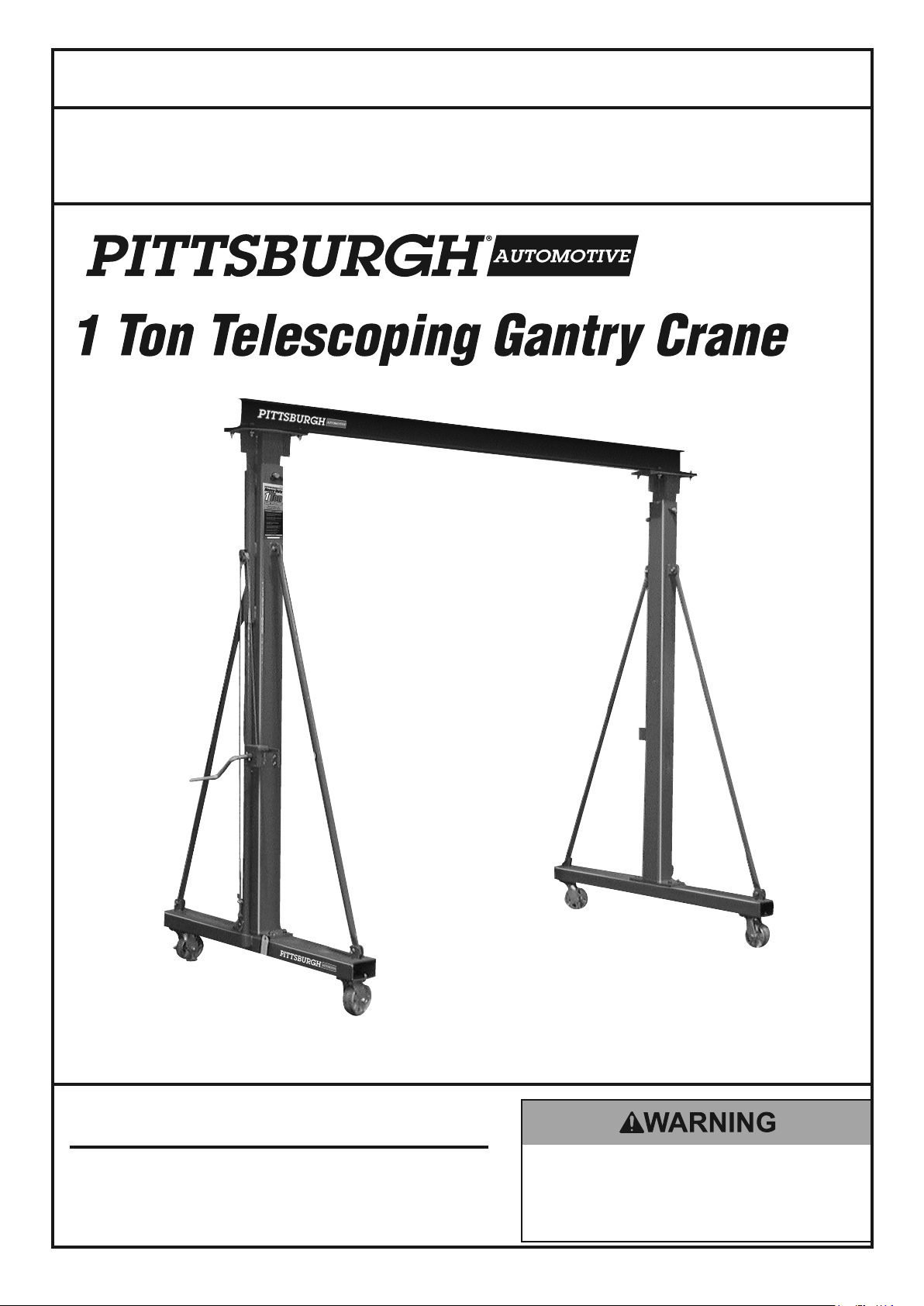

Harbor Freight Tools 41188, 69513 Product manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the manual

near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

ITEMS

41188 69513

Visit our website at: http://www.harborfreight.com

REV 14l

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 1999 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Email our technical support at: productsupport@harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Table of Contents

Safety .................................................2

Specifications .....................................4

SAFETY OPERATION MAINTENANCEASSEMBLY

Assembly ............................................4

Operation ...........................................10

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Maintenance ......................................14

Parts List and Assembly Diagram......18

Warranty ............................................20

IMPORTANT SAFETY INFORMATION

TO PREVENT SERIOUS INJURY AND DEATH:

Basic Safety Information

1. Do not lift more than rated load.

Be aware of dynamic loading!

