

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS ..................... 4

ASSEMBLY INSTRUCTIONS .................................................................. 6

OPERATING INSTRUCTIONS ............................................................... 15

TIRE INFORMATION .............................................................................. 16

Tire Terminology Glossary ..................................................................................16

Tire Markings ........................................................................................................17

Tire Ination and Load Limit ...............................................................................18

TIRE CARE ............................................................................................. 19

Checking Tire Pressure .......................................................................................19

Steps for Maintaining Proper Tire Pressure ......................................................19

Tire Size ................................................................................................................20

Tire Tread ..............................................................................................................20

Tire Rotation .........................................................................................................20

Tire Balance and Alignment ................................................................................20

Tire Repair ............................................................................................................20

VEHICLE LOAD LIMIT ........................................................................... 21

Steps for Determining Correct Load Limit .........................................................21

INSPECTION, MAINTENANCE, AND CLEANING ................................ 21

PARTS LIST AND DIAGRAMS ............................................................... 22

Parts List ...............................................................................................................22

Assembly Diagram ...............................................................................................23

Wiring Diagram .....................................................................................................24

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 2

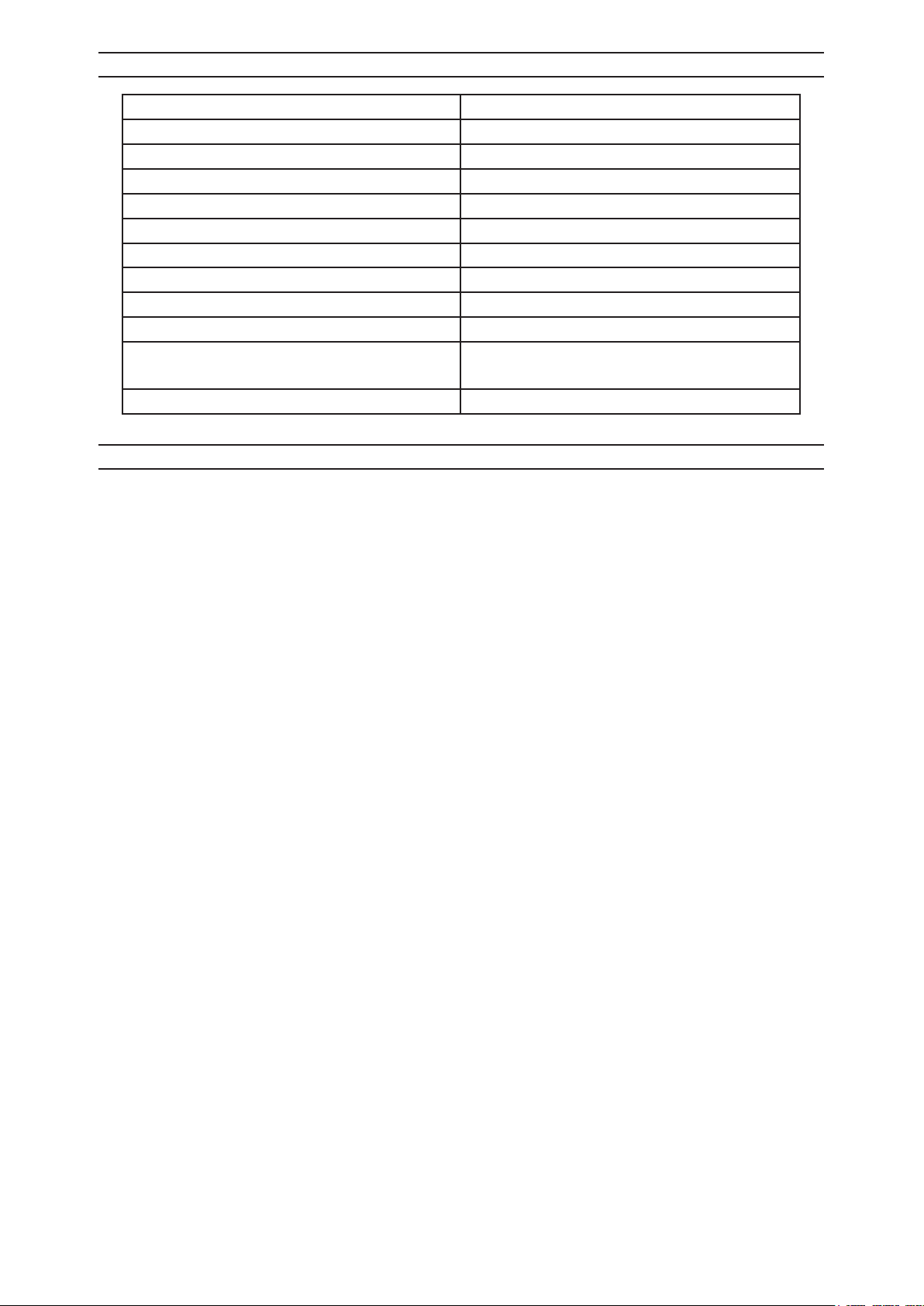

SPECIFICATIONS

Maximum Payload Capacity 1,090 lb.

GVWR 1,250 lb.

Net Weight 151 lb.

Rim Size 4.80/4.00 - 12″ w/4 Lug Nut Pattern

Tire Size 4.80 x 12, 4PR

Tire Pressure 60 PSI, cold

Hitch Ball 1-7/8″, Class I

Bed Frame 40-1/2″ x 48″

Axle Clearance 7″

Tongue Height 12-1/2″

Safety Chain 1″ Link (Welded)

7/32″ Diameter x 42″ L w/S Hooks

Lights & Wiring 12 VDC / DOT Approved

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp, or wet work areas invite

injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be stored

in a dry location to inhibit rust. Always lock up tools and equipment, and keep out

of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgement or

reexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this product.

5. USE EYE PROTECTION. Wear ANSI approved safety impact eye goggles when

