Harbor Freight Tools 62120 Product manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

REV 14g

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2014 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Email our technical support at: productsupport@harborfreight.com

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Table of Contents

Safety .......................................... 3

Specifications ............................5

Overview.....................................5

Definitions .................................. 6

Control Modules ........................6

I/M Monitors ............................... 7

Diagnostic Test Modes ..............8

Diagnostic Trouble Code ...........9

Setup - Before Use: ..................10

Operating Instructions ............. 12

Connect Scan Tool ...................12

Setup ........................................13

I/M Readiness Quick-Check ..... 17

Diagnostic Test Modes .............18

Read Trouble Codes...............19

DTC Lookup ...........................20

Erase Codes ........................... 21

View Live PID Data .................22

Record Live PID Data ............. 24

Playback Live PID Data .......... 27

View Freeze Frame Data ........28

I/M Readiness.........................28

02 Monitor Test .......................31

On-Board Monitor Test ...........32

Component Test .....................33

Vehicle Information .................32

Modules Present.....................33

Review Data ...........................34

Ready Test ..............................34

Print Data................................35

Install/Update Software ..........35

About .........................................36

Maintenance .............................. 37

Troubleshooting .......................38

Parts List ...................................39

Warranty ....................................40

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Page 2 For technical questions, please call 1-888-866-5797. Item 62120

Important Safety Information

Work Area Safety

1. Keep your work area clean and well lit.

Cluttered benches and dark

areas may cause accidents.

2. Do not connect or disconnect the

Scan Tool while the ignition is

on or the engine is running.

3. DO NOT attempt to operate

the Scan Tool while driving

the vehicle. Have a passenger

operate the Scan Tool.

4. Before testing a vehicle, engage the

parking brake and chock the tires.

5. NEVER smoke or allow a spark or

flame in vicinity of battery or engine.

6. Operate the vehicle in a well ventilated

work area.

Exhaust gases are poisonous.

7. Do not operate the Scan Tool

in explosive atmospheres, such

as in the presence of flammable

liquids, gases, or heavy dust.

8. Keep a fire extinguisher suitable for

gasoline/chemical/electrical fires nearby.

9. Use extreme caution when working

around the ignition coil, distributor

cap, ignition wires and spark plugs.

These components create hazardous

voltages when the engine is running.

10. Keep bystanders, children and visitors

away while operating the Scan Tool.

11. This product is not a toy. Do not allow

children to play with or near this item.

12. Use as intended only.

13. Inspect before every use; do not use

if parts are loose or damaged.

14. Do not place the Scan Tool

on any unstable surface.

15. Handle the Scan Tool with care. If

the Scan Tool is dropped, check for

breakage and any other conditions

that may affect its operation.

16. Keep the Scan Tool dry, clean,

free from oil, water or grease.

Use a mild detergent on a clean

cloth to clean the outside of the

Scan Tool, when necessary.

17. Store the Scan Tool and

accessories in a locked area

out of the reach of children.

18. Maintain product labels and

nameplates. These carry

important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

Electrical Safety

1. Do not use the Scan Tool

while standing in water.

2. Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators.

3. Do not expose the Scan Tool to rain or

wet conditions.

Water entering the Scan Tool

increases the risk of electric shock.

4. Make sure your hands are dry

before operating the Scan Tool.

Page 3For technical questions, please call 1-888-866-5797.Item 62120

Personal Safety

1. Wear ANSI-approved safety

goggles during use.

2. Do not wear loose clothing or jewelry.

Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

3. Do not use the Scan Tool while tired or

under the influence of drugs, alcohol, or

medications. A moment of interruption

can result in serious personal injury.

4. People with pacemakers should

consult their physician(s) before

use. Electromagnetic fields in close

proximity to heart pacemaker could

cause pacemaker interference

or pacemaker failure.

5. WARNING: The cord of this product

contains lead, a chemical known

to the State of California to cause

cancer, and birth defects or other

reproductive harm. Wash hands

after handling. (California Health &

Safety Code § 25249.5, et seq.)

