Page 1

Instruction Manual

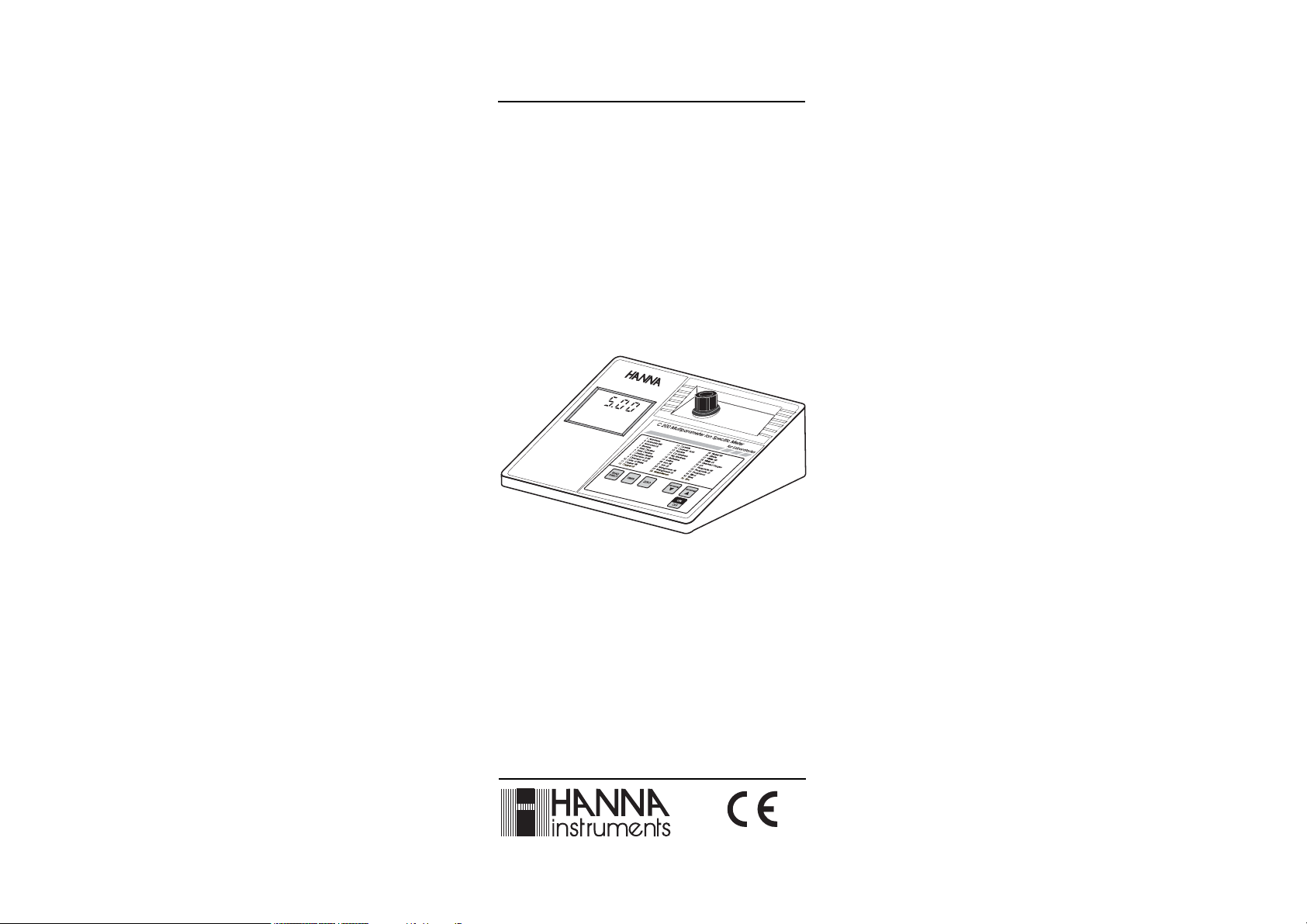

C 99 & C 200

Series

Multiparameter Bench

Photometers

Manufacturers since 1978

1

These Instruments are in

Compliance with the CE Directives

Page 2

Dear Customer,

Thank you for choosing a Hanna product. Please read this instruction

manual carefully before using the meter. This manual will provide you

with the necessary information for the correct use of the instrument. If

you need additional technical information, do not hesitate to e-mail

us at tech@hannainst.com. These instruments are in compliance

with directives.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PRELIMINARY EXAMINATION ............. 3

GENERAL DESCRIPTION ..................... 3

SPECIFICATIONS .............................. 4

PRINCIPLE OF OPERATION ................ 4

FUNCTIONAL DESCRIPTION ............... 6

GUIDE TO DISPLAY CODES ................. 7

TIPS FOR AN ACCURATE MEASURE-

MENT ........................................... 10

PARAMETERS REFERENCE TABLES ... 12

OPERATIONAL GUIDE ...................... 19

ABBREVIATIONS.................................20

ALUMINUM ................................... 21

AMMONIA HIGH RANGE .................. 23

AMMONIA MEDIUM RANGE ............. 25

AMMONIA LOW RANGE ................... 27

BROMINE ..................................... 29

FREE CHLORINE ............................ 31

FREE CHLORINE HIGH RANGE .......... 34

TOTAL CHLORINE ........................... 37

TOTAL CHLORINE HIGH RANGE ......... 40

CHLORINE DIOXIDE ........................ 43

CHROMIUM VI HIGH RANGE ............ 46

CHROMIUM VI LOW RANGE ............. 48

COLOR OF WATER .......................... 50

COPPER HIGH RANGE ..................... 52

COPPER LOW RANGE ...................... 54

CYANIDE ....................................... 56

CYANURIC ACID ............................. 59

FLUORIDE ..................................... 61

CALCIUM HARDNESS ...................... 64

MAGNESIUM HARDNESS ................ 67

TOTAL HARDNESS HIGH RANGE ........ 70

TOTAL HARDNESS MEDIUM RANGE .. 73

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent of the

copyright owner, Hanna Instruments Inc., Woonsocket, Rhode Island, 02895 , USA.

TOTAL HARDNESS LOW RANGE ......... 76

HYDRAZINE ................................... 79

IODINE ......................................... 82

IRON HIGH RANGE ......................... 84

IRON LOW RANGE .......................... 86

MANGANESE HIGH RANGE .............. 89

MANGANESE LOW RANGE ............... 91

MOLYBDENUM .............................. 94

NICKEL HIGH RANGE ...................... 97

NICKEL LOW RANGE ....................... 99

NITRATE ...................................... 102

NITRITE HIGH RANGE .................... 104

NITRITE LOW RANGE ..................... 106

OXYGEN DEMAND, CHEMICAL HR .. 108

OXYGEN DEMAND, CHEMICAL MR .. 111

OXYGEN DEMAND, CHEMICAL LR ... 114

OXYGEN, DISSOLVED .................... 117

pH ............................................. 120

PHOSPHATE HIGH RANGE ............. 122

PHOSPHATE LOW RANGE .............. 124

PHOSPHORUS ............................ 126

SILICA ........................................ 128

SILVER ....................................... 131

ZINC ........................................... 134

INTERFACE WITH PC ..................... 137

STANDARD METHODS ................... 139

BATTERY REPLACEMENT ................ 140

ACCESSORIES ............................. 141

WARRANTY ................................. 143

CE DECLARATION OF CONFORMITY..144

HANNA LITERATURE.........................145

USER NOTES...................................146

2

Page 3

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it

carefully to make sure that no damage has occurred during shipment. If there is any damage, notify your Dealer.

Each Meter is supplied complete with:

• Two Sample Cuvets and Caps*

• One Transport Cap

• Two 9 V Batteries

• 12 VDC Transformer (HI 710005 or HI 710006)

Note: Save all packing material until you are sure that the instru-

ment functions correctly. Any defective item must be returned

in its original packing with the supplied accessories.

* C99 & C200, C206, C207, C209, C210 and C213 are supplied with 3 cuvets and caps

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

C 99 & C 200 Series is a line of 15 different bench, microprocessorbased photometers that measure up to 46 parameters in water and

wastewater. These multipurpose meters are manufactured to measure

the most important parameters of the application they have been

especially designed for:

C 99 Laboratories, with COD C 200 Laboratories

C 203 Aquaculture C 205 Boilers & Cooling Towers

C 206 Environmental Testing C 207 Industrial Wastewater

C 208 Water Conditioning C 209 Education

C 210 Pulp & Paper Mills C 211 Chemical Manufacturers

C 212 Power Plant Utilities C 213 Municipal Wastewater

C 215 Nutrient Analyses C 216 Swimming Pool Applic.

C 218 Environmental Applic.

All meters use an exclusive positive-locking system to ensure that the cuvet

is in the same position every time it is placed into the measurement cell.

The reagents are in liquid or powder form and are supplied in bottles

or in packets. The amount of reagent is precisely dosed to ensure the

maximum repeatability.

Display codes aid the user in routine operations.

The meters have an auto-shut off feature, turning the unit off after

10 minutes of non-use.

The C 99 & C 200 Series can be connected to a personal computer via

the HI 920010 three wire RS 232 cable. The HI 92000 Hanna

Windows® Compatible Software aids the user to manage all test

data.

3

Page 4

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

Light Life Life of the instrument

Light Detector Silicon Photocell

Environment 0 to 50°C (32 to 122°F);

max 95% RH non-condensing

Power Supply 2 x 9 V batteries / 12 to 20 VDC through

voltage adapter

Auto-Shut off After 10' of non-use

Dimensions 230 x 165 x 70 mm (9.0 x 6.5 x 2.8")

Weight 640 g (22.6 oz.)

For specifications related to each single parameter (e.g. range,

accuracy, etc.), refer to the related measurement section.

PRINCIPLE OF OPERATIONPRINCIPLE OF OPERATION

PRINCIPLE OF OPERATION

PRINCIPLE OF OPERATIONPRINCIPLE OF OPERATION

Absorption of Light is a typical phenomenon of interaction between

Electromagnetic Radiation and Matter. When a light beam crosses a

substance, some of the radiation may be absorbed by atoms,

molecules or crystal lattices.

If pure absorption occurs, the fraction of light absorbed depends both

on the optical path length through the matter and on the physicochemical characteristics of substance according to the Lambert-Beer

Law:

-log I/Io = ελ c d

or

A = ε

c d

λ

Where:

-log I/Io=Absorbance (A)

Io=intensity of incident light beam

I =intensity of light beam after absorption

ελ=molar extinction coefficient at wavelength λ

c =molar concentration of the substance

d =optical path through the substance

Therefore, the concentration "c" can be calculated from the absorbance

of the substance as the other factors are known.

Photometric chemical analysis is based on the possibility to develop an

absorbing compound from a specific chemical reaction between sample

and reagents.

4

Page 5

Given that the absorption of a compound strictly depends on the

wavelength of the incident light beam, a narrow spectral bandwidth

should be selected as well as a proper central wavelength to optimize

measurements.

The optical system of Hanna's C 99 & C 200 multiparameter

photometers is based on special subminiature tungsten lamps and

narrow-band interference filters to guarantee both high performance

and reliable results.

Four measuring channels (at four different wavelengths) allow a wide

range of tests.

C 200 Block diagram (optical layout)

A microprocessor controlled special tungsten lamp emits radiation

which is first optically conditioned and beamed to the sample

contained in the cuvet. The optical path is fixed by the diameter of

the cuvet. Then the light is spectrally filtered to a narrow spectral

bandwidth, to obtain a light beam of intensity Io or I.

The photoelectric cell collects the radiation I that is not absorbed by

the sample and converts it into an electric current, producing a

potential in the mV range.

The microprocessor uses this potential to convert the incoming value

into the desired measuring unit and to display it on the LCD.

The measurement process is carried out in two phases: first the meter

is zeroed and then the actual measurement is performed.

The cuvet has a very important role because it is an optical element

and thus requires particular attention. It is important that both the

measurement and the calibration (zeroing) cuvets are optically identical to provide the same measurement conditions. Whenever possible

use the same cuvet for both.

It is also necessary that the surface of the cuvet is clean and not

scratched. This is to avoid measurement interference due to unwanted

reflection and absorption of light. It is recommended not to touch the

cuvet walls with hands.

Furthermore, in order to maintain the same conditions during the

zeroing and the measuring phases, it is necessary to close the cuvet

to prevent any contamination.

5

Page 6

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

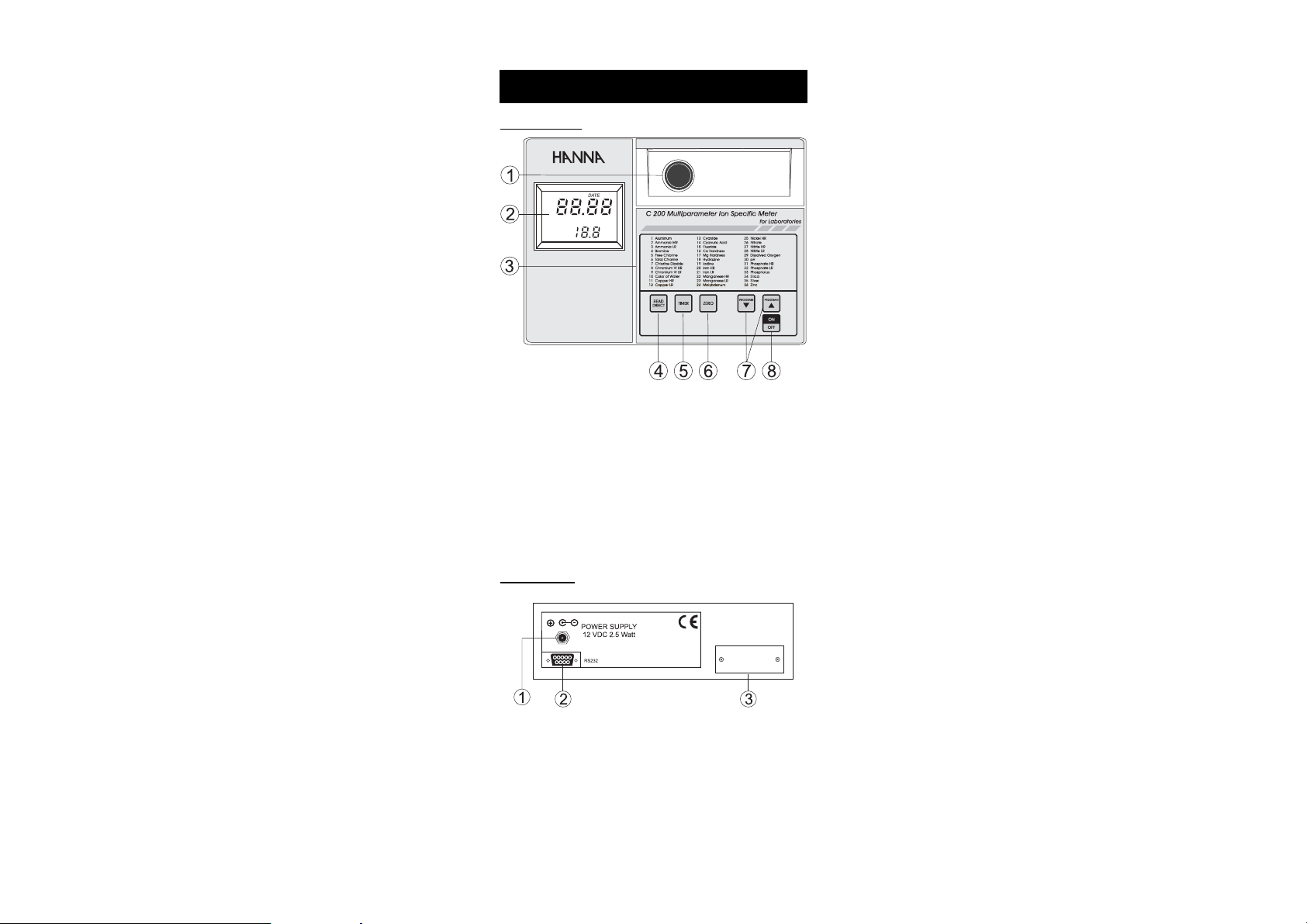

FRONT PANEL

1) Cuvet Holder

2) Dual Level Liquid Crystal Display

3) Programs List

4) READ DIRECT, to perform measurement immediately

5) TIMER, to perform measurements after a preprogrammed

countdown

6) ZERO, to zero the meter prior to measurement

7) Program W and V, to select the desired parameter

8) ON/OFF, to turn the meter on and off

REAR PANEL

1) Power Supply 12 VDC 2.5 Watt

2) RS 232 Socket

3) Batteries Compartment

6

Page 7

GUIDE TO DISPLAY CODESGUIDE TO DISPLAY CODES

GUIDE TO DISPLAY CODES

GUIDE TO DISPLAY CODESGUIDE TO DISPLAY CODES

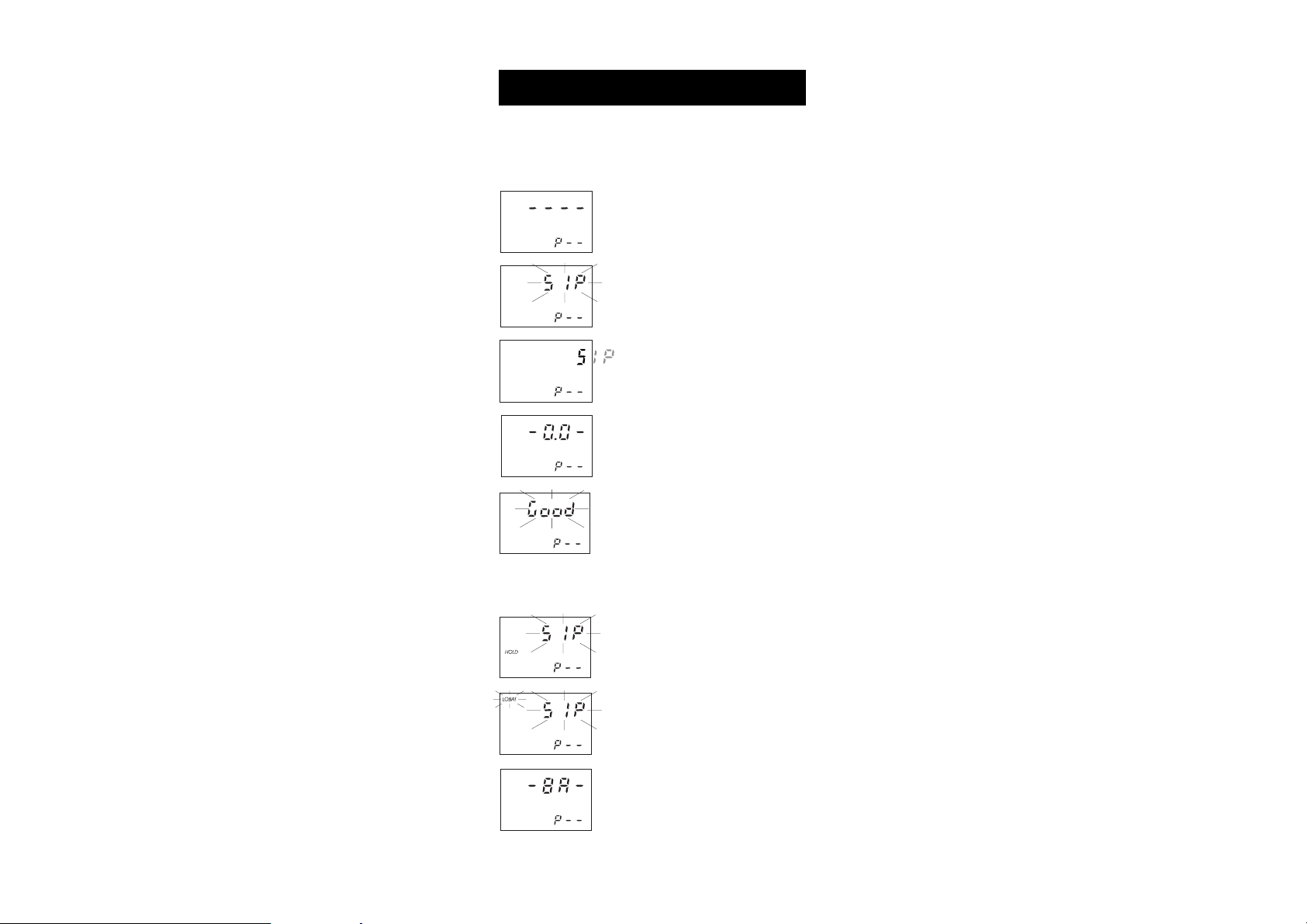

Note: The secondary LCD below shows a generic "P– –", whereas the

meter will indicate the exact program number (e.g. in C 200,

"P1" for Aluminum).

This indicates that the meter is in a ready

state and zeroing can be performed.

Sampling in progress. This flashing

prompt appears each time the meter is

performing a measurement.

The microprocessor is adjusting the light

level, indicated by a scrolling "SIP".

