Page 1

Instruction Manual

95mm MIN

3.74"

76mm

3"

0.25/4mm

0.01/0.160"

79mm

3.11"

ADJUSTABLE

LOCATION

BRACKET

HI 7871- HI 7873

HI 7874

Level Controllers

Dear Customer,

Thank you for choosing a Hanna product.

This manual will provide you with the necessary information

for a correct operation.

If you need additional technical information, do not hesitate

to e-mail us at tech@hannainst.com.

These instruments are in compliance with the directives.

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully. If any damage has occurred during shipment,

immediately notify your Dealer or the nearest Hanna Customer

Service Center.

Note: Conserve all packing material until the instrument has

been observed to function correctly. Any defective item

must be returned to the Dealer in its original packing.

FUNCTIONAL DESCRIPTION

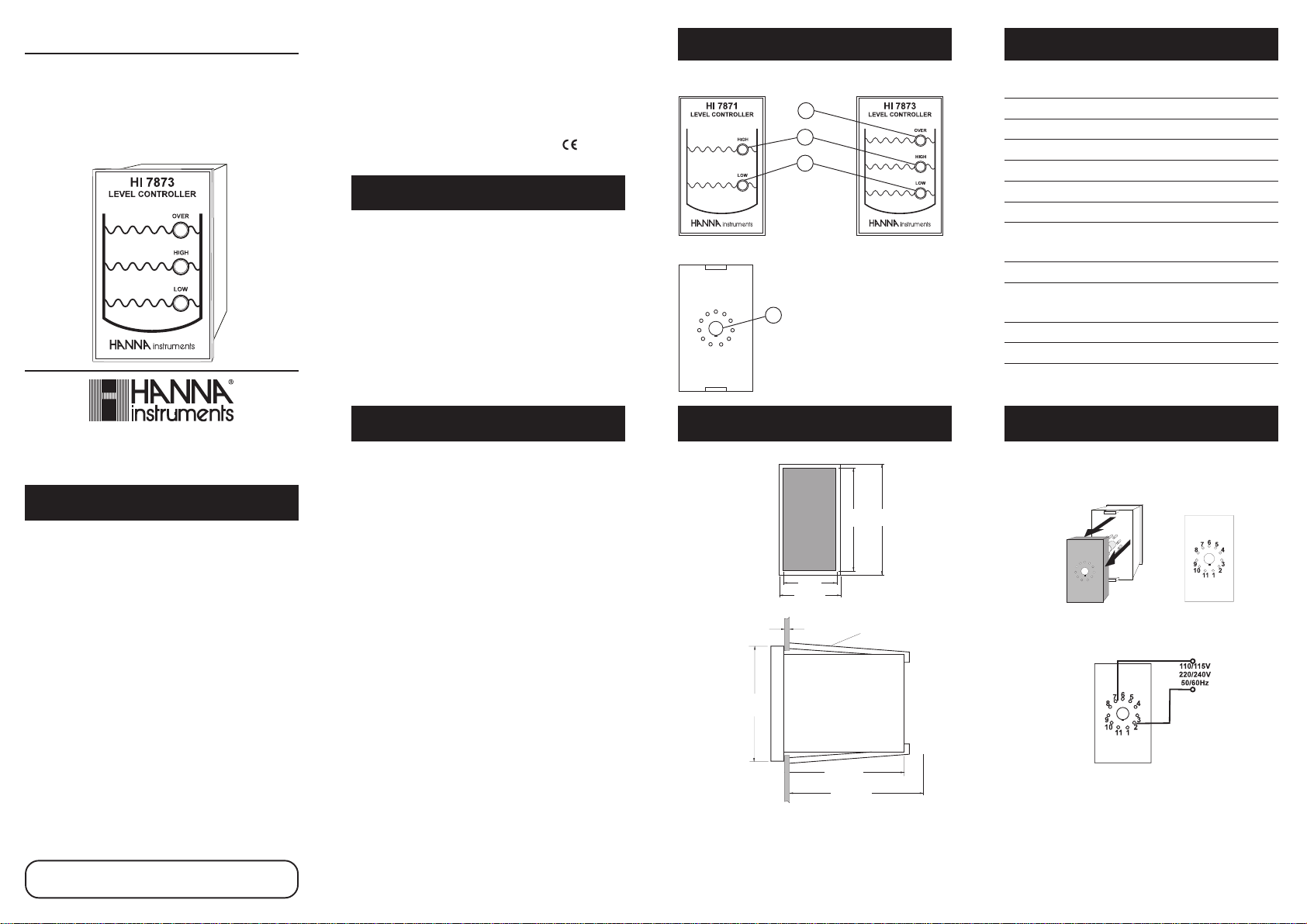

FRONT PANEL

1

2

3

REAR PANEL

1. OVER LED (HI 7873 only)

indicates an overflow condition

2. HIGH LED indicates full tank

4

3. LOW LED indicates low liquid

level

4. 11-pin socket

SPECIFICATIONS

HI 7871 HI 7873

Transmission max 100 m (330 feet)

Electrical Connection* HI 7164 undecal connector

Level Adjustment high, low high, low, overflow

Level Indication high, low high, low, overflow

Sensing Bars* 34

Transmitter* HI 7874

Output Contact 1 relay 2 relays

(2A/250 Vac, 30Vdc)

Power Supply 110/115 Vac or 220/240 Vac; 50/60 Hz

Environment 0 to 50°C (32 to 122°F);

RH max 85% non-condensing

Dimensions 83 x 53 x 95 mm (3.1 x 1.9 x 3.7")

Weight 250 g (8.8 oz.)