Sudden load movement may briefly create

excess load causing product failure.

2. Do not operate hoist when load

is not centered under hoist.

3. Do not operate hoist with twisted,

kinked, or damaged chain or rope.

4. Do not operate a damaged or

malfunctioning gantry crane.

Inspect gantry crane carefully and

test operation before every use.

5. Do not lift people or lift loads over people.

Falling loads can injure or kill people.

6. Do not operate with other

than manual power.

7. Do not remove or cover

warning labels and/or tags.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

8. The warnings, precautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by

the operator that common sense and caution

are factors which cannot be built into this

product, but must be supplied by the operator.

Page 2 For technical questions, please call 1-888-866-5797. Items 41188 69513

Assembly Specific Safety Information

1. Assemble completely according to instructions

and install Height Pins and R-pins before use.

Improper assembly can create hazards.

2. Assemble or adjust height

only with assistance.

3. Keep assembly area clean and well lit.

4. Keep bystanders out of the

area during assembly.

5. Do not assemble when tired or when under

the influence of drugs or medication.

6. Weight capacity and other product

capabilities apply to properly and

completely assembled product only.

7. Inspect the gantry crane as explained

in Frequent Inspection on page 14

after assembly but before use.

Operation Specific Safety Information

1. Use on a hard, smooth, level surface

only. The surface the gantry crane

rests on must be designed to withstand

the loads and forces imposed by the

gantry crane for the rated load.

2. Use in location that allows the operator

to move and stay clear of the load.

3. Use warning signs and barriers on the floor

beneath the gantry crane where overhead

maintenance work creates a hazard.

5. This product is not a toy. Do not allow

children to play with or near this item.

6. Use as intended only.

Do not use to handle molten material.

Do not use for aircraft purposes.

7. Use crane at lowest height

possible for the application.

8. Do not adjust height while under load.

9. Do not move loaded crane.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

4. Wear ANSI-approved safety goggles,

ANSI-approved hard hat, and steel-toed work

boots during setup and use.

Inspection, Testing, and Maintenance

Specific Safety Information

1. Perform a “Frequent Inspection”

at least monthly, see page 14.

2. Perform a “Periodic (Thorough) Inspection”

at least yearly, see page 14.

3. More frequent inspections are needed for

gantry cranes that are used heavily.

4. Raise test loads only to the minimum

extent needed and stay well clear of

load at all times during testing.

SAVE THESE INSTRUCTIONS.