This indicates that the meter is in a zeroed

state and measurement can be performed.

The light level is accepted. The instrument

is ready to perform a zero reading. This

flashing prompt will only appear when a

second zero reading needs to be performed.

Follow the measurement procedure described in the related chapter.

The instrument is performing an internal

check-up.

The blinking "LOBAT" indicates that the

battery voltage is getting low and the

batteries need to be replaced.

This indicates that the batteries are dead

and must be replaced.

7

Page 8

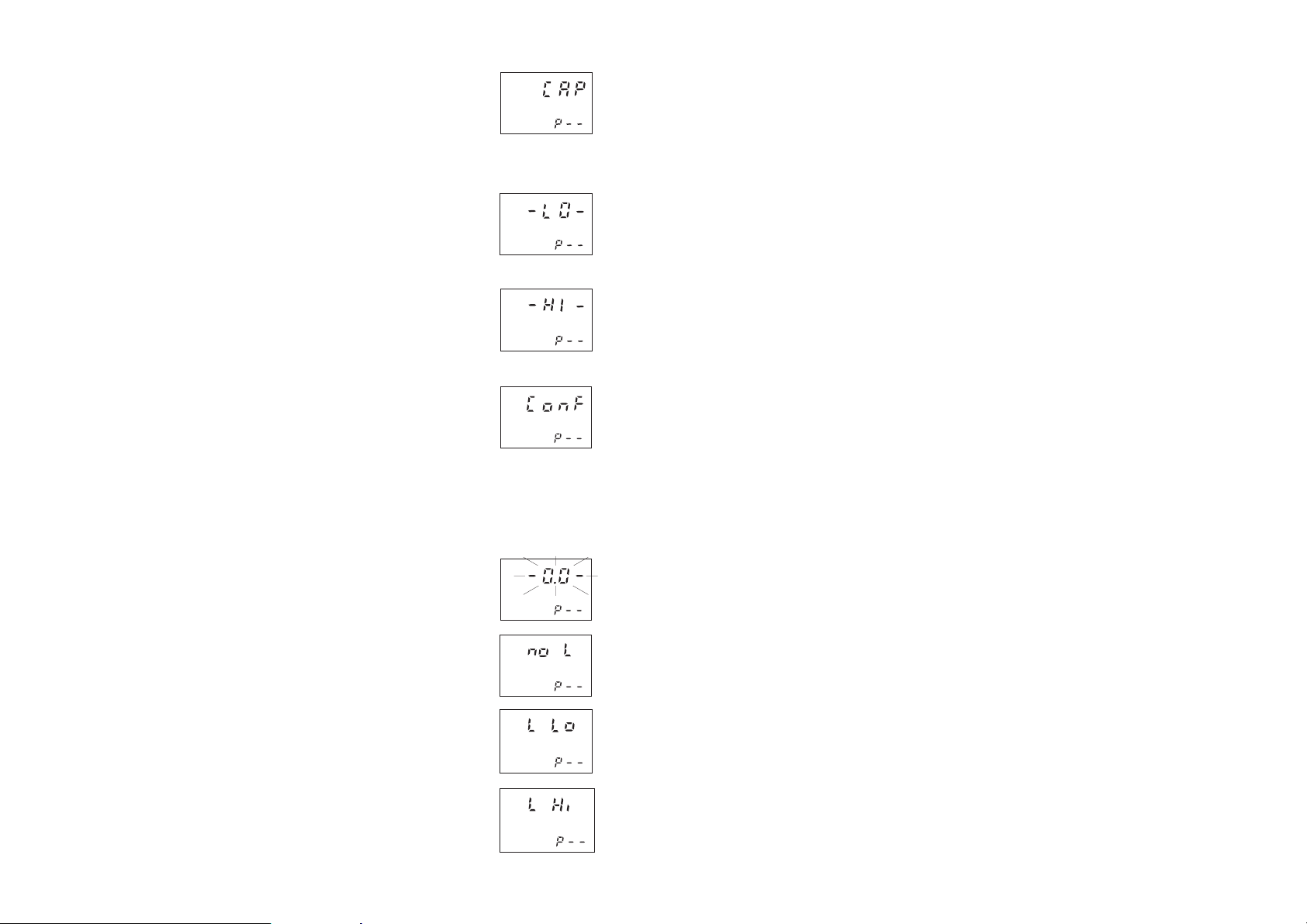

ERROR MESSAGESERROR MESSAGES

ERROR MESSAGES

ERROR MESSAGESERROR MESSAGES

a) on zero reading:a) on zero reading:

a) on zero reading:

a) on zero reading:a) on zero reading:

Light over range. The cuvet is not inserted

correctly and an eccess ambient light is

reaching the detector. If the cuvet is

properly inserted, then contact your dealer

or the nearest Hanna Customer Service

Center.

The lamp is not working properly. Contact

your dealer or the nearest Hanna Customer

Service Center.

The lamp is not working properly. Contact

your dealer or the nearest Hanna Customer

Service Center.

This indicates that the meter has lost its

configuration. Contact your dealer or the

nearest Hanna Customer Service Center.

This indicates that the zeroing procedure

failed due to a low signal-to-noise ratio. In

this case press ZERO again.

The instrument cannot adjust the light

level. Please check that the sample does not

contain any debris.

There is not enough light to perform a

measurement. Please check the preparation of the zero cuvet.

There is too much light to perform a

measurement. Please check the preparation of the zero cuvet.

8

Page 9

b) on sample reading:b) on sample reading:

b) on sample reading:

b) on sample reading:b) on sample reading:

There is too much light for the sample

measurement. Please check if the right

sample cuvet is inserted.

The sample and zero cuvet are inverted.

A zero reading was not taken. Follow the

instruction described in the measurement

procedures for zeroing the meter.

Under range. A blinking "0.00" indicates

that the sample absorbs less light than the

zero reference. Check the procedure and

make sure that you use the same cuvet for

reference (zero) and measurement.

1) A flashing value of the maximum

concentration indicates an over range

condition. The concentration of the sample

is beyond the programmed range: dilute

the sample and rerun the test.

2) A flashing value lower than the

maximum concentration indicates a low

signal-to-noise ratio condition. In this case

accuracy of the result is not guaranteed.

Repeat the reading procedure.

9

Page 10

TIPS FOR AN ACCURATE MEASUREMENTTIPS FOR AN ACCURATE MEASUREMENT

TIPS FOR AN ACCURATE MEASUREMENT

TIPS FOR AN ACCURATE MEASUREMENTTIPS FOR AN ACCURATE MEASUREMENT

The instructions listed below should be carefully followed during

testing to ensure best accuracy.

• Color or suspended matter in large amounts may cause interference, therefore, these should be removed by treatment with active

carbon and by prior filtration.

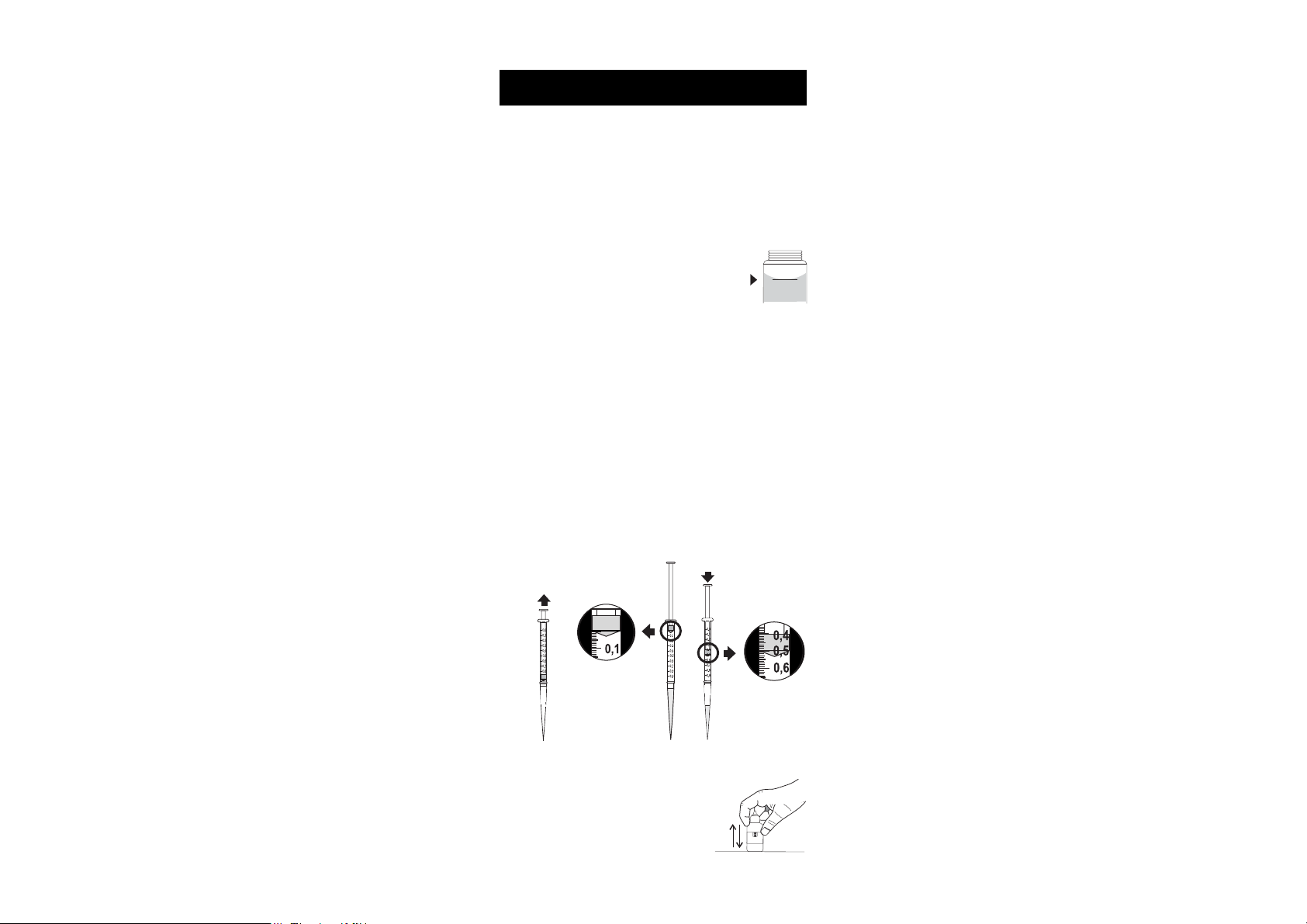

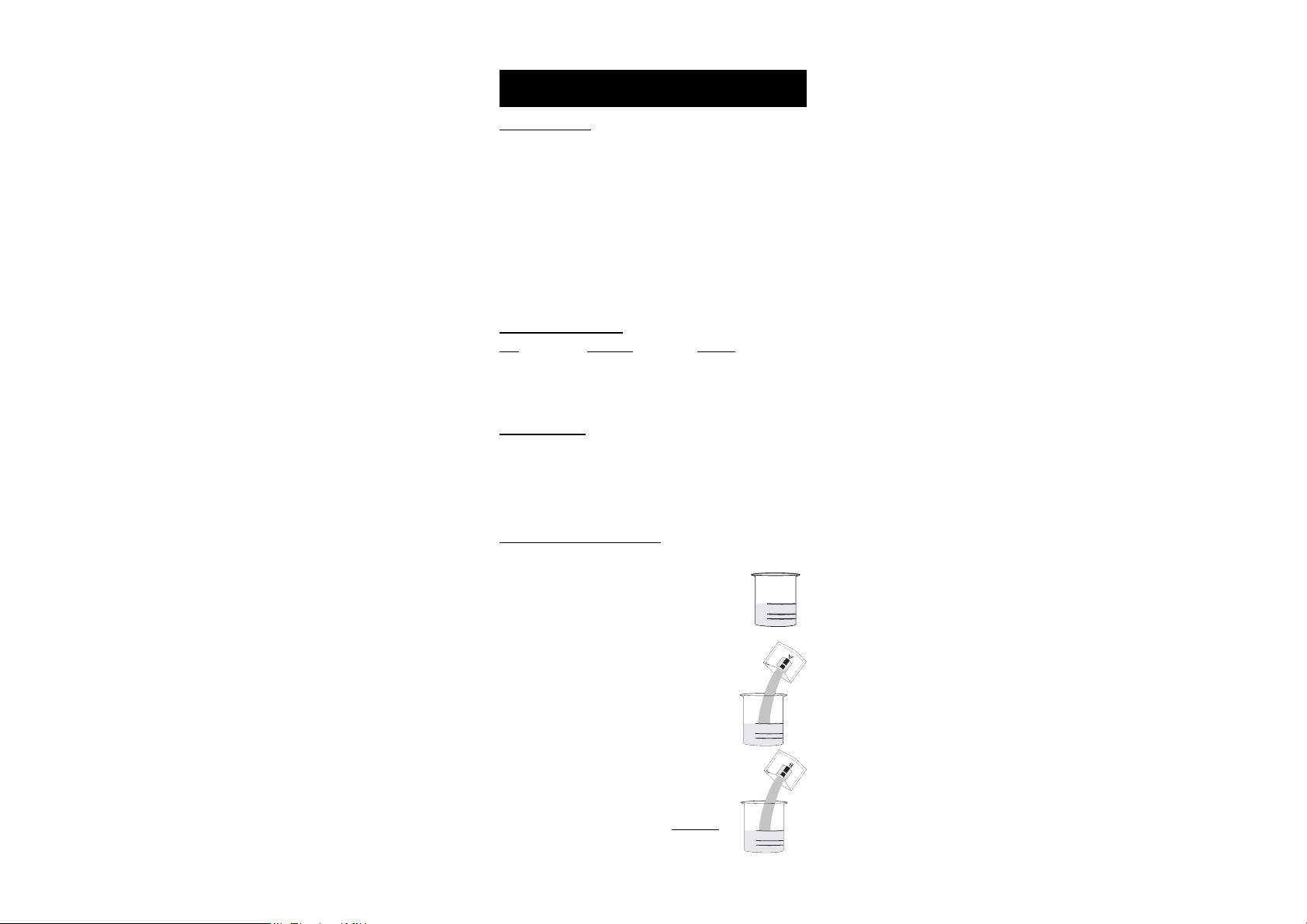

• For a correct filling of the cuvet: the

liquid in the cuvet forms a convexity

on the top; the bottom of this convexity must be at the same level of the

10 mL mark.

• In order to measure exactly e.g. 0.5 mL of sample or reagent

with the 1 mL syringe, push the plunger completely into the

syringe and insert the tip into the solution. Pull the plunger up

to above the 0.0 mL mark. Take out the syringe and clean the

outside of the syringe tip. Then, adjust the plunger to the 0.0 mL

mark (the lower edge of the seal must be exactly on the 0.0 mL

mark). Be sure that no drops are hanging on the tip of the

syringe, if so eliminate them. Then, keeping the syringe in vertical

position above the cuvet, push the plunger down until the lower

edge of the seal is exactly on the 0.5 mL mark. Now the exact

amount of 0.5 mL has been added to the cuvet, even if the tip

still contains some reagent or sample.

10 mL

• Proper use of the dropper: to get good

reproducible results, tap the dropper on the

table for several times and wipe the outside

of the dropper tip with a cloth. Always keep

the dropper bottle in a vertical position

while dosing the reagent.

10

Page 11

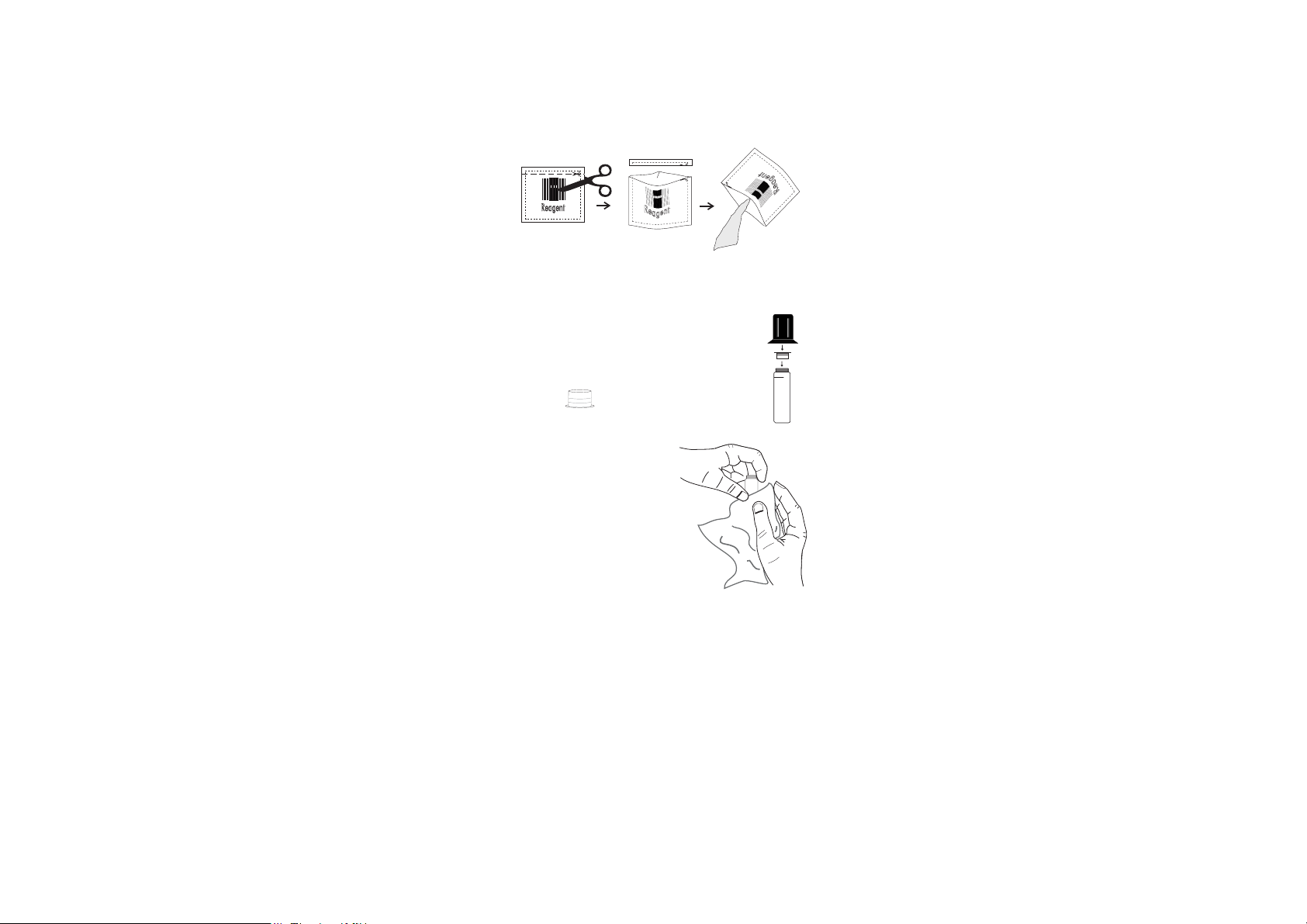

• Proper use of the powder reagent packet:

(a) use scissors to open the powder packet;

(b) push the edges of the packet to form a spout;

(c) pour out the content of the packet.

(a)

(b)

(c)

• It is important that the sample does not contain any debris. This

would corrupt the readings.

• Do not let the reacted sample stand too long after reagent is

added, or accuracy will be lost.

• In order to avoid reagent leaking and to obtain

more accurate measurements, it is recommended to

close the cuvet first with the supplied HDPE plastic

stopper and then with the black cap.

• Each time the cuvet is used, the cap must be

tightened to the same degree.

• Whenever the cuvet is placed into

the measurement cell, it must be

dry outside, and completely free of

fingerprints, oil or dirt. Wipe it

thoroughly with HI 731318 or a

lint-free cloth prior to insertion.

• It is possible to take multiple readings in a row, but it is recommended

to take a new zero reading for each sample and to use the same

cuvet for zeroing and measurement.

• It is important to discard the sample immediately after the

reading is taken because the glass might become permanently

stained.

• All the reaction times reported in this manual are referred to 20°C

(68°F). As a general rule of thumb, they should be doubled at

10°C (50°F) and halved at 30°C (86°F).

