Page 1

Instruction Manual

GENERAL DESCRIPTION

INSTALLATION

HI 7635 - HI 7636

4-PIN IN-LINE

CONDUCTIVITY PROBES

www.hannainst.com

Dear Customer,

Thank you for choosing a Hanna product.

This manual will provide you with the necessary information

for the correct use of the probe. Please read it carefully

before installing the probe.

If you need additional technical information, do not hesitate

to e-mail us at tech@hannainst.com.

Hanna Instruments reserves the right to modify the design, construction and

appearance of its products without advance notice.

HI 7635 and HI 7636 are one-piece-molded conductivity

probes with pipe threads (1" NPT) at both ends.

This allows the probes to attach to an in-line system, and to

be used in conjunction with the HI 8936 conductivity

transmitters.

Measurements are highly accurate, and performed by using

a 4-ring potentiometric measuring method.

Probes require very little maintenance; the construction of

the housing is rugged, fiber-reinforced polypropylene.

HI 7635 also incorporates a built-in NTC sensor for temperature compensated conductivity measurements.

The max working pressure of these units is 5 bar (72.5 psi).

Do not use in systems where the temperature exceeds

80°C (176°F).

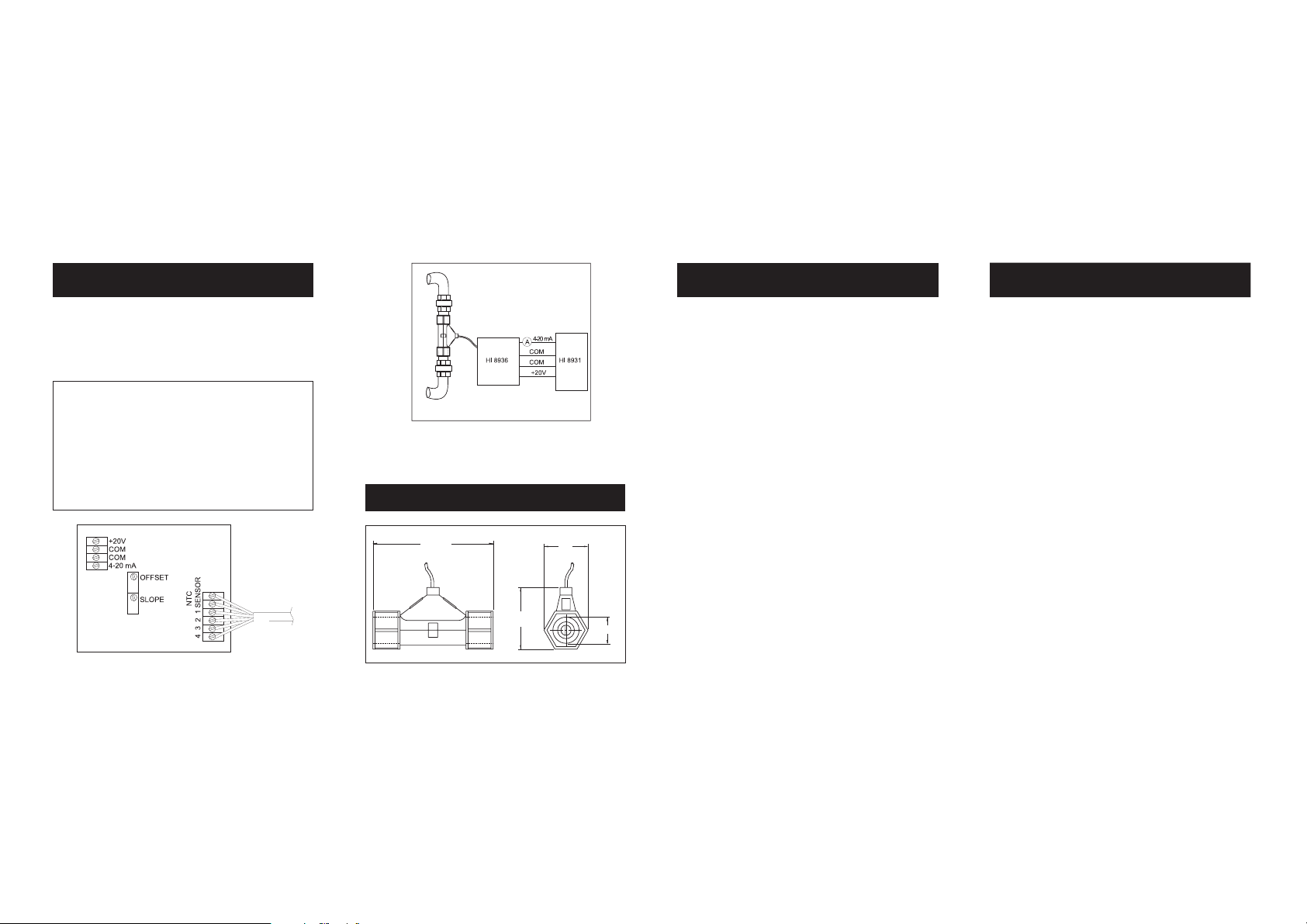

For the installation of the in-line conductivity probes, it is

necessary to use rubber seals between the probe and the

pipe or elbow joints. A pipe sealant is also recommended to

ensure a leak free joint. When screwing the joints, take care

not to overtighten as excessive pressures can cause the probe

damage.

TYPICAL IN-LINE ASSEMBLY FOR HI 7635 (or HI 7636).

Page 2

CONNECTIONS

PROBE MAINTENANCE

WARRANTY

The probes are supplied with a 4 m cable. The wires from

the cable must be connected to the HI 8936 process

Conductivity Transmitter as shown below. The connections

are color coded for an easy installation.

BLACK NTC SENSOR (HI 7635 only)

RED NTC SENSOR (HI 7635 only)

GREY/BROWN probe pin 1

BLUE probe pin 2

WHITE probe pin 3

GREEN probe pin 4

TYPICAL CONNECTION OF THE HI 7635 (or HI 7636) PROBE

AND THE HI 8936 TRANSMITTER TO THE HI 8931 CONTROLLER.

MECHANICAL DIMENSIONS

142mm

5.60"

73mm

2.87"

52mm

2.04"

1" NPT

The probes can be compensated for normal contamination

by a process of re-calibration. However, it is recommended to

remove regularly the process conductivity probes from the

system for maintenance.

Deposits on the probe can be removed by immersing it in

0.1N Hydrochloric acid for about 30 minutes. Heavier

deposits may demand longer immersion time.

Clean the electrode thoroughly with water prior to the

reinstallation. On reinstalling, check the seals carefully to

ensure a leak connection.

Note: Always recalibrate the meter when attaching a new

probe.

All Hanna Instruments probes are warranted for a period of six months.

This warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase, serial number and the nature of the problem. If the repair is not

covered by the warranty, you will be notified of the charges incurred. If

the instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. If the repair is not

covered by the warranty, you will be notified of the charge for repair or

replacement. When shipping any instrument, make sure it is properly

packaged for complete protection.

All rights are reserved. Reproduction in whole or in part is prohibited without the written

consent of the copyright owner.

IST7635R1 06/05

Loading...

Loading...