Page 1

SEWING MACHINE - SINGLE NEEDLESEWING MACHINE - SINGLE NEEDLE

SEWING MACHINE - SINGLE NEEDLE

SEWING MACHINE - SINGLE NEEDLESEWING MACHINE - SINGLE NEEDLE

03914

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2003 by Harbor Freight Tools®. All rights reser ved. No portion of

this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

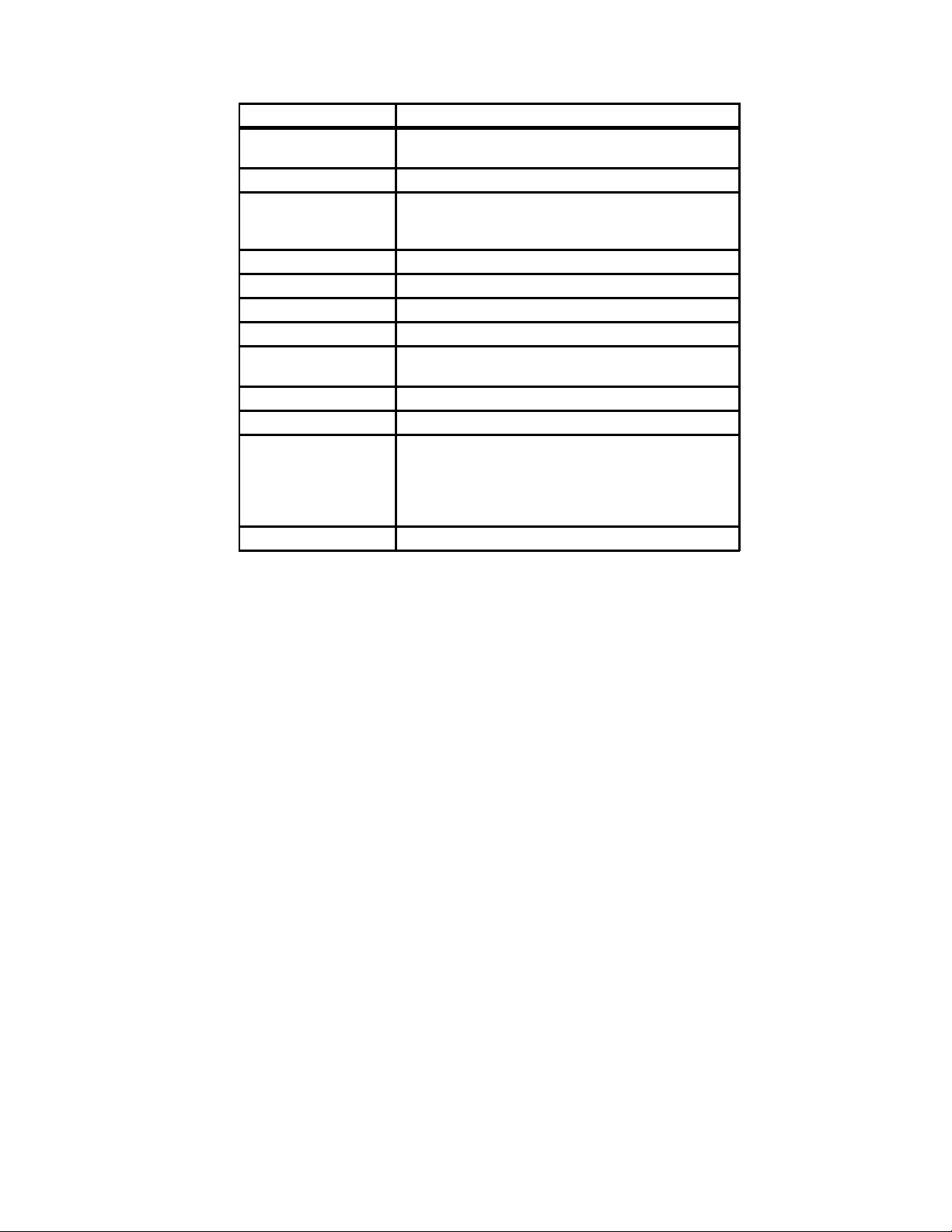

Specifications

ITEM DESCRIPTION

Machine Type

Drive V-belt driven

Action

Sewing Thickness 5/16 inch maximum

Feed Type Link style needle feed reduces slippage

Sewing Directions Forwar d and reverse feed

Stitching Speed 5500 Stitches per minute

Motor Type

Overall weight 61.6 lbs

Machine Dimensions 20-3/4 (L) x 10 (H) inches

Accessories

Table Stand Kit Table Stand Kit (Model 03929) not included

Heavy duty, industrial sewing machine; high

speed, single needle-lock stitch

Foot pedal operation, along wit h a knee and

manual lifting arm for presser foot. Presser

tension adjustment

Clutch motor; 3450 RPM, 5.8 amps, 110 VAC at

60 Hz; single phase

- S cre wdriver s

- 3 Bobbins

- Small lubr icating bottl e wit h tip

- 10 pack of needles

- Power Switch

110/220V,

Caution: Make certain that the voltage switch on the motor is set correctly

for your use. See page 6.

This Machine requires oil to be added before use -see page 6 for details.

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front co v er. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should alwa ys be f ollowed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use , tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

Page 2SKU 03914

Rev 04/03 REV 05/03 REV 03/04

Page 3

5. Use the right product for the job. Do not attempt to force a small product or

attachment to do the work of a larger industrial tool. There are certain applications for

which this product was designed. It will do the job better and more safely at the rate

for which it was intended. Do not modify this product and do not use this product for a

purpose for which it was not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair.