11

Page 12

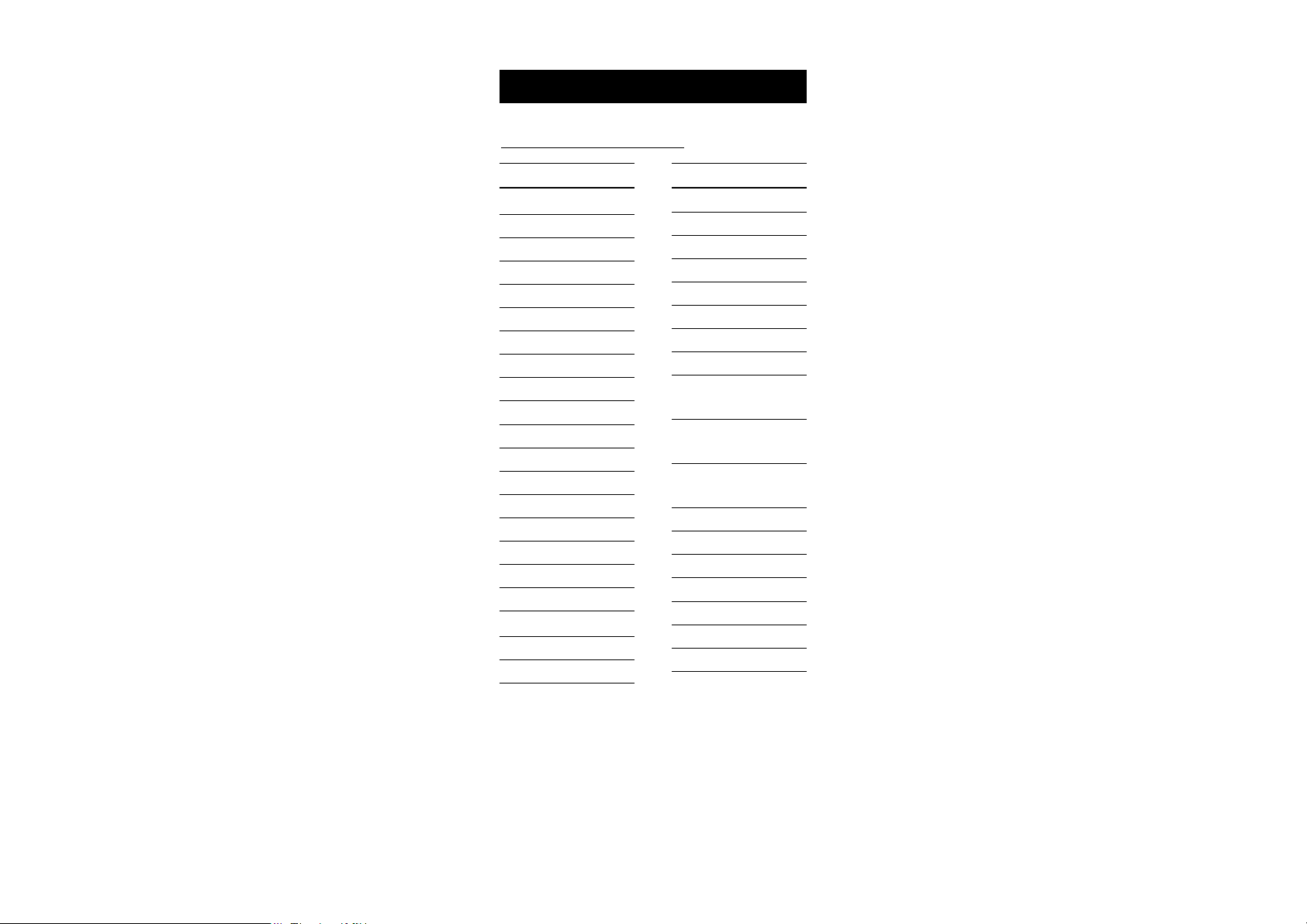

PARAMETERS REFERENCE TABLESPARAMETERS REFERENCE TABLES

PARAMETERS REFERENCE TABLES

PARAMETERS REFERENCE TABLESPARAMETERS REFERENCE TABLES

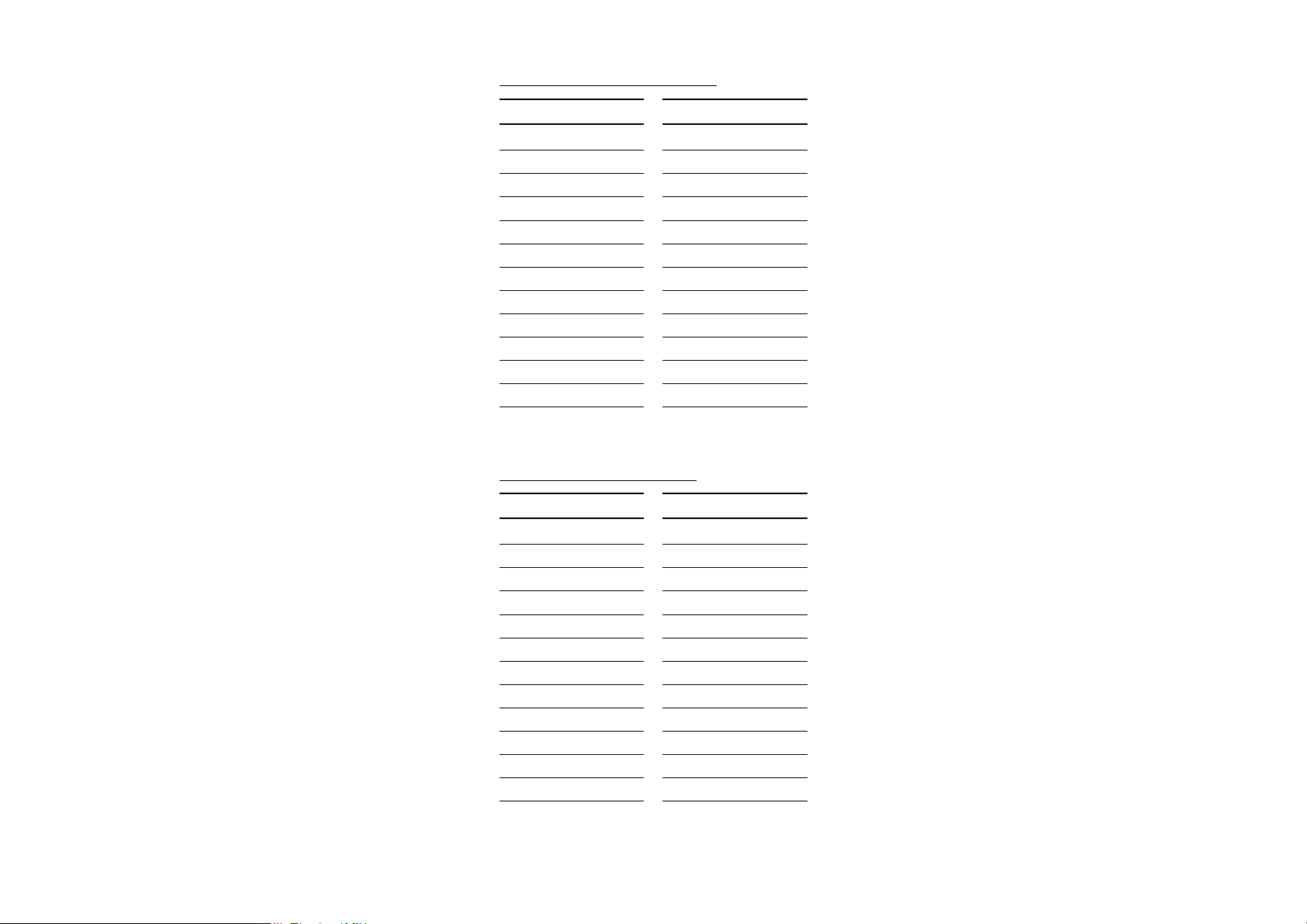

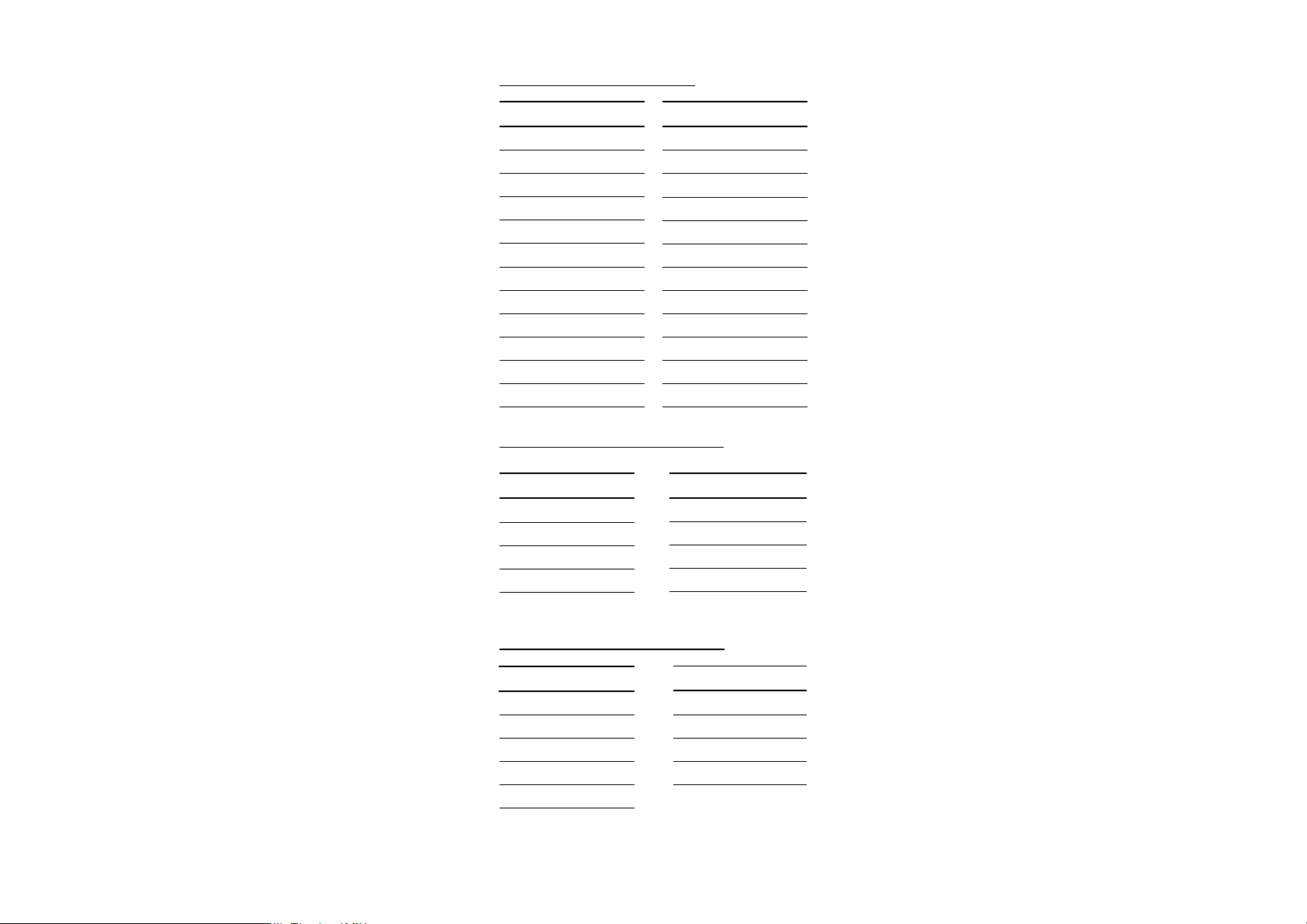

C99 - LABORATORIES, with COD

Code Parameter Page

1 Aluminum 21

2 Ammonia MR 25

3 Ammonia LR 27

4 Bromine 29

5 Free Chlorine 31

6 Total Chlorine 37

7 Chlorine Dioxide 43

8 Chromium VI HR 46

9 Chromium VI LR 48

10 Color of Water 50

11 Copper HR 52

12 Copper LR 54

13 Cyanide 56

14 Cyanuric Acid 59

15 Fluoride 61

16 Ca Hardness 64

17 Mg Hardness 67

18 Hydrazine 79

19 Iodine 82

20 Iron HR 84

21 Iron LR 86

Code Parameter Page

22 Manganese HR 89

23 Manganese LR 91

24 Molybdenum 94

25 Nickel HR 97

26 Nitrate 102

27 Nitrite HR 104

28 Nitrite LR 106

29 Oxygen, Dissolved 117

30 Oxygen Demand,

Chemical (COD) HR 108

31 Oxygen Demand,

Chemical (COD) MR 111

32 Oxygen Demand,

Chemical (COD) LR 114

33 pH 120

34 Phosphate HR 122

35 Phosphate LR 124

36 Phosphorus 126

37 Silica 128

38 Silver 131

39 Zinc 134

12

Page 13

PARAMETERS REFERENCE TABLESPARAMETERS REFERENCE TABLES

PARAMETERS REFERENCE TABLES

PARAMETERS REFERENCE TABLESPARAMETERS REFERENCE TABLES

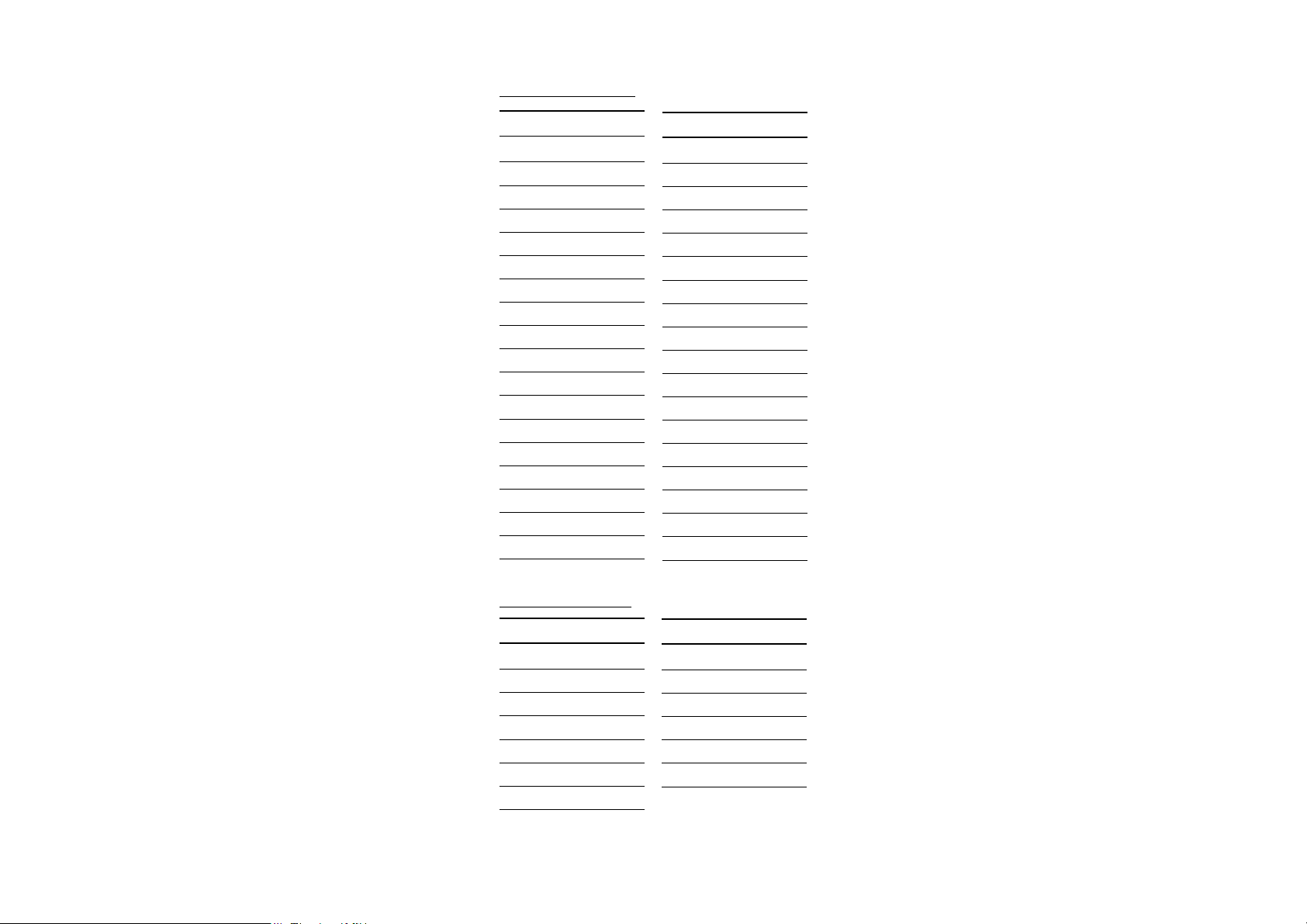

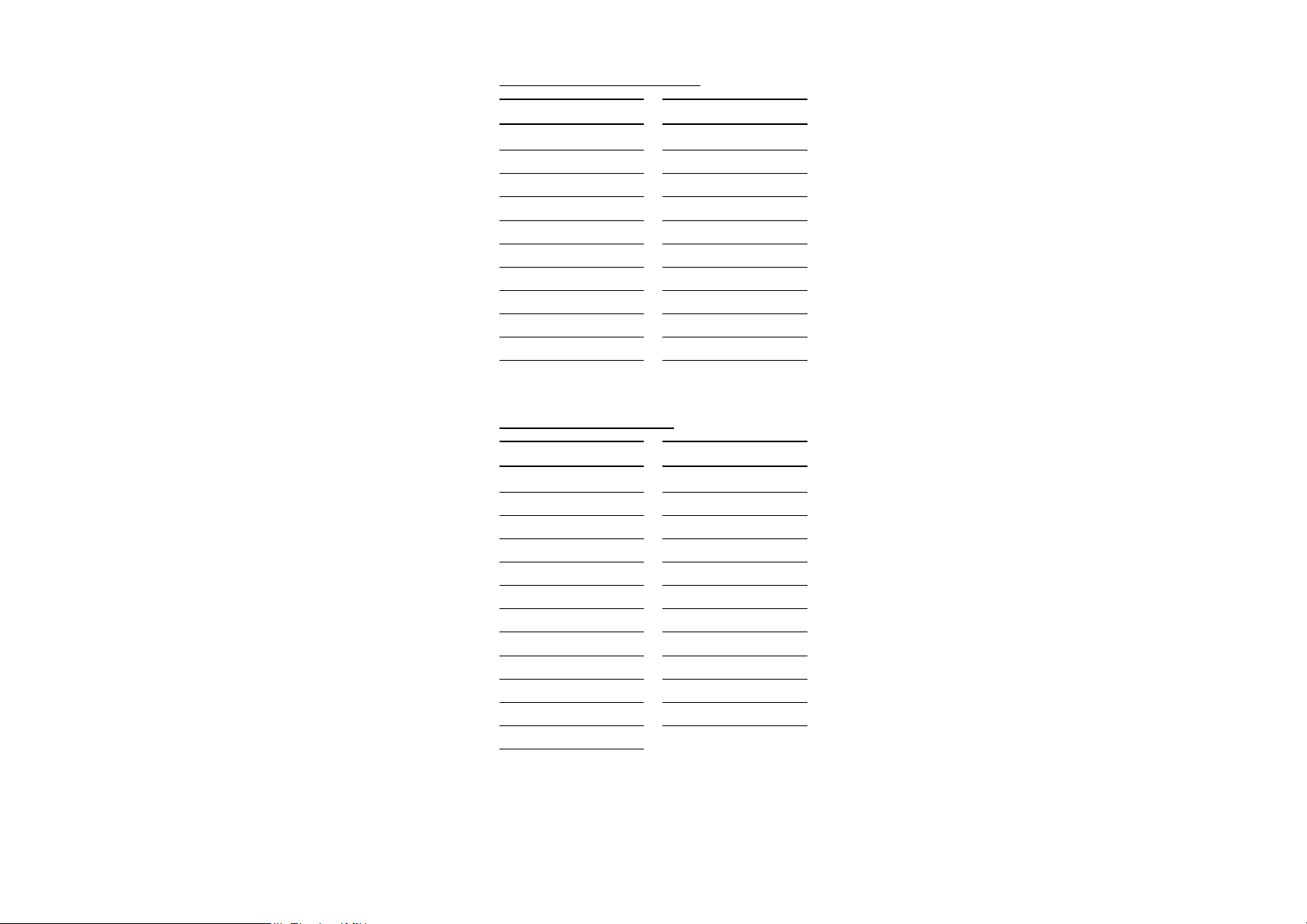

C 200 - LABORATORIES

Code Parameter Page

1 Aluminum 21

2 Ammonia MR 25

3 Ammonia LR 27

4 Bromine 29

5 Free Chlorine 31

6 Total Chlorine 37

7 Chlorine Dioxide 43

8 Chromium VI HR 46

9 Chromium VI LR 48

10 Color of Water 50

11 Copper HR 52

12 Copper LR 54

13 Cyanide 56

14 Cyanuric Acid 59

15 Fluoride 61

16 Ca Hardness 64

17 Mg Hardness 67

18 Hydrazine 79

Code Parameter Page

19 Iodine 82

20 Iron HR 84

21 Iron LR 86

22 Manganese HR 89

23 Manganese LR 91

24 Molybdenum 94

25 Nickel HR 97

26 Nitrate 102

27 Nitrite HR 104

28 Nitrite LR 106

29 Oxygen, Dissolved 117

30 pH 120

31 Phosphate HR 122

32 Phosphate LR 124

33 Phosphorus 126

34 Silica 128

35 Silver 131

36 Zinc 134

C 203 - AQUACULTURE

Code Parameter Page

1 Ammonia MR 25

2 Ammonia LR 27

3 Free Chlorine 31

4 Total Chlorine 37

5 Copper HR 52

6 Copper LR 54

7 Nitrate 102

Code Parameter Page

8 Nitrite HR 104

9 Nitrite LR 106

10 Oxygen, Dissolved 117

11 pH 120

12 Phosphate HR 122

13 Phosphate LR 124

13

Page 14

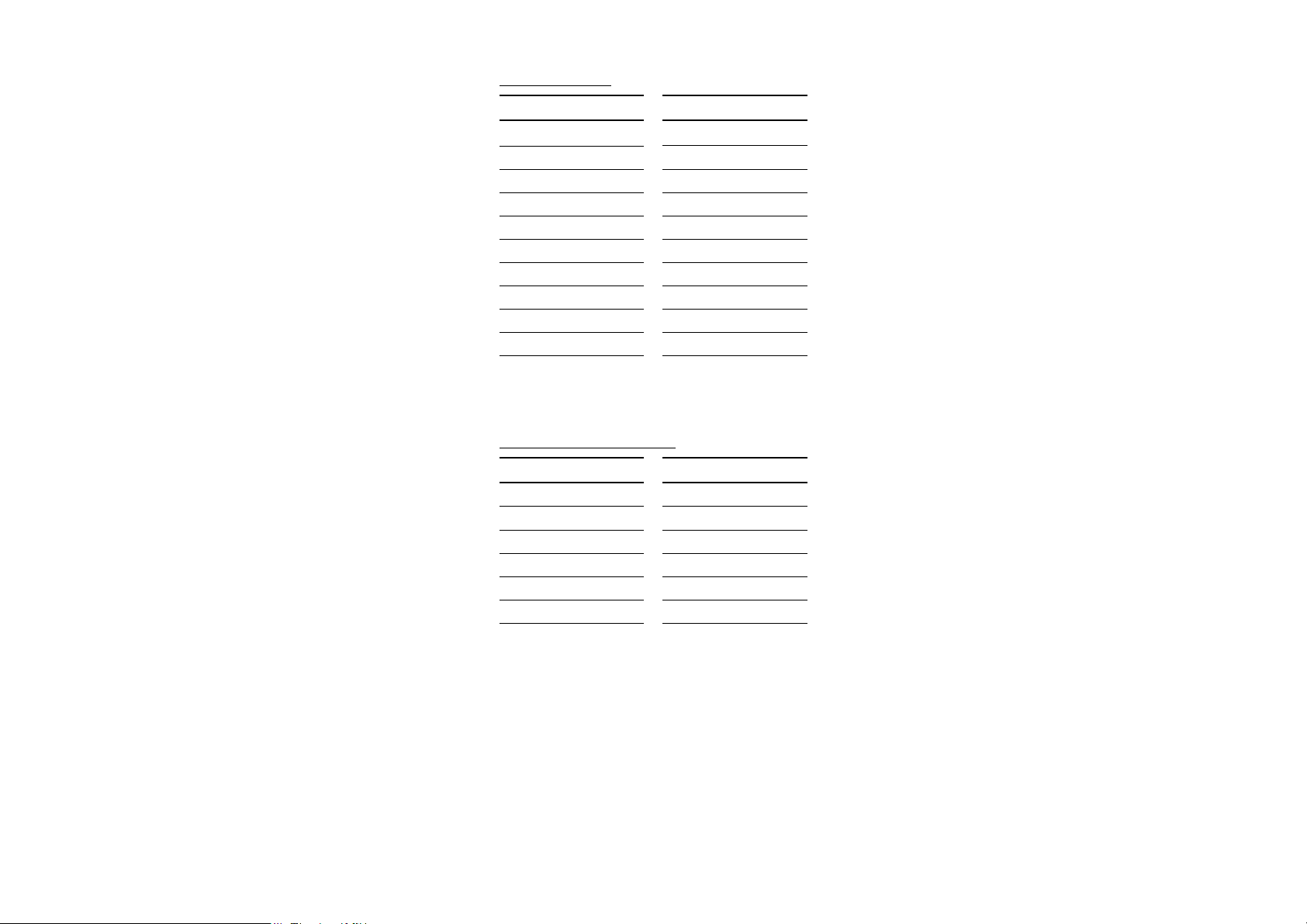

C 205 - BOILERS & COOLING TOWERS

Code Parameter Page

1 Aluminum 21

2 Ammonia MR 25

3 Ammonia LR 27

4 Bromine 29

5 Free Chlorine 31

6 Total Chlorine 37

7 Chlorine Dioxide 43

8 Chromium VI HR 46

9 Chromium VI LR 48

10 Copper HR 52

11 Copper LR 54

12 Hydrazine 79

Code Parameter Page

13 Iron HR 84

14 Iron LR 86

15 Molybdenum 94

16 Nitrate 102

17 Nitrite HR 104

18 Nitrite LR 106

19 Oxygen, Dissolved 117

20 pH 120

21 Phosphate HR 122

22 Phosphate LR 124

23 Silica 128

24 Zinc 134

C 206 - ENVIRONMENTAL TESTING

Code Parameter Page

1 Ammonia MR 25

2 Ammonia LR 27

3 Free Chlorine 31

4 Total Chlorine 37

5 Chromium VI HR 46

6 Chromium VI LR 48

7 Color of Water 50

8 Copper HR 52

9 Copper LR 54

10 Cyanuric Acid 59

11 Molybdenum 94

12 Nickel HR 97

Code Parameter Page

13 Nickel LR 99

14 Nitrate 102

15 Nitrite HR 104

16 Nitrite LR 106

17 Oxygen, Dissolved 117

18 pH 120

19 Phosphate HR 122

20 Phosphate LR 124

21 Phosphorus 126

22 Silica 128

23 Silver 131

24 Zinc 134

14

Page 15

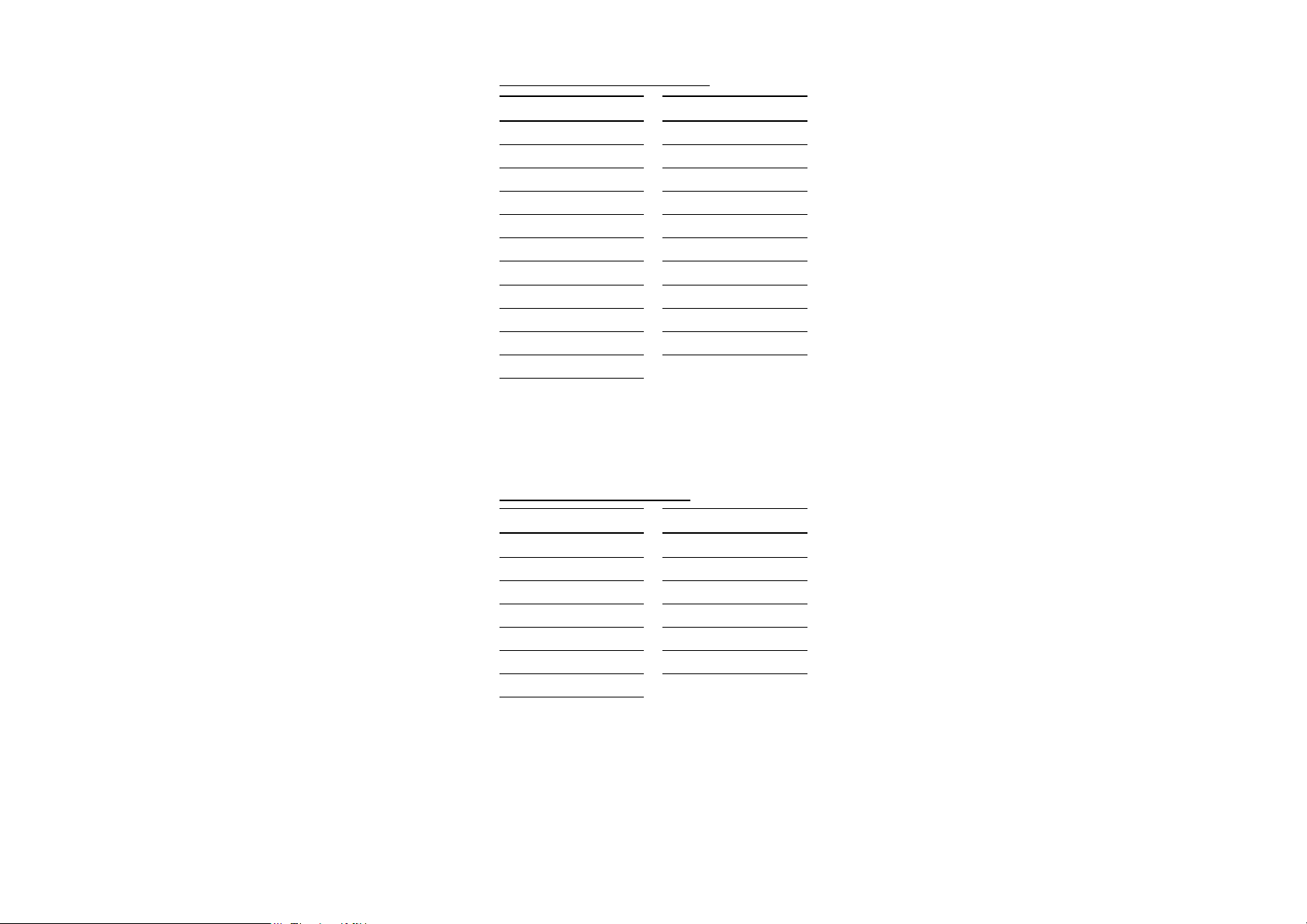

C 207 - INDUSTRIAL WASTEWATER

Code Parameter Page

1 Aluminum 21

2 Free Chlorine 31

3 Total Chlorine 37

4 Color of Water 50

5 Copper HR 52

6 Copper LR 54

7 Fluoride 61

8 Manganese HR 89

9 Manganese LR 91

10 Molybdenum 94

C 208 - WATER CONDITIONING