Page 3For technical questions, please call 1-888-866-5797.Items 41188 69513

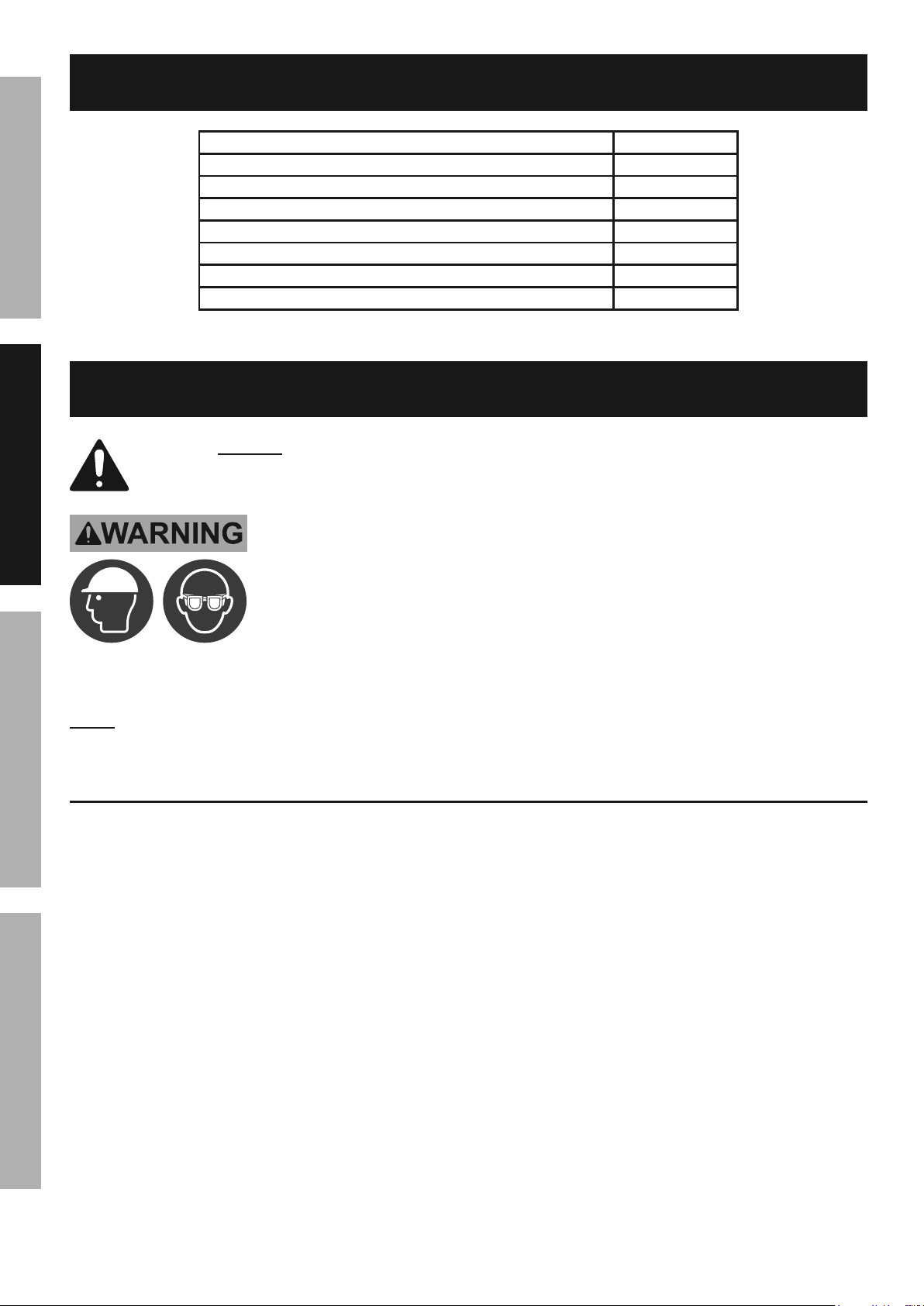

Specifications

SAFETY OPERATION MAINTENANCEASSEMBLY

Load Rating 2,000 lb

Minimum Overall Height 99"

Maximum Overall Height 147-1/2"

Overall Width 128"

Minimum Vertical Clearance* (under I-Beam) 94"

Maximum Vertical Clearance* (under I-Beam) 142-1/2"

Clearance Between Posts 93-11/16"

I-Beam 3″W x 5″H

* Factor in size of beam trolley and hoist when determining required clearance.

Assembly

Read the ENTIRE IMPORTANT SAFETY INFORMATION section

at the beginning of this manual including all text under

subheadings therein before set up or use of this product.

TO PREVENT SERIOUS INJURY AND DEATH:

Wear ANSI-approved safety goggles, hard hat,

heavy-duty work gloves, and steel-toed work boots

during assembly and operation.

The correct bolts must be used during assembly. If any doubts arise regarding proper

assembly, contact Harbor Freight at the number at the bottom of this page before use.

Note: For additional information regarding the parts listed in the following pages,

refer to Parts List and Assembly Diagram on page 18.

Assembly Setup

1. More than one person will be

needed for assembly.

2. Use a large, clean and uncluttered

area for assembly.

3. Consider vertical clearance when

choosing operation area. Assemble

close to operation area.

4. Use saw horses (not included) to

support larger items such as Posts

and I-Beam during assembly.

5. The Post Insert (1) and Post Sleeve (2)

are pre-assembled.

