Page 1

4 Gallon, 2 HP Peak

®

Pancake Compressor

Model 38898

ASSEMBLY and OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

www.HarborFreight.com

Copyright© 1999 by Harbor Freight Tools®. All Rights Reserved.

No portion of this manual or any artwork contained herein may be reproduced

in any shape or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

REV 11/04; 10/05; 02/06

Page 2

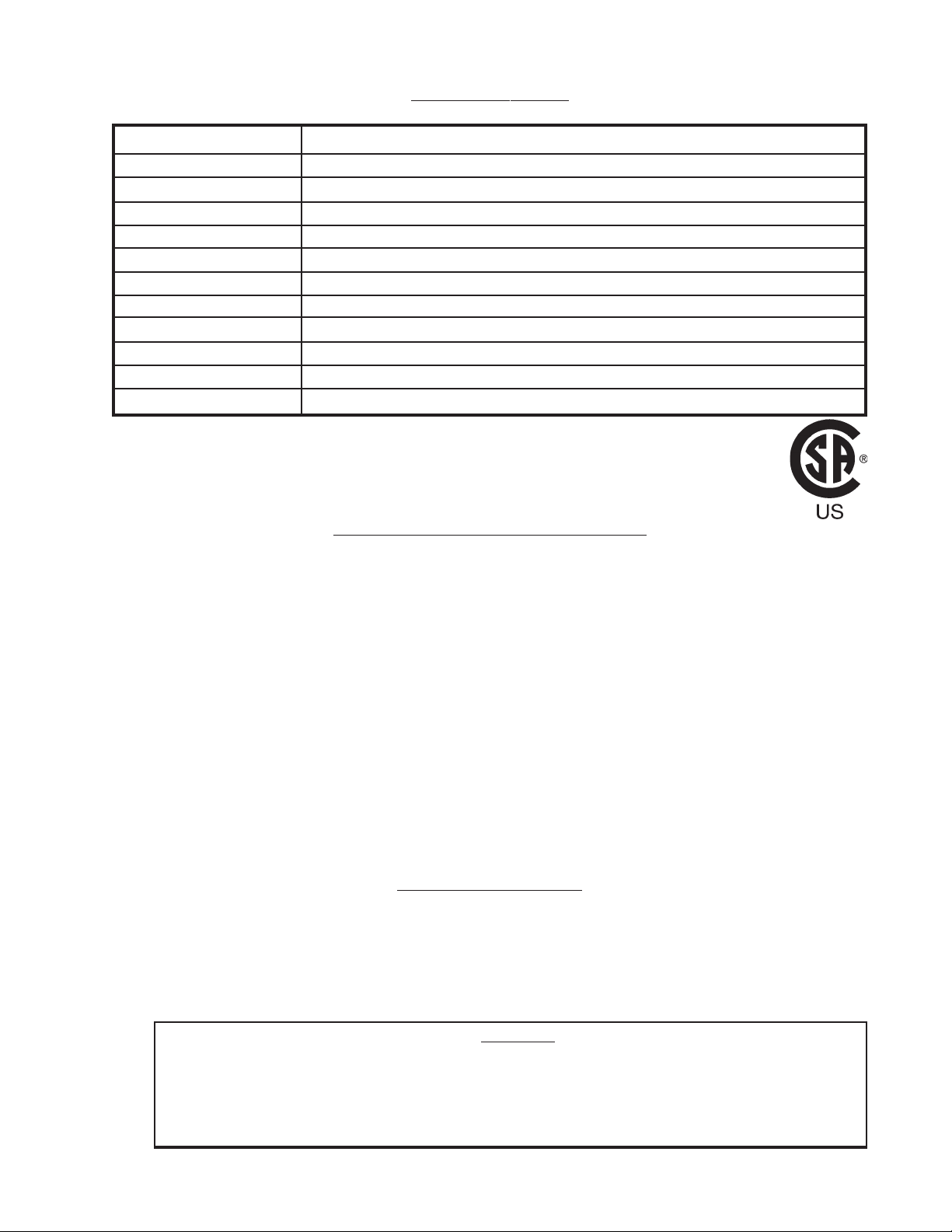

SPECIFICATIONS

Motor 1-3/4 HP Rated

Electrical 120 V~, 11 Amps, 3450 RPM, Single Phase, 60 Hz

Power Cord 3 prong grounded 14 AWG X 3C, double insulated, UL listed, 20’ long

Air Outlet Fitting 1/4” NPT barbed

Drive Type Direct

Pump Stage Single

Air Tank Size 4 Gal.

