Page 1

10” Auto PlAner

Model

41921

®

ASSEMBLY AND OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 1999 by Harbor Freight Tools®. All rights reserved. No portion of this manual or

any artwork contained herein may be reproduced in any shape or form without the express

written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

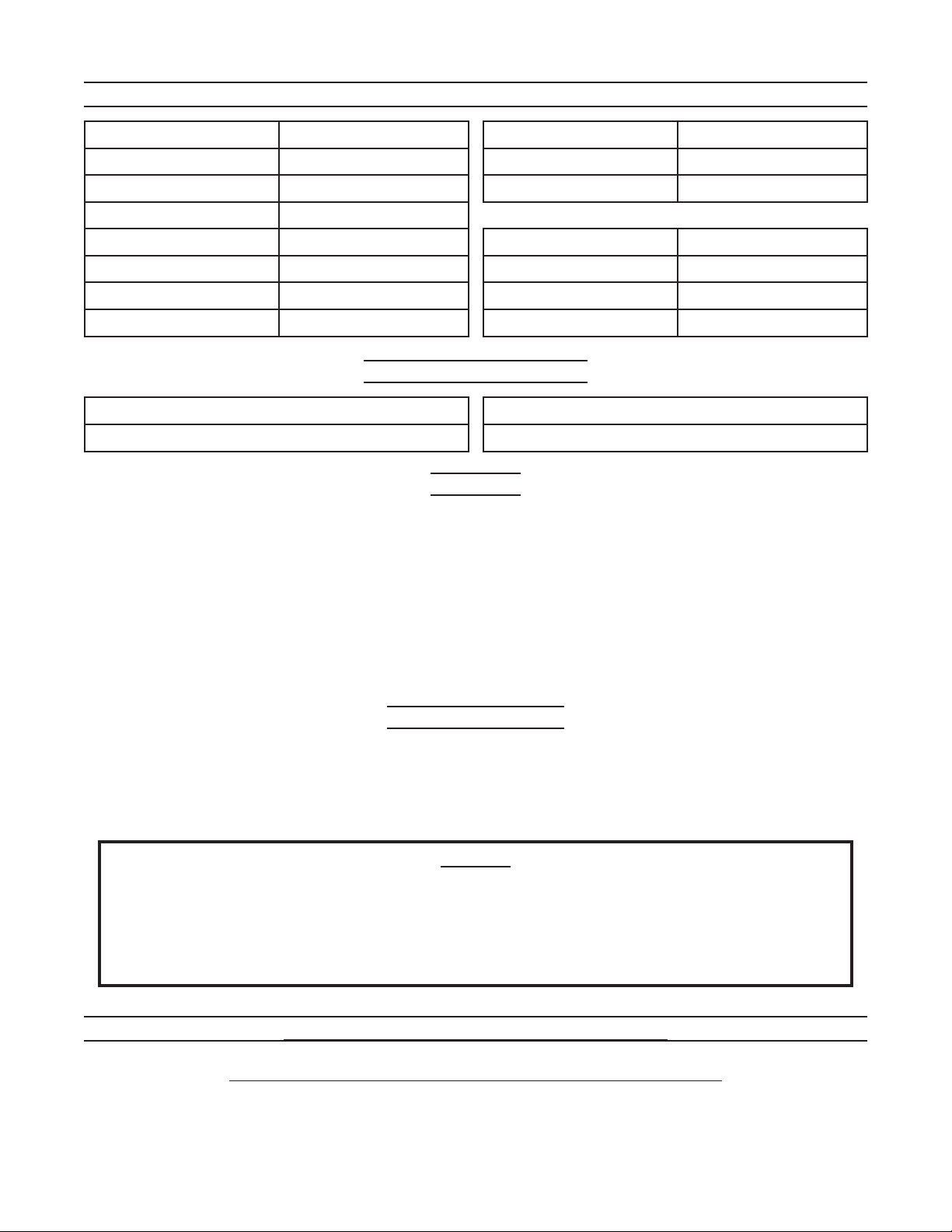

SPECIFICATIONS

Motor 115 V/60 Hz. 2.2 HP

Amps 7.1 (no load)

Cuts per Minute 16,000

Cutter Head RPM’s 8,000 (no load)

Cutting Knives 2, Bi-Metal, M-2 edge

Feed Rate 23 feet per minute

Table Dimension 12-5/8”L x 10-1/4”W

Sound Level 94 dB

Included Accessories

Combination wrench

2 hex wrenches

1.

2.

3.

Adjustable extensions to support long workpieces.

Anti-kickback safety devices prevent workpieces from being ejected toward the operator.

Two bi-metallic blades are adjustable and replaceable for powerful cutting performance.

Power Cord 5’9”, 3-pole, UL listed

Overall Dimensions 22” x 16” x 23-1/4”

Weight 89.5 lb.