Code Parameter Page

1 Ammonia MR 25

2 Ammonia LR 27

3 Free Chlorine 31

4 Total Chlorine 37

5 Copper HR 52

6 Copper LR 54

7 Fluoride 61

8 Iron HR 84

9 Iron LR 86

10 Manganese HR 89

11 Manganese LR 91

12 Molybdenum 94

Code Parameter Page

11 Nickel HR 97

12 Nickel LR 99

13 Nitrate 102

14 Oxygen, Dissolved 117

15 pH 120

16 Phosphate HR 122

17 Phosphate LR 124

18 Phosphorus 126

19 Silver 131

20 Zinc 134

Code Parameter Page

13 Nickel HR 97

14 Nickel LR 99

15 Nitrate 102

16 Oxygen, Dissolved 117

17 pH 120

18 Phosphate HR 122

19 Phosphate LR 124

20 Phosphorus 126

21 Silica 128

22 Silver 131

23 Zinc 134

15

Page 16

C 209 - EDUCATION

Code Parameter Page

1 Ammonia MR 25

2 Ammonia LR 27

3 Free Chlorine 31

4 Total Chlorine 37

5 Chromium VI HR 46

6 Chromium VI LR 48

7 Color of Water 50

8 Copper HR 52

9 Copper LR 54

10 Nitrate 102

C 210 - PULP & PAPER MILLS

Code Parameter Page

1 Aluminum 21

2 Free Chlorine 31

3 Total Chlorine 37

4 Chlorine Dioxide 43

5 Color of Water 50

6 Dissolved Oxygen 117

Code Parameter Page

11 Nitrite HR 104

12 Nitrite LR 106

13 Oxygen, Dissolved 117

14 pH 120

15 Phosphate HR 122

16 Phosphate LR 124

17 Phosphorus 126

18 Silica 128

19 Silver 131

20 Zinc 134

Code Parameter Page

7 pH 120

8 Phosphate HR 122

9 Phosphate LR 124

10 Silica 128

11 Silver 131

12 Zinc 134

16

Page 17

C 211 - CHEMICAL MANUFACTURERS

Code Parameter Page

1 Aluminum 21

2 Ammonia MR 25

3 Ammonia LR 27

4 Chromium VI HR 46

5 Chromium VI LR 48

6 Copper HR 52

7 Copper LR 54

8 Cyanuric Acid 59

9 Iodine 82

10 Iron HR 84

11 Iron LR 86

Code Parameter Page

12 Molybdenum 94

13 Nickel HR 97

14 Nickel LR 99

15 pH 120

16 Phosphate HR 122

17 Phosphate LR 124

18 Phosphorus 126

19 Silica 128

20 Silver 131

21 Zinc 134

C 212 - POWER PLANT UTILITIES

Code Parameter Page

1 Ammonia MR 25

2 Ammonia LR 27

3 Free Chlorine 31

4 Total Chlorine 37

5 Copper HR 52

6 Copper LR 54

7 Hydrazine 79

Code Parameter Page

8 Molybdenum 94

9 Phosphate HR 122

10 Phosphate LR 124

11 Phosphorus 126

12 Silica 128

13 Silver 131

17

Page 18

C 213 - MUNICIPAL WASTEWATER

Code Parameter Page

1 Aluminum 21

2 Ammonia MR 25

3 Ammonia LR 27

4 Bromine 29

5 Free Chlorine 31

6 Total Chlorine 37

7 Chromium VI HR 46

8 Chromium VI LR 48

9 Color of Water 50

10 Copper HR 52

11 Copper LR 54

12 Iodine 82

Code Parameter Page

13 Nickel HR 97

14 Nickel LR 99

15 Nitrate 102

16 Nitrite HR 104

17 Nitrite LR 106

18 Oxygen, Dissolved 117

19 pH 120

20 Phosphate HR 122

21 Phosphate LR 124

22 Phosphorus 126

23 Silver 131

24 Zinc 134

C 216 - SWIMMING POOL APPLICATION

Code Parameter Page

1 Free Chlorine HR 34

2 Total Chlorine HR 40

3 Cyanuric Acid 59

4 Bromine 29

Code Parameter Page

5 pH 120

6 Total Hardness LR 76

7 Total Hardness MR 73

8 Total Hardness HR 70

C 218 - ENVIRONMENTAL APPLICATION

Code Parameter Page

1 Ammonia MR 25

2 Ammonia HR 23

3 Cyanide 56

4 Chromium VI HR 46

5 Chromium VI LR 48

Code Parameter Page

6 Phosphorus 126

7 Nitrite HR 104

8 Nitrite LR 106

9 Nitrate 102

18

Page 19

OPERATIONAL GUIDEOPERATIONAL GUIDE

OPERATIONAL GUIDE

OPERATIONAL GUIDEOPERATIONAL GUIDE

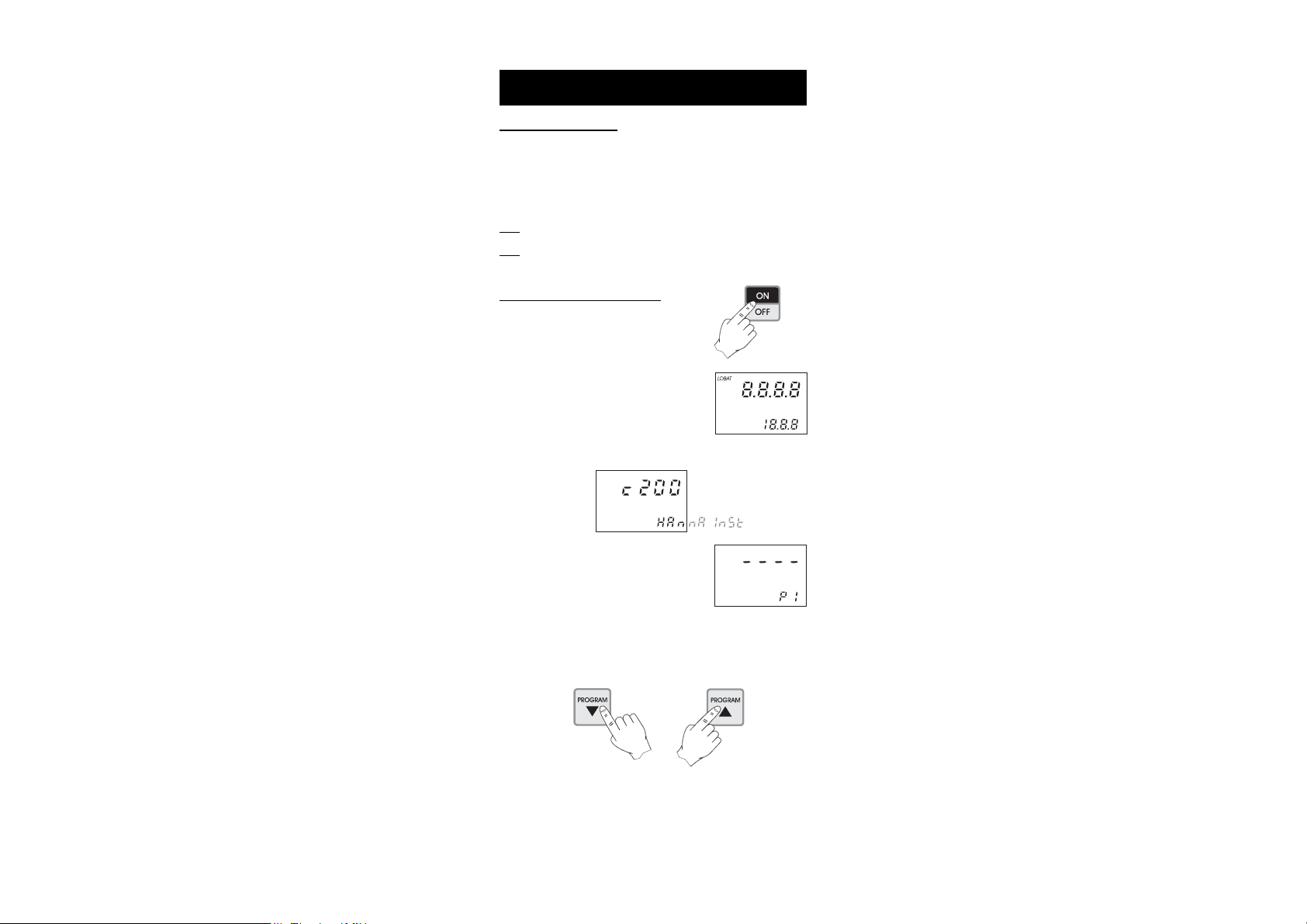

POWER CONNECTION

Plug the 12VDC adapter (HI 710005 - 110VDC, or HI 710006 220VDC) into the DC socket. Plug the adapter into the outlet.

Alternatively, remove the battery cover on the back of the meter;

attach 2 fresh 9V batteries and replace the cover.

Note: Insure the main line is surge protected.

Note: Always turn the meter off before unplugging it to insure no

data is lost.

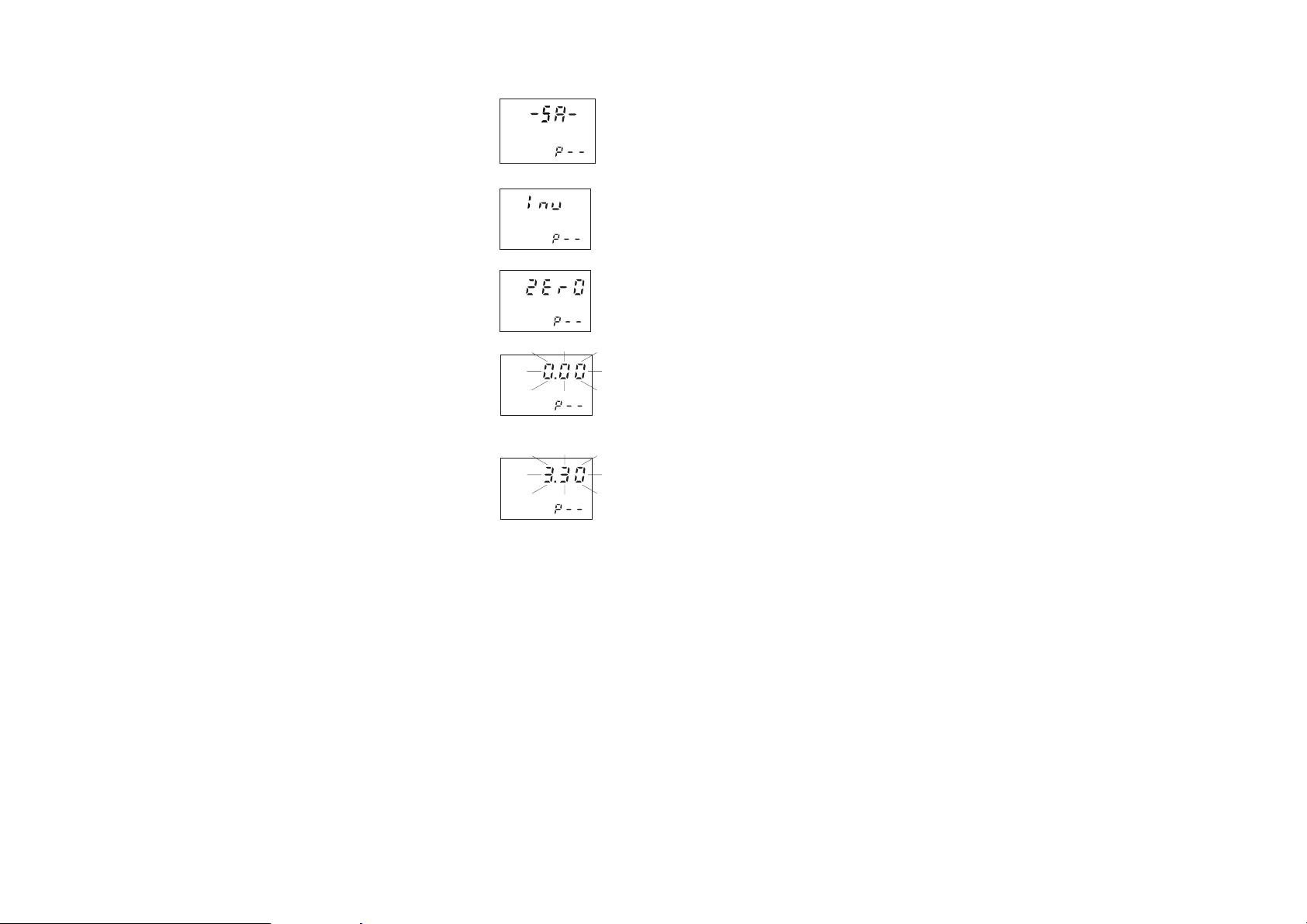

MEASUREMENT PROCEDURE

• Turn the meter on by pressing ON/OFF.

