Page 1

Instruction Manual

HI 8001 & HI 8002

Panel-mounted and Wall-mounted

Fertigation Controllers

Manufacturers since 1978

These Instruments are in

Compliance with the CE Directives

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Product. Please read this instruction

manual carefully before using the instrument.

This manual will provide you with the necessary information for a correct use

of the instrument, as well as a precise idea of its versatility.

If you need more technical information, do not hesitate to e-mail us at

tech@hannainst.com.

These instruments are in compliance with directives.

TABLE OF CONTENTS

1 THEORY OF FUNCTION ...................................................................4

2 GENERAL DESCRIPTION ...................................................................5

3 FUNCTIONAL DESCRIPTION ........................................................ 6

3.1 Irrigation Control .................................................................... 6

3.2 Conductivity Control ............................................................... 9

3.3 Fertilization Control ................................................................ 10

3.4 pH Control ............................................................................ 10

3.5 PID Control ........................................................................... 11

3.6 Agitator Control ..................................................................... 14

3.7 Filter Control ......................................................................... 14

3.8 Manual Functions ................................................................. 14

3.9 Alarms .................................................................................. 15

3.10 Logging (Diary) Functions ...................................................... 16

3.11 Date and time controller settings ............................................ 16

3.12 Password setup ..................................................................... 16

4 USER INTERFACE ........................................................................ 17

4.1 Operating Modes ................................................................... 17

4.2 Panels Browsing Methods ....................................................... 20

4.3 Panel List .............................................................................. 20

5 PANEL DESCRIPTION ................................................................... 22

5.1 General consulting panel code ............................................... 22

5.2 Consulting Program Settings .................................................... 24

5.3 Statistics Consulting ............................................................... 34

2

Page 3

5.4 Alarms Consulting ................................................................ 37

5.5 Log Consulting ...................................................................... 37

5.6 General Settings .................................................................... 39

5.7 Program Settings .................................................................... 40

5.8 Manual Commands .............................................................. 49

5.9 Customized Settings ................................................................ 50

6 CALIBRATION PROCEDURES ........................................................ 57

6.1 Sensor Calibration Procedure .................................................. 57

6.2 PID Calibration Procedure ...................................................... 58

7 ALARMS DESCRIPTION ................................................................ 64

8 TROUBLE SHOOTING GUIDE ...................................................... 66

9 ELECTRICAL DIAGRAM .............................................................. 68

APPENDIX 1: KEYBOARD OPERATING MODES ................................. 72

APPENDIX 2: OUTLET ASSIGNMENT TABLE ...................................... 73

APPENDIX 3: GRAPHICAL REPRESENTATION .................................... 74

APPENDIX 4: LIST OF PANELS ......................................................... 77

APPENDIX 5: INSTALLATION BLOCK DIAGRAM ................................. 85

WARRANTY ................................................................................... 87

3

Page 4

1 THEORY OF FUNCTION

Irrigation is one of the most important operation in agriculture. With proper

irrigation the quality and quantity of crops can be significantly enhanced.

Correct irrigation is not a simple process: the quantity of water must be sufficient for crops, and if not, photosynthesis and overall growth is impeded.

However, if the amount of water is more than required, plant growth may

become excessive producing a taller, softer and/or damaged product.

The Fertigation Controller can control the quantity of irrigation water based

on time or volume. Different sectors can be irrigated at different times during

a day with different water quantities.

In the Fertigation Controller each irrigation program provides control of pH

and conductivity. When necessary, a specific program performs a pH correction by the introduction of an acid or base into the irrigation water. pH control

is based on multiple sensor input and a specified set point, while conductivity

control is directly related to the level of fertilization.

When the Fertigation Controller commands the addition of 1 to multiple fertilizers to the irrigation stream, conductivity sensors continually monitor the

conductivity of the stream and the overall amount of fertilization is maintained

based on a specified set point (limit). The Fertigation Controller can command the addition of multiple (1 to 4) fertilizers to irrigation water. The percentage of each fertilizer is set by the user and controlled by a specific program based on the conductivity set point.

If a pH or conductivity control problem arises, the program generates an

alarm to inform the user. All operations of both control processes are stored in

memory.

The Fertigation Controller performs all necessary operations in the monitoring

and control of irrigation and fertilization processes. These operations are conducted continuously throughout the day, month and year. To use and manage the system properly, all the necessary control values must be set (Setup

mode). During monitoring operations (Consulting mode) the user can obtain information about how the system and irrigation process are functioning,

in addition to the history of all operations for current and previous days. To

view the required information on the display or set a specific parameter, the

appropriate display panel has to be selected, as explained in this manual.

4

Page 5

2 GENERAL DESCRIPTION

The Fertigation Controller is a micro-processor-based system used in fertilization and irrigation control for greenhouses or open fields with powerful, flexible programming features.

The main function of the Fertigation Controller is supplying and controlling

the necessary water and fertilizers for crops according to several parameters

such as acidity, conductivity and received solar radiation.

The user interface is structured in two parts:

1. Consulting (numbered panels indicated by Cxx)

2. Setting (numbered panels indicated by Sxx).

This instruction manual will present the interface in 2 forms:

1. Fertigation Controller functions

2. Panel order

Fertigation Controller is capable of executing the following functions:

- Irrigation control by time or by volume

- pH control

- Conductivity control

- Fertilization control

- Irrigation adjustment due to solar radiation

- Manual correction

- Agitator control

- Filter control

- Water supply control

- Main pump control

- Sector control

- Serial communication

- Alarm function

- Logging function

5

Page 6

3 FUNCTION DESCRIPTION

In this chapter the main functions of the Fertigation Controller are presented. For

a better understanding see the typical installation schemes utilized for irrigation

and fertilization presented in the Installation Block Diagram, Appendix 5.

3.1 IRRIGATION CONTROL

The Fertigation Controller can control 8 to 32 sectors (one valve per sector) for

each of the ten irrigation programs:

- 1 to 32 valves (sectors) can be selected specifying the sector’s number and

the desired value of irrigation time or volume for a specified irrigation

program-using Panel S 38 (SET SECTORS). The panel displays the num-

ber of set sectors for the respective irrigation program

- The current status, set value plus irrigation extension and “Done” time/

volume value for the selected irrigation program/sector are shown on Panel

C 14 (SECTOR STATE).

Irrigation can be controlled by time or volume – irrigation control mode can be

switched between time and volume using panel S 53 (IRRIG CTRL MODE).

Each irrigation program can be started by:

TIME:

- 1 to 6 different timetables (values) per program can be set using panel S 35

(SET START TIME). “Start cond” must be the selected option on panel S 34

(START CONDITION).

ACCUMULATED SOLAR RADIATION:

- A Solar Radiation set point can be established for starting each program

- The accumulated solar radiation level can be used as a starting condition

for each program

- There are 3 parameters used to start a program by solar radiation:

- The solar radiation sensor threshold value can be established for each

irrigation program. When the solar radiation measured value exceeds the

sensor threshold value the accumulated solar radiation value is increased.

This parameter can be modified on panel S 43 (Level: xxxxW/m2).

- The accumulated solar radiation value is used to keep track of the measured solar radiation level during the time interval determined by the previous start moment of the irrigation program and the actual moment. This

parameter can be seen on panel S 06 (Irrig = xxxxWh/m2).

6

Page 7

- The accumulated solar radiation starting level value is used as a threshold

value for the accumulated solar radiation. When the accumulated solar

radiation value exceeds this threshold level the irrigation program is started

(or it is brought in READY state if there are other programs currently running at that moment). This parameter can be modified on panel S 43 (Acc

= xxxx Wh/m2) and can be seen also on panel C 06 (Acc = xxxxWh/m2)

EXTERNAL TANK LEVEL:

- One external tank (level indication) can be assigned to each irrigation

program, that can start the specified irrigation program – this option is set

using panel S 34 (START CONDITION).

MANUAL ACTIVATION:

- A program can be started using panel S 47 (PROG MAN START)

- A program can be stopped using panel S 48 (PROG MAN STOP)

Each irrigation program can be repeated a specified number of times. The number of repetitions as well as pause time between two repetitions can be specified

using panel S 36 (PROGRAM REPEATS).

Each irrigation program can be given a priority in relation to others (5 priority

levels). Priorities and maximum open sectors per group can be specified for

each program and can be set using panel S 33 (SET PRIORITY).

Below we present the setting requirements for each irrigation program:

THE WORKING PERIOD :

- (between start date (day/month) and end date (day/month)) – use panel S

31 (ACTIVE TIMETABLE). For more details see Appendix 3.

THE WORKING TIME DURING A DAY:

- (between start time and end time) – use panel S 31 (ACTIVE TIMETABLE).

For more details see Appendix 3.

THE CYCLE WORK/ REST DAY:

- can be set using panel S 32 (WORKDAY).

For more details see Appendix 3.

THE WORKING DAYS IN A WEEK:

- use panel S 32 (WORKDAY). For more details see Appendix 3.

Working time status for each irrigation program, if selected (irrigation program is

in work period of year, day and week) is displayed in panel C 08 (WORK TIME

COND).

The percent of irrigation time or set volume can be automatically modified by the

following factors:

7

Page 8

SOLAR RADIATION FACTOR:

- This option can be set using panel S 42 (CORRECTIONS). This factor

affects the irrigation time or volume extension in accordance with the set

value of the solar radiation sensor level and solar radiation accumulation.

The solar radiation accumulation extension setting and current value is

displayed on panel C 06 (SOLAR RAD IRRIG). Solar radiation extension

correction can be viewed using panel C 11 (SOL RAD EXTENT).

MANUAL FACTOR:

- This option can be set using panel S 42 (CORRECTIONS). Percentage

and corresponding value of time or volume can be viewed using panel C

12 (MAN FACTOR).

Total correction percentage, time or volume value is displayed on panel C 13

(TOTAL CORRECTION).