7. Do not overreach. Keep proper footing and balance at all times. Do not reach over

or across running machines.

8. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect

tool cords periodically and, if damaged, have them repaired by an authorized

technician. The handles must be kept clean, dry, and free from oil and grease at all

times.

9. Disconnect power. Unplug product when not in use.

10. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the machine work surface before plugging it in.

11. Avoid unintentional starting. Be sure the switch is in the Off position when not in

use and before plugging in.

12. Stay alert. Watch what you are doing, use common sense. Do not operate when you

are tired.

13. Check for damaged parts. Before using any product, any par t that appears

damaged should be carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment and binding of moving par ts; any

broken parts or mounting fixtures; and any other condition that may affect proper

operation. Any part that is damaged should be properly repaired or replaced by a

qualified technician. Do not use if any switch does not turn On and Off properly.

14. Guard against electric shock. Prevent body contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerator enclosures.

15. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor

Freight Tools.

16. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

Page 3SKU 03914

Page 4

17. Use proper size and type extension cord. If an extension cord is required, it must be

of the proper size and type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or cause electrical damage to

the tool. This tool requires use of an extension cord with up to 10 amps capability (up

to 50 feet), with wire size r ated at 18 AWG. Longer extension cords require larger size

wire. If you are using the tool outdoors, use an extension cord rated for outdoor use.

(signified by “WA” on the jacket).

20. Maintenance. For your saf ety, service and maintenance should be performed

regularly by a qualified technician.

21. Pacemaker safety warning. People with pacemakers should consult with their

physician(s) before using this product; operation of equipment in close proximity to a

heart pacemaker could cause interference or failure of the pacemaker.

Note: Performance of this tool may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied b y the operator.

Sewing Safety Precautions

1. Keep hands away from the needle when you turn the power switch on, or while the

machine is operating.

2. Do not place your fingers into the thread take-up cover while the machine is

operating.

3. Always turn the machine off and unplug the power cord to the electrical outlet before

tilting the machine head or removing the V-belt.

4. Never leave the machine running and unattended.

5. During operation, never place your head, hair, or hands in the proximity of the hand

wheel, V-belt, bobbin winder, or motor.

6. Do not operate the machine with any safety guards removed.

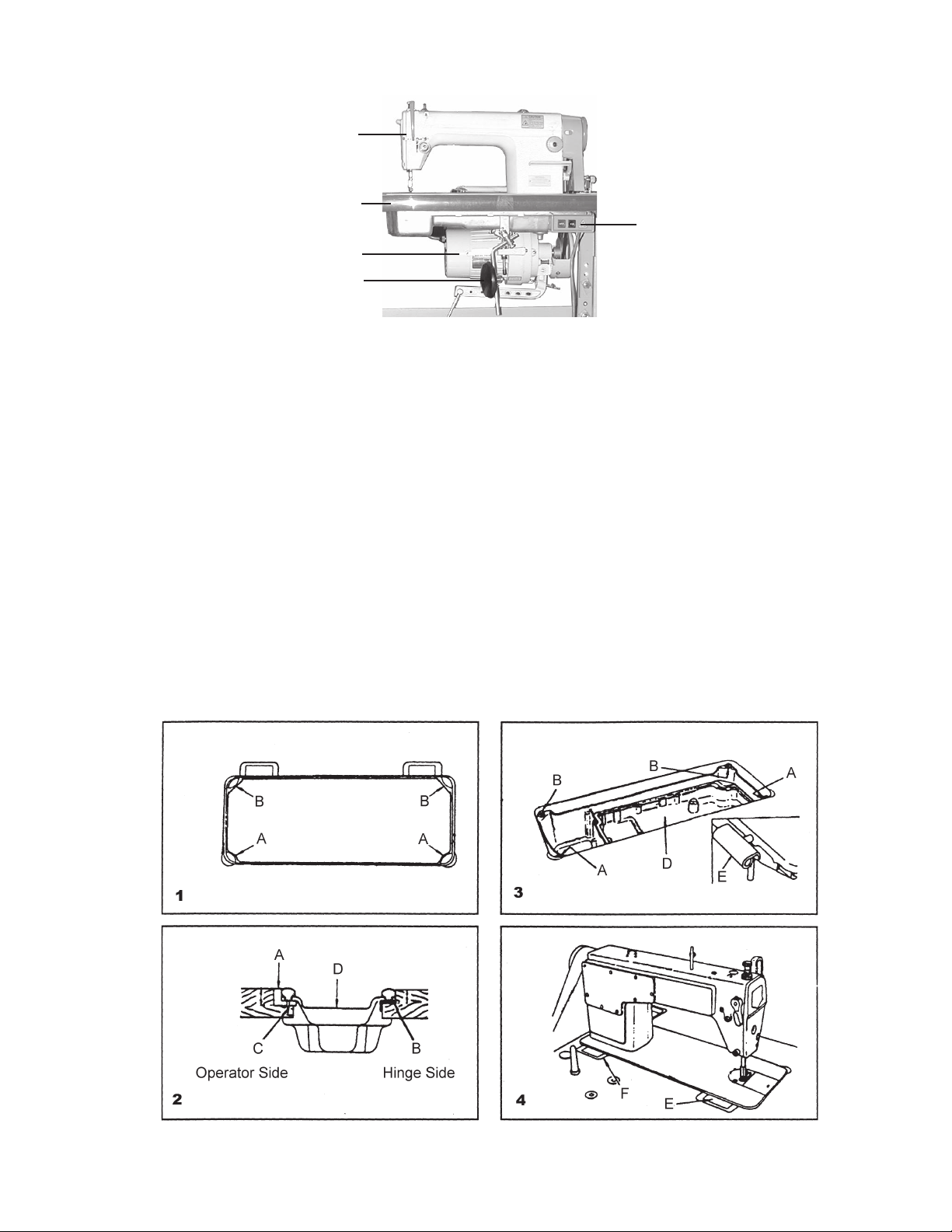

Unpacking

When unpacking, check to make sure that the par ts shown in the photo on the following

page are included. Note that the machine table shown is not included, and must be ordered

separately. If any parts are missing or broken, please call Harbor Freight Tools at the number on the cover of this manual as soon as possible.

