Page 1

1” SDS ROTARY HAMMER

®

41983

OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 2000 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 08/05; 09/06

Page 2

SPECIFICATIONS

Motor 110 V~, 60 Hz, 620 W, n0 750/min

Capacity 1”

Chuck Type SDS

Rotation Reversible

Cord 7’ UL Listed with 2-Pole Polarized Plug

BPM 2920

Weight 10.5 lb.

Also Includes Spanner, (4) SDS Drill Bits (10,12,14 and 22 mm), 4 Point

Chisel, Depth Gauge Rod, Grease, and Carbon Brush Set

E194601E194601

Save This Manual

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep your

invoice with this manual. Write the invoice number on the inside of the front cover. Write the

product’s serial number in the back of the manual near the assembly diagram, or write month and

year of purchase if product has no number. Keep this manual and invoice in a safe and dry place

for future reference.

GENERAL SAFETY RULES

1.

2.

3.

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control. Protect others in the work area from debris such as chips

and sparks. Provide barriers or shields as needed.

For technical questions, please call 1-800-444-3353.

Page 2SKU 41983

Page 3

ELECTRICAL SAFETY

1.

2.

3.

4.

5.

Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the

tools should electrically malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

Double insulated tools are equipped with a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double

insulation eliminates the need for the three wire grounded power cord and grounded

power supply system.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the Power Cord. Never use the Power Cord to carry the tools or pull

the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp edges, or

moving parts. Replace damaged Power Cords immediately. Damaged Power Cords

increase the risk of electric shock.

6.

1.

2.

3.

4.

5.

When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W”. These extension cords are rated for outdoor use, and reduce the risk of electric

shock.

PERSONAL SAFETY

Stay alert. Watch what you are doing, and use common sense when operating a

power tool. Do not use a power tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may result

in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

Avoid accidental starting. Be sure the Power Switch is off before plugging in. Carrying

power tools with your finger on the Power Switch, or plugging in power tools with the Power

Switch on, invites accidents.

Remove adjusting keys or wrenches before turning the power tool on. A wrench or a

key that is left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the power tool in unexpected situations.

For technical questions, please call 1-800-444-3353.

Page 3SKU 41983

Page 4

6.

Use safety equipment. Always wear eye protection. Dust mask, nonskid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions. Always wear ANSI-

approved safety goggles and a dust mask/respirator when using or performing maintenance

on this tool.

TOOL USE AND CARE

1.

2.

3.

4.

5.

6.

7.

Use clamps (not included) or other practical ways to secure and support the workpiece

to a stable platform. Holding the work by hand or against your body is unstable and may

lead to loss of control.

Do not force the tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed. Do not force the tool and do

not use the tool for a purpose for which it is not intended.

Do not use the power tool if the Power Switch does not turn it on or off. Any tool that

cannot be controlled with the Power Switch is dangerous and must be replaced.

Disconnect the Power Cord Plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures reduce the

risk of starting the tool accidentally. Always unplug the tool from its electrical outlet

before performing any inspection, maintenance, or cleaning procedures.

Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with a sharp cutting edge are less likely to bind and are easier to control. Do not use

a damaged tool. Tag damaged tools “Do not use” until repaired.

Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

8.

1.

2.

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

SERVICE

Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions in the

“Inspection, Maintenance, And Cleaning” section of this manual. Use of unauthorized

parts or failure to follow maintenance instructions may create a risk of electric shock or

injury.

For technical questions, please call 1-800-444-3353.

Page 4SKU 41983

Page 5

SPECIFIC SAFETY RULES

1.

2.

3.

4.

5.

6.

7.

8.

Hold tools by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

Wear ear protectors when using the tool for extended periods. Prolonged exposure to

high intensity noise can cause hearing loss.

Maintain labels and nameplates on the tool. These carry important information. If

unreadable or missing, contact Harbor Freight Tools for a replacement.

Maintain a safe working environment. Make sure there is adequate surrounding

workspace. Do not use this product in a damp or wet location.

When using a handheld power tool, always maintain a firm grip on the tool with both

hands to resist starting torque. Always use the Auxiliary Handle to control kickback and

torque reactions.

Do not operate the Rotary Hammer if any of the following problems occur: Hammer

is too hot, insulation is torn, frayed or missing or if excessive sparking occurs.

Move the Switching Knob (22) and Main Handle (91) only when the motor is stopped.

Attempting to move either one while the motor is engaged will result in abrupt bit rotation,

and can cause serious personal injury and/or property damage.

Do not allow the bit to stop while in the hole. Remove the bit while it is still rotating. If

the bit stops while in the hole, do not restart the Rotary Hammer. Remove the bit from the

Hammer and then remove it from the material being worked on.

9.

10.

11.

12.

13.

Avoid unintentional starting. Make sure you are prepared to begin work before turning

on the tool.

Always keep the extension cord away from moving parts on the tool.

WARNING! People with pacemakers should consult their physician(s) before using this

product. Electromagnetic fields in close proximity to a heart pacemaker could cause

interference to or failure of the pacemaker. In addition, people with pacemakers should

adhere to the following:

Avoid operating power tools alone.

•

Don’t use a power tool with the power switch locked on.

•

If powered via a power cord be certain that the tool is properly grounded. A ground fault

•

interrupt (GFCI) system is also a good precaution. This inexpensive device is a good

safety measure because it prevents a sustained electrical shock.

Properly maintain and inspect all tools before use to avoid electrical shock.

•

Never lay the tool down until it has come to a complete stop. Moving parts can grab

the surface and pull the tool out of your control.

Never leave the tool unattended when it is plugged into an electrical outlet. Turn off

the tool, and unplug it from its electrical outlet before leaving.

For technical questions, please call 1-800-444-3353.

Page 5SKU 41983

Page 6

14.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities, contain chemicals known (to the State of California) to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

Lead from lead-based paints.

•

Crystalline silica from bricks and cement or other masonry products.

•

Arsenic and chromium from chemically treated lumber.

•

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well-ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. Do not modify the power cord plug provided with the tool. Never remove

the grounding prong from the plug. Do not use the tool if the power cord or plug is

damaged. If damaged, have it repaired by a service facility before use. If the plug will

not fit the outlet, have a proper outlet installed by a qualified electrician.

1.

2.

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

Tools marked with “Grounding Required” have a three wire cord and three prong grounding

plug. The plug must be connected to a properly grounded outlet. If the tool should electrically

malfunction or break down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk of electric shock. (See Figure A.)

The grounding prong in the plug is connected through the green wire inside the cord to the

grounding system in the tool. The green wire in the cord must be the only wire connected

to the tool’s grounding system and must never be attached to an electrically “live” terminal.

(See Figure A.)

For technical questions, please call 1-800-444-3353.

Page 6SKU 41983

Page 7

3.

Your tool must be plugged into an appropriate outlet, properly installed and grounded in

accordance with all codes and ordinances. The plug and outlet should look like those in

the following illustration. (See Figure A.)

FIGURE A FIGURE B

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

Note: This tool has a two-prong plug.

1.

2.

1.

2.

3.

4.

Tools marked “Double Insulated” do not require grounding. They have a special double

insulation system which satisfies OSHA requirements and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard Association, and the

National Electrical Code. (See Figure B.)

Double insulated tools may be used in either of the 120 volt outlets shown in the preceding

illustration. (See Figure B.)

EXTENSION CORDS

Grounded tools require a three wire extension cord. Double Insulated tools can use either

a two or three wire extension cord.

As the distance from the supply outlet increases, you must use a heavier gauge extension

cord. Using extension cords with inadequately sized wire causes a serious drop in voltage,

resulting in loss of power and possible tool damage.

(See Figure C, next page.)

The smaller the gauge number of the wire, the greater the capacity of the cord. For example,

a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Figure C.)

When using more than one extension cord to make up the total length, make sure each

cord contains at least the minimum wire size required. (See Figure C.)

5.

6.

If you are using one extension cord for more than one tool, add the nameplate amperes

and use the sum to determine the required minimum cord size.

(See Figure C.)

If you are using an extension cord outdoors, make sure it is marked with the suffix “W-A”

(“W” in Canada) to indicate it is acceptable for outdoor use.