Page 4 For technical questions, please call 1-888-866-5797. Items 41188 69513

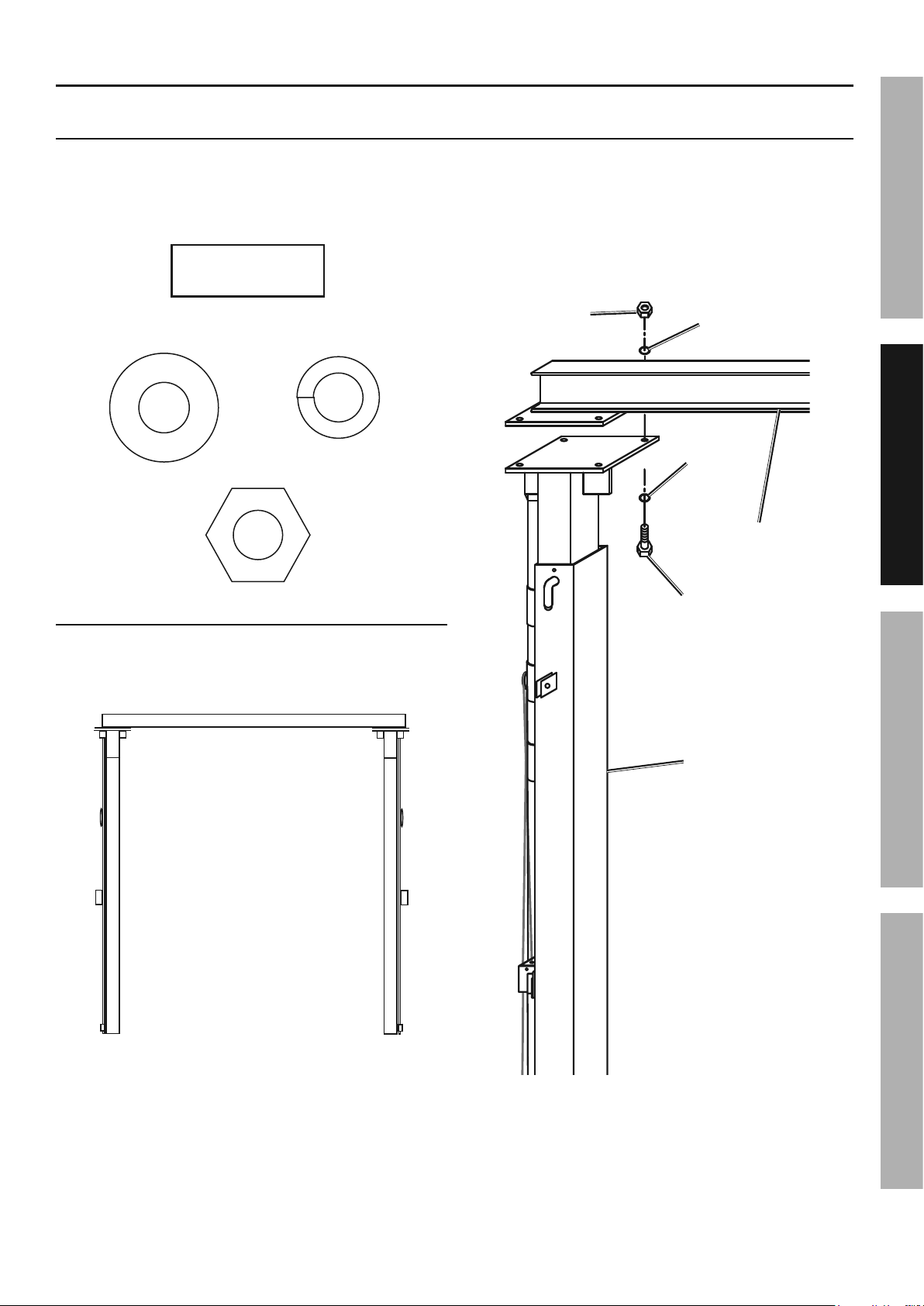

Assembly Instructions

Attaching Posts to I- Beam

Hardware - 8 each:

(29) Beam

Bolt M12 x 35

Threaded

Shaft Size

(19) Washer

M12

(16) Nut

M12

(15) Spring

Washer M12

2. Attach Left Post Assembly to I-Beam

using four Beam Bolts (29), Washers (19),

Spring Washers (15), and Nuts (16).

3. Tighten connections securely.

4. Repeat for right Post Assembly.

Nut (16)

Washer

Spring

Washer (15)

(19)

I-Beam

SAFETYOPERATIONMAINTENANCE ASSEMBLY

1. Lay I-Beam (4) on the ground. Lay left

and right Post Assemblies on the ground

so Pulleys and cables are facing out.

I-Beam

(4)

Left Post

Assembly

Figure A

Right Post

Assembly

Beam

Bolt (29)

