Page 1

Instruction Manual

LP2000-11

Precision Bench

Turbidity Meter

with PC Communication

www.hannainst.com

Page 2

Dear Customer,

Thank you for choosing a Hanna Product. Please read this instruction

manual carefully before using the instrument. It will provide you with

the necessary information for the correct use of the instrument, as well

as a precise idea of its versatility.

If you need additional technical information, do not hesitate to e-mail

us at tech@hannainst.com.

These instruments are in compliance with the directives.

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it to make

sure that no damage has occurred during shipping. If there is any

damage, notify your Dealer.

LP2000-11 is supplied with:

• Glass cuvet with cap

• AMCO-EPA-1 turbidity calibration solutions (HI 93703-0 @0 FTU

and HI 93703-10 @10 FTU), 30 mL each

• 12 Vdc power adapter and instruction manual

Note: Save all packing material until you are sure that the instrument

functions correctly. Any defective item must be returned in its

original packaging with the supplied accessories.

TABLE OF CONTENTS

Preliminary Examination ............................................................. 3

General Description ..................................................................... 3

Principle of Operation ................................................................. 4

Specifications.............................................................................. 5

Functional Description ................................................................. 6

Operational Guide ...................................................................... 7

Power Connection ........................................................ 7

Measurement Procedure ...................................................... 7

Storing samples in memory ................................................ 10

Clearing Logged Data........................................................ 10

Viewing Logged Data ........................................................ 11

Date and Time setup ......................................................... 11

Error Codes ....................................................................... 12

Ensure Accurate Measurements ........................................... 13

Sources of Interference ....................................................... 14

Calibration............................................................................... 14

Calibration Procedure ........................................................ 14

Viewing Calibration Date ................................................... 16

Ensure Accurate Calibration ................................................ 17

Standard Suspension ........................................................ 17

RS 232 Connection ................................................................... 18

Accessories ................................................................................ 18

Warranty................................................................................. 19

GENERAL DESCRIPTION

LP2000-11 turbidity meter is a bench top, microprocessor-based instrument

used to determine the turbidity of water and wastewater. The meter covers

a 0-1000 FTU range in two scales: 0.00 to 50.00 FTU and 50 to 1000

FTU. The autoranging feature sets the appropriate range for the

measurement.

The serial interface is supported connecting any available serial port on

your PC and a 5-pin socket on the meter.

Note: LP2000-11 has been designed according to the ISO 7027

International Standard, consequently the turbidity

measurement units are expressed in FTU (Formazine Turbidity

Unit). FTU is identical to the other internationally recognized

unit NTU (Nephelometric Turbidity Unit).

LP2000-11 is housed in a rugged and lightweight case, with an

easy-to-read LCD.

The meter is simply to use. All operations can be carried out with only

five keys and troubleshooting functions can be performed with

displayed error code guides. A positive-locking system guarantees that

the cuvet is firmly placed in the cell. The keypad is water-resistant

and can be wiped with a moist cloth for quick cleanups.

Two or three points calibration (0, 10, 500 FTU*) can be easily

performed using available standards.

* 1 FTU = 1 NTU

32

Page 3

CUVET

LIGHT

D

In addition, LP2000-11 automatically stores the last calibration

date, that may be retrieved by a single key touch.

10 FTU* was chosen as the standard calibration point because its

value best fits the water turbidity measurements in a wide range of

applications, from drinking water to wastewater treatment.

Hanna uses the primary standard AMCO-AEPA-1 to avoid all formazinerelated problems. In fact formazine is a toxic, unstable substance, which

requires particular care. Its standards have to be prepared only a few

minutes before performing the calibration, and cannot be reused because

of their short life.

Hanna standards are extremely stable, can be reused, and last up to six

months, if free from contaminations.

LP2000-11 can be used with both standards.

As noted above, FTU is equal to the NTU. However, other known

measurements include: Jackson Turbidity Unit or JTU (based on the

old method of Jackson's candle), and Silica Unit in mg/L of SiO2.