Cutting Capacity

Length of unbutted stock 8” minimum

Width of stock 10” max.

Thickness of stock 1/4” - 5”

Depth of cut 1/8” max.

Carbon Brush set

Blade / Knife Gauge

Features

4.

5.

6.

7.

Compact and lightweight machine can plane workpieces up to 10” wide and 5” thick.

Positive adjusting table with crank handle and easy to read thickness gauge.

ON/OFF switch has removable safety lock device to prevent unauthorized use of the machine.

Integral circuit breaker protects the motor from burn out.

Save this manual

You will need the manual for the safety warnings and cautions, assembly instructions, operating

procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep both this manual and your invoice

in a safe, dry place for future reference.

NOTICE

The Warnings, Cautions, and Instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

SAFETY WARNING & CAUTIONS

1.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL!

Warning! Make sure blade is fastened and tightened down securely.

For technical questions, please call 1-800-444-3353.

Page 2SKU 41921

Page 3

2.

Keep work area clean. Cluttered areas invite injuries.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Observe work area conditions. Do not use tools in damp, wet, or poorly lit locations. Don’t ex-

pose to rain. Keep work area well lit. Do not use electrically powered equipment in the presence

of flammable gases or liquids.

Keep children away. Children must never be allowed in the work area. Do not let them handle

machines, tools, or equipment.

Store idle equipment. When not in use, tools must be locked up in a dry location to inhibit rust.

Always lock up tools and keep out of reach of children.

Do not force the tool. It will do the job better and more safely at the rate for which it was intended.

Do not use inappropriate attachments in an attempt to exceed the tool’s capacities.

Use the right tool for the job. Do not use a tool for a purpose for which it was not intended.

Dress properly. Do not wear loose clothing or jewelry, as they can be caught in moving parts.

Non-skid footwear is recommended. Wear restrictive hair covering to contain long hair. Always

wear appropriate work clothing.

Use eye, ear, and breathing protection. Always wear ANSI approved impact safety goggles if you

are producing metal filings or wood chips. Wear an ANSI approved dust mask or respirator when

working around metal, wood, and chemical dusts and mists. Use ANSI approved ear protection

when working in a loud or noisy environment.

Do not abuse the power cord. Protect the power cord from damage, either from impacts, pulling

or corrosive materials. Do not yank machine’s cord to disconnect it from the receptacle.

Do not overreach. Keep proper footing and balance at all times. Do not reach over or across run-

ning machine.

12.

13.

14.

15.

16.

17.

18.

Maintain tools with care. Keep tools sharp and clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect power cord periodically and, if dam-

aged, have it repaired by an authorized technician. Inspect all hydraulic seals for leaks prior to

use. Control handle and power switch must be kept clean, dry, and free from oil and grease at all

times.

Remove adjusting keys and wrenches. Be sure that keys and adjusting wrenches are removed

from the tool or machine work surface before operation.

Avoid unintentional starting. Be sure that you are prepared to begin work before turning the

start switch on.

Stay alert. Watch what you are doing. Do not operate this machine when you are tired.

Do not operate this machine while under the influence of alcohol, drugs, or prescription

medicines.

Check for damaged parts. Before using any tool, any part that appears damaged should be care-

fully checked to determine that it will operate properly and perform its intended function. Check

for alignment and binding of moving parts, any broken parts or mounting fixtures, and any other

condition that may affect proper operation. Any part that is damaged should be properly repaired

or replaced by a qualified technician. Do not use the tool if any switch does not turn on and off

properly.

Replacement parts and accessories. When servicing, use only identical replacement parts in-

tended for use with this tool. Replacement parts are available from harbor freight tools. Use of any

other parts will void the warranty.

For technical questions, please call 1-800-444-3353.

Page 3SKU 41921

Page 4

Special Warnings when using this Planing Machine

Using this Planer may create special hazards.

Take particular care to safeguard yourself and those around you.

1.

2.

3.

4.

5.

Electrical Safety. Never operate any tool if there is an electrical hazard. Never operate an

electrical tool in wet conditions. Never operate a tool with an improper electrical cord or extension

cord. Never operate an electrical tool unless it is plugged into a properly grounded outlet, which

supplies 110-120 Volts at 60 Hz. We recommend you use a circuit which is protected by an ap-

propriate circuit breaker.

Ejected Material. Use safe practices to avoid injury from ejected material. Because the planer

turns at high speed, there is a danger of being injured by materials that may be ejected. Always

wear ANSI-certified eye protection. Always stand to one side of the line in which the materials are

being inserted or extruded, to avoid being hit if particles are ejected. Never allow bystanders to

be in the proximity of the Planer while in operation.