PRE/POST IRRIGATION:

In each irrigation program the pre-irrigation and post-irrigation time or volume

value (used to clean the irrigation pipes with pre-irrigation water) can be set

using panel S 37 (PRE/POST IRRIG).

Panel C 01 (GENERAL INFO) displays the active irrigation program and active

sectors.

The active irrigation program is displayed on panel C 02 (SENSORS STATE).

Related data regarding the active irrigation program (active irrigation program

number, last start condition and current / set repetition number) are displayed on

panel C 03 (PROGRAM STATE).

Information about selected irrigation program, priority and irrigation program

conflict are displayed on panel C 09 (PRIOR & CONFLICTS). Set value data,

correction value and irrigation completion (“Done”) value are displayed on

panel C 10 (IRRIG STATE).

Information about the last start condition, date and time are displayed on panel

C 18 (PROG LAST START).

Total accumulation value from a previous date is displayed on panel C 19

(TOTAL ACCUMUL).

Accumulation value from previous date and activation number for a selected

irrigation program are displayed on panel C 20 (PROGRAM ACCUMUL).

Accumulation value from previous date, for a selected sector, is displayed on

panel C 21 (SECTOR ACCUMUL). In addition, this panel displays the valve

number assigned with the corresponding sector.

- Accumulations erase mode can be chosen on panel S 61 (ERASE STATISTICS). The accumulation erase can be performed for all programs and

8

Page 9

sectors using one of the following ways:

- Manually

- Every day at specified hour

- Automatically when the accumulations counter value overflows

3.2 CONDUCTIVITY CONTROL

Conductivity control is used to control the fertilization and a reading can be

obtained with one to three conductivity sensors, one to two for fertilization control

and one for water supply conductivity control.

When using two conductivity sensors, the second for safety, the maximal admissible difference between these two sensors can be set using panel S 55 (SENSORS CONFIG).

A third conductivity sensor can be used to measure the conductivity of the water

supply.

Conductivity sensor (S1 main, S2 second and S-for water input) status and

conductivity reference are displayed on panel C 05 (EC STATE). In addition, the

main conductivity sensor value is displayed on panels C 01 (GENERAL INFO)

and C 02 (SENSORS STATE);

Solar radiation accumulation setting and current value for conductivity reference

correction is displayed on panel C 07 (SOLAR RAD FERT).

The conductivity control is made in accordance with a preset conductivity reference value, specific for each irrigation program. In addition, the conductivity

reference has a minimum offset and maximum offset. The reference value, minimum and maximum offset can be set using panel S 41 (COND CONTROL).

When the conductivity is not within the specified range for a period of time (more

than the time specified) or the difference between the 2 primary conductivity

sensors is greater than the specified difference, the conductivity control will generate a conductivity alarm . Specified difference can be set using panel S 55

(SENSORS CONFIG). The conductivity alarm threshold can be set using panel

S 41 (COND CONTROL). “EC Out of Range”-the conductivity alarm can also

be generated when the EC IN sensor’s value exceeds the specified EC sensor

difference.

Given a conductivity alarm condition, conductivity control can be maintained if

“Ctrl on EC alarm” is selected using panel number S 52 (ALARM BEHAVIOR).

Statistical values of total conductivity are displayed on panel C 22 (TOTAL AVERAGES). For each irrigation program’s conductivity average see panel C 23

(PROGRAM AVERAGES) and for each individual sector’s conductivity average

see panel C 24 (SECTOR AVERAGES).

9

Page 10

3.3 FERTILIZATION CONTROL

Fertigation Controller can use up to 4 fertilizer tanks.

Each irrigation program can specify the percentage for each type of fertilizer.

These values can be set using panel S 39 (SET FERTILIZERS).

The fertilization is done in accordance with the conductivity control. Each irriga-

tion program has a specified conductivity target value (conductivity reference

value which is set using panel S 41 (COND CONTROL);

The percent of applied fertilization can be automatically modified with respect to

an amount of solar energy accumulated since the previous application. The

current fertilizer status (set and current percentage value) can be checked on

panel C 16 (FERTILIZ STATE).

3.4 pH CONTROL

The pH control is necessary to correct and maintain the pH of irrigation water

within specified values (min and max offset values). Minimum and maximum

offset values are set using panel S 40 (pH CONTROL). To choose between acid

or alkaline correction you must go to panel C 51 (pH CTRL OPTIONS). In this

panel you can also select pH correction in pre/post irrigation.

The pH correction is made in accordance with a selected pH reference value

specific for each irrigation program. This value can be set using panel S 40 (pH

CONTROL).

pH control is made with two pH sensors for additional safety and accuracy.

Current status of sensors (main and secondary) in addition to the reference value

is displayed on panel C 04 (pH STATE).

Main pH sensor value is displayed on panel C 01 (GENERAL INFO) and C 02

(SENSORS STATE)

When the pH is not within the specified range for a period of time (more than

the time specified) or the difference between the 2 pH sensors (main and secondary) is greater than the specified difference the pH control will generate a pH

alarm. The specified difference can be set using panel S 55 (SENSORS CONFIG).

The pH alarm threshold can be set using panel S 40 (PH CONTROL).

Given a pH alarm condition, the pH control can be maintained if “Ctrl on PH

alarm” is selected using panel number S 52 (ALARM BEHAVIOR).

Given a pH alarm condition, the irrigation can be maintained if “Irrig on PH

alarm” is selected using panel number S 52 (ALARM BEHAVIOR).

Statistical values of pH are displayed on panel C 22 (TOTAL AVERAGES). For

each irrigation program’s pH average see panel C 23 (PROGRAM AVER-

10

Page 11

AGES). For each individual sector’s pH average see panel C 24 (SECTOR

AVERAGES). All pH averages can be deleted manually or at specified time of

day using panel S 61 (ERASE STATISTICS).

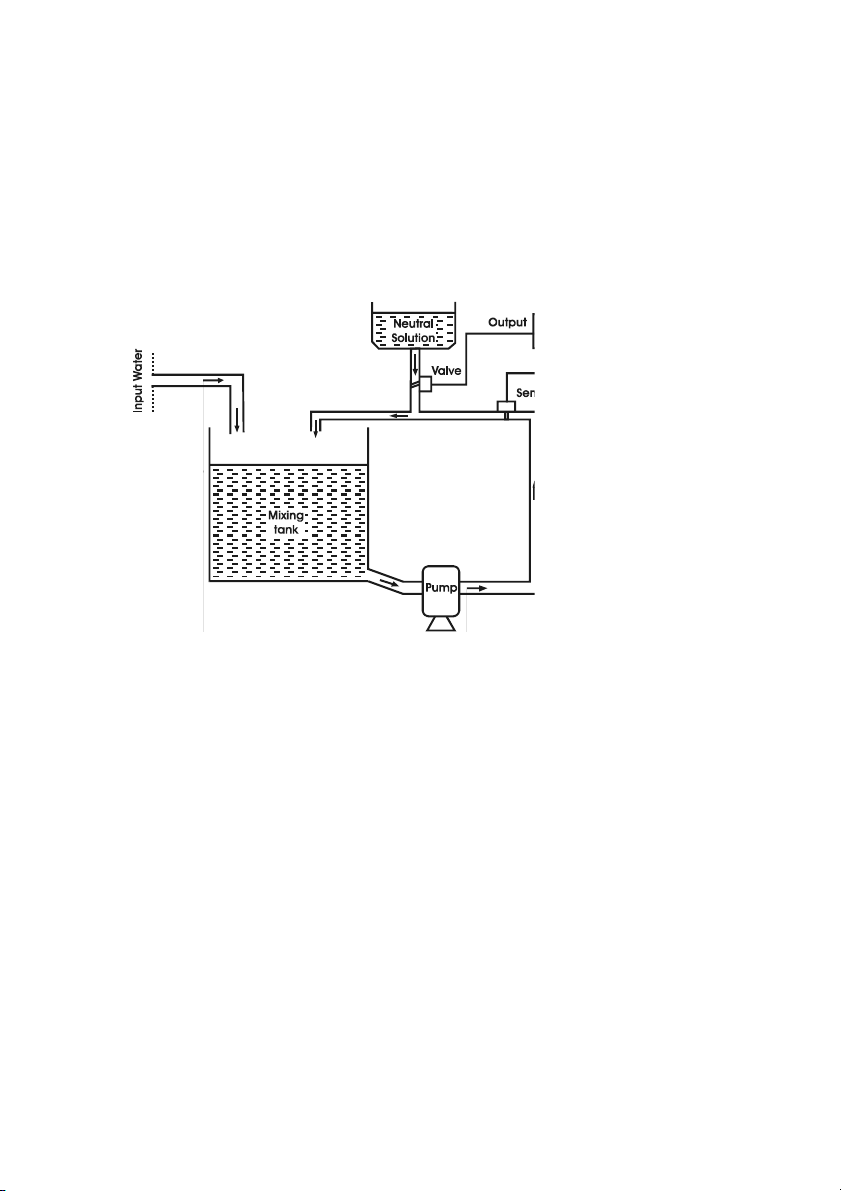

3.5 PID CONTROL

A simplified schematic of the control (pH and EC):

EC and pH control is performed using an automatic regulated system with PID

controller (Proportional, Integral and Derivative). The role of this controller is to

maintain a set pH and EC value within a mixing tank prior and during distribution (see diagram). The control of pH and EC is made separately.

The components are as follows:

- The mixing tank where the influent and additives are combined

- The neutral (additive) solution tank containing an acid, base or fertilizer

- The valve for introducing the additive solution into the mixing tank con-

trolled by the PID controller

- PID Controller

- The input (influent) water source

- The pump for pumping water from the tank to the irrigation sectors

The Fertigation Controller automatically provides a command output signal to a

control element such as a pump or valve based on a sensor input signal. The

function of the Fertigation Controller is to proportionally control the pH and EC

of the process at a specified set point. The above output signal commands the

11

Page 12

12

Page 13

opening and closing of a valve through which a neutral solution is circulated.

