Harbor Freight Tools 62114 Product manual

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INFORMATION

Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in serious injury.

Save all warnings and instructions for future reference.

The warnings and precautions discussed in this manual cannot cover all

possible conditions and situations that may occur. It must be understood

by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator.

Work area

1. Turn off the engine,

set the parking brake, and block the

tires before working on a vehicle.

2. Keep the work area clean and

well lighted. Cluttered benches

and dark areas increase the

risk of injury to persons.

Page 2 For technical questions, please call 1-888-866-5797. Items 62114

3. Keep bystanders and children away

while operating the tool. Distractions

can result in loss of control of the tool.

Personal safety

1. Stay alert. Watch what you

are doing and use common

sense when operating the tool.

Do not use the tool while tired

or under the influence of drugs,

alcohol, or medication. A moment

of inattention while operating the tool

increases the risk of injury to persons.

Tool use and care

1. Do not force the tool. Use the correct

tool for the application. The correct

tool will do the job better and safer at

the rate for which the tool is designed.

2. Store the tool when it is idle out of

reach of children and other untrained

persons. A tool is dangerous in

the hands of untrained users.

3. Check for misalignment or binding

of moving parts, breakage of

parts, and any other condition

that affects the tool’s operation.

If damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

4. Use only accessories that are

identified by the manufacturer

for the specific tool model.

Use of an accessory not intended

for use with the specific tool model,

increases the risk of injury to persons.

2. Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep hair, clothing, and gloves

away from moving parts.

Loose clothes, jewelry, or long hair

increases the risk of injury to persons as

a result of being caught in moving parts.

3. Use safety equipment.

Wear ANSI-approved safety goggles

and heavy-duty work gloves during use.

5. Avoid off-center loads. If the

Pump seems unusually hard to

operate, immediately stop. Adjust the

Ram to eliminate or diminish

an off-center load. The Ram Toe

and Plunger Toe must only be used

together to prevent an off-center load.

6. Protect the Hose. Do not drop

heavy objects on the Hose.

Avoid kinks in the Hose.

Maintain proper clearance to avoid

damage to the Hose and Couplers.

7. Inspect repair before using vehicle.

Repairs to structural or frame members

must be inspected by a qualified

technician to ensure that the

structure is still strong enough

to safely fulfill its function.

Service

1. Tool service must be performed

only by qualified repair personnel.

SAVE THESE INSTRUCTIONS.

2. When servicing a tool, use only

identical replacement parts.

Use only authorized parts.

Page 3For technical questions, please call 1-888-866-5797.Items 62114

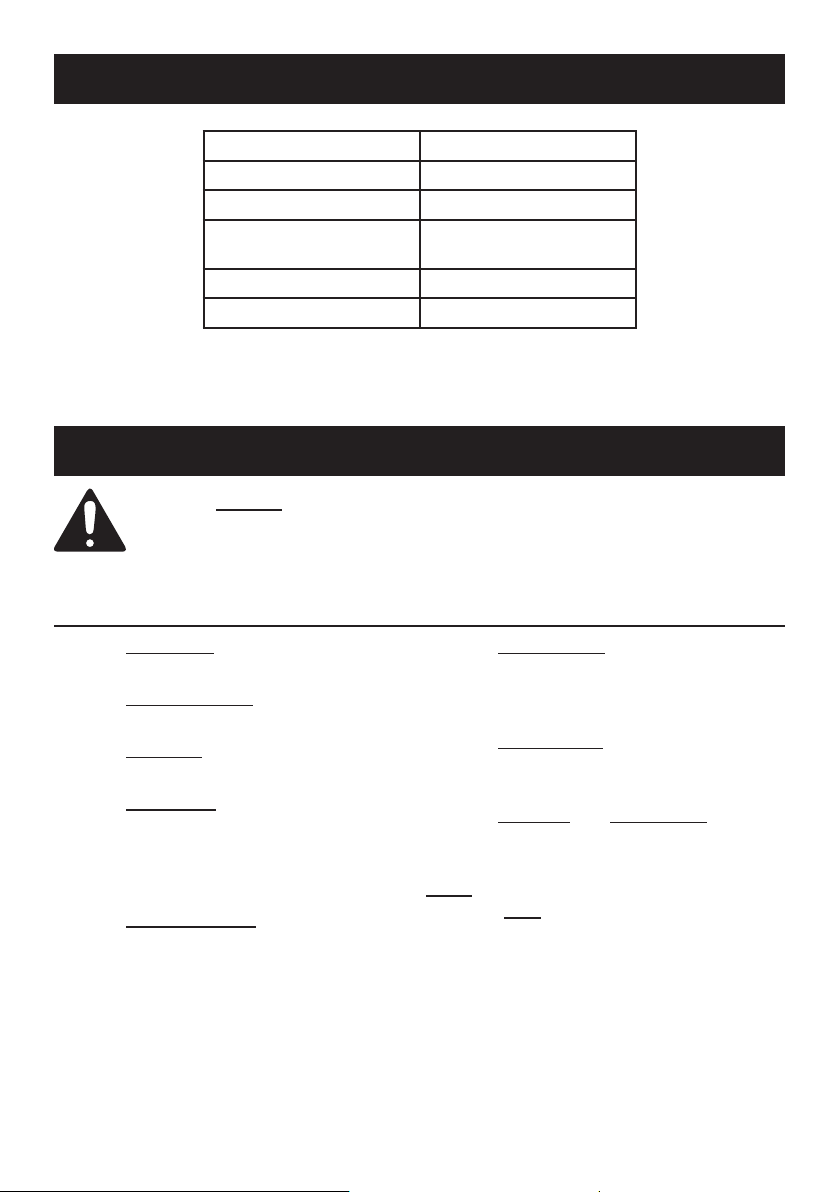

Specifications

Ram Capacity 10 Tons

Ram Travel 5"

Extension Tubes

Spreader Capacity

Hose Length 5'

Setup

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this document including all text under subheadings therein

before set up or use of this product.

Ram Attachments

Model 62114

4-3/8", 10-3/8" (2),

14-3/8", 20-1/2"

1

⁄2 Ton

1. The Extensions connect in different

combinations to reach desired lengths.

2. The Male Connector is used to connect

the female end of the Ram to a Base.

3. The Flat Base is used on the stationary

side to spread out the force of the Ram.

4. The 90° V Base is used to offset the

force of the Ram when there is not a

straight line between the stationary

side and the damaged side, or

to spread out force on curved surfaces.

5. The Serrated Saddle is used on the

pushing end to prevent slipping.

Page 4 For technical questions, please call 1-888-866-5797. Items 62114

6. The Rubber Head is used for popping

dents out of sheet metal such as

doors or body panels and to minimize

damage to the work surface.

7. The Wedge Head is used to repair

small dents and areas located

in angles and tight spaces.

8. The Ram Toe and Plunger Toe are

used together to allow spreading in

areas that the Ram cannot fit into.

Note: The Ram Toe and Plunger

Toe must only be used together

to prevent an off-center load.

Loading...

Loading...