Page 1

BENCH GRINDER

37822, 37823,

39797, 39798,

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 1998 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 09d

Page 2

CONTENTS

INSTRUCTIONS FOR PUTTING

INTO USE .................................... 9

IMPORTANT SAFETY

INFORMATION ............................3

GENERAL TOOL SAFETY

WARNINGS ......................................3

GROUNDING INSTRUCTIONS ..... 5

110-120 V~ GROUNDED TOOLS:

TOOLS WITH THREE PRONG

PLUGS .............................................5

GRINDER SAFETY WARNINGS ........6

SPECIFICATIONS ..........................8

ALL MODELS .....................................8

MODEL 37822 ....................................8

MODEL 37823 ....................................8

ASSEMBLY.........................................9

OPERATING INSTRUCTIONS .... 11

WORK PIECE AND WORK AREA

SET UP ..........................................11

GENERAL OPERATING

INSTRUCTIONS ............................11

MAINTENANCE AND

SERVICING ...............................12

CLEANING, MAINTENANCE, AND

LUBRICATION ...............................12

TROUBLESHOOTING ......................13

PARTS LIST .................................14

MODEL 39797 ....................................8

MODEL 39798 ....................................8

UNPACKING .................................. 8

ASSEMBLY DIAGRAM ................15

LIMITED 1 YEAR / 90 DAY

WARRANTY ..............................16

Bench Grinder For technical questions, please call 1-800-444-3353. Page 2

Page 3

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial

number in the back of the manual near the

assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and

dry place for future reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

General Tool Safety Warnings

WARNING Read all safety

warnings and instructions.

Failure to follow the warnings and

instructions may result in electric

shock, re and/or serious injury.

Save all warnings and

instructions for future reference.

KEEP GUARDS IN PLACE and in 1.

working order.

REMOVE ADJUSTING KEYS AND 2.

WRENCHES. Form habit of checking to see that keys and adjusting

wrenches are removed from tool

before turning it on.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

Bench Grinder For technical questions, please call 1-800-444-3353. Page 3

KEEP WORK AREA CLEAN. Clut-3.

tered areas and benches invite accidents.

DON’T USE IN DANGEROUS EN-4.

VIRONMENT. Don’t use power tools

in damp or wet locations, or expose

them to rain. Keep work area well

lighted.

KEEP CHILDREN AWAY. All visitors 5.

should be kept safe distance from

work area.

MAKE WORKSHOP KID PROOF 6.

with padlocks, master switches, or by

removing starter keys.

Page 4

DON’T FORCE TOOL. It will do the 7.

job better and safer at the rate for

which it was designed.

USE RIGHT TOOL. Don’t force tool 8.

or attachment to do a job for which it

was not designed.

