Page 1

Instruction Manual

HI 96822

Seawater Refractometer

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna product. This manual will provide you with the necessary

information for the correct use of this instrument. Please read it carefully before using the meter. If

you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com.

This instrument is in compliance with

directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ............................................................................................. 2

GENERAL DESCRIPTION .....................................................................................................3

SPECIFICATIONS .................................................................................................................. 3

PRINCIPLE OF OPERATION ................................................................................................4

FUNCTIONAL DESCRIPTION................................................................................................ 5

DISPLAY ELEMENTS............................................................................................................ 6

MEASUREMENT GUIDELINES .............................................................................................. 6

CALIBRATION PROCEDURE ................................................................................................ 7

MEASUREMENT PROCEDURE ............................................................................................. 8

TO CHANGE MEASUREMENT UNIT .....................................................................................9

TO CHANGE TEMPERATURE UNIT...................................................................................... 9

MAKING A STANDARD SOLUTION...................................................................................... 9

BATTERY REPLACEMENT .................................................................................................10

WARRANTY ........................................................................................................................ 10

ERROR MESSAGES ............................................................................................................11

PRELIMINARY EXAMINATION

Remove the instrument from the packing materials and examine carefully to ensure no

damage has occurred during shipping. If any damage has occurred, notify your Dealer

or closest Hanna Customer Service Center.

Each instrument is supplied with:

• 9 V battery

• Instruction manual

Note:Save all packing material until you are sure that the instrument functions

correctly. A defective instrument must be returned in its original packing.

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent of the

copyright owner, Hanna Instruments Inc., Woonsocket, Rhode Island, 02895, USA.

2

Page 3

GENERAL DESCRIPTION

The HI 96822 Digital Refractometer is a rugged portable, water resistant device that utilizes the

measurement of refractive index to determine the salinity of natural and artificial seawater, ocean

water or brackish intermediates.

The HI 96822 device benefits from Hanna’s years of experience as a manufacturer of analytical

instruments. The digital refractometer eliminates the uncertainty associated with mechanical refractometers and is easily potable for ship, shore or home use.

The HI 96822 refractometer is an optical device that is simple and quick to use. After a simple user

calibration with distilled or deionized water, a seawater sample is in introduced to the sample well.

Within seconds, the refractive index and temperature are measured and converted into one of 3

popular measurement units; Practical Salinity Units (PSU), Salinity in parts per thousand (PPT), or

Specific Gravity (S.G. (20/20)). All conversion algorithms are based upon respected scientific

publications using the physical properties of seawater (not sodium chloride). The temperature (in °C

or °F) is also displayed on the large dual level display along with helpful message codes.

Key features include:

• IP65 waterproof protection

• Automatic Temperature Compensation (ATC)

• Battery operation with Low Power indicator (BEPS)

• Automatically turns off after 3 minutes of non-use

SPECIFICATIONS

USPTPP)02/02(.G.S)F°(C°

:egnaR 05ot0051ot0411.1ot000.1)F°671ot23(C°08ot0

:noituloseR 11 100.0)F°1.0(C°1.0

:ycaruccA 2

±2±200.0±)F°5.0±(C°3.0±

Temperature Compensation: Automatic between 0 and 40 °C (32 - 104 °F)

Measurement Time: Approximately 1.5 seconds

Minimum Sample Volume: 100 μL (cover prism totally)