Jamming. Avoid causing the planer to bog down or jam by avoiding the following situations. Do not

attempt to plane more than 1/8” at a time, or less if the wood is very hard. Do not attempt to feed

more than the stated feed rate, or less if the wood is very hard. Be sure your knife blades are kept

sharp. Check all workpieces for knots and foreign objects before planing. If the workpiece jams, it

is likely the circuit breaker will break to protect the motor.

Entanglement. Use extreme caution to prevent loose materials from being caught in the

machine. Never operate this Planer with loose clothing, long hair, jewelry, or other items which

may become caught in the blades or workpieces. In case of entanglement, press the OFF switch

immediately.

People with pacemakers should consult their physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause pacemaker interference or pacemaker failure.

6.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activi-

ties, contains chemicals known [to the State of California] to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are: Lead from lead-based paints

Crystalline silica from bricks and cement or other masonry products Arsenic and chromium from

chemically treated lumber. Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specially designed

to filter out microscopic particles. (California Health & Safety Code § 25249.5, et seq.)

NOTICE: No list of warnings can be all inclusive.

The operator must supply common sense, and operate this tool in a safe manner.

UNPACKING

1.

2.

Remove protective crating and materials carefully. In the event of damage in transit, contact Harbor

Freight Tools. Be sure you have all small parts accounted for before discarding packing materi-

als.

Check to be sure all parts are present. In addition to the planer, you should receive the accessories

noted on page 2. You should also receive a crank handle, 2 carrying handles, and 2 table exten-

sions, with their related hardware. If the 4 base brackets are not installed, they should be included,

together with attaching hardware.

For technical questions, please call 1-800-444-3353.

07i

Page 4SKU 41921

Page 5

INSTALLATION

1.

2.

3.

It is important that the machine be located on a solid, level platform. Find a location that has easy

access to 110-120 Volt electrical service. Make sure this machine is located in a well lighted and

well ventilated area. The floor should be resistant to vibration. There must be adequate room to

insert and remove workpieces through the planer.

To permanently install the machine, check the platform to be sure it is even and level. Make any

required corrections to the platform. If the base brackets are not attached to each lower corner

of the machine, attach them using the supplied hardware. Mark and drill holes, and mount the

machine using bolts and nuts.

If the machine will not be permanently installed, it is advisable to attach it to wooden skids by

means of the base brackets. The skids should be solid hardwood at least 1” in thickness and 2”

in width. Route these skids along each side of the machine from front to back. Each skid should

extend several inches beyond the machine to allow them to be firmly clamped to the work surface

before using the machine.

WARNING: Never operate this machine if it is not firmly attached to a work surface. If

left unattached, the machine may move along the work surface possibly falling over,

ejecting the work piece, or creating other hazards which can cause serious injury.

Electrical Power

This machine requires a 110-120V 60 Hz grounded power supply. This power is available in most

common household or workshop outlets in the United States. Please observe the following safety

precautions. (Note: Voltage variations of more than + or - 10% from the specification will result

in noticeable reduction of service, and may cause damage to the motor).

1.

2.

3.

4.

Route the power cord in a way that avoids damage to the cord from other tools or machinery, and

isolates the cord from exposure to wet or corrosive conditions.

Avoid routing cord along the floor, walkways, or halls, where it may cause a trip hazard.

Be sure the outlet is grounded and protected with an appropriate circuit breaker. Check with a

qualified electrician if you have any doubts or concerns about your electrical service.

If you will use an extension cord, be sure to use a 3-prong, grounded cord. Preferably the cord will

be UL listed. Know that long extension cords cause a noticeable power drop. It is necessary to

use cords of the proper gauge to avoid excessive resistance or power drop within the cord. Please

comply with the following table.