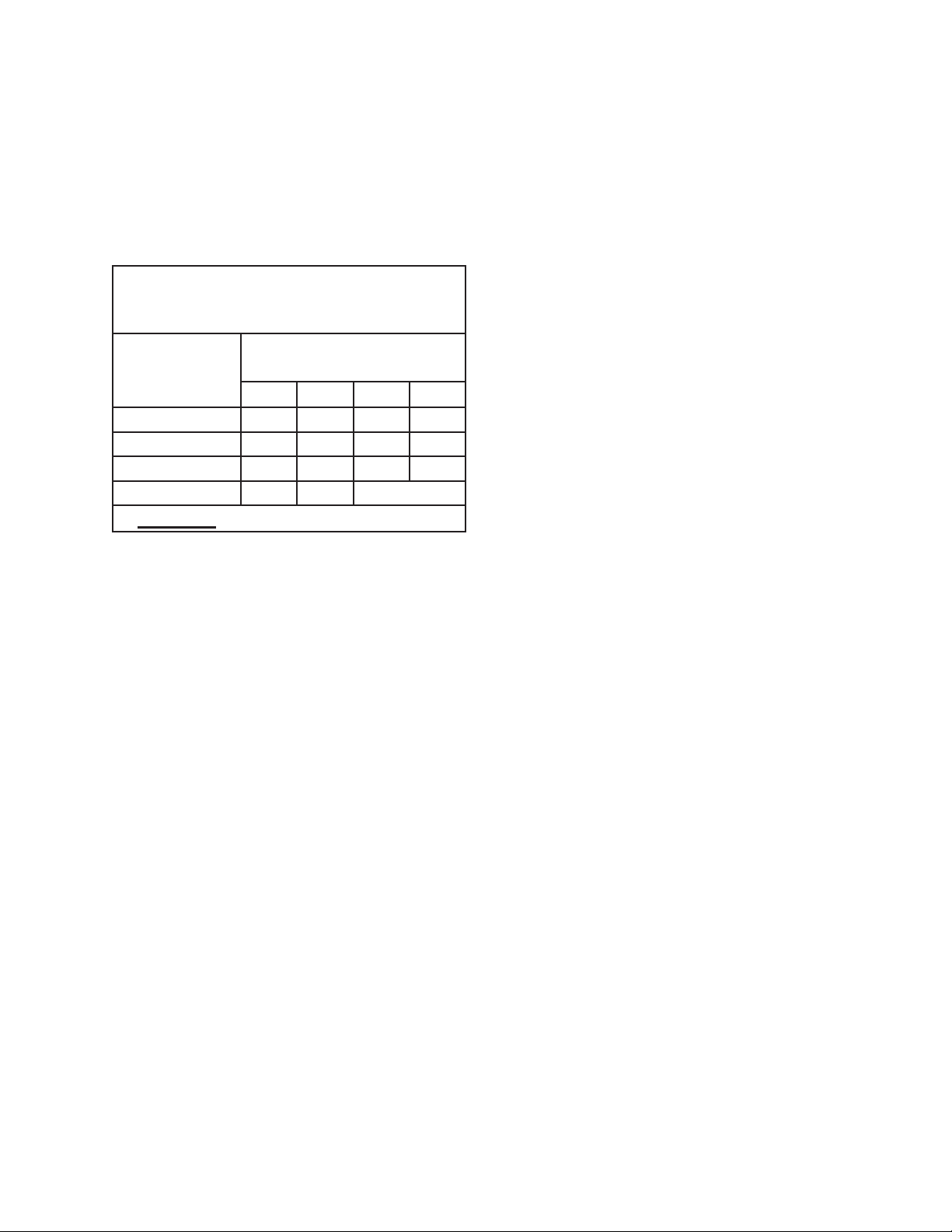

RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS

(120 VOLT)

NAMEPLATE

AMPERES

(at full load)

0 – 6 18 16 16 14

6.1 – 10 18 16 14 12

10.1 – 12 16 16 14 12

12.1 – 16 14 12 Do not use.

EXTENSION CORD

LENGTH

25’ 50’ 100’ 150’

TABLE A

glasses only have impact resistant

lenses, they are NOT safety glasses.

DON’T OVERREACH. Keep proper 12.

footing and balance at all times.

MAINTAIN TOOLS WITH CARE. 13.

Keep tools sharp and clean for best

and safest performance. Follow

instructions for lubricating and changing accessories.

DISCONNECT TOOLS before ser-14.

vicing; when changing accessories,

such as blades, bits, cutters, and the

like.

REDUCE THE RISK OF UNINTEN-15.

TIONAL STARTING. Make sure

switch is in off position before plugging in.

USE PROPER EXTENSION CORD. 9.

Make sure your extension cord is

in good condition. When using an

extension cord, be sure to use one

heavy enough to carry the current

your product will draw. An undersized

cord will cause a drop in line voltage

resulting in loss of power and overheating. Table A shows the correct

size to use depending on cord length

and nameplate ampere rating. If in

doubt, use the next heavier gauge.

The smaller the gauge number, the

heavier the cord.

WEAR PROPER APPAREL. Do not 10.

wear loose clothing, neckties, rings,

bracelets, or other jewelry which may

get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair covering to contain long

hair.

ALWAYS USE SAFETY GLASSES. 11.

