Page 1

Instruction Manual

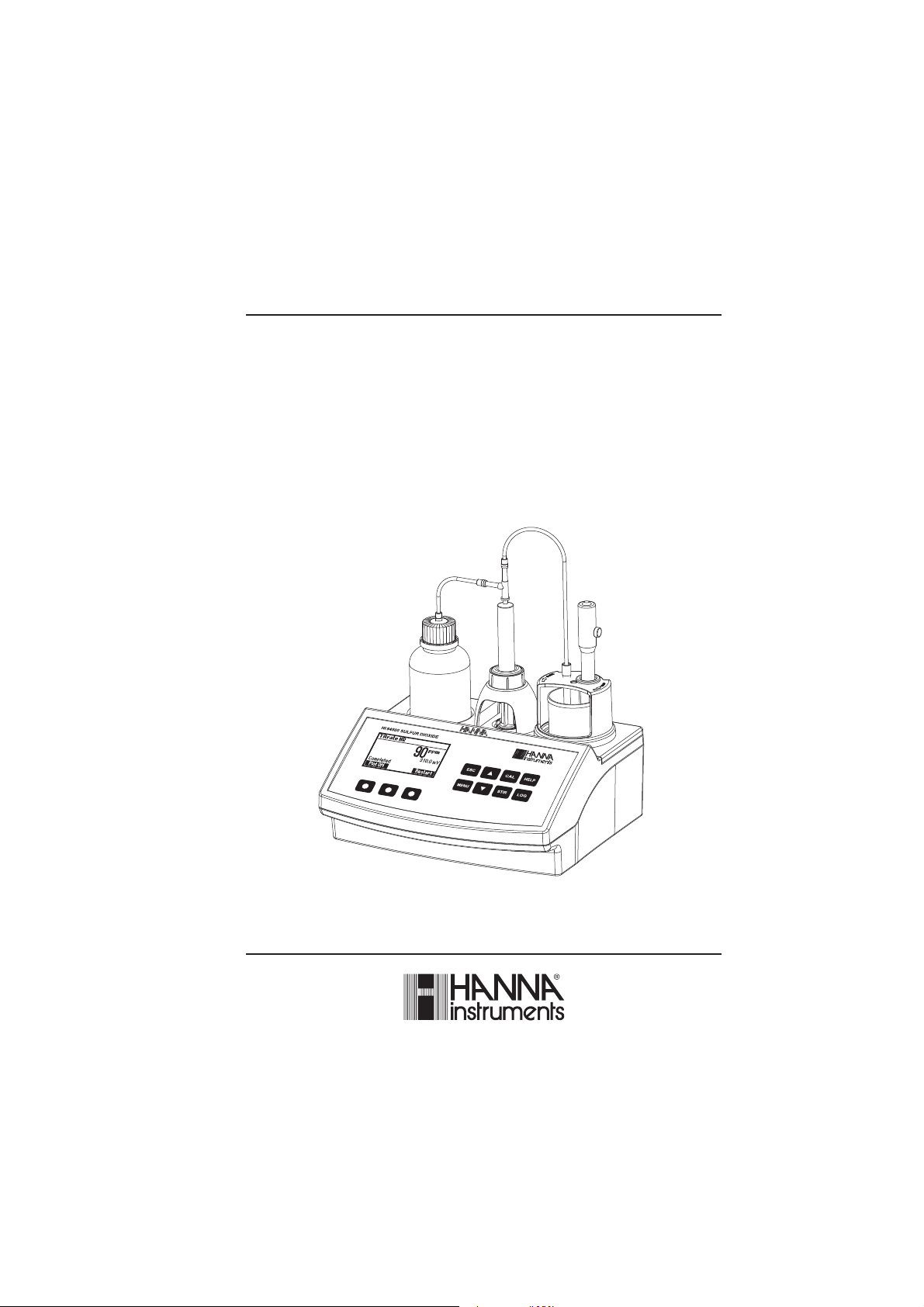

HI 84500

FREE & TOTAL SULFUR DIOXIDE

MINITITRATOR

for wine analysis

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using this instrument. This manual will

provide you with the necessary information for correct use of this instrument, as well as a precise

idea of its versatility.

If you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com

or view our worldwide contact list at www.hannainst.com.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION................................................................................................. 3

GENERAL DESCRIPTION ........................................................................................................ 3

SPECIFICATIONS ................................................................................................................... 5

PRINCIPLE OF OPERATION .................................................................................................... 6

FUNCTIONAL DESCRIPTION................................................................................................... 7

TITRATOR STARTUP ............................................................................................................. 9

SETUP MENU .................................................................................................................... 10

GUIDE TO DISPLAY CODES ................................................................................................... 13

ELECTRODE PREPARATION .................................................................................................. 16

DOSING PUMP INSTALLATION ............................................................................................. 17

DOSING PUMP PRIME PROCEDURE ..................................................................................... 17

ELECTRODE CHECK PROCEDURE .......................................................................................... 19

PUMP CALIBRATION PROCEDURE ........................................................................................ 19

FREE SO2 MEASUREMENT PROCEDURE................................................................................ 21

TOTAL SO2 MEASUREMENT PROCEDURE .............................................................................. 24

ORP MEASUREMENT .......................................................................................................... 28

PC INTERFACE AND DATA TRANSFER ................................................................................... 30

TROUBLESHOOTING GUIDE ................................................................................................ 31

ELECTRODE CONDITIONING AND MAINTENANCE .................................................................. 32

ACCESSORIES ..................................................................................................................... 34

WARRANTY........................................................................................................................ 35

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent

of the copyright owner, Hanna Instruments Inc., Woonsocket, Rhode Island, 02895, USA.

2

Page 3

PRELIMINARY EXAMINATION

Please examine this product carefully. Make sure that the instrument is not damaged. If any

damage occurred during shipment, please notify your Dealer.

Each HI 84500 minititrator is supplied complete with:

• HI 84500-70 Reagent Kit for SO2 determination

• HI 3148B ORP electrode

• HI 7082 Electrode Fill Solution (30 mL)

• Two 100 mL beakers

• Two 20 mL beakers

• Scissors

• Dosing Pump Valve

• 5 mL Syringe

• 1 mL Plastic Pipette

• Tube set (aspiration tube with titrant bottle cap and dispensing tube with tip)

• Stir bar

• Power Adapter

• Two sachets of cleaning solution for wine deposits

• Two sachets of cleaning solution for wine stains

• Instruction manual

Note:Save all packing material until you are sure that the instrument works correctly.

Any defective item must be returned in its original packing.

GENERAL DESCRIPTION

The HI 84500 is a low-cost, easy to use, microprocessor-based automatic titrator that benefits

from Hanna’s years of experience as a manufacturer of analytical instrumentation.

The instrument incorporates a simple and reliable dosing pump which ensures high dosing

reproducibility. Pump calibrations, performed with the provided Hanna reagents, assure the

accuracy of the instrument.

The instrument comes with a preprogrammed method for Free and Total Sulfur Dioxide

measurements in wine. The instrument uses a powerful algorithm which analyzes the shape of

the electrode response in order to determine when the titration has reached completion.

The HI 84500 provides a simple user interface. By simply pressing the Start key in Titration

mode, the instrument will automatically titrate the sample to the equivalence point and the

results are immediately displayed in ppm. Another titration can be started immediately by

pressing Restart.

3

Page 4

Hp 0.3 1.3 2.3 3.3 4.3 5.3 6.3 7.3 8.3 9.3

OSeerF

2

41 81 22 82 53 44 55 96 78 901

A dedicated HELP key aids in setup, calibration, status and troubleshooting.