For technical questions, please call 1-800-444-3353.

Page 7SKU 41983

Page 8

7.

Make sure your extension cord is properly wired and in good electrical condition. Always

replace a damaged extension cord or have it repaired by a qualified electrician before

using it.

8.

Protect your extension cords from sharp objects, excessive heat, and damp or wet areas.

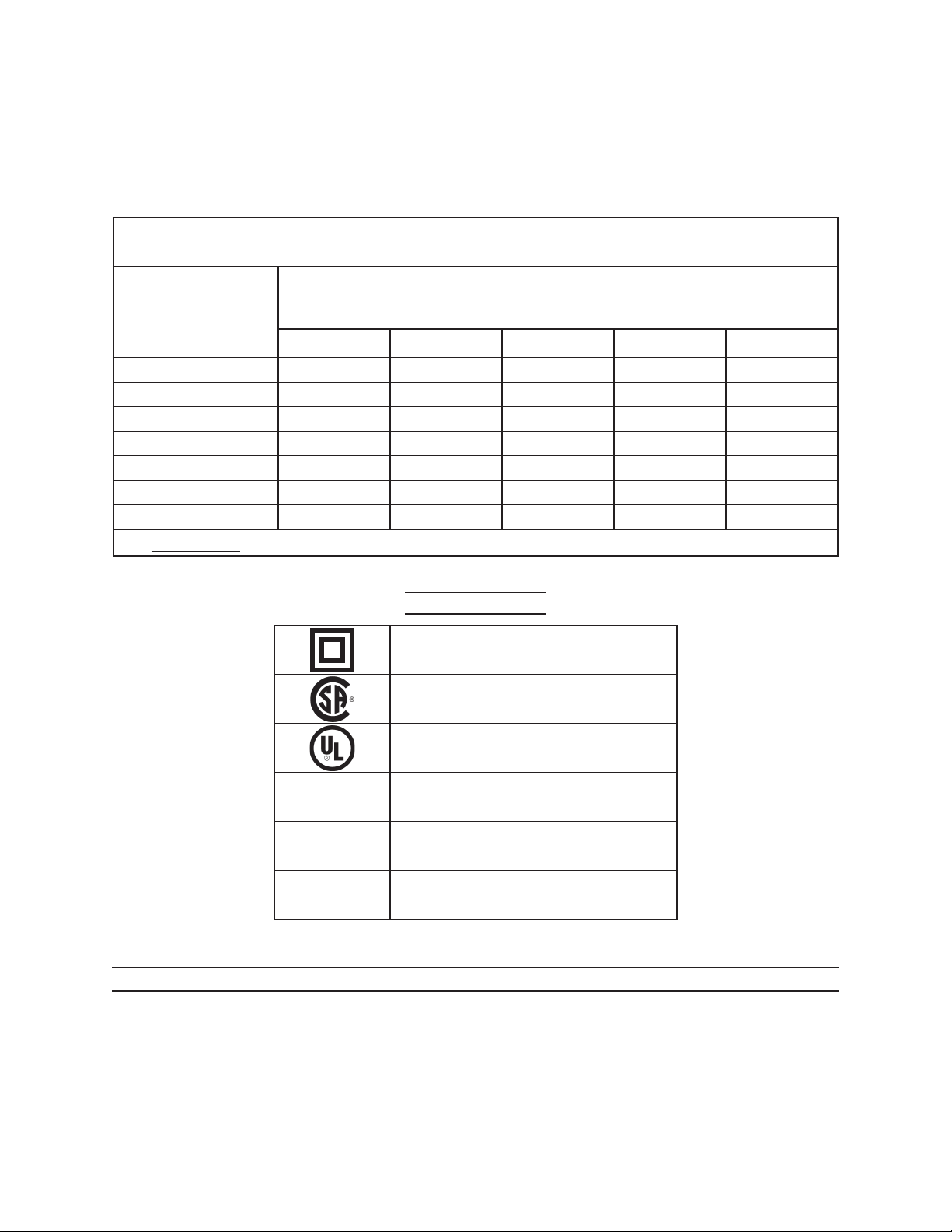

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS*

(120 OR 240 VOLT)

NAMEPLATE

EXTENSION CORD LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

FIGURE C

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

* Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

SYMBOLOGY

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

A

n0 xxxx/min.

Volts Alternating Current

Amperes

No Load Revolutions per Minute (RPM)

UNPACKING

When unpacking, check to make sure that the item is intact and undamaged. If any

parts are missing or broken, please call Harbor Freight Tools at the number shown on the

cover of this manual as soon as possible.

For technical questions, please call 1-800-444-3353.

Page 8SKU 41983

Page 9

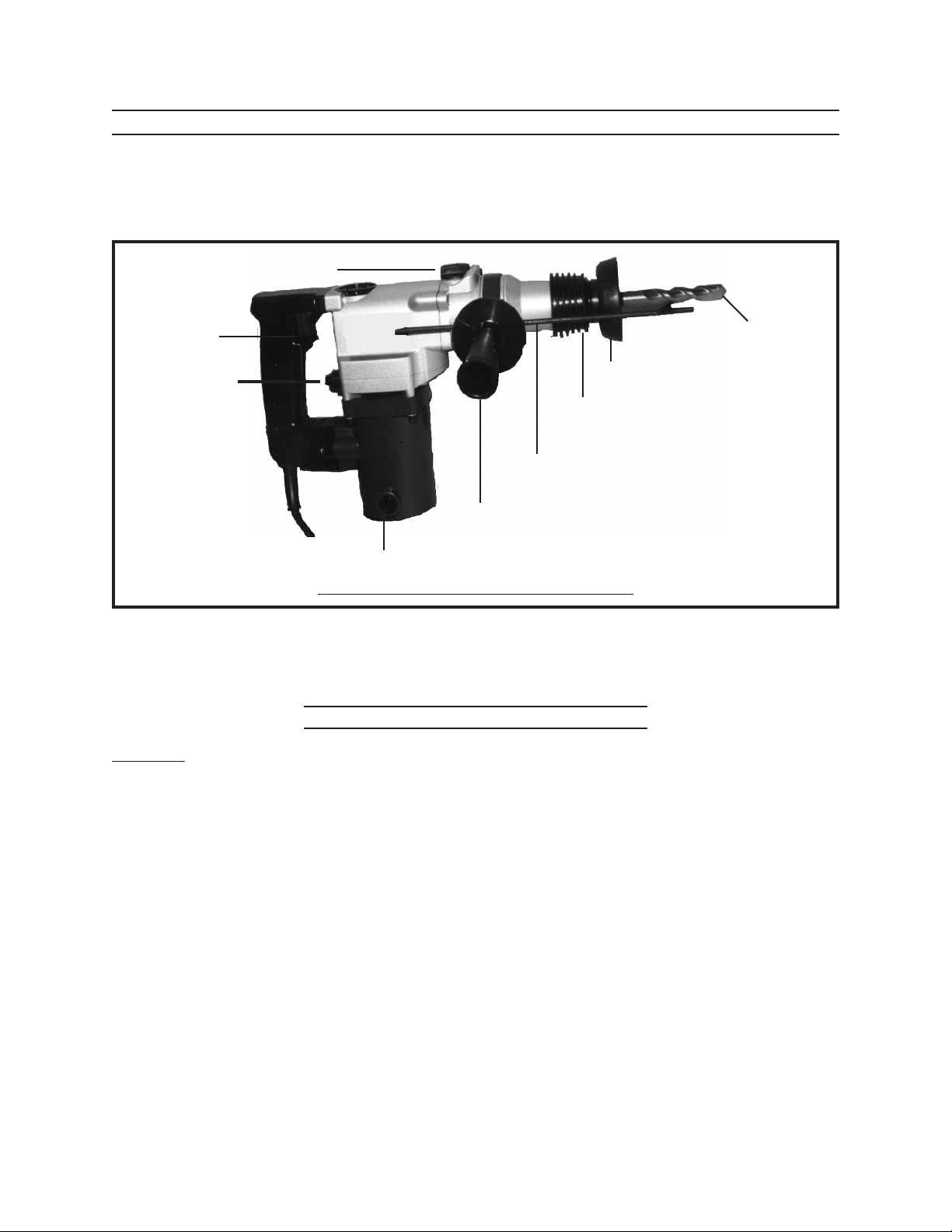

SETUP AND SETTINGS

The 1” Rotary hammer is designed to be used in the following applications:

For drilling stone, concrete, and other hard and brittle materials.