Pressure Range Pressure Switch On at 80 PSI; Pressure Switch Off at 115 PSI

Air Delivery 4.2 SCFM at 90 PSI; 5.2 SCFM at 40 PSI

Pressure Disconnect Automatically releases pressure if overloaded to 120 PSI

Oil Requirement Standard non-detergent 30 weight compressor or motor oil

Weight 51 Lbs.

Note: When using extensions cords (not included) - To avoid circuit breaker and

voltage drop problems, we recommend using only 12 gauge x 50 foot extension

cords (Item #41444 or #45287), available from Harbor Freight Tools).

FEATURES OF THIS COMPRESSOR

1. This small, portable compressor is ideal for use in shops with limited storage space.

2. 80-115 PSI operating range is ideal for most shop uses including air tools, spraying,

tire inflation, air cleaning, etc.

3. Pressure switch maintains correct operating pressure at all times.

4. Pressure gauge gives continuous, real-time readout of current pressure delivery.

5. Maximum pressure disconnect safety valve prevents over-pressurization of tank.

6. Delivers enough air for continuous use in most applications.

7. Sturdy construction will deliver years of satisfactory service.

8. Your compressor is fully assembled when you receive it.

#233060

Warning: Fill compressor with oil before using;

running with NO or LOW OIL voids warranty.

Optimal oil tank capacity is 7.8 ounces.

SAVE THIS MANUAL

You will need the manual for the safety warnings and cautions, assembly instructions, operating

procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice

with this manual. Write the invoice number on the inside of the front cover. Keep both this manual

and your invoice in a safe, dry place for future reference.

The Warnings, Cautions, and Instructions discussed in this instruction manual cannot

cover all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

Page 2 SKU # 38898

NOTICE

REV 08/01; 01/02; 03/04; 11/04; 10/05; 02/06

Page 3

SAFETY WARNING & CAUTIONS

WARNING: When using pneumatic equipment, basic safety precautions should always be followed

to reduce the risk of personal injury and hazards.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL!

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. OBSERVE WORK AREA CONDITIONS. Do not use tools in damp, wet, or poorly lit locations.

Don’t expose to rain. Keep work area well lit. Do not use electrically powered air compressors in

the presence of flammable gases or liquids.

3. KEEP CHILDREN AWAY. Children must never be allowed in the work area. Do not let them

handle machines, tools, or hoses.

4. STORE IDLE EQUIPMENT. When not in use, tools must be locked up in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool’s capacities.

6. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or attachment to do

the work of a larger industrial tool. Do not use a tool for a purpose for which it was not intended.

7. DRESS PROPERLY. Do not wear loose clothing or jewelry as they can be caught in moving parts.

Nonskid footwear is recommended. Wear restrictive hair covering to contain long hair.

8. USE EYE AND EAR PROTECTION. Always wear ANSI-approved chemical splash goggles when

working with chemicals. Always wear ANSI-approved impact safety goggles at other times. Wear

a full face shield if you are producing metal filings or wood chips. Wear an ANSI-approved dust

mask or respirator when working around metal, wood, and chemical dusts and mists.

9. DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach over or across

running machines.

10. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect hydraulic lines and seals

periodically and, if damaged, have them repaired by an authorized technician. Inspect all hoses for

leaks prior to use. The handles must be kept clean, dry, and free from oil and grease at all times.

11. REMOVE ADJUSTING KEYS AND WRENCHES. Make it a habit to check that keys and adjusting wrenches are removed from the tool or machine work surface before plugging it in.

12. STAY ALERT. Watch what you are doing, use common sense. Do not operate any tool when you are

tired.

13. CHECK DAMAGED PARTS. Before using any tool, any part that appears damaged should be

carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment and binding of moving parts; any broken parts or mounting fixtures; and any

other condition that may affect proper operation. Any part that is damaged should be properly

repaired or replaced by a qualified technician. Do not use the tool if any switch does not turn on and

off properly.

14. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for use with this

tool. Approved accessories are available from Harbor Freight Tools.

15. DO NOT OPERATE TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS. Read

warning labels on prescriptions to determine if your judgment or reflexes are impaired while taking

drugs. If there is any doubt, do not operate the tool.

16. MAKE SURE ALL EQUIPMENT IS RATED TO THE APPROPRIATE CAPACITY. Do not attempt any operations or hook up any equipment that would not meet the rated capacities of this tool.

