Page 1

Instruction Manual

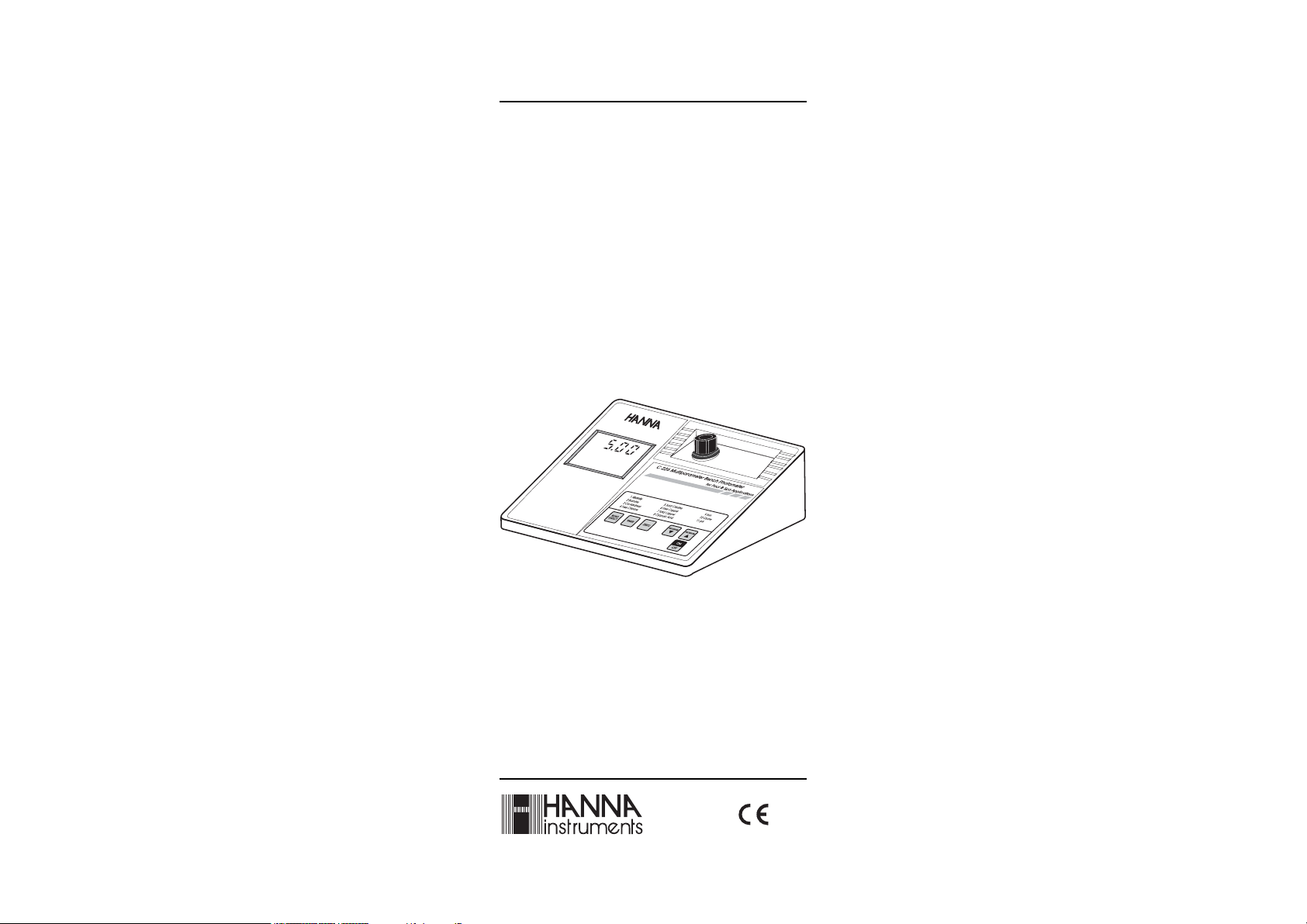

C 216 & C 226

Multiparameter Bench

Photometers

for

Pool & Spa Applications

www.hannainst.com

These Instruments are in

Compliance with the CE Directives

1

Page 2

Dear Customer,

Thank you for choosing a Hanna product. Please read this instruction

manual carefully before using the meter. This manual will provide you

with the necessary information for the correct use of the instrument. If

you need additional technical information, do not hesitate to e-mail

us at tech@hannainst.com. These instruments are in compliance with

directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ........... 3

GENERAL DESCRIPTION ................... 3

ABBREVIATIONS ............................. 4

SIGNIFICANCE OF POOL AND SPA

TESTING .........................................5

SPECIFICATIONS ........................... 10

PRECISION AND ACCURACY ............ 10

PRINCIPLE OF OPERATION .............11

FUNCTIONAL DESCRIPTION ............13

GUIDE TO DISPLAY CODES ............. 14

TIPS FOR AN ACCURATE

MEASUREMENT ............................17

PARAMETERS REFERENCE TABLES ..19

OPERATIONAL GUIDE .................... 20

ALKALINITY ...................................22

BROMINE .