•

For chiseling.

•

Switching Knob (22)

Switch (96)

Main Handle (91)

Dust Cover (104)

Spring (41)

Depth

Gauge (106)

Auxiliary Handle (107)

Carbon Brush (82)

FIGURE 1 - Operating Your Rotary Hammer

Drill Bit

See Figure 1 above to become familiar with the various features of the Rotary Hammer.

A complete part number listing is shown on page 9. The complete Assembly Diagram is located

on page 10.

Inserting and Removing Drill Bits

Warning: Always wear gloves to provide protection when inserting and removing drill bits. Drill

bits become very hot in use. Do not remove drill bits until the bit has completely cooled off.

Do not strike stuck bits with a hammer as metal chips may fly off.

Always remove the electrical plug from the electrical outlet when inserting and removing

bits and chisels.

1.

2.

3.

4.

Your Rotary Hammer comes with a Dust Cover (104). Slide the Dust Cover over the Front

Cover (39).

Add a coating of grease or machine oil to the drill or bit shank.

Pull back on the Spring (41) - see Figure 1, while simultaneously inserting and turning the

drill bit until it slides all the way in. Release the Spring (41) so that it returns to its original

position. You should not be able to move the bit without pulling back on the spring again.

Make certain the bit does not move, this will ensure that it is properly installed.

To remove the bit, pull back on the Spring (41) and pull out the bit.

For optimal performance, always keep bit and chisels properly sharpened.

For technical questions, please call 1-800-444-3353.

Page 9SKU 41983

Page 10

Note: When drilling a hole larger than 1-1/4” diameter, always use a drill bit with 4 cutting

edges.

Adjusting the Auxiliary Handle

The Auxiliary Handle (107) can be placed into a variety of different positions.

To rotate the Auxiliary Handle (107), turn the Auxiliary Handle (107) counterclockwise to

loosen the band and Foursquare Bolt (111). Once loosened, turn the Auxiliary Handle to

the position desired. Turn the Handle clockwise to tighten into place.

Using the Depth Gauge

The Depth Gauge (106) can only be used if the Auxiliary Handle (107) is positioned on

either side or the top of the Rotary Hammer. The body of the Hammer will interfere with the Depth

Gauge if the handle is in the bottom position.

1.

2.

Main Handle-Left Side Position

3.

Loosen the Auxiliary Handle (107) by twisting the Handle counterclockwise.

Once the Auxiliary Handle (107) is sufficiently loose, pull back on the Handle Holder (108)

until the hole in the Handle Holder (108) is fully open.

Slide the Depth Gauge (106) in to the desired length.

The tip of the Depth Gauge on the front of the Hammer should be the desired depth of the

hole to be drilled. The depth is from the tip of the bit to the tip of the Depth Gauge. For

example for a 2” hole, measure 2” back from the tip of the bit. Position the front tip of the

Depth Gauge at that spot (See Figure 1).

Main Handle-Right Side Position

FIGURE 2 - Changing Settings

Switching Knob

4.

After the Depth Gauge (106) is positioned in the desired position, slide the Handle Holder

(108) up and twist the Auxiliary Handle clockwise until tight. The Depth Gauge should be

securely in position, and should not move.

Changing the Settings

Your Rotary Hammer has both a Switching Knob (22) and a Main Handle (91) which must

•

be adjusted before drilling, hammer drilling, or chiselling - see Figure 2.

For technical questions, please call 1-800-444-3353.

Page 10SKU 41983

Page 11

Warning: Move the Switching Knob and Main Handle only when the motor is stopped.

Attempting to move either the Switching Knob or Handle while the motor is engaged

will result in abrupt bit rotation and can cause serious personal injury and/or property

damage.

Warning: When moving the Switching Knob and Handle, make sure both actively

click into the desired position. If not actively engaged, the Knob or Handle could

slip out of position, resulting in unexpected tool performance.

The front Switching Knob (22) has on one side- a symbol of a Hammer and a Drill. On

•

the other side is a symbol of just a Hammer. The Main Handle (91) can be pointed either

right or left. There are symbols for a Hammer and Drill on the left side and a symbol for

a Drill only on the right side.

To drill only, set the Switching Knob (22) so that the picture of the Hammer and Drill are

•

facing forward. Turn the Main Handle (91) so that it points to the right at the Drill symbol

(See Figure 2).

To Hammer Drill, set the Switching Knob (22) so that the Hammer and Drill are facing

•

forward. Turn the Main Handle (91) so that it points to the left at the Hammer and Drill

symbol.

To Chisel, set the Switching Knob (22) so that the picture of the Hammer only points

•

forward. Turn the Main Handle (91) so that it points left to the Hammer and Drill

symbol.

NOTE: Break Point (Bull) Bits and cold chisels are to be used when the Selector Switch is in the

hammering position only. Using these bits/chisels with the Selector Switch in the hammer/drill

position will result in unexpected tool performance.

OPERATION

1.

2.

3.

4.

Before plugging in the electrical cord, insert the desired bit and adjust the Auxiliary Handle

and Depth Gauge to the desired positions (See earlier sections).

While keeping your finger off the “ON” trigger Switch (96), plug in the electrical cord.

When ready to use the Rotary Hammer, first depress the “ON” trigger Switch (96) and allow

the unit to run without load for approximately one minute. This allows parts to become

properly lubricated. Check to see if the operating tool sounds normal. Once the tool has

been warmed up, it is ready for use.

To turn off the Rotary Hammer, release the trigger Switch (96).

For technical questions, please call 1-800-444-3353.

Page 11SKU 41983

Page 12

INSPECTION, MAINTENANCE, AND CLEANING

1.

2.

3.

4.

5.

WARNING! Make sure the Power Switch of the tool is in its “OFF” position and that the

tool is unplugged from its electrical outlet before performing any inspection, maintenance,

or cleaning procedures.

BEFORE EACH USE, inspect the general condition of the tool. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, damaged electrical

wiring, and any other condition that may affect its safe operation. If abnormal noise or

vibration occurs, have the problem corrected before further use. Do not use damaged

equipment.

CLEANING: Regularly clean the work surface with a dry brush or clean cloth. Keep moving

parts lightly greased. Always keep the Motor and vent areas free of dust and debris.

LUBRICATION: Use the enclosed spanner wrench to unscrew the Seal Cap (18) located

on top of the housing. Add the enclosed grease and replace and tighten the Seal Cap.

CHANGING THE CARBON BRUSHES:

Using a small standard screwdriver, remove the Brush Covers (81). When you remove

a.

the Brush Caps, the Carbon Brush Holder (83) may spring out. Do not lose the Carbon

Brushes. If the Brush Holder does not spring out, gently remove it by using the tip of your

screwdriver. Examine the surface of each brush. The surface should be smooth and

clean. If scratch marks appear, or if the brush is broken, replace the brush immediately

with an approved replacement brush from Harbor Freight Tools.

If the brush is not damaged but is only dirty, you may clean it off with a pencil eraser.

b.

Gently rub with the eraser until the dirt has been removed. Remove any eraser dust

which may have accumulated during cleaning.

Re-install each Carbon Brush (82) by inserting it back into the Brush Holder (83). Screw

c.

the Brush Cover (81) back into the Brush Holder and tighten.

MAINTENANCE CHART

Maintenance Type

Inspect tool for damage

Clean outside and lubricate

exposed moving parts

Lubricate*

Replace Carbon Brushes

*The Rotary Hammer is pre-greased from the factory. Lubrication is only needed starting after approximately 50 working hours.

Before

Use

X

After

Use

X

After Every 50

Hours of Use

X

After Every 100

Hours of Use

X

For technical questions, please call 1-800-444-3353.