• The meter will first perform an LCD self

diagnostic test by displaying a full set of

figures.

• Then it will show a scrolling "c --- Hanna Inst" message.

• When the LCD displays “----”, the meter is

ready. On the secondary LCD "P1" will

appear to inform that the first parameter

measurement procedure (e.g. in C200, P1

for Aluminum) can be performed.

• Press the PROGRAM W and PROGRAM V keys to select the

desired parameter.

For the program number, see the tables on page 12 or look at

the list printed on the mask of the meter.

19

Page 20

• After the desired program number appears on the secondary

display, follow the measurement procedure described in the

related chapter.

• Select a new parameter measurement procedure by pressing the

PROGRAM W and PROGRAM V keys.

Note: in the following measurement sections, a generic "P– –" will be placed on

the secondary LCD instead of the exact

related message (e.g. in C 200, "P1" for

Aluminum).

• Before performing a test read carefully all the instructions related

to the selected parameter.

ABBREVIATIONSABBREVIATIONS

ABBREVIATIONS

ABBREVIATIONSABBREVIATIONS

°C°C

°C: degree Celsius

°C°C

EPAEPA

EPA: US Environmental Protection Agency

EPAEPA

°F°F

°F: degree Fahrenheit

°F°F

g/Lg/L

g/L: grams per liter (ppt)

g/Lg/L

HRHR

HR: High Range

HRHR

LRLR

LR: Low Range

LRLR

mg/Lmg/L

mg/L: milligrams per liter (ppm)

mg/Lmg/L

mLmL

mL: milliliter

mLmL

MRMR

MR: Medium Range

MRMR

µµ

g/Lg/L

µ

g/L: micrograms per liter (ppb)

µµ

g/Lg/L

PANPAN

PAN: 1-(2-pyridylazo)-2-naphtol

PANPAN

TPTZTPTZ

TPTZ: 2,4,6-tri-(2-pyridyl)-1,3,5-triazine

TPTZTPTZ

20

Page 21

ALUMINUMALUMINUM

ALUMINUM

ALUMINUMALUMINUM

SPECIFICATIONS

Range 0.00 to 1.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.02 mg/L ±4% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the aluminon method. The reac-

tion between aluminum and reagents causes a

reddish tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93712A-0 Ascorbic acid 1 packet

HI 93712B-0 Aluminon reagent 1 packet

HI 93712C-0 Bleaching powder 1 packet

REAGENT SETS

HI 93712-01 Reagents for 100 tests

HI 93712-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Aluminum on the

secondary LCD by pressing PROGRAM W and V.

• Fill a graduated beaker with 50 mL of sample.

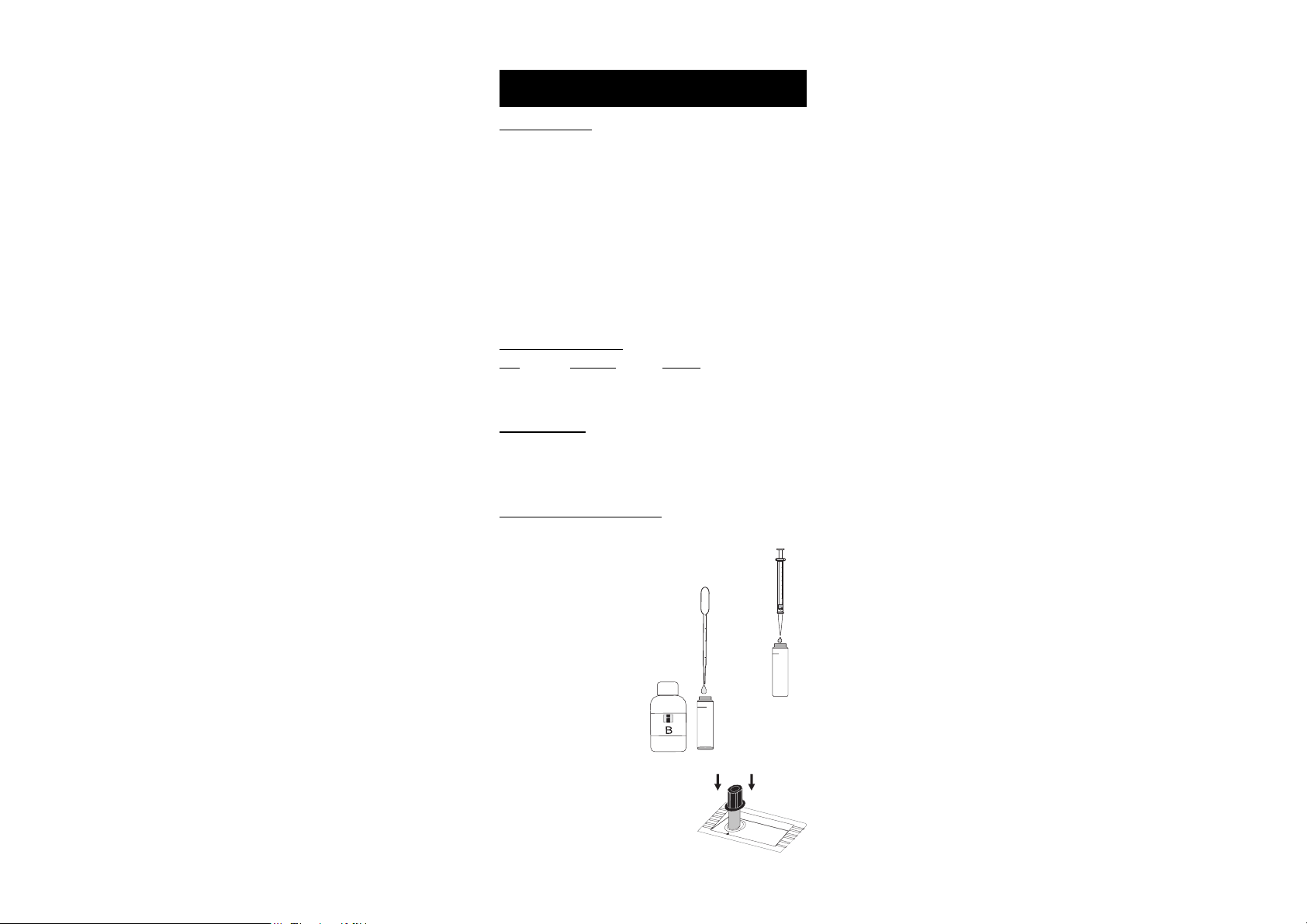

• Add the content of one packet of HI 93712A

Ascorbic acid reagent and mix until dissolution is

complete.

• Add the content of one packet of HI 93712B

Aluminon reagent and mix until dissolution is

complete. This is the sample.

21

Aluminum

Page 22

• Fill two cuvets with 10 mL of sample

each (up to the mark).

• Add the content of one HI 93712C

Bleaching powder packet to one of

the two cuvets. Replace the cap

and shake vigorously until dissolution

is complete. This is the blank.

# 1

# 1

10 mL10 mL

# 2

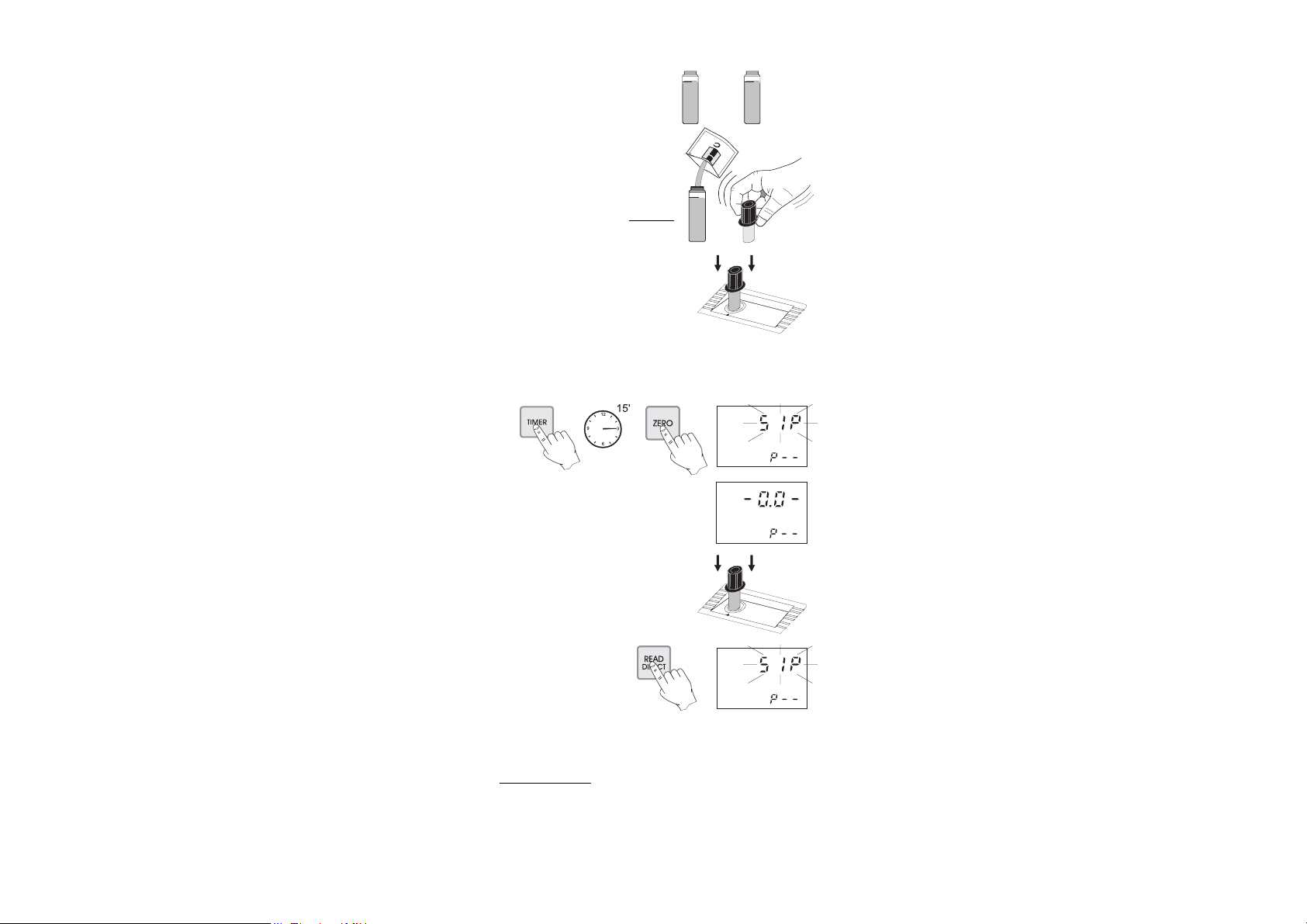

• Place the blank into the holder and

# 1

ensure that the notch on the cap is

positioned securely into the groove.

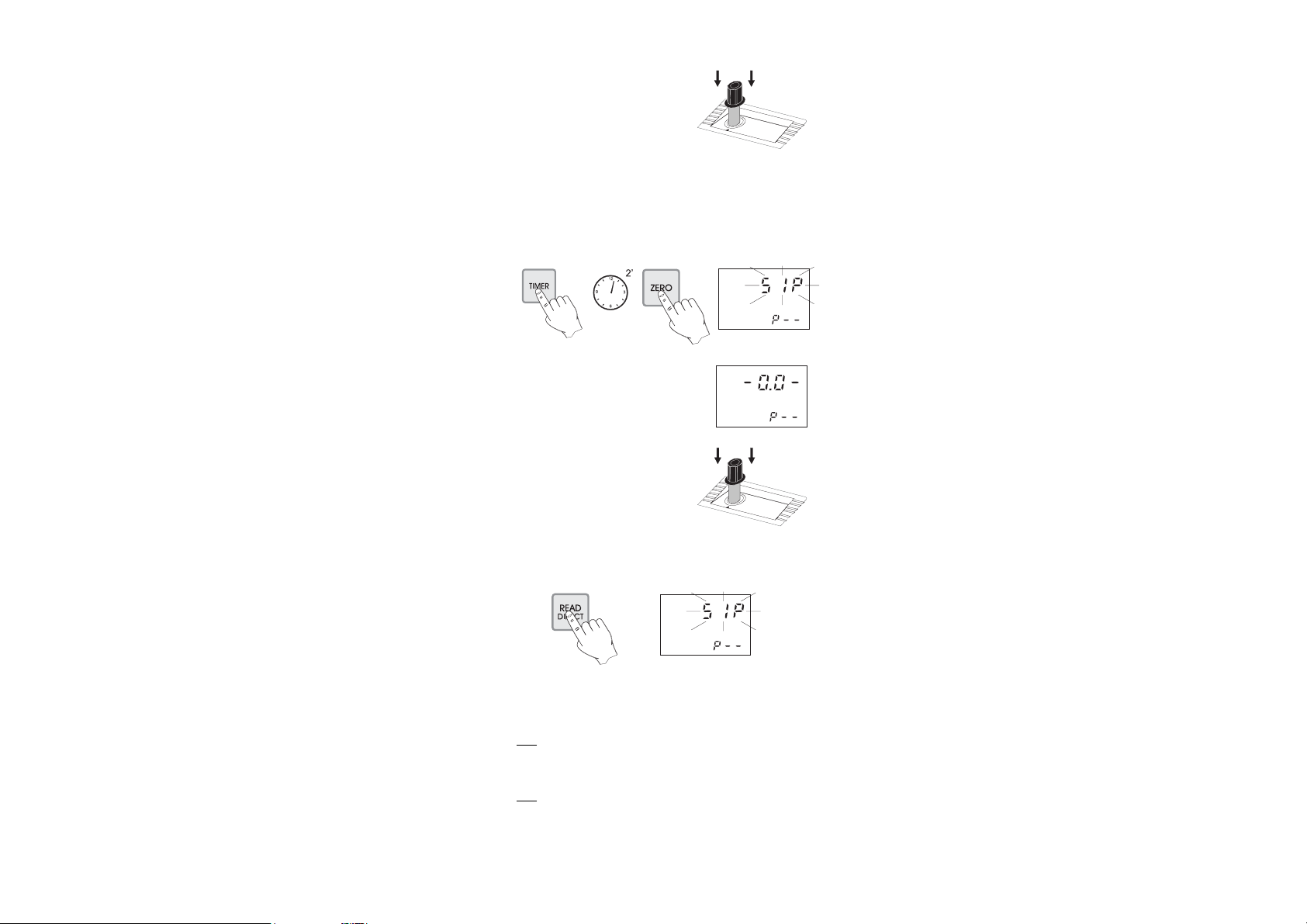

• Press TIMER and the display will show the countdown prior to

zeroing the blank. Alternatively wait for 15 minutes and then

press ZERO. "SIP" will blink during zeroing.

• Wait for a few seconds and the display will

show "-0.0-". Now the meter is zeroed and

ready for measurement.

• Remove the blank and insert the other

# 2

cuvet into the instrument.

• Press READ DIRECT.

"SIP" will blink during

measurement.

• The instrument directly displays concentration in mg/L of aluminum

on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by:

Iron above 20 mg/L Alkalinity above 1000 mg/L

Phosphate above 50 mg/L Fluoride must be absent

Aluminum

22

Page 23

AMMONIA HIGH RANGEAMMONIA HIGH RANGE

AMMONIA HIGH RANGE

AMMONIA HIGH RANGEAMMONIA HIGH RANGE

SPECIFICATIONS

Range 0.0 to 50.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.5 mg/L ±5% of reading

Typical EMC ±0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 420 nm

Method Adaptation of the ASTM Manual of Water and

Environmental Technology, D1426-92, Nessler

method. The reaction between ammonia and

reagents causes a yellow tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93733A-0 Nessler Reagent 4 drops (in fresh and seawater)

HI 93733B-0 Ammonia Reagent 9 mL (in fresh and seawater)

REAGENT SETS

HI 93733-01 Reagents for 100 tests

HI 93733-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Ammonia HR on the

secondary LCD by pressing PROGRAM W and V.

• Fill a cuvet with 1 mL of unreacted sample, by

means of the syringe.

1 mL of

sample

• Add 9 mL of HI 93733B

9 mL

Ammonia Reagent, by

means of the 3 mL plastic

pipette. Place the cap and

swirl the solution to mix.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

23

Ammonia HR

Page 24

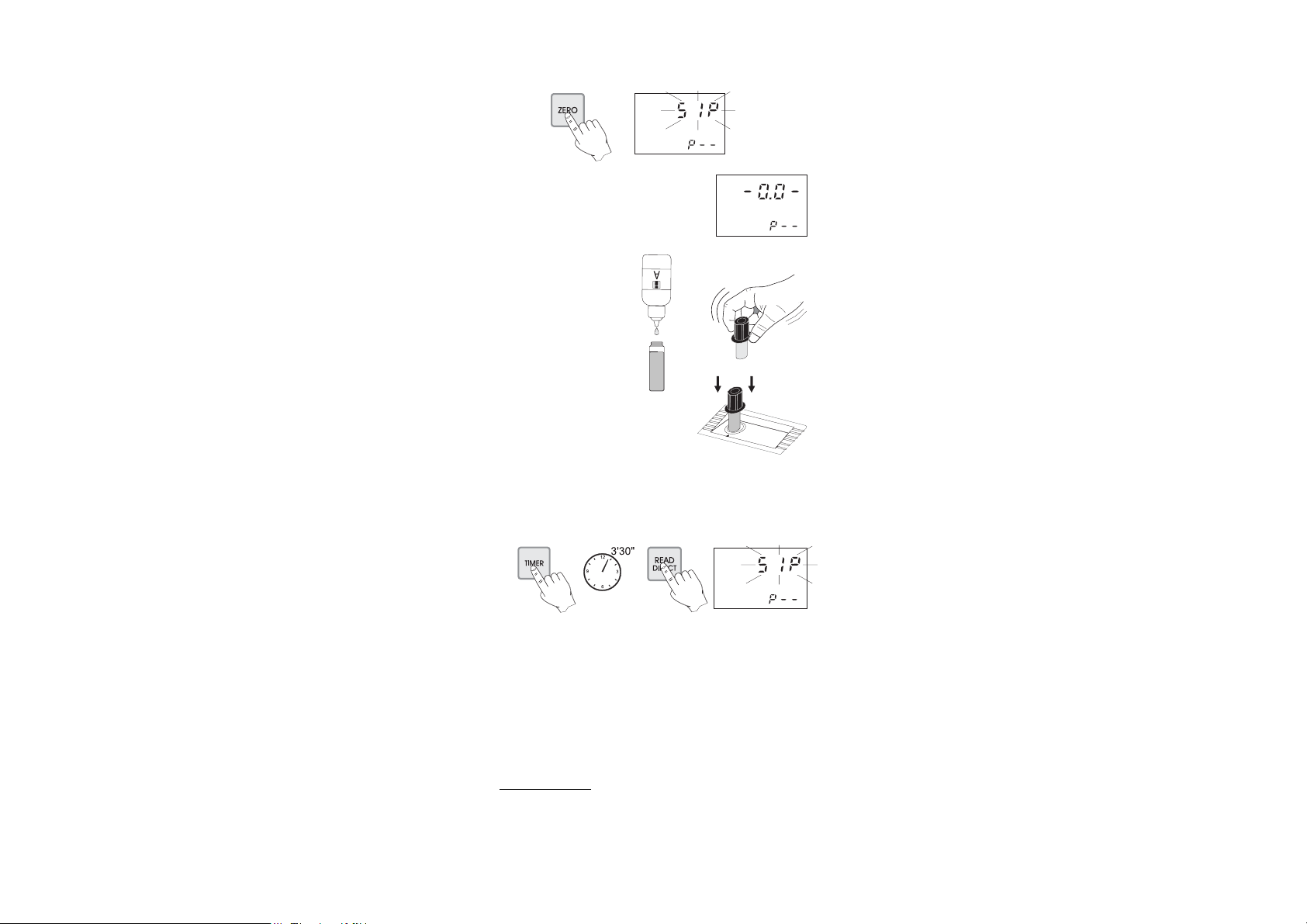

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

• Remove the cuvet.

