Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the manual

near the assembly diagram (or month and year of purchase if product has no number). Keep this manual and

the receipt in a safe and dry place for future reference.

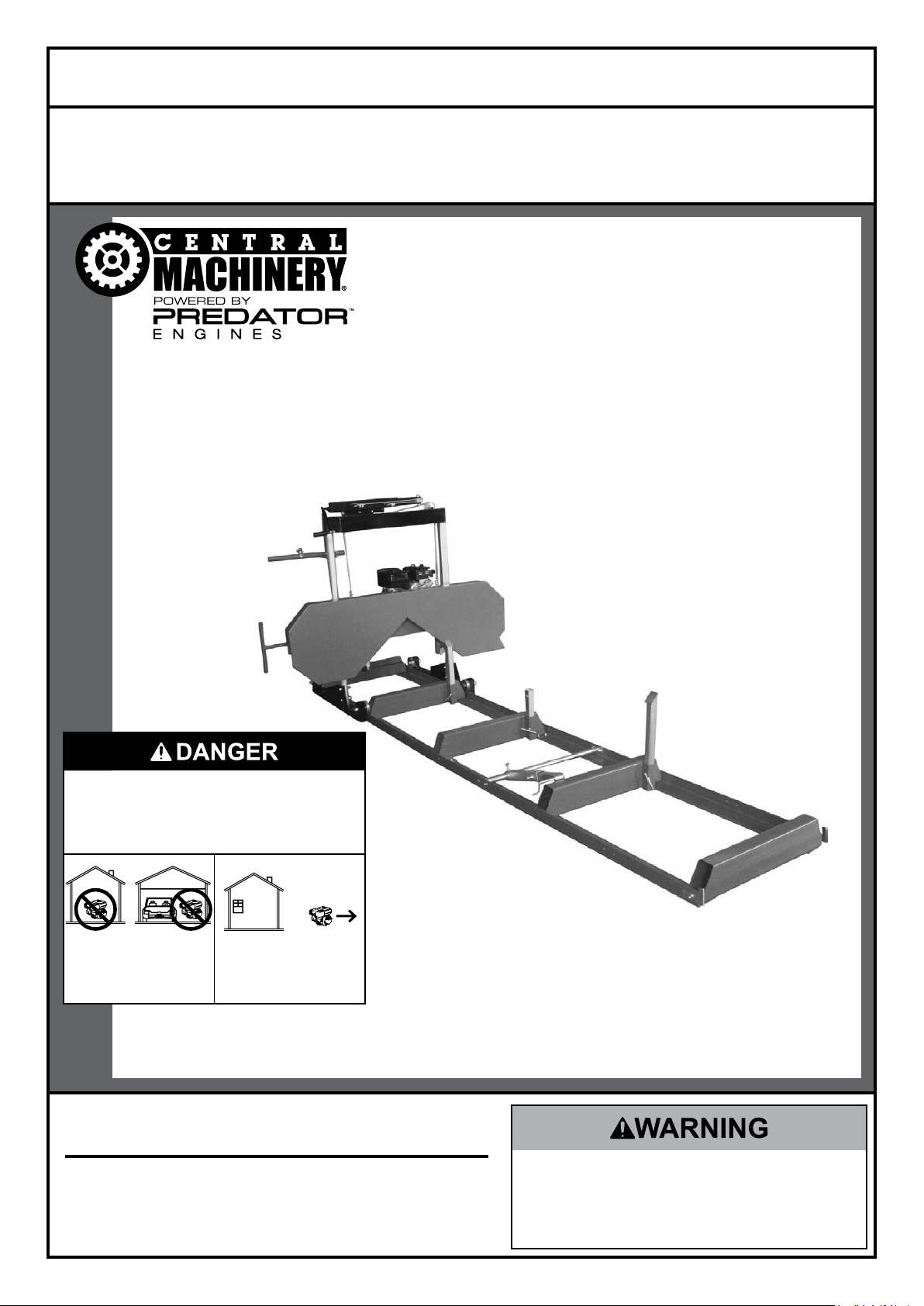

280cc

Saw Mill

Using an engine indoors

CAN KILL YOU IN MINUTES.

Engine exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside

a home or garage,

EVEN IF doors and

windows are open.

When unpacking, make sure that the product is intact and undamaged.

If any engine parts are missing or broken,

please call 1-800-520-0882 (engine parts) or

1-800-444-3353 (other parts) as soon as possible.

Copyright© 2013 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Only use OUTSIDE

and far away from

windows, doors,

and vents.

Visit our website at: http://www.harborfreight.com

Email our technical support at: tech@harborfreight.com

or engine technical support at: predator@harborfreight.com

ITEM 61712

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Table of Contents

Safety ......................................................... 3

Specications ............................................. 6

Assembly .................................................... 6

SAFETY OPERATION MAINTENANCEASSEMBLY

Operation ................................................... 10

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Maintenance .............................................. 12

Parts List and Diagrams ............................ 14

Warranty .................................................... 19

WARNING SYMBOLS AND DEFINITIONS

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Page 2 For technical questions, please call 1-800-520-0882. ITEM 61712

IMPORTANT SAFETY INFORMATION

WARNING! Read all instructions.

Failure to follow all instructions listed below may result in re, serious injury and/or DEATH.

The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Set Up Precautions

SAFETYOPERATIONMAINTENANCE ASSEMBLY

1. Gasoline fuel and fumes are ammable, and

potentially explosive. Use proper fuel storage

and handling procedures. Do not store fuel

or other ammable materials nearby.