The amount of neutral solution added is relative to the opening of the valve,

which is directly proportional to the magnitude of difference between the mixing

tank pH and the set point.

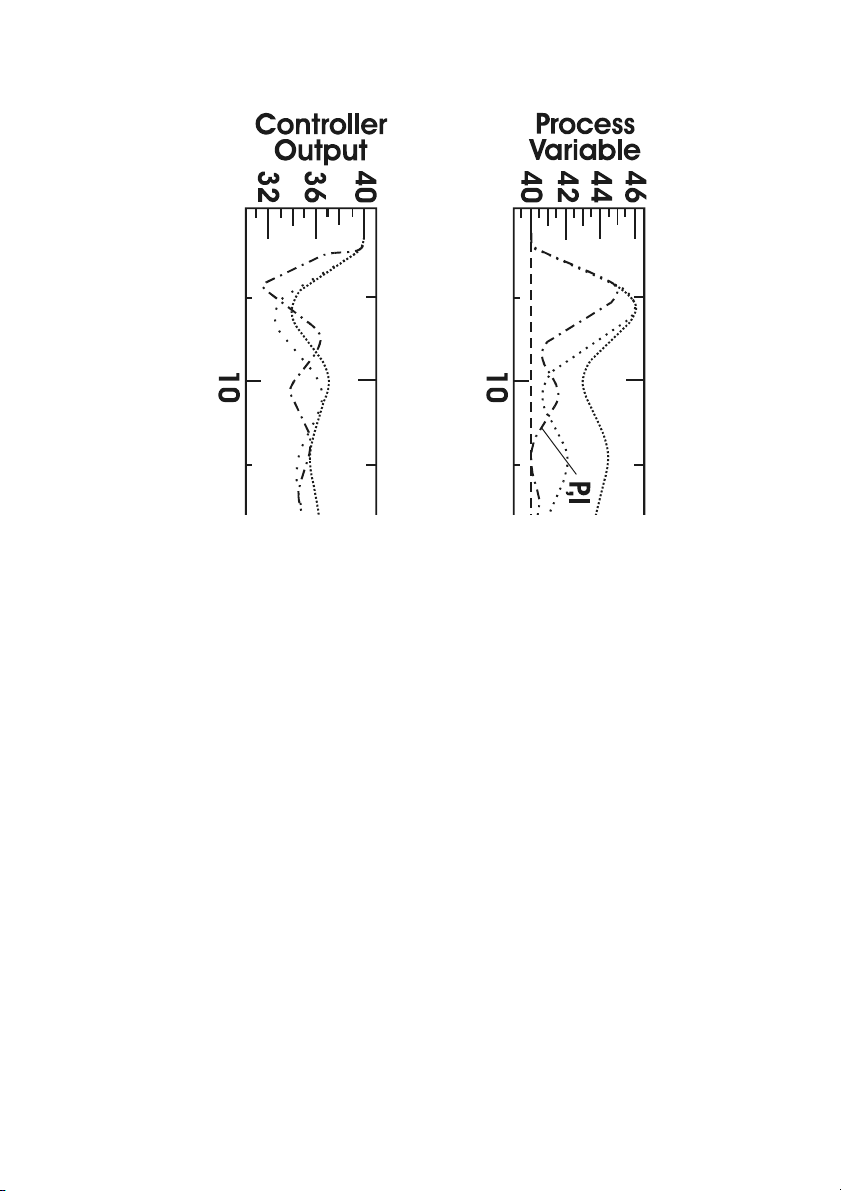

Control of pH implies a complex adjustment. The relation between the added

reagent and the process pH is logarithmic. There is the possibility to introduce

large errors in the process due to over dosing or under dosing reagent creating

an oscillation effect. PID control can be used to reduce the possibility of overshoot and large oscillations in the process by creating control output proportional to the magnitude of deviation from the set point (P), time integral of error

(I), and rate of change of the measurement (D). Proportional, Integral, and

Derivative (PID) control can be used individually (typically Proportional control

only) or in combination such as PI, PD or PID. How these control actions are

used depends upon the requirements of the process.

Set point (reference value) is the desired value of the measurement. The error is

defined as the difference between the set point and measurement:

Error = Setpoint – Measurement

The descriptions and definitions of the individual control actions are as follows:

PROPORTIONAL ACTION (P):

The simplest continuous control mode is proportional control, so called because

the controller output is proportional to the magnitude of error. However, the

proportional control is subject to one major limitation, steady state offset (steady

deviation from the set point). Increasing the sensitivity of the controller (controller gain) can reduce the steady state offset but only with slow processes. For this

reason the proportional control by itself it is used primarily for slow, consistent

processes that can tolerate high controller gain, which minimizes the steady state

offset. Consequently, high gain control action can throw the process into oscillation if the process variable becomes unstable and begins to change rapidly.

INTEGRAL ACTION (I):

To eliminate offset droop and tighten the control of the process, the integral

action is introduced in conjunction with proportional control (PI). Integral control produces control action proportional to the time integral of the error. As

long as the error exists (steady deviation from the set point), the integral term will

continue to increase, adding more control action, driving the error toward zero.

DERIVATIVE ACTION (D):

With derivative action, the controller output is proportional to the rate of change

of the measurement and is primarily used to avoid overshoots. Derivative action

13

Page 14

can compensate for changes in the process variable (measurement) and is particularly good for slowly moving processes. When a change occurs in the process the derivative action causes the controller gain to move the “wrong” way

until the measurement gets near the set point.

3.6 AGITATOR CONTROL

Each of the 4 fertilizer tanks may have an agitator.

An agitator can be activated in a specific tank prior to tank selection by an

irrigation program. The pre-agitation time can be set using panel S 45 (SET

AGITATORS); the pre-agitation occurs only when the pre-irrigation time is set.

During the irrigation program, the agitators can be stopped (if working time is

zero), set to work continuously (if pause time is zero) and intermittently (if working

time and pause is different than zero).

The work and pause time can be set using panel S 45 (SET AGITATORS).

The agitator settings are displayed on panel C 17 (AGITATOR STATE).

3.7 FILTER CONTROL

Fertigation Controller has the capability to check and automatically clean two

filters controlled by two filter-cleaning programs.

Each filter cleaning program can be started by the following conditions:

- Following one specified irrigation program. This irrigation program can

be set in panel S 46 (FILTERS CTRL).

- When a “dirty filter” alarm is activated. Cleaning by this option is set using

panel S 46 (FILTERS CTRL).

- The working time for filter-cleaning programs can be set using panel S 46

(FILTERS CTRL).

3.8 MANUAL FUNCTIONS

The Fertigation Controller has the following Manual function capabilities:

- To switch the controller state between STOP, WORK and INIT, use panel S

49 (CONTROLLER STATE).

- The controller state can be checked using panel C 01 (GENERAL INFO).

- To manually start a program use panel S 47 (PROG MAN START).

- To manually stop a program use panel S 48 (PROG MAN STOP).

- To check and to change the value for each of the outputs, use panel S 50

(OUTLET MAN CTRL).

14

Page 15

- To erase all statistics, use panel S 61 (ERASE STATISTICS). Statistics indicates pH and conductivity averages for all irrigation programs and sectors

in addition to average total irrigation accumulation.

- To erase the settings of one irrigation program or to erase all settings for all

irrigation programs, use panel S 62 (ERASE SETTINGS).

3.9 ALARMS

The Fertigation Controller has the capability to supervise and generate an alarm

for the following conditions:

- Conductivity sensor out of range. Reference, minimal and maximal offset

and threshold for conductivity alarm are set using panel S 41 (COND

CONTROL). The current values of conductivity sensors are displayed on

panel C 05 (EC STATE)

- A difference greater than the set value between the first and second conductivity sensors; Maximum value of difference is set using panel S 55

(SENSORS CONFIG)

- pH sensor out of range. The reference, minimum and maximum offset and

threshold for pH alarm are set using panel S 40 (PH CONTROL). The

current values of pH sensors are displayed on panel C 04 (pH STATE)

- A difference greater than the set value between pH sensors; the maximum

difference value is set using panel S 55 (SENSORS CONFIG)

- Problems with the water supply

- Dirty filters

When the level is low in the fertilizer and acid tanks the system will take appropriate action and record the alarm. These actions can be:

- in case of a pH alarm condition, the irrigation process can be suspended

or continued depending on the choice set within panel S 52 (ALARM

BEHAVIOR) depending on the choice set within.

- in case of an EC alarm condition, the irrigation process can be suspended

or continued depending on the choice set within panel S 52 (ALARM

BEHAVIOR) depending on the choice set within.

- in case of a dirty filter alarm condition, start the filter cleaning program in

accordance with the priority and working time settings

- in case of a water supply alarm situation, the Controller will stop every

irrigation process until the alarm is shot off.

All alarm situations are displayed on panel C 25 (ALARM).

All anomalies (old alarm conditions) are displayed on panel C 27 (ANOMALY).

15

Page 16

3.10 LOGGING FUNCTIONS

The Fertigation Controller has the capability to log the most important occurred

events and values of different parameters that can offer a description of the

evolution of the entire process;

The most important values are:

- Number and time period of every program activation;

- Filter cleaning;

- Averages of pH and conductivity;

- Accumulations;

- Modifications to preset fertilization values (e.g. manual, solar radiation);

- Alarms;

The logging level for recording and consulting can be set using panel S 59 (SET

LOG LEVELS).

The date of desired logging records can be set using panel C 26 (VIEW LOG

DATE).

The logging records are displayed on panel C 28 (LOG).

The selectable log recording/consulting levels range from 1 to 3. They are as-

signed as it follows:

Level 1: - records the sensors deviations events

Level 2: - records statistics (pH and EC averages, accumulations)

Level 3: - records programs and controller status events.

3.11 DATE AND TIME CONTROLLER SETTINGS

The controller date and time can be checked on panel C 01 (GENERAL INFO)

and can be set using panel S 30 (SET DATE & TIME).

