Page 1

AIR/OVER HYDRAULIC JACKAIR/OVER HYDRAULIC JACK

AIR/OVER HYDRAULIC JACK

AIR/OVER HYDRAULIC JACKAIR/OVER HYDRAULIC JACK

20 TON20 TON

20 TON

20 TON20 TON

41487

ASSEMBLY AND OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www .harborfreight.com

Copyright © 1999 by Harbor F reight Tools. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

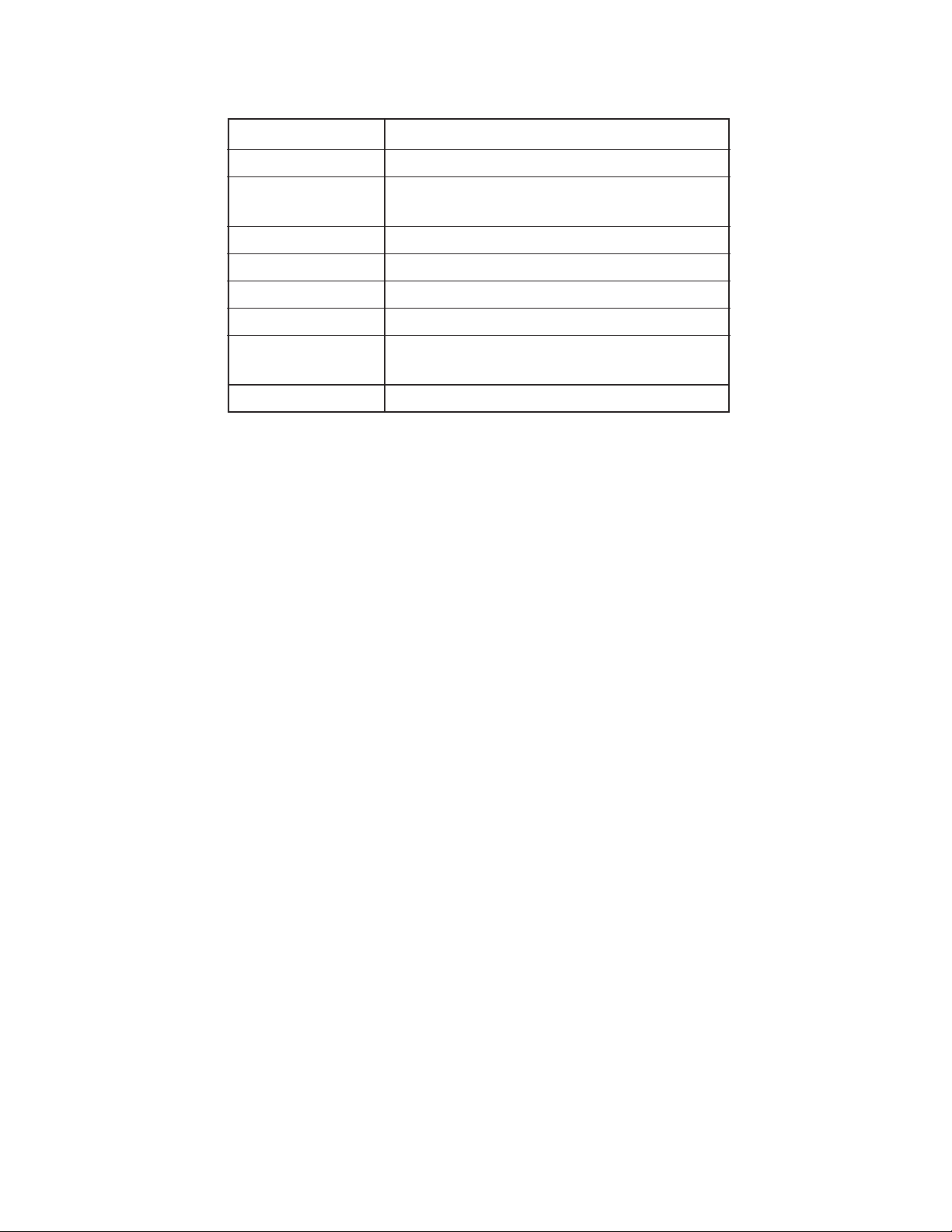

Specifications

METINOITPIRCSED

yticapaCmumixamsnot02

tnemevoMthgieH

maRhtgnelhcni2/1-6;retemaidhcni21.2

gnittiFtelnIriATPNhcni4/1

thgieW.sbl6.63

snoisnemiDesaB"4/3-4x"2/1-7

esoHriA

erusserPriAISP521-09

)muminim(hcni8/3-01

)mumixam(hcni4/1-02

htiwgnolsehcni84x).D.O(hcni8/3

sgnittifesohdepmirc

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. K eep the man ual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce

the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Do not overload this equipment. Know the weight of the item being lifted.

2. Use Jack for lifting only. Do not use this equipment for any other purpose.

Immediately after lifting, support the load with appropriate supporting equipment.

3. Place Jack correctly. Only use this equipment on a surface that is stable, le vel, clean

and dry , and capable of sustaining the load.

4. Stabilize load. Ensure that the load remains stable at all times. Do not move load

while on the Jack.

5. Vehicle lifting. When lifting a vehicle, apply the emergency brake, and block all

wheels.

6. Keep work area clean. Cluttered areas invite injuries.

7. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

8. Keep children awa y. Children must nev er be allo w ed in the work area. Do not let

them handle machines, tools, or extension cords.

Page 2SKU 41487

Page 3

9. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

10. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

11. Use the right tool for the job. Do not attempt to f orce a small tool or attachment to do

the work of a larger industrial tool. Do not use a tool for a purpose for which it was not

intended.

12. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair .

13. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear an ANSI

approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists.

14. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

15. Maintain tools with care. K eep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

16. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

17. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

18. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and an y other condition that ma y aff ect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician. Do

not use the tool if any switch does not turn On and Off properly.

19. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

20. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

21. Not to be used for any aircraft purposes.

REV 02/04

Page 3SKU 41487

Page 4

Warning: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that

may occur . It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must be

supplied by the operator .

Unpacking

When unpacking, check to make sure the following parts are included. If any parts are

missing or broken, please call Harbor F reight Tools at the number on the cover of this

manual as soon as possible.

kcaJeldnaHeceip-owT

sgnittiFdnaesoHgnittiFtelnIriA

Assembly

1. Screw the Connector (3) into the Air Pump (4) and tighten.

2. Connect the Air Hose (2) to the Connector (3).

Tighten the Air Hose to prevent air loss.

3. Connect the other end of the Air Hose to the Valv e Body (1.6).

4. Connect the tw o pipe Handles (5, 6) together.

Operation

Lifting

1. Place the slotted end of the Lo w er Handle (6) over the Release Valve (18, 21).

Refer to the photo on the next page and the Assembly Drawing on the last page of this

manual.

2. Turn the Valve Release screw clockwise until snug.

3. Place the Jack into position under the load.

Caution: Follow all Safety and Precautions listed on pages 2 and 3.

4. Adjust the Extension Screw (44) as needed.

Turn Counterclockwise to raise, clockwise to lower.

5. Insert the big end of the Handle assembly into the Handle Sleeve (7).

6. Connect the air supply hose lock fitting into the Air Inlet Fitting.

The Lever (1.13) should be Off (not in the locked position).

Page 4SKU 41487

REV 05/04

Page 5

7. Press the Lever (1.13) to the On position and lock using the Lock Lever (1.17)

This provides a continuous air supply to the Air Pump (4).

8. Raise the Jack by alternately lifting and lowering the Handle assembly.

Extension Screw (44)

Connector (3)

Handle fits in

Handle Sleeve

(7)

Release V alv e (18, 21)

Lever (1.13) and

Lever Lock (1.17)

Hose Connector (1.1)

Air Pump

(4)

Air Hose (2)

Handle (5, 6)

Lowering

Caution: Avoid rapid descent of the load. Turn the Release Valve slowly.