Page 4SKU 03914

Page 5

Sewing Machine

Table Stand and

Top (not provided)

Motor

Knee Lifting Arm

for Presser Foot

Po wer Switch

Assembly

The assembly instructions describe mounting the Single-Needle Sewing Machine (Model

03914) to the Table Stand (Model 03929), not included. In order to complete this procedure,

you must first purchase and assemble the Table Stand Kit (Model 03929).

1. Locate four corner rests in the rectangular hole of the Table Stand where the machine

will sit.

2. Place two rubber seats (A) on the operator-side, corner rests and secure with

supplied hardware (C). See figure 1.

3. Place two cushion seats (B) on the hinge-side, corner rests and secure with supplied

hardware (C).

4. Seat the Oil Pan (D) on the corner seats (A) and (B). See figure 2.

5. Insert Hinges (E) into the opening in the machine bed. See figure 3.

Page 5SKU 03914

Page 6

6. Fit the machine head to the table rubber hinges (F) before placing the machine head

on the corner seats. See figure 4.

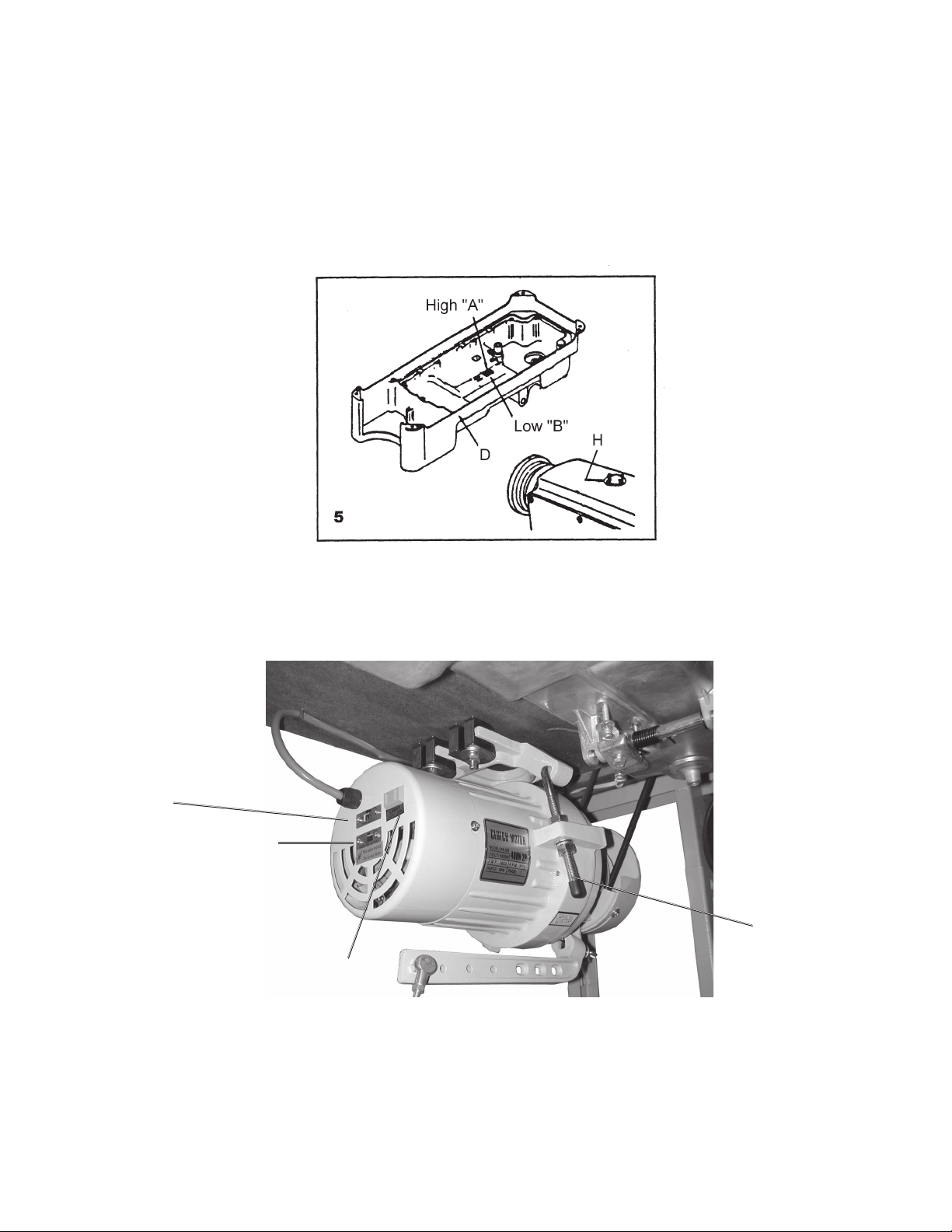

7. Tilt the machine back to expose the Oil Pan (D). See figure 5.

8. Fill the Oil Pan with sewing machine lubrication oil (#7 white oil) to the “high” mark “A”.

Add more oil when the level is to the “low” mark “B”. After lubrication, and during

operation, oil splashing can be seen through the Oil Sight Window (H).