3.12 PASSWORD SETUP

The access to Fertigation Controller can be protected by a password. This password can be set using panel S 60 (SET PASSWORD), also this password can be

disabled using the same panel.

16

Page 17

4 USER INTERFACE

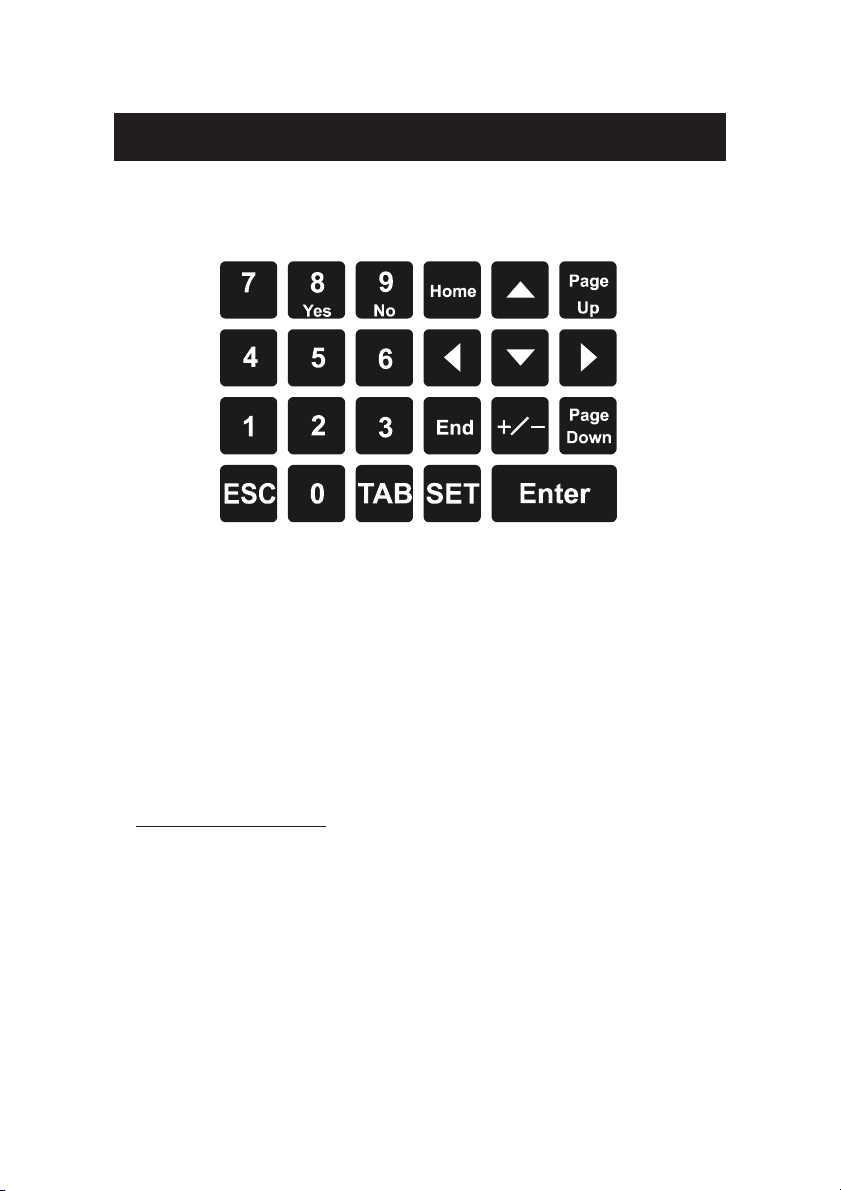

The Fertigation Controller’s user interface consists of a 4 x 20 character LCD

and a 23-key keyboard.

Keyboard structure.

4.1 OPERATING MODES

The Fertigation Controller operates primarily in two major modes:

Consulting Mode Setting Mode

User interface panels (screens) are broken down into two categories:

1. CONSULTING PANELS

2. SETTING PANELS

Both modes of operation are readily available to the user.

1. CONSULTING MODE

The consulting mode allows the user to view the current state and set the conditions of the Fertigation Controller. The setting panels are in consulting mode

until the SET key is pressed. The primary consulting screens are designated from

C 01 through C 29. The following outline highlights the functions of the consulting mode.

- 2 browsing methods are enabled. See Section 4.2 “PANEL BROWSING

METHODS”.

- UP and DOWN ARROWS KEYS can be used to switch the panel index

(where available) allowing user to view the same kind of data assigned to

17

Page 18

different controller entities (programs, sectors, fertilizers etc.) within the same

panel.

- LEFT and RIGHT ARROWS KEYS can be used to move the cursor within

the selected parameter’s limits.

- ESC key can be used as a shortcut key to access the C 03 (PROGRAM

STATE) panel from any currently viewed panel.

- HOME key can be used as a shortcut key to access the C 01 (GENERAL

INFO) panel from any currently viewed panel.

- END key can be used as a shortcut key to access the S 48 (PROG MAN

STOP) panel from any currently viewed panel.

- TAB key can be used to switch the focus between the panel number object

and the panels index parameter if the current panel is indexed. If there is no

index parameter present on the current panel, the TAB key has no effect.

Panels are typically indexed by the program number. For example, panel

C 03 (PROGRAM STATE) displays the current state for each program.

Once panel C 03 is selected and the TAB key pressed, the focus (cursor) is

shifted from the panel number to the program number “Prog 01”. The

ARROW KEYS can now be used to scroll through each program state

consecutively without leaving the panel.

- ENTER key is used to confirm any new values entered in any of the selected

panels. This is only possible if data items on a panel (screen) are selectable.

2. SETTING MODE

The setting mode allows configuration of all the adjustable parameters of the

Fertigation Controller. The setting screens are designated from S 30 to S 62.

These panels can be viewed by one of 2 browsing methods. Selecting the appropriate screen and pressing the SET key initiates the setting mode. Once the

setting mode is entered both panel-browsing methods are disabled and navigation is allowed only within the currently selected panel. The following outline

highlights the functions of the Setting Mode.

- Both panel (screen) browsing methods are disabled. See Section 4.2 “PANEL

BROWSING METHODS”.

- Focus (cursor location) is automatically shifted to the first editable data

object on the selected panel.

- UP, DOWN arrow keys allow navigation between all editable data objects

within the current panel.

18

Page 19

- LEFT, RIGHT arrow keys allow navigation within the currently focused

data object. If the cursor exceeds the boundaries of the data object then the

focus is transferred to the previous or next editable item within the current

panel.

- TAB key can be used to move only in a forward direction, from one data

object to the next within the selected panel.

- ENTER key confirms all the data entered in a current panel. Once the

ENTER key is pressed and data confirmed, the controller reverts to consult-

ing mode. The SET key must be pressed to reenter the setting mode.

- ESC key cancels new data entered in the currently focused data object

and exits the setting mode. The change of data is not saved in the current

object and the previous setting is maintained.

19

Page 20

4.2 PANEL BROWSING METHODS

In consulting mode, two browsing methods are available to view each of the 62

panels (screens) of the Fertigation Controller.

- Step-by-step browsing: pressing the PAGE UP and PAGE DOWN keys

allow consecutive navigation from one panel to the next. The direction is

dependent upon which key is selected.

- Direct access browsing: the number of the desired panel can be entered

directly using the panel number located on the bottom right corner of every

panel, prefixed by a C or S. The panel number object is the initially focused

object on each screen. After entering the value by using the keypad and

ARROW KEYS, press the ENTER key to view the selected panel.

NOTE: If a panel is selected and the SET key is pressed entering the setting

mode, both browsing methods are disabled.