Page 12SKU 41983

Page 13

TROUBLESHOOTING

Problem Possible Causes Probable Solutions

Motor does not rotate

switch on power

supply.

Abnormal noise from

motor; does not rotate

or rotates slowly.

Partial short circuit Partial short circuit or open circuit at

Main voltage too low Main power voltage too low. Adjust main power voltage.

Disrupted power supply.

1.

Poor contact at the switch.

2.

Armature or field coil burnt.

3.

Breakage of the Stator coil.

4.

Carbon Brushes worn out.

5.

Overload of motor caused by

excessive drilling depth or pressure.

Armature.

Check power supply.

1.

Repair switch.

2.

Change coil.

3.

Replace Stator Coil.

4.

Replace Carbon Brushes.

5.

Reduce drilling depth or pressure.

Decrease force.

Repair or change Armature.

Gearbox becomes too

hot.

Sparking Short circuit or break at Armature.

Overload, dull bit.

1.

Damp coils.

2.

Incorrect fitting.

3.

Decrease in voltage.

4.

1.

Surface of Armature not smooth

2.

and clean.

WARRANTY

Reduce load, sharpen bit.

1.

Dry coils.

2.

Repair or change armature.

3.

Adjust voltage.

4.

Repair Armature.

1.

Inspect and clean Armature.

2.

For technical questions, please call 1-800-444-3353.

Page 13SKU 41983

Page 14

PARTS LIST

Part Description Q’ty

1 O-ring 1

2 Steel Ball 3

3 Cylinder 1

4 Feather Key 2

5 Piston 1

6 O-ring 1

7 Spring Holder 1

8 Spring 1

9 Clutch 1

10 Third Gear 1

11 O-ring 1

12 Piston 1

13 Connecting Shaft 1

14 Needle Bearing 1

15 O-ring 1

16 O-ring 1

17 Marking Plate 1

18 Oil-Sealing 1

19 Gear Housing 1

20 Name Plate 1

21 Screw M 4 x 8 1

22 Switching Knob 1

23 Spring 1

24 Steel Ball 1

25 Fixing Board 1

26 O-ring 1

27 Half-Circle Block 1

28 Screw M 3 X 8 2

29 Draw Shaft 1

30 Screw M5 x 25 4

31 Spring 4

32 Cylinder Case 1

33 Cylinder Cap 1

34 Oil Seal 1

35 Washer 1

36 Bearing 1

37 Distance Ring 1

38 Distance Cover 1

Part Description Q’ty

39 Front Cover 1

40 O-ring 1

41 Spring 1

42 Steel Column 2

43 Retainer Sleeve 1

44 O-ring 2

45 O-ring 2

46 Second Hammer 1

47 Spring 1

48 Name Plate 1

49 Oil Sealing Ring 1

50 Gear Balling 1

51 Distance Ring 1

52 Bearing 1

53 Spacer 1

54 Washer 2

55 Slip Plate 2

56 No. 2 Gear 1

57 Spring Washer 1

58 Special Nut 1

59 Bearing 1

60 Crank Shaft 1

61 Steel Ball 3

62 Bearing 1

63 Washer 1

64 Bearing Cover 1

65 Screw M5 X 60 2

66 No. 1 Gear 1

67 Washer 1

68 Spring 1

69 Clutch Shaft 1

70 Center Cover 1

71 Bearing 1

72 Armature 1

73 Fan Guide 1

74 Field Screw 2

75 Washer 2

76 Inductance 2

For technical questions, please call 1-800-444-3353.

Page 14SKU 41983

Page 15

Parts List (continued)

Part Description Q’ty

77 Bearing 1

78 Housing 1

79 Washer 4

80 Screw M5 x 50 4

81 Brush Cover 2

82 Carbon Brush 2

83 Brush Holder 2

84 Tapping Screw $ x 16 2

85 Back Cover 1

86 Fixed Screw M5 X 6 2

87 Self Tapping Screw M4 X 23 3

88 Needle Bearing 1

89 Spring Holder 1

90 O-ring 1

91 Main Handle 1

92 Left Handle Cover 1

93 Insulating Sleeve 4

94 Switch Cover 1

Part Description Q’ty

95 Capacitor 1

96 Switch 1

97 Cord Pressing Board 1

98 Self Tapping Screw 4 X 16 2

99 Board 1

100 Handle Pad 1

101 Right Handle Cover 1

102 Self Tapping Screw 5 X 25 2

103 Screw M 5 X 25 2

104 Dust cover 1

105 Blow Box 1

106 Depth Gauge 1

107 Auxiliary Handle 1

108 Handle Holder 1

109 Handle Shaft 1

110 Pressing Board 1

111 Foursquare Bolt 1

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

For technical questions, please call 1-800-444-3353.

Page 15SKU 41983

Page 16

ASSEMBLY DIAGRAM

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

For technical questions, please call 1-800-444-3353.

Page 16SKU 41983

Page 17

1 ” SDS MARTEAU ROTATIF

®

41983

LES INSTRUCTIONS D’OPÉRATION

IMPORTANT!

Cette édition de langue

française est une traduction

du manuel anglais original

accompagnant ce produit. Si

une partie du manuel anglais

original est inconsistante

avec cette traduction, le

manuel anglais original

gouvernera.

En raison des améliorations continuantes, le produit réel peut différer légèrement du produit décrit ici.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visitez notre site Internet à http://www.harborfreight.com

POUR ÉVITER LA BLESSURE SÉRIEUSE, LISEZ

ET COMPRENEZ TOUS LES AVERTISSEMENTS

ET LES INSTRUCTIONS AVANT L’UTILISATION.

Le Copyright© 2000 par le Harbor Freight Tools®. Tous droits réservés. Aucune portion de

ce manuel ou de n’importe quel travail d’art contenu ici ne peut être reproduite dans aucune

forme ou forme sans le consentement écrit explicite de Harbor Freight Tools.

Pour les questions techniques et les pièces détachées,

appelez-vous s’il vous plaît 1-800-444-3353.

Page 18

CARACTÉRISTIQUES

Moteur 110 V~, 60 Hz, 620 W, no 750/min

Capacité 1”

Type de Mandrin SDS

Rotation Reversible

Cordon 7’ UL Listed avec Fiche polarisée à 2-Pole

BPM 2920

Poids 10.5 lb.

Aussi inclus

Gardez ce guide pour les conseils de sécurités et précautions, assemblage, instructions d’utilisation, inspection, entretien et nettoyage, la liste des pièces et le schéma

du produit. Gardez votre facture avec ce guide. Inscrivez le numéro à l’intérieur de la

couverture. Gardez ce guide et facture dans un endroit sécuritaire et sec pour pouvoir le

consulter à l’avenir.

Clé (4) SDS Forets (10, 12, 14, et 22 mm), 4 Point Ciseau,

Jauge de Profondeur, Graisse, et Les deux Balais de Carbone

GARDEZ CE GUIDE

1.

2.

3.

REGLES DE SECURITE

AVERTISSEMENT!

LISEZ ET ASSUREZ-VOUS DE BIEN COMPRENDRE TOUTES LES

INSTRUCTIONS.

Le non -respect des instructions ci -après peut entrainer un risque

de choc electrique d’incendie et/ou de blessures graves.

GARDEZ CES INSTRUCTIONS

ESPACE DE TRAVAIL

Assurez-vous que l’espace de travail est propre et bien éclairé. Un établi en-

combré ou un endroit sombre est propice aux accidents.

N’utilisez pas un outil électrique dans un environnement aux propriétés ex-

plosives, comme en présence de poussière, de liquides ou de gaz inflamma-

bles. Les outils électriques produisent des étincelles qui peuvent enflammer les

poussières ou les vapeurs.

Gardez les spectateurs, les enfants et les visiteurs à l’écart pendant que vous

utilisez l’outil. Une distraction pourrait vous faire perdre la maîtrise de l’outil. Pro-

tégez des gens dans l’espace de travail de débris. Si nécessaire, construisez des

barrières.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 2SKU 41983

Page 19

SECURITE ELECTRIQUE

1.

2.

3.

4.