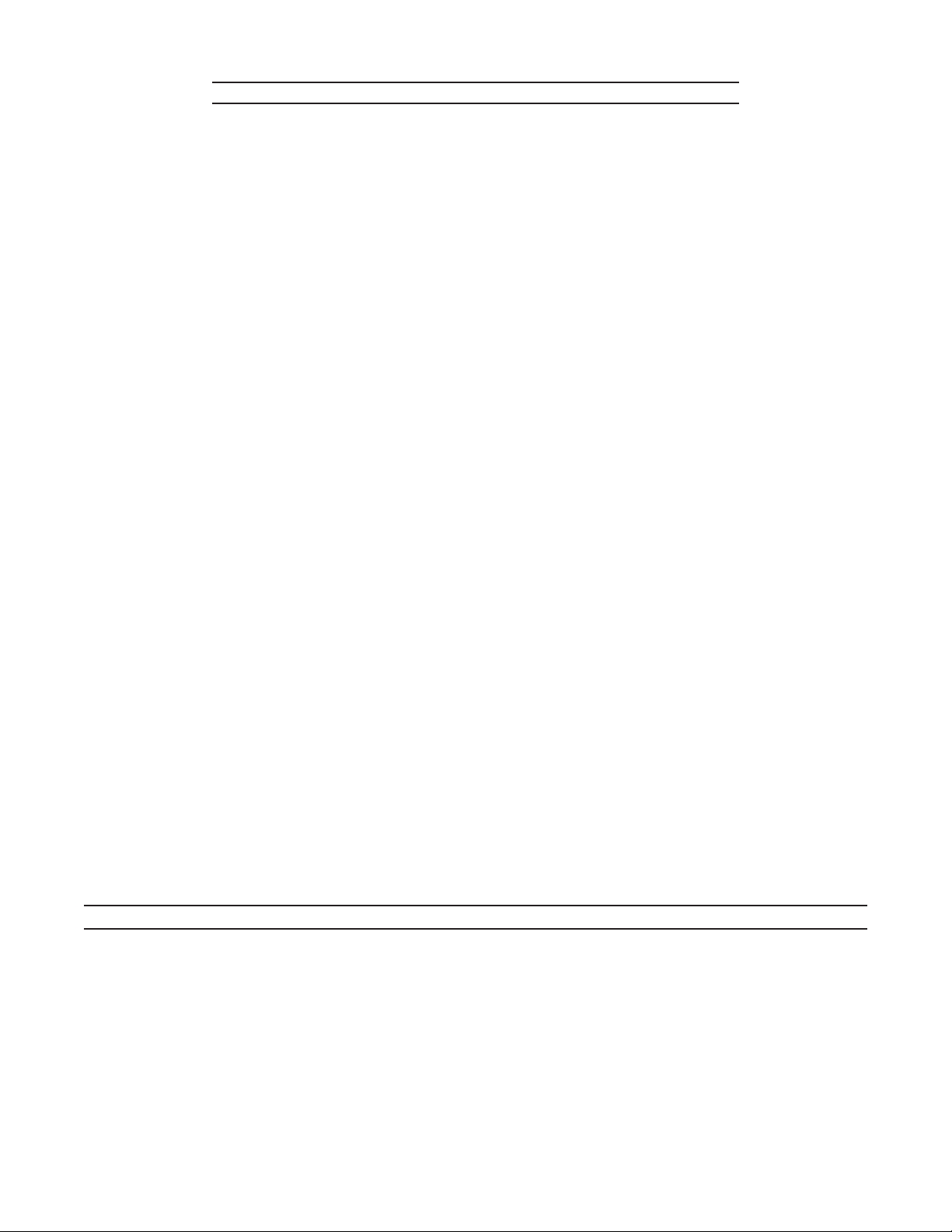

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS* (120 OR 240 VOLT)

NAMEPLATE AMPERES

(at full load)

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

* Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

EXTENSION CORD LENGTH

For technical questions, please call 1-800-444-3353.

Page 5SKU 41921

Page 6

Completing Assembly

WARNING: Unplug the machine before any assembly or adjustment.

Attaching the Carrying Handles

1.

2.

Installing the table extensions

1.

2.

Setting the Cutting Depth

1.

2.

3.

Locate the two carrying handles (349), and their hardware, Screws (327).

Attach the handles to the top of the machine firmly using the screws.

With the roller up, place each table extension bracket (157) onto the table (125) and attach using

two cap screws (164). Be sure the bracket assemblies are firmly attached, but are able to rotate

up for storage.

Adjust each table extension so that a workpiece supported by the roller is level and in the same

plane with the table. Do this by adjusting the cap

screws (1) in or out as required. See Figure 2. Check

the adjustment by placing a straight edge at least

24” long through the machine, and resting on the

table and both extension rollers. When the extension

is properly adjusted, lock the cap screws in place

with the lock nuts (2).

Place the Table Adjustment Handle (150) over the square-ended Control Screw (130) which pro-

trudes through the top of the machine.

Turn the Table Adjustment Handle to raise or lower the Table to the desired cutting thickness.

Read the cutting depth on the scale on the right of the machine.

Figure 2. Table Extension AdjustmentFigure 2. Table Extension Adjustment

4.

Remove the Table Adjustment Handle before operating.

Operating the Power Switch

1.

2.

3.

The power switch is on the lower right front of the machine.

The Safety Switch Cover must be in place to operate the Power

Switch. You can remove the Cover and store it in a safe place

to prevent unauthorized use.

Press the Switch UP to turn

the machine ON, and DOWN

to turn it OFF.

Integral Circuit Breaker

1.

2.

The circuit breaker trips if the

amp draw exceeds 10 A., pre-

venting motor burn out if the

planer jams, or if there is a

power surge.

To reset, correct the error

condition and press the button

back in.