Other features:

• ORP meter

• Stirrer speed control

• Graphic mode to display the titration data

• Data can be stored using the log feature and then exported to a USB stick or transferred

to a PC using the USB connection

• Log on demand for up to 400 samples (200 for mV measurements; 200 for titration

results)

• GLP feature, to view calibration data for the pump

SIGNIFICANCE OF USE

Wine makers add sulfur dioxide to wine in order to inhibit bacteria and wild yeast growth and to

serve as an antioxidant to prevent browning.

When SO2 is added to wine, a portion of it becomes immediately bound while a remaining portion

is unbound SO2. The portion that is unbound is also called free; it is responsible for protecting the

wine. The bound and unbound SO2 together are referred to as total SO2.

The relationship between the amount of SO2 added and the amount of free SO2 is complex. This

relationship is governed by the total amount of SO2 in the wine. The exact relationship between free

and bound will vary wine to wine. The amount of free SO2 depends on how much is added, how much

was present before the addition and how much was immediately bound.

Free SO2 exists in two forms. Bisulfite (HSO3¯) is the predominante form but is relatively ineffective.

Molecular SO2 is the minor form and is responsible for protecting the wine.

The amount of molecular SO2 available in wine is depended on the amount of free SO2 present and

the pH. Typically 0.8 ppm of molecular SO2 provides adequate protection against bacteria growth

and oxidation. In order to obtain this value for a wine sample that has a pH of 3.2 you would need

22 ppm of free SO2, if the pH was at 3.5 you would need double, 44 ppm.

Molecular SO2 can be detected by human senses at about 2.0 ppm. This level is needed for

maximum protection of wine. Higher levels are needed for sweet and most notable, botrytised wine.

The HI 84500

can be used to test for free and total SO2 in all wines, including red, which are

difficult to test using traditional methods associated with a distinctive color change to determine the

end point.

4

Page 5

SPECIFICATIONS

Titrator Range Low Range: 1.0 to 40.0 ppm of SO

High Range: 30 to 400 ppm of SO

2

2

Resolution Low Range: 0.1 ppm

High Range: 1 ppm

Accuracy Low Range: 3% of reading or ±0.5 ppm @ 25 °C, whichever is greater

High Range: 3% of reading or ±1 ppm @ 25 °C, whichever is greater

Sample volume 50 mL

Titration method Ripper method

Principle Equivalence point redox titration

Pump speed 10 mL/min

Stirring speed 700 rpm

Log data Up to 200 samples

ORP meter ORP meter -2000.0 to 2000.0 mV

ORP Resolution 0.1 mV

ORP Accuracy ± 1 mV

Log data Up to 200 samples

ORP Electrode HI 3148B

Environment 0 to 50 °C (32 to 122 °F); max 95% RH non-condensing

Power supply 12 Vdc power adapter

Dimensions 235 x 200 x 150 mm (9.2 x 7.9 x 5.9”)

Weight 1.9 kg (67.0 oz.)

REQUIRED REAGENTS

Code Description

HI 84500-50 Low Range Titrant

HI 84500-51 High Range Titrant

HI 84500-55 Calibration Standard

HI 84500-60 Acid Reagent

HI 84500-61 Alkaline Reagent (Total SO2)

HI 84500-62 Stabilizer Packet

5

Page 6

PRINCIPLE OF OPERATION

The HI 84500 determines the free and total sulfur dioxide concentration in wine using the Ripper

method. Excess iodide added to the wine sample reacts with iodate introduced by the titrant to

produce iodine.

-

IO

+ 5I- + 6H

3

+

→ 3I

+ 3H2O

2

The iodine produced in the sample then reacts with sulfur dioxide in the wine according to the redox

reaction below:

H2SO3 + I

→ H

2

2SO4

+ 2HI

The HI 84500 utilizes an ORP electrode to monitor the redox titration. The integrated algorithm

detects when the reaction is complete (equivalence point). The volume of titrant required to reach the

equivalence point, the titrant concentration and the sample size are used to calculate the sulfur

dioxide concentration in the wine sample.

6

Page 7

FUNCTIONAL DESCRIPTION

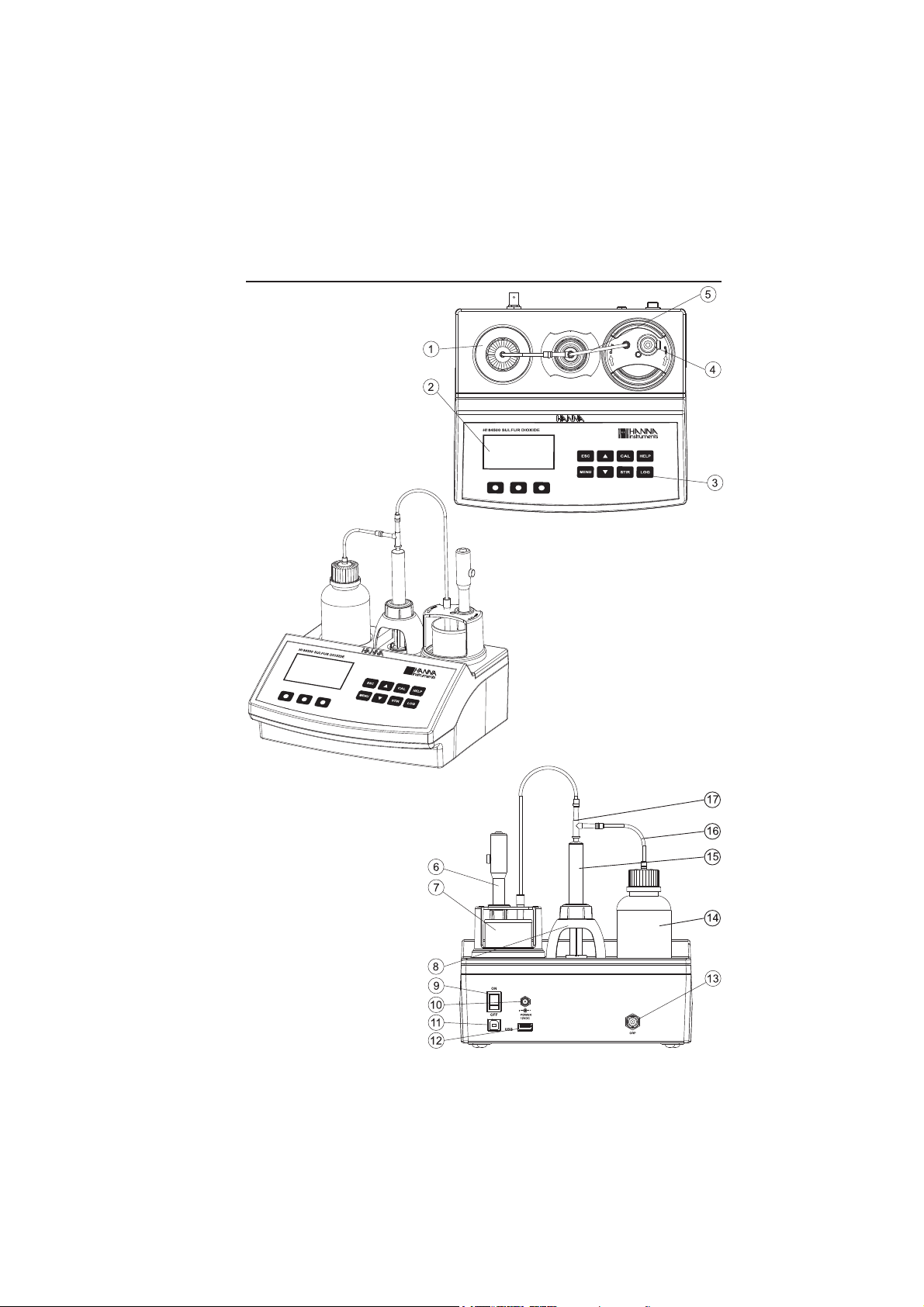

OVERHEAD VIEW

1) Titrant bottle

2) Liquid Crystal Display (LCD)

