Page 1

Instruction Manual

C 219

Maple Syrup

Transmittance Analyzer

www.hannainst.com

WARRANTY

C 219 is warranted for two years against defects in workmanship and materials when used for its intended purpose and

maintained according to instructions.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of

prescribed maintenance are not covered.

If service is required, contact the dealer from whom you

purchased the instrument. If under warranty, report the model

number, date of purchase, serial number and the nature of the

failure. If the repair is not covered by the warranty, you will be

notified of the charges incurred. If the instrument is to be

returned to Hanna Instruments, first obtain a Returned Goods

Authorization Number from the Customer Service department

and then send it with shipment costs prepaid. When shipping

any instrument, make sure it is properly packaged for complete

protection.

All rights are reserved. Reproduction in whole or in part is

prohibited without the written consent of the copyright owner,

Hanna Instruments Inc.

Dear Customer,

Thank you for choosing a Hanna product. This manual will

provide you with the necessary information for the correct

operation of the meter. Please read it carefully before using

the meter. If you need additional technical information, do not

hesitate to e-mail us at tech@hannainst.com or call

1-800-426-6287. This instrument is in compliance with

directives EN 50081-1 & EN 50082-1.

Remove the instrument from the packing material and

examine it carefully to make sure that no damage has

occurred during shipment. If there is any damage, notify

your Dealer.

Each C 219 instrument is supplied complete with

• Two 9V Batteries

• One Light Shield Cap

• One Transport Cap

• 12 VDC Transformer (HI 710005 or HI 710006)

Note

: save all packing material until you are sure that the

instrument works correctly. Any defective item must be

returned in its original packing.

PRELIMINARY EXAMINATION

GENERAL DESCRIPTION

The C 219 instrument measures the percent light transmittance

of maple syrup as compared to analytical reagent glycerol. The

transmittance value allows identification of syrup quality class.

Measurements are done by using matched square optical

cuvets having a 10 mm light path.

Display codes aid the user in routine operations.

The meters have an auto-shut off feature that will turn the

instrument off after 10 minutes of non-use.

SPECIFICATIONS

Range 0.0 to 100.0 % Transmittance

Resolution 0.1 in % Transmittance

Accuracy ±1% of reading @ % Transmittance=75.0

Typical EMC ±0.1 in % Transmittance

Deviation

Light Source Tungsten lamp with narrow band

interference filter @ 560 nm

Method Direct Measurement

Light Detector Silicon Photocell

Environment 0 to 50°C (32 to 122°F);

max 95% RH non-condensing

Battery Type 2 x 9 volt

Auto-Shut off After 10' of non-use

Dimensions 230 x 165 x 70 mm (9.0 x 6.5 x 2.8")

Weight 640 g (22.6 oz.)

REQUIRED ST

ANDARD

4 mL Glycerol (see accessories)