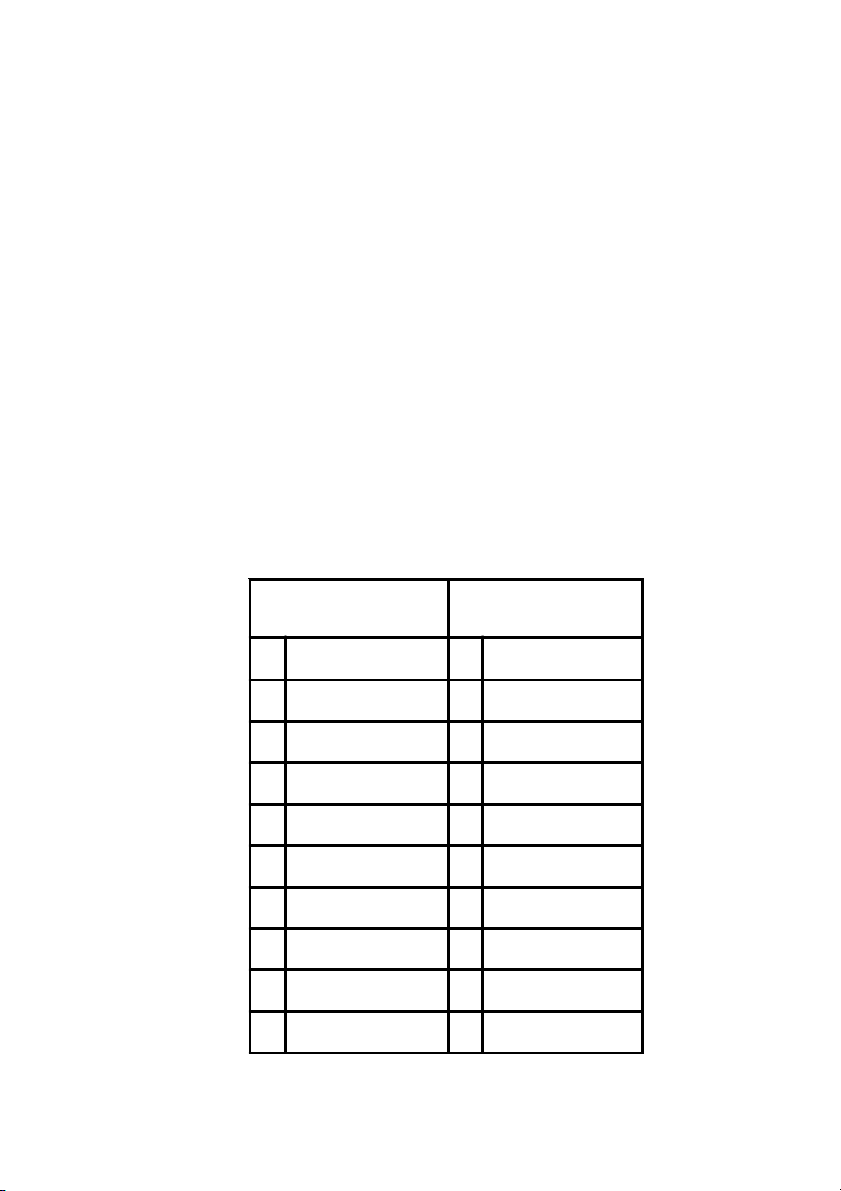

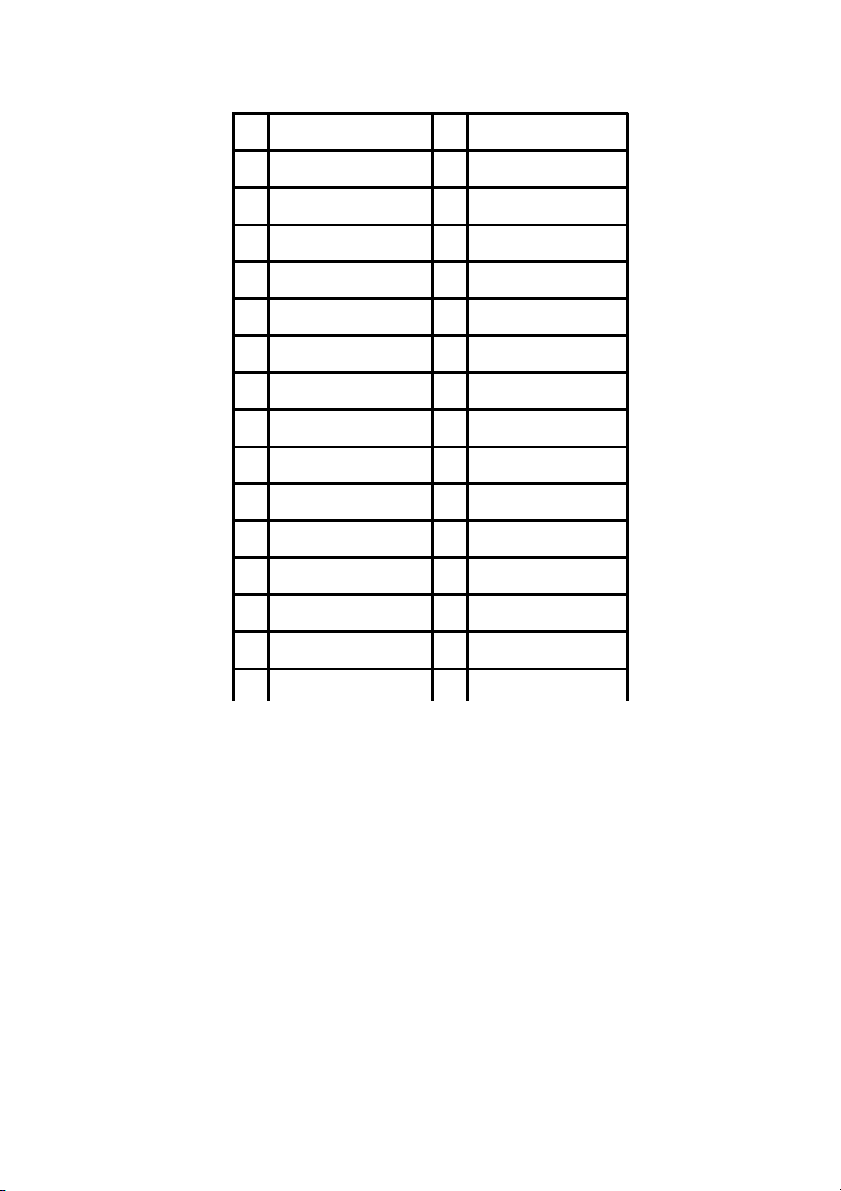

4.3 PANEL LIST

PANEL TABLE

CONSULTING PANELS SETTING PANELS

01 GENERAL INFO 30 SET DATE & TIME

02 SENSORS STATE 31 ACTIVE TIMETABLE

03 PROGRAM STATE 32 WORKDAY

04 PH STATE 33 SET PRIORITY

05 EC STATE 34 START CONDITION

06 SOLAR RAD IRRIG 35 SET START TIME

07 - 36 PROGRAM REPEATS

08 WORK TIME COND 37 PRE / POST IRRIG

09 PRIOR & CONFL ICTS 38 SET SE CTORS

10 IRRIG STATE 39 SET FERTILIZERS

20

Page 21

11 SOL RAD EXTENS 40 PH CONTROL

12 MAN CORRECTION 41 COND CONTROL

13 TOTAL CORRECTION 42 CORRECTIONS

14 SECTOR STATE 43 SOLAR RAD IRRIG

15 - 44 -

16 FERTILIZ STATE 45 SET AGITATORS

17 AGITATOR STATE 46 FIL TERS CTRL

18 PROG LAST START 47 PROG MAN START

19 TOTAL ACCUMUL 48 PROG MAN STOP

20 PROGRAM ACCUMUL 49 CONTROLLER STATE

21 S ECTOR A CCUMUL 50 OUTL ET MAN CTRL

22 TOTAL AVERAGES 51 PH CTRL OPTIONS

23 PROGRAM AVERAGES 52 ALARM BEHAVIOR

24 SECTOR AVERAGES 53 IRRIG CTRL MODE

25 ALARM 54 CALIBRATE SENSOR

26 VIEW LOG DATE 55 SENSORS CONFIG

NOTE: Data that has been changed in an editable data object is saved once

focus has been removed from that object by pressing the ARROW KEYS

or TAB .

21

Page 22

5 PANEL DESCRIPTION

5.1 GENERAL CONSULTING

The following panels C 01 through C 29 are for the general consulting of

controller settings and current measurements. The data objects within each

panel are described from left to right unless otherwise specified.

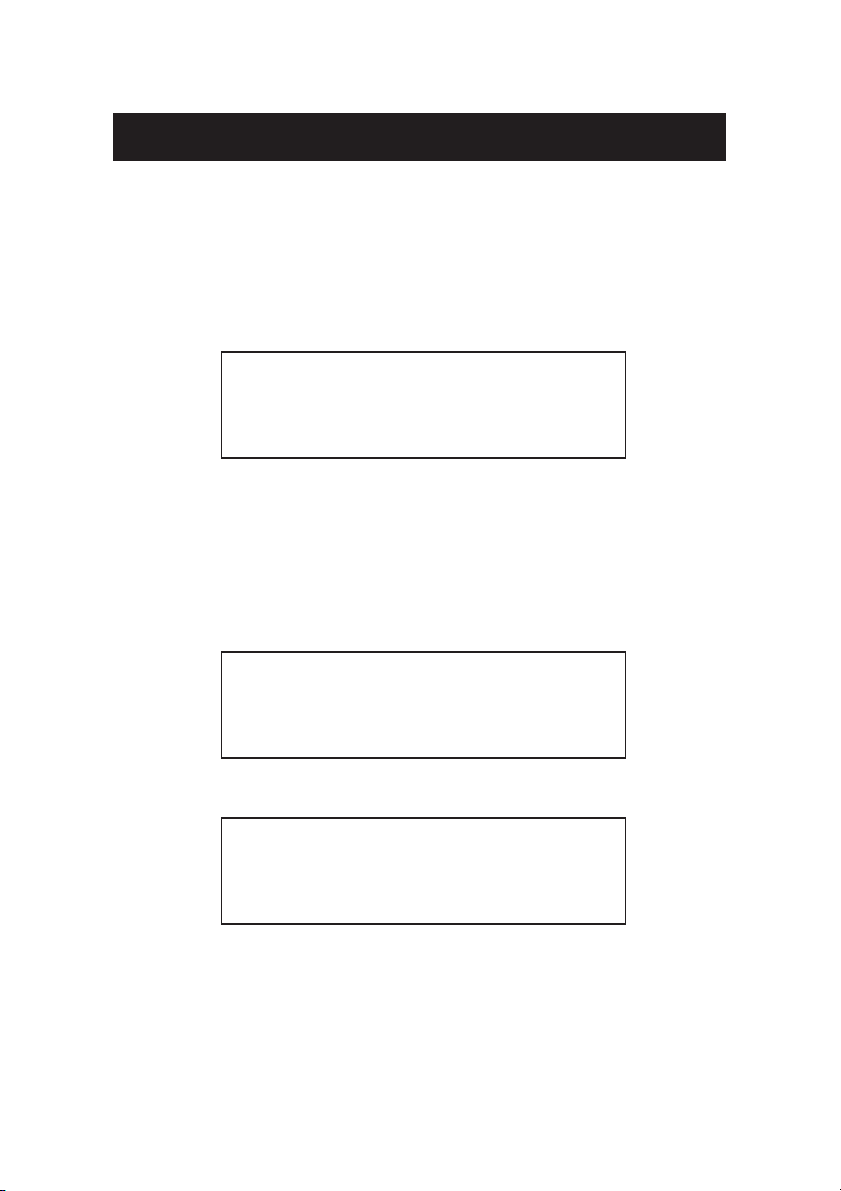

5.1.1 INITIALIZATION PANEL

HANNA INSTRUMENTS

F1 CONTROLLER V0.90

INITIALIZATION

Loading String Table

This panel is shown during the Fertigation Controller Initialization state; it contains the HANNA INSTRUMENTS logo, the name of the controller and the

software version. The last line is used to display the current status of the initialization sequence. This panel is also used to display any possible errors that may

occur during the start up sequence.