3) Keypad

4) Electrode holder

5) Dispensing tube

FRONT VIEW

REAR VIEW

6) ORP Electrode

7) Beaker

8) Dosing pump

9) Power switch

10) Power adapter

11) USB connector (PC interface)

12) USB connector (Storage interface)

13) BNC electrode connector

14) Titrant bottle

15) Syringe

16) Aspiration tube

17) Dosing Pump Valve

7

Page 8

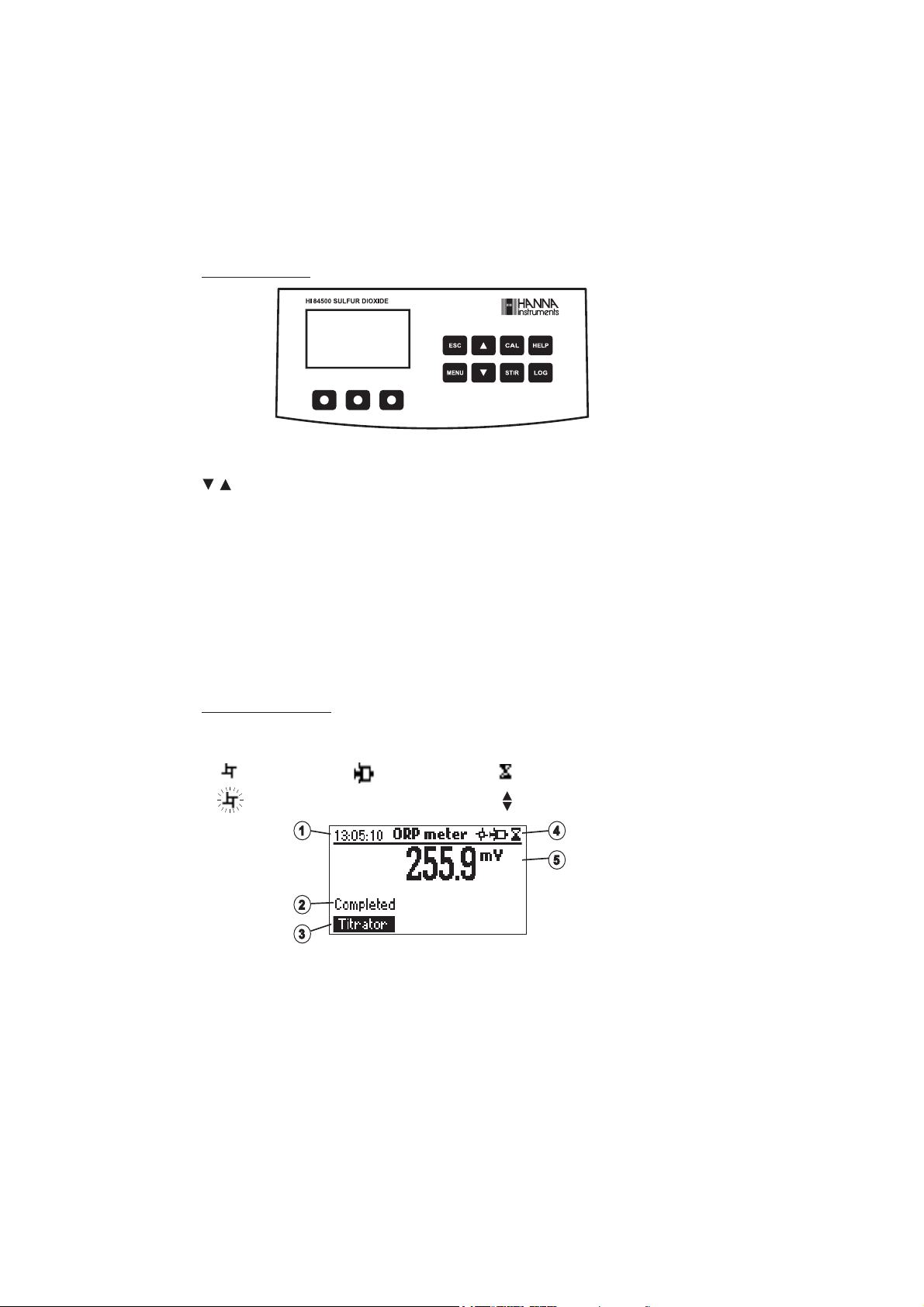

KEYPAD FUNCTION

ESC - used to leave the current screen and to return either to the previous screen or to the

main screen. In Setup menu, exits a parameter without changing the value.

/ - used to modify the parameter values, to scroll the information displayed while

viewing a help screen or to move between the options from the instrument’s Setup menu

CAL - used to access the Pump calibration

HELP - used to access/exit the instrument’s contextual help

LOG - used to save the current mV-ORP reading in ORP meter mode and the titration result

MENU - used to enter Setup, Recall or GLP selection menu, while instrument is in ORP or

Titration mode

STIR - used to start/stop the stirrer

Note: The stirrer starts automatically during pump calibration and titration, it cannot

be stopped by pressing STIR key.

GUIDE TO INDICATORS

During the instrument’s operation information is displayed on the LCD.

Displayed icons:

Unstable reading.Stirrer on. Pump running.

Stirrer is not working properly.

1) Current time and instrument mode information (ORP meter or Titrator)

2) Instrument status

3) Virtual option keys

4) Stirrer and reading status

5) Main reading information

8

Parameter can be modified.

Page 9

DOSING PUMP

The dosing pump is based on a valve that automatically moves the titrant between the titrant

bottle and syringe when filling the syringe and between the syringe and sample when

dispensing. A replaceable 5 mL plastic syringe is used to limit the amount of titrant used per test

to ensure the highest possible accuracy. Before a set of titrations, it is necessary to prime the

dosing system.

Note: Once titrations have been completed, the dosing system should be cleaned with deionized

water using the prime feature.

TITRATOR STARTUP

This is a general outline of the steps required to perform a titration. The following topics are

expanded upon in each section that follows.

• Place the instrument on a flat table. Do not place the instrument in direct sun light.

• Connect the power adapter to the instrument.

• Turn the instrument ON using the power switch from the rear panel of the instrument.

• Set up the instrument. See the “Setup Menu” section for details.

• Connect the ORP sensor to the instrument.

• Connect the tubes and the valve. See the “Dosing Pump Installation” section for the

procedure.

• Remove the titrant bottle cap and replace it with the bottle cap with tubes. Place the titrant

bottle in the appropriate place on the titrator top.

Note: Different titrants are required based on the concentration. See “Pump Calibration Procedure”

for details.

• Prime the syringe. To assure high accuracy, verify there are no air bubbles in the syringe or

tubing.

• Calibrate the pump.

Note: Different volumes of standard are required based on the concentration. See “Pump

Calibration Procedure” for details.

• Prepare the sample.

• Run a titration and log sample results.

9

Page 10

SETUP MENU

The titrator’s setup menu may be accessed from the main screen (meter or titrator mode) by

pressing the MENU key, then Setup.