2. Have multiple ABC class re extinguishers nearby.

3. Operation of this equipment may create sparks that

can start res around dry vegetation.

A spark arrestor may be required.

The operator should contact local re

Engine Precautions

Follow engine precautions and instructions in

the included engine instruction manual.

Operating Precautions

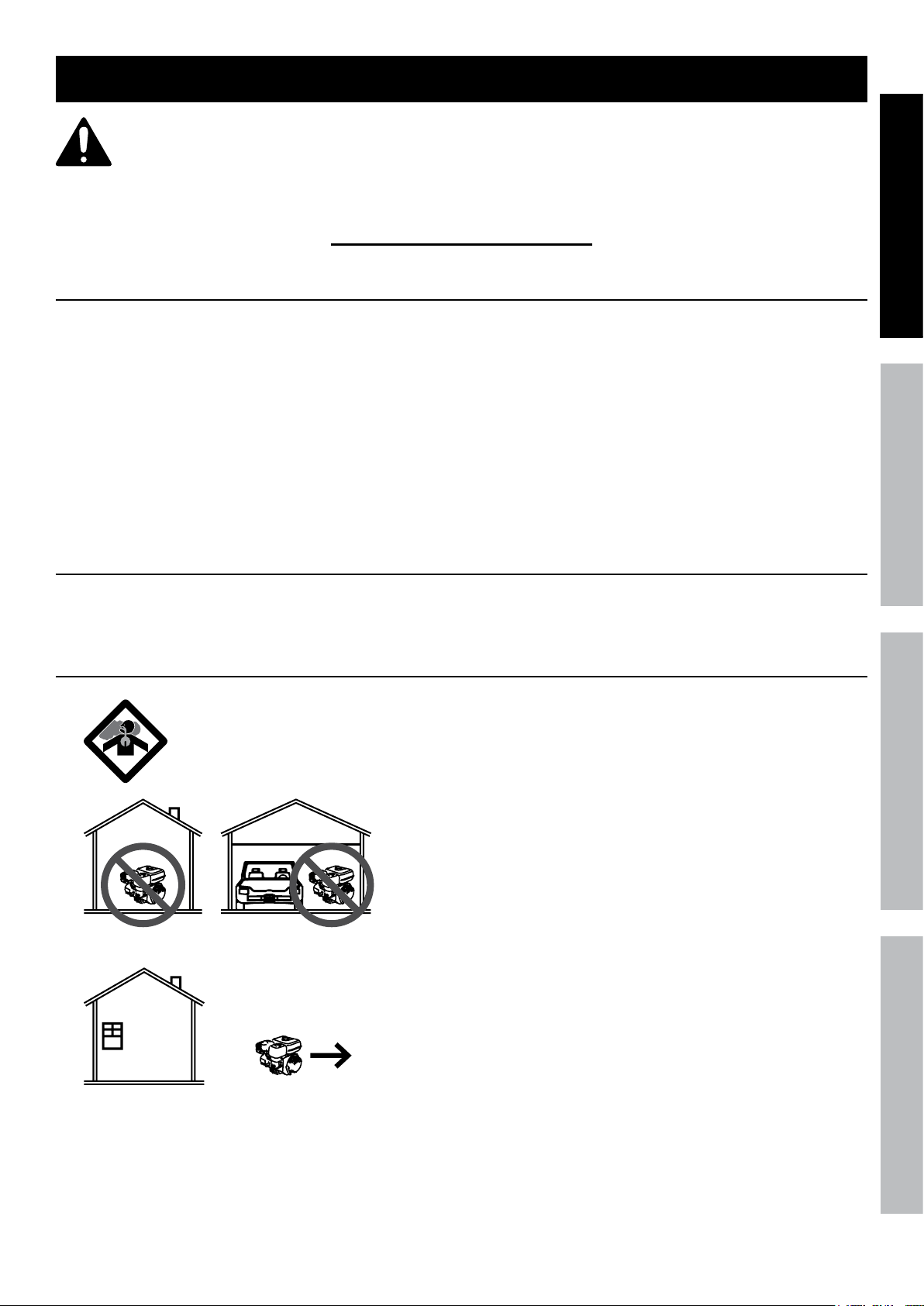

1. CARBON MONOXIDE HAZARD

Using an engine indoors CAN KILL

YOU IN MINUTES.

Engine exhaust contains carbon

monoxide. This is a poison you cannot

see or smell.

agencies for laws or regulations relating

to re prevention requirements.

4. Set up and use only on a at, level,

well-ventilated surface.

5. Wear ANSI-approved safety goggles, heavy-duty

work gloves, and dust mask/respirator during set up.

6. Use only lubricants and fuel recommended

in the engine manual or in the

Specications chart of this manual.

2. Keep children away from the equipment,

especially while it is operating.

3. Do not leave the equipment unattended when it is

running. Turn off the equipment (and remove safety

keys, if available) before leaving the work area.

NEVER use inside a home or garage,

EVEN IF doors and windows are open.

Only use OUTSIDE and far away from windows,

doors, and vents.

4. Wear ANSI-approved safety glasses, hearing

protection, and NIOSH-approved dust mask/

respirator under a full face shield during use.

5. Wear heavy-duty work gloves

when handling the blade.

6. People with pacemakers should consult their

physician(s) before use. Electromagnetic

elds in close proximity to a heart pacemaker

could cause pacemaker interference or

pacemaker failure. Caution is necessary when

near the engine's magneto or recoil starter.