* Not included with HI 7871 and HI 7873.

www.hannainst.com

WARRANTY

HI 7871, HI 7873 and HI 7874 are warranted for two years

against defects in workmanship and materials when used for their intended purpose and maintained according to instructions. This warranty is

limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase,

serial number and the nature of the failure. If the repair is not covered by

the warranty, you will be notified of the charges incurred. If the instrument

is to be returned to Hanna Instruments, first obtain a Returned Goods

Authorization Number from the Customer Service department and then

send it with shipment costs prepaid. When shipping any instrument, make

sure it is properly packaged for complete protection.

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner, Hanna Instruments.

Hanna Instruments reserves the right to modify the design, construction

and appearance of its products without advance notice.

GENERAL DESCRIPTION MECHANICAL DIMENSIONS

HI 7871 and HI 7873 are 2-wire transmitter level controllers

designed especially for long distance control of liquid levels in

tanks (e.g. in biological and industrial water treatment).

A complete system should include:

• HI 7871 or HI 7873 level controller

• HI 7874 level transmitter & bar holder

• HI 7164 undecal connector

• 3 or 4 measuring bars

The level transmitter is basically a molded electrode holder

with 4 sockets to screw in the level sensors. The longest bar

has to be the common electrode and connected to the COM

port. The remaining bars can be connected in any sequence,

after cutting them to the required lengths.

HI 7874 contains a completely resinated amplifier circuit and

a 2-wire terminal board. It also comes with a mounting

bracket for quick and easy installation.

HI 7874 uses stainless steel measuring bars and employs 9V

peak to peak AC to measure the liquid level. It can be used

in liquids with conductivity greater than 10 µS/cm.

HI 7871 requires only 3 bars, whereas HI 7873 needs 4.

HI 7871 is a basic high and low level controller. HI 7873 has

an additional overflow alarm control.

FRONT VIEW

73mm

79mm

2.87"

3.11"

42mm

1.65"

49mm

1.93"

SIDE VIEW

The supplied adjustable brackets allow the controller to slide

into the cut-out and hold the unit in place. 95 mm (3.74")

is the minimum space required to install the controller with

the cables connected.