This Instrument is in Compliance

with the CE Directives

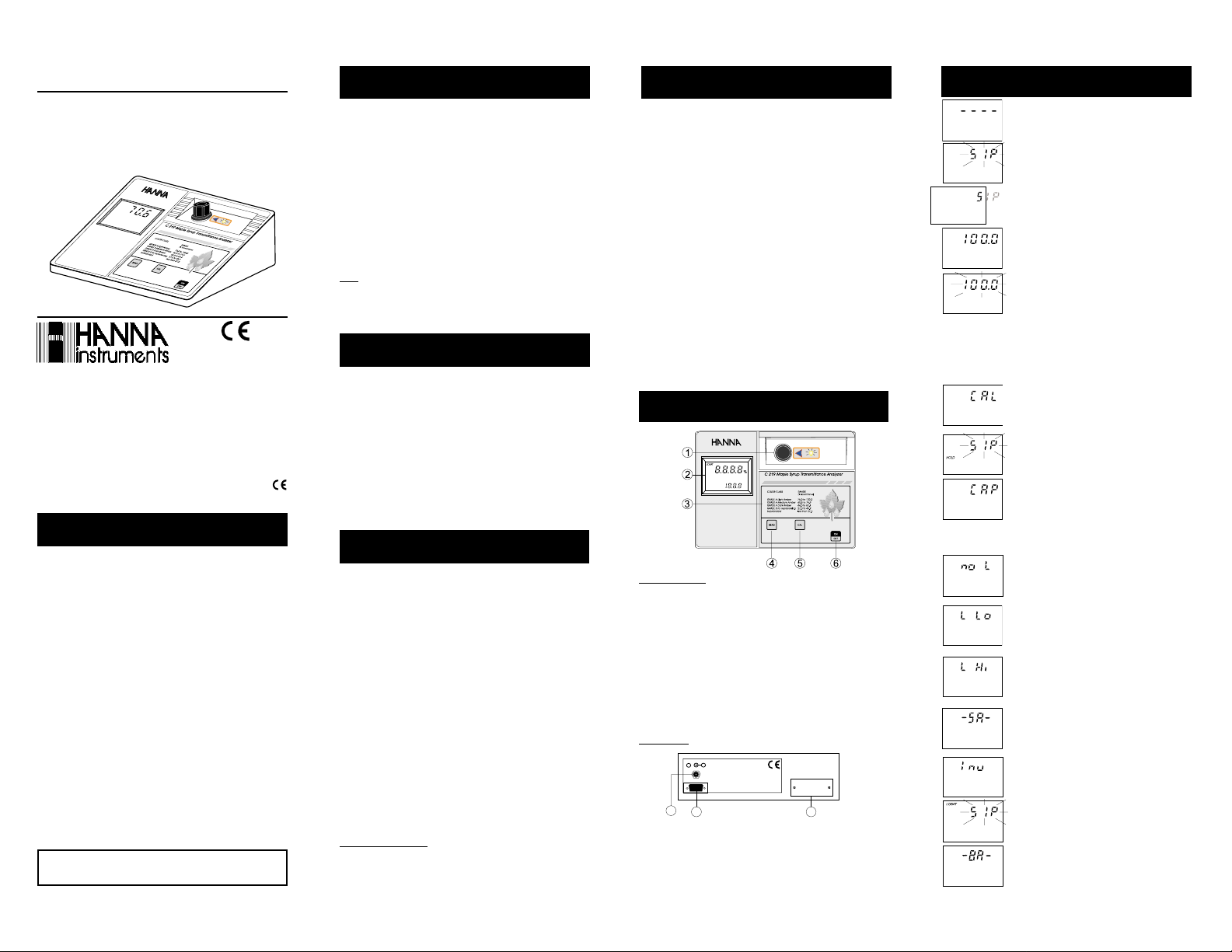

FRONT P

ANEL

1) Cuvet Holder

2) Liquid Crystal Display

3) Color Class/% Transmittance Table

4) READ, to perform measurement

5) CAL, to calibrate the meter prior to measurement

6) ON/OFF, to turn the meter on and off

REAR P

ANEL

1) Power Supply 12 VDC 2.5 Watt

2) RS 232 Socket

3) Batteries Compartment

FUNCTIONAL DESCRIPTION

SIGNIFICANCE AND USE

The primary characteristic for classifying maple syrup is color.

When syrup is very light in color, as matching the minimum light

transmittance standards, the grade assigned to syrup is high.

When syrup color is dark, the grade is low. Color classes are

expressed in percent of light transmission as compared to an analytical glycerol standard fixed at one hundred percent transmission. All syrup is considered to be at minimum density, 66.0

degrees Brix at 68 degrees F (20

0

C), and to have no flavors

nor other characteristics extraneous to pure maple syrup.

COLOR CLASS RANGE (% Transmittance)

Extra light 75.0 to 100.0

Light 60.5 to 74.9

Medium 44.0 to 60.4

Amber 27.0 to 43.9

Dark less than 27.0

GUIDE TO DISPLAY CODES

23

POWER SUPPLY

12 VDC 2.5 Watt

RS232

ooooo

oooo

1

+

-

%

%

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance notice.

This indicates that the meter is in a ready state and

calibration can be performed.