6. WARNING: This product contains

lead, a chemical known to the State

of California to cause cancer and

birth defects or other reproductive

harm. (California Health &

Safety Code § 25249.5, et seq.)

7. The warnings, precautions, and

instructions discussed in this instruction

manual cannot cover all possible

conditions and situations that may

occur. It must be understood by the

operator that common sense and

caution are factors which cannot

be built into this product, but must

be supplied by the operator.

Service

There are no user serviceable parts. Scan Tool service must

be performed only by qualified repair personnel.

Page 4 For technical questions, please call 1-888-866-5797. Item 62120

Specifications

Display Screen TFT Color (320 x 240)

Operating Temperature 32°F to 140°F

Storage Temperature -4°F to 158°F

Power 8V to 18V power provided by vehicle battery

Overview

OBD II On-Board Diagnostics

It is required by the EPA that all 1996 and

newer vehicles sold in the United States be

equipped with an OBD II computer system.

OBD II is an early warning system

designed to monitor engine, transmission,

and emissions control components by

performing specific diagnostic tests.

When a fault condition is detected, the

system captures important data and

activates the “Check Engine” light.

Vehicle Coverage

This Scan Tool is designed to work with

all OBD II compliant vehicles, including

those equipped with a CAN bus.

OBD II was installed in some 1994 and

1995 model year gasoline vehicles.

If the light comes on, the vehicle might have

a condition that wastes fuel, shortens engine

life, or causes excessive air pollution. If

the problem that caused the light to come

on is addressed, for instance a loose gas

cap is tightened, the light will go out.

If the light comes on and stays on, a minor

engine fault condition is occurring and

should be addressed as soon as possible

If the light is blinking, a severe engine

fault condition is occurring and should

be addressed immediately.

The Scan Tool connects to the vehicle’s

computer system and captures information

that can help identify the fault condition.

To verify if a 1994 or 1995 vehicle is

OBD II compliant, check the Vehicle

Emissions Control Information label, which

is located in the engine compartment.

Page 5For technical questions, please call 1-888-866-5797.Item 62120

Definitions

• EOBD: European On-Board

Diagnostics

Essentially the same as OBD II, with

the same Data Link Connector and

Communication Protocols.

• Communication Protocol: Allows

different systems and sensors in a

vehicle to communicate.

There are currently five Protocols:

CAN Bus

J1850 VPW

ISO 9141-2

J1850 PWM

ISO 14230 KWP

• CAN: Controller Area Network

Message-based Communication

Protocol serial bus.

• CAN Vehicle

2008 and newer.

• Pre-CAN Vehicle

2007 and older.

• DLC: Data Link Connector

The 16-cavity connector on the vehicle

that allows communication between the

computer system and the Scan Tool.

• Drive Cycle

A set of driving procedures that,

when met, provide the Enabling

Criteria for the I/M Monitors to run

and complete their diagnostic tests.

• Enabling Criteria

Operating conditions that must

occur during a Drive Cycle to

cause the I/M Monitors to run and

complete their diagnostic tests.

• MIL: Malfunction Indicator Lamp

The vehicle’s “Check Engine”

warning light that activates

when a DTC is stored.

• DTC: Diagnostic Trouble Code

A code stored in the computer

system’s memory, which helps to

identify the fault condition that is

causing the MIL to activate.

• Freeze Frame Data

Operating conditions that are

stored when a DTC is stored.

• PID - Parameter Identification Data

Data returned by the vehicle’s

Control Modules to the Scan Tool.

Control Modules

Control Modules are individual computers that operate and monitor different

systems in the vehicle. Control Modules vary depending on manufacturer.

ID codes are assigned to each Control Module, which are

defined by the vehicle’s Communication Protocol.

For example, a vehicle may use ID code $7E8 for the PCM and $7E9 for the TCM.

Control Module Control Module Definition

PCM/ECU Powertrain Control Module/Engine Control Unit

TCM Transmission Control Module

Figure A: Common Control Modules

Page 6 For technical questions, please call 1-888-866-5797. Item 62120

I/M Monitors

Inspection and Maintenance diagnostic tests that the Control Modules

perform on specific sub-systems of the vehicle.