9. Lower the machine head to the table top.

10. Mount the Motor to the underside of the table top as shown below. Use the supplied

hardware.

Note: Top switch is for

rotation. Switch left for

counterclockwise;

switch right for clockwise

rotation.

Note: Motor is 110/220V

Single Phase. Flip switch

to desired voltage (no

re-wiring needed). Switch

left for 110V, switch right

for 220V.

Note: Receptacle for 6 volt work

light (not included).

(K)

11. Place the V-belt around the Sewing Machine Pulley, through the slot in the table top,

and around the Motor pulley. Attach the Pulley Safety Cover.

12. Tighten the V-belt tension by adjusting the long bolt and nut at location (K). The

proper tension is reached when the V-belt can only be pushed in 1/2 inch.

Page 6SKU 03914

REV 04/03 REV 05/03

Page 7

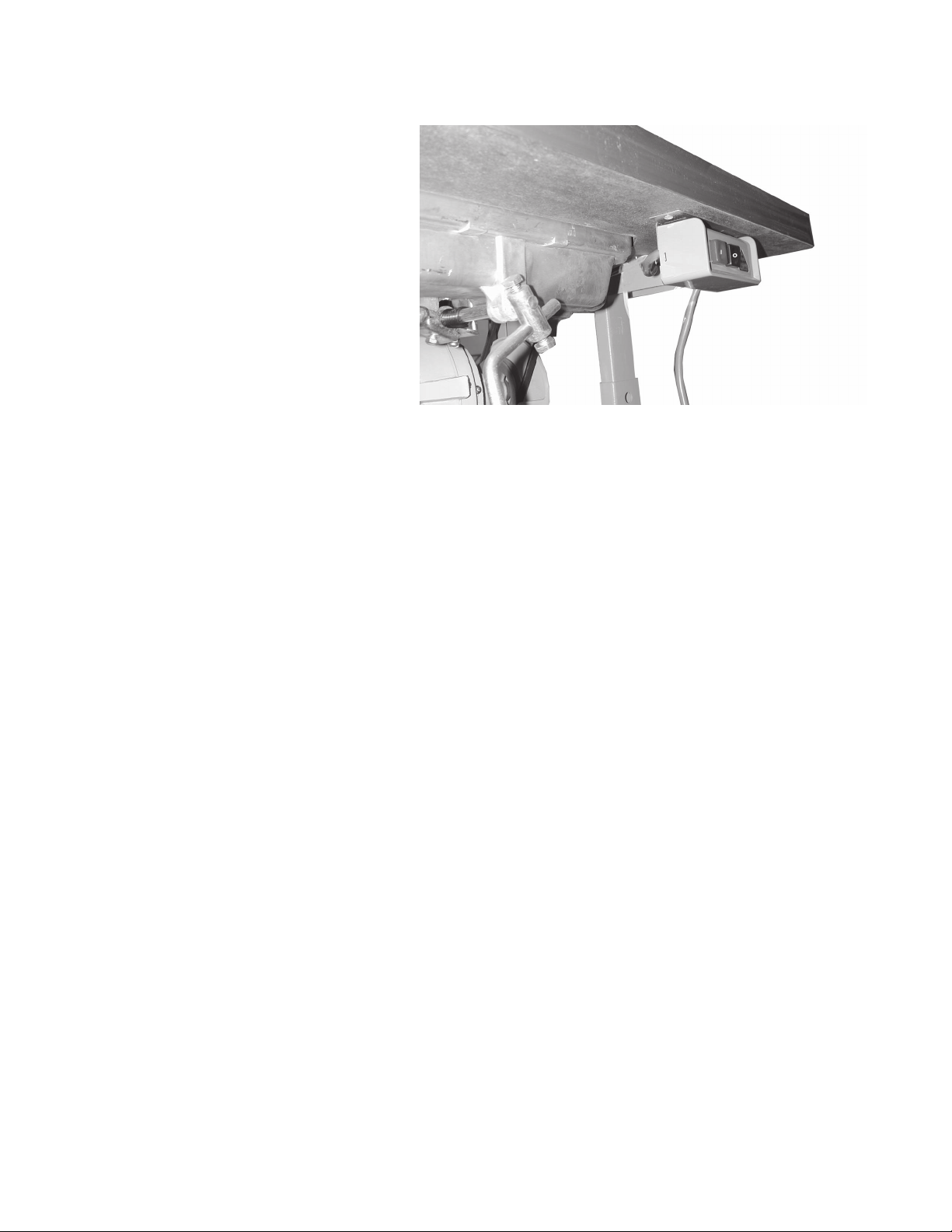

13. Mount the Po wer Switch under the table top, on the operator’s side. Use the supplied

hardware.

Po wer Switch

Mounting the Thread Stand

Note: The Thread Stand is designed to be mounted on the Table Stand Kit

(Model 03929-not included). Unless indicated otherwise , all parts referred

to in this set of instructions are listed in the

Unit Parts List

found on page 28. During assembly, it will be helpful to

Bobbin Winder & Thread Stand

refer to that list and the diagram that follows it on page 29.