assembling this product. ANSI approved safety impact eye goggles are available

from Harbor Freight Tools.

6. DRESS SAFELY. Do not wear loose clothing or jewelry, as they can become caught

in moving parts. Wear a protective hair covering to prevent long hair from becoming

caught in moving parts. If wearing a long-sleeve shirt, roll sleeves up above elbows.

7. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etc.

8. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENTS.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do not

use this product when you are tired or distracted from the job at hand.

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 3

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged parts

and any other conditions that may affect the operation of this product. Replace or

repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES: When servicing, use only identical

replacement parts. Only use accessories intended for use with this product.

Approved accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this product clean and dry for

better and safer performance.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualied technician.

14. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force small equipment

to do the work of larger industrial equipment. There are certain applications for

which this equipment was designed. It will do the job better and more safely at the

capacity for which it was intended. Do not modify this equipment, and do not use

this equipment for a purpose for which it was not intended.

15. WARNING: The warnings, precautions, and instructions discussed in this manual

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be built

into this product, but must be supplied by the operator.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. TO AVOID PERSONAL INJURY AND/OR PROPERTY DAMAGE, DO NOT

EXCEED THE TRAILER’S MAXIMUM CAPACITY PAYLOAD OF 1,090 LBS.

2. BEFORE EACH USE, ALWAYS EXAMINE THE TRAILER FOR PROPER TIRE (16)

AIR PRESSURE, DAMAGED TAIL LIGHTS (29, 29A), DAMAGED SIDE RUNNING

LIGHTS (30), LOOSE BOLTS AND NUTS, STRUCTURAL CRACKS, BENDS, AND

ANY OTHER CONDITION THAT MAY AFFECT ITS SAFE OPERATION. Do not

use the Trailer even if minor damage appears.

3. NEVER ALLOW ADULTS, CHILDREN, OR PETS TO RIDE IN THE TRAILER.

4. BEFORE EACH USE, ALWAYS ATTACH THE SAFETY CHAIN (25) OF THE

TRAILER TO THE TOWING VEHICLE. Make sure the Safety Chain is attached

to the towing vehicle with the same length for each side. Do not allow the Safety

Chain to drag on the ground.

5. ALWAYS CHECK TO MAKE SURE THE PAYLOAD BEING TRANSPORTED IS

PROPERLY AND SAFELY SECURED IN THE TRAILER. Load the Trailer evenly

from side to side with 60% of the load forward of the Axle (12).

6. MAKE SURE THE TOWING VEHICLE IS CAPABLE OF TOWING THE TRAILER

AND ITS PAYLOAD. Make sure the hitch on the towing vehicle is capable of towing

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 4

the Trailer and its payload. The towing capacity of the hitch is typically stamped

on the hitch drawbar.

7. MAKE SURE THE COUPLER (23) AND THE VEHICLE’S BALL HITCH (not

included) ARE OF EQUAL MATING SIZE (1-7/8″) AND ARE RATED EQUAL

TO OR GREATER THAN THE WEIGHT OF THE TRAILER AND ITS PAYLOAD.