Les outils mis à la terre doivent être branchés dans une prise de courant cor-

rectement installée et mise à la terre conformément à tous les codes et règle-

ments pertinents. Ne modifiez jamais la fiche de quelque façon que ce soit, par

exemple en enlevant la broche de mise à la terre. N’utilisez pas d’adaptateur

de fiche. Si vous n’êtes pas certain que la prise de courant est correctement

mise à la terre, adressez-vous à un électricien qualifié. En cas de défaillance

ou de défectuosité électrique de l’outil une mise à la terre offre un trajet de faible

résistance à l’électricité qui autrement risquerait de traverser l’utilisateur.

Les outil à double isolation sont munis d’une fiche polarisée (une lame est

plus large que l’autre). Cette fiche s’enfonce d’une seule façon dans une

prise de courant polarisée. Si la fiche ne s’insère pas à fond dans la prise de

courant, inversez-la. Sinon, communiquez avec un électricien qualifié pour

installer une prise de courant polarisée. Ne modifiez jamais la fiche. La double

isolation élimine le besoin d’utiliser un cordon d’alimentation à trois broches avec

fil de mise à la terre et un circuit d’alimentation mis à la terre.

Évitez tout contact du corps avec les surfaces reliées à la terre telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque de choc électrique

est accru lorsque le corps est mis à la terre.

N’exposez pas les outils électriques à la pluie ni à l’humidité. Toute infiltration

d’eau dans l’outil augmente les risques de choc électrique.

5.

6.

1.

2.

Évitez l’emploi abusif du cordon. N’utilisez jamais le cordon pour transporter

l’outil ou pour le débrancher de la prise de courant en tirant dessus. Tenez

le cordon à l’écart de la chaleur, de l’huile, des arêtes vives et des pièces

mobiles. Remplacez sans tarder un cordon endommagé. Les risques de choc

électrique augmentent lorsqu’un cordon est endommagé.

Lorsque vous utilisez un outil électrique à l’extérieur, vous devez vous servir

d’une rallonge électrique portant le symbole « W-A » ou « W ». Ces cordons

ont une tolérance appropriée à un usage extérieur et réduisent les risques de choc

électrique.

SECURITE PERSONNELLE

Soyez vigilant, surveillez ce que vous faites et faites preuve de bon jugement

lorsque vous utilisez un outil électrique. Ne vous servez pas de l’outil lorsque

vous êtes fatigué ou sous l’influence de la drogue, de l’alcool ou de médi-

caments. Lorsque vous utilisez un outil électrique un moment d’inattention peut

entraîner des blessures graves.

Portez des vêtements appropriés. Ne portez pas de vêtements amples ni des

bijoux. Attachez-vous les cheveux s’ils sont longs. Gardez vos cheveux, vos

vêtements et vos gants éloignés des pièces mobiles. Des vêtements amples,

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 3SKU 41983

Page 20

des bijoux, ou des cheveux longs non retenus peuvent rester coincés dans les

pièces mobiles.

3.

4.

5.

6.

1.

Évitez les démarrages accidentels. Assurez-vous que l’interrupteur se trouve

à la position d’arrêt (OFF) avant de brancher l’outil. Le fait de transporter l’outil

en gardant le doigt sur l’interrupteur ou de le brancher alors que l’interrupteur est

en position de marche (ON) peut provoquer un accident.

Retirez les clés de réglage ou les autres clés avant de mettre l’outil en marche.

Le fait de laisser une clé quelconque en prise sur une pièce rotative de l’outil peut

causer des blessures.

Évitez tout état de déséquilibre. Tenez-vous de façon stable et maintenez votre

équilibre en tout temps pour vous permettre de garder la maîtrise de l’outil en cas

d’imprévu.

Utilisez l’équipement de sécurité. Portez toujours une protection oculaire.

Utilisez un masque ante poussière, des chaussures de sécurité antidérapantes,

un casque de sécurité ou un protecteur auditif, selon les stipulations. Lorsque vous

utilisez cet outil, portez toujours des lunettes protectrices et un masque ante pous-

sière approuvée par ANSI.

UTILISATION ET ENTRETIEN DE L’OUTIL

Utilisez des serre-joints (pas fournis) ou un autre moyen pratique de retenir

et de soutenir la pièce à travailler sur une plate-forme stable. Le fait de tenir

la pièce à travailler avec une main ou contre votre corps constitue une situation

instable qui pourrait vous faire perdre la maîtrise de l’outil.

2.

3.

4.

5.

6.

Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil approprié fonc-

tionne mieux et de façon plus sécuritaire. Respectez aussi la vitesse de travail qui

lui est propre.

N’utilisez pas l’outil si son interrupteur ne fonctionne pas normalement. Un

outil qui ne peut être contrôlé au moyen de son interrupteur est dangereux et doit

être réparé.

Débranchez la fiche de sa source d’alimentation avant de faire des réglages,

de changer des accessoires ou de ranger l’outil. De telles mesures préventives

réduisent les risques de démarrage accidentel de l’outil. Débranchez toujours

l’outil de la prise de courant électrique avant d’y placer ou d’en enlever des

pièces ou avant un nettoyage.

Rangez les outils non utilisés hors de la portée des enfants et des person-

nes inexpérimentées. Les outils sont dangereux dans les mains d’un utilisateur

inexpérimenté.

Entretenez les outils avec soin. Gardez les accessoires de coupe propres et

bien affûtés. Des outils bien entretenus ayant des bords tranchants bien affûtés

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 4SKU 41983

Page 21

n’ont pas tendance à bloquer et se maîtrisent plus facilement. N’utilisez pas l’outil

endommagé. Faites étiqueter l’outil endommagé « N’ UTILISEZ PAS » jusqu’à ce

que vous le répare.

7.

8.

1.

2.

Vérifiez si des pièces mobiles sont désalignées ou coincées, si des pièces sont

endommagées ou toute autre situation pouvant nuire au bon fonctionnement

de l’outil. Si l’outil est endommagé, faites-le réparer avant de vous en servir.

De nombreux accidents sont causés par des outils mal entretenus.

Utilisez uniquement les accessoires recommandés par le fabricant. Des acces-

soires convenant à un outil en particulier peuvent être dangereux s’ils sont utilisés

avec un autre outil.

ENTRETIEN

L’entretien de cet outil doit être effectué uniquement par une personne qua-

lifiée. Tout entretien réalisé par une personne non qualifiée peut entraîner des

risques de blessures.

Lors de l’entretien de l’outil, utilisez uniquement des pièces de rechange

identiques à celles d’origine. Suivez les instruction décrites à la section d’ins-

pection, entretien et nettoyage de ce guide. L’utilisation de pièces non autorisé

ou le non-respect des consignes d’entretien peut entraîner des risques de choc

électrique ou de blessures.

1.

2.

3.

4.

5.

REGLES DE SECURITE SPECIFIQUES

Lors de l’exécution d’une opération au cours de laquelle l’outil de coupe peut

venir en contact avec les fils cachés ou son propre cordon, tenez l’outil par

ses surfaces isolées de préhension. Le contact avec un fil sous tension rendra

les pièces métalliques exposées de l’outil sous tension et causera des chocs à

l’opérateur.

Portez des protège oreilles avec un marteau perforateur. Une exposition au

bruit peut provoquer une perte auditive.

Entretenez les étiquettes et plaques signalétique qui paraissent sur votrequi paraissent sur votre

outil. Des informations importantes y paraissent. S’il manque de l’information ou

si les informations sont mal écrites, communiquez avec Harbor Freight Tools pour

faire remplacer l’outil.

Maintenez l’aire de travail. Assurez – vous que l’espace de travail est bien éclairé.

Protégez l’outil des conditions mouillées.

Toujours tenez solidement l’outil avec les deux mains pour le démarrer, car

le couple du moteur pourrait vous l’arracher des mains. Utilisez toujours La

Manche Auxiliaire de contrôler des réactions de la couple.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 5SKU 41983

Page 22

6.

N’utilisez pas l’outil s’il est très chaud, s’il manque de l’isolation, si l’isolations’il manque de l’isolation, si l’isolation l’isolation, si l’isolation si l’isolation

est endommagée ou usé et si l’outil produit des étincelles.si l’outil produit des étincelles.