14. Locate the large hole in the far right corner (from the location that the operator will be

seated) of the Table (not included). Place the Rub ber W asher (45) and W asher (37) onto

the Lower Spool Rest Rod (36) and insert the Rod into the hole mentioned above. Place

another W asher (37) o v er the end of the Rod, and thread on and tighten a Nut (38).

15. Place the Spool Support (46) ov er the Low er Spool Rest Rod (36) about halfway down.

Insert a Screw (31) and Nut (47) through the Support.

Note: The Support has tabs that hold onto the corners of the Nut to make tightening

easier. When assembling, place the Nut on the side with these tabs.

Tighten the Screw.

16. Inser t the threaded end of the Spool Pin (40) through one of the holes in the top of the

arm of the Spool Support (46). Place a W asher (32) and Nut (35) ov er the end of the Pin

and tighten. Place the Spool Rest (41), Spool Mat (42), and the Spool Vibration Stopper

(39) over the end of the Spool Pin. Repeat this step for both of the Spool Pins (40).

17. Place the Column Pipe Connector (33) over the top of the Lower Spool Rest Rod (36)

until the Rod is about halfway through the Connector. Place a Screw (34) and Nut (35)

through the bottom hole in the Connector and finger-tighten.

18. Place the Upper Spool Rest Rod (30) into the top of the Column Pipe Connector (33).

Place a Screw (34) and Nut (35) through the top hole in the Connector . Tighten all of the

Screws and Nuts in the Connector.

19. Place the Thread Hanger (28) about halfway over the top of the Upper Spool Rest Rod

(30). Inser t a Screw (31) and Nut (47) through the Hanger as explained in the note in

step 14, above. Tighten the Screw and place the Column Cap (29) over the end of the

Upper Spool Rest Rod (30).

Page 7SKU 03914

REV 03/04

Page 8

Mounting the Bobbin Winder

Note: Unless indicated otherwise, all parts

referred to in this set of instructions are listed

in the

Bobbin Winder & Thread Stand Unit

Parts List

found on page 28. During

assembly, it will be helpful to refer to that list

and the diagram that follows it on page 29.

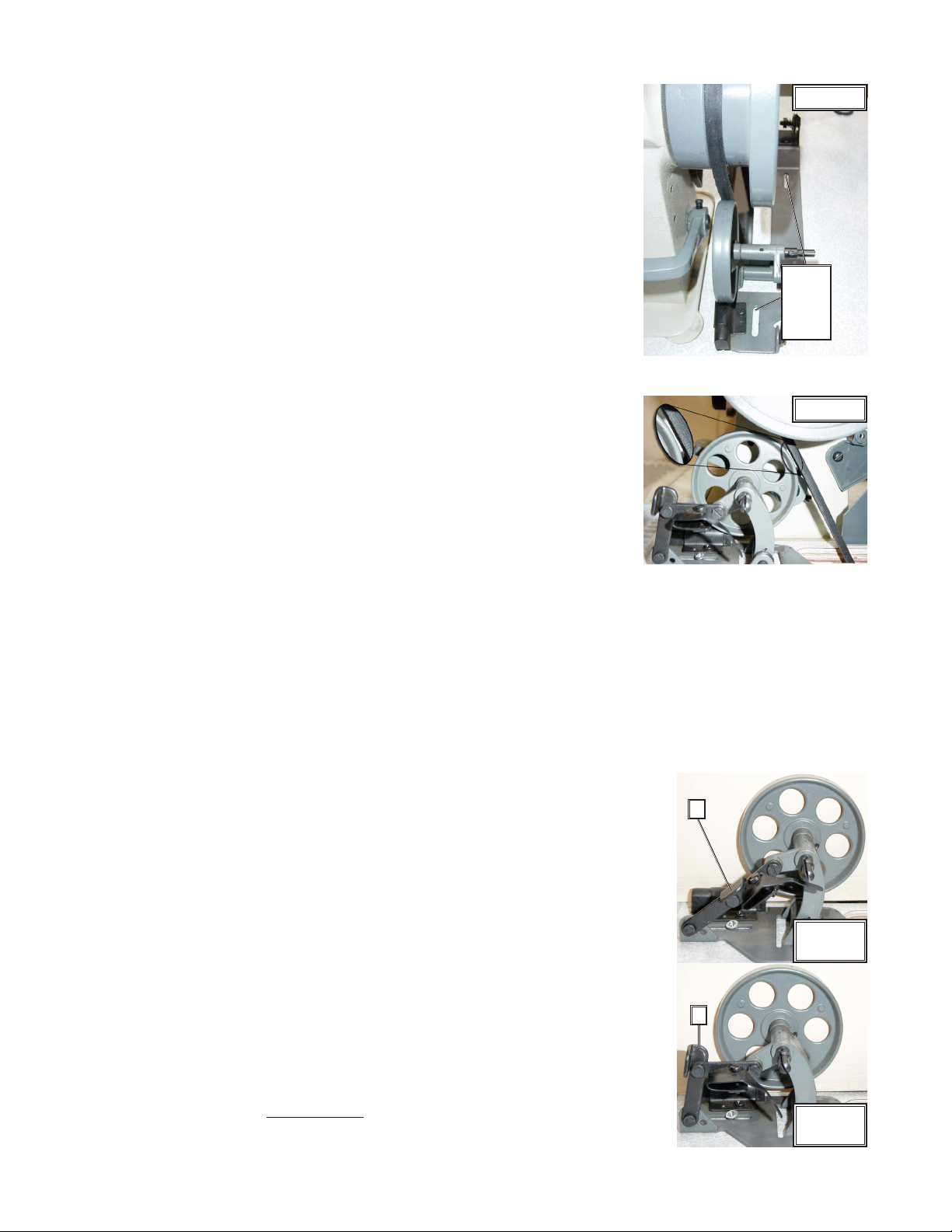

Figure A

20. Remove the Belt Cover (par t 4, on page 27). Swing the

sewing machine so the base is in the operating position,

resting on the table. Set the Bobbin Winder to the ‘ON’

Position-see

ON Position,

below.