See the conversion table below for these units:

JTU FTU/NTU SiO2 (mg/L)

JTU 1 19 2.5

FTU /NTU 0.053 1 0.13

SiO2 (mg / L) 0.4 7.5 1

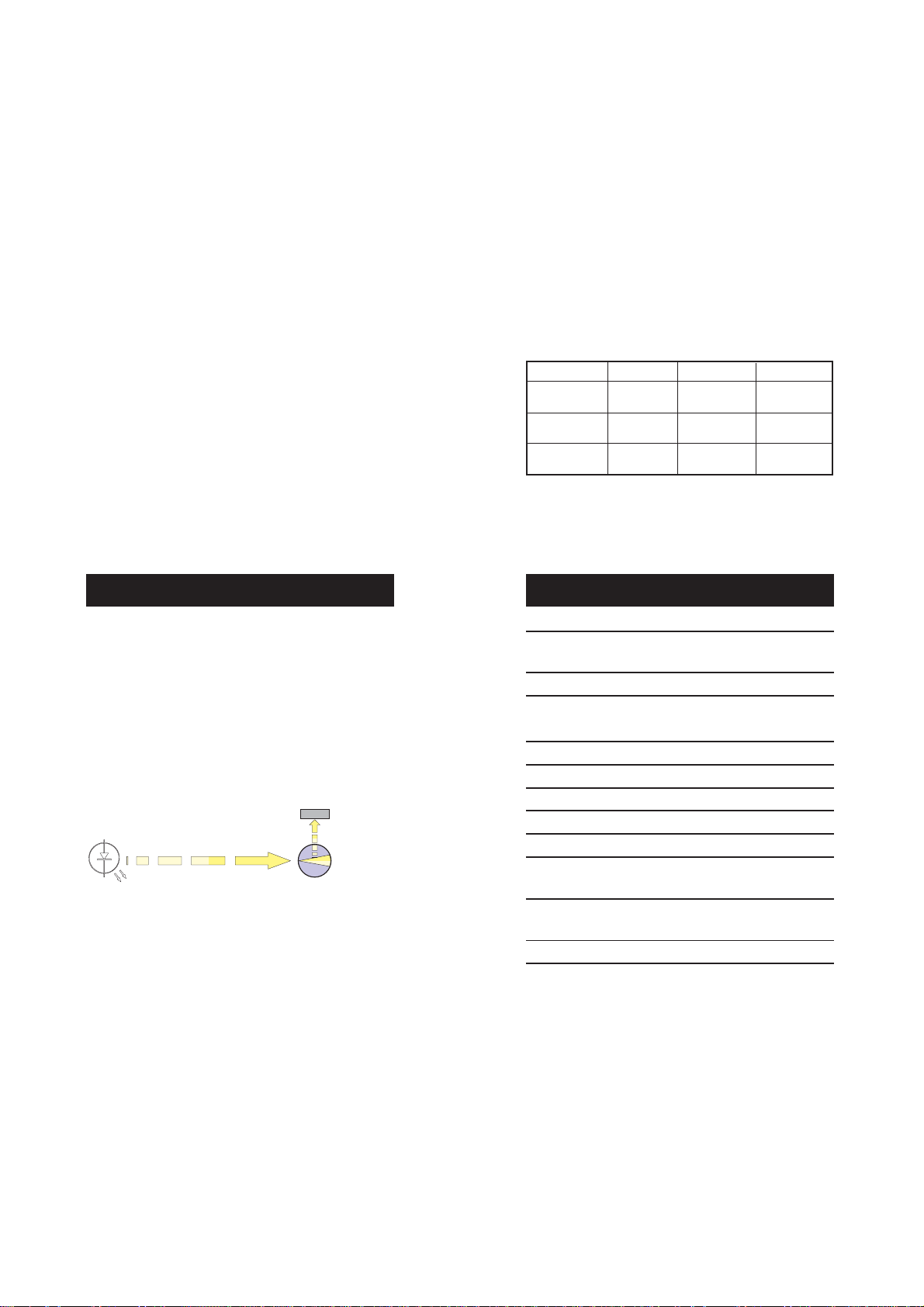

PRINCIPLE OF OPERATION

LP2000-11 has been designed to perform measurements according

to the ISO 7027 International Standards.

The instrument works by passing a beam of infrared light through a

vial containing the sample to be measured.

The light source is a High Emission Infrared LED with a wavelength

peaking at 890 nm, which reduces interferences caused by colored

samples to a minimum.

DETECTOR

IR LED

EMITTED LIGHT (890 nm)

A sensor, positioned at 90° with respect to the direction of light,

detects the amount of light scattered by the undissolved particles

present in the sample. The microprocessor converts such readings into

FTU values.