7. Use only accessories that are recommended

by Harbor Freight Tools for your model.

Accessories that may be suitable for one

piece of equipment may become hazardous

when used on another piece of equipment.

Page 3For technical questions, please call 1-800-520-0882.ITEM 61712

8. Do not operate in explosive atmospheres,

such as in the presence of ammable

liquids, gases, or dust. Gasoline-powered

engines may ignite the dust or fumes.

9. Stay alert, watch what you are doing and

SAFETY OPERATION MAINTENANCEASSEMBLY

use common sense when operating this

piece of equipment. Do not use this piece of

equipment while tired or under the inuence

of drugs, alcohol or medication.

10. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the equipment in unexpected situations.

11. Dress properly. Do not wear loose clothing

or jewelry. Keep hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

18. WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities, contains chemicals known [to the State

of California] to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement or

other masonry products

• Arsenic and chromium from

chemically treated lumber

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to lter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

12. Parts, especially exhaust system components,

get very hot during use. Stay clear of hot parts.

13. Do not cover the engine or

equipment during operation.

14. Keep the equipment, engine, and

surrounding area clean at all times.

15. Use the equipment, accessories, etc., in accordance

with these instructions and in the manner intended for

the particular type of equipment, taking into account

the working conditions and the work to be performed.

Use of the equipment for operations different from

those intended could result in a hazardous situation.

16. Do not operate the equipment with known

leaks in the engine's fuel system.

17. WARNING: The brass components of

this product contain lead, a chemical

known to the State of California to cause

birth defects (or other reproductive harm).

(California Health & Safety code § 25249.5, et seq.)

19. This product contains or, when used, produces a

chemical known to the State of California to cause

cancer and birth defects or other reproductive harm.

(California Health & Safety Code § 25249.5, et seq.)

20. When spills of fuel or oil occur, they must be

cleaned up immediately. Dispose of uids and

cleaning materials as per any local, state, or

federal codes and regulations. Store oil rags in

a bottom-ventilated, covered, metal container.

21. Keep hands and feet away from moving parts.

Do not reach over or across

equipment while operating.

22. Before use, check for misalignment or binding

of moving parts, breakage of parts, and any

other condition that may affect the equipment's

operation. If damaged, have the equipment

serviced before using. Many accidents are

caused by poorly maintained equipment.

23. Use the correct equipment for the application.

Do not modify the equipment and do not use the

equipment for a purpose for which it is not intended.

Page 4 For technical questions, please call 1-800-520-0882. ITEM 61712

Service Precautions

1. Before service, maintenance, or cleaning:

a. Turn the engine switch to its “OFF” position.

b. Allow the engine to completely cool.

c. Then, remove the spark plug wire(s)

from the spark plug(s).

2. Keep all safety guards in place and in

proper working order. Safety guards include

mufer, air cleaner, mechanical guards,

and heat shields, among other guards.

3. Do not alter or adjust any part of the

equipment or its engine that is sealed by the

manufacturer or distributor. Only a qualied

service technician may adjust parts that may

increase or decrease governed engine speed.

4. Wear ANSI-approved safety goggles, heavy-duty

work gloves, and dust mask/respirator during service.

5. Maintain labels and nameplates on the equipment.

These carry important information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

6. Have the equipment serviced by a qualied repair

person using only identical replacement parts.

This will ensure that the safety of the equipment

is maintained. Do not attempt any service or

maintenance procedures not explained in this

manual or any procedures that you are uncertain

about your ability to perform safely or correctly.

7. Store equipment out of the reach of children.

8. Follow scheduled engine and

equipment maintenance.

9. Refueling:

a. Do not smoke, or allow sparks, ames,

or other sources of ignition around the

equipment, especially when refuelling.

b. Do not rell the fuel tank while the

engine is running or hot.

c. Do not ll fuel tank to the top. Leave a little

room for the fuel to expand as needed.

d. Refuel in a well-ventilated area only.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

SAVE THESE INSTRUCTIONS.

Page 5For technical questions, please call 1-800-520-0882.ITEM 61712

Specications

Log Diameter 20″ Maximum

Board Width 20″ Maximum

Cutting Thickness 4-1/2″ Maximum

Cutting Length 9′-2″ Maximum (110″)

Note: Engine specications are found in the

engine manual supplied with this equipment.

SAFETY OPERATION MAINTENANCEASSEMBLY

Fuel

Type

Capacity 1 Gallon

Coolant Tank Capacity 4.2 Quarts

Blade Speed 3,279 FPM

87+ octane unleaded

gasoline

Assembly

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

TO PREVENT SERIOUS INJURY:

Operate only with proper spark arrestor installed. Operation of this equipment may create sparks that can

start res around dry vegetation. A spark arrestor may be required.

The operator should contact local re agencies for laws or

regulations relating to re prevention requirements.

TO PREVENT SERIOUS INJURY: The Saw Mill is dangerous when assembled incorrectly.

If you do not feel completely comfortable assembling it, then have a qualied technician assemble it.

Note: For additional information regarding

the parts listed, refer to Assembly Diagram

near the end of this manual.