Page 3 SKU # 38898

Page 4

Compressor

Oil Dipstick

Oil Reservoir

Oil Drain Plug

Air Tank

Power Cord

Handle

ON / OFF Power Switch

Pressure Gauge

Air Flow Valve

Pressure Release Valve

Tank Drain Valve

Foot

ELECTRICAL SET UP

Your compressor has a grounded, three-prong plug. If using an extension cord, it must be a

three-prong type. You must connect to a three-prong receptacles only. The third prong is for grounding;

do not remove or disable the third prong, as this will create an unsafe condition.

Common household current is 110-120 Volts. As long as your compressor is rated from 110120 Volts, there will be no complications in using power from a household receptacle. Never try to plug

a tool designed for 110-120 Volts into a 220-240 Volt receptacle. 220V plugs and outlets are shaped

differently to prevent this.

Only use rounded jacket extension cords, preferably listed by Underwriter’s Laboratories (UL).

Make sure the cord is rated for outdoor use, even if your application is indoors. Outdoor use

cords have the letters “WA” on the cord jacket.

The extension cord must have a minimum wire size depending on the amperage of the tool and

the length of the extension cord. The size is signified by its AWG (American Wire Gauge) rating; the

smaller the gauge, the greater the cable’s capacity.

Note: When using extension cords - To avoid circuit breaker and voltage

drop problems when using extension cords, we recommend using only

12 gauge x 50 foot extension cords (Item #41444 or #45287), available from

Harbor Freight Tools).

Page 4 SKU # 38898 Rev 01/02

Page 5

SET UP & OPERATION

Your compressor is fully assembled when you receive it. Before using it, perform the following set up

operations.

Before using your compressor for the first time,

check to be sure the oil reservoir is filled.

Note: Optimal oil tank capacity is 7.8 ounces.

1. Unscrew the threaded Oil Dipstick to re-

move it from the oil reservoir.

2. Look at the oil level on the dip stick. The

proper oil level is shown on the illustration

to the right.

3. If the oil level is low, add standard, non-

detergent 30-weight non detergent compres-

sor oil, (use lighter weight oil for cold

weather operation). Add a little at a time,

and check the level before each addition.

Do not overfill. If overfilled, you can re-

move the drain plug to allow oil to drain

out.

4. When the oil level is correct, replace the

dipstick.

Next, connect your air hoses, filter and regulator to the compressor, as illustrated in Figure 2

below.

Oil

Dipstick

Proper

Oil Level

Figure 1. Checking the Oil Level

Use Pipe Thread Seal tape on all

Warning: Fill with compressor oil before using;

NOTE:

threaded connections.

running with NO or LOW OIL voids warranty.

Warning: Do not remove

factory sealed Air Flow Valve

(#9A); removal of valve voids

warranty.

Figure 2 — Connecting the Air Compressor

1. The provided air outlet is 1/4” NPT. Connect the high pressure air hose to the air outlet.

Note: For easy connection or removal, a quick coupler (included) should be installed on the

end of the outlet (a female and a male coupler are also included to use with the quick coupler).

2. For best service, you should incorporate an oiler, a regulator, and a filter in line; as shown in the

above diagram.

3. Hoses, Couplings, Fittings, Oilers, Regulators, and Filters are all available from Harbor Freight

Tools.

Page 5 SKU # 38898 Rev 02/01 REV 03/04 REV 05/05

Page 6

OPERATION

1. Before each use, perform the following checks:

Check to be sure the drain valve at the bottom of

the tank is closed. Check to be sure the oil level

Note: Always use a 120V electrical source

(±10% maximum variation).

is between the marks on the dip stick. Be sure

the safety pressure release valve has not been

Pressure Gauge

Pressure Release Valve

damaged, and is functional.

2. Turn the Air Flow Valve to the OFF position. In

ON / OFF Switch

Air Flow Valve

the OFF position, the red handle is across (per-

pendicular to) the line of the air hose fitting.

In the ON position, the red handle is parallel with

the line of the air hose fitting.

3. Turn ON the compressor, by pulling the Red ON/

OFF Switch up. Turn OFF the compressor by

pushing the ON /OFF switch down.

4. Allow the compressor to build up at least 80 PSI

as indicated on the pressure gauge.

Fig. 3. Controls

5. While the compressor is building up pressure,

attach the hoses, fittings, and air tools you will use.

6. When the pressure has reached 80 PSI; open the air flow valve to allow the hoses and tools to

become pressurized. Check for any significant air leaks, and check the operation of your tool.