90° SCATTERE

LIGHT

SPECIFICATIONS

Range 0.00 to 50.00 FTU*

50 to 1000 FTU*

Resolution 0.01 / 1 FTU*

Accuracy (@ 20°C/68°F) ±0.5 FTU*

±5% of reading (whichever greater)

Calibration 3 points (0, 10 and 500 FTU*)

Light Source High-emission infrared LED

Light Source Life Life of the instrument

Light Detector Silicon photocell

Power Supply 12 Vdc power adapter (included)

Environment 0 to 50°C (32 to 122°F);

RH max 95% non-condensing

Dimensions 230 x 170 x 70 mm

(9.1 x 6.7 x 2.7")

Weight 600 g (1.3 lb.)

* 1 FTU = 1 NTU* 1 FTU = 1 NTU

54

Page 4

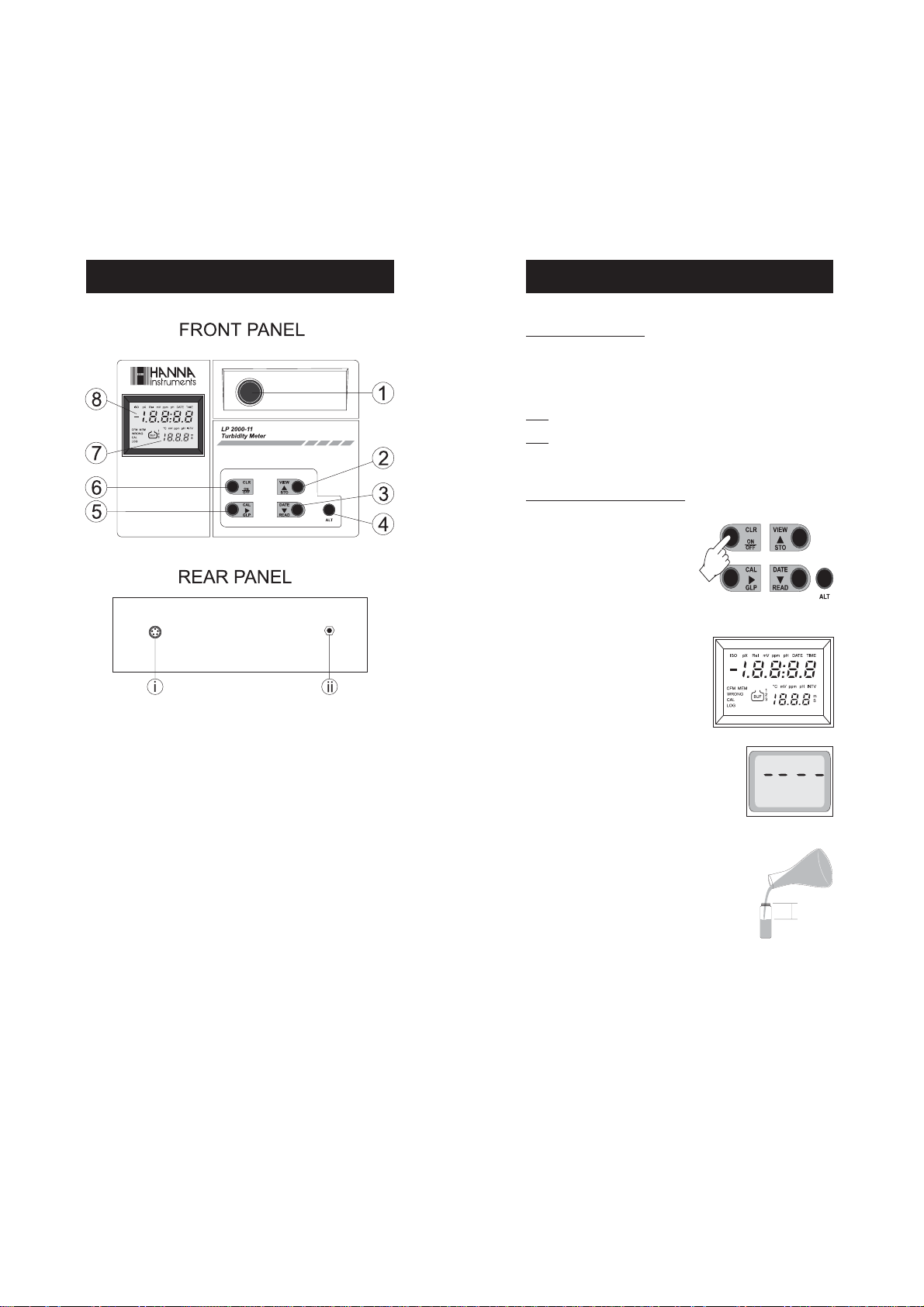

FUNCTIONAL DESCRIPTION

OPERATIONAL GUIDE

POWER CONNECTION

Plug the supplied 12 Vdc adapter into the proper instrument socket

and to the mains.