Light Source: Yellow LED

Sample Cell: Stainless Steel ring and flint glass prism

Case Material: ABS

Enclosure Rating: IP 65

Battery Type / Life: 1 X 9V / 5000 readings

Auto-Off: After 3 minutes of non-use

Dimensions: 19.2(W) x 10.2(D) x 6.7(H) cm

Mass: 420 g

3

Page 4

PRINCIPLE OF OPERATION

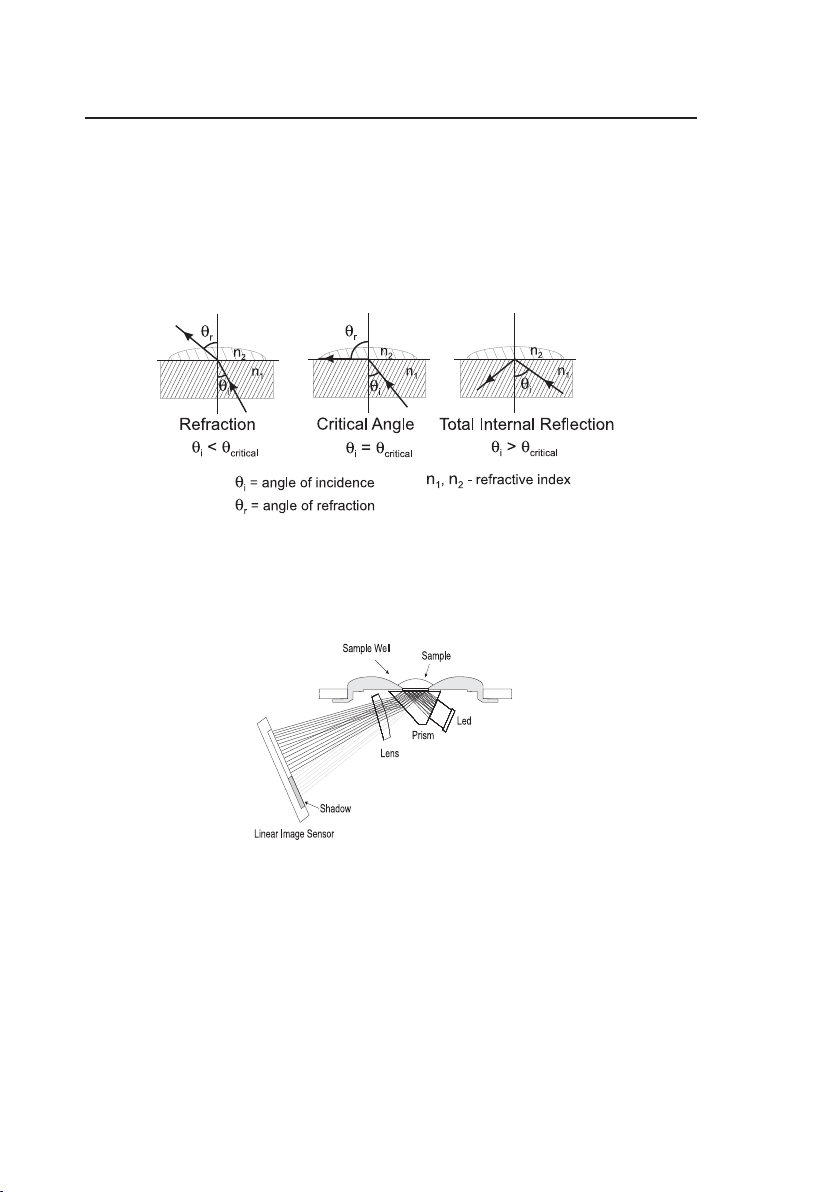

Salinity determinations are made by measuring the refractive index of seawater. Refractive Index is

an optical characteristic of a substance and the number of dissolved particles in it. Refractive Index

is defined as the ratio of the speed of light in empty space to the speed of light in the substance. A

result of this property is that light will “bend”, or change direction, when it travels through a

substance of different refractive index. This is called refraction.

When passing from a material with a higher to lower refractive index, there is a critical angle at

which an incoming beam of light can no longer refract, but will instead be reflected off the interface.

The critical angle can be used to easily calculate the refractive index according to the equation:

sin (θ

) = n2 / n

critical

1

Where n2 is the refractive index of the lower-density medium; n1 is the refractive index of the

higher-density medium.

In the HI 96822 refractometer, light from an LED passes through a prism in contact with the sample.

An image sensor determines the critical angle at which the light is no longer refracted through the

sample.

Specialized algorithms then apply temperature compensation to the measurement and convert the

refractive index to: PSU, PPT or S.G. (20/20).

PSU is defined as a definitive salinity-conductivity ratio relationship. It is based upon the work of

the UNESCO, ICES, SCOR and IAPSO. This information is published in The Joint Panal of Oceanographic

Tables and Standards. PPT (10-3) is an older used salinity scale where salinity is defined by “the

salt content is the weight of the inorganic salts contained in 1 kg of seawater if all bromide and

iodide are replaced by an equivalent amount of oxides” (Knudsen, 1901).

4

Page 5

Specific Gravity (20/20) is based upon the published relationship between density at 20 °C and the

mass of the dissolved salts in the seawater sample (CRC Handbook of Chemistry and Physics, 87

Edition).

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

TOP VIEW

1. Liquid Crystal Display (LCD)

2. READ Key (User Measurement)

3. ZERO Key (User Calibration)

4. RANGE Key (User Measurement Unit)

5. ON/OFF

6. Stainless Steel Sample Well and Prism

7. Secondary Display

8. Primary Display

th

BOTTOM

9. Battery Cover

10.Battery Compartment

5

Page 6

DISPLAY ELEMENTSDISPLAY ELEMENTS

DISPLAY ELEMENTS

DISPLAY ELEMENTSDISPLAY ELEMENTS

1. Battery (blinks when low battery condition detected)

2. Measurement in Progress Tag

3. SETUP: Factory Calibration Tag

4. CAL: Calibration Tag

5. Automatic Temperature Compensation

(blinks when temperature exceeds 0-40°C / 32-104°F range)

6 Primary Display (displays measurement and error messages)

7. Temperature Units

8. Secondary Display (displays temperature measurements; when blinking,

temperature has exceeded operation range: 0-80°C / 32-176°F)

9. Range indicator

MEASUREMENT GUIDELINESMEASUREMENT GUIDELINES

MEASUREMENT GUIDELINES

MEASUREMENT GUIDELINESMEASUREMENT GUIDELINES

• Handle instrument carefully. Do not drop.