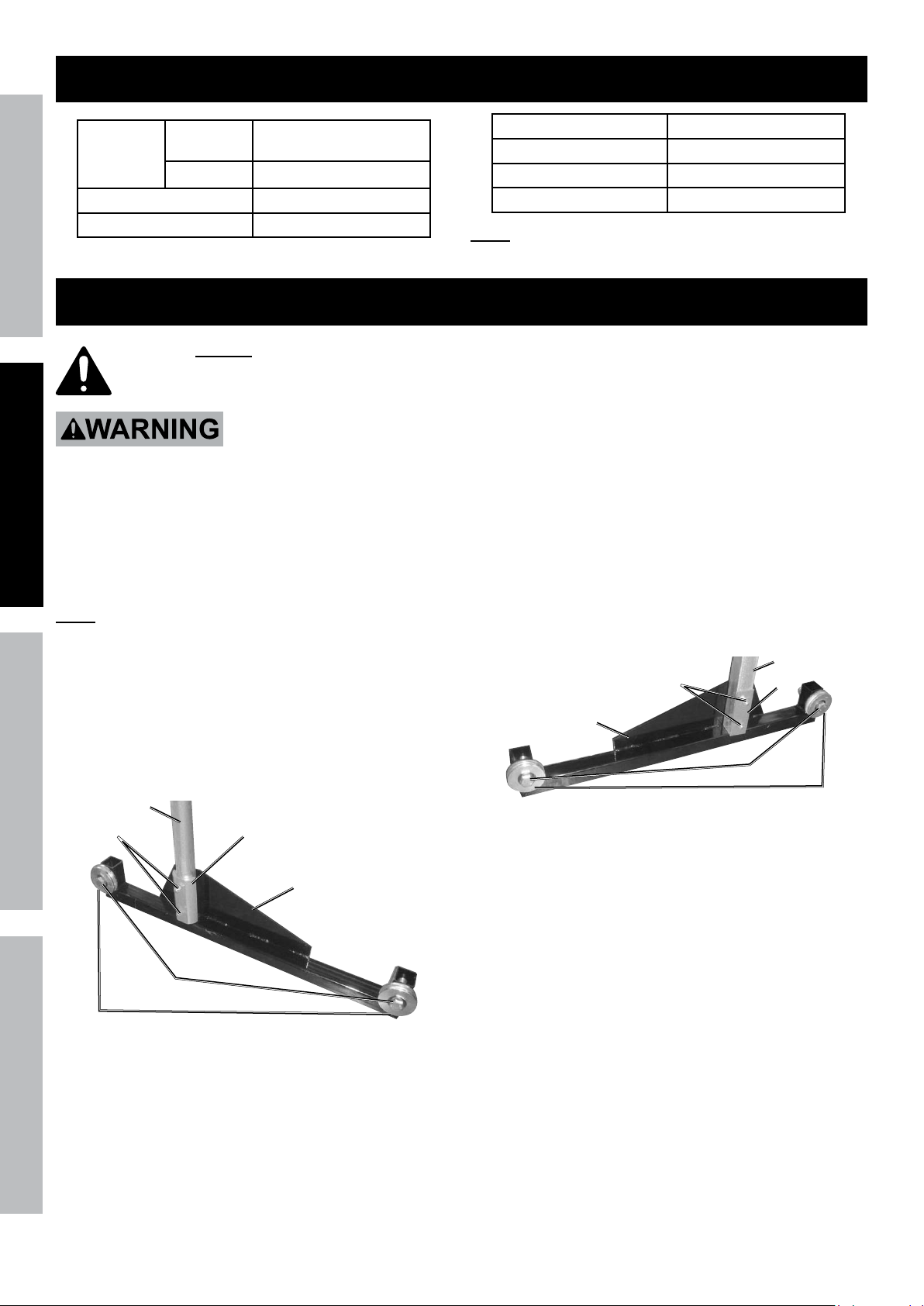

1. Secure Wheels (1) onto Right Wheel Frame (7a)

with two Hex Bolts M20x100 (6) and Hex Nuts

M20 (2). Attach Right Wheel Frame, Round

Post (20) and the Round Clamp (10) with two

Hex Bolts M12x80 (8) and Hex Nuts M12 (9).

Note: Do not tighten Bolts (8) and Nuts (9).