Note: Insure the main line is fuse protected.

Note: Always turn the meter off before unplugging it to ensure no

data is lost.

MEASUREMENT PROCEDURE

• Turn the meter on by pressing

the ON/OFF key.

• The meter will carry out a self-test

by displaying a full set of figures.

1. Measurement cell

2. STO/VIW key, to store sample after reading and view log memory

3. READ/DATE key, to perform measurements and display (toggle)

current date/time

4. ALT key, to activate the ALT functions (orange keys)

5. GLP/CAL key, to display (toggle) last calibration date/time and

enter the calibration mode

6. ON/OFF/CLR key to switch the meter ON and OFF, and clear log

memory

7. Secondary LCD (displays the year when date is on the primary level,

the sample index when storing a value or viewing the log memory)

8. Primary LCD (Liquid Crystal Display)

i. 5-pin RS232 connector

ii. Power supply socket

• When the LCD displays “- - --” the

meter is ready to take measurements.

• Fill a clean cuvet up to 0.5 cm

(one quarter inch) from its rim

with the thoroughly agitated

sample.

1/4“

0.5 cm

• Allow sufficient time for bubbles to escape before securing the cap.

Note: Do not overtighten the cap.

76

Page 5

Note: Wipe the cuvet thoroughly with

HI93703-70 or a lint-free tissue before

inserting it into the measurement cell.

The cuvet must be completely free of

fingerprints and other oil or dirt, particularly in the area where the light goes

through (approx. the bottom 2 cm/1").

• Place the cuvet into the cell and

check that the notch on the cap is

positioned securely into the groove.

• The mark on the cuvet cap should point

towards the keyboard.

• Even though LP2000-11 covers a wide turbidity range, highly

accurate readings exceeding 40 FTU* require dilution as recommended by the Standard Methods.

Use the formula below to calculate the amount of HI 93703-0 or

turbidity-free water needed for accurate dilution.

The total volume = 100 mL.

Vos = 3000 / T

where:

Vos = volume of original sample (mL) to be added to HI 93703-0

to obtain the total diluted volume of 100 mL.

T = LP2000-11 reading (exceeding 40 FTU)

E.g.: LP2000-11 reading = 200 FTU*

3000 / 200 = 15 mL (Vos)

15 mL (Vos)+85 mL (HI 93703-0) = 100 mL

At this point, take a sample of this diluted solution and measure its

turbidity.

The correct turbidity value of the original sample is derived by:

Ta= Tn x 100 mL / Vos

where:

Ta = actual turbidity value of the original sample

Tn = LP2000-11 reading of the diluted solution

E.g. If Tn = 27

Ta = 27 x 100 mL / 15 mL = 180 FTU*

• Press the READ key and the LCD will

display a blinking “SIP” (Sampling in Process). The turbidity

value will appear after approximately 20 seconds.

Note: Any sample above 1000 FTU* will show out of range by blinking

“1000”.

* 1 FTU = 1 NTU

98

Page 6

STORING SAMPLES IN MEMORY

VIEWING LOGGED DATA

• After taking a reading, press the STO

button. The last sample read will be

stored in memory and the display will

also show on the bottom right hand

corner the reference number of the

stored sample.

Note: When the maximum number of

samples has been reached (500), the

display will show "FULL". This is a warning that you will be overwriting the oldest

sample recorded. To store the current

sample, press the STO button again and

this will overwrite the oldest sample in the

memory. All samples are shifted and

sample number one is always the oldest

sample.

CLEARING LOGGED DATA

• Press the ALT & CLR buttons. The display will show

"CLR" for confirmation.

Press ALT & CLR again to

clear memory or any other

key to abort the operation.

• Press the ALT & VIEW buttons. The last stored sample

will be displayed.

• Press the right arrow to

scroll between turbidity

value, date and time

sample was taken.

• Press the UP/DOWN arrows

to scroll between samples

taken.