Sampling in Progress. This flashing prompt appears

each time the meter is performing a measurement.

The microprocessor is adjusting the light level, indicated by a scrolling “SIP”.

This indicates that the meter has been calibrated

and measurement can be performed.

Calibration was not performed. Follow the instructions

described in the measurement procedures for

calibrating the meter.

The instrument is performing an internal check-up.

The instrument cannot adjust the light level. Please

check that the sample does not contain any debris.

There is not enough light to perform a measurement.

Please check the preparation of the Glycerol cuvet.

There is too much light to perform a measurement.

Please, check the preparation of the Glycerolcuvet.

There is too much light for the sample measurement.

Please check if the right sample cuvet is inserted.

The sample and Glycerol cuvet are inverted.

The blinking "LOBAT" indicates that the battery voltage

is getting low and the battery needs to be replaced.

This indicates that the battery is dead and must be

replaced.

Light over range. The cuvet is not inserted correctly

and an eccess ambient light is reaching the detector.

If the cap is properly installed, contact your

dealer or the nearest Hanna Customer Service Center.

This indicates that the calibration procedure failed

due to a low signal-to-noise ratio. In this case press

CAL again. Or, it may indicate over range: a flashing 100.0% value as result of a reading

indicates that the sample absorbs less light than

the glycerol standard.

Page 2

Excel©Copyright of "Microsoft Co."

Lotus 1-2-3©Copyright of "Lotus Co."

TELIX®is registered Trademark of "Deltacomm"

Windows®and Windows Terminal®are registered Trademark of "Microsoft Co."