20

8, 9

6, 2

1

10

7a

Figure A: Right Wheel Frame

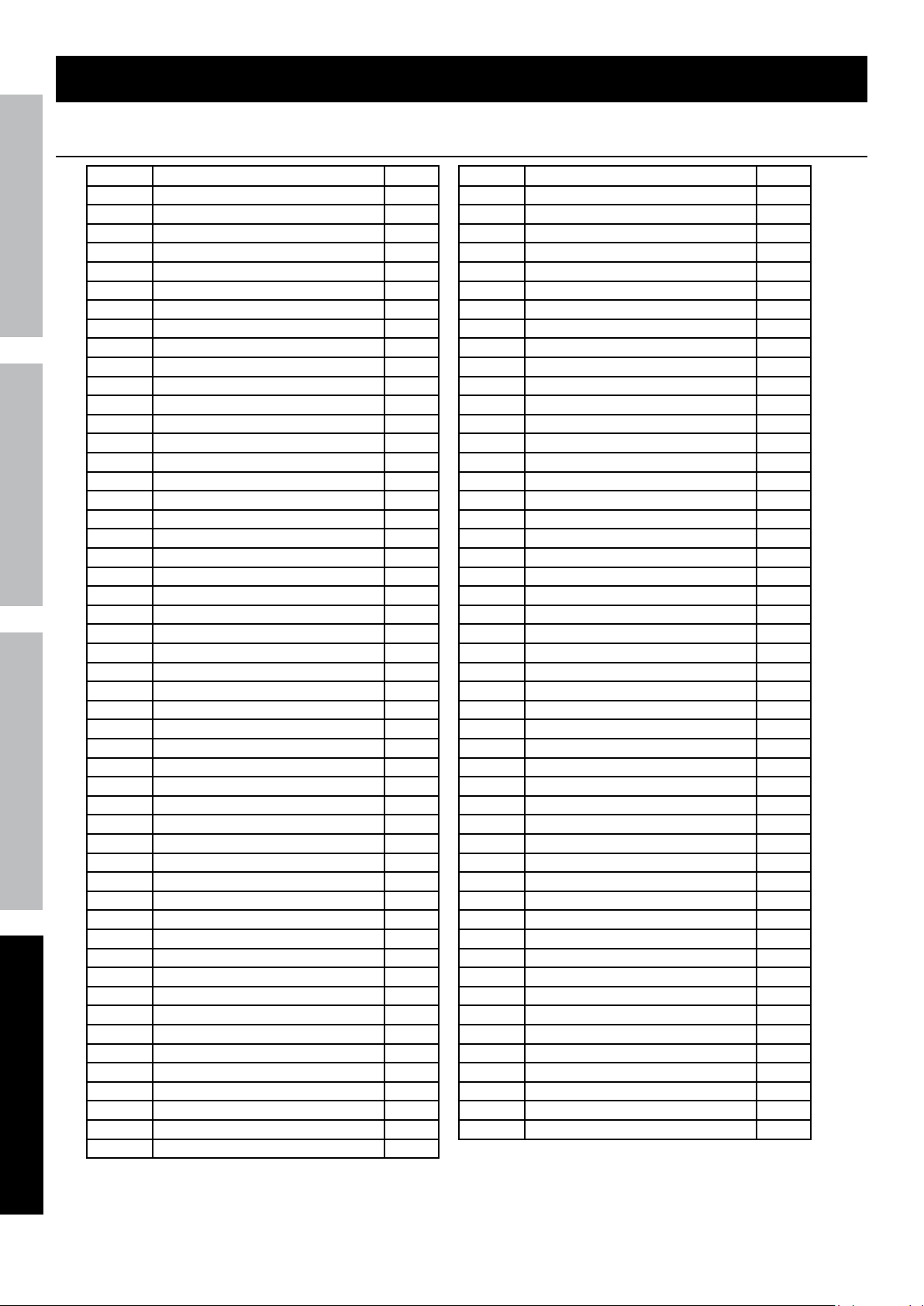

with two Hex Bolts (58) and Hex Nuts (5).

Note: Do not tighten Bolts (58) and Nuts (5).

58, 5

3a

48

4

6, 2

1

Figure B: Left Wheel Frame

3. Slide the Round Post (20) into the Blade Guard (50),

as shown below. Adjust the bolts until Blade Guard

2. Secure Wheels (1) onto Left Wheel Frame (3a)

with two Hex Bolts M20x100 (6) and Hex

Nuts M20 (2). Then attach Left Wheel Frame,

Square Post (48) and Square Clamp (4)

Page 6 For technical questions, please call 1-800-520-0882. ITEM 61712

can move smoothly on the round post. Then secure

it in place with the Right Lock Handle (59).

6. Use the Bolts (22) and Nuts (25) to fasten the End

Stops (79) to the Track Sections, as shown below.

Round Post (20)

Blade

Guard

(50)

Right

Lock

Handle

(59)

Figure C: Right Lock Handle

4. Slide the Square Post (48) into the Blade Guard,

as shown below. Adjust the bolts until it can

move smoothly on the square post. Then secure

it in place with the Left Lock Handle (54).

7. Use the Flange Bolts (77) and Flange

Nuts (84) to fasten the Center Support (90a)

and Middle Supports (81a) to the Track

Sections (78, 92), as shown below.

NOTE: The Track (78) and Track (92) must be aligned

not only on the top surface, but also on the side surface.

The gap between these two parts must be small.

If the top surface of the Tracks are not aligned, use

a grinder or le (not included) to smooth them out.

8. Install the Rocker Tube (88) and Round

Tube (85) assembly as shown below.

78

84

83

77

85

86a

87

88

89

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Left Lock

Handle (54)

Square

Blade

Guard (50)

Post

(48)

Figure D: Left Lock Handle

NOTE: After assembly, the central distance

5. Lay out the Track sections (78, 92) as shown below.

of the Track must be 30.315″ + 0.04″

90a

81a

78

92

Figure F: Rocker Tube

9. Place the carriage onto the track.

Saw mill

starts cut from

this end.

92

80a

77

Saw mill

nishes cut

at this end.

25

22

79

82

92

78

91

Figure E: Track Assembly

Page 7For technical questions, please call 1-800-520-0882.ITEM 61712

10. Place the Top Frame (23) on the Posts (20, 48).

SAFETY OPERATION MAINTENANCEASSEMBLY

Figure G: Top Frame

11. Secure the two Bolts (22) attaching

the Top Frame (23) to the

Round Post (20) as shown below.

15. Thread the Cable Anchor Bolts (46) into

the Blade Guard (50) as shown below.

Figure K: Cable Anchor Bolt Locations

16. Route Cables as shown below.

Hook the loops around the two posts on the

back of the External Tube (34). The lower cable

attaches to the lower post. Adjust the Cable

Anchor Bolts (46) until the two cables are equal.

Figure H: Top Frame Bolts

12. Attach the Top Frame (23) to the

Square Post (48) using the Bolts (49) and

Top Frame Brace (101) as shown below.