There are two types of Monitors:

• Continuous: Monitors that

perform tests all the time while

the engine is running.

Gasoline Engine Monitors

Continuous

MIS - Misfire

FUEL - Fuel System

CCM - Comprehensive Components

Diesel Engine Monitors

• Non-Continuous: Monitors that require

specific operating conditions to be met

during a Drive Cycle in order for the

Monitors to run their testing sequences.

Note: Not all Monitors are

supported by all vehicles.

Non-Continuous

CAT - Catalyst

HCAT - Heated Catalyst

EVAP - Evaporative System

AIR - Secondary Air System

O2S - Oxygen Sensors

HTR - Oxygen Sensor Heater

EGR - EGR System

Continuous

MIS - Misfire

FUEL - Fuel System

CCM - Comprehensive Components

Non-Continuous

HCCAT - NMHC Catalyst

NCAT - NOx Aftertreatment

BP - Boost Pressure System

EGS - Exhaust Gas Sensor

PM - PM Filter

EGR - EGR System

Page 7For technical questions, please call 1-888-866-5797.Item 62120

Diagnostic Test Modes

Diagnostic Test Modes as described in the latest OBD II standard SAE J1979.

Note: Not all Modes are

supported by all vehicles.

$01 - Request Current Powertrain

Diagnostic Data

$02 - Request Powertrain

Freeze Frame Data

$03 - Request Emission-Related

Stored DTCs

$04 - Clear/Reset Emission-Related

Diagnostic Information

$05 - Request Oxygen Sensor Monitoring

Test Results (2007 and older vehicles only)

$06 - Request On-Board Monitoring Test

Results for Specific Monitored Systems

$07 - Request Emission-Related

Stored DTCs Detected During Current

or Last Completed Driving Cycle

$08 - Request Control of On-Board

System, Test or Component

$09 - Request Vehicle Information

$0A - Request Emission-Related

Permanent DTCs

Page 8 For technical questions, please call 1-888-866-5797. Item 62120

Diagnostic Trouble Code

A five digit alphanumeric identifier for a fault condition identified

by the OBD II system. There are three types of DTCs:

1. Pending - When a fault condition

is identified during a Drive Cycle,

but does not meet enough

criteria to activate the MIL.

If the fault condition occurs during two

consecutive Drive Cycles, it will turn into

a Stored DTC and the MIL will activate.

2. Stored - A DTC is stored when a fault

condition has occurred that meets

enough criteria to activate the MIL.

3. Permanent - A stored DTC that can only

be cleared by the OBD II system, after

repairs are made, and a set number of

Driving Cycles have been completed.

Example: P0303 - Cylinder 3 Misfire

Systems

B - Body

C - Chassis

P - Powertrain

U - Network

Code Types*

0 - Generic

1 - Manufacturer Specific

2 - Generic Powertrain/Manufacturer Specific

3 - Generic Powertrain/Manufacturer Specific

Sub-Systems

1 - Fuel and Air Metering

2 - Fuel and Air Metering

(injector circuit malfunction only)

3 - Ignition Malfunction or Engine Misfire

4 - Auxiliary Emission Controls

5 - Vehicle Speed or Idle Controls

6 - Computer Output Circuits

7 - Transmission Controls

8 - Transmission Controls

03 - Cylinder 3

P 0 3 0 3

*The Scan Tool supports the following Code Types:

Generic (SAE):

B0, B3

C0, C3

P0, P2, P34-P39

U0, U3

Manufacturer Specific:

B1, B2

C1, C2

P1, P30-P33

U1, U2

Figure B

Page 9For technical questions, please call 1-888-866-5797.Item 62120

Setup - Before Use:

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this document including all text under subheadings therein

before set up or use.