• Add 4 drops of HI 93733A

x 4

Nessler Reagent. Replace the

cap and mix the solution.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to

measurement or, alternatively, wait for 3 minutes and 30 seconds

and then press READ DIRECT. In both cases the display will show

“SIP” during measurement.

• The instrument directly displays concentration in mg/L of Ammonium ion (NH

+

) on the Liquid Crystal Display.

4

• To convert the reading to mg/L of ammonia (NH3), multiply by a

factor of 0.944.

• To convert the reading to ammonia nitrogen (NH3-N), multiply by

a factor of 0.776.

INTERFERENCES

Interference may be caused by:

acetone, alcohols, aldehydes, glycine, hardness above 1 g/L, iron,

organic chloramines, sulfide, various aliphatic and aromatic amines.

Ammonia HR

24

Page 25

AMMONIA MEDIUM RANGEAMMONIA MEDIUM RANGE

AMMONIA MEDIUM RANGE

AMMONIA MEDIUM RANGEAMMONIA MEDIUM RANGE

SPECIFICATIONS

Range 0.00 to 10.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.05 mg/L ±5% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 420 nm

Method Adaptation of the ASTM Manual of Water and

Environmental Technology, D1426-92, Nessler

method. The reaction between ammonia and

reagents causes a yellow tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93715A-0 First Reagent 4 drops (6 drops in seawater)

HI 93715B-0 Second Reagent 4 drops (10 drops in seawater)

REAGENT SETS

HI 93715-01 Reagents for 100 tests

HI 93715-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Ammonia MR on the

secondary LCD by pressing PROGRAM W and V.

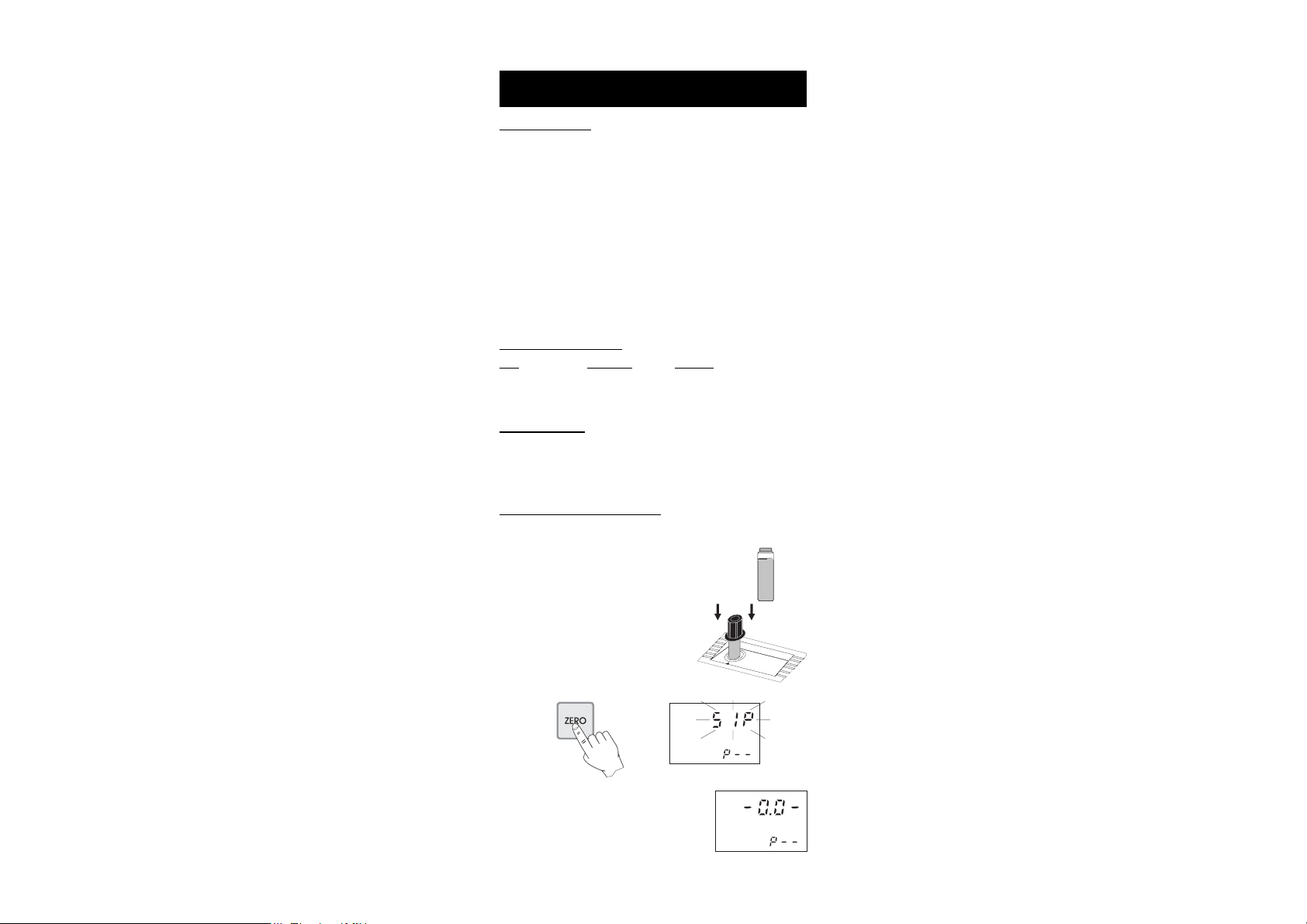

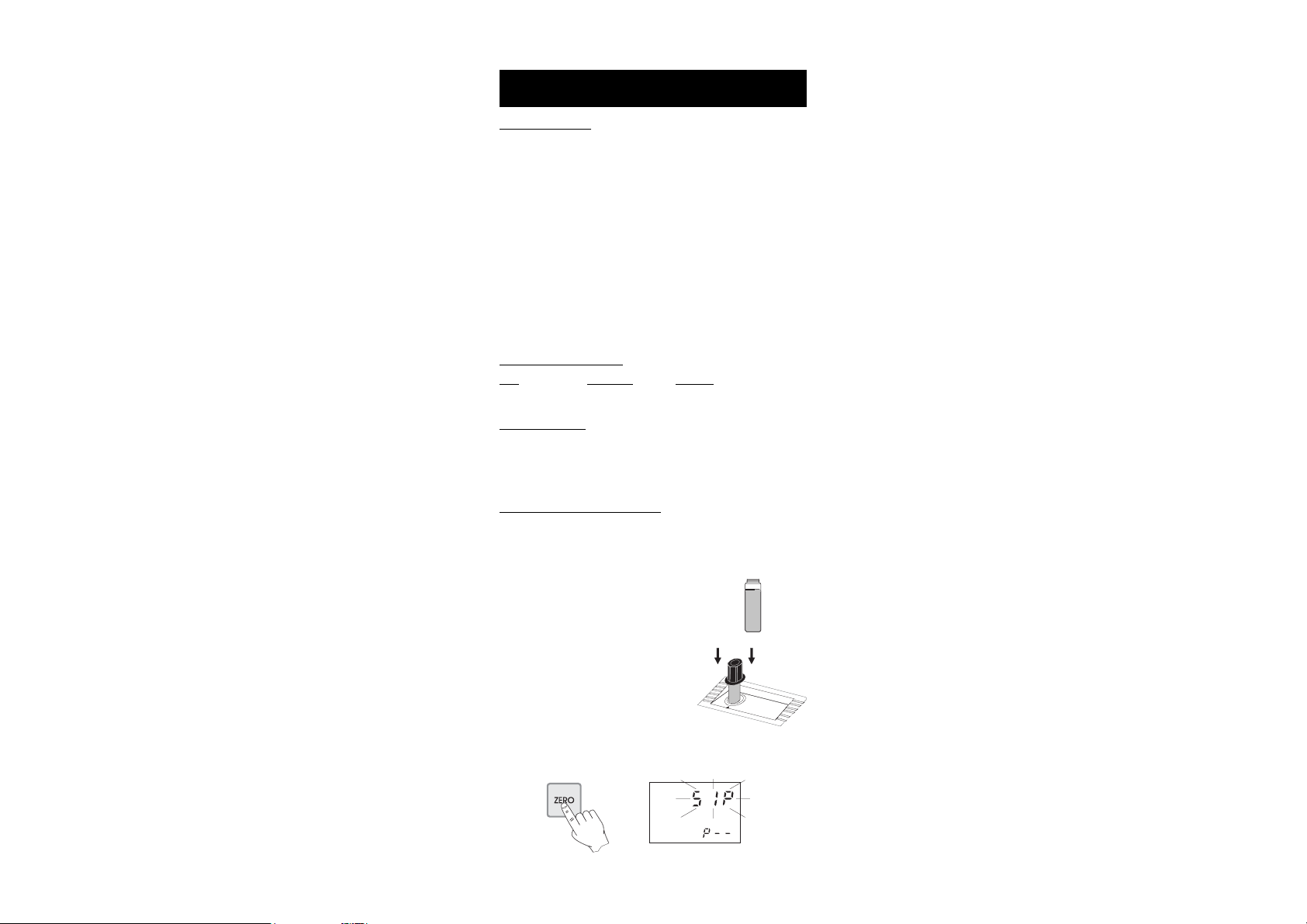

• Fill the cuvet with 10 mL of unreacted sample (up

to the mark) and replace the cap.

10 mL

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

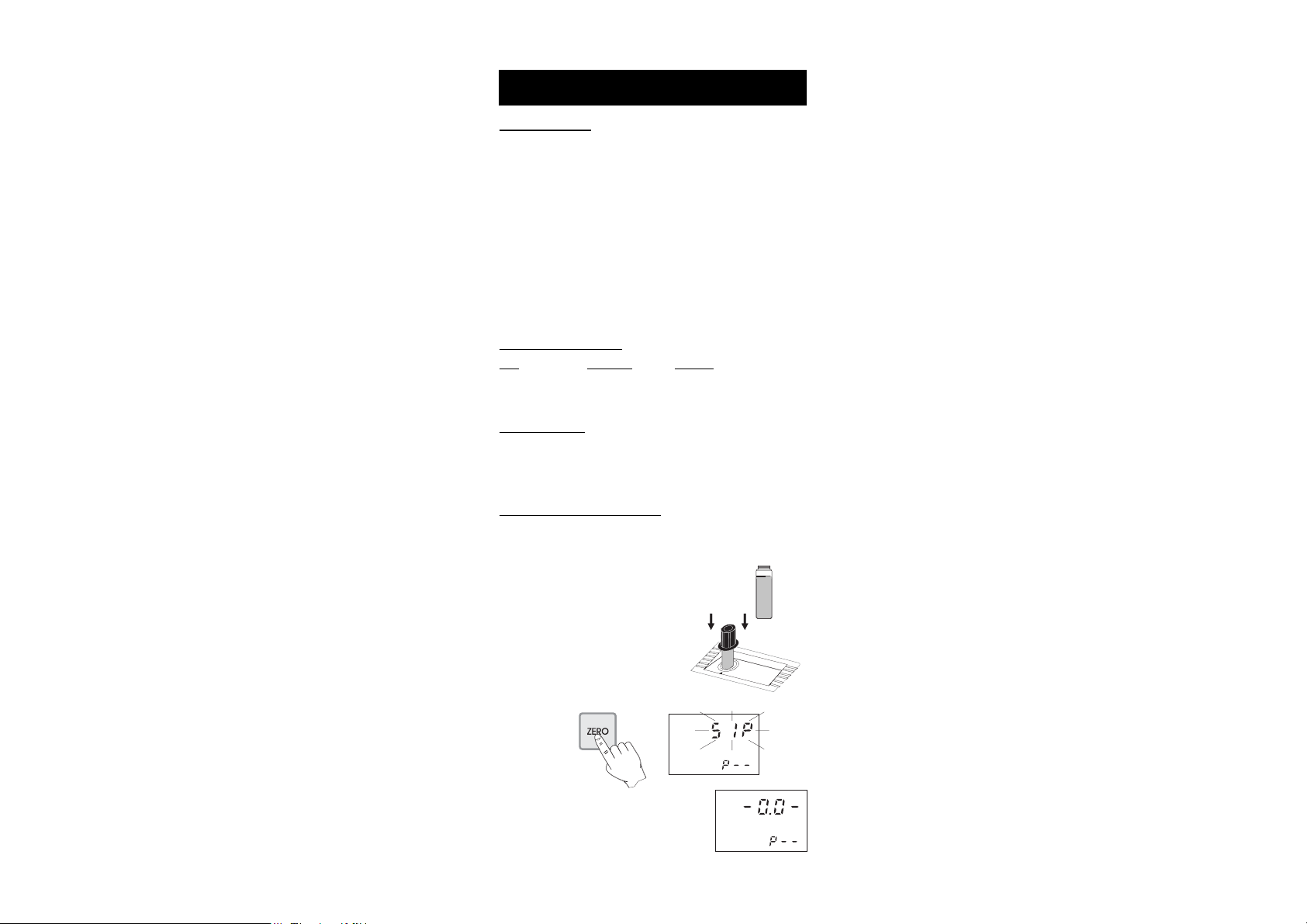

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

25

Ammonia MR

Page 26

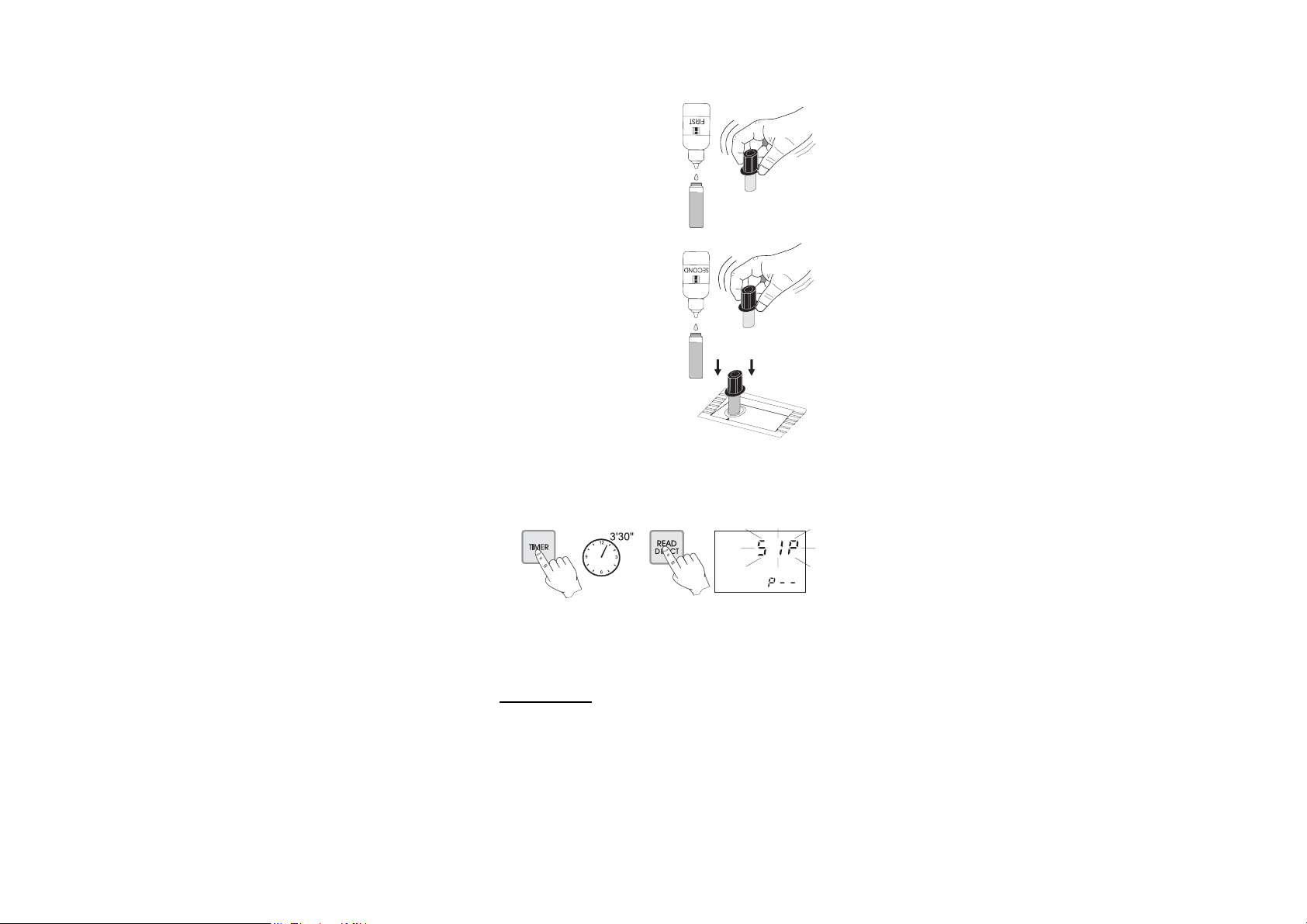

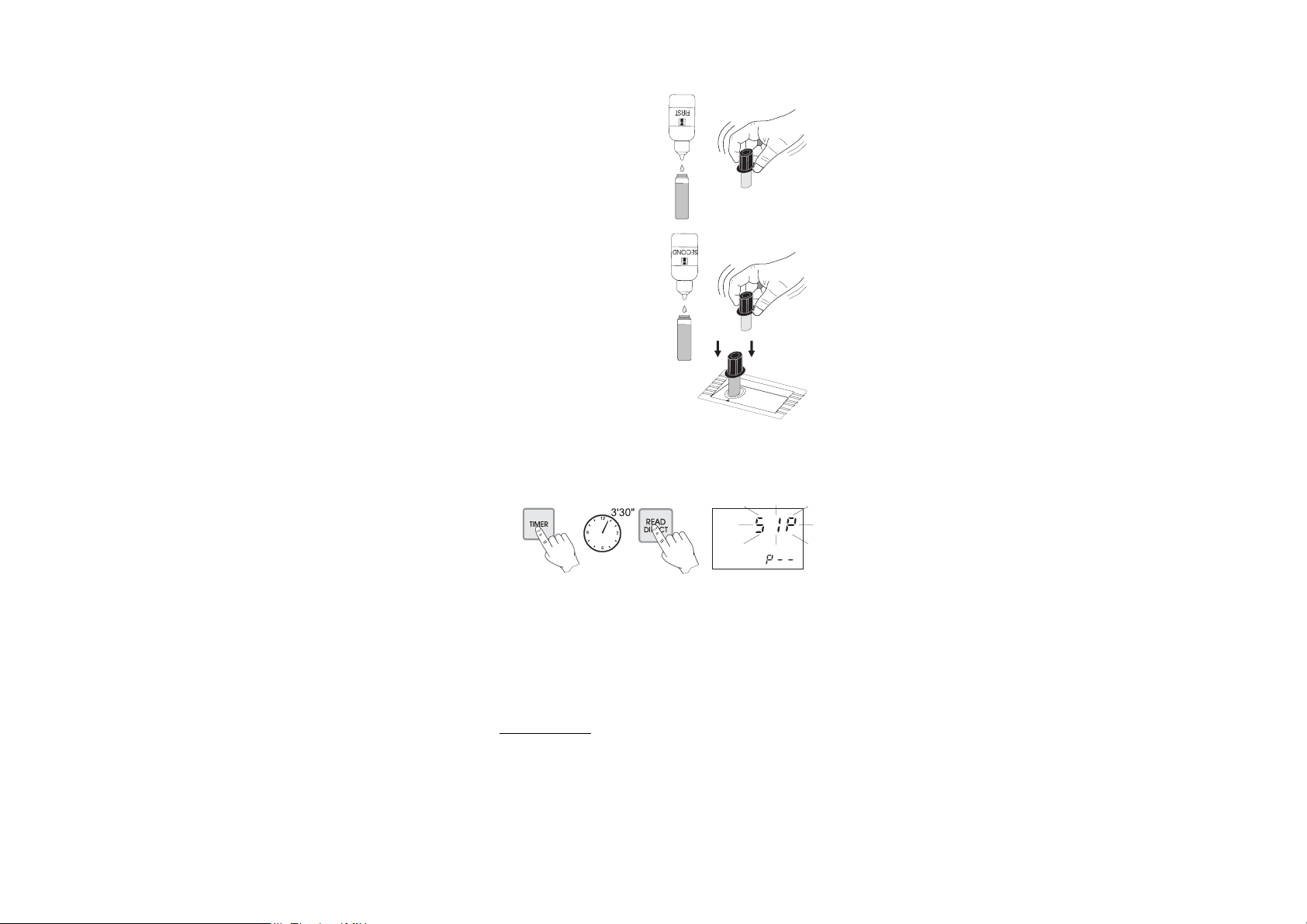

• Remove the cuvet.