Figure I: Top Frame Bolts 2

13. Tighten the Bolts (8,58) and Nuts (5,9).

14. Attach the External Tube (34) and the Water Tank

Tray (45) to the Top Frame (23) using the Bolts (44),

Spring Washer (98), and Nut (99), as shown below.

34

44

98

99

Figure L: Cable Route

17. Loosen the Bolt (70) and the Fixed Block (71) to

move the Fixed Block away from the Blade. Rotate

the Tension Handle (14) in a clockwise direction

to properly tension the Blade, as shown below.

Figure M: Tension Handle

NOTE: Pull up on Blade at Center Guard.

Allow for no more than 1/4″ - 1/2″

movement up or down (“give”) on the Blade.

The 1/4″ - 1/2″ give indicates proper Blade tension.

45

23

Page 8 For technical questions, please call 1-800-520-0882. ITEM 61712

Figure J: Water Tank Tray and External Tube

18. Slide Fixed Block until it gently touches the Blade.

Then tighten the Bolt, fastening it in place.

See below. Repeat for the remaining Fixed

Blocks until there is 0.02″-0.04″ clearance

between Fixed Blocks and Blade.

Fixed Block (71) Bolt (70)

Figure N: Fixed Block and Manual Rotation

19. Rotate the Bandwheel (66) slowly

counterclockwise, watching relative position of

the Blade (69) and the Bandwheels (66).

20. If the Blade stays centered on the wheels, tighten

the lock nuts shown on Figure O. If the Blade

does not stay centered, adjust the bolts shown

on Figure O slightly and then rotate the belt

wheel again. See instructions that follow.

E

C

A

G

B

Refer to Figure O for the following instructions:

BEFORE any adjustment, loosen Bolts

E and F and Nuts C and D.

If after replacement Blade starts to shift back

towards operator, loosen Nut A and hold Bolt G with

a wrench. Then tighten Nut A after adjustment.

If the Blade shifts back from the operator,

loosen Nut B and hold Bolt G with a wrench.

Then tighten Nut B after Blade adjustment.

Continue making small adjustments until

Blade stays centered, AFTER any adjustment,

tighten Bolts E and F and Nuts C and D.

21. Install Throttle Control (93) on Pushing

Handle (94) as shown below.

Figure P: Throttle Control

22. Lubricate the Round Post (20) and the

Square Post (48) with lithium grease to

allow the sawhead to move smoothly.

23. Install the Water Tank (95) into

the Water Tank Tray (45).

SAFETYOPERATIONMAINTENANCE ASSEMBLY

D

F

adjusting boltadjusting lock nut

Figure O: Adjustment Bolts

NOTE: Adjust Blade again after replacement.

24. Route the Water Tube (97) through the bracket on the

lower right of the Blade Guard (50) Secure in place

with the tip facing the blade using the water tube

holding bolt shown below, but do not overtighten.

Blade

Guard

Water

Tube (97)

(50)

lower

right

bracket

Water Tube

Holding

Bolt

Figure Q: Water Tube

25. For horizontal Blade adjustment, loosen the Nut (47)

and adjust the left and right Lock Handles (54,59)

until the distance between the ends of the Blade and

the top of the Middle Support (81a) are the same.

NOTE: Use a tape measure to verify distances match.

Page 9For technical questions, please call 1-800-520-0882.ITEM 61712

Operating Instructions

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

SAFETY OPERATION MAINTENANCEASSEMBLY

beginning of this manual including

Engine Operation

Inspect engine and equipment looking

for damaged, loose, and missing

parts before set up and starting.

If any problems are found, do not use

equipment until xed properly.

Start Procedure

Before starting the engine:

a. Follow the Set Up Instructions to

prepare the equipment. Follow all

Equipment Operation

1. Wear heavy-duty work gloves, ANSI-approved

goggles behind a full face shield, steel-toed

work boots, and a dust mask.

2. Operate only with assistance.

3. Fill the Water Tank with clean water.

4. The maximum log diameter that can be cut is 20″.

The maximum board width that can be cut is 20″.

The lumber must be at least 3′ 8″ long and

must rest on at least two Supports (81a, 90a)

to prevent instability.

5. Cut branches off the lumber to be

processed before milling.

all text under subheadings therein

before set up or use of this product.

instructions in the separate engine

manual provided with the engine.

b. Inspect the equipment and engine.

c. Fill the engine with the proper

amount and type of fuel and oil.

d. Read the Equipment Operation

section that follows.

1. Start and operate the engine according

to the provided engine manual.

2. Replacement engine operating instructions can

be obtained from the engine manufacturer.

7. Choose the Short Log Supports (91) or the Long Log

Supports (82) according to the lumber diameter.

8. Place the lumber to be cut on the Supports.

See picture below. Brace the lumber against

the Log Supports (82, 91) to prevent movement

during milling. The lumber should be positioned so

that the force of cutting holds it against the supports.

Clamp

Lumber

Here

Lumber on

Supports

6. WARNING! To prevent death and

serious injury. Do not cut lumber containing

foreign objects (nails, metal, etc.).

Figure R: Lumber Position

9. Clamp the lumber in place against the Log

Supports (82, 91) using the Log Clamp (89) in

the location shown above. Position the Log

Clamp is below the level of the blade.

10. Tighten all Bolts and T-Handles on the Log

Clamp (89) and the Log Supports (82, 91). Verify

that they are securely in place before proceeding.