• Press ALT & VIEW buttons again to exit this mode.

DATE AND TIME SETUP

VIEWING:

• Press ALT & DATE to toggle

between date and time.

SETTING:

• Press and hold ALT & DATE for

3-4 seconds.

ALL SAMPLES PREVIOUSLY STORED WILL BE ERASED FROM

MEMORY!

• Press UP/DOWN arrows to correct and set the year.

1110

Page 7

• Press right arrow to scroll to month and day, use UP/DOWN to set.

• Press right arrow again to scroll to time, use UP/DOWN to set.

• Internal Bus error*

err5

• Press right arrow again to save and exit date and time setup.

Note: Press ALT & DATE to leave this mode without saving.

ERROR CODES

Every time the meter is switched on, the Real Time Clock and EEPROM are

tested, and if an error is found the corresponding error code will be

displayed. The list of error codes is as follows:

• NO cover error (check cuvet position)

• Calibration error

(check calibration standard value)

cap

err1

err2

• RTC (Real Time Clock) error *

• EEPROM error*

err3

• Low LED Voltage*

* Contact the nearest HANNA Customer Service Center.

ENSURE ACCURATE MEASUREMENTS

• Each time the cuvet is used, tighten the cap to the same degree.

• Discard the sample immediately after reading to prevent permanent clouding of the glass.

• All glassware used to contain the standards and the samples

should be kept clean, washed with HI93703-50 cleaning solution

and rinsed with HI93703-0 or turbidity-free water.

• Samples should be collected in clean glass or plastic bottles with

appropriate stoppers. Analysis should be performed shortly after.

If the sample requires storage, it should be kept in a cool dark

place. Stored samples should be restored to room temperature

prior to the analysis. Samples may not be stored for longer than

24 hours.

• To obtain a representative sample, gently and thoroughly, stir

the solution. To prevent air bubbles from forming do not shake or

let the solution settle prior to sampling.

• It is recommended to calibrate the meter by using the supplied

HI93703-10 (10 FTU* standard), at least monthly or more

frequently for greater accuracy.

• Before inserting cuvets into the instrument, wipe them with

HI 93703-70 or a soft, lint-free tissue. Handle vials so that no

fingerprints are left on the areas where light passes through

(approx. the bottom 2cm / 3/4”).

• Serial communication error*

err4

If you experience any problems in taking measurements, please

contact your dealer or the nearest Hanna Customer Service Center.

1312

Page 8

SOURCES OF INTERFERENCE

• The presence of floating debris and coarse sediments which may

settle out rapidly will give false readings.

• The infrared light source of LP2000-11 turbidity meter complies

with the ISO 7027 International Standard and can effectively

minimize errors due to colored dissolved substances. This effect,

called “True Color”, is a common interference for most commercially

available instruments operating in the range of visible light.

• Air bubbles and the effect of vibrations that disturb the surface of

the sample may produce false results and should be avoided.

• Dirty, scratched, or etched glassware could also affect readings.

• Place the 0.00 FTU standard in the cuvet

holder.

• Press CAL; SIP and CL will start blinking.

CALIBRATION

To check the date of last calibration, simply press the GLP key. Press again

to toggle between date and time.

To make sure that the meter is calibrated, take a measurement of a

standard solution.

The instrument can be calibrated at two or three points and a monthly

calibration is recommended.

CALIBRATION PROCEDURE

• Turn the meter on and wait for the display

to show "----".

• Press the ALT & CAL buttons. The "CAL" message will blink on the display

for 3 seconds. The meter then enters the calibration mode, displaying

"0.00" and prompting the user to insert the 0.00 FTU standard.

• If “ERR1” appears on the LCD, please check

the standard solution.

• After approximately 30 seconds the meter

will display “10.00”, prompting the user

to place the 10.00 FTU standard solution

in the cuvet holder.

• Place the 10.00 FTU standard in the

holder and press CAL. SIP and CL will start

blinking.

• After approximately 30 seconds the meter

will display 500, asking the user to place

the 500 FTU standard solution in the cuvet

holder.

Note: At this point the user can save the two-point calibration setup

and leave the calibration mode by pressing ALT & CAL buttons.

err1

1514

Page 9

To perform a three point calibration, place the

500 FTU standard solution in the cuvet

holder.

• Press CAL; SIP and CL will start blinking.