Fig. 4 Power Switch and

Fig. 4 Power Switch and

Integral Circuit Breaker

Integral Circuit Breaker

Fig. 3 Crank and

Fig. 3 Crank and

Cutting Depth Scale

Cutting Depth Scale

For technical questions, please call 1-800-444-3353.

Page 6SKU 41921

Page 7

SAFETY CHECK PRIOR TO OPERATION

WARNING: Unplug the machine and turn the power switch OFF before inspecting the machine.

1.

2.

3.

Plug in the machine to prepare to check the motor and blade function.

1.

2.

Check to be sure all parts and fasteners are properly attached and tight.

Be sure the blade is properly installed and adjusted.

Check the operation of the Table Adjustment Handle (150). One rotation of the handle will raise

or lower the table by 2mm (0.0787”).

Turn ON the machine by moving the switch up. Note: The safety switch cover must be in place for

the switch to operate.

Do not insert any work materials into the planer. Allow it to spin up to full speed. Determine if the

machine is operating smoothly, not making any excessive noises or vibrations. If not, the machine

is ready to operate.

WARNING: CHECK BLADE SETTING AND TIGHTNESS BEFORE INITIAL USE.

OPERATION

WARNING: Wear ANSI-approved eye protection, and observe all safety precautions when operating.

1.

2.

Measure your workpiece to determine its current thickness, and the amount you desire to plane

off. Maximum depth of cut is 1/8”; if you need to remove more than this, make repeated cuts.

Set the cutting depth by turning the Table Adjustment Handle (150) until the pointer indicates the

correct depth on the scale.

3.

WARNING: Attempting to plane more than 1/8” at a time may cause the planer to jam; potentially

causing the workpiece to splinter and be ejected from the machine, or the motor to jam and

possibly burn out. Never plane more than 1/8” at a time.

4.

5.

6.

7.

Turn the machine OFF and unplug the power cord. Insert the workpiece into the planer and visually

check your setting to assure that no more than 1/8” will be planed off the workpiece.

When you are satisfied the cut is properly set up, remove the workpiece from the machine. Plug in

the planer, and turn the power switch ON. Allow the planer to spin up to full speed.

Position the workpiece on the extension roller and table so that it is level. If you are planing a long

board, you may need support tables on both sides

of the planer to keep the workpiece level as its full

length passes through the planer.

Feed the workpiece into the planer, no faster than

the stated feed rate (23 feet per minute). The planer

should maintain its speed. If the planer slows down

noticeably, reduce the feed rate. If the planer still

bogs down, remove the workpiece and adjust for

a shallower cut.

Use a wooden pusher tool to push the board through

the planer. You can also grip the finished portion of

the workpiece, and pull it out of the planer.

WARNING: Keep hands farther away from intake than

rollers on extensions.

For technical questions, please call 1-800-444-3353.

Fig 5. DO NOT Place Your Hand

Inside the Extension Rollers

Page 7SKU 41921

Page 8

SUGGESTIONS FOR BETTER PLANING

This tool is ideal for finishing wood boards. You can use it to level or remove veneers. You can level warped

boards. You can convert rough boards into finished wood. You can shape boards to a desired size.

Select your wood with care.

1.

2.

3.

4.

Plan the best way to handle warped and bowed boards.

1.

2.

3.

Be sure your wood is dry and properly cured. Green or wet wood will continue to shrink and may

warp after planing.

Do not use splintered wood, or wood which may splinter while being worked. Some species such

as Eucalyptus or Bamboo are prone to splintering and are not suitable for planing.

Do not use any boards with loose knots, or knots which are significantly harder than the surround-

ing wood. These can break out or come loose during planing, which can jam the machine.

Check your workpiece for foreign objects, such as nails, screws or stones which may be embed-

ded in the wood. Remove any foreign objects before planing, or select another workpiece. Foreign

objects may come loose and be ejected from the machine causing a hazard. Foreign objects may

also damage the knife blades.

Boards which are warped across the width of the board

(“cupped” boards) should have the top planed flat first,

then turned over and the bottom planed flat.

Depending on the width of the board, you can reduce

waste in planing cupped boards by ripping them length-

wise first, then planing both resulting pieces.

Boards which are warped lengthwise (“bowed” boards)

are difficult to successfully straighten out. The feed roll-

ers in the planer will effectively straighten out bowed

boards as they pass through. But the board will remain

bowed when freestanding. If the bowed board cannot

be used as is, it is best to select another board.

Figure 6. A Cupped Board

Figure 6. A Cupped Board

Figure 7. A Bowed Board

Figure 7. A Bowed Board

It is important to consider wood grain when planing.

1.

2.

It is best to cut in such a way that the planer’s knife

blades are cutting with the grain. This will reduce chip-

ping, and result in a smoother finished surface. You

can identify the grain direction by looking at the edge

or end of the board. You can also often feel the grain

with your fingers.