8. DO NOT EXCEED 45 MILES PER HOUR WHEN TOWING THE TRAILER.

Excess speed is a major cause of vehicle-trailer accidents.

9. THE TAIL LIGHT BULBS SUPPLIED WITH THIS TRAILER ARE FOR A 12 VOLT

DC ELECTRICAL SYSTEM ONLY. Do not attempt to power the Light Bulbs with

any other type or voltage electrical current.

10. WHENEVER POSSIBLE, PARK THE TRAILER ON A FLAT, LEVEL, PAVED,

SURFACE AND CHOCK BOTH TIRES TO KEEP THE TRAILER FROM

ACCIDENTLY MOVING.

11. TRAILER LICENSING NOTICE: Some states may consider this Trailer a vehicle

requiring registration, licensing, and titling. Check with your State Department of

Motor Vehicles for information and guidance on registering, licensing, and titling

the Trailer.

12. MAINTAIN LABELS AND NAMEPLATES ON THE TRAILER. These carry

important information. If unreadable or missing, contact Harbor Freight Tools for

a replacement.

13. REPORTING SAFETY DEFECTS: If you believe your vehicle has a defect which

could cause a crash or could cause injury or death, you should immediately inform

the National Highway Trafc Safety Administration (NHTSA) in addition to notifying

the manufacturer, Changzhou Nanxiashu Tool Company. If NHTSA receives similar

complaints, it may open an investigation, and if it nds that a safety defect exists in

a group of vehicles, it may order a recall and remedy campaign. However, NHTSA

cannot become involved in individual problems between you, Harbor Freight Tools,

or the manufacturer. To contact NHTSA, you may either call the Auto Safety Hotline

toll-free at 1-800-424-9393 or 202-366-0123 or write NHTSA, U.S. Department,

400 7th Street SW NSA-11, Washington, D.C. 20590. You may also obtain other

information about motor vehicle safety from the Hotline.