Page 10 For technical questions, please call 1-800-520-0882. ITEM 61712

11. Align the Blade with the top of the lumber, loosen the

Scale Knob and adjust the Scale Pointer to point at

0″ on the Scale. Tighten the Scale Pointer Knob.

Scale

Pointer

14. WARNING! The operator and any assistants

must stay clear of the front and back of the

blade whenever the engine is running.

15. Start and operate the engine according

to the provided engine manual.

16. Adjust the Throttle to bring the Blade

up to speed. The Locking Ring can be

turned to lock the Throttle in place.

Height

Adjustment

Handle (30)

Scale

Pointer

Knob

Scale

Figure S: Scale and Scale Pointer

12. Release both Lock Handles (54, 59). Turn the Height

Adjustment Handle (30) and adjust the cutting

height until the Scale Pointer points to the desired

thickness. Engage both Lock Handles (54, 59).

13. The cut direction must be as shown below. If the

log is cut from the other direction, the saw blade

will push the lumber away from the supports and

may cause the lumber to become unstable.

Start

of cut

CUTTING DIRECTION

Locking Ring

Throttle Lever

Figure U: Throttle Control

17. Throttle speed may need to be increased

when the Saw is under load.

18. Move the Saw Head slowly along the track

and against the lumber to make the cut.

NOTE: Repeated adjustments will need

to be made during cutting.

19. Shut off engine if blade binds, breaks,

or another problem is suspected.

Do not try to back the blade out of an

incomplete but while engine is running.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Figure T: Direction of Cut

End

of cut

20. Trim off the rounded sides of the lumber.

21. After the lumber is squared-off,

boards or posts can be cut.

22. To prevent accidents, turn off the engine and

disconnect its spark plug wire after use. Wait for the

engine to cool, clean external parts with clean cloth,

then store the equipment out of children's reach

according to the Storage instructions in this manual.

Page 11For technical questions, please call 1-800-520-0882.ITEM 61712

Servicing

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL STARTING:

SAFETY OPERATION MAINTENANCEASSEMBLY

Turn the Power Switch of the equipment to its “OFF” position, wait for the engine to cool, and disconnect

the spark plug wire(s) before performing any inspection, maintenance, or cleaning procedures.

TO PREVENT SERIOUS INJURY FROM EQUIPMENT FAILURE:

Do not use damaged equipment. If abnormal noise, vibration, or excess

smoking occurs, have the problem corrected before further use.

Maintenance Procedures

Many maintenance procedures, including those not detailed in this manual, will need to be

performed by a qualied technician for safety. If you have any doubts about your ability to safely

service the equipment or engine, have a qualied technician service the equipment instead.

Note: These procedures are in addition to the regular checks and maintenance

explained as part of the regular operation of the engine and equipment.

Engine Maintenance and Service

Follow the instructions found in the

included engine manual.

Storage

1. Wait for engine to cool, then clean

equipment with clean cloth.

2. Clean the engine and/or prepare it for storage

according to engine manual instructions.

3. Apply a thin coat of rust preventive

oil to all uncoated metal parts.

Equipment Lubrication

1. Lubricate the Bandwheel Axles and Square and

Round Posts with machine oil before each use.

2. Lubricate the Tension Handle with grease monthly.

4. Cover and store in a dry, well-ventilated

area out of reach of children.

5. For cold weather operation, store the

equipment in a cool dry area to prevent

condensation and premature wear.

Page 12 For technical questions, please call 1-800-520-0882. ITEM 61712

Equipment Troubleshooting

Problem Possible Causes Probable Solutions

Excessive blade

breakage.

Premature

blade dulling.

Blade cuts crooked.

Blade cuts rough.

Blade is twisting.

Unusual wear

on back or side

of blade.

Teeth ripping

from blade.

1. Insufcient blade tension.

2. Incorrect speed or feed rate.

3. Lumber loose.

4. Blade rubs against wheel ange.

5. Blade teeth too coarse for

lumber, or blade too thick.

6. Teeth contacting lumber before

blade up to full speed.

7. Misaligned guides.

1. Teeth too coarse.

2. Blade rotating too quickly.

3. Hard spots or scale in/on material.

4. Blade installed backwards.

5. Insufcient blade tension.

1. Lumber not square.

2. Feed pressure/rate too great.

3. Inadequate blade tension.

4. Dull blade.

5. Blade guide loose.

1. Too much blade speed and/

or rate of feed.

2. Blade is too coarse.

1. Cut is binding blade.

2. Blade tension too high.

1. Blade guides worn.

2. Blade guide bearing bracket is loose.

1. Teeth too coarse.

2. Feed rate incorrect.

3. Lumber loose.

4. Teeth lled with debris.

1. Increase blade tension.

2. Adjust speed or feed rate for the lumber being cut.

3. Make sure lumber is securely positioned

against supports. Remove stray branches

that prevent proper positioning.

4. Adjust blade tracking.

5. Use recommended blade only.

6. Allow blade to reach operating speed before cutting.

7. Align guides.

1. Use recommended blade only.

2. Use lower speed.

3. Reduce speed, increase feed pressure.

4. Properly install blade.

5. Tension blade properly.

1. Adjust lumber so that it is square with the blade.

2. Reduce feed rate.

3. Increase blade tension slightly.

4. Replace blade.

5. Adjust and secure blade guide.

1. Reduce blade speed and feed rate.

2. Use recommended blade only.

1. Decrease feed pressure.

2. Decrease blade tension.

1. Replace blade guides.

2. Tighten blade guide bearing bracket.

1. Use recommended blade only.

2. Adjust feed rate.

3. Make sure lumber is securely positioned

against supports. Remove stray branches

that prevent proper positioning.