Also use face or dust mask if grinding

operation is dusty. Everyday eye-

USE RECOMMENDED ACCESSO-16.

RIES. Consult the owner’s manual for

recommended accessories. The use

of improper accessories may cause

risk of injury to persons.

NEVER STAND ON TOOL. Serious 17.

injury could occur if the tool is tipped

or if the grinding tool is unintentionally

contacted.

CHECK DAMAGED PARTS. Before 18.

further use of the tool, a guard or

other part that is damaged should

be carefully checked to determine

that it will operate properly and perform its intended function – check for

alignment of moving parts, binding

of moving parts, breakage of parts,

mounting, and any other conditions

that may affect its operation. A guard

or other part that is damaged should

be properly repaired or replaced.

DIRECTION OF FEED. Feed work 19.

into a blade or cutter against the

Bench Grinder For technical questions, please call 1-800-444-3353. Page 4

Page 5

direction of rotation of the blade or

cutter only.

equipment-grounding conductor to a

live terminal.

NEVER LEAVE TOOL RUNNING 20.

UNATTENDED. TURN POWER OFF.

GROUNDING INSTRUCTIONS

TO PREVENT

ELECTRIC SHOCK

AND DEATH FROM

INCORRECT GROUNDING

WIRE CONNECTION

READ AND FOLLOW THESE

INSTRUCTIONS:

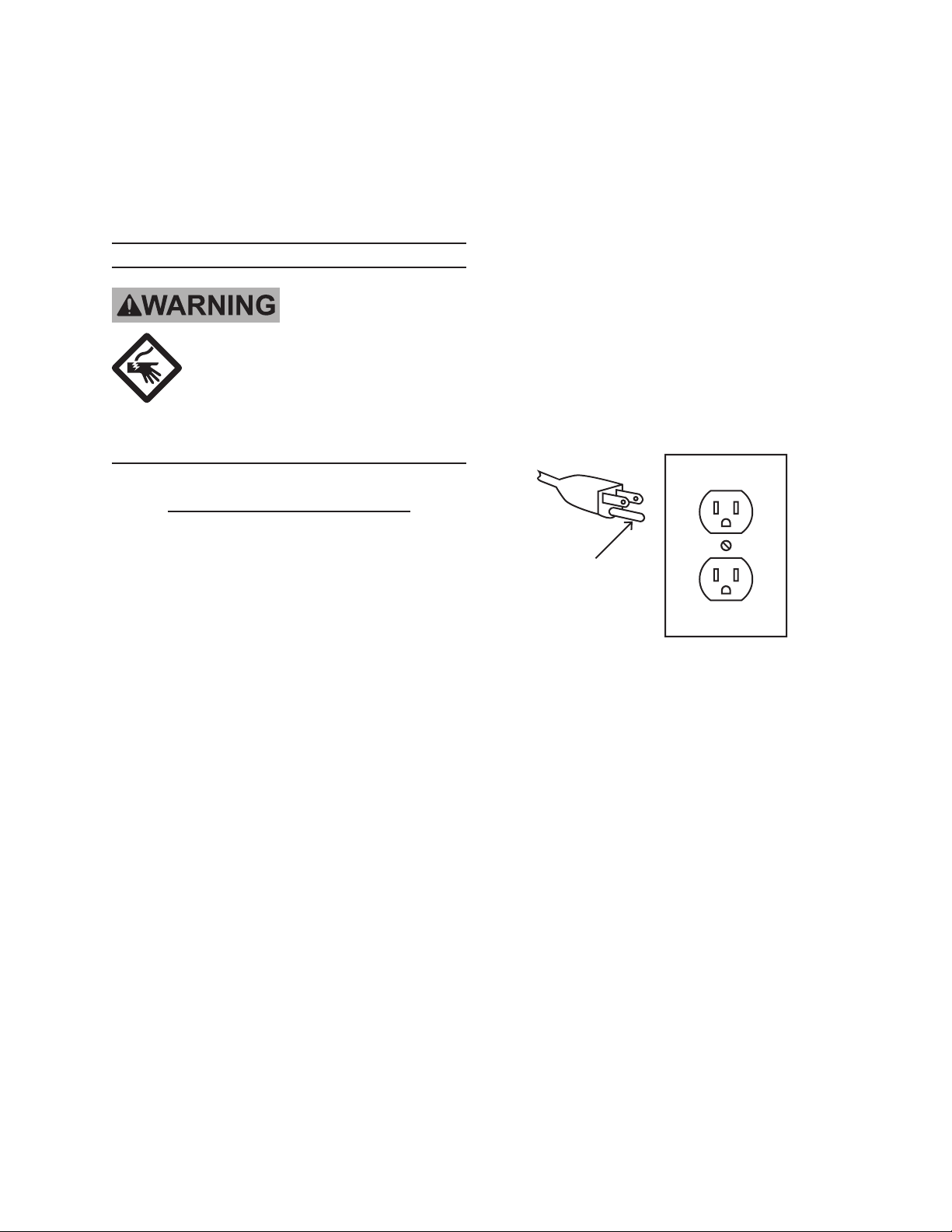

110-120 V~ Grounded Tools: Tools

with Three Prong Plugs

In the event of a malfunction or 1.

breakdown, grounding provides a

path of least resistance for electric

current to reduce the risk of electric

shock. This tool is equipped with an

electric cord having an equipmentgrounding conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided – if it 2.

will not t the outlet, have the proper

outlet installed by a qualied electri-

cian.

Improper connection of the equip-3.

ment-grounding conductor can result in a risk of electric shock. The

conductor with insulation having an

outer surface that is green with or

without yellow stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

Check with a qualied electrician or 4.

service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether the

tool is properly grounded.

Use only 3-wire extension cords that 5.

have 3-prong grounding plugs and

3-pole receptacles that accept the

tool’s plug.

Repair or replace damaged or worn 6.

cord immediately.

Grounding

Pin

125 V~ 3-Prong Plug and Outlet

(for up to 125 V~ and up to 15 A)

This tool is intended for use on a cir-7.

cuit that has an outlet that looks like

the one illustrated above in 125 V~

3-Prong Plug and Outlet. The tool

has a grounding plug that looks like

the plug illustrated above in 125 V~

3-Prong Plug and Outlet.

The outlet must be properly installed 8.

and grounded in accordance with all

codes and ordinances.

Do not use an adapter to connect this 9.

tool to a different outlet.

Bench Grinder For technical questions, please call 1-800-444-3353. Page 5

Page 6

Grinder Safety Warnings

For Your Own Safety Read Instruction

Manual Before Operating Grinder

Wear eye protection.1.

Use grinding wheel suitable for speed 2.

of grinder.

Replace cracked wheel immediately.3.

Always use guards and eye shields.4.

Do not overtighten wheel nut.5.

adequate protection. Eye protection

must be ANSI-approved and breathing protection must be NIOSH-ap-

proved for the specic hazards in the

work area.

Industrial applications must follow 15.

OSHA guidelines.

Maintain labels and nameplates on 16.

the tool. These carry important safety

information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

Use only anges furnished with the 6.

grinder.

Adjust distance between wheel and 7.

work rest to maintain 1/16 inch or

less separation as the diameter of the

wheel decreases with use.

Frequently clean grinding dust from 8.

beneath grinder.

Wear a full face shield over ANSI-9.

approved safety goggles during use.

Do not grind with side of wheel un-10.

less wheel is specically designed for

that type of grinding.

DO NOT OPERATE WITH ANY 11.

GUARD DISABLED, DAMAGED,

OR REMOVED.

The use of accessories or attach-12.

ments not recommended by the

manufacturer may result in a risk of

injury to persons.

When servicing use only identical 13.

replacement parts.

Only use safety equipment that has 14.

been approved by an appropriate

standards agency. Unapproved

safety equipment may not provide

Avoid unintentional starting. Prepare 17.

to begin work before turning on the

tool.

People with pacemakers should 18.

consult their physician(s) before use.