Left Post

Assembly

Figure B

Page 5For technical questions, please call 1-888-866-5797.Items 41188 69513

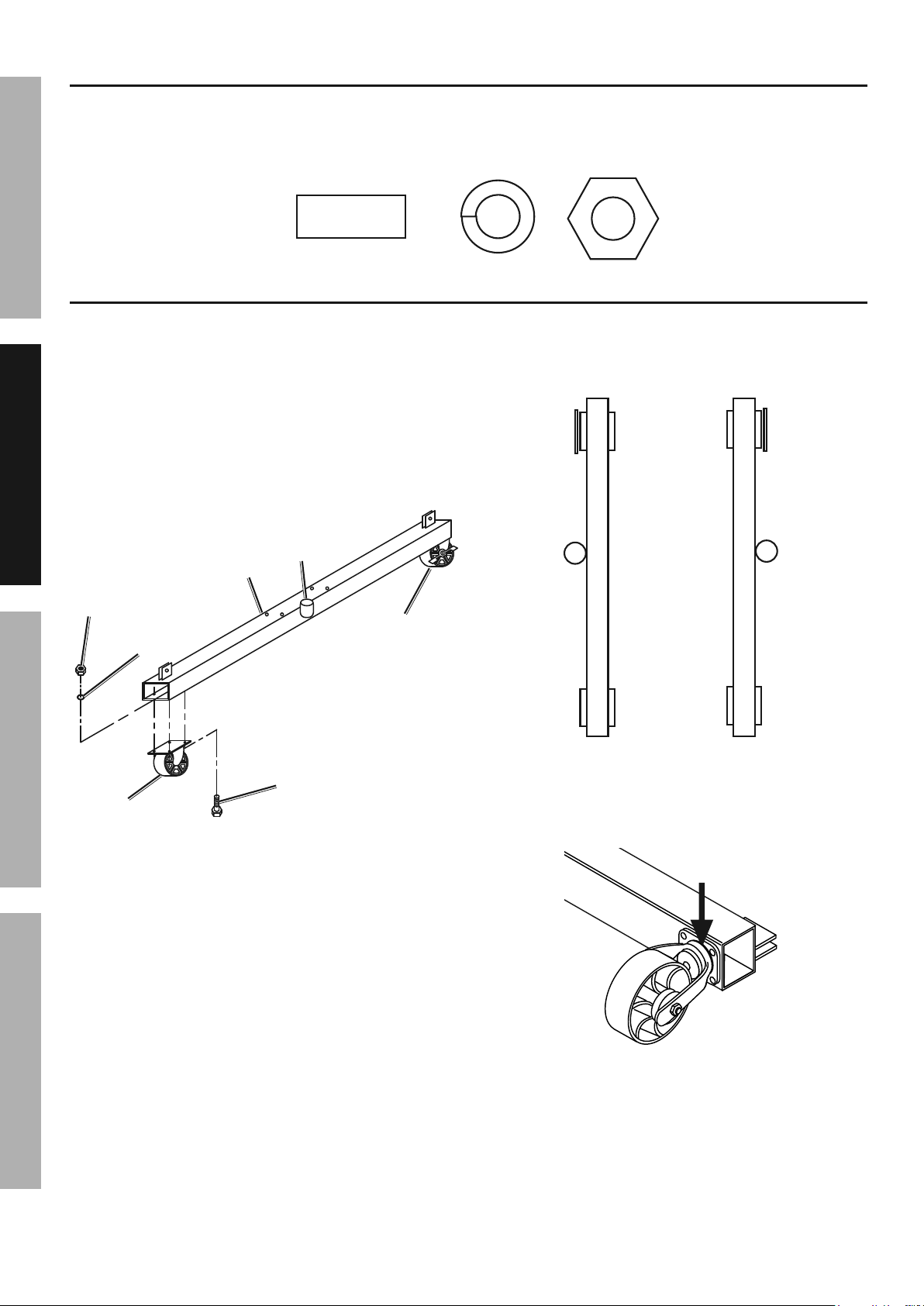

Attaching Casters to Bases

Hardware - 16 each:

(11) Caster

SAFETY OPERATION MAINTENANCEASSEMBLY

1. Attach one Swivel Caster (9a) to one end of

Base (3) using four sets of Caster Bolts (11),

Spring Washers (12) and Nuts (13).

2. Attach one Locking Swivel Caster (9b) to other

end of Base using four sets of Caster Bolts

(11), Spring Washers (12) and Nuts (13).

3. Tighten connections securely.

Base

(3)

Nut

(13)

Spring

Washer

(12)

Bolt M10 x 25

Threaded

Shaft Size

Sleeve

Locking

Swivel

Caster (9b)

(12) Washer

M10

4. Repeat for other Base, making sure

that Sleeves are to the outside and

Locking Swivel Casters are on the same end.

Sleeve

(13) Nut

M10

Locking

Swivel

Casters

Sleeve

Swivel

Caster (9a)

Caster

Figure C

Bolt

(11)

Swivel

Casters

Figure D

5. Apply grease to each Caster bearing.

Grease

here

Figure E

Page 6 For technical questions, please call 1-888-866-5797. Items 41188 69513

Loading...

Loading...