• After approximately 30 seconds the LCD will

display "----".

Now the instrument is calibrated and ready

for use.

Note: If "ERR1" is displayed, the calibration data is maintained.

ENSURE ACCURATE CALIBRATION

The procedure below should be carefully followed during testing and

calibration:

• All glassware that comes into contact with standards should be kept

clean. Wash it with HI93703-50 cleaning solution and rinse it with

HI93703-0 or turbidity free water.

• Rinse the cuvet twice with 5 ml of the liquid to be tested. This procedure

removes the effect of any previous liquid and any dust or objects that

may be inside. Gently pour the liquid down the side of the vial to reduce

air bubbles (no mixing is required when HI93703-0 and HI93703-

10 AMCO-AEPA-1 standards are used).

• Before inserting the cuvet into the instrument, wipe it with HI 9370370 or a soft, lint-free tissue. Handle vials so that no fingerprints can

get on the areas where light passes (approx. bottom 2 cm/1") .

STANDARD SUSPENSION

VIEWING CALIBRATION DATE

To display the last calibration time and date, press the GLP button. If

display shows "FS", the instrument has factory calibration settings loaded

and no date will be displayed.

VIEWING FIRMWARE VERSION

To display the firmware version, turn the meter on, then press and hold

the ON/OFF key for approximately 10 seconds.

Presently, there are only two recognized primary standards: AMCO-AEPA1 and formazine.

Hanna supplies LP2000-11 with the AMCO-AEPA-1 which has a much

longer shelf life at all concentrations (approx. six months, if free from

contamination). In addition, no special handling or disposal is required

and a much higher stability of suspended particles has been observed.

On the other hand, formazine is a toxic substance, generated by a

carcinogen, with poor stability (particles flocculate and settle quickly). Low

concentrations change value within a few days or hours after dilution.

The consistency of LP2000-11 readings by using both standards has been

separately established by Advanced Polymer Systems and Hanna

Instruments.

Additional documentation about the formazine standard and more

complex calibration procedures is available upon request.

1716

Page 10

RS232 CONNECTION

WARRANTY

To communicate with the instrument through the HI92000 software,

simply use HI920011 (optional) cable to connect the 9-pin serial port of

an IBM compatible computer and the 5 pin connector of the meter.

A connected meter will fully maintain its functionality, being able to perform

data transfer while the meter is operating.

Note: RS232 communication is not allowed while calibrating the meter.

ACCESSORIES

HI 710005 12 Vdc / 115 Vac power adapter, US plug

HI 710006 12 Vdc / 230 Vac power adapter, European plug

HI 731318 Tissue for wiping the cuvets (4 pcs)

HI 731321 Glass cuvet (4 pcs)

HI 93703-0 0 FTU* AMCO-AEPA-1 calibration solution

(30 mL)

HI 93703-05 500 FTU* AMCO-AEPA-1 calibration solution

(30 mL)

HI 93703-10 10 FTU* AMCO-AEPA-1 calibration solution

(30 mL)

HI 93703-50 Cuvet cleaning solution (230 mL)

HI 92000 Windows® compatible software

HI 920011 PC connection serial cable (5 to 9-pin)

All Hanna Instruments meters are warranted for two years

against defects in workmanship and materials when used for their

intended purpose and maintained according to instructions. This

warranty is limited to repair or replacement free of charge.

Damage due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact the dealer from whom you purchased

the instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair

is not covered by the warranty, you will be notified of the charges

incurred. If the instrument is to be returned to Hanna Instruments,

first obtain a Returned Goods Authorization number from the Customer Service department and then send it with shipping costs

prepaid. When shipping any instrument, make sure it is properly

packaged for complete protection.

Hanna Instruments reserves the right to modify the design, construction and appearance of its products without advance notice.

* 1 FTU = 1 NTU

Recommendations for Users

Before using this product, make sure that it is entirely suitable for the environment

in which it is used.

Operation of this instrument in residential area could cause unacceptable

interferences to radio and TV equipments, requiring the operator to take all necessary

steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the

instrument's EMC performance.

To avoid electrical shock, do not use this instrument when voltages at the

measurement surface exceed 24VAC or 60VDC.

To avoid damages or burns, do not perform any measurement in microwave ovens.

1918

Page 11

SALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and complete list of Sales and

Technical offices, please see www.hannainst.com

20

MANLP2000-11 11/05

Loading...

Loading...