CE DECLARATION

OF CONFORMITY

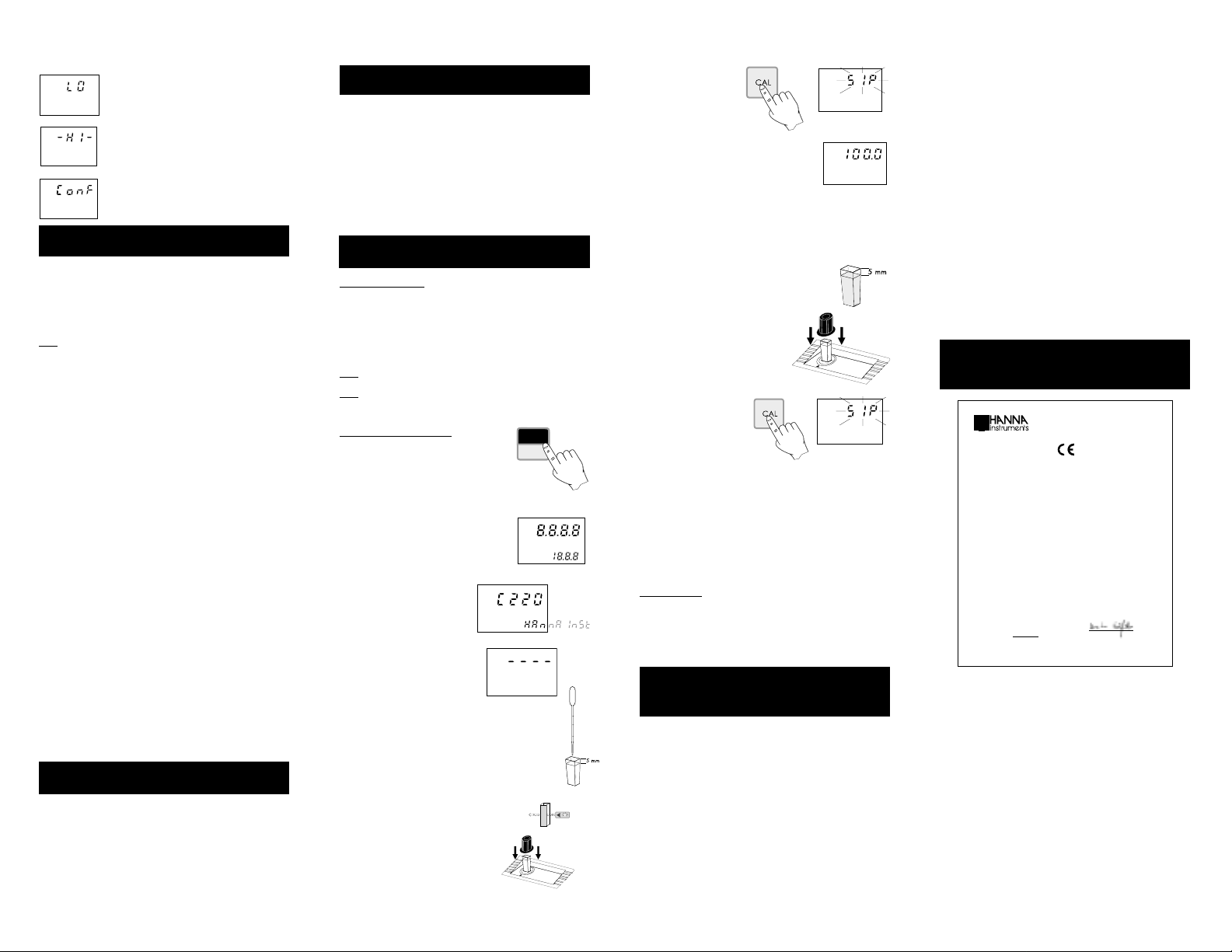

• Press CAL and

“SIP” will appear

on the display.

• Wait for a few seconds and the

display will show “100.0%”. Now

the meter is calibrated and ready

for measurement.

• Remove the Glycerol cuvet.

• Add to a second cuvet 4 ml of maple syrup,

up to 5 mm (0.2") below the rim, using a

second syringe. This is the

sample.

• Place the sample cuvet into the

holder, then put the black cap on.

• Press READ and “SIP”

will appear during

measurement.

• The instrument directly displays percent of light transmittance as compared to glycerol standard (fixed at one hundred percent).

• Check in the manual or the front panel to which color class

the transmittance value corresponds.

INTERFERENCES

Interference may be caused by air bubbles or turbidity in the

sample. Scratched or dirty cuvets will also affect readings.

Always check clearness of cuvets prior to use.

%

• It is recommended to take and analyze samples at room

temperature.

• It is recommended to take the sample of maple syrup in

the middle of the container.

• Do not use the same cuvet with glycerol for more than

5-10 times to perform calibration and dispose of it after 1

day has passed.

• Never re-use maple syrup sample cuvets, dispose of them

after one use.

• Use 1 syringe for glycerol, and the other one for syrup in

order to avoid contamination.

• Samples should be completely free of air bubbles. If bubbles are present, let the samples stand until air bubbles

have completely disappeared (not more thant 30 minutes,

see note below).

NOTE: Maple syrup samples exposed to direct sunlight and/or

air will darken over time. This is caused by microorganisms.

ISTRC219R1 11/01

OPERATIONAL GUIDE

START

STOPSTOP

POWER CONNECTION

Plug the 12VDC adapter (HI 710005 - 110VDC, or HI 710006

- 220VDC) into the DC socket. Plug the adapter into the outlet.

Alternatively, remove the battery cover on the back of the

meter; attach two fresh 9 V batteries and replace the cover.

Note: insure the main line is surge protected.

Note: always turn the meter off before unplugging it to

insure no data is lost.

MEASUREMENT PROCEDURE

• Turn the meter on by pressing

ON/OFF.

• The meter will first perform an LCD

self diagnostic test by displaying a full

set of figures.

• Then it will show a scrolling

"C219 Hanna Inst"

message.

• When the LCD displays “----”,

the meter is ready.

• To perform calibration, use a first syringe

to fill one cuvet with 4 mL of Glycerol, up to

5 mm (0.2") below the rim.

• Place the Glycerol cuvet into the

holder paying attention to the

direction of the light indicated by

the arrow, then put the black cap

on.

BATTERY REPLACEMENT

Battery replacement must only take place in a non-hazardous

area using two 9V alkaline batteries.