7. As long as the power switch is pulled ON, the operation of the compressor is automatic, con-

trolled by an internal pressure switch. The compressor will turn on automatically when the

pressure drops to 80 PSI, and will turn off when the pressure reaches 115 PSI. Warning: This

pressure switch is adjustable but changes to the pressure levels are not recommended;

any change to the automatic ON/OFF pressure levels will cause additional stress on the

motor which may result in shortened motor life.

NOTE: If it is necessary to quickly depressurize the air compressor,

First: Turn it off by pushing the ON / OFF switch down.

Then: Pull out on the ring on the pressure release valve to quickly release stored pressure.

Note: Compressor has a Thermal Overload Switch (#41). If Compressor shuts down from overheating or related problems, turn Compressor OFF and allow it to cool down for 10 minutes. Once

cooled, push in Thermal Overload Switch and restart Compressor.

WARNING

1. To reduce the risk of fire or explosion, never spray flammable liquids in a confined area. Al-

ways operate the compressor in a well ventilated area. Do not smoke while spraying. Do not

spray where sparks or flame are present. Keep the compressor as far away from the spray area

as possible.

2. Never directly inhale the compressed air produced by the compressor. It is not suitable for

breathing purposes.

3. Never weld on the tank of this compressor. Welding of the tank could affect tank strength and

result in an extremely hazardous condition.

4. To avoid the potential for electric shock, never use this compressor outdoors when it is raining,

and never use the compressor on a wet surface.

5. Never point any nozzle or sprayer towards a person or animal.

6. Never work on or make adjustments to the tank when the tank is under pressure.

7. Never service or make adjustments to this product without first unplugging the electrical cord.

8. Never place flammable objects near the compressor. Never spray water or flammable liquids

toward or near the compressor.

9. Always push the ON/OFF switch down into the OFF position when the unit is not in use.

10. Do not transport the pancake compressor when the tank is under pressure.

11. Only operate in a well-ventilated area which has proper air circulation.

Page 6 SKU # 38898

Rev 03/00, REV 10/01, REV 11/04

Page 7

Compressor Assembly

Part # Description

1 Screw

2 Screw

3 Washer

4 Washer

5 Air Filter

6 Cylinder Case

7 Gasket, Crankshaft Cover

8 Valve Seat

9 Gasket, Valve Seat

10 Valve Plate

11 Valve Seat

12 Gasket, Valve Seat

13 Cylinder

14 Cylinder Gasket

15 Compression Ring

16 Scraping Oil Ring

17 Piston

18 Piston Pin

19 Crankshaft Retainer

20 Oil Stick

21 Screw

Part# Description

22 Connecting Rod

23 Crankshaft

24 Gasket, Front Cover

25 Front Cover

26 Washer

27 Washer

28 Bolt

29 Screw

30 Crankshaft Case

31 Nut

32 Seal Washer

33 Bearing

34 Electric Capacitor

35 Bolt

36 Screw

37 Motor

38 Washer

39 Radiating Fan Wheel

40 Radiating Cover

41 Thermal Switch

MAINTENANCE

1.

Check the oil before each use to be sure the level of oil is correct (see illustration on page 5). If

the oil level is too low, add oil. If it is too high, drain some oil out by removing the drain plug.

2. Drain and replace the oil once per year. Replace more often if the compressor is used heavily or

the oil appears dirty.

3. Check the air filter every six months, or more often if compressor is used in a dirty or dusty

environment. Replacement air filters are available from Harbor Freight Tools.

4. Drain the air tank after each use, by turning the drain petcock clockwise to open it. Turn the

petcock counterclockwise to close it. It is a good practice to leave the drain plug open between

uses to ensure that the tank remains dry.

5. Never use flammable liquids or solvents to clean the compressor. For cleaning, unplug the unit,

and clean with a mild detergent and water. Be careful not to introduce water into any electrical

components.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY: NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT: IN FACT THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS

TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 7 SKU # 38898 Rev 03/00 REV 11/01 REV 03/04

Page 8

PARTS DIAGRAM

NOTE: Part # 7,8,9,10,11,12 are only available as a kit ( Rebuild Kit SKU 27349 )

Page 8 SKU # 38898 Rev 03/00 REV 11/01 REV 03/04 REV 11/05

Page 9

4A

PARTS DIAGRAM (CONTINUED)

9A

10A

11A

5A

6A

Parts List A

4A Bolt

5A Hose

6A Rubber Foot

9A Air Flow Valve

10A Pressure-release Valve

11A Pressure Gauge

12A No-return Valve

12A

13A

14A

13A Tank

14A Tank Drain Valve

Page 9 SKU # 38898 Rev 03/04 REV 11/05

Loading...

Loading...