Electromagnetic elds in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

WARNING: Some dust created by 19.

power sanding, sawing, grinding, drilling, and other construction activities,

contains chemicals known [to the

State of California] to cause cancer,

birth defects or other reproductive

harm. Some examples of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and ce-

ment or other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your

exposure to these chemicals: work in

a well ventilated area, and work with

approved safety equipment, such as

those dust masks that are specially

designed to lter out microscopic

Bench Grinder For technical questions, please call 1-800-444-3353. Page 6

Page 7

particles. (California Health & Safety

Code § 25249.5, et seq.)

white or blue ngers), seek medical

advice as soon as possible.

WARNING: Handling the cord on 20.

this product will expose you to lead,

a chemical known to the State of

California to cause cancer, and birth

defects or other reproductive harm.

Wash hands after handling. (California Health & Safety Code § 25249.5,

et seq.)

The warnings, precautions, and in-21.

structions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

Vibration Safety

This tool vibrates during use. Repeated or long-term exposure to

vibration may cause temporary or

permanent physical injury, particularly

to the hands, arms and shoulders. To

reduce the risk of vibration-related

injury:

Do not smoke during use. Nico-2.

tine reduces the blood supply to the

hands and ngers, increasing the risk

of vibration-related injury.

Wear suitable gloves to reduce the 3.

vibration effects on the user.

Use tools with the lowest vibration 4.

when there is a choice between different processes.

Include vibration-free periods each 5.

day of work.

Grip tool as lightly as possible (while 6.

still keeping safe control of it). Let

the tool do the work.

To reduce vibration, maintain the tool 7.

as explained in this manual. If any

abnormal vibration occurs, stop use

immediately.

SAVE THESE

INSTRUCTIONS.

Anyone using vibrating tools regu-1.

larly or for an extended period should

rst be examined by a doctor and

then have regular medical checkups to ensure medical problems are

not being caused or worsened from

use. Pregnant women or people

who have impaired blood circulation

to the hand, past hand injuries, nervous system disorders, diabetes, or

Raynaud’s Disease should not use

this tool. If you feel any medical or

physical symptoms related to vibration (such as tingling, numbness, and

Bench Grinder For technical questions, please call 1-800-444-3353. Page 7

Page 8

SPECIFICATIONS

UNPACKING

All Models

180264

Motor No Load Speed 3450 RPM

Arbor Size 5/8” with 1/2” Adapter

Base Size 5” x 7”

Mounting Holes 2 x 3/8”

Work Light Bulb 40 W Household type

MODEL 37822

Electrical Input 120 V~ / 60 Hz / 1/2 HP

Wheel Size 6” x 3/4” x 1/2”

Work Light Bulb 40 W Household type

MODEL 37823

Electrical Input 120 V~ / 60 Hz / 3/4 HP

Wheel Size 8” x 3/4” x 5/8”

Work Light Bulb 40 W Household type

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon

as possible.

MODEL 39797

Electrical Input 120 V~ / 60 Hz / 1/2 HP

Wheel Size 6” x 3/4” x 1/2”

MODEL 39798

Electrical Input 120 V~ / 60 Hz / 3/4 HP

Wheel Size 8” x 3/4” x 5/8”

Bench Grinder For technical questions, please call 1-800-444-3353. Page 8

Page 9

INSTRUCTIONS FOR

PUTTING INTO USE

shown in Figure 1. Use bolts and

washers to secure them in place as

shown in Figure 1.

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn the tool off and unplug it

before assembling or making

any adjustments to the tool.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Assembly

Installing Tool Rests -1.

Turn the Grinder off and unplug it.a.

Note: There is a left and a right tool rest.

Refer to Figure 1 to be certain that

you install them correctly.

The tool rests should be adjusted to c.

within 1/16” of the grinding wheel.

To adjust this distance, move Adjustable Rests (22 and 35) by loosening

bolts and moving them to the proper

position.

Installing Spark Guards -2.

FIGURE 2

a. Select spark guards (17 and 18),

washer and bolt. Install the right

spark guard to the wheel guard as

shown in Figure 2.

Adjust the spark guard to within b.