Remove the battery cover on the back of the meter, attach two

fresh 9V batteries and replace the cover while paying attention

to the correct polarity.

INTERFACE WITH PC

ACCESSORIES

C219/C220 Kit Kit for maple syrup analysis,

including, 82 cuvets, 30 mL of

Glycerol & two 5 mL syringe

(80 tests average)

HI 721310 9V battery (10 pcs)

HI 731318 Tissue for wiping cuvets (4 pcs)

HI 731325 Caps (4 pcs)

Light under range. The standard is to dark for proper

calibration. If this is not the case, contact your dealer

or the nearest Hanna Customer Service Center.

Light over range. The standard is to light for proper

calibration. If this is not the case, contact your dealer

or the nearest Hanna Customer Service Center.

This indicates that the meter has lost its configuration. Contact your dealer or the nearest Hanna

Customer Service Center.

To connect your meter to the PC use the optional HI 920010

cable (available from your Hanna Dealer). Make sure that your

meter is switched off and plug the connectors, one into the meter

RS 232C socket, the other into the serial port of your PC.

Note

: cables other than HI 920010 may use a different configuration, in which case, communication between the meter and

the PC may not be possible.

Data transmission from the instrument to the PC is now much

easier with HI 92000 Windows®compatible application software offered by Hanna Instruments.

HI 92000 allows you to use the powerful capabilities of most

spread sheet programs (e.g. Excel®, Lotus 1-2-3®). Simply

open your file downloaded by HI 92000 from your spread

sheet program and then it is possible to make any elaboration

available with your software (e.g. graphics, statistic analysis).

User friendly, HI 92000 offers a variety of features and has an

on line help to support you throughout any situation.

To install HI 92000 you need a 3.5” drive and a few minutes to

follow the instructions conveniently printed on the disk label.

For acquiring data with PC from the C219 instrument select

“Real-Time Logging”. Click on “Settings” and then select the

communication port (1 to 4) and set the baud rate. The

transmission speed (baud rate) of the meter and the external

device must be identical. The meter is factory set to 2400.

If you wish to change this value, please contact your nearest

Hanna Center.

Data are recorded on PC by pressing “log sample” after

measurement has been performed. Follow the on line help for

more details.

TIPS FOR AN ACCURATE

MEASUREMENT

The instruction listed below should be carefully followed during

testing to ensure best accuracy.

• Do not touch the cuvet walls with hands.

• Whenever the cuvet is placed into the measurement cell, it

must be completely free of fingerprints, oil or dirt. Wipe it

thoroughly with HI 731318 or a lint-free cloth prior to

insertion.

• It is important that the sample does not contain any debris.

This would corrupt the readings.

• Use matched square cuvets, having 4 clear faces and a

10 mm path length.

Recommendations for Users

Before using these products, make sure that they are entirely suitable for

the environment in which they are used.

Operation of these instruments in residential area could cause unacceptable

interferences to radio and TV equipments, requiring the operator to take all

necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instruments' EMC performance.

To avoid damages or burns, do not perform any measurement in microwave ovens.

LOBAT

%

DECLARATION OF CONFORMITY

We

Hanna Instruments Italia Srl

via E.Fermi, 10

35030 Sarmeola di Rubano - PD

ITALY

herewith certify that the bench meter:

has been tested and found to be in compliance with EMC Directive 89/336/EEC and Low

Voltage Directive 73/23/EEC according to the following applicable normatives:

EN 50082-1:Electromagnetic Compatibility - Generic Immunity Standard

IEC 801-2 Electrostatic Discharge

IEC 801-3 RF Radiated

IEC 801-4 Fast Transient

EN 50081-1:Electromagnetic Compatibility - Generic Emission Standard

EN 55022 Radiated, Class B

EN61010-1:Safety requirements for electrical equipment for measurement,

Date of Issue: 10-11-2001

C219

control and laboratory use

D.Volpato - Engineering Manager

On behalf of

Hanna Instruments S.r.l.

Loading...

Loading...