In some boards, the grain direction reverses part

way along the board. If possible, cut such boards

at the transition point, and plane each piece sepa-

rately.

Avoiding Kickback.

1.

2.

WARNING: Avoid kickback by never overloading the machine.

Always insert boards for planing into the front of the

machine. The insertion direction is indicated by the arrow on top of the left belt cover.

Anti-kickback devices are installed along the top edge of the front opening of the planer.

For technical questions, please call 1-800-444-3353.

Figure 8. Feed the Board so the

Figure 8. Feed the Board so the

Knife Blades cut WITH the Grain

Knife Blades cut WITH the Grain

Figure 9. Boards Whose Grain

Figure 9. Boards Whose Grain

Changes Direction in the Middle.

Changes Direction in the Middle.

Page 8SKU 41921

Page 9

MAINTENANCE

When not in use, keep the machine unplugged and covered. Store it in a dry place. Store the

safety switch cover in a safe place to prevent unauthorized use. Unplug the machine before

doing any maintenance.

1.

Note: Do not apply grease to the belts.

2.

Regular lubrication is required to keep your planer in good condition, and assure a long

service life.

a.

Keep the table guide rods clean, and coated with a light coat of grease.

b.

Occasionally remove the top and apply a light grease to the bearings at each end of the cutter

head. The motor bearings are sealed and do not require additional lubrication.

c.

Remove the panels on both sides of the planer, and apply a light grease to the chains.

d.

Apply a light coat of grease to the chain on the underside of the machine.

Keep the motor and electrical controls dry and clean. Keep the motor free of chips, sawdust,

grease, and debris.

ADJUSTING THE CUTTING KNIVES

WARNING: Be sure the machine is turned OFF and

UNPLUGGED before attempting any adjustments.

The Cutter Head assembly can be accessed by

removing the cover from the top of the machine.

1.

2.

Remove the top cover (326) from the machine by

removing the bolts securing it.

Please refer to Figure 11 when checking knife ad-

justment. Position the knife Gauge (E) on the cutter

head and knife blade as shown. The gauge must

contact the knife blade and the cutter head at all

three points shown. The blade is adjusted too low if there is a

visible space between the blade edge and the gauge. The knife

blade is too high when the gauge rocks from side to side on the

cutter head when contacting the knife blade.

Figure 10. Checking the Knife Blade

Figure 10. Checking the Knife Blade

3.

Note: It is important that you adjust the blade along its entire length,

4.

To adjust the blade setting, loosen the locking nuts (A) just

enough to allow the blade (C) to move against the Lock Bar

(B). To raise the knife blade, turn adjustment screw (D) counter-

clockwise. To lower the knife blade, turn the adjustment screw

clockwise and press down on the blade.

so the blade has a consistent depth.

When the knife blade is properly adjusted, tighten the locking

nuts (A) firmly to lock it in place. Be sure these nuts are on tight.

Re-check alignment to be sure the knife blade did not slip during tightening.

For technical questions, please call 1-800-444-3353.

Figure 11. Knife Blade Gauge

Figure 11. Knife Blade Gauge

Page 9SKU 41921

Page 10

TROUBLESHOOTING

Unplug the machine before attempting any repairs.

If the Planer runs roughly or has excessive vibration:

1.

2.

3.

4.

If the Planer will not operate at all:

1.

2.

3.

4.

If the Motor runs roughly or slowly:

1.

2.

3.

If the Planer cuts unevenly, poorly, or produces a rough or chipped finish:

Verify that Knife Blades are not chipped, are securely installed, and are adjusted properly.

Verify that all chains and belts are properly routed on their pulleys and sprockets, and are not

loose.

Verify that the Table is not damaged, and operates smoothly.

Be sure the Crank is removed from the Planer before operation.

Verify that the planer is plugged in, the main circuit breaker in the power source is operational, and

the integral circuit breaker on the machine is operational. If either circuit breaker is open, investigate

further to determine and repair the cause of the fault.

Verify that the Planer is not jammed.

Inspect the carbon brushes in the motor to determine if they are in good condition.

Look for broken, damaged, or loose electrical connections. Repair before continuing.

Check for debris in the cutting assembly or in the chains or belts.

Inspect the carbon brushes, replace if necessary.

Verify that the power source supplies the correct Voltage and Amperage.

1.

2.

3.

4.

Changing the Carbon Brushes:

1.

2.

3.

Inspect the Knife Blades to be sure they are properly installed and adjusted.

Remove the Knife Blades and have them sharpened by a sharpening service.

Review the suggestions for selecting a workpiece, and adjusting the depth of cut.

Cut only with the wood grain.

Check carbon brushes every 10-15 hours of opera-

tion.

Brushes are accessed by turning the machine on its

side. Motor is on machine’s underside. The brush

holders are on the sides of the motor. Remove brush

holders by turning them with a coin.