Mark

Pilot

Holes

Here.

21. Make sure the Bobbin Winder is in the ‘ON’ position.

Position the Base (Bobbin Winder Base Assembly) (1) so

that the Thread Winder Assembly (3) lines up with and just

Figure B

touches the belt. Mark pilot hole locations on the table at

the far end of each of the two channels in the Base as

indicated in

Figure A

.

22. Set the Base (1) aside and swing the sewing machine out

of the way. Carefully drill straight pilot holes for each of the

two locations marked above. Place the base in location

and secure using two W ood Screws (26) and Washers (27).

Leave the Screws just loose enough to allow the Base to slide.

23. Swing the Sewing Machine back into it’s operating position. Put the Bobbin Winder in

the ‘OFF’ position-see

to the belt until it just barely doesn’t touch it (1/8” gap or less)-see

OFF Position,

below.. Slide the Bobbin Winder Assembly close

Figure B

, above. Tighten

the W ood Scre ws (26) from step 22, abo ve .

24. Put the Belt Cover back on the Sewing Machine before use.

Operation

Caution: To properly break-in your new sewing machine, and

avoid possible damage to the machine, sew at moderate to slow

speeds for the first 15 minutes of use.

Bobbin Winder Operation

The Bobbin Winder not only assists in winding thread onto the

Bobbin, but it also makes the belt tight, operating the rest of the

machine. The Bobbin Winder has two positions, ‘ON’ and ‘OFF’:

OFF Position The Bobbin Winder won’t contact the belt, causing

the machine to ‘idle’.

WARNING: While the machine is ‘idling’ the needle or

other parts can possibly still move at any time. Shut the

machine off completely before working around the needle

or other moving parts.

Page 8SKU 03914

6

ON

Position

6

OFF

Position

REV 03/04

Page 9

ON Position This position is with the Connecting Rod

(6) pressed, as shown in

Figure C

. The Bobbin

Winder will put pressure on the belt and cause the

machine to operate. The Shaft on the Bobbin Winder

will also spin; winding thread onto the Bobbin, if the

Winder is set up to do so.

Winding Thread Onto the Bobbin

1. Place a Bobbin onto the Bobbin Winder Shaft (5) as

shown at point

Figure C

, right.

d

in

2. Route the Thread from the Spool (not shown) up through

the Thread Guide Tube (43,

point a

), the hole in the

Thread Tension Bracket Assembly (18, b), over and

under the far side of the T ension Disc (21, c), and connect

it to the Bobbin (d).-See

Figure D

, right.

3. While the Connecting Rod (6) is pressed (as shown in

both

Figures C

and D) the Bobbin Winder will be in the

‘ON’ position and the Bobbin will fill with thread. When

finished, release the Connecting Rod and the Bobbin

Winder will reset to the ‘OFF’ position.

