Page 1

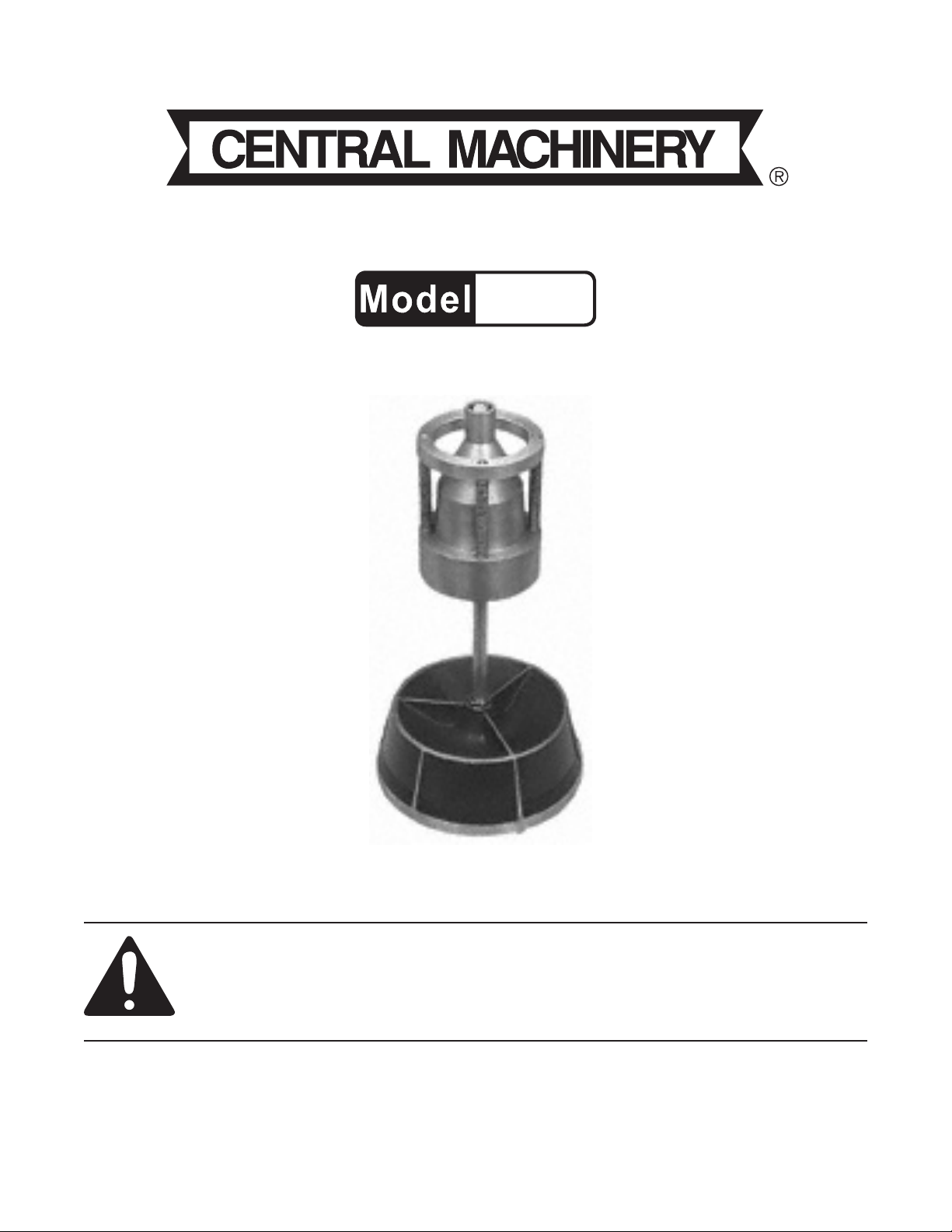

WHEEL BALANCER

39741

ASSEMBLY AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 1998 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained

herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing improvements, actual product may

differ slightly from the product described herein. Tools required for assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Revised Manual 09k

Page 2

Specifications

Wheel Balancer includes: Base, Balancer, and Leadscrew

Overall Dimensions: 22-5/8" x 11-7/8" x 11-7/8"

Base Diameter: 11-7/8"; Center Rod diameter: .813"

Hub Diameter: 1.495"; Tool Weight: 13.40 Lbs.

Designed for use: Light Truck and Automobile Wheels

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce

the risk of personal injury and damage to equipment.

Read all instructions before using this product!

1. Do not use the Wheel Balancer until properly trained. This product is intended for use

by properly trained and experienced personnel only. If you are not familiar with the proper

and safe operation of a wheel balancer, do not use until trained.

2. Keep work area clean. Cluttered areas invite injuries.

3. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically powered tools in the presence of flammable gases or liquids.

4. Keep children away. Children must never be allowed in the work area. Do not let them

handle machines, tools, or extension cords.

5. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

6. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool capacity.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically nonconductive clothes and nonskid footwear are recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles. Wear

a full face shield if you are producing metal filings or wood chips. Wear an ANSI approved

dust mask or respirator when working around metal, wood, and chemical dusts and mists.

#39741 For technical questions, please call 1-800-444-3353. Page 2

Page 3

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect tool cords periodically and, if damaged, have them repaired by an authorized technician. The handles must

be kept clean, dry, and free from oil and grease at all times.

11. Stay alert. Watch what you are doing; use common sense. Do not operate any tool when

you are tired.

12. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts or

mounting fixtures; and any other condition that may affect proper operation. Any part that

is damaged should be properly repaired or replaced by a qualified technician.

13. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for use

with this tool. Approved accessories are available from Harbor Freight Tools.

14. Do not operate tool if under the influence of alcohol or drugs. Read warning labels

on prescriptions to determine if your judgment or reflexes are impaired while taking drugs.

If there is any doubt, do not operate the tool.

Note: The warnings and instructions contained in this instruction

manual cannot cover all possible conditions and situations that may

occur when using this product. It must be understood that common

sense and caution are factors which cannot be built into this product.

These factors must be supplied by the person operating the tool.

Unpacking

When unpacking, check the Parts Diagram and Part Number Listing on page 5 to make

sure all parts are included. If any parts are missing or broken, please call Harbor Freight Tools

at the number on the cover of this manual.

Assembling the Wheel Balancer

The Wheel Balancer is easily assembled by following the steps shown below. Part numbers

used below refer to the Parts Diagram and Part Number Listing on page 5.

1. Insert the threaded end of the Shaft (#9) into the Base (#12). Use Flat Washer (#11), Lock

Washer (#13) and two Nuts (#10) to tightly secure the Shaft - see the Parts Diagram for proper

assembly order of hardware.

#39741 For technical questions, please call 1-800-444-3353. Page 3

Page 4

2. The Balancing Cone Set (#7) rests on top of the tip located on top of the Shaft (#9). Make

sure the tip of the Shaft (#9) fits into the recessed area on the underside of the Balancing Cone

Set. When properly fitted, the bubble on the Level Bubble (#4) should be perfectly centered.

Note: When finding a location for the Wheel Balancer, use a level to make sure this tool

is positioned on a flat, level surface.

3. With the Wheel Balancer in place, check the balance of the Flange Set (#1). Lightly tilt the

Flange Set and let it come to rest. It should easily rock back and forth and come to rest with

the bubble centered in the Level Bubble.

Using the Wheel Balancer

1. Use a wheel clipper tool to remove all old lead wheel weights on the wheel to be balanced.

2. Lay the rim of the wheel to be balanced down over the top of the Flange Set (#1). Make

sure the wheel rim is evenly distributed on top of the Flange Set (#1). If the wheel is not properly balanced, you will notice that the bubble inside the Level Bubble (#4) is not centered and

rests to one side of the Level Bubble (#4).

3. To balance the wheel, lead wheel weights must be added to the side of the rim where the

off-center bubble rests. Place one or more lead wheel weights in place to bring the bubble

back to the center of the Level Bubble (#4). When the bubble is centered the wheel is balanced. Tap the lead wheel weights to secure them to the rim.

4. Once balanced, remove the wheel from the Flange Set (#1).

Note: Wheel Clipper Tool is available from Harbor Freight Tools.

Rev 2000f

#39741 For technical questions, please call 1-800-444-3353. Page 4

Page 5

Part Number Listing and Parts Diagram

Part # Description Qty

1 Flange Set 1

2 Spring 4

3 Screw ST2.2x10 3

4 Level Bubble 1

5 Washer 1

6 Bubble Spring 1

7 Balancing Cone Set 1

8 Retaining Pin 2

9 Shaft 1

10 Nut M20x1.5A 2

11 Flat Washer 1

12 Base 1

13 Lock Washer 1

#39741 For technical questions, please call 1-800-444-3353. Page 5

Page 6

LIMITED 1 YEAR WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality

and durability standards, and warrants to the original purchaser that this product is free from

defects in materials and workmanship for the period of one year from the date of purchase (90

days if used by a professional contractor or if used as rental equipment). This warranty does not

apply to damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or

alterations outside our facilities, normal wear and tear, or to lack of maintenance. We shall in no

event be liable for death, injuries to persons or property, or for incidental, contingent, special or

consequential damages arising from the use of our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion

may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. Proof of purchase date and an explanation of the complaint must

accompany the merchandise. If our inspection verifies the defect, we will either repair or replace

the product at our election or we may elect to refund the purchase price if we cannot readily and

quickly provide you with a replacement. We will return repaired products at our expense, but if

we determine there is no defect, or that the defect resulted from causes not within the scope of

our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

#39741 For technical questions, please call 1-800-444-3353. Page 6

Loading...

Loading...