Each brush has a line marked on its side. When the

brush has worn to the line, or if it is cracked or chipped,

replace both carbon brushes.

Figure 12. Checking and

Figure 12. Checking and

Replacing the Carbon Brushes

Replacing the Carbon Brushes

For technical questions, please call 1-800-444-3353.

Page 10SKU 41921

Page 11

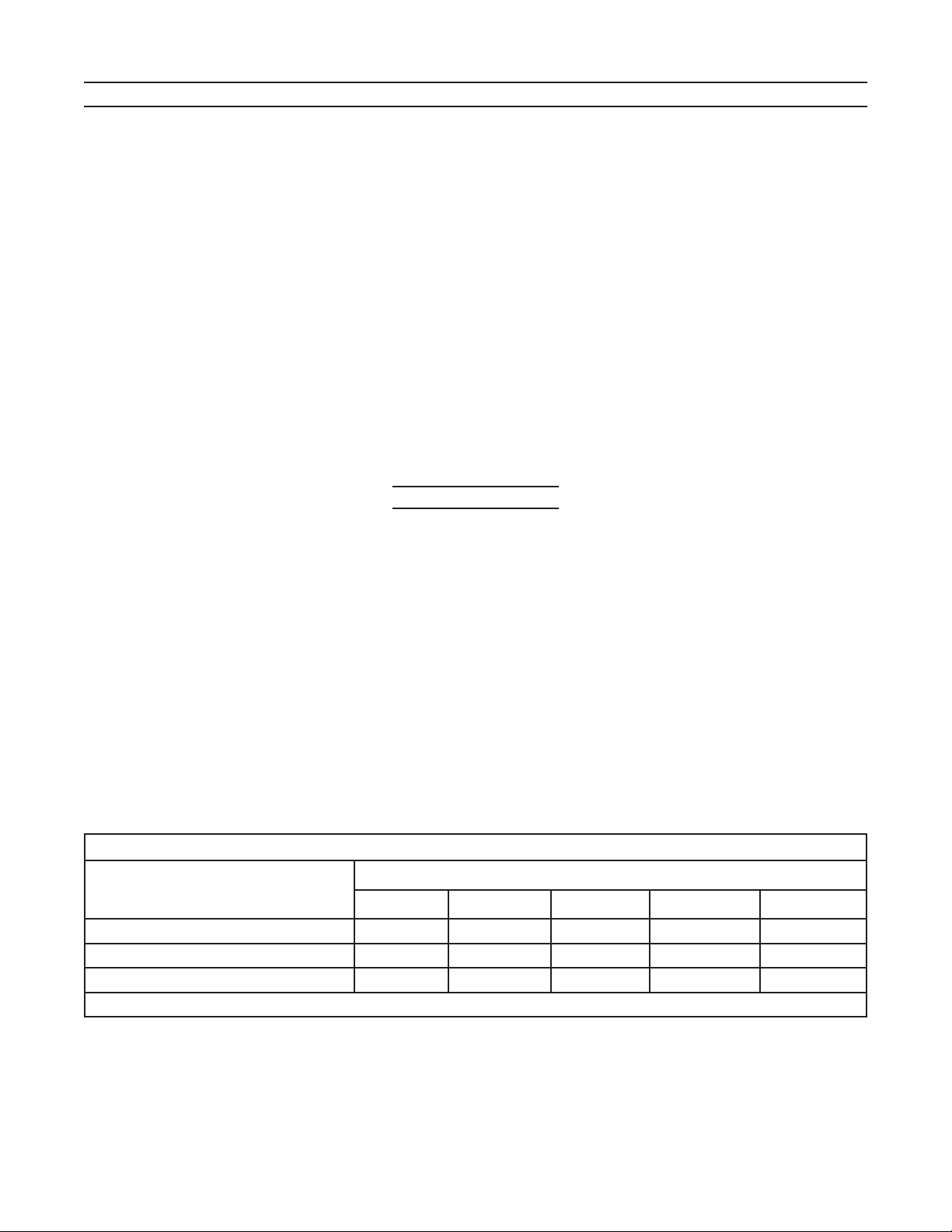

#41921 10” AUTO PLANER PARTS LIST, MAIN UNIT

Please refer to Parts Diagram on Page 12

Part Description Q’ty

101 Washer, m6 2

102 Cap Screw, m6 x 12 2

103 Screw, m6 x 50 1

104 Washer, m6 1

105 Retaining Ring, m15 1

106 Shaft 1

107 Sprocket 1

108 Retaining Ring, m15 1

109 Shaft 1

110 Pawl 15

111 Bushing 31

112 Washer, m6 4

113 Sprocket Cover 1

114 Cap Screw, m6 x 16 4

115 Screw Bolt 1

116 Frame 2

117 Sprocket, m16 3

118 Sprocket Frame 4

119 Sprocket 4

120 Washer, m10 4

121 Nut, m10 4

122 Washer, m8 2

123 Nut, m8 2

124 Sprocket Frame 4

125 Table 1

126 Side Guide 4

127 Screw, m5 x 10 8

128 Backing Board 1

129 Chain 1

130 Control Screw, m16 1

131 Pointer 1

132 Screw, m6 x 10 1

Part Description Q’ty

133 Wood Screw 4

134 Base Bracket 4

135 Cap Screw, m6 x 16 8

136 Nut, m6 8

137 Scale 1

138 Washer, m6 8

139 Screw, m6 x 16 8

140 Washer, m8 8

141 Right Cover 1

142 Bolt Screw, m8 x 50 2

143 Screw, m8 x 16 8

144 Switch Cover 1

145 Switch 1

146 Power Cord 1

147 Belt Cover 1

148 Washer, m6 2

149 Nut, m6 2

150 Table Adjustment Handle 1

151 Left Cover 1

152 Cap Screw, m8 x 20 8

153 Cap Screw, m8 x 16 4

154 Motor Cord 1

155 Circuit Breaker, 230V/10A 1

156 Strain Relief Bushing 1

157 Table Extension Bracket 2

158 Roller 2

159 Block 4

160 Cap Screw, m6 x 16 4

161 Pin, m8 x 20 4

162 Cap Screw, m6 x 20 4

163 Nut, m6 4

164 Screw, m8 x 16 4

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY: NETHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT: IN FACT THE MANUFACTURER A ND/OR DISTRIBUTOR EXPRESSLY STATES THAT

ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING

OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR

ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