1/16” of the grinding wheel. Repeat

for left side.

Note: There is a left and right spark guard.

Refer to Figure 2 to be certain that

you install them correctly.

FIGURE 1

b. Install adjustable rests (22 and 35)

to the wheel guards (7 and 27) as

Bench Grinder For technical questions, please call 1-800-444-3353. Page 9

REV 01b

Page 10

Installing Bracket to Eye Shield -3.

FIGURE 3

a. Select one at bracket and one eye

shield. Assemble as shown in Figure 3.

Repeat for left eye shield.b.

Installing Eye Shield to Grinder -4.

For installation of the right eye shield a.

(19), make sure that the holes in the

eye shield bracket face downward.

FIGURE 4

b. Push eye shield bracket onto mount-

ing bracket until it locks into place as

shown in Figure 4.

Repeat for left eye shield.c.

Bench Grinder For technical questions, please call 1-800-444-3353. Page 10

Page 11

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Work Piece and Work Area Set Up

Designate a work area that is clean 1.

and well-lit. The work area must not

allow access by children or pets to

prevent distraction and injury.

Route the power cord along a safe 2.

route to reach the work area without

creating a tripping hazard or exposing

the power cord to possible damage.

There must not be objects, such as 3.

utility lines, nearby that will present a

hazard while working.

General Operating Instructions

TO PREVENT

SERIOUS INJURY:

DO NOT OPERATE WITH ANY

GUARD DISABLED,

DAMAGED, OR REMOVED.

outward from the edge of the shank

of the screwdriver. They should be

at with intersecting faces perpendicular. Hold each face of the screwdriver against the wheel to true it up,

then ease the end straight into the

stone to grind it true.

Sharpening Knives - 3.

Remove metal from both faces of

most knives, working from the heavy

end of the blade toward the tip.

Sharpening Twist Drill Bits - 4.

Drill bits are best sharpened on a

sharpening jig but some sharpening

can be done on your bench grinder.

Begin on one side of the point at the

existing angle, then twist the bit while

maintaining a constant angle with the

grinding surface. Sharpen only the

tip. This technique requires considerable practice so try it a few times with

the grinder off. Be sure to maintain

the original cutting edge angle as this

is important to maintaining the efciency of your bits.

To prevent accidents, turn off the tool 5.

and disconnect its power supply after

use. Clean, then store the tool indoors out of children’s reach.

Sharpening Scissors - 1.

If possible take the scissors apart

to make the sharpening operation

easier and safer. Remove material

only from the outside surface and

work from the heavy end of the blade

toward the tip.

Sharpening Screwdrivers - 2.

The end of a properly sharpened

screwdriver will be a perfect rectan-

gle, absolutely at and perpendicular

to the center line of the shank. The

two sides and two faces will taper

Bench Grinder For technical questions, please call 1-800-444-3353. Page 11

Page 12

MAINTENANCE AND

SERVICING

Proceduresnotspecically

explained in this manual

must be performed only by a

qualiedtechnician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn the Power Switch of the

tool to its “OFF” position and

unplug the tool from its

electrical outlet before

performing any inspection,

maintenance, or cleaning

procedures.

TO PREVENT SERIOUS

INJURY FROM TOOL

FAILURE:

Do not use damaged

equipment. If abnormal noise

or vibration occurs, have the

problem corrected before

further use.

grooved, rounded, chipped, out of

true or loaded with foreign material.

Cracked wheels should be replaced

immediately.

Wheel Replacement - 4.

If you must replace a wheel be sure

to obtain one with a safe rated speed

at least as high as the rated RPM of

this grinder. Be sure tool is switched

off and unplugged before attempting

repairs.

Bulb Replacement - 5.

Allow bulb to cool completely before

replacing it. Replace it only with a 40

W or less household bulb.

6. WARNING! If the supply cord of

this power tool is damaged, it must

bereplacedonlybyaqualied

service technician.

Cleaning, Maintenance, and

Lubrication

BEFORE EACH USE,1. inspect the

general condition of the tool. Check

for loose hardware, misalignment or

binding of moving parts, cracked or

broken parts, damaged electrical wiring, and any other condition that may

affect its safe operation.