4. Clean debris off blade.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Follow all safety precautions whenever diagnosing or servicing the equipment or engine.

Page 13For technical questions, please call 1-800-520-0882.ITEM 61712

Parts List and Diagrams

Parts List

SAFETY OPERATION MAINTENANCEASSEMBLY

Part Description Qty

1 Wheel 4

2 Hex Nut M20 4

3a Left Wheel Frame 1

4 Clamp 1 1

5 Hex Nut M12 6

6 Hex Bolt M20×100 4

7a Right Wheel Frame 1

8 Hex Bolt M12×80 5

9 Hex Nut M12 6

10 Clamp 2 1

11 Hex Bolt M8×20 9

12 Hex Bolt M10×25 21

13 Hex Bolt M12×65 3

14 Tension Handle 1

15 Flat Washer 12 2

16 Hex Bolt M12×145 1

17 Hanging Plate 1

18 Hex Bolt M8×16 5

19 Right Clamp 1

20 Round Post 1

21 Lumber Thickness Scale 1

22 Hex Bolt M8×25 12

23 Top Frame 1

24 Flat Washer 8 9

25 Hex Nut M8 36

26 Taper Pin B6×40 2

27 Elastic Pin 5×20 1

28 Round Nut M14×1.5 2

29 Height Adjustment Arm 1

30 Height Adjustment Handle 1

31 Hex Bolt M12×65 3

32 Hex Nut M12 6

33 Guide Screw Base 1

34 External Tube 1

35 Pulley 5

36 Bolt M12×20 3

37 Snap Ring 12 3

38 Washer 3

39 Internal Tube 1

40 Hex Bolt M12×70 1

41 Washer 1

42 Flat Washer 2

43 Hex Nut M12 1

44 Bolt M10×45 2

45 Water Tank Tray 1

46 Cable Anchor Bolt 2

47 Hex Nut M10 4

48 Square Post 1

49 Hex Bolt M12×65 2

50 Blade Guard 1

51 Hex Bolt M12×45 1

Part Description Qty

52 Hex Nut M12 4

53 Hex Bolt M12×100 1

54 Left Lock Handle 1

55 Hex Bolt M8×45 6

56 Support Tube 1

57 Beam 1

58 Hex Bolt M12×80 2

59 Right Lock Handle 1

60 Hex Bolt M10×25 2

61 Elastic Washer 10 2

62 Flat Washer 10 2

63 Snap Ring 62 2

64 Bearing 6305 RZ 4

65 V- Belt B1900 1

66 Bandwheel 2

67 Clutch 1

68 Pin 1

69 Blade 1

70 Bolt M8×45 4

71 Fixed Block 4

72 Blade Guide 2

73 Blade Guide Shaft 2

74 Short Bandwheel Axle 1

75 Long Bandwheel Axle 1

76 V- Belt B1422 1

77 Hex Flange Bolt M10×25 28

78 Track 1 2

79 End Stop 4

80a End Support 2

81a Middle Support 2

82 Log Support 2

83 Rod Support 2

84 Hex Flange Nut M10 32

85 Round Tube 1

86a Rocker Tube Sleeve 1

87 Log Support T-Handle

88 Rocker Tube 1

89 Log Clamp 1

90a Center Support 1

91 Short Log Support 2

92 Track 2 2

93 Throttle Control 1

94 Pushing Handle 1

95 Water Tank 1

96 Switch 1

97 Water Tube 1

98 Spring Washer 10 2

99 Hex Nut M10 4

100 Blade Roller Bearing 2

101 Top Frame Brace 1

M10x1.5x30 5

Page 14 For technical questions, please call 1-800-520-0882. ITEM 61712

Assembly Diagram

101

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Page 15For technical questions, please call 1-800-520-0882.ITEM 61712

Assembly Diagram (continued)

SAFETY OPERATION MAINTENANCEASSEMBLY

100

100

Page 16 For technical questions, please call 1-800-520-0882. ITEM 61712

Assembly Diagram (continued)

SAFETYOPERATIONMAINTENANCE ASSEMBLY

78

91

92

90a

84

83

88

86A

85

89

81a

87

78

82

92

80a

22

79

25

77

Page 17For technical questions, please call 1-800-520-0882.ITEM 61712

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

SAFETY OPERATION MAINTENANCEASSEMBLY

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Page 18 For technical questions, please call 1-800-520-0882. ITEM 61712

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure

that its products meet high quality and durability

standards, and warrants to the original purchaser

that this product is free from defects in materials and

workmanship for the period of 90 days from the date

of purchase. This warranty does not apply to damage

due directly or indirectly, to misuse, abuse, negligence

or accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and

tear, or to lack of maintenance. We shall in no event

be liable for death, injuries to persons or property, or

for incidental, contingent, special or consequential

damages arising from the use of our product. Some

states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation of

exclusion may not apply to you. THIS WARRANTY IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part

must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation

of the complaint must accompany the merchandise. If

our inspection veries the defect, we will either repair

or replace the product at our election or we may elect

to refund the purchase price if we cannot readily and

quickly provide you with a replacement. We will return

repaired products at our expense, but if we determine

there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then

you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may

also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009

Camarillo, CA 93011 • (800) 444-3353

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Page 19For technical questions, please call 1-800-520-0882.ITEM 61712

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 520-0882

Loading...

Loading...