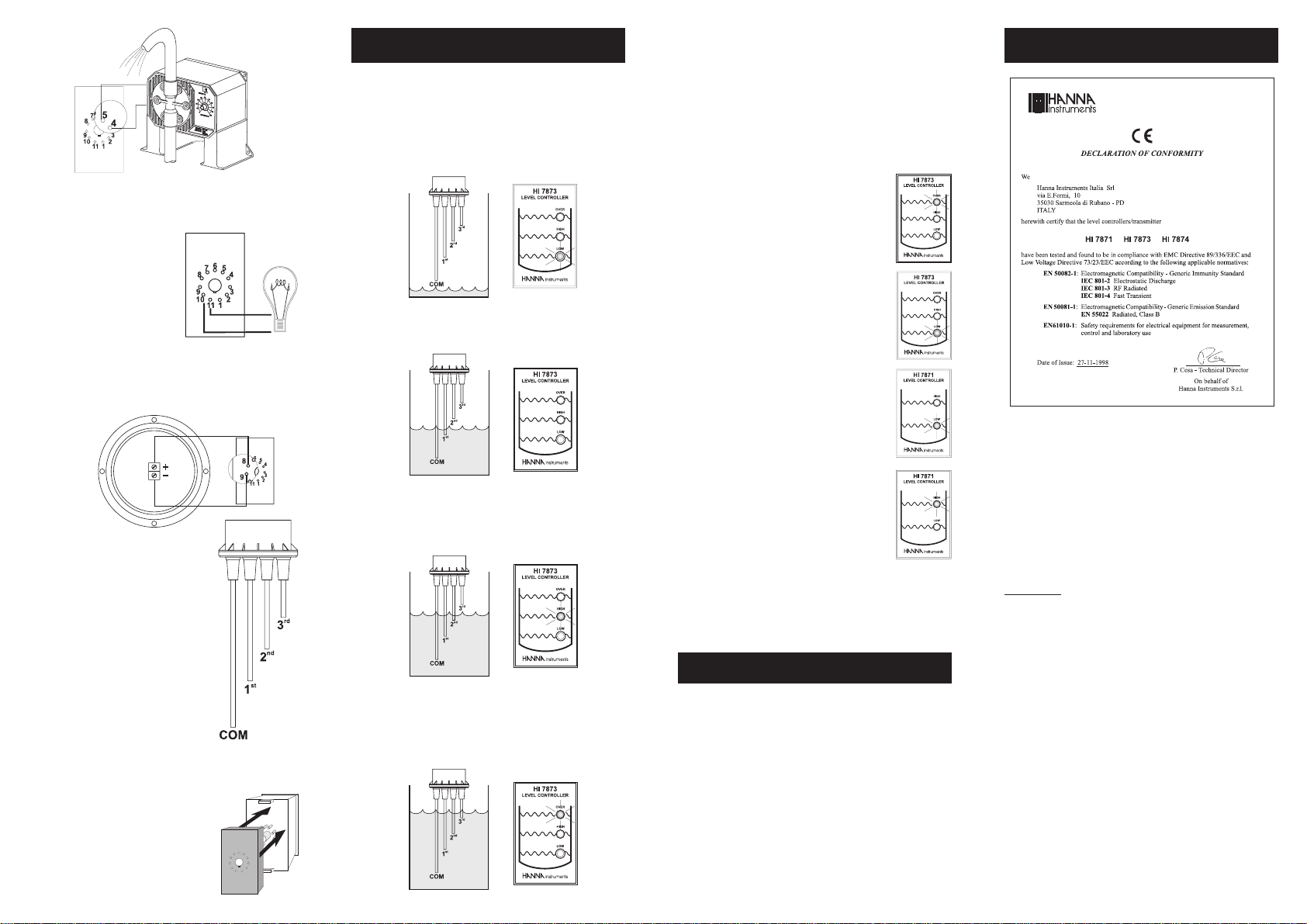

CONNECTIONS

• Remove the 11-pin connector from the rear of the level

controller.

• Connect a 2-wire power cable to terminals #2 and #7

(no ground connection).

• Connect the output terminals #4 (common) and #5

(low) to a relay switch (max 2A/230V) to start and stop

a pump or to open and close an electrovalve. These two

contacts act only as a switch and the pump or electrovalve

have to be powered independently.

Page 2

OPERATIONAL GUIDE

• Turn on the power supply. After approx. 8 seconds, the

controller can activate a pump or electrovalve.

• When liquid level is below the COM (reference) or the 1

bar, LOW LED turns on and output contacts (#4 & #5)

close, activating a pump/electrovalve.

• Subsequently, when liquid level drops below the 3rd bar,

OVER LED goes off and HIGH LED comes on. When liquid

CE DECLARATION OF CONFORMITY

level drops below the 2nd bar, HIGH LED goes off. LOW

LED lights up when the level drops below the 1st bar.

st

• HI 7873 can also detect faulty conditions, such as a short

or open circuit, in the 2-wire connection between #8 and

#9 terminals with HI 7874 bar holder.

The common terminal (#4) and #3 can also be connected to a device to indicate a “full tank” state.

• With HI 7873, connect termi-

nals #10 and #11 to an

alarm for monitoring Over Flow

condition.

• Remove the cover of HI 7874 (bar holder) and connect a

2-wire cable from #8 to positive (+) and #9 to

negative (–) terminals of the holder.

• Screw the longest bar to the hole

marked as COMM. This bar will be

used as the reference electrode. Screw

the other measuring bars into the

remaining sockets in any order. The

bars should be cut to the required

lengths for low, high and over. The

reference (COM) and the low bar

(1st) can be the same length.

• With HI 7871, connect only 3 bars

to the holder: reference, low and

high. With HI 7873, connect 4 bars

to the holder: reference, low, high

and over.

• Insert the 11-pin connector to the

back of the level controller.

• When liquid level reaches the low (1st) bar, LOW LED goes

off but the contacts (#4 & #5) remain closed.

• When liquid level reaches the high (2nd) bar, HIGH LED

turns on and the output contact (#5) opens (pump/

electrovalve disactivated) while #3 & #4 close.

• With HI 7873, if after reaching HIGH level, liquid level

continues to rise and reaches the 3rd bar, the alarm

contacts close and the OVER LED comes on.

If the 2-wire is shorted, the OVER LED

goes on and the alarm contacts close.

If the 2-wire is damaged and the circuit

is open, LOW LED goes on and the alarm

contacts close.

• With HI 7871, LOW LED goes on with an

open circuit. If the LOW LED remains lit

but the pump/electrovalve is not activated, it indicates an open circuit.

A short circuit will instead give a HIGH

LED indication.

Note: It takes about 8 seconds for the controller to activate

the relay from when an alarm condition occurs.

ACCESSORIES

HI 7164 Undecal connector

HI 7875/P Stainless steel threaded measuring bars (5 pcs)

Note: The sensing bars are made in such a way that they

can be screwed one into each other to provide any

required length. It is recommended to keep the bars

separate with a non-conductive material, such as

plastic to ensure they do not touch each other, specially in deep tanks.

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment

in which they are used.

Operation of these instruments in residential areas could cause unacceptable interferences

to radio and TV equipment.

Any variation introduced by the user to the supplied equipment may degrade the instrument's

EMC performance.

For HI 7874 only:

The measuring bars at the end of the sensor are sensitive to electrostatic discharges. Avoid

touching these bars at all times.

Connection to level controller should be done with the recommended ferrite close to level

controller.

IST7871R2 06/05

Loading...

Loading...