5.1.2 START PANEL

HANNA INSTRUMENTS

F1 CONTROLLER

Fri 15-03-2000 13:15

STOP Press ENTER

5.1.3 INPUT PASSWORD PANEL

Enter password

****

This panel is displayed during the password authentication sequence. If this

sequence fails, the user will be logged out and the START panel will be displayed.

If the password is correct panel C 01 (GENERAL INFO) is displayed. The default password is 0000. See section 6.9.10 (Setting Password, S 60) for instructions on setting this feature.

22

Page 23

Although access to the controllers features are denied, the functionality of the

controller is not directly effected if a password authentication sequence fails.

5.1.4 GENERAL INFO – C 01

WORK Anomalies 00

Prog 08 06.4pH

Sect 07 02.1mS 13:15

GENERAL INFO C01

This panel displays the following information starting from top left:

Fertigation Controller Functional State (top left corner)

When the controller is running it can be in one of the following states:

INITIALIZATION, STOP, WORK, BLOCK. When the Fertigation Controller is

first powered on the first state is INITIALIZATION. In this state the unit

performs internal tests. In STOP state all programs are suspended. Under

normal conditions the functional state is WORK. In the WORK state all

irrigation and fertilization programs are executed. If an alarm occurs the

Fertigation Controller enters the BLOCK state until the alarm condition is

corrected. The user can customize the alarm management system behavior

using setting panels S 40, S 41 (pH and EC CONTROL) and panel S 52

(ALARM BEHAVIOR).

Anomalies (top right corner)

The anomalies counter represents the number of alarms triggered since

the last reset of the counter. This counter can be customized and cleared

along with all system statistics via setting panel S 61 (ERASE STATISTICS).

Program Number

Reflects the selected program (can be selected only inside panel C 03). If

no program is active a number is not visible.

pH sensor reading

Current (main) pH sensor reading.

Sector Numbers

All sectors assigned to the active program are displayed (cyclically) but

only when an active program is running. If a program is not active the

number is not visible.

EC sensor reading

Current (main) EC sensor reading.

System clock

If an alarm condition is present the time indication will also flash “ALARM”

to alert the user.

23

Page 24

NOTE:

- If the user is logged in and the operational mode is CONSULTING MODE,

this panel can be accessed anytime and from any panel using the HOME key

as a shortcut.

- The Real Time Clock, pH and EC sensors are always visible regardless of

state.

- Whenever the Fertigation Controller is connected to a PC that runs the specific

application of the fertigation controller on PC in “ON LINE” mode, this

panel displays the label “PCCom” above the controller clock position. In this

case the Fertigation Controller’s keyboard is disabled until the connection is

lost due to different reasons.

5.1.5 SENSORS STATE – C 02

Active Program: 04

06.3pH 1200W/m2

06.4mS 13:15

SENSORS STATE C02

This panel provides an overview of the real time values of the system’s main

sensors. This panel contains the following information:

Active program number

Displays the number of the executing program. If no program is running a

number is not displayed.

pH sensor reading

Solar Radiation sensor reading

EC sensor reading

System clock

5.2 CONSULTING PROGRAM SETTINGS

The following panels allow viewing the program setting of the Fertigation Controller. The program number can be changed only in C 03 with the UP and

DOWN keys. In addition, the TAB key can be used only in C 03 to toggle the

cursor (focus) between the panel number and the program number. The desired

program number can then be entered directly by using the keypad.

24

Page 25

5.2.1 PROGRAM STATE – C 03

PROG 08 ACTIVE

Started by Solar Rad

Repeat 02/05 13:15

PROGRAM STATE C03

The purpose of this panel is to allow the user to inspect the status and settings of

a particular program. The program number indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Program State

During the lifetime of a program it cycles through several states. Each

program is initially in NO SET state which means no settings have been

applied to the program by the user. Once the settings have been applied

the program is considered in SET state. Once a specific condition such as

start time is met the program passes to READY state to await execution.

Once the program reaches the highest priority and the start time is met, the

program passes to ACTIVE state and executes. The program may be suspended and placed in WAIT state due to a higher priority program moving

to ACTIVE state or a specific alarm condition triggering. When a program

completes execution it is placed in FINISHED state. The cycle may be

repeated and the program returned to ready state if the program repeats

were specified after a set delay period.

Program Started by

Displays how the last program start was triggered. Programs can be started

by a met time condition, solar radiation level, manual start, low level in

external tank, or directly after the completion of another program. If the

program is in NO SET (no settings applied to program) or in SET (settings

applied but conditions not met) state, “Started by” is blank.

Repeat

Displays the current repetition followed by (/) the maximum number of the

programmed repetitions.

System clock

25

Page 26

REMINDER: In CONSULTING MODE the ESC key can be used as a short-

cut key to access this panel from any panel.

5.2.2 PH STATE – C 04

Prog 08 Ref=06.4pH

S1=05.4PH

S2=05.5PH 13:15

PH STATE C04

The purpose of this panel is to allow the user to inspect the current pH reference

point for a specific program and the real time pH sensor readings. The program

number indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Ref = Reference or set point pH value for the specified program.

S1 = Real time value of pH sensor 1. This reading applies to the entire process

and is not program specific.

S2 = Real time value of pH sensor 2. This reading applies to the entire process

and is not program specific.

System clock

5.2.3 EC STATE – C 05

Prog 08 Ref=02.0mS

S1=02.0mS SIn=03.2mS

S2=02.1mS 13:15

EC STATE C05

The purpose of this panel is to allow the user to inspect the current EC reference

point for a specific program and the real time EC sensor readings. The program

number indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Ref = Reference or set point EC value for the specified program.

S1 = Real time value of EC sensor 1. This reading applies to the entire process

and is not program specific.

S2 = Real time value of EC sensor 2. This reading applies to the entire process

26

Page 27

and is not program specific.

S in = Real time value of EC input sensor. This is an option sensor input to

measure the conductivity of the incoming water supply. This reading applies to

the entire process and is not program specific.

System clock

5.2.4 SOLAR RAD IRRIG – C 06

Prog 08

Irrig=0720Wh/m2

Acc=0720Wh/m2 13:15

SOLAR RAD IRRIG C06

This panel displays the solar radiation irrigation settings. Due to the effects of

solar radiation it may be necessary to augment (correct) the irrigation process

accordingly. The program number indexes this panel. This panel contains the

following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Irrig = The set level of accumulated solar radiation used for irrigation correction. This is a set point. Radiation beyond this limit will trigger a correction to the

irrigation process.

Acc = Real time value of accumulated solar radiation.

System clock

5.2.5 WORK TIME COND – C 08

Prog 08 Time Y

Day Y

Period Y 13:15

WORK TIME COND C08

The program number indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Time

Indicates if the selected program is set to run on a time schedule.

27

Page 28

Day

Indicates if the selected program is set to run on a daily schedule.

Period

Indicates if the selected program is set to run on a yearly schedule.

System clock

5.2.6 PRIOR & CONFLICTS – C 09

Prog 08 Priority 05

Conflict Programs 02

13:15

PRIOR & CONFLICTS C09

This panel indicates the priority level of the indexed program. Priority settings

play a roll in program execution when two or more programs have similar starting conditions. The priority for a given program can be set using panel S 33

(SET PRIORITY). The Conflict Programs counter displays cyclically all programs

that are in conflict with the currently active program. Programs can be in conflict

if their specific start and running conditions are synchronous. Given this scenario, the program that has the highest priority will become active.

The program number indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Priority

Displays priority of indexed program.

Conflict Programs

Cyclically displays the program number of programs in conflict with the

currently active program.

System clock

5.2.7 IRRIG STATE – C 10

Prog 08 IRRIG

Set 01:15:20+005:55

Done 00:45:10 13:15

IRRIG STATE C10

28

Page 29

This panel displays the current irrigation state of the indexed program. Time or

volume can control irrigation and the above panel displays the set value and the

amount of irrigation currently completed. The mode of irrigation (time or volume) can be selected using panel S 53 (IRRIG CTRL MODE). The program

number indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Set

Displays the required (set) value of irrigation in time or volume.

Irrigation correction value

(number directly following the Set value)

Done

Displays the current point of irrigation in time or volume.

System clock

5.2.8 SOL RAD EXTENT – C 11

Prog 08

+010%

+00:05:55 13:15

SOL RAD EXTENT C11

This panel displays how much the programmed irrigation parameters are modified (extended) due to the effects of solar radiation. The program number indexes

this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Irrigation extension percentage

Displays the overall extension percentage of irrigation for the selected program due to solar radiation.

Irrigation extension value

Displays (in time or volume) the extension value of irrigation for the selected program due to solar radiation.

System clock

29

Page 30

5.2.9 MAN CORRECTION – C 12

Prog 08

+015%

+00:05:55 13:15

MAN CORRECTION C12

This panel displays how much the programmed irrigation parameters are manually modified (corrected). The program number indexes this panel. This panel

contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Irrigation extension percentage

Displays the overall extension percentage of irrigation for the selected program due to manual correction.

Irrigation extension value

Displays (in time or volume) the extension value of irrigation for the selected program due to manual correction.

System clock

5.2.10 TOTAL CORRECTION – C 13

Prog 08

+035%

+12:00:13 13:15

TOTAL CORRECTION C13

This panel displays how much the programmed irrigation parameters are modified due to both manual and solar radiation corrections. The program number

indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Irrigation extension percentage

Displays the overall extension percentage for a selected program.

Irrigation extension value

Displays (time or volume) the total extension value of irrigation for the

selected program.

System clock

30

Page 31

5.2.11 SECTOR STATE – C 14

Prog 08 Sect 21/21

Set 00:10:30+009:45

Done 00:03:10 13:15

SECTOR STATE C14

This panel displays the state of each sector. Each sector has an electro-valve.