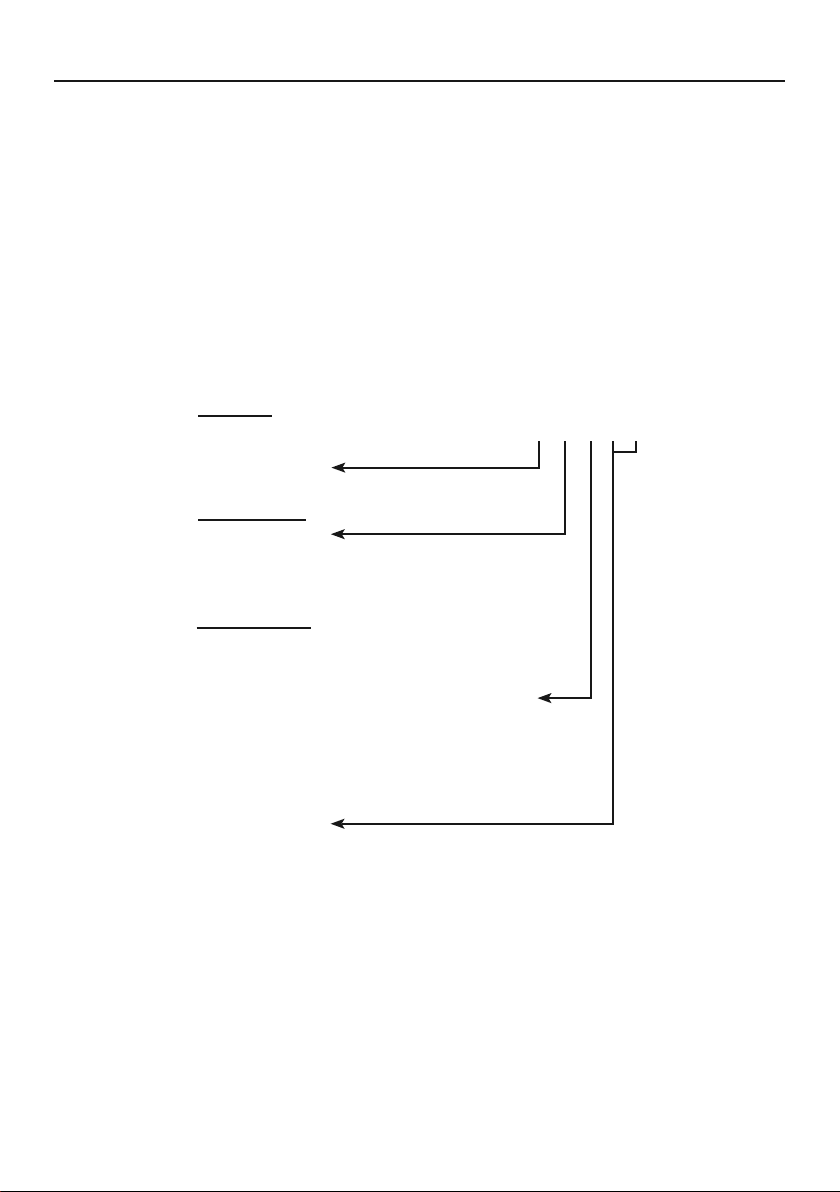

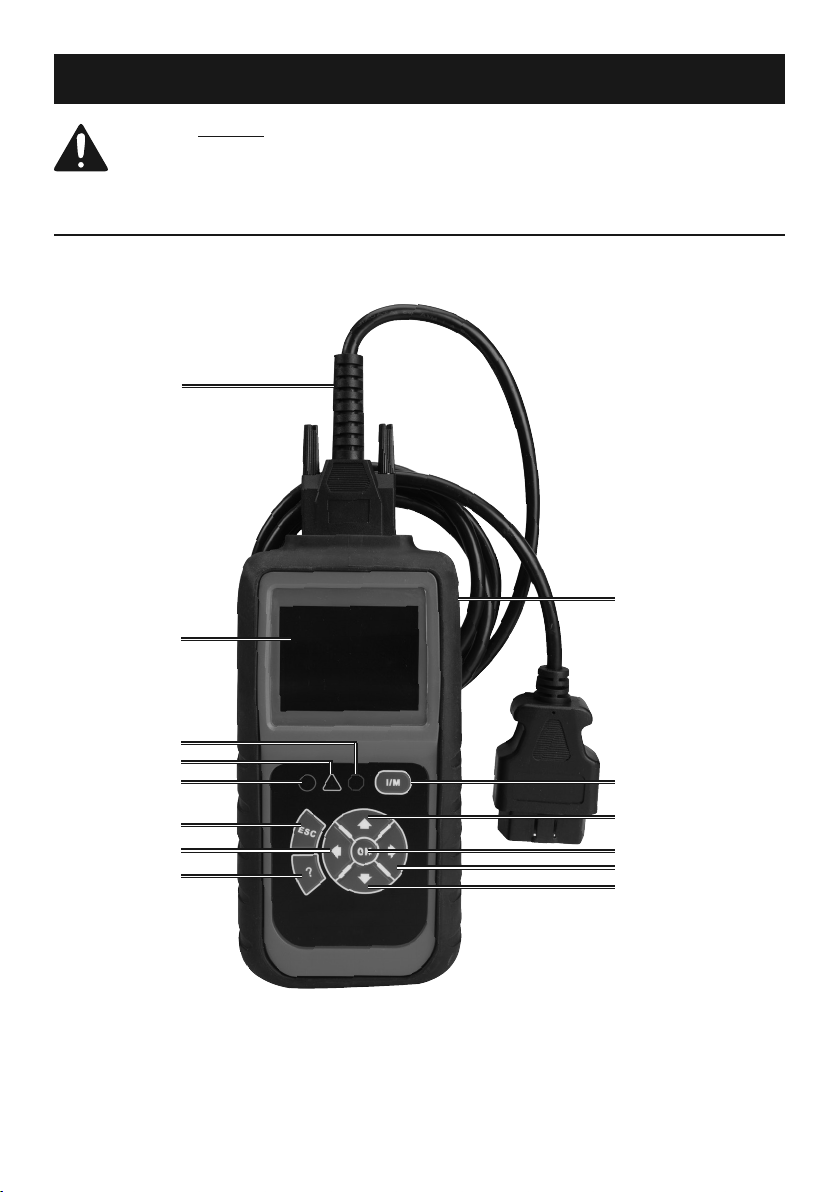

Functions

1

2

9

(located

on side)

3

4

5

6

7

8

Figure C

Page 10 For technical questions, please call 1-888-866-5797. Item 62120

10

11

12

13

14

1. OBD II Cable

Connects the Scan Tool to

the vehicle’s DLC.

2. LCD Screen

3. Red LED !

Indicates there is a fault condition

in one of the vehicle’s systems

and stored DTCs are present.

8. Help Button ?

View detailed information, if available.

9. USB Connector

Connects the Scan Tool to a PC for

updating software and printing.

10. I/M Button I/M

Quick-checks emissions test readiness

and Drive Cycle verification.

4. Yellow LED !

Indicates there are pending DTCs

and/or there are Monitors that

have not finishing running.

5. Green LED √

Indicates that engine systems

are running normally and no

pending DTCs are present.

6. Cancel/Go Back ESC

Cancels a selection from a menu or

returns to the previous screen.

7. Left Button

Moves to previous screen if information

covers more than one screen.

11. Up Button

Moves up through menu and submenus.

Moves to previous screen if information

covers more than one screen.

12. Select Button OK

Confirms a selection.

13. Right Button

Moves to next screen if information

covers more than one screen.

14. Down Button

Moves down through menu and

submenus.

Moves to next screen if information

covers more than one screen.

Page 11For technical questions, please call 1-888-866-5797.Item 62120

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this document including all text under subheadings therein

before set up or use of this product.

TO PREVENT SERIOUS INJURY AND DEATH:

Exhaust gases are poisonous. Operate the vehicle in a well ventilated work area.

Wear ANSI-approved safety goggles during use.

Connect Scan Tool

CAUTION: Do not connect or disconnect

the Scan Tool while the ignition

is on or the engine is running.

Note: The Scan Tool is powered

by the vehicle’s battery.