• Do not immerse instrument under water.

• Do not spray water to any part of instrument except the “sample well” located over the prism.

• The instrument is intended to measure seawater solutions. Do not expose instrument or prism

to solvents that will damage it. This includes most organic solvents and extremely hot or cold

solutions.

• Particulate matter in a sample may scratch the prism. Absorb sample on soft tissue and rinse

sample well with deionized or distilled water between samples.

• Use plastic pipettes to transfer all solutions. Do not use metallic tools such as needles, spoons

or tweezers as these will scratch the prism.

• Cover sample well with hand if measuring in direct sun.

6

Page 7

CALIBRATION PROCEDURECALIBRATION PROCEDURE

CALIBRATION PROCEDURE

CALIBRATION PROCEDURECALIBRATION PROCEDURE

Calibration should be performed daily, before measurements are made, when the battery has

been replaced, between a long series of measurements, or if environmental changes have

occured since the last calibration.

1. Press the ON/OFF key, then release. Two instrument test screens will be displayed briefly;

all LCD segments followed by the percentage of remaining battery life. It will briefly display

an indication of the measurement units set. When the LCD displays dashes, the instrument is

ready.

2. Using a plastic pipette, fill the sample well with distilled or deionized water. Make sure the

prism is completely covered.

Note: If the ZERO sample is subject to intense light such as sunlight or another strong source,

cover the sample well with your hand or other shade during the calibration.

3. Press the ZERO key. If no error messages appear, your unit is calibrated.

(For a description of ERROR MESSAGES see page 11).

Note: The 0 screen will remain until a sample is measured or the instrument is turned off.

4. Gently absorb the ZERO water standard with a soft tissue. Use care not

to scratch the prism surface. Dry the surface completely. The instrument

is ready for sample measurement.

Note: If instrument is turned off the calibration will not be lost.

7

Page 8

MEASUREMENT PROCEDUREMEASUREMENT PROCEDURE

MEASUREMENT PROCEDURE

MEASUREMENT PROCEDUREMEASUREMENT PROCEDURE

Verify the instrument has been calibrated before taking measurements.

1. Wipe off prism surface located at the bottom of the sample well. Make sure the prism and

sample well are completely dry.

2. Using a plastic pipette, drip sample onto the prism surface. Fill the well completely.

Note: If the temperature of the sample differs significantly from the temperature of the

instrument, wait approximately 1 minute to allow thermal equilibration.

3. Press the READ key. The results are displayed in unit of interest.

Note: The last measurement value will be displayed until the next sample is measured or the

instrument is turned off. Temperature will be continuously updated.

Note: The ”ATC” tag blinks and automatic temperature compensation is disabled if the

temperature exceeds the 0-40 °C / 32-104 °F range.

4. Remove sample from the sample well by absorbing with a soft tissue.

5. Using a plastic pipette, rinse prism and sample well with distilled or deionized water. Wipe

dry. The instrument is ready for the next sample.

8

Page 9

TO CHANGE MEASUREMENT UNITTO CHANGE MEASUREMENT UNIT

TO CHANGE MEASUREMENT UNIT

TO CHANGE MEASUREMENT UNITTO CHANGE MEASUREMENT UNIT

Press the RANGE key to select measurement units. The instrument toggles between the three

measurement scales each time the key is pressed and the primary display indicates “PSU”,

“PPt” and “S.G.”. When the instrument displays the screen with 4 dashes, the instrument is

ready for measurement. A number on the display indicates the selected unit: “1” denotes PSU, “2”

denotes PPT and “3” denotes Specific Gravity.

TO CHANGE TEMPERATURE UNITTO CHANGE TEMPERATURE UNIT

TO CHANGE TEMPERATURE UNIT

TO CHANGE TEMPERATURE UNITTO CHANGE TEMPERATURE UNIT

To change the temperature measurement unit from Celsius to Fahrenheit (or vice versa), follow this

procedure.

1. Press and hold the ON/OFF key continuously for approximately 8 seconds. The LCD will

display the “all segment” screen followed by a screen with the model number on the primary

display and the version number on the secondary display. Continue pressing the ON/OFF

key.