A list of setup parameters will be displayed with currently configured setting.

While in the setup menu it is possible to modify the instrument’s operation parameters. The

ARROW keys permit the user to scroll the setup parameters.

Press HELP to view the contextual help.

Press ESC to return to the main screen.

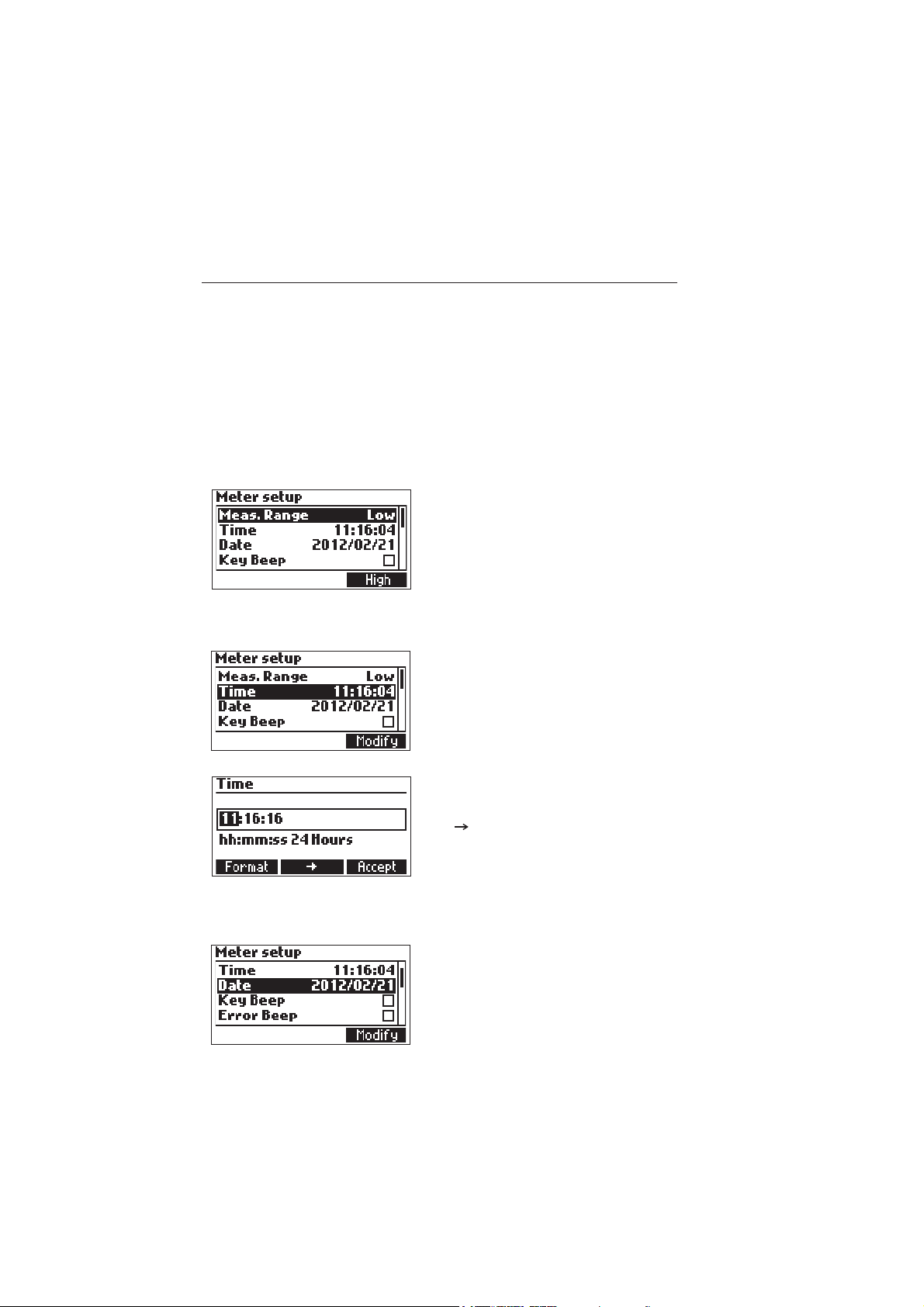

Range Setup

Use Low measurement range for 1.0 - 40.0 ppm.

Use High measurement range for 30 - 400 ppm.

Use the appropriate titrant for each range.

To ensure a high accuracy, it is recommended to

recalibrate the pump after the valve, titrant or

electrode has been changed.

Time

Press the Modify key to change the time and time

format.

Date

Press Format to switch between 12 hour (am/pm)

and 24 hour mode.

Press to highlight the value to be modified. Use

the ARROW keys to change the value. Press Accept

to confirm the new value or ESC to return to the

setup.

Press the Modify key to change the date and date

format.