7.

8.

9.

10.

Ne laissez pas d’arrêter le foret pendant qu’il est dans le trou. Retirez le foret

pendant qu’il tourne. Si le foret arrêt de tourner pendant qu’il soit dans le trou, ne

remettez-la pas en marche. Retirez le foret du Marteau et puis retirez – le du ma-

tériau.

Évitez les démarrages accidentels. Assurez-vous que vous êtes prêté à travailler

avant de mettre en marche l’outil.

Tenez toujours le cordon à l’écart des pièces mobiles de l’outil.

Avertissement ! Consultez votre médecin avant d’utiliser cet outil si vous portez un

stimulateur cardiaque. Le champ magnétique à proximité d’un cœur peut causer

du brouillage ou s’affaiblir le fonctionnement du stimulateur. En plus vous devriez

respecter les suivants :

Evitez d’Utiliser un outil tout seul

•

Si câblé par un cordon d’alimentation, assurez –vous que l’outil est mise à la

•

terre correctement. Un système « Ground Fault Interrupt » (GFCI) est une bonne

précaution. Cet appareil ne coûte pas cher et est une manière d’éviter des blessures graves.

Afin de eviter des chocs électriques, entretenez et inspectez toutes les outils

•

avant de l’utiliser.

11.

12.

13.

Ne déposez jamais l’outil avant que le moteur ait complètement cessé de

tourner. Le moteur en rotation risque de causer des blessures.

Lorsque l’outil est branché, ne laissez-le jamais sans surveillance. Mettez

l’interrupteur en position « arrêt » puis retirez la fiche de la prise avant de sortir.

AVERTISSEMENT! Certains outils, tels que les sableuses électriques, les scies,

les meules, les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles (en Californie)

d’entraîner le cancer des malformations congénitales ou pouvant être nocifs pour

le système reproductif. Parmi ces produits chimiques, on retrouve :

le plomb dans les peintures à base de plomb;

•

la silice cristalline dans les briques et le ciment et autres produits de maçonne-

•

rie;

l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique.

•

Le risque associé à telles expositions peut varier selon la fréquence avec laquelle

on effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler

dans un endroit bien ventilé et utiliser l’équipement de sécurité approprié, tel un

masque anti poussière spécialement conçu pour filtrer les particules microscopique.

(California Health & Safety Code § 25249.5, et seq.)

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 6SKU 41983

Page 23

MISE À LA TERRE

AVERTISSEMENT!

Une mauvaise connexion du fil de terre de l’outil peut entraîner un risque de choc

électrique. En cas de doutes, consultez un électricien qualifié ou une personne

affectée à l’entretien. Ne modifiez pas la fiche de l’outil. Ne modifiez pas la fiche

mise à la terre à trois broches. N’utilisez pas l’outil si le cordon d’alimentation

ou la fiche est endommagé. S’il est endommagé le faites réparer dans un centre

de service avant de l’utiliser.

LES OUTILS MISE À LA TERRE : LES OUTILS FICHE À TROIS BROCHES

1.

2.

3.

Les outils étiquetés «Mise à la terre requis» sont munis d’un cordon tri filaire mise

à la terre et une prise de mise à la terre. La fiche doit être branché à un cordon mis

à la terre. En cas de fonctionnement défectueux ou de panne, la mise à la terre

assure un parcours sécuritaire de faible résistance pour le courant électrique, ce

qui réduit les risques de choc électrique. (Voir L’IMAGE A.)

La broche de mise à la terre à l’intérieur de la fiche est raccordée à travers le fil

vert à l’intérieur du cordon au conducteur de mise à la terre de l’outil. Le fil vert à

l’intérieur du cordon doit être le seul fil raccordé au conducteur de mise à la terre

de l’outil et ne devrait jamais être raccordé à une lame sous tension.

(Voir L’IMAGE A.)

L’outil doit être branché dans une prise de courant correctement installée et mise

à terre conformément à tous les codes et règlements locaux. La fiche et la prise de

courant semblable à celles l’illustrée ci-après. (Voir L’IMAGE A.)

1.

L’IMAGE A L’IMAGE B

LES OUTILS À DOUBLE ISOLATION: LES OUTILS AVEC

FICHE À DEUX BROCHES

La double isolation élimine le besoin d’un cordon tri filaire mis à la terre et d’un

système d’alimentation mise à la terre. Ils ont un système spécial double isolation

qui se conforme aux exigences de OSHA et conforme aux normes de Underwri-

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 7SKU 41983

Page 24

ters Laboratories, Inc., de L’Association Canadienne de Normalisation et du Code

Electrique National. (Voir L’IMAGE B.)

2.

1.

2.

3.

4.

5.

6.

Les outils à double isolation peuvent être utilisé dans l’un ou l’autre de la prise de

courant d’un circuit de 120 volts comme le montre l’illustration ci-dessus.

(Voir L’IMAGE B.)

CORDONS DE RALLONGE

L’outil avec mise à la terre doit utiliser une rallonge à trois fils. Les outils a double

isolation peuvent utiliser une rallonge à deux ou trois fils.

L’utilisation d’un cordon de calibre inférieur occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. (Voir L’IMAGE C.)

Le calibre du fil est inversement proportionnel à sa grosseur. (Voir L’IMAGE C.)

Lorsque vous utilisez plus d’un cordon de rallonge pour longueur, assurez-vous

que le calibre des fils des cordons convient à l’intensité du courant consommé par

l’outil. (Voir L’IMAGE C.)

Si vous utilisez un cordon de rallonge pour multiples outils, mettez l’intensité nominale de la plaque signalétique et utiliser le somme de déterminer le calibre de

cordon minimum requis. (Voir L’IMAGE C.)

Lorsque vous utilisez un outil électrique à l’extérieur, vous devez vous servir d’une

rallonge électrique portant le symbole « W-A » ou « W ».au Canada. Ces cordons

ont une tolérance appropriée à un usage extérieur.

7.

8.

Assurez-vous que la rallonge est bien câblée et en bon état. Si la rallonge est endommagée, remplacez-la ou faites-la réparer par un électricien qualifié avant de

vous en servir.

La rallonge ne doit pas venir en contact avec des objets tranchants, être exposée

à de la chaleur excessive ni être utilisée dans un endroit mouillé ou humide.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 8SKU 41983

Page 25

CALIBRE MINIMUM DES RALLONGES *

(COURANT DE 120 OU 240 V SEULEMENT)

L’INTENSITÉ

Longueur de la rallonge en pieds

NOMINALE

(au maximum)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

L’IMAGE C

25 pieds 50 pieds 75 pieds 100 pieds 150 pieds

*Basé sur limitant le volt du cordon, baissez à cinq volts à

150 % de l’intensité nominale.

SYMBOLES

Construction de Classe 2

Association Canadienne de

Normalisation

V~

A

n0 xxxx/min.

Underwriters Laboratories Inc.

Volts

Ampères

Sous Vide xxxx/tours à la minute

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 9SKU 41983

Page 26

DÉBALLER

Lorsque vous déballez, assurez-vous que les pièces ne sont pas endommagées.

S’il manque des pièces ou si des pièces sont endommagées, communiquez le plus vite

possible avec Harbor Freight Tools au numéro qui figure sur la couverture de ce guide.

ASSEMBLER ET RÉGLAGE

Le 1” Marteau rotatif est conçu d’être utilisé dans l’application suivante :Marteau rotatif est conçu d’être utilisé dans l’application suivante :

Pour perçage dans la pierre et dans la maçonnerie.

•

Pour ciseler.

•

Interrupteur (22)

Interrupteur

(96)

Manche

Supérieure (91)

Protecteur (104)

Ressort (41)

Jauge de

Profondeur

(106)

Manche

Auxiliaire (107)

Balai de Carbone (82)

L’IMAGE 1 – Faire Fonctionner Le Marteau Rotatif.

Foret

Voir L’IMAGE 1 au-dessus pour vous familiariser avec les caractéristiques divers

de la marteau rotatif. Une liste complète de numéro de la pièce figure à la page 9. Le

Schéma du Produit complet se figure à la page 10.