Figure C

6

d

b

a

Figure D

6

d

b

c

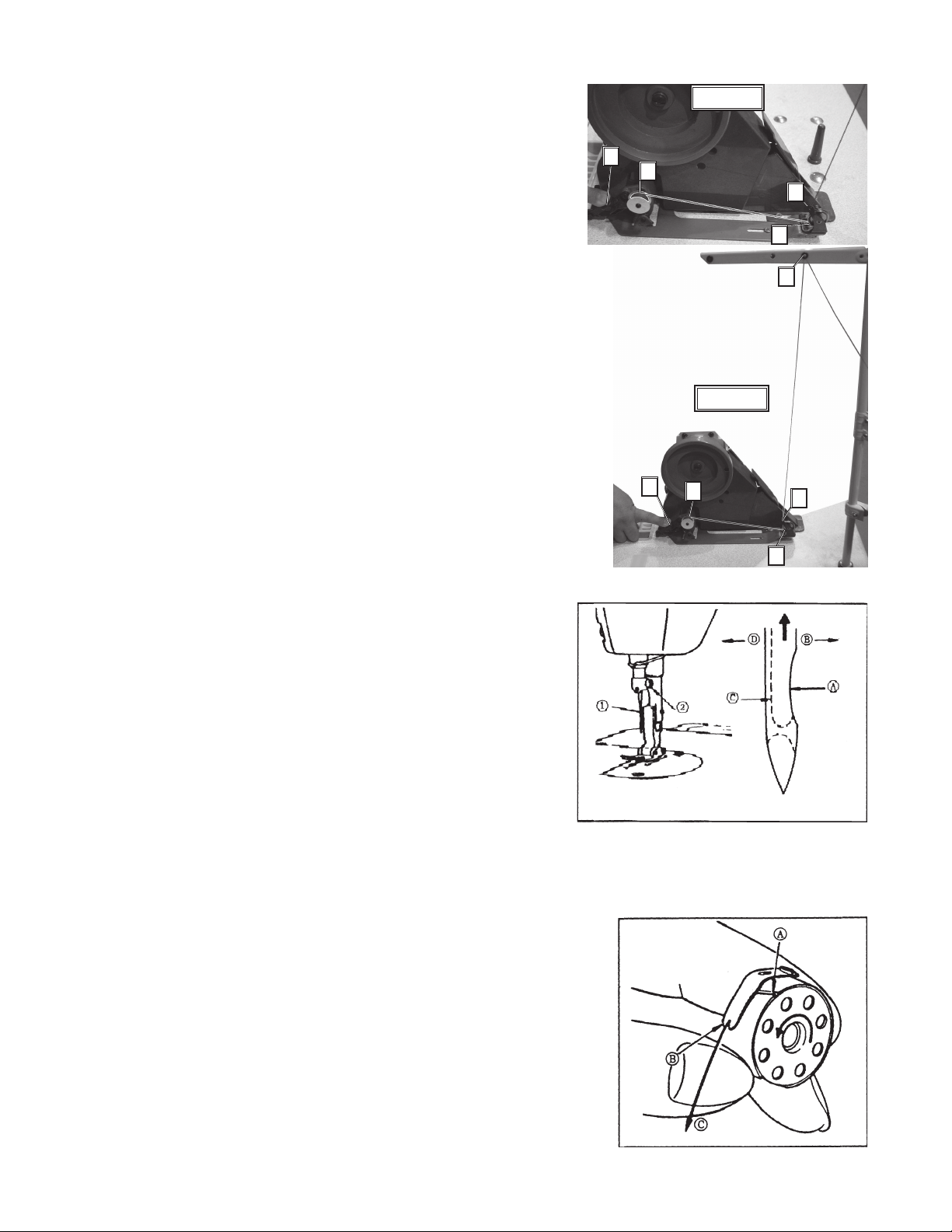

Attaching the Needle

1. Unplug the Pow er Cord from the electrical outlet.

2. Select a proper needle size according to the

thread count and type of material being sewn.

3. Turn the Hand Wheel until the needle bar

reaches the highest point of its stroke.

4. Loosen Screw (2) and hold needle (1) with its

indented part “A” facing exactly to the right in

direction “B”.

5. Insert the needle and push it up until it will go no further.

6. While holding in place, securely tighten Screw (2).

Setting the Bobbin into the Bobbin Case

1. Hold the Bobbin so that the thread exit is to the left,

and push the Bobbin into its case.

2. Feed the thread through slit “A” and pull the thread in

direction “B”. By doing so, the thread will pass under

the tension spring and exit at notch “B”.

3. V erify that the Bobbin rotates in the direction of the

arrow when thread “C” is pulled.

Page 9SKU 03914

REV 03/04

Page 10

Threading the Machine Head

Set the thread spool on its holder and guide the thread through the machine as illustrated

below. The numbers in the illustration indicate the threading sequence.

Adjusting the Stitch Length

1. To increase the stitch length, turn the Stitch Length

Dial (1) to the desired number (in millimeters) as

indicated under the scale dot (A) on the machine.

2. To decrease the stitch length, turn the Stitch Length

Dial (1), while pressing the Feed Lever (2).

Adjusting the Needle Thread Tension

1. Turn Tension Adjustment Knob (1) clockwise (A) to

increase thread tension.

2. Turn Tension Adjustment Knob (1)

counterclockwise (B) to decrease thread tension.

Adjusting the Bobbin Thread Tension

1. Turn the Tension Adjustment Screw (2) clockwise

(A) to increase bobbin tension.

2. Tur n the Tension Adjustment screw (2)

counterclockwise (B) to decrease bobbin tension.

Page 10SKU 03914

Page 11

Changing the Thread T ake-up Spring Stroke and Pressure

1. Loosen Set Screw (2).

2. To increase the stroke, turn the Tension

Knob Screw (3) clockwise (A).

3. To decrease the stroke, turn the Tension

Knob Screw (3) counterclockwise (B).

4. Loosen Set Screw (2) and pull out the

Tension Arm (5).

5. Loosen Set Screw (4) and remove the

Tension Knob Screw (3).

6. Turn the Tension Knob Screw (3) clockwise (A) to increase pressure; or turn

counterclockwise (B) to decrease pressure.

7. Replace Tension Knob Screw (3), tighten Set Screw (4), and replace the assembly.

Setting the Hand Lifter

1. To stop the machine with its Presser Foot up,

turn the Hand Lifter (1) up (A).

The Presser Foot will go up about 1/4 inch and

stop.

2. To set the Presser Foot to its original position,

turn the Hand Lifter (1) down (B).

Using the Knee Lifter, y ou can get the standard Presser F oot lift of about 1/2 inch.

Setting the Presser Foot Pressure

1. Loosen Nut (2), and turn the Presser Spring

Regulator (1) clockwise (A) to increase Presser

Foot pressure.

2. To decrease Presser Foot pressure, turn the

Presser Spring Regulator (1) counterclockwise.

3. After adjustment, tighten Nut (2).

Adjusting the Feed Timing

1. Loosen Set Screws (2) and (3) on the Feed

Eccentric Cam (1) and properly position the

Eccentric Cam. Retighten the Set Screws.

2. To advance the feed timing in order to prevent

uneven material feed, move the Feed Eccentric

Cam up (clockwise).

Page 11SKU 03914

Page 12

3. To delay the feed timing in order to increase stitch tightness, move the Feed Eccentric

Cam down (counterclockwise).

Adjusting the Height of the Feed Dog

The Feed Dog is factory adjusted so that it juts

out from the Throat Plate surface 0.8 mm to 0.9

mm. If the Feed Dog juts out too much, puckering may result when sewing lightweight materials. To adjust the height of the Feed Dog:

1. Loosen Screw (2) of Crank (1).

2. Move the Feed Bar up or down to make

the adjustment.