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 5

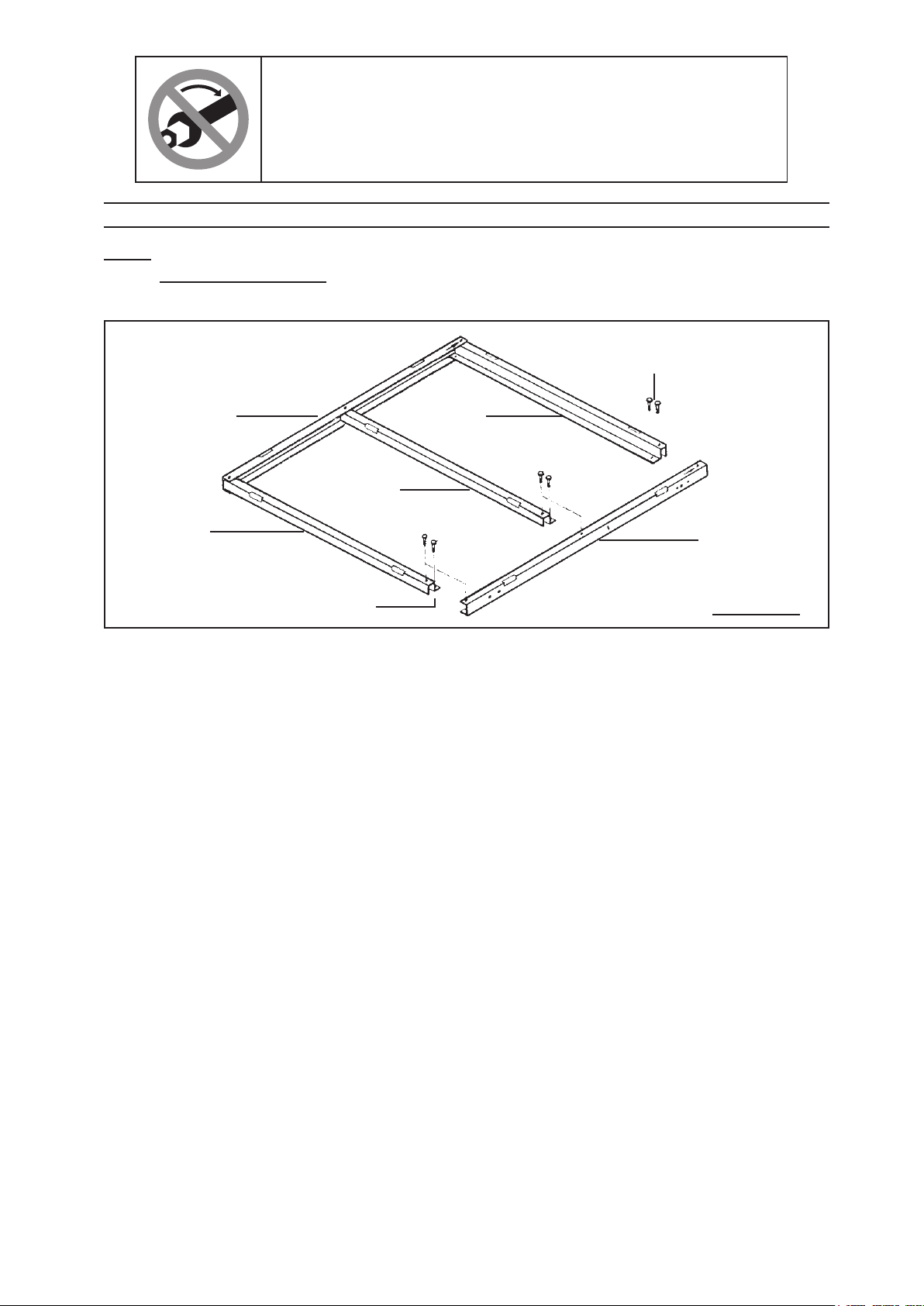

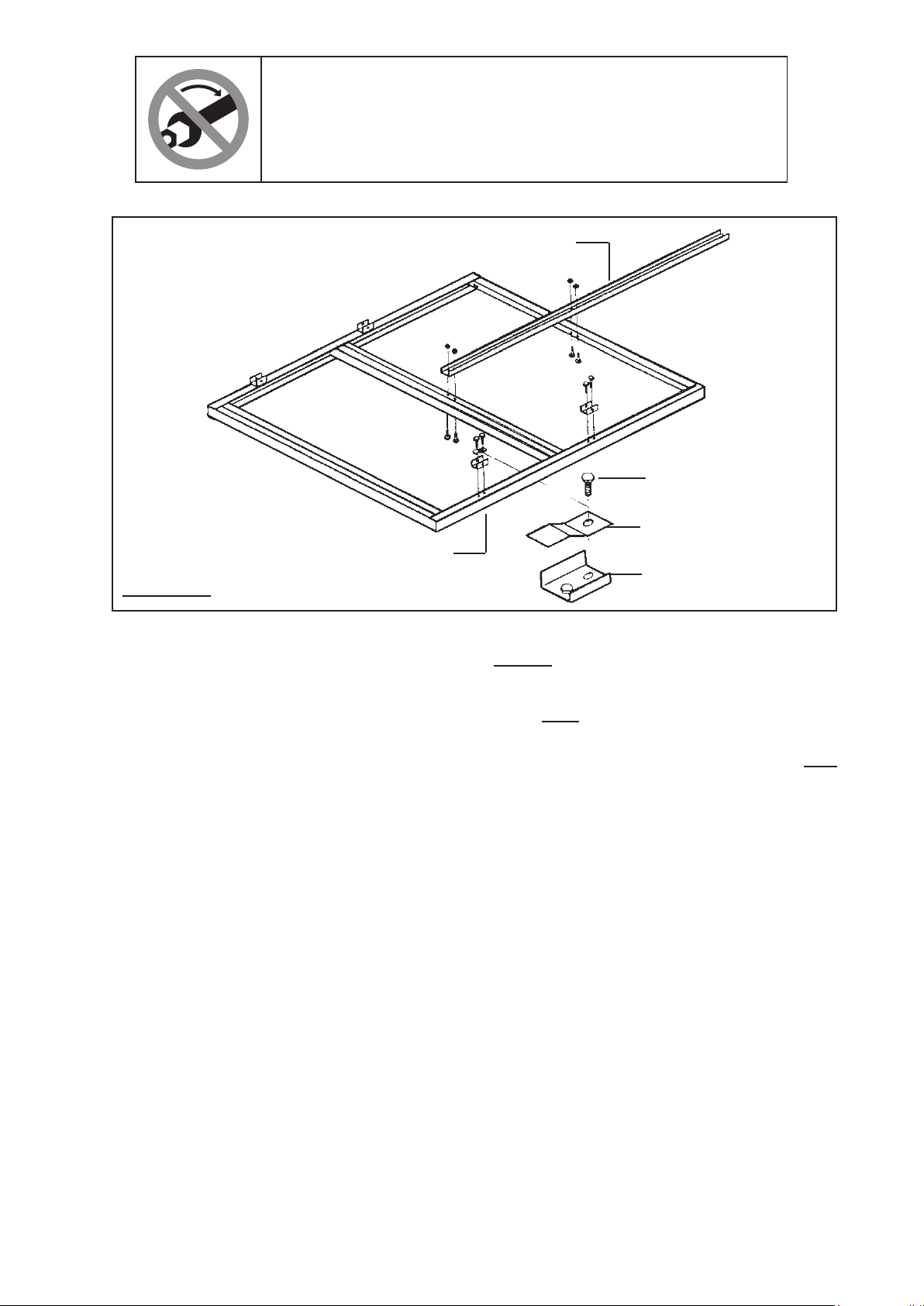

DON’T TIGHTEN YET!

TO MAKE ASSEMBLY EASIER, wait until assembly is

complete and all hardware is in place before tightening

any nut or bolt. Leave hardware snug until then.

ASSEMBLY INSTRUCTIONS

Note: For additional references to the parts listed on the following pages, refer to the

Assembly Diagram near the end of this manual. Be sure to read the Bearing

Packing instructions on the last page of this manual.

HEX BOLT

(1)

FRONT

REAR

1.

LEFT

SIDE RAIL

(5)

CROSS

MEMBER

(4)

CROSS

MEMBER

(4)

NYLON NUT (3)

(NOT SHOWN)

CROSS

MEMBER

(4)

RIGHT

SIDE RAIL

(5A)

FIGURE A

Lay out three Cross Members (4), the Right Side Rail (5A), and the Left Side Rail

(5). Then assemble the parts, using Hex Bolts (1) and Nylon Nuts (3).

(See Figure A.)