When a particular sector requires irrigation the electro-valve is opened for a

specified period of time. Valve number along with sector label (upper right

corner of display) indexes this panel. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Sect

The first number displayed is the sector number followed by “/” the valve

number assigned to that sector. This parameter indexes the sectors for this

panel.

Set

Displays the set value in time or volume for the selected sector/valve of the

indicated program.

Done

Displays the current point of irrigation in time or volume for the selected

sector/valve of the indicated program.

System clock

NOTE: The sector’s label can be assigned as customized numeric “tags” for all

the Fertigation Controller’s valves. Labels can be specified using panel

S 38 (SET SECTORS). As default, the sector label will be identical to the

corresponding valve number.

5.2.12 FERTILIZ STATE – C 16

Prog 02 Fert 02

Set 40%

Current 20% 13:15

FERTILIZ STATE C16

31

Page 32

This panel displays the set and current amount of fertilizer used for a specific

program. The Fertigation Controller controls the dosing of 4 fertilizers. In this

panel the fertilizer number is used as the index, allowing inspection of the percent values for up to four fertilizer tanks involved in the selected irrigation program. This panel contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Fert

Represents the index for this panel. Fertilizer tank number. Each program

can control 1 to 4 fertilizer tanks.

Set

The set percentage of one of four selected fertilizers to be dosed.

Current

The current consumed percentage of one of four selected fertilizers.

System clock

NOTE: The fertilizers percentage values can be specified using S 39 (SET FER-

TILIZERS).

5.2.13 AGITATOR STATE – C 17

Prog 08

Work 00:03 WORK

Pause 00:02 13:15

AGITATOR STATE C17

To each of the 4 fertilizer tanks an agitator can be assigned . The agitators can

be activated before dosing of a fertilizer, during dosing, or intermittently throughout the program. See Section 3.6 AGITATOR CONTROL for more information.

In this panel the agitator number is used as the index. This panel contains the

following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Work

The set working time value for the indexed agitator of the selected pro-

gram.

32

Page 33

Pause

The set pause time value for the indexed agitator of the selected program.

System clock

NOTE: The agitator’s working time values can be specified using panel S 45

(SET AGITATORS).

5.2.14 PROG LAST START – C 18

Prog 08 Filter -Last start Manual

At 28-08 18:32 13:15

PROG LAST START C18

This panel displays the last start data for the indexed program, including the

filter-cleaning programs. There are 2 filter-cleaning programs, one for each

filter. The filter programs follow the indexed irrigation programs. For example, if

the Fertigation Controller is equipped with 10 irrigation programs, “Prog” number 11 and 12 will be designated for the two filter cleaning programs on the

above panel. In this case the first 10 program numbers will indicate the last start

data for the irrigation process. Programs 11 and 12 will indicate the last start

data for filter cleaning. The program number indexes this panel. This panel

contains the following information:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Filter

Filter number

Last Start

The last start trigger for the indexed program (irrigation or filter cleaning).

At

The time of the last start for the indexed program.

System clock

33

Page 34

5.3 STATISTICS CONSULTING

5.3.1 TOTAL ACCUMUL – C 19

From: 09-26 13:37;12

0007654L

13:15

TOTAL ACCUMUL C19

This panel provides a total (in time or volume) of the entire irrigation process (all

programs) from the reset time. All Fertigation Controller’s statistics including

accumulations can be erased (manually, daily at specified hour, on overflow )

within panel S 61 (ERASE STATISTICS).

This panel contains the following information:

From

Time stamp indicating the beginning of the overall irrigation process.

Accumulation

Total accumulation in time or volume

System clock

5.3.2 PROGRAM ACCUMUL – C 20

From: 09-26 13:37;12

000:00:25 Prog 01

Activations 03 13:15

PROGRAM ACCUMUL C20

This panel provides a total (in time or volume) for each of the irrigation programs. The program number indexes this panel. This panel contains the following information:

From

Time stamp indicating the start of recording (statistics).

Accumulation

Total accumulation in time or volume for the indexed program.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Activations

The number of activations of the indexed program since the recording start.

System clock

34

Page 35

5.3.3 SECTOR ACCUMUL – C 21

From: 09-26 13:37;12

000:00:17 Sect 01/01

13:15

SECTOR ACCUMUL C21

This panel provides a total (in time or volume) for each of the irrigation sectors.

The valve number indexes this panel. This panel contains the following information:

From

Time stamp indicating the start of recording (statistics).

Accumulation

Total accumulation in time or volume for the indexed valve.

Sect

The sector number (label) / valve number (index for this panel).

System clock

5.3.4 TOTAL AVERAGES – C 22

From: 09-26 13:37;12

05.3pH

06.7mS 13:15

TOTAL AVERAGES C22

This panel indicates the overall average of pH and conductivity for the entire

irrigation process. This panel contains the following information:

From

Time stamp indicating the start of recording (statistics).

pH

The pH total average.

mS

The EC total average.

System clock

35

Page 36

5.3.5 PROGRAM AVERAGES – C 23

From: 09-26 13:37;12

05.3pH Prog 01

06.7mS 13:15

PROGRAM AVERAGES C23

This panel provides a pH & EC average for each of the irrigation programs. The

program number indexes this panel. This panel contains the following information:

From

Time stamp indicating the start of recording (statistics).

pH

The pH average for the indexed program.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

mS

The EC average for the indexed program.

System clock

5.3.6 SECTOR AVERAGES – C 24

From: 09-26 13:37;12

05.3pH Sect 01/01

06.7mS 13:15

SECTOR AVERAGES C24

This panel provides an average pH and EC reading for each of the irrigation

sectors. The valve number indexes this panel. This panel contains the following

information:

From

Time stamp indicating the start of recording (statistics).

pH

The average pH reading for the indexed valve.

Sect

The sector number (label) / valve number (index for this panel).

mS

The average EC reading for the indexed valve.

System clock

36

Page 37

5.4 ALARMS CONSULTING

5.4.1 ACTIVE ALARMS – C 25

Low level fert: 4

ACTIVE Alarm

26-12 14:36:22 13:15

ALARM 02/07 C25

This displays the active alarms current in the system. Once viewing the panel all

of the alarms can be scrolled and viewed using the UP and DOWN or ENTER

keys. This panel contains the following information:

Alarm Description

Time of alarm occurrence.

Alarm

The alarm number and (/) total number of all active alarms.

System clock

When at least one active alarm is present, the system clock blinks “ALARM”.

This indication is displayed on all panels having the system clock.

NOTE: The alarm management system is designed to provide self-update

behavior, thereby no user intervention is required to restore the status of

the interrupted program once the condition is resolved. If the condition

of the active alarms change, the panel will reflect the change accordingly without user intervention.

5.5 LOG CONSULTING

5.5.1 VIEW LOG DATE – C 26

Log consulting date:

26-12

15:05

VIEW LOG DATE C26

This panel allows the user to view log data from a specific date. The SET key is

used to enter the date of choice thus entering the setting mode. After entering the

panel and pressing the SET key, the cursor (focus) is shifted from the panel

number to the first place of the day indicator. The key pad and arrow keys can be

used to enter the selected date followed by the ENTER key. Once ENTER is

37

Page 38

pressed the Fertigation Controller will search for the logged data. If no data is

found the panel is shifted to C 28 (LOG) and “no records found” is displayed.

This panel contains the following information:

Log consulting date

The initial viewing date set by the user.

System clock

5.5.2 ANOMALIES (ALARMS HISTORY) – C 27

Low level fert: 4

CLEARED ALARM

26-12 14:36:22 13:15

ANOMALY 0193/22 C27

This screen displays anomalies. Anomalies are considered alarm history. This

screen displays alarm conditions that are no longer active. Once viewing the

panel all of the anomalies (prior alarms) can be scrolled and viewed using the

UP and DOWN or ENTER keys.

This panel contains the following information:

Alarm Description

Cleared Alarm indication

Time stamp

Time of alarm occurrence.

System clock

ANOMALY

The anomaly log record number and “/” the number of all anomalies since

the system statistics were recorded.

The anomalies log record number can be erased on panel C 61 erasing

the statistics.

5.5.3 LOG – C 28

Ext state: ACTIVE

Prog State changed.

18-08 15:05:30 15:05

Log 0012 Lev 03 C28

The Fertigation Controller log system is a three level hierarchically designed,

which means that the events are classified in three selectable categories. The

consulting log level displayed in this panel can be changed directly using the

38

Page 39

SET key or via panel S 59 (SET LOG LEVELS). The UP and DOWN arrow keys

are available to move between log records in a “select previous/next” manner.

This panel displays the following information:

Log record

Log record description.

Time stamp

Time stamp of logged occurrence.

Log record number

Log consulting level

System clock

5.6 GENERAL SETTINGS

The Setting panels provide an interface by which the user can set up the functionality of the Fertigation Controller to suite the application requirements. The

parameters in any setting panel can be modified only if the user presses the SET

key (entering the setting mode). Once pressing the SET key the cursor (focus) is

passed to the first adjustable parameter on the panel. Using the keypad along

with the arrow keys the user can set the desired parameters and navigate within

the panel. The ENTER key validates all entries. In SET MODE panel the browsing methods are disabled until the user exits from SET MODE by pressing the

ENTER (validation) or ESC (cancel) key.

To change program number you must go to panel C 03 and then continue.

5.6.1 SET DATE & TIME – S 30

Date: Fri-22-09-2000

Time: 17:03:20

17:03

SET DATE & TIME S30

This panel allows the setting of the following parameters:

Date

Day / Month / Year format. The day is automatically updated once the

numeric date is entered and confirmed.

Time

Hour / Minute / Seconds format. The time is automatically updated once

the numeric time is entered.