3. Tighten Screw (2), being careful not to

overtighten.

Adjusting Needle-to-hook Timing

1. Tur n the Hand Wheel to bring the needle

bar down to the lowest point of its stroke.

2. Loosen Set Screw (1).

3. When using a DBX1 needle, align to

marker line “A” on the needle bar (2) with

the bottom end of the needle bar lower

bushing (3), then tighten Set Screw (1).

When using a DAX1 needle, align to

marker line “B” on the needle bar (2) with

the bottom end of the needle bar lower

bushing (3), then tighten Set Screw (1).

4. When using a DBX1 needle, loosen three

Hook Set Screws, turn the Hand Wheel,

and align the marker line “B” on the needle

bar (2) with the bottom end of the needle

bar lower bushing (3).

When using a DAX1 needle, align the marker line “D” on the needle bar (2) with the

bottom end of the needle bar lower bushing (3).

5. After making the adjustments in steps 3 and 4, align the Hook Blade point (5) with the

center of the needle (4).

Provide a clearance of .001” to .004” (0.04 to 0.1 mm) between the needle and the

hook. This clearance is less than 1/64” (almost touching). Securely tighten the three

Set Screws. If the clearance is too small, the tip of the hook will be abraded. If it is too

large, it will lead to skip over.

Page 12SKU 03914

Page 13

Adjusting the Presser Bar Height

1. Loosen Set Screw (1) and manually adjust the Presser Bar

height, and the angle of the Presser Foot.

2. After adjusting, securely tighten the Set Screw (1).

Adjusting the Thread T ake-up Stroke

1. When sewing heavy weight materials,

move the Thread Guide (1) to the left (A) to

increase the length of thread pulled out by

the Thread T ake-up .

2. When sewing lightweight materials, move

the Thread Guide (1) to the right (B) to

decrease the length of thread pulled out by

the Thread T ake-up .

3. The normal setting is when the marker line

“C” on the Thread Guide (1) is aligned with

the center of the screw .

Adjusting the Height of the Knee Lifter

The standard height of the Presser Foot lifted using the Knee Lifter is 0.39 inch (10 mm).

1. To adjust the Presser Foot lift up to 0.5 inch (13 mm), adjust the Screw (1).

2. When the Presser Foot lift is adjusted over 0.39 inch (10 mm), be sure that the bottom

end of the Needle Bar (2) does not hit the Presser Foot (3).

This can be manually checked by turning the Hand Wheel.

Maintenance

1. Machine adjustments should only be performed by a qualified technician.

2. Check the oil level weekly when the machine is used daily. Add sewing machine oil as

required to the high level marking.

3. Clean the machine with a clean, damp cloth. Do not use solvents or thinners.

4. When not in use, cover the machine and store in a clean and dry location.

Page 13SKU 03914

Page 14

ARM BED PARTS LIST

Ref. Amt.

No. Part No. Description Req.

Page 14SKU 03914

Page 15

ARM BED ASSEMBLY DRAWING

NOTE: When ordering parts from the following lists, alwa ys include the

list title, item number and description, and page number. For example,

to order the first part from page 14 list, you would state:

- Arm Bed Parts List

- Item #1 - Arm Bed Assembly

- Page: 14

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTA TION OR WARRANTY OF ANY KIND T O THE BUYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY ST A TES THAT ALL REP AIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NO T BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING

OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 15SKU 03914

Page 16

MAIN SHAFT THREAD TAKE-UP PARTS LIST

Ref. Amt.

No. Part No. Description Req.

Page 16SKU 03914

Page 17

MAIN SHAFT THREAD T AKE-UP ASSEMBL Y DRAWING

Page 17SKU 03914

Page 18

FABRIC--PIERCING HOOK DRIVING PARTS LIST

Ref. Amt.

No. Part No. Description Req.

Page 18SKU 03914

Page 19

FABRIC--PIERCING HOOK DRIVING ASSEMBLY DRAWING

Page 19SKU 03914

Page 20

PRESSER BAR PARTS LIST

Ref. Amt.

No. Part No. Description Req.

Page 20SKU 03914

Page 21

PRESSER BAR ASSEMBLY DRAWING

Page 21SKU 03914

Page 22

FEED MECHANISM PARTS LIST

Ref. Amt.

No. Part No. Description Req.

Page 22SKU 03914

Page 23

FEED MECHANISM ASSEMBLY DRAWING

Page 23SKU 03914

Page 24

LUBRICATION PARTS LIST

Ref. Amt.

No. P a r t No. Description Req.

Page 24SKU 03914

Page 25

LUBRICATION ASSEMBLY DRAWING

Page 25SKU 03914

Page 26

OIL RESERVOIR & KNEE LIFTER ASSEMBLY DRAWING AND PARTS LIST

Ref. Amt.

No. P a r t No. Description Req.

Page 26SKU 03914

Page 27

MACHINE HEAD ACCESSORIES PARTS LIST AND ASSEMBLY DRAWING

Ref. Amt.

No. Part No. Description Req.

Page 27SKU 03914

Page 28

BOBBIN WINDER & THREAD STAND UNIT PARTS LIST

Ref. Amt.

No. Part No. Description Req.

Page 28SKU 03914

REV 03/04

Page 29

BOBBIN WINDER & THREAD STAND UNIT ASSEMBLY DRAWING

Page 29SKU 03914

REV 03/04

Loading...

Loading...