• Add 4 drops of the First reagent (6

drops in case of seawater analysis).

Replace the cap and mix the

x 4

solution.

• Add 4 drops of the Second reagent

(10 drops in case of seawater

analysis). Replace the cap and mix

the solution.

x 4

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 3 minutes and 30 seconds

and press READ DIRECT. In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of ammonia

nitrogen (NH3-N) on the display.

• To convert the reading to mg/L of ammonia (NH3), multiply by a

factor of 1.216.

INTERFERENCES

Interference may be caused by:

acetone, alcohols, aldehydes, glycine, hardness above 1 g/L, iron,

organic chloramines, sulfide, various aliphatic and aromatic amines.

Ammonia MR

26

Page 27

AMMONIA LOW RANGEAMMONIA LOW RANGE

AMMONIA LOW RANGE

AMMONIA LOW RANGEAMMONIA LOW RANGE

SPECIFICATIONS

Range 0.00 to 3.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.04 mg/L ±4% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 420 nm

Method Adaptation of the ASTM Manual of Water and

Environmental Technology, D1426-92, Nessler

method. The reaction between ammonia and

reagents causes a yellow tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93700A-0 First Reagent 4 drops (6 drops in seawater)

HI 93700B-0 Second Reagent 4 drops (10 drops in seawater)

REAGENT SETS

HI 93700-01 Reagents for 100 tests

HI 93700-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Ammonia LR on the

secondary LCD by pressing PROGRAM W and V.

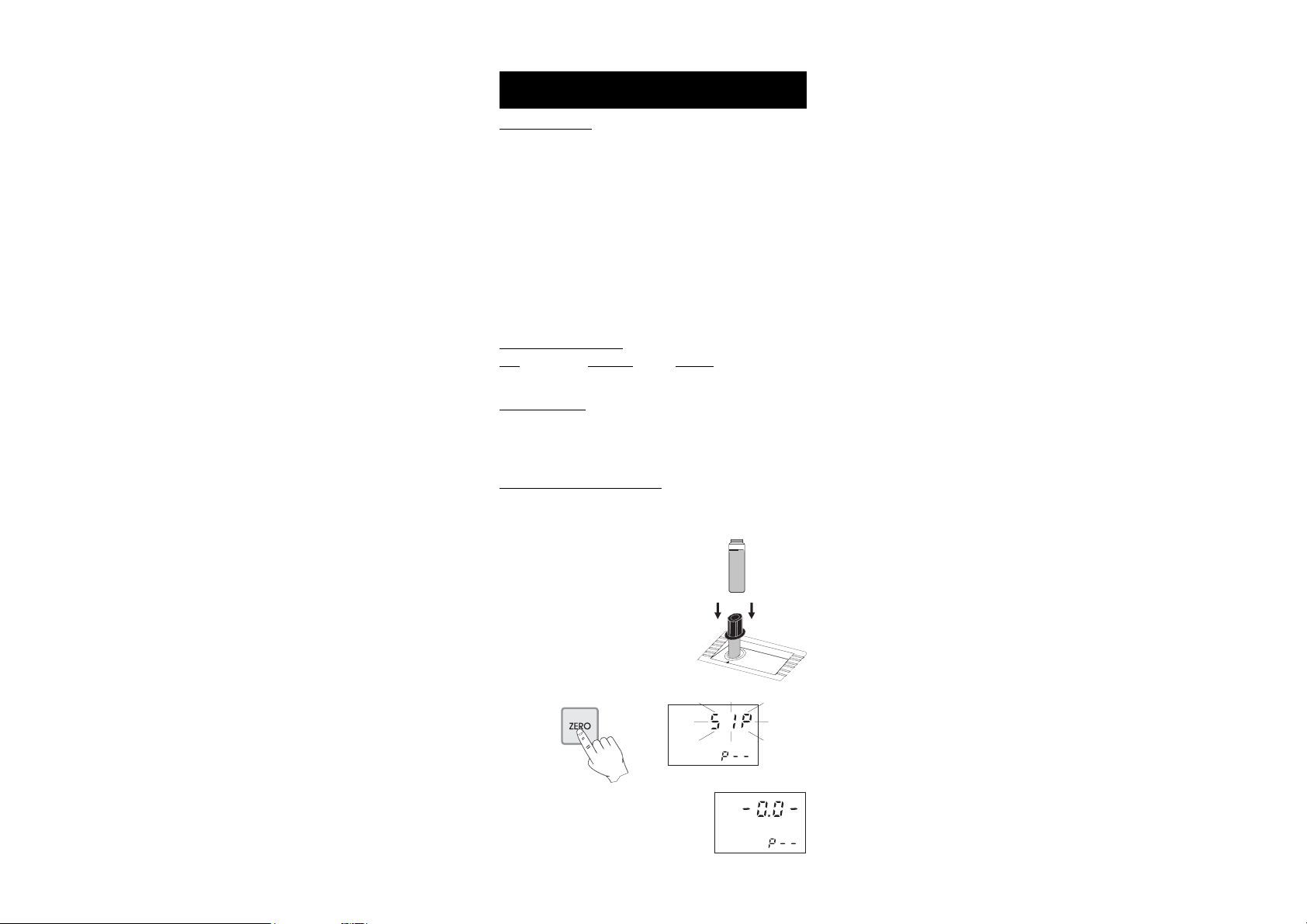

• Fill the cuvet with 10 mL of unreacted sample, up

to the mark, and replace the cap.

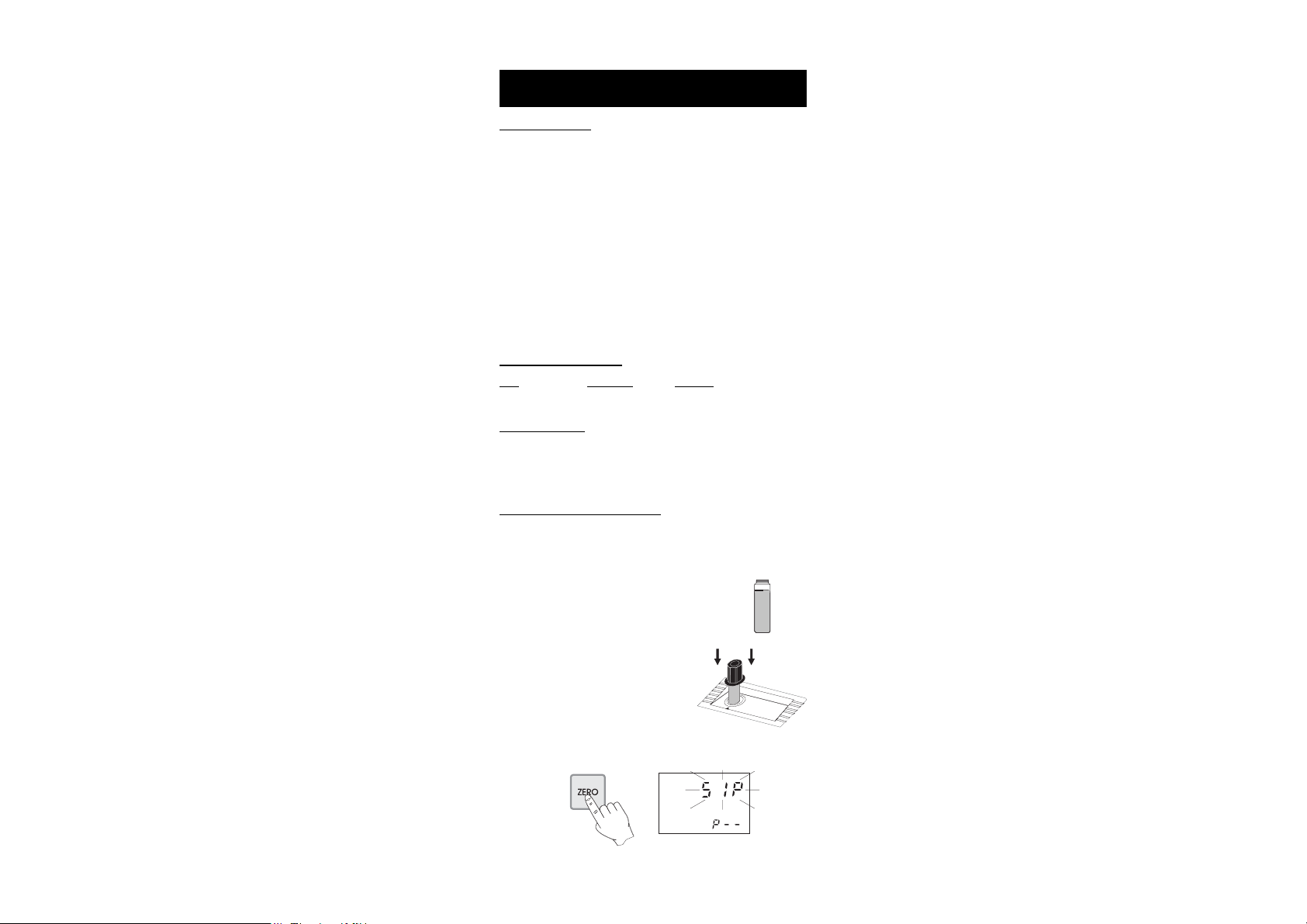

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

27

10 mL

Ammonia LR

Page 28

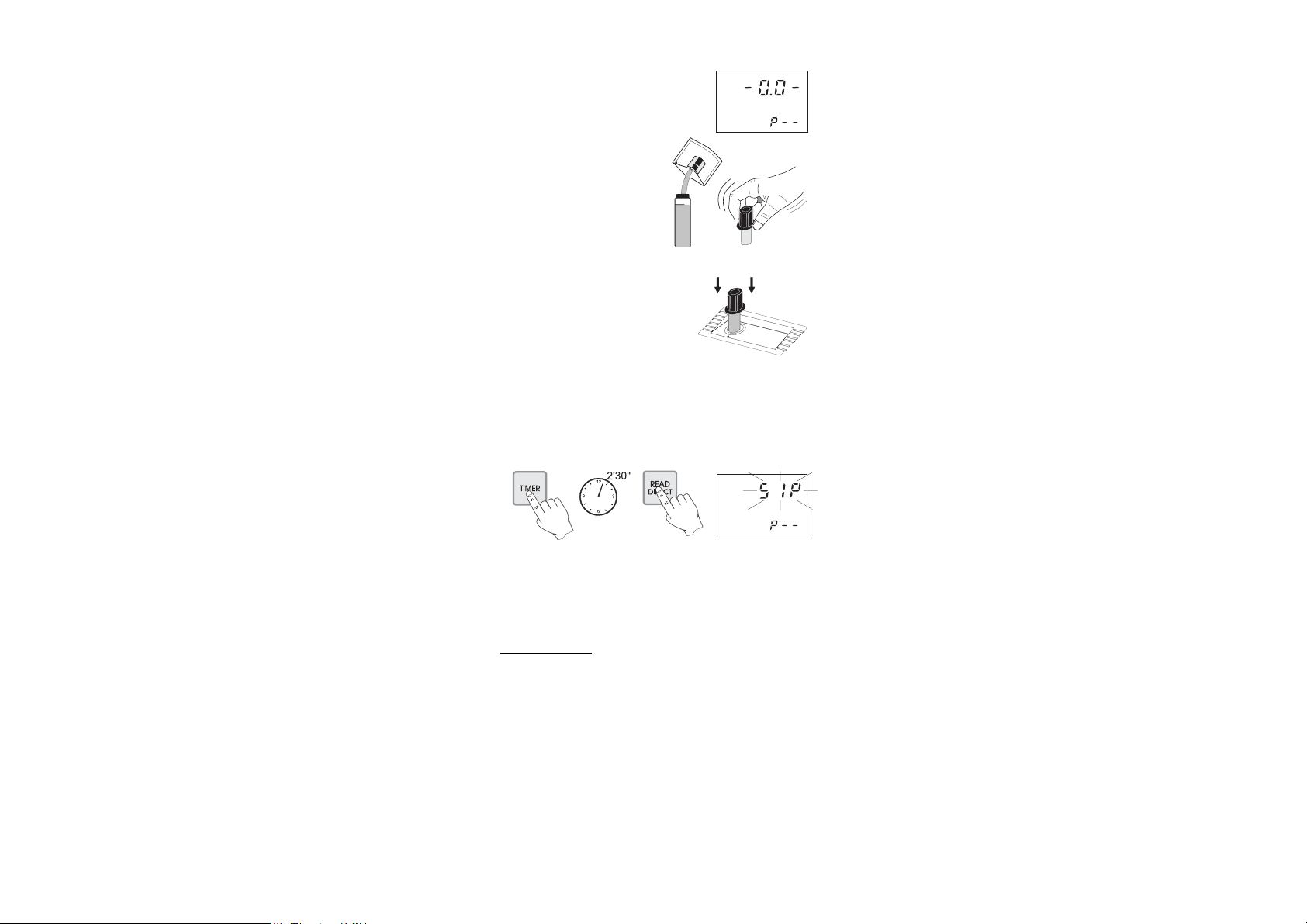

• Remove the cuvet.

• Add 4 drops of the First reagent

(6 drops in case of seawater

analysis). Replace the cap and

mix the solution.

x 4

• Add 4 drops of the Second

reagent (10 drops in case of

seawater analysis). Replace the

cap and mix the solution.

x 4

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 3 minutes and 30 seconds

and press READ DIRECT. In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of ammonia

nitrogen (NH3-N) on the display.

• To convert the reading to mg/L of ammonia (NH3), multiply the

display by a factor of 1.216.

INTERFERENCES

Interference may be caused by:

acetone, alcohols, aldehydes, glycine, hardness above 1 g/L, iron,

organic chloramines, sulfide, various aliphatic and aromatic amines.

Ammonia LR

28

Page 29

BROMINEBROMINE

BROMINE

BROMINEBROMINE

SPECIFICATIONS

Range 0.00 to 8.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.08 mg/L ±3% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the Standard Methods for the

Examination of Water and Wastewater, 18

edition, DPD method. The reaction between bro-

mine and the reagent causes a pink tint in the

sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93716-0 DPD Reagent 1 packet

REAGENT SETS

HI 93716-01 Reagents for 100 tests

HI 93716-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Bromine on the

secondary LCD by pressing PROGRAM W and V.

th

• Fill the cuvet with 10 mL of unreacted sample (up

to the mark) and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

29

10 mL

Bromine

Page 30

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

• Remove the cuvet and add the

content of one packet of HI 93716

reagent. Replace the cap and

shake gently for about 20 seconds

to dissolve most of the reagent.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 2 minutes and 30 seconds

and press READ DIRECT. In both cases "SIP" will blink during

measurement.

• The instrument directly displays concentration in mg/L of bromine

on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Chlorine, Iodine, Ozone, Oxidized

forms of Chromium and Manganese.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the reagent.

In case of water with alkalinity greater than 250 mg/L CaCO3 or

acidity greater than 150 mg/L CaCO3, the color of the sample may

develop only partially, or may rapidly fade. To resolve this, neutralize

the sample with diluted HCl or NaOH.

Bromine

30

Page 31

FREE CHLORINEFREE CHLORINE

FREE CHLORINE

FREE CHLORINEFREE CHLORINE

SPECIFICATIONS

Range 0.00 to 2.50 mg/L

Resolution 0.01 mg/L

Accuracy ±0.03 mg/L ±3% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the EPA DPD method 330.5. The

reaction between free chlorine and the DPD reagent causes a pink tint in the sample.

REQUIRED REAGENTS

POWDER:

Code Description Quantity

HI 93701-0 DPD 1 packet

LIQUID:

Code Description Quantity

HI 93701A-F DPD1 Indicator 3 drops

HI 93701B-F DPD1 Buffer 3 drops

REAGENT SETS

HI 93701-F Reagents for 300 tests (liquid)

HI 93701-01 Reagents for 100 tests (powder)

HI 93701-03 Reagents for 300 tests (powder)

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Free Chlorine on the

secondary LCD by pressing PROGRAM W and V.

10 mL

• Fill the cuvet with 10 mL of unreacted sample (up

to the mark) and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

31

Free Chlorine

Page 32

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

• Remove the cuvet.

Powder reagents procedure

• Add the content of one packet

of HI 93701 DPD reagent.

Replace the cap and shake

gently for 20 seconds (or 2

minutes in case of seawater

analysis).

• Wait for a minute to allow the

undissolved reagent to precipitate

and reinsert the cuvet into the

instrument.

• Press READ DIRECT and the display will show “SIP” during

measurement.

• The instrument directly displays concentration in mg/L of free

chlorine on the Liquid Crystal Display.

32Free Chlorine

Page 33

Liquid reagents procedure

• To an empty cuvet add 3

drops of HI 93701A-F DPD1

indicator and 3 drops of

HI 93701B-F DPD1 buffer.

Swirl gently to mix, and

immediately add 10 mL of

x 3

x 3

unreacted sample. Replace

the cap and shake gently

again.

• Reinsert the cuvet into the instrument.

• Press READ DIRECT and the display will show “SIP” during

measurement.

• The instrument directly displays concentration in mg/L of free

chlorine on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Bromine, Iodine, Ozone, Oxidized

forms of Chromium and Manganese.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the powder

reagent.

In case of water with alkalinity greater than 250 mg/L CaCO3 or

acidity greater than 150 mg/L CaCO3, the color of the sample may

develop only partially, or may rapidly fade. To resolve this, neutralize

the sample with diluted HCl or NaOH.

33 Free Chlorine

Page 34

FREE CHLORINE HIGH RANGEFREE CHLORINE HIGH RANGE

FREE CHLORINE HIGH RANGE

FREE CHLORINE HIGH RANGEFREE CHLORINE HIGH RANGE

SPECIFICATIONS

Range 0.0 to 10.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.1 mg/L ±3% of reading

Typical EMC ±0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the EPA DPD method 330.5. The

reaction between free chlorine and the DPD reagent causes a pink tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93701-0 DPD 1 packet

HI 93734B-0 Free & Total Chlorine HR Reagent 5 mL

REAGENT SETS

HI 93734-01 Reagents for 100 tests

HI 93734-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Free Chlorine HR on

the secondary LCD by pressing PROGRAM W and V.

• Add to the cuvet 5 mL of HI 93734B

reagent by means of the 5 mL syringe.

Free Chlorine HR

34

5 mL

Page 35

Note: To measure exactly 5 mL of reagent with the syringe, push

the plunger completely into the syringe and insert the tip into

HI 93734B reagent bottle. Pull the plunger out until the lower

edge of the seal is on the 5 mL mark of the syringe.

probable level of liquid

taken up by syringe

5 mL

• Fill the cuvet up to the 10 mL mark

of sample

with 5 mL of unreacted sample, using

the 3 mL plastic pipette.

Note: rinse the 3 mL plastic pipette 2

10 mL

or 3 times with sample before adding it

to the cuvet with reagent.

• Replace the cap and shake gently.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and "SIP" will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

35

Free Chlorine HR

Page 36

• Remove the cuvet.

• Add the content of one packet

of HI 93701 DPD reagent. Replace the cap and shake gently

for 20 seconds (or 2 minutes in

case of seawater analysis).

• Wait for a minute to allow the

undissolved reagent to precipitate

and reinsert the cuvet into the

instrument.

• Press READ DIRECT and the display will show “SIP” during

measurement.

• The instrument directly displays concentration in mg/L of free

chlorine on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Bromine, Iodine, Ozone, Oxidized

forms of Chromium and Manganese.

Alkalinity above 250 mg/L or acidity above 150 mg/L will not

reliably develop the full amount of color or it may rapidly fade. To

resolve this, neutralize the sample with diluted HCl or NaOH.

In case of water with hardness greater than 1000 mg/L CaCO3,

shake the sample for approximately 1 minute after adding the

powder reagent.

Free Chlorine HR

36

Page 37

TOTAL CHLORINETOTAL CHLORINE

TOTAL CHLORINE

TOTAL CHLORINETOTAL CHLORINE

SPECIFICATIONS

Range 0.00 to 3.50 mg/L

Resolution 0.01 mg/L

Accuracy ±0.03 mg/L ±3% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the EPA DPD method 330.5. The

reaction between the chlorine and the DPD reagent causes a pink tint in the sample.