1. Turn the engine and ignition OFF.

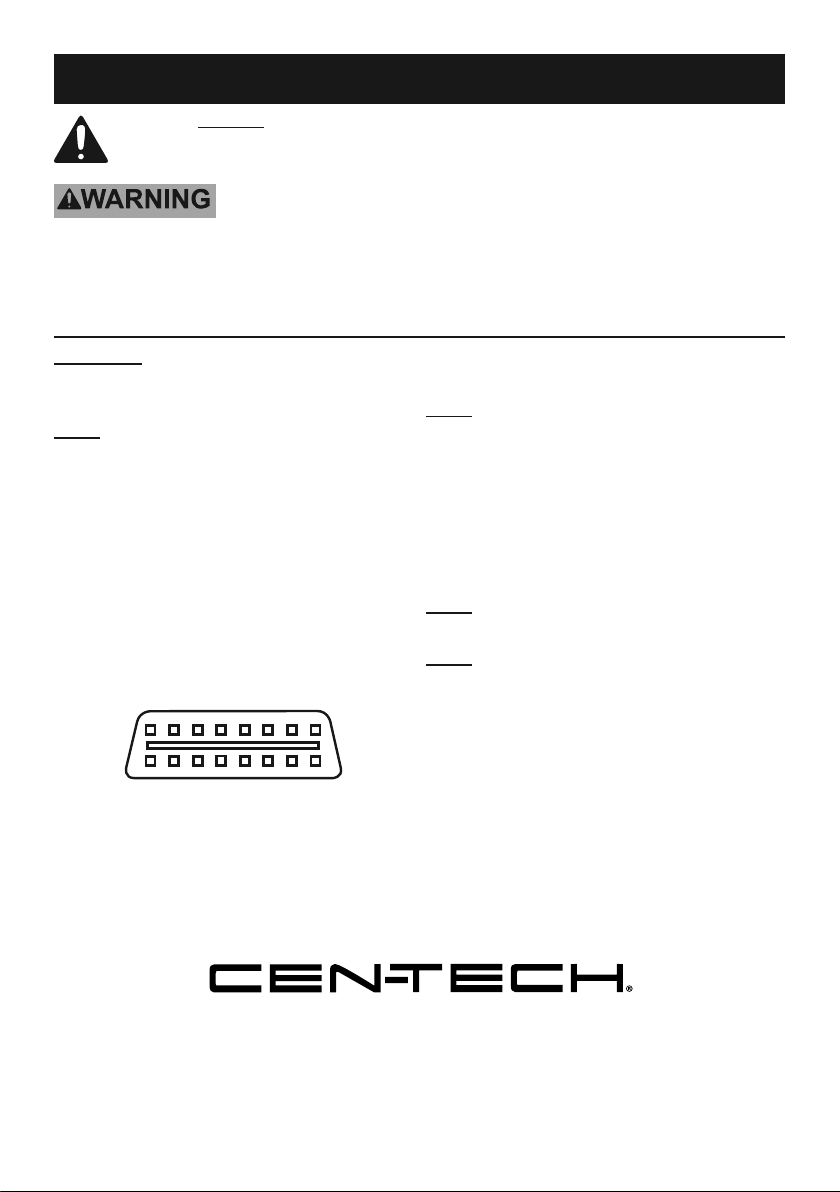

2. Connect the OBD II Cable

to the Scan Tool.

3. Connect the other end of the

Cable to the 16-cavity DLC.

The DLC is normally located under

the dashboard on the driver’s

side. (Refer to vehicle’s owner’s

manual for location of DLC.)

Figure D: DLC

4. Turn the vehicle’s ignition ON

with the engine OFF.

Note: If Linking Error! message displays:

• Press the ESC button

• Verify the ignition is ON

• Verify the vehicle is OBD II compliant

5. If the message does not go away,

have the Scan Tool inspected

by a qualified technician.

Note: To quick-check Emissions

Test Readiness, see page 17.

Note: To read Diagnostic Trouble

Codes, see page 19.

Page 12 For technical questions, please call 1-888-866-5797. Item 62120

Loading...

Loading...