INSTALLATION ET RETRAIT DES FORETS

Avertissement : Lorsque vous installez et retirez des forets, portez toujours des gants

pour vous protéger. Les forets peuvent devenir très chaudes lors de l’utilisation.

Laissez bien refroidir les forets avant de les retirer. Ne frappez pas des forets

coincés avec un marteau, ceci peut faire projeter des particules et entraîner des

dommages. Débranchez toujours la prise de courant lorsque vous installez et re-

tirez des forets et ciseaux.

1.

2.

Cet outil est muni d’Une Protecteur (104). Faites glisser la Protecteur sur la Cou-

vercle à l’avant (39).

Ajutez une couche de graisse ou l’huile à la machine dans la perceuse ou dans la

tige du foret.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 10SKU 41983

Page 27

3.

Se retirez sur le Ressort (41) – voir L’IMAGE 1, pendant que vous insérez et tour-

nez le foret jusqu’à ce qu’il glisse. Relâchez le Ressort (41) pour qu’il retourne à

sa position originale. Ne devriez pas être pu déplacer le foret sans se retirez sur

le ressort. Assurez – vous que le foret ne déplace pas, ceci s’assurera qu’il est

bien installé.

4.

Pour retirer le foret, retirez – vous sur le Ressort (41) et retirez le foret. Pour des

performances optimales, gardez toujours le foret et ciseaux bien affûtes.

Remarque: Lorsque vous percez un trou plus grand que 1-1\4” diamètre, assurez – vous

que vous utilisez un foret avec 4 tranchants.

AJUSTER LA MANCHE AUXILIAIRE

La Manche Auxiliaire (107) peut être mis dans une variété de positions. Pour tourner

la Manche Auxiliaire (107), tournez la Manche Auxiliaire (107) dans le sens des

aiguilles d’une montre pour desserrer la bande et La boulon à quatre perpendiculaire

(111). Une fois desserrée, tournez la Manche Auxiliaire à la position désiré. Pour

serrer, tournez la manche vers le droit.

UTILISER LA JAUGE DE PROFONDEUR

La Jauge de Profondeur (106) peut être utilisé si la Manche Auxiliaire (107) est

placé sur l’une ou l’autre côté ou le dessus de l’outil. Le corps de l’outil bloquera la Jauge

de Profondeur si la manche est à la position inférieur.

1.

2.

Desserrez la Manche Auxiliaire (107) en tordant La Manche vers le droit.

Une fois La Manche Auxiliaire (107) est suffisamment desserré, retirez –vous sur

Le Support de Manche (108) jusqu’à ce que le trou dans Le Support de Manche

(108) est pleinement ouvert.

Poignée Supérieure

– Position à gauche

3.

Glissez La Jauge de Profondeur (106) à la longueur désirée.

La pointe de La Jauge de Profondeur à l’avant de l’outil doit être la profondeur

désirée du trou pour être percé. La profondeur est de la pointe du foret jusqu’à la

Poignée Supérieure

– Position à droite

L’IMAGE 2 – CHANGER LA RÉGLAGE

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Interrupteur

Page 11SKU 41983

Page 28

pointe de La Jauge de Profondeur. Par exemple, pour un trou de 2 ” mesurez 2 ”

de la pointe du foret. Placez la pointe à l’avant de La Jauge de Profondeur à cette

positon la. (Voir L’IMAGE 1).

4.

Après La Jauge de Profondeur (106) est placé dans la position désirée, glissez La

Support de Manche (108) vers le haut et tordez La Manche Auxiliaire vers le droit

jusqu’à ce qu’elle est serrée. La Jauge de Profondeur devrait être bien placée, et

ne devrait pas déplacer.

CHANGER LA POSITION

Le Marteau Rotatif a un Interrupteur (22) et une Poignée Supérieure (91) que doit

•

être ajusté avant de percer, ou ciseler – voir L’IMAGE 2.

L’Interrupteur à l’avant (22) a sur un côté- un symbole du Marteau et une Perceuse.

•

Situé à l’autre côté est un symbole de juste un marteau. La Poignée Supérieure

(91) peut être braqué à gauche ou à droite. Il y a des symboles pour un marteau et

une perceuse à gauche et seulement un symbole pour une perceuse à droite.

Pour percer, fixé L’Interrupteur (22) pour que l’image du Marteau et de la Perceuse

•

soit tournée vers l’avant. Tournez La Poignée Supérieure (91) pour qu’elle tourné

vers le droit au symbole de la perceuse (Voir L’ Image 2).

Pour percer avec le marteau, fixé L’Interrupteur (22) pour que le marteau et la

•

perceuse soient tourné vers l’avant. Tournez La Poignée Supérieure (91) pour

qu’elle soit tourné vers la gauche aux symboles du Marteau et de la perceuse.

Pour ciseler, fixé L’Interrupteur (22) pour que seulement l’image du Marteau soit

•

tourné vers l’avant. Tournez La Poignée Supérieure (91) pour qu’elle soit tourné

vers la gauche au symbole du Marteau et la perceuse.

1.

2.

3.

4.

FONCTIONNEMENT

Avant de brancher le cordon électrique, insérez le foret désiré et ajustez La Manche

Auxiliaire et Jauge de Profondeur à la position désirée (Voir les sections précèdent).

En gardant votre doigt à l’écart de L’Interrupteur « ON » (96), branchez le cordon

électrique.

Lorsque vous êtes prêt à utiliser Le Marteau Rotatif, enfoncez L’Interrupteur « ON »

(96) et faites fonctionner l’outil sans charge pendant environ une minute. Ceci permet

les pièces pour être correctement lubrifié. Vérifiez si l’outil fonctionne bien. Une fois

l’outil est réchauffé, il est prêt pour utilisation.

Pour débrancher le Marteau Rotatif, relâchez L’Interrupteur (96).

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 12SKU 41983

Page 29

INSPÉCTION, ENTRETIEN ET NETTOYAGE

1.

2.

3.

4.

5.

ATTENTION ! Assurez – vous que L’Interrupteur est réglé à « OFF » et que

l’outil est débranché de la prise de courant électrique avant d’y placer ou d’en

enlever des pièces ou avant un nettoyage.

AVANT CHAQUE UTILISATION, vérifiez l’état de l’outil. Vérifiez si des pièces

mobiles sont désalignées ou coincées, si des pièces sont endommagées ou toute

autre situation pouvant nuire au bon fonctionnement de l’outil. Si l’outil est endommagé, faites-le réparer avant de vous en servir. Ne utilisez pas votre outil si une

pièce est endommagée.

NETTOYAGE : Nettoyez régulièrement l’aire de travail avec une brosse sec ou un

chiffon propre. Gardez les pièces mobiles légèrement huilées. Conservez toujours

le moteur et les conduits libres de poussière et de débris.

LUBRICATION : Utilisez la clé anglaise dans cette trousse de desserrer Le Capuchon Plombé (18) situé au dessus du boîtier. Ajuté l’huile inclus dans cette trousse

et remplacez et serrez Le Capuchon Plombé.

CHANGER LES BALAIS DE CARBONE:

En utilisant un petit tournevis, retirez La Bouchon de Porte-balai (81). Lorsque

a.

vous retirez Les Bouchon de Porte-balai, Le Porte – Balai (83) peut surgir. Ne

desserrez pas Les Balai de Carbone. Si Le Porte – Balai ne surgie pas, retirez

– le doucement en utilisant la pointe du tournevis. Vérifiez la surface de chaque

balai. La surface doit être lisse et propre. S’il y a des éraflures, ou si la balai

est brisé, remplacez – la sans tarder avec un balai de recharge approuvé de

Harbor Freight Tools.

Si le balai n’est pas endommagé et est sale, vous pouvez le nettoyer avec une

b.

gomme. Utilisez la gomme de retirez la saleté. Retirez des poussières laissées

lors de l’utilisation de la gomme.

Réinstallez chaque Balai de Carbone (82) en la réinsérant dans La Porte – Balai

c.

(83). Vissez La Bouchon de Porte – Balai (81) dans La Porte – Balai et serrez.