1. Release the Lock Lever (1.17) to stop air flow to the Air Pump (2).

2. Remove air supply hose from the Air Inlet Fitting.

3. Place the slotted end of the Handle (5, 6) assemb ly over the Release Valve (18, 21).

4. Slowly and carefully lower the load by turning the Release Valve counterclockwise in

extremely small increments using only the Handle assembly (never your hand).

5. Lower the Extension Screw (44) as needed by turning clockwise.

6. Remove the Jack.

Maintenance

General Care

1. Periodically lubricate the joints and Extension Screw (44) with a light oil as needed.

2. Clean the outside of the J ac k with a dry, clean cloth.

3. If the Jack is exposed to moisture, wipe dry with a clean cloth and lubricate as noted

above.

4. Store jack with Extension Screw (44) and Ram (48) fully collapsed.

Page 5SKU 41487

REV 05/04

Page 6

Purging Air from the Hydraulic System

Air bubbles can become trapped inside the hydraulic system thereby reducing the efficiency

of the Jack. Purge the air from the system if lift efficiency drops.

1. Place the slotted end of the Handle (5, 6) assembly over the Valve Release screw (18,

21) and turn 1-1/2 turns counterclockwise.

2. Remove the oil Filler Plug (23) on the side of the jack Reservoir (37) by gently pulling

and turning it.

3. Rapidly pump the Handle assembly several times to purge the air from the hydraulic

system.

4. Turn the Release Valve screw clockwise until snug using the Handle assembly.

5. Top off jack Reservoir (37) as described below.

5. Replace the Filler Plug (23).

Oil Replacement

1. Place Jack in an upright position.

2. Completely lower the Ram (48).

3. Remove the Filler Plug (23).

4. Fill with high-quality hydraulic jack oil to the lower rim of the fill hole.

5. Purge air from the hydraulic system as previously described.

6. Top off with more hydraulic oil.

7. Replace Filler Plug (23).

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY

OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY

PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR

HER REP AIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT P ARTS THERET O,

OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS

THERETO.

Page 6SKU 41487

REV 05/04

Page 7

Parts List

traPnoitpircseD.ytQtraPnoitpircseD.ytQ

1.1rotcennoCesoH181wercSevlaVesaelR1

2.1tuNgnitcennoC191laeSevlaVesaeleR1

3.1retliFriA10253.6llaBleetS1

4.14.2X81gnir-O112niP1

5.1rotcennoC122gnirpSevlaV2

6.1ydoBevlaV132gulPrelliF1

7.1gnirpS142wercS2

8.1gnikcaP152wercSgulP1

9.1elttorhT162rehsaWegnulP1

01.16.1X3gnir-O172wercSevlaVdaolrevO1

11.14.2X81gnir-O182gnirpSevlaVytefaS1

21.1tuN192evlaVdaolrevOgnirepaT1

31.1reveL103teNretliF2

41.1gniRreveL1138rehsaWgnirpS2

51.1rotcennoCesoH1238tuN2

61.1dnaBesoH2335.3X8MtloB2

71.1reveLkcoL143esaB1

2esoHriA153wercSgulP4

3rotcennoC163laeSmottoBrednilyC1

4pmuPriA173riovreseR1

5reppU,eldnaH183gnikcaP1

6rewoL,eldnaH193rednilyC1

7eveelSeldnaH104reniateRllaBleetS2

8niPtfahS314laeSpoTrednilyC1

9niPrettoC324gnir-01

01regnulPpmuP134tuNpoT1

11reniateRregnulPpmuP144wercSnoisnetxE1

21gnir-O154gnir-01

31gniRtnatsiseR-tsuD164renruteRgnir-01

41riovreseRpmuP174redaeHmaR1

51rehsaWreppoC184maR1

616llaBleetS694gnirpS2

71doRgnitcennoCregnulP105etalPgnirpS1

Page 7SKU 41487

REV 05/04

Page 8

Assembly Drawing

Page 8SKU 41487

REV 05/04

Loading...

Loading...