AFTER USE,2. wipe external surfaces

of the tool with clean cloth.

Care of Grinding Wheels - 3.

As a result of normal use, grinding wheels may become cracked,

Bench Grinder For technical questions, please call 1-800-444-3353. Page 12

Page 13

Troubleshooting

Problem Possible Causes Likely Solutions

Tool will not start. Cord not connected.1.

Tool operates

slowly.

Performance

decreases over

time.

Excessive noise or

rattling.

Overheating. Forcing machine to work too fast.1.

Power being reduced by long or

small diameter extension cord.

Carbon brushes worn or damaged. Have qualied technician replace brushes.

Internal damage or wear. (Carbon

brushes or bearings, for example.)

No power at outlet. 2.

Tool’s thermal reset breaker 3.

tripped (if equipped).

Internal damage or wear. (Carbon 4.

brushes or switch, for example.)

Blocked motor housing vents. 2.

Motor being strained by long or 3.

small diameter extension cord.

Check that cord is plugged in.1.

Check power at outlet. If outlet is 2.

unpowered, turn off tool and check circuit

breaker. If breaker is tripped, make sure

circuit is right capacity for tool and circuit

has no other loads.

Turn off tool and allow to cool. Press 3.

reset button on tool.

Have technician service tool.4.

Eliminate use of extension cord. If an

extension cord is needed, use one with the

proper diameter for its length and load. See

Extension Cords in GROUNDING section.

Have technician service tool.

Allow machine to work at its own rate.1.

Wear ANSI-approved safety goggles and 2.

NIOSH-approved dust mask/respirator

while blowing dust out of motor using

compressed air.

Eliminate use of extension cord. If 3.

an extension cord is needed, use one

with the proper diameter for its length

and load. See Extension Cords in

GROUNDING section.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect power supply before service.

Bench Grinder For technical questions, please call 1-800-444-3353. Page 13

Page 14

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

PARTS LIST

Note: Specify grinder model number when ordering parts.

Part Description

1 Screw

2 Left Cover

3 Nut

4a Outer Flange

4b Inner Flange

5* Grinding Wheel

6 Screw

7 Left Wheel Guard

8 Screw

9 Motor End Bell

10 Ball Bearing

11 Nut

12 Motor Stator

13 Motor Case

14 Motor Rotor

15 Washer

16 Bolt

17 Left Spark Guard

18 Right Spark Guard

19 Eye Shield

20 Washer

21 Bolt

Part Description

22 Left Adjustable Rest

23 Wire

24 Strain Relief

25 Plate

26 Terminals

27 Right Wheel Guard

28 Right Cover

29 Base Plate

30 Condenser

31 Screw

32 Pad

33 Base

34 Switch

35 Right Adjustable Rest

36 Screw

37 Mounting Plate

38** Lamp

39** Washer

40** Nut

* Specify grit when ordering.

** Items 37822 or 37823 only.

Bench Grinder For technical questions, please call 1-800-444-3353. Page 14

Page 15

4b

ASSEMBLY DIAGRAM

4a

38

39

40

4b

4a

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

Bench Grinder For technical questions, please call 1-800-444-3353. Page 15

REV 01k

Page 16

LIMITED 1 YEAR / 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that for a period

of ninety days from date of purchase that the engine/motor, the belts (if so equipped),

and the blades (if so equipped) are free of defects in materials and workmanship. Harbor Freight Tools also warrants to the original purchaser, for a period of one year from

date of purchase, that all other parts and components of the product are free from

defects in materials and workmanship (90 days if used by a professional contractor or

if used as rental equipment). This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our

facilities, normal wear and tear, or to lack of maintenance. We shall in no event be liable

for death, injuries to persons or property, or for incidental, contingent, special or consequential damages arising from the use of our product. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation

of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection veries the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect

resulted from causes not within the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Bench Grinder For technical questions, please call 1-800-444-3353. Page 16

Loading...

Loading...