10

Page 11

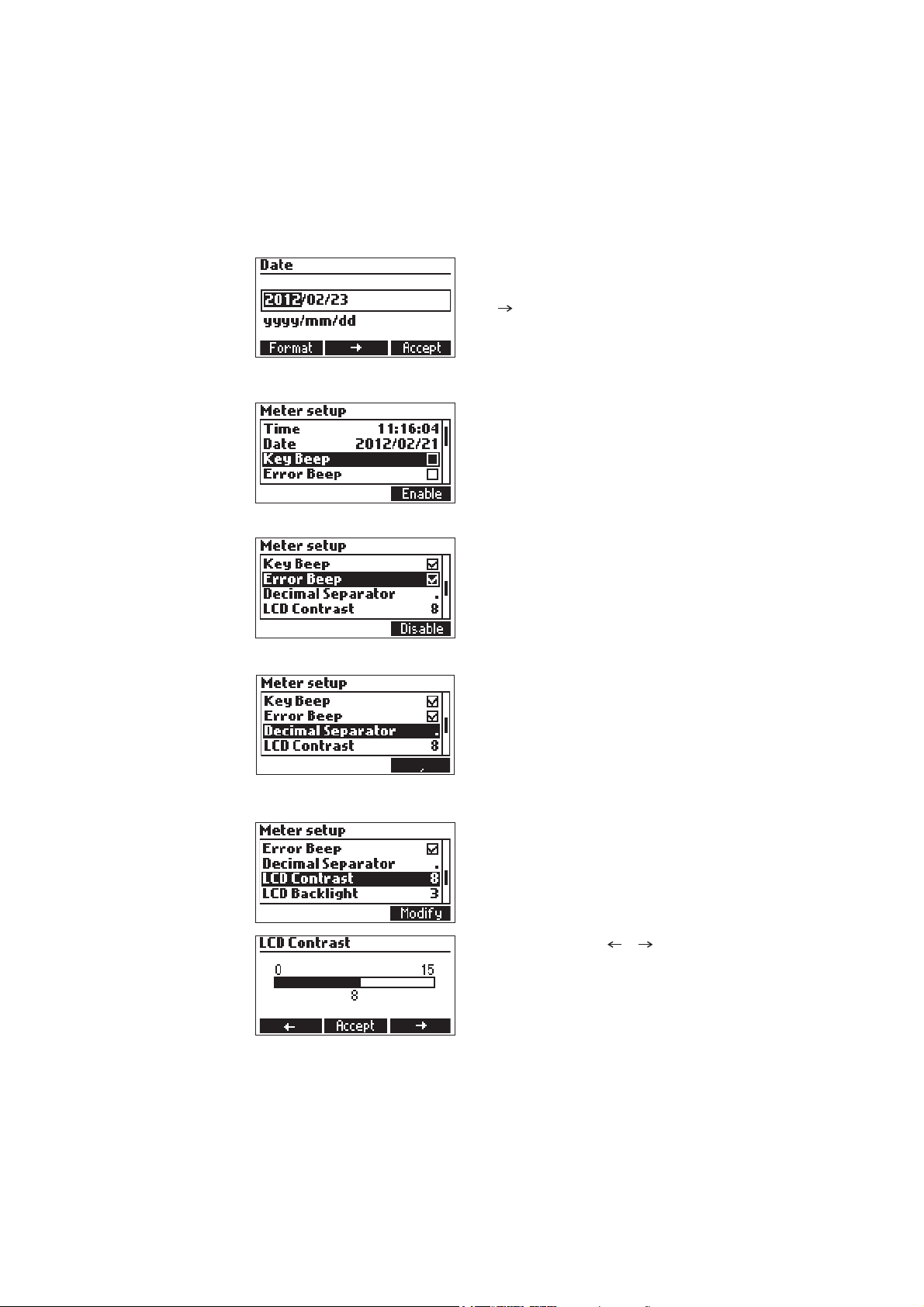

Key Beep

Error Beep

Decimal Separator

Press Format to cycle between the available date

formats.

Press to highlight the value to be modified. Use

the ARROW keys to change the value. Press Accept

to confirm the new value or ESC to return to the

setup.

Select Enable to activate or Disable to deactivate

the Key Beep function.

If enabled, a short beep will be heard every time a

key is pressed.

Select Enable to activate or Disable to deactivate

the Error Beep function.

If enabled, a beep will be heard when an error

condition occurs.

This option allows the user to select the symbol

used for a decimal separator.

LCD Contrast

This option is used to set the display’s contrast.

Press Modify to change the display’s contrast.

The default value is 8.

Use the ARROW keys or / to increase/

decrease the value. Press Accept to confirm the value

or ESC to return to the setup menu.

11

Page 12

LCD Backlight

Language

Tutorial

Press Modify to change the backlight level.

The default value is 3.

Use the ARROW keys or / to increase/

decrease the backlight level.

Press Accept to confirm or ESC to return to the

setup menu.

Press the corresponding virtual option key to change

the language.

If the selected language cannot be loaded, the

previously selected language will be reloaded.

If no language can be loaded at startup the instrument

will work in “safe mode”. In “safe mode” all

messages are displayed in English. Tutorial and help

information are not available.

Enable or Disable the Tutorial. This helpful tool

offers additional information during calibration and

titration.

Meter Information

Press Select to view the firmware version, language

version, mV factory calibration date and time,

method version.

Press ESC to return to the setup menu.

12

Page 13

Restore Factory Settings

GUIDE TO DISPLAY CODES

Press Select to restore the factory settings.

Press Yes to confirm the restore process or No to

return without restoring.

Press ESC to return to the setup menu.

This screen appears when the instrument is turned

on during the initialization process.

Titration screen display.

Titration screen when a titration is in progress.

Prime burette screen.

13

Page 14

PUMP CALIBRATION MESSAGES

Prime burette screen when the dosing system is

running.

This error message appears when the pump is not

working properly. Check the tubing, valve and

syringe. Press Restart to try again.

Pump calibration is initiated by pressing the Start

key.

This screen appears while pump calibration is in

progress. Press ESC or Stop key to return to the

Pump Calibration screen.

This screen appears when pump calibration is

complete.

This error message appears during pump calibration

when the end point can not be reached and the

maximum amount of titrant is exceeded. Check

standard, electrode and/or dosing system and try

again.

14

Page 15

The calibration was outside the acceptable limits.

Prepare a new standard and try again.

This error message appears when the input reading

(mV) exceeds the input limits (± 2000.0 mV).

This screen appears when the stirrer is not working

properly. Check the stir bar and beaker content.

Press Restart to try again.

This error message appears when the pump is not

working properly. Check the tubing, valve and

syringe. Press Restart to try again.

TITRATION MESSAGES

This screen is displayed when the instrument is in

titration mode. Press Start to begin a titration, Meter

to enter ORP meter mode or Prime to enter into the

prime function.

The titration result, expressed as the concentration of

sulfur dioxide in ppm (mg/L), is displayed

automatically at the end of the titration. Press Restart

to start another titration or ESC to return to the main

screen.

15

Page 16

This error message appears when the input reading

(± 2000 mV) exceeds the input limits during a

titration.

This screen appears when the sample concentration

is out of range.

This screen appears when the stirrer is not working

properly. Check the stir bar and beaker content.

Press Restart to try again.

This error message appears when the pump is not

working properly. Check the tubing, valve and

syringe. Press Restart to try again.

ELECTRODE PREPARATION

PREPARATION PROCEDURE

Remove the electrode protective cap.

DO NOT BE ALARMED IF ANY SALT DEPOSITS ARE PRESENT. This is normal with electrodes and

they will disappear when rinsed with distilled/deionized water.

During transport tiny bubbles of air may have formed inside the glass bulb. The electrode cannot

function properly under these conditions. These bubbles can be removed by "shaking down" the

electrode as you would do with a glass thermometer.

If the bulb is dry, soak the electrode in HI 70300 Storage Solution for at least one hour.

16

Page 17

DOSING PUMP INSTALLATION

To install the dosing pump follow the procedure below:

• Extend the plunger on the 5 mL syringe to its maximum volume.

• Place the syringe in the dedicated spot on the top of the meter (1).

• Arrange the bottom of the syringe into the holder on the pump (2). Once the syringe is in place

lower the barrel until it sits flush on the holder.

• Put the o-ring and syringe-fixing nut over the syringe (3) and turn clockwise to secure it in place (4).

• Place the valve on the top of the syringe (5). Ensure it fits securely.

• Insert the aspiration tube into the left side of the valve (6) and replace the titrant bottle cap with

the attached cap (7).

• Insert the dispensing tube into the top of the valve (8).

DOSING PUMP PRIME PROCEDURE

Prime cycle should be performed:

• if you notice there is no titrant in the tip

• whenever the dosing system tubes are replaced

• whenever a new bottle of titrant is used

• before starting a pump calibration

• before starting a series of titrations

The prime cycle is used to fill the syringe before starting a set of titrations.

Two rinse cycles of the syringe are shown in the figure below. The dispensing tube is connected to

the top of the valve and the aspiration tube on the left side.

17

Page 18

Note: •The aspiration tube must be inserted in the titrant bottle. The dosing tip must be placed

over a rinse beaker.

•Before starting the prime procedure, make sure you are using the appropriate titrant

solution for the selected range.

• To prime the burette, select Prime option from Titration mode.

• Adjust the rinses number by pressing the and keys and press Start.

• The number of syringe rinses can be set between 1 and 5 (at least three rinses are recommended

to ensure that the air bubbles are completely removed).

• To pause the prime process press the Pause key; to continue press the Continue key. To stop the

prime process press the Stop key.

Note: This error message appears when the pump is

not working properly. Check the tubing, valve

and syringe. Press Restart to try again.

18

Page 19

egnaRwoL egnaRhgiH

mpp0.04ot0.1 mpp004ot03

ELECTRODE CHECK PROCEDURE

Before taking any measurements with the HI 84500 minititrator, it is recommended to check

the HI 3148B ORP electrode using the following steps:

• Press Meter to enter mV mode.

• Pour roughly 15 mL of HI 7021 into a 20 mL beaker. This does not need to be exact, as

long as the PTFE junction is covered by the solution.

• Place the electrode in the solution, stir gently for a few seconds and verify the mV reading.