For technical questions, please call 1-800-444-3353.

Page 11SKU 41921

Page 12

#41921 10” AUTO PLANER PARTS DIAGRAM, MAIN UNIT

Please refer to Parts List on Page 11

For technical questions, please call 1-800-444-3353.

Page 12SKU 41921

Page 13

#41921 10” AUTO PLANER, ADDITIONAL PARTS LIST

Please refer to Parts Diagrams on Page 14 and 15

Part Description Q’ty

Motor Assembly

201 Motor Housing 1

202 Stator 1

203 Washer, m5 1

204 Fan Casing 1

205 Screw, m5 x 85 2

206 Bearing, 6201ZZ 1

207 Silicone Steel Sheet 1

208 Bearing, 6029ZZ 1

209 Motor Pulley 1

210 Brush Holder 2

211 Carbon Brush 2

212 Brush Cap 2

213 Motor Box 1

214 Cap Screw, m5 x 12 4

215 Washer, m5 4

216 Pad Head Screw, m5 x 50 2

217 Pad Head Screw, m5 25 2

Cutter Assembly

301 Frame Support 2

302 Screw 2

303 Girder Stay 2

304 Screw 1

305 Splash Apron 1

306 Spring 4

307 Roller Chain 1

308 Retaining Ring 6

309 Sprocket 4

310 Bushing 4

311 Free Roller 2

312 Tension Spring 1

313 Chain 1

314 Cap Screw, m6 x 22 8

315 Free Roller Bracket 2

316 Bearing, 60203ZZ 2

Part Description Q’ty

317 Cutter Head 1

318 Key, m5 x 5 x 20 1

319 Driven Pulley 1

320 Knife Gauge 1

321 Adjustable Bolt 4

322 Non-Belt, J-750-6 1

323 Nut, m16 x 1.5 2

324 Knife Lock Plate 2

325 Blade Knife 2

326 Top Cover 1

327 Screw, m8 x 20 4

328 Gear Box 1

329 Gear 1

330 Shaft 1

331 Steel Ball, m4 1

332 Steel Ball, m5 1

333 Pinion 1

334 Gear 1

335 Knife Lock Bolt 12

336 Collar 2

337 Pinion 1

338 Steel Ball, m4 1

339 Gear 1

340 Bearing, 6029ZZ 1

341 Bearing, 60202ZZ 1

342 Pinion Gear 1

343 Free Pully 1

344 Non-Belt, J-246-4 1

345 Face Screw 6

346 Axle 1

347 Collar 31

348 Pawl 30

349 Handle 2

350 Cover 1

For technical questions, please call 1-800-444-3353.

Page 13SKU 41921

Page 14

#41921 10” AUTO PLANER PARTS DIAGRAM, MOTOR ASSEMBLY

Please refer to Parts List on Page 13

For technical questions, please call 1-800-444-3353.

Page 14SKU 41921

Page 15

#41921 10” AUTO PLANER PARTS DIAGRAM, CUTTER ASSEMBLY

Please refer to Parts List on Page 13

For technical questions, please call 1-800-444-3353.

Page 15SKU 41921

Loading...

Loading...