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 6

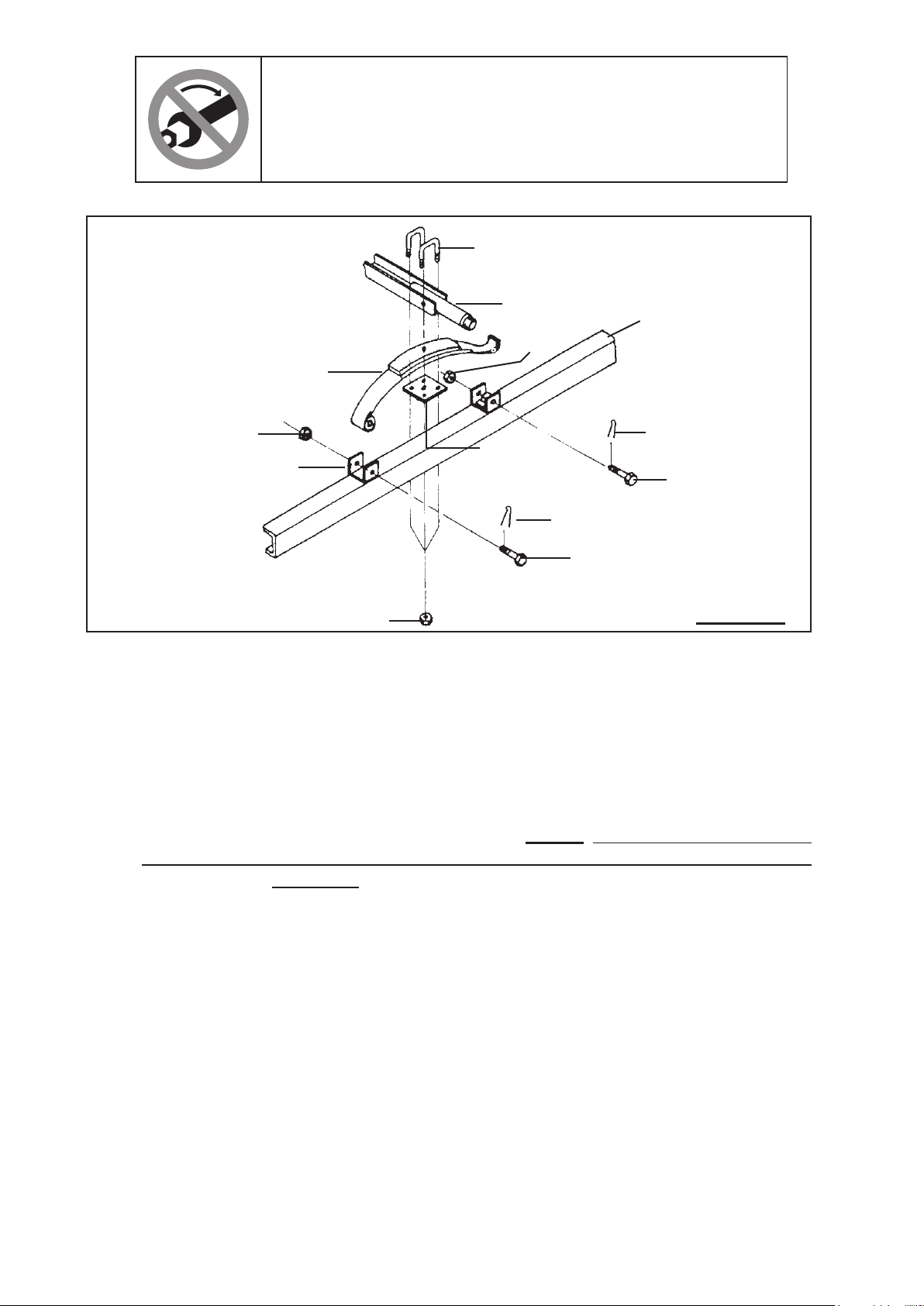

DON’T TIGHTEN YET!

TO MAKE ASSEMBLY EASIER, wait until assembly is

complete and all hardware is in place before tightening

any nut or bolt. Leave hardware snug until then.

TOW BAR

(6)

FRONT

REAR

FIGURE B

2.

Turn the frame assembly upside down. Attach the Towbar (6) to the frame assembly,

NYLON NUT (3)

(NOT SHOWN)

HEX

BOLT

(1)

SPRING SIDE PLATE (8)

SPRING

HANGER

(7)

using Hex Bolts (1) and Nylon Nuts (3). NOTE: Observe the direction in which the

Hex Bolts are inserted. (See Figure B.)

3. Attach two of the Spring Hangers (7) to the front portions of the Right Side Rail

(5A) and the Left Side Rail (5), using Hex Bolts (1) and Nylon Nuts (3). Then attach

the remaining two Spring Hangers, each with a Spring Side Plate (8), to the rear

portions of the Right Side Rail (5A) and the Left Side Rail (5), using Hex Bolts (1)

and Nylon Nuts (3). (See Figure B.)

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 7

DON’T TIGHTEN YET!

TO MAKE ASSEMBLY EASIER, wait until assembly is

complete and all hardware is in place before tightening

any nut or bolt. Leave hardware snug until then.

SLIPPER SPRING (9)

NUT (11)

SPRING HANGER (7)

FRONT

4.

Place the Slipper Springs (9) in the Spring Hangers (7). Secure the Slipper Springs

to the Spring Hangers, using Bolts (10) and Nuts (11). Then, insert a Cotter Pin

(33) through the hole in the end of the Bolts and spread it. (See Figure C.)

NYLON NUT (3)

U-BOLT (13)

AXLE (12)

NUT

(11)

SPRING

PLATE

(14)

REAR

LEFT SIDE RAIL (5)

COTTER PIN (33)

HEX BOLT (10)

COTTER PIN (33)

HEX BOLT (10)

FIGURE C

5. Place the Axle (12) on top of the Slipper Springs (9). Position a Spring Plate (14)

under the Slipper Springs. Place two U-Bolts (13) over each end of the Axle and

each Slipper Spring. Then insert the U-Bolts through the holes in the Spring Plates

and secure the Spring assembly, using Nylon Nuts (3). (See Figure C.)

6. Attach the Grease Fitting (35) to the Hub (15). NOTE: Every 2,000 to 3,000 miles

of use, make sure to lubricate the Hub assembly with a heavy duty bearing grease.

(See Figure D, next page.)

7. Carefully slide the Hubs (15) over the Spindles at each end of the Axle (12). Follow

the Bearing Packing Instructions as explained on the last page of this manual.

Insert the Bearing (18) and a 3/4″ Flat Washer (19) on the Spindles. Screw a

Castle Nut (20) tightly onto each Spindle. Then back the Castle Nuts off slightly so

that the Hubs (15) can just move freely. (See Figure D.)

Item 90153 For technical questions, please call 1-800-444-3353. PAGE 8

Loading...

Loading...