If the mV reading is 240 ± 20 mV this indicates the electrode is in good condition and can

be used for titrations. A mV reading of 240 ± 30 mV indicates the electrode is beginning

to drift. Follow the “Electrode Conditioning and Maintenance”, Probe Maintenance section

on page 32. If the mV reading is greater than 240 ± 40 mV replace the electrode.

• Remove the electrode from the solution and rinse thoroughly with deionized or distilled water.

PUMP CALIBRATION PROCEDURE

Pump calibration must be performed every time the syringe, pump tube, the titrant bottle or the ORP

electrode is changed. A pump calibration is recommended before each set of titrations or after the

titrator is left idle for several hours.

• Press MENU, select Setup and select the corresponding range according to the table below:

• Ensure the pump is primed with the correct titrant for the selected range (HI 84500-50 Low

Range Titrant or HI 84500-51 High Range Titrant).

Sample preparation: Use a clean pipette to precisely add the appropriate amount of

HI 84500-55 Calibration Standard to a clean beaker as indicated below:

Low Range (Free & Total SO2) - 1 mL

High Range (Free & Total SO2) - 10 mL

Note: Failure to use a clean pipette will result in erroneous readings.

• Fill the beaker up to the 50 mL mark with the distilled or

deionized water.

• Fill the 20 mL beaker up to the 5 mL mark with the HI 84500-60

Acid Reagent and add the contents to the 100 mL beaker.

• Add the contents of one packet of HI 84500-62 Stabilizer

Packet to the sample beaker.

• Press CAL key.

Note: DO NOT PLACE THE TIP INTO THE CALIBRATION BEAKER,

PLACE THE TIP OVER A WASTE BEAKER. A SMALL AMOUNT

OF TITRANT IS DISPENSED WHEN THE PUMP RESETS.

19

Page 20

• Press Start, wait for the syringe to refill.

• Place the stir bar in the beaker and put the beaker in the

minititrator top.

• Place the probe holder on the top of the beaker and secure it

by turning clockwise.

• Rinse the ORP electrode with deionized water and immerse

into the sample until the PTFE reference junction is completely

submerged. Be sure that the tip of the electrode is not

hitting the stir bar. If necessary additional distilled or

deionized water can be added.

• Insert the dosing tip into the titrant tube sleeve. IT IS

CRITICAL THAT THE TIP BE IMMERSED APPROXIMATELY

0.25 CM (0.1”) INTO THE SOLUTION BEING TITRATED.

• Press Continue to begin the calibration and Stop to abort it.

• At the end of the calibration, “Calibration Completed“

appears on display. To repeat the calibration press Restart

and ESC to return to the main screen.

Note:

• If an erroneous situation is encountered during

the calibration, an error message is displayed

and the calibration can be restarted by pressing

Restart. Prepare a new standard, rinse electrode

and dosing tip and try again.

• If the calibration doesn’t complete and the

max titrant volume of titrant is reached, an

error message will be displayed. The calibration

can be restarted by pressing Restart. Prepare

a new standard, rinse the electrode and dosing

tip and try again.

• This error message appears when the input

reading (mV) exceeds the input limits

(± 2000.0 mV).

20

Page 21

egnaRwoL

)elpmasLm05(

egnaRhgiH

)elpmasLm05(

mpp0.04ot0.1 mpp004ot03

• This screen appears when the stirrer is not

working properly. Check the stir bar and beaker

content. Press Restart to try again.

• This error message appears when the pump is

not working properly. Check the tubing, valve

and syringe. Press Restart to try again.

FREE SO2 MEASUREMENT PROCEDURE

• Refer to “Setup Menu” (see page 10) to set up the instrument for your measurement.

• For best accuracy, before taking any measurement, ensure that the pump is calibrated on the

selected range following the “Pump Calibration Procedure” (see page 19).

• Select the corresponding range according to the table below:

• Ensure the pump is primed with the correct titrant for the selected range (HI 84500-50 Low

Range Titrant or HI 84500-51 High Range Titrant).

Sample preparation: Use a clean pipette to precisely add the appropriate amount of wine

sample to a clean 100 mL beaker as indicated below:

Low Range (Free & Total SO2) - 50 mL

High Range (Free & Total SO2) - 50 mL

Note: •The volume of wine added is critical to the measurement

accuracy. Pipettes are recommended.

•Failure to use a clean pipette will result in erroneous

readings.

• Fill the 20 mL beaker up to the 5 mL mark with the HI 84500-60

Acid Reagent and add the contents to the 100 mL beaker.

• Add the contents of one packet of HI 84500-62 Stabilizer

Packet to the 100 mL beaker.

• Press Titrator.

21

Page 22

Note: DO NOT PLACE THE TIP INTO THE SAMPLE BEAKER.

PLACE THE TIP OVER A WASTE BEAKER. A SMALL

AMOUNT OF TITRANT IS DISPENSED WHEN THE PUMP

RESETS.

• Press Start to begin a titration.

• Wait for the syringe to refill.

• Place the stir bar in the beaker and put the beaker into the beaker

holder.

• Place the probe holder on the top of the beaker and secure it by

turning clockwise.

• Rinse the ORP electrode with deionized water and immerse into

the sample until the PTFE reference junction is completely

submerged. Be sure that the tip of the electrode is not hitting the

stir bar.

• Insert the dosing tip into the titrant tube sleeve. IT IS CRITICAL

THAT THE TIP BE IMMERSED APPROXIMATELY 0.25 CM (0.1”)

INTO THE SOLUTION BEING TITRATED.

• Press Continue to begin the titration and Stop to abort it.

• The instrument will continuously update the concentration on the display. The value will be

displayed blinking. When the reading is under range “----” symbol appears blinking.

• The titration curve can be visualized during a titration by pressing Plot ON. Press Plot OFF to

exit this mode.

22

Page 23

• At the end of the titration the instrument displays the concentration in ppm of SO2. The titration

curve can be viewed by pressing Plot ON. Press Plot OFF to exit this mode.

• Press LOG to record the concentration value and the titration curve into the instrument’s

memory. A message will be displayed for a few seconds indicating the amount of free log

space. Up to 200 log samples can be recorded in the instrument’s memory.

• Press Restart to begin a new titration or ESC to return to the titration menu.

• If the concentration exceeds the range limits (>40.0 ppm for Low Range, >400 ppm for

High Range), the exceeded range limit will be displayed blinking. Another titration can be

started by pressing Restart.

• “Wrong input” error message appears when the input reading (mV) exceeds the specified

limits. The mV value and the concentration will blink indicating an error.

• This screen appears when the stirrer is not working properly. Check the stir bar and beaker

content. Press Restart to try again.

23

Page 24

egnaRwoL

)elpmasLm05(

egnaRhgiH

)elpmasLm05(

mpp0.04ot0.1 mpp004ot03

• This error message appears when the pump is not working properly. Check the tubing, valve

and syringe. Press Restart to try again.

TOTAL SO2 MEASUREMENT PROCEDURE

• For best accuracy, before taking any measurement, ensure that the pump is calibrated on the

selected range following the “Pump Calibration Procedure” (see page 19).

• Select the corresponding range according to the table below:

• Ensure the pump is primed with the correct titrant for the selected range (HI 84500-50 Low

Range Titrant or HI 84500-51 High Range Titrant).

Sample preparation: Use a clean pipette to precisely add the appropriate amount of wine

sample to a clean 100 mL beaker as indicated below:

Low Range (Free & Total SO2) - 50 mL

High Range (Free & Total SO2) - 50 mL

Note: •The volume of wine added is critical to the measurement

accuracy. Pipettes are recommended.

•Failure to use a clean pipette will result in erroneous readings.

• Fill the 20 mL beaker up to the 5 mL mark with the HI 84500-61

Alkaline Reagent, add the contents to the 100 mL beaker containing

the sample.

• Cover the beaker, swirl and wait for 10 minutes.

• Fill the 20 mL beaker up to the 5 mL mark with the HI 84500-60

Acid Reagent, add the contents to the 100 mL beaker containing

the sample.

• Add the contents of one packet of HI 84500-62 Stabilizer Packet

to the 100 mL beaker.

• Place the beaker into the beaker holder.

• Press Titrator.

24

Page 25

Note: DO NOT PLACE THE TIP INTO THE SAMPLE BEAKER.

PLACE THE TIP OVER A WASTE BEAKER. A SMALL

AMOUNT OF TITRANT IS DISPENSED WHEN THE PUMP

RESETS.

• Press Start to begin a titration.

• Wait for the syringe to refill.

• Place the stir bar in the beaker and put the beaker into the

beaker holder.

• Place the probe holder on the top of the beaker and secure it by

turning clockwise.

• Rinse the ORP electrode with deionized water and immerse into

the sample until the PTFE reference junction is completely

submerged. Be sure that the tip of the electrode is not hitting

the stir bar.

• Insert the dosing tip into the titrant tube sleeve. IT IS CRITICAL

THAT THE TIP BE IMMERSED APPROXIMATELY 0.25 CM (0.1”)

INTO THE SOLUTION BEING TITRATED.

• Press Continue to begin the titration and Stop to abort it.

• At the end of the titration the instrument displays the concentration in ppm of SO2. The titration

curve can be viewed by pressing Plot ON. Press Plot OFF to exit this mode. For more information

about this feature, see page 22.

• Press LOG to record the concentration value and the titration curve into the instrument’s

memory. A message will be displayed for a few seconds indicating the amount of free log

space. Up to 200 log samples can be recorded in the instrument’s memory.

• Press Restart to begin a new titration or ESC to return to the titration menu.

25

Page 26

TIPS FOR AN ACCURATE MEASUREMENT

The instructions listed below should be followed carefully to ensure measurements are conducted

with the highest possible accuracy and precision.

• IT IS CRITICAL THAT THE TIP BE IMMERSED IN THE SOLUTION BEING TITRATED

(APPROXIMATELY 0.25 CM).

• Use a clean, volumetric pipette to measure and transfer the wine sample into the titration

beaker.

• Calibrate the pump prior to each series of titrations.

• Calibrate the pump if the meter is left idle for several hours.

• Analyze the wine sample immediately after it is obtained.

• Clean the electrode with HI 700635 or HI 700636 cleaning solutions specially designed for

the wine industry.

VIEW/DELETE TITRATOR RECORDED DATA

Press MENU then Recall to access the Titrator logs.

When an external USB storage device is connected, the Export key is displayed. It saves the meter

and titrator logs in two text format files on the storage device.

Press Meter or Titrator to view the respective logs.

The instrument will display a list of all the records stored in the log.

Use the ARROW keys to scroll the stored records list.

If the saved concentration was out of range, the “<” or “>” symbols are displayed in front of

the reading.

Press Delete to delete the selected log from the memory.

Press Del.All to delete all records.

Press Info to see detailed information about the highlighted record.

26

Page 27

The selected record data and the titration curve data file name are displayed.

When a USB storage device is connected, the Export key is displayed. It saves the titration curve

data as a text file on the storage device using the displayed file name.

Use the ARROW keys when is displayed to scroll between the log records.

Press ESC to return to the previous screen.

Press Plot

to visualize the titration curve or ESC to return to the previous screen. On the titration

curve, the end point volume and mV are displayed. The titration data (Total Titrant Volume on the

x-axis and mV on the y-axis) can be scanned through with the dotted line by using the ARROW keys.

To zoom on the titration curve press Zoom.

If Delete or Del.All is pressed the instrument will ask for confirmation.

Press Yes to delete the record or No to return to the previous screen.

Deleting a single record will renumber the list of records.

If the titrator log is empty, the message “No records available!” will be displayed.

27

Page 28

TITRATOR GLP INFORMATION

Press MENU then GLP.

The pump’s last calibration time, date and slope is displayed.

If a calibration hasn’t been performed, the message “Not Calibrated” will be displayed.

ORP MEASUREMENT

The HI 84500 can be used as an ORP meter for direct measurements.

Set the instrument to ORP meter. From titrator mode press Meter until mV units are displayed.

Rinse the ORP tip with distilled or deionized water.

Place ORP electrode into electrode holder.

For a faster response and to avoid cross-contamination of the samples, rinse the electrode tip

with a few drops of the solution to be tested before taking measurements.

Immerse the ORP sensor in the sample until the PTFE reference junction is completely

submerged and stir gently for a few seconds.

When the reading becomes stable the (unstable measurement) symbol will disappear.

If the potential reading is less than -2000.0 mV or greater than 2000.0 mV the closest full-scale

value will be displayed blinking.

28

Page 29

Press LOG to save the current reading.

During ORP measurements with stirrer on, the stirrer icon will be displayed. In case of a stirrer

malfunction, the stirrer will stop and the stirrer icon will start blinking.

VIEW/DELETE RECORDED ORP DATA

To view or delete previously logged ORP records, press MENU then Recall to access meter logs.

When an external USB storage device is connected, the Export key is displayed. It saves the

meter and titrator logs in two text format files on the storage device.

Press Meter or Titrator to view the respective logs.

The instrument will display a list of all the records stored in the log.

Use the ARROW keys to scroll the list of records.

If the saved ORP measurements are out of range, the “<” or “>” symbols are displayed in front

of the reading.

Press Delete to delete the selected log from the memory.

Press Del.All to delete all records.

Press Info to see detailed information about the highlighted record.

Use ARROW keys when is displayed to scroll between the records.

29

Page 30

If Delete or Del.All is pressed the instrument will ask for confirmation.

Press Yes to delete the record or No to return to the previous screen without deleting.

Deleting a single record will renumber the list of records.

If the ORP log is empty, the message “No records available!” will be displayed.

PC INTERFACE AND DATA TRANSFER

Data stored on the meter with the LOG function during mV measurement and titrations can be

transferred from the meter to a USB stick using the Export function from the log recall menu.

Two text files are transferred on the USB stick. These files can be used for further analysis on a PC.

The logged data can also be transferred from the instrument to the PC using a USB cable.

Connect the USB cable and the following screen will be displayed.

Press Meter to generate the text file with Meter log data.

Press Titrator to generate the text file with Titrator log data.

Press Plot to generate the text files with Titration Plots.

The generated files are now visible and can be used fot further analysis.

If the instrument has no logged Meter or Titrator records, the PC connected screen is displayed.

30

Page 31

TROUBLESHOOTING GUIDE

SMOTPMYS MELBORP NOITULOS

evissecxe/esnopserwolS

.tfird

.edortcelePROytriD

nipitedortceleehtkaoS

1607IH noitulosgninaelc

setunim03rof . htiwllifeR

.noitulosllifhserf

pusetautculfgnidaeR

.)esion(nwoddna

.noitcennocelbaC

nipitedortceleehtkaoS

1607IH noitulosgninaelc

setunim03rof . htiwllifeR

.noitulosllifhserf

oitcennocelbackcehC otn

retem evitcetorpyfirevdna

.ffosipac

retemPROnielihW

ro0002-,edom

siVm0002+

.gniknilbdeyalpsid

.egnarfotuognidaeR

otnoitcennocelbackcehC

evitcetorpyfirevdnaretem

ehtkcehC.ffosipac

.elpmasehtfoytilauq

llifeR.sedortceleehtnaelC

.noitulosllifhserfhtiw

noitarbilacpmupehT

demrofrepebt'nac

ro,gnibut,evlaV

.eussiegnirys

detanimatnocrognorW

noitarbilacpmup

.noitulos

.edortcelePROnekorB

,evlav,gnibutyfireV

dnatcatnieraegnirys

nehwsessapnoitulos

ondnademirpsipmup

.tneserperaselbbubria

pmupehtkcehC

.noitulosnoitarbilac

,dradnatsrehtonaeraperP

dnapmupehtemirp

.noitarbilacehttratser

eht,noitartitaretfA

syalpsidtnemurtsni

,RL-L/gm0.04

RH-L/gm004

.gniknilb

.edortcelenekorB

fotuonoitartnecnoC

.egnar

.detcelesegnargnorW

.edortceleehtnaelc/kcehC

.pmupehtetarbilaceR

,egnartcerrocehttceleS

.pmupehtetarbilacer

retemehtputratstA

ANNAHehtsyalpsid

.yltnenamrepogol

.kcutssisyekehtfoenO

rodraobyekehtkcehC

.rodnevehttcatnoc

siegassem"xxrorrE"

.deyalpsid

.rorrelanretnI

dnaretemehtfforewoP

fI.niaganotirewopneht

tcatnoc,stsisreprorreeht

.rodneveht

31

Page 32

ELECTRODE CONDITIONING AND MAINTENANCE

SMOTPMYS MELBORP NOITULOS

siegassem"rorrererritS"

fodneehttadeyalpsid

ronoitarbilacpmup

.noitartit

dnarabritsehtkcehC

.tnetnocrekaeb

tcatnoc,stsisreprorreehtfI

.rodneveht

nocirerritsgninnips-noN

retemPROnigniknilb

.edom

dnarabritsehtkcehC

.tnetnocrekaeb

tcatnoc,stsisreprorreehtfI

.rodneveht

siegassem"rorrepmuP"

.deyalpsid

evlav,gnibutehtkcehC

.egnirysdna

tcatnoc,stsisreprorreehtfI

rodneveht .

retemehtputratstA

sdohteM"syalpsid

."detpurroc

sawelifdohtemehT

.detpurroc

.rodnevehttcatnoC

PREPARATION PROCEDURE

Remove the protective cap of the ORP electrode (HI 3148B).

DO NOT BE ALARMED IF SALT DEPOSITS ARE PRESENT. This is normal with electrodes. They will

disappear when rinsed with distilled/deionized water.

During transport, tiny bubbles of air may have formed inside the glass bulb, affecting proper

functioning of the electrode. These bubbles can be removed by "shaking down" the electrode as

you would do with a glass thermometer.

32

Page 33

If the bulb and/or junction is dry, soak the electrode in HI 70300L Storage Solution for at least

one hour.

If the fill solution (electrolyte) is more than 2½ cm (1”) below the fill hole, add HI 7082 3.5M

KCl Electrolyte Solution.

For faster response, unscrew the fill hole screw during measurements.

STORAGE PROCEDURE

To minimize clogging and assure a quick response time, the glass bulb and junction of the

electrode should be kept moist and not allowed to dry out.

Replace the solution in the protective cap with a few drops of HI 70300L Storage Solution or,

in its absence, HI 7082 Fill Solution. Follow the Preparation Procedure before taking

measurements.

Note: NEVER STORE THE ELECTRODE IN DISTILLED OR DEIONIZED WATER.

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The cable used for connection to the instrument must be

intact and there must be no points of broken insulation on the cable or cracks on the electrode

stem or bulb. Connectors must be perfectly clean and dry. If any scratches or cracks are present,

replace the electrode. Rinse off any salt deposits with water.

PROBE MAINTENANCE

Refill the reference chamber with fresh electrolyte (HI 7082). Allow the electrode to stand

upright for 1 hour. Follow the Storage Procedure above.

CLEANING PROCEDURE

•

Wine deposits

•

Wine stains

IMPORTANT: After performing any of the cleaning procedures, rinse the electrode thoroughly

with distilled water, refill the reference chamber with fresh electrolyte and soak the electrode in

HI 70300 Storage Solution for at least 1 hour before taking measurements.

Soak in Hanna HI 70635 cleaning solution for 15 minutes

Soak in Hanna HI 70636 cleaning solution for 15 minutes

33

Page 34

ACCESSORIES

REAGENTS

HI 84500-50 Low Range Titrant (230 mL)

HI 84500-51 High Range Titrant (230 mL)

HI 84500-55 Calibration Standard (120 mL)

HI 84500-60 Acid Reagent (230 mL)

HI 84500-61 Alkaline Reagent (120 mL)

HI 84500-62 Stabilizer Packet (100 pcs.)

ELECTRODE TEST SOLUTION

HI 7021M ORP Test Solution (230 mL)

HI 7021L ORP Test Solution (500 mL)

ELECTRODE

HI 3148B ORP Electrode

ELECTRODE FILL SOLUTION

HI 7082 Electrode fill solution (4 x 30 mL)

ELECTRODE STORAGE SOLUTION

HI 70300L Electrode storage solution (500 mL)

CLEANING SOLUTION

HI 70635L Cleaning solution for wine deposits (500 mL)

HI 70636L Cleaning solution for wine stains (500 mL)

OTHER ACCESSORIES

HI 70500 Tube set with cap for titrant bottle, tip and valve

HI 71005/8 115 Vac to 12 Vdc, 800 mA

HI 71006/8 230 Vac to 12 Vdc, 800 mA

HI 731319 Stir bar (10 pcs., 25 x 7 mm)

HI 740036P Beaker 100 mL (10 pcs.)

HI 740037P Beaker 20 mL (10 pcs.)

HI 740236 5 mL Syringe for minititrator

HI 920013 PC Connection Cable

34

Page 35

WARRANTY

HI 84500 is guaranteed for two years against defects in workmanship and materials when used

for it’s intended purpose and maintained according to instructions. Electrodes and probes are

guaranteed for six months. This warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact your dealer from whom you purchased the instrument. If under

warranty, report the model number, date of purchase, serial number and the nature of the

problem. If the repair is not covered by the warranty, you will be notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods

Authorization number from the Technical Service department and then send it with shipping costs

prepaid. When shipping any instrument, make sure it is properly packed for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the

date of purchase.

RECOMMENDATION FOR USERS

Before using this product, make sure that it is entirely suitable for your specific application and for the

environment in which it is used.

Operation of this instrument may cause unacceptable interferences to other electronic equipment, this

requiring the operator to take all necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instrument’s EMC

performance.

To avoid damages or burns, do not put the instrument in microwave ovens. For your’s and the instrument’s

safety do not use or store the instrument in hazardous environments.

Hanna Instruments reserves the right to modify the design, construction or appearance of its products

without advance notice.

35

Page 36

Hanna Instruments Inc.

Highland Industrial Park

584 Park East Drive

Woonsocket, RI 02895 USA

Technical Support for Customers

Tel. (800) 426 6287

Fax (401) 765 7575

E-mail tech@hannainst.com

www.hannainst.com

Local Sales and Customer Service Office

Printed in ROMANIA

MAN84500 12/12

36

Loading...

Loading...