FICHE D’ENTRETIEN

Type d’Entretien

Vérifiez si l’outil est

endommagé

Nettoyez l’extérieure et lubrifiez

des pièces mobiles exposées

Lubrifiez*

Remplacez Les Balai de

Carbone

*La Lubrification du Marteau Rotatif est complétée à l’usine. L’outil devrait être lubrifié après 50 heures d’utilisation.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Avant

d’Utilisation

X

Après

Utilisation

X

Après Chaque

50 heures

d’Utilisation

X

Après Chaque

100 Heures

d’Utilisation

X

Page 13SKU 41983

Page 30

GUIDE DE DÉPANNAGE

Problème Explication Possible Solution

Le moteur ne mets

pas en marche l’outil

L’outil semble faire

trop de bruit ; ne

tourne pas ou tourne

lentement

Court – circuit partiel Court –circuit partiel ou circuit ouvert

Basse tension au

voltage principal

Boîte de Vitesse est

très chaude

Il y a des étincelles Court –circuit ou casse à l’Armature

Alimentation électrique coupée

1.

Vérifiez les branchements

2.

Armature ou bobine de champ brûlé

3.

Casse de bobine de stator

4.

Les Balai de Carbone usé

5.

Moteur surchargé à la suite de la

profondeur de perçage excessif ou

tension

à l’Armature

Voltage de l’alimentation électrique

trop bas

Surchargé, foret émoussé

1.

Bobines humides

2.

Ajustage incorrect

3.

Basse de volts

4.

1.

Surface de Armature ne lisse pas

2.

et ne propre pas

Examinez l’alimentation électrique

1.

Réparez l’interrupteur

2.

Changez la bobine électrique

3.

Remplacez la bobine de stator

4.

Remplacez Les Balai de Carbone

5.

Réduisez la profondeur de perçage ou

tension. Baissez la force.

Réparez ou changez L’Armature.

Ajustez la puissance de voltage

principal

Réduisez la charge, aiguisez le foret.

1.

Essuyez les bobines électriques.

2.

Réparez ou changez l’armature

3.

Ajustez le voltage.

4.

Réparez L’Armature

1.

Inspectez et nettoyez L’Armature.

2.

GARANTIE

Déférez au texte

anglais pour

l’explication de

garantie.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 14SKU 41983

Page 31

LES PIÈCES

Pièce Description Q’ty

1 Joint Torique 1

2 Balle d’Acier 3

3 Cylindre 1

4 Clavette Parallèle fixée par vis 2

5 Piston 1

6 Joint Torique 1

7 Support de Ressort 1

8 Ressort 1

9 Embrayage 1

10 Troisième Rapport 1

11 Joint Torique 1

12 Piston 1

13 Arbre de Couplage 1

14 Roulement à Aiguilles 1

15 Joint Torique 1

16 Joint Torique 1

17 Planche à Cadrer 1

18 Capuchon Plombé 1

19 Carter d’engrenage 1

20 Plaque Signalétique 1

21 Vis M4 x 8 1

22 Interrupteur 1

23 Ressort 1

24 Balle d’Acier 1

25 Planche 1

26 Joint Torique 1

27 Bloc à demi cercle 1

28 Vis M3 x 8 2

29 Gaine 1

30 Vis M5 x 25 4

31 Ressort 4

32 Bloc Cylindre 1

33 Culasse 1

34 Bague d’Etanchéité d’huile 1

35 Rondelle d’Etanchéité 1

36 Alésage 1

37 Bague Entretoise 1

38 Couvercle à Distance 1

Pièce Description Q’ty

39 Couvercle à l’avant 1

40 Joint Torique 1

41 Ressort 1

42 Poteau d’acier 2

43 Bague de fond 1

44 Joint Torique 2

45 Joint Torique 2

46 Deuxième Marteau 1

47 Ressort 1

48 Plaque Signalétique 1

49 Bague à Huile d’étanchéité 1

50 Pignon 1

51 Bague Entretoise 1

52 Alésage 1

53 Coussinet/ Entretoise 1

54 Rondelle d’ Etanchéité 2

55 Plaque à Perte Volumétrique 2

56 Pignon No. 2 1

57 Rondelle Élastique 1

58 Écrou Spécial 1

59 Alésage 1

60 Vilebrequin 1

61 Balle d’Acier 3

62 Alésage 1

63 Rondelle d’Etanchéité 1

64 Chapeau de Palier 1

65 Vis M5 x 60 2

66 Pignon No. 1 1

67 Rondelle d’ Etanchéité 1

68 Ressort 1

69 Arbre d’Embrayage 1

70 Couvercle Principal 1

71 Alésage 1

72 Armature 1

73 Guide de Ventilateur 1

74 Vis de Champ 2

75 Rondelle d’ Etanchéité 2

76 Induction 2

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 15SKU 41983

Page 32

LES PIÈCES

Pièce Description Q’ty

77 Alésage 1

78 Boîtier 1

79 Rondelle d’ Etanchéité 4

80 Vis M5 x 50 4

81 Bouchon de Porte-balai 2

82 Balai de Carbone 2

83 Porte – Balai 2

84 Vis auto taraudeuse $ x 16 2

85 Couvercle à l’arrière 1

86 Vis fixée M5 x 6 2

87 Vis auto taraudeuse M4 x 23 3

88 Roulement à Aiguilles 1

89 Support de Ressort 1

90 Joint Torique 1

91 Poignée Supérieure 1

92 Couvercle à gauche 1

93 Manchon Isolant 4

94 Couvercle d’Interrupteur 1

Pièce Description Q’ty

95 Condensateur 1

96 Interrupteur 1

97 Planche à pressant cordon 1

98 Vis auto taraudeuse 4 x 16 2

99 Planche 1

100 Poignée à Bloc 1

101 Couvercle angle droit 1

102 Vis auto taraudeuse 5 x 25 2

103 Vis M5 x 25 2

104 Protecteur 1

105 Caisson de Soufflage 1

106 Jauge de Profondeur 1

107 Manche Auxiliaire 1

108 Support de Manche 1

109 Manche 1

110 Carton pour emboutissage 1

111

La Boulon à quatre perpendiculaires

1

LISEZ S’IL VOUS PLAÎT LE SUIVANT SOIGNEUSEMENT

LE FABRICANT ET-OU LE DISTRIBUTEUR A FOURNI LA LISTE DE PIÈCES ET LE DIAGRAMME

DE MONTAGE DANS CE MANUEL COMME UN INSTRUMENT DE RÉFÉRENCE SEULEMENT.

AUCUN LE FABRICANT OU LE DISTRIBUTEUR FONT N’IMPORTE QUELLE REPRÉSENTATION

OU GARANTIE DE N’IMPORTE QUELLE SORTE À L’ACHETEUR QU’IL OU ELLE EST AUTORISÉ

POUR FAIRE N’IMPORTE QUELLES RÉPARATIONS AU PRODUIT, OU QU’IL OU ELLE EST AUTORISÉ POUR REMPLACER N’IMPORTE QUELLES PIÈCES DU PRODUIT. EN FAIT, LE FABRICANT

ET-OU LE DISTRIBUTEUR DÉCLARE EXPRESSÉMENT QUE TOUTES LES RÉPARATIONS ET LES

REMPLACEMENTS DE PIÈCES DEVRAIENT ÊTRE ENTREPRIS PAR LES TECHNICIENS DIPLÔMÉS

ET AGRÉÉS ET PAS PAR L’ACHETEUR. L’ACHETEUR SUPPOSE TOUT LE RISQUE ET LA RESPONSABILITÉ SURVENANT DU FAIT DE SES RÉPARATIONS AU PRODUIT ORIGINAL OU AUX PIÈCES

DÉTACHÉES Y, OU SURVENANT DU FAIT DE SON INSTALLATION DE PIÈCES DÉTACHÉES Y.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 16SKU 41983

Page 33

SCHÈMA DU PRODUIT

Notez le Numéro de Série du Produit ici:

Remarque: S’il n’y a pas de numéro de série, notez la date d’achat.

Remarque: Des pièces figurant sur la liste ont pour but d’illustrer seulement, et ne sont

pas disponible comme des pièces de rechange.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 17SKU 41983

Loading...

Loading...