REQUIRED REAGENTS

POWDER:

Code Description Quantity

HI 93711-0 DPD 1 packet

LIQUID:

Code Description Quantity

HI 93701A-T DPD1 indicator 3 drops

HI 93701B-T DPD1 buffer 3 drops

HI 93701C DPD3 solution 1 drop

REAGENT SETS

HI 93701-T Reagents for 300 total chlorine tests (liquid)

HI 93711-01 Reagents for 100 total chlorine tests (powder)

HI 93711-03 Reagents for 300 total chlorine tests (powder)

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Total Chlorine on

the secondary LCD by pressing PROGRAM W and V.

• Fill the cuvet with 10 mL of unreacted sample

(up to the mark) and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

37

10 mL

Total Chlorine

Page 38

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

• Remove the cuvet.

Powder reagents procedure

• Add 1 packet of HI 93711

reagent. Replace the cap and

shake gently for 20 seconds

(or 2 minutes in case of seawater analysis).

• Reinsert the cuvet into the

instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 2 minutes and 30 seconds

and press READ DIRECT. In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of total

chlorine on the Liquid Crystal Display.

Liquid reagents procedure

• To an empty cuvet

add 3 drops of HI

93701A-T DPD1

indicator, 3 drops of

HI 93701B-T DPD1 buffer

and 1 drop of HI 93701C

x 3

x 3

x 1

DPD solution. Swirl

gently to mix and

immediately add 10

38Total Chlorine

Page 39

mL of unreacted sample. Replace the cap and shake gently

again.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 2 minutes and 30 seconds

and press READ DIRECT. In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of total

chlorine on the Liquid Crystal Display.

Note: free and total chlorine have to be measured separately with

fresh unreacted samples following the related procedure if both

values are requested.

INTERFERENCES

Interference may be caused by: Bromine, Iodine, Ozone, Oxidized

forms of Chromium and Manganese.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the powder

reagent.

In case of water with alkalinity greater than 250 mg/L CaCO3 or

acidity greater than 150 mg/L CaCO3, the color of the sample may

develop only partially, or may rapidly fade. To resolve this, neutralize

the sample with diluted HCl or NaOH.

39

Total Chlorine

Page 40

TOTAL CHLORINE HIGH RANGETOTAL CHLORINE HIGH RANGE

TOTAL CHLORINE HIGH RANGE

TOTAL CHLORINE HIGH RANGETOTAL CHLORINE HIGH RANGE

SPECIFICATIONS

Range 0.0 to 10.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.1 mg/L ±3% of reading

Typical EMC ±0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the EPA DPD method 330.5. The

reaction between free chlorine and the DPD reagent causes a pink tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93701-0 DPD 1 packet

HI 93734B-0 Free & Total Chlorine HR Reagent 5 mL

HI 93734C-0 Total Chlorine HR Reagent 3 drops

REAGENT SETS

HI 93734-01 Reagents for 100 tests

HI 93734-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Total Chlorine HR on

the secondary LCD by pressing PROGRAM W and V.

• Add to the cuvet 5 mL of HI 93734B reagent

by means of the 5 mL syringe.

5 mL

Total Chlorine HR

40

Page 41

Note: To measure exactly 5 mL of reagent with the syringe, push

the plunger completely into the syringe and insert the tip into

HI 93734B reagent bottle. Pull the plunger out until the lower

edge of the seal is on the 5 mL mark of the syringe.

probable level of liquid

taken up by syringe

5 mL

• Fill the cuvet up to the 10 mL mark

of sample

with 5 mL of unreacted sample, using

the 3 mL plastic pipette.

Note: rinse the 3 mL plastic pipette 2

10 mL

or 3 times with sample before adding it

to the cuvet with reagent.

• Replace the cap and shake gently.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and "SIP" will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

41 Total Chlorine HR

Page 42

• Remove the cuvet.

• Add 3 drops of HI 93734C reagent to the cuvet.

• Add the content of one

x 3

packet of HI 93701 DPD

reagent to the cuvet.

Replace the cap and

shake gently for 20 seconds (or 2 minutes in

case of seawater analysis).

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show a countdown prior to the

measurement or, alternatively, wait for 2 minutes and 30 seconds

and press READ DIRECT. The display will show “SIP” during

measurement.

• The instrument directly displays concentration in mg/L of total

chlorine on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Bromine, Iodine, Ozone, Oxidized

forms of Chromium and Manganese.

Alkalinity above 250 mg/L or acidity above 150 mg/L will not

reliably develop the full amount of color or it may rapidly fade. To

resolve this, neutralize the sample with diluted HCl or NaOH.

In case of water with hardness greater than 1000 mg/L CaCO3,

shake the sample for approximately 1 minute after adding the

powder reagent.

Total Chlorine HR

42

Page 43

CHLORINE DIOXIDECHLORINE DIOXIDE

CHLORINE DIOXIDE

CHLORINE DIOXIDECHLORINE DIOXIDE

SPECIFICATIONS

Range 0.00 to 2.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.10 mg/L ±5% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 575 nm

Method Adaptation of the Chlorophenol Red method. The

reaction between chlorine dioxide and reagents

causes a colorless to purple tint in the sample.

REQUIRED REAGENT

Code Description Quantity

HI 93738A-0 Reagent A 1 mL

HI 93738B-0 Dechlorinating Reagent B 1 packet

HI 93738C-0 Reagent C 1 mL

HI 93738D-0 Reagent D 1 mL

REAGENT SETS

HI 93738-01 Reagents for 100 tests

HI 93738-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Chlorine Dioxide on

the secondary LCD by pressing PROGRAM W and V.

• Fill two graduated mixing cylinders (#1 & #2) up to the

25 mL mark with the sample.

• Add 0.5 mL of HI 93738A chlorine dioxide reagent to each

cylinder (#1 & #2), close them and invert several times to mix.

#1

25 ml

#2

25 ml

#1

43

#1 & #2

#2

Chlorine Dioxide

Page 44

• Add the content of one packet of HI 93738B dechlorinating

reagent to only one of the two cylinders (#1), close and invert it

several times until it is totally dissolved. This is the blank.

#1

• Add precisely 0.5 mL of HI 93738C chlorine dioxide reagent to

each cylinder (#1 & #2), close them and invert several times to

mix.

#1 & #2

#1

#2

• Add 0.5 mL of HI 93738D chlorine dioxide reagent to each

cylinder (#1 & #2), close them and invert several times to mix.

Cylinder #2 is the reacted sample.

#1 & #2

#1

• Fill a cuvet with 10 mL of the blank

#2

#1

10 mL

(#1) up to the mark and replace the

cap.

• Place the blank (#1) into the holder

#1

and ensure that the notch on the cap

is positioned securely into the groove.

Chlorine Dioxide

44

Page 45

• Press ZERO and "SIP" will blink on the display.

• Wait for a few seconds and the display will

show "-0.0-". Now the meter is zeroed and

ready for measurement.

• Fill another cuvet with 10 mL of the reacted

sample (#2) up to the mark and replace

the cap.

• Insert the sample into the instrument.

#2

10 mL

#2

• Press READ DIRECT and "SIP" will blink during measurement.

• The instrument directly displays concentration in mg/L of chlorine

dioxide on the Liquid Crystal Display.

SAMPLING PROCEDURE

It is recommended to analyze chlorine dioxide samples immediately

after collection. Chlorine dioxide samples must be stored in dark glass

stoppered bottles, with minimal head space. Excessive heat (above

25°C/78°F), agitation and exposure to light must be avoided.

INTERFERENCES

Interferences may be caused by strong oxidants.

45

Chlorine Dioxide

Page 46

CHROMIUM VI HIGH RANGECHROMIUM VI HIGH RANGE

CHROMIUM VI HIGH RANGE

CHROMIUM VI HIGH RANGECHROMIUM VI HIGH RANGE

SPECIFICATIONS

Range 0 to 1000 µg/L

Resolution 1 µg/L

Accuracy ±5 µg/L ±4% of reading

Typical EMC ±1 µg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the ASTM Manual of Water and

Environmental Technology, D1687-92,

Diphenylcarbohydrazide method. The reaction

between chromium VI and the reagent causes a

purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93723-0 Powder reagent 1 packet

REAGENT SETS

HI 93723-01 Reagents for 100 tests

HI 93723-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Chromium VI HR on

the secondary LCD by pressing PROGRAM W and V.

• Fill the cuvet up to the mark with 10 mL of

unreacted sample and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

Chromium VI HR

46

10 mL

Page 47

• Remove the cuvet and add the

content of one packet of HI

93723 reagent. Replace the cap

and shake vigorously for about

10 seconds.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 6 minutes and press READ

DIRECT. In both cases "SIP" will blink during measurement.

• The instrument directly displays concentration in µg/L of chromium

VI on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by:

Vanadium above 1 ppm. However, waiting 10 minutes before

reading, the interference is removed

Iron above 1 ppm

Mercurous and mercuric ions cause slight inhibition of the reaction.

47

Chromium VI HR

Page 48

CHROMIUM VI LOW RANGECHROMIUM VI LOW RANGE

CHROMIUM VI LOW RANGE

CHROMIUM VI LOW RANGECHROMIUM VI LOW RANGE

SPECIFICATIONS

Range 0 to 300 µg/L

Resolution 1 µg/L

Accuracy ±1 µg/L ±4% of reading

Typical EMC ±1 µg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the ASTM Manual of Water and

Environmental Technology, D1687-92,

Diphenylcarbohydrazide method. The reaction between chromium VI and the reagent causes a

purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93749-0 Powder reagent 1 packet

REAGENT SETS

HI 93749-01 Reagents for 100 tests

HI 93749-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Chromium VI LR on

the secondary LCD by pressing PROGRAM W and V.

• Fill the cuvet with 10 mL of unreacted sample

(up to the mark) and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

48Chromium VI LR

10 mL

Page 49

• Remove the cuvet and add the

content of one packet of HI

93749 reagent. Replace the

cap and shake vigorously for

about 10 seconds.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 6 minutes and press READ

DIRECT. In both cases "SIP" will blink during measurement.

• The instrument directly displays concentration in µg/L of Chromium VI on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by:

Vanadium above 1 ppm. However, waiting 10 minutes before

reading, the interference is removed

Iron above 1 ppm

Mercurous and mercuric ions cause slight inhibition of the reaction.

49

Chromium VI LR

Page 50

COLOR OF WATERCOLOR OF WATER

COLOR OF WATER

COLOR OF WATERCOLOR OF WATER

SPECIFICATIONS

Range 0 to 500 PCU (Platinum Cobalt Units)

Resolution 1 PCU

Accuracy ±10 PCU ±5% of reading

Typical EMC ± 1 PCU

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 420 nm

Method Adaptation of the Standard Methods for the

Examination of Water and Wastewater, 18

edition, Colorimetric Platinum Cobalt method.

REQUIRED ACCESSORIES

0.45 µm membrane for true color measurement.

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Color of Water on

the secondary LCD by pressing PROGRAM W and V.

th

• Fill one cuvet up to the mark with deionized

water and replace the cap. This is the blank.

• Place the blank (# 1) into the holder

and ensure that the notch on the cap

is positioned securely into the groove.

• Press ZERO and "SIP" will blink on the display.

• Wait for a few seconds and the display will

show "-0.0-". Now the meter is zeroed and

ready for measurement.

• Remove the blank.

Color of Water

50

10 mL

# 1

# 1

Page 51

• Fill another cuvet up to the mark with

unfiltered sample and replace the cap.

This is the apparent color.

• Filter 10 mL of sample through a filter with a

0.45 µm membrane into the third cuvet, up

to the 10 mL mark and replace the cap. This is

the true color.

10 mL

# 2

# 3

• Insert the apparent color cuvet (# 2)

# 2

into the instrument and ensure that

the notch on the cap is positioned

securely into the groove.

• Press READ DIRECT and "SIP" will blink on the display.

• The meter directly displays the value of apparent color in PCU on

the Liquid Crystal Display.

• Remove the cuvet, insert the true color

# 3

cuvet (# 3) into the instrument and

ensure that the notch on the cap is

positioned securely into the groove.

• Press READ DIRECT and "SIP" will blink on the display.

• The meter directly displays the value of true color in PCU on the

Liquid Crystal Display.

51 Color of Water

Page 52

COPPER HIGH RANGECOPPER HIGH RANGE

COPPER HIGH RANGE

COPPER HIGH RANGECOPPER HIGH RANGE

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.02 mg/L ±4% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 575 nm

Method Adaptation of the EPA method. The reaction

between copper and the bicinchoninate reagent

causes a purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93702-0 Bicinchoninate 1 packet

REAGENT SETS

HI 93702-01 Reagents for 100 tests

HI 93702-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Copper HR on the

secondary LCD by pressing PROGRAM W and V.

• Fill the cuvet with 10 mL of unreacted

sample (up to the mark) and replace the

cap.

10 ml

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

52Copper HR

Page 53

• Remove the cuvet.

• Add the content of one packet

of HI 93702 reagent. Replace

the cap and shake gently for

about 15 seconds.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 45 seconds and press

READ DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays concentration in mg/L of copper

on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by:

Silver

Cyanide

For samples overcoming buffering capacity of reagent (around pH 6.8),

pH should be adjusted between 6 and 8.

53

Copper HR

Page 54

COPPER LOW RANGECOPPER LOW RANGE

COPPER LOW RANGE

COPPER LOW RANGECOPPER LOW RANGE

SPECIFICATIONS

Range 0 to 1000 µg/L

Resolution 1 µg/L

Accuracy ±10 µg/L ±5% of reading

Typical EMC ±1 µg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 575 nm

Method Adaptation of the EPA method. The reaction

between copper and the bicinchoninate reagent

causes a purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93747-0 Bicinchoninate 1 packet

REAGENT SETS

HI 93747-01 Reagents for 100 tests

HI 93747-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Copper LR on the

secondary LCD by pressing PROGRAM W and V.

• Fill the cuvet with 10 mL of unreacted sample (up

to the mark) and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed and

ready for measurement.

Copper LR

54

10 mL

Page 55

• Remove the cuvet.

• Add the content of one packet

of HI 93747 reagent. Replace

the cap and shake gently for

about 15 seconds.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 45 seconds and press

READ DIRECT. In both cases "SIP" will blink during measurement.

• Multiply the reading on the Liquid Crystal Display by 10 to

obtain the concetration in mg/L of oxygen demand.

INTERFERENCES

Interference may be caused by:

Silver

Cyanide

For samples overcoming buffering capacity of reagent (around pH 6.8),

pH should be adjusted between 6 and 8.

55

Copper LR

Page 56

CYANIDECYANIDE

CYANIDE

CYANIDECYANIDE

SPECIFICATIONS

Range 0.000 to 0.200 mg/L

Resolution 0.001 mg/L

Accuracy ±0.005 mg/L ±3% of reading

Typical EMC Dev. ±0.001 mg/L

Light Source Tungsten lamp with narrow band interference

filter @ 610 nm

Method Adaptation of the Standard Methods for the

Examination of Water and Wastewater, 18

edition, Pyridine-Pyrazolone method. The reac-

tion between cyanide and reagents causes a

blue tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93714A-0 Reagent A 1 spoon

HI 93714B-0 Reagent B 1 packet

HI 93714C-0 Reagent C 1 packet

REAGENT SETS

HI 93714-01 Reagents for 100 tests

HI 93714-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Cyanide on the

secondary LCD by pressing PROGRAM W and V.

th

• Fill the cuvet with 10 mL of unreacted sample (up

to the mark) and replace the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display will

show “-0.0-”. Now the meter is zeroed

and ready for measurement.

Cyanide

56

10 mL

Page 57

• Remove the cuvet and add 1

level spoon of HI 93714A Cyanide Reagent. Remember to close

the reagent bottle immediately

after use.

Note: Pay attention to the way the spoon is filled:

- do not press the powder;

- do not overfill it.

• Place the HDPE plastic stopper

and cap immediately, to prevent

the escape of chlorine gas which

is developed during the reaction,

and shake gently for 30 seconds.

• Wait for 30 seconds leaving the

cuvet tightly capped and undisturbed, then add the content of

one packet of HI 93714B reagent and shake gently for 10

seconds.

10"

12

9

3

6

• Immediately add the content of

one packet of HI 93714C reagent, replace the cap and shake

vigorously for 20 seconds.

• Reinsert the cuvet into the instrument.

57

Cyanide

Page 58

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 25 minutes and press

READ DIRECT. In both cases "SIP" will blink during measurement.

Note: Shake gently the cuvet 4 or 5 times during the first 20

minutes of the countdown prior to the measurement. Accuracy is

not affected by undissolved reagent powder.

• The instrument directly displays concentration in mg/L of cyanide

on the Liquid Crystal Display.

• To convert the result in mg/L of Potassium Cyanide (KCN) multiply

by a factor of 2.5.

Note: for most accurate results perform the test at 20-25 °C.

INTERFERENCES

Interference may be caused by large amounts of turbidity that will

cause high readings.

Oxidizing (like chlorine) or reducing agents (such as sulfide or sulfur

dioxide) are known to interfere with the measurement. Distillation will

remove these.

Samples with high pH values should be adjusted to approximately

pH 7 before testing.

CAUTION: cyanides, their solutions, and hydrogen cyanide liberated

by acids, are very poisonous.

Cyanide

58

Page 59

CYANURIC ACIDCYANURIC ACID

CYANURIC ACID

CYANURIC ACIDCYANURIC ACID

SPECIFICATIONS

Range 0 to 80 mg/L

Resolution 1 mg/L

Accuracy ±1 mg/L ±15% of reading

Typical EMC ±1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 525 nm

Method Adaptation of the turbidimetric method. The reac-

tion between cyanuric acid and the reagent

causes a white suspension in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93722-0 Powder reagent 1 packet

REAGENT SETS

HI 93722-01 Reagents for 100 tests

HI 93722-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Cyanuric Acid on the

secondary LCD by pressing PROGRAM W and V.

• Fill the cuvet with 10 mL of unreacted sample

(up to the mark) and replace the cap.

10 mL

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

59 Cyanuric Acid

Page 60

• Fill a graduated beaker

up to the 25 mL mark

with the sample, add the

content of one packet of

HI 93722 reagent and

swirl gently to mix.

• Fill a second cuvet with 10 mL of the

10 mL

reacted sample up to the mark. Replace

the cap.

• Reinsert the cuvet into the instrument.

• Press TIMER and the display will show the countdown prior to the

measurement or, alternatively, wait for 45 seconds and press

READ DIRECT. In both cases "SIP" will blink during measurement.

• The instrument directly displays concentration in mg/L of cyanuric

acid on the Liquid Crystal Display.

Cyanuric Acid

60

Page 61

FLUORIDEFLUORIDE

FLUORIDE

FLUORIDEFLUORIDE

SPECIFICATIONS

Range 0.00 to 2.00 mg/L

Resolution 0.01 mg/L

Accuracy ±5% of reading

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference

filter @ 575 nm

Method Adaptation of the Standard Methods for the

Examination of Water and Wastewater, 18

edition, SPADNS method. The reaction between

fluoride and the liquid reagent causes a red tint

in the sample.

REQUIRED REAGENT

Code Description Quantity

HI 93729-0 SPADNS Reagent 4 mL

REAGENT SETS

HI 93729-01 Reagents for 100 tests

HI 93729-03 Reagents for 300 tests

For other accessories see page 141.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Fluoride on the

secondary LCD by pressing PROGRAM W and V.

th

• Add 2 mL of HI 93729 SPADNS

reagent to two cuvets.

• Fill one of the cuvets with distilled water

(up to the mark), replace the cap and

invert several times to mix.

• Fill the other cuvet with sample (up to

the mark), replace the cap and invert

several times to mix.

61

2 ml

10 ml

# 1

10 ml

# 2

Fluoride

Page 62

• Place the cuvet with the reacted distilled

# 1

water (# 1) into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

zeroing the blank or, alternatively, wait for two minutes and

press ZERO and "SIP" will blink on the display.

• Wait for a few seconds and the display

will show "-0.0-". Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

# 2

• Insert the other cuvet (# 2) with the

reacted sample into the instrument.

• Press READ DIRECT and "SIP" will blink on the LCD during

measurement.

• The instrument directly displays concentration in mg/L of fluoride

on the Liquid Crystal Display.

Note: For wastewater or seawater samples, before performing

measurements, distillation is required.

Note: For most accurate results, use two graduated pipettes to

deliver exactly 8 mL of distilled water and 8 mL of sample.

Fluoride

62

Page 63

INTERFERENCES

Negative interferences may be caused by:

Alkalinity (as CaCO3) above 5000 mg/L

Aluminum above 0.1 mg/L

Iron, ferric above 10 mg/L

Positive interferences may be caused by:

Chloride above 700 mg/L

Phosphate, ortho above 16 mg/L

Sodium hexametaphosphate above 1.0 mg/L

Sulfate above 200 mg/L

Highly colored and turbid samples may require distillation

Highly alkaline samples can be neutralized with nitric acid.

63

Fluoride

Page 64

CALCIUM HARDNESSCALCIUM HARDNESS

CALCIUM HARDNESS