8 seconds

2. While continuing to hold the ON/OFF key, press the ZERO key. The temperature unit will

change from °C to °F or vice versa.

°C or °F

MAKING A STANDARD SOLUTIONMAKING A STANDARD SOLUTION

MAKING A STANDARD SOLUTION

MAKING A STANDARD SOLUTIONMAKING A STANDARD SOLUTION

Sodium Chloride solutions can be used to check the accuracy of the meter. The table below lists

several Sodium Chloride solutions and there expected ppt Seawater value.

9

Page 10

To make a Standard NaCl Solution (g/100 g), follow the procedure below:

• Place container (such as a

• Tare the balance.

• To make an X NaCl solution weigh out X grams of high purity dried Sodium Chloride (CAS #:

7647-14-5: MW 58.44) directly into the container.

• Add distilled or deionized water to the container so the total weight of the solution is 100 g.

lCaN%5 00.500.5900.00184

lCaN%01 00.0100.0900.00169

glass vial or dropper bottle that has a cover) on an analytical balance.

lCaNfogretaWfogthgieWlatoTeulaVretawaeStppdetcepxE

lCaN%51 00.510

BATTERY REPLACEMENTBATTERY REPLACEMENT

BATTERY REPLACEMENT

BATTERY REPLACEMENTBATTERY REPLACEMENT

To replace the instrument’s battery, follow these steps:

• Make sure the instrument is off.

• Turn instrument upside down and remove the battery cover by turning it counterclockwise.

• Extract the battery from its location.

• Replace with a new 9V battery making sure to observe polarity.

• Insert the back battery cover and fasten it by turning clockwise to engage.

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

The HI 96822 is warranted for two years against defects in workmanship and materials when

used for its intended purpose and maintained according to the instructions.

This warranty is limited to repair or replacement free of charge.

Damage due to accident, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact your dealer. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is not covered by the warranty,

you will be notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization

Number from the Customer Service Department and then send it with shipment costs prepaid. When

shipping any instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the

date of purchase.

0.5800.001541

10

Page 11

ERROR MESSAGESERROR MESSAGES

ERROR MESSAGES

ERROR MESSAGESERROR MESSAGES

edoCrorrEDCLnoitpircseD

“rrE“

“OL“ yalp

sidyramirP

otrewopelcyC.eruliaflareneG

tcatnoc,stsisreprorrefI.tnemurtsni

.annaH

ehtnahtrewolgnidaersielpmaS

retemrofdesudradnats0

.noitarbilac

“IH“ yalpsidyramirP

“OL“ yalpsidyramirP

“LAC“ NOtnemges

“IH“ yalpsidyramirP

“LAC“ NOtnemges

“OLt“ yalpsidyramirP

“LAC“ NOtnemges

“IHt“ yalpsidyramirP

“LAC“ NOtnemges

“riA“ .derevocyltneiciffusniecafrusmsirP

“tLE“

“tLn“

gniknilbtnemgesyrettaB.gniniamersiefilyrettabfo%5<

eelpmaS

.egnartnemerusaem

sni

murtsni

4(

htiw

sserP.retawdellitsid OREZ .

sserP.retawdellitsid OREZ .

bilacgnirud)C°0(

.dnah

.annaHtcatnoC

mumixamsdeecx

orezotdesunoitulosgnorW

rodezinoiedesU.tnemurt

orezotdesunoitulosgnorW

rodezinoiedesU.tne

timilwolCTAsdeecxeerutarepmeT

.noitar

timilhgihCTAsdeecxeerutarepmeT

.noitarbilacgnirud)C°0

rofthgillanretxehcumooT

llewelpmasrevoC.tnemerusaem

.detcetedtonsithgilDEL

“ C°0.0 “ro“ C°0.08 “

“ CTA “gniknilbtn

“ PUTES “gniknilbtnemges

emges

eraseulaverutarepmeT

gniknilb

.)C°04ot0(egnar

catnoC

.tsolnoitarbilacyrotcaF

.annaHt

fotuotnemerusaemerutarepmeT

.)C°08ot0(egnargnilpmas

noitasnepmocerutarepmetedistuO

11

Page 12

Hanna Instruments Inc.

Highland Industrial Park

584 Park East Drive

Woonsocket, RI 02895 USA

Local Sales and Customer Service office

Hanna Instruments United States Inc.

Highland Industrial Park

584 Park East Drive

Woonsocket, RI 02895 USA

Tel. (800) 426 6287

Fax (401) 765 7575

www.hannainst.com/usa

Technical Support for customers

Telephone (800) 426 6287

Fax (401) 765 7575

E-mail tech@hannainst.com

Printed in Romania, EU MAN96822 07/09

12

Loading...

Loading...