System clock

39

Page 40

5.7 PROGRAM SETTINGS

5.7.1 ACTIVE TIMETABLE – S 31

Between Prog 07

Date: 01-04 31-10

Time: 07:00 23:00

ACTIVE TIMETABLE S31

This panel allows the user to set the scheduled limits for the indexed program.

The program number indexes this panel (For more details see Section 3.1 and

Appendix 3). This panel allows the setting of the following parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Date

The yearly schedule limits for the selected program.

This sets the limit of program operation between day / month and day /

month.

Time

The daily schedule limits the selected program. This sets the limit of program operation hour:min to hour:min.

5.7.2 WORKDAYS – S 32

Work day 02 Prog 07

Rest day 03

Weekday SMTWTFS

WORKDAY NNNNNNN S32

This panel allows the user to set a workday scheduled for the indexed program.

Once the yearly and daily limits are established for the indexed program using

the previous panel, two methods can be used to set up a consistent work schedule. Workdays and rest days simply stated “days on” and “days off” are selectable.

If the application requires specific days of execution during the week, then specific workdays are selectable by entering a Y (yes) or N (no) under the day of

choice. Only one of the methods can be used for each program. By setting one

of the two choices the other is deactivated. The program number indexes this

panel. This panel displays and allows the setting of the following parameters

40

Page 41

(for more details see Section 3.1 and Appendix 3):

Work day

The number of consecutive workdays.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Rest day

The number of consecutive rest days.

Weekday

Week-day labels.

Workday

Use the yes or no indication (on the keypad) below each weekday label to

indicate specific workdays for the indexed program.

5.7.3 SET PRIORITY – S 33

Prog 07

Priority 04

Sectors/Group 08

SET PRIORITY S33

This panel allows the setting of priority level for each program. Programs can

share the same priority level. When a conflict occurs between two programs with

the same priority, the program that has the earliest starting time will be executed

first. The program number indexes this panel (For more details see Section 3.1

and appendix 3). This panel displays and allows the setting of the following

parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Priority

The priority level. This number can be set from 1 to 5, where 5 is the highest

priority.

Sectors / Group

The number of sectors/groups for the indexed program is the maximum

number of valves that will be opened simultaneously.

41

Page 42

5.7.4 START CONDITIONS – S 34

Time cond y Prog 07

Solar rad N

Ext tank: -- Link 02

START CONDITION S34

Using this panel we can set up how a particular program is triggered (started).

Multiple start conditions can be chosen for a program at the same time. In this

panel, a program can be set up to activate at a certain time, by the amount of

accumulated solar radiation, by the level of an external tank, or directly after the

completion of another program. The program number indexes this panel, which

displays and allows the setting of the following parameters:

Time cond

Time condition start. On keypad select Y for yes or N for no.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Solar rad

Accumulated solar radiation start. On keypad select Y for yes or N for no.

Ext tank

By selecting external tank trigger, the start of the program is based on the

low level of an assigned external tank number.

Link

By selecting Link and entering a master program number, the start of the

program directly follows (linked to) the completion of another program.

5.7.5 SET START TIME – S 35

Prog 07

07:00 09:20 10:30

12:00 14:00 16:00

SET START TIME S35

If time is selected as the starting trigger for an indexed program, we can select up

to six different starting times within the daily scheduled limits (see panel S 31,

ACTIVE TIMETABLE). When the time start condition is not set on panel S 34 non

of the settings on this panel has effect. The program number indexes this panel

(for more details see Section 3.1 and Appendix 3). This panel displays and

42

Page 43

allows the setting of the following parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Start times

Six individual (selectable) hour settings start within the daily schedule limits

for the indexed program.

NOTE: 00:00 is the not set value of the start time and the irrigation program

does not start at 00:00.

5.7.6 SET PROGRAM REPEATS – S 36

Prog 07

Repeats 04

Pause 00:30:00

PROGRAM REPEATS S36

Once a program is triggered it is possible to set it to be repeated by using this

panel. The program number indexes this panel (for more details see Section 3.1

and Appendix 3). This panel displays and allows the setting of the following

parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Repeats

Selects the total number of repetitions following the initial execution of the

indexed program.

Pause

Selects the amount of delay time between repetitions.

5.7.7 PRE/POST IRRIG – S 37

Prog 07

PreIrrig: 000:00:05

PostIrrig: 000:00:05

PRE/POST IRRIG S37

Prior to and/or after the execution of the indexed program, the amount of pre

and post irrigation can be specified in time or volume. To set irrigation control

43

Page 44

mode, see panel S 53 (IRRIG CTRL MODE). The program number indexes this

panel (for more details see Section 3.1 and Appendix 3). This panel displays

and allows the setting of the following parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

PreIrrig

The selectable amount of pre-irrigation in time or volume.

PostIrrig

The selectable amount of post-irrigation in time or volume.

5.7.8 SET SECTORS – S 38

Valve 05 Prog 07

Sector 01 Total 03

Value: 00:00:05

SET SECTORS S38

Each valve can be set for the indicated program using this panel. The panel

allows the setting of the sector (label) number for each valve. A value in time or

volume is entered to determine the duration or amount of activation. Once a

value is entered, it is considered assigned to the indicated program and added

to the total number of valves displayed on the panel. To remove valves from a

program simply enter zeros in the value setting. The valve number indexes this

panel. This panel displays and allows the setting of the following parameters:

Valve

Panel index.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Sector

Selectable sector (label) number for each valve. Unique or similar numbers can be assigned to the valves.

To ta l

Total number of valves assigned to the indicated program.

Value

The selectable irrigation (time or volume) value for the indexed valve.

44

Page 45

5.7.9 SET FERTILIZERS – S 39

Prog 07

Fer1=020% Fer2=055%

Fer3=060% Fer4=040%

SET FERTILIZERS S39

The fertilizer dosing is controlled by conductivity. The Fertigation Controller can

control up to 4 fertilizer tanks. Using this panel we can set a percentage of each

dosed fertilizer. Each tank can be set to dose from 0 to 100%.

Setting each tank to dose 100% would represent maximum dosing of all fertilizers relative to the conductivity set point and control settings. The program number indexes this panel. This panel displays and allows the setting of the following

parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03).

See Section 5.2.

Fert settings

Selectable fertilizer settings (percent) for tanks 1 through 4.

5.7.10 pH CONTROL – S 40

pHRef=07.3pH Prog 07

-00.5pH +00.5pH

Alarm threshold: 02

pH CONTROL S40

Typically an acid is added to reduce the pH to a desired level. The Fertigation

Controller can control one acid tank. A desired pH set point or target reference

is programmed and the acid dosing is controlled relative to the set point. The

program number indexes this panel. This panel displays and allows the setting

of the following parameters:

pH Ref

The selectable pH set point programmed for acid dosing.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Dead band

The selectable dead band around the pH reference. The desired (target)

pH range.

45

Page 46

Alarm threshold

Selectable pH control alarm threshold represents the time interval (measured in the Fertigation Controller’s control cycles) considered from the

moment when the alarm condition actually appears and the moment when

the alarm will be triggered.

5.7.11 COND CONTROL – S 41

ECRef=07.3mS Prog 07

-00.5mS +00.5mS

Alarm threshold: 02

COND CONTROL S41

The EC settings are programmed using this panel. EC control determines the

overall amount of fertilizer added to the irrigation water in order to maintain the

desired conductivity value. Using this panel the Fertigation Controller controls

up to 4 acid tanks relative to the established EC settings. The program number

indexes this panel. This panel displays and allows the setting of the following

parameters:

EC Ref

The selectable EC set point programmed for fertilizer dosing.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Dead band

The selectable dead band around the EC reference. The desired (target)

EC range.

Alarm threshold

Selectable pH control alarm threshold represents the time interval (measured in the Fertigation Controller’s control cycles) considered from the

moment when the alarm condition actually appears and the moment when

the alarm will be triggered.

5.7.12 CORRECTIONS – S 42

Manual +050% Prog 07

SolRad irrig +010%

CORRECTIONS S42

This panel allows the setting of corrections (adjustments) to the irrigation and

46

Page 47

fertilization process. The program number indexes this panel. This panel displays

and allows the setting of the following parameters:

Manual

The selectable manual adjustment to the irrigation process.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

SolRad irrig

The selectable adjustment to the irrigation process as a result of the effects

of accumulated solar radiation.

5.7.13 SOLAR RAD IRRIG – S 43

Prog 07

Level: 0350W/m2

Accumul: 2500Wh/m2

SOLAR RAD IRRIG S43

This panel allows the settings regarding the accumulated solar radiation feature.

The program number indexes this panel. This panel displays and allows the

setting of the following parameters:

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Level

The selectable solar radiation sensor threshold.

Accumul

The selectable solar radiation accumulation threshold used to initiate the

counting of accumulation for irrigation control.

5.7.14 SET AGITATORS – S 45

Pre 00:33 Prog 08

Work 00:10

Pause 00:05

SET AGITATORS S45

An agitator can be assigned to each of the 4 fertilizer tanks . The agitators can

be activated before dosing the fertilizer, during dosing, or intermittently throughout the program. If “Pre” is set, the agitator will activate prior to dosing. If

“Work” is set without “Pause” the agitator will work throughout the lifetime of the

47

Page 48

program. If “Work” and “Pause” are set the agitator will function intermittently

relative to the time settings. In this panel the agitator number is used as the index.

This panel displays and allows the setting of the following parameters:

Pre

The selectable pre-activation time for the agitator. The pre-agitation is done

only if the program has pre-irrigation and during of it.

Program Number

Reflects the selected program (can be selected only inside panel C 03). See

Section 5.2.

Work

The selectable activation time for the indexed agitator. Working time during

irrigation.

Pause

The selectable pause time following work time setting.

5.7.15 FILTERS CTRL – S 46

Link 05 Filter 01

Clean on alarm: Y

Clean time: 01:01:02

FILTERS CTRL S46

Both filter-cleaning programs are set via this panel. In this panel the Filter number is used as the index. This panel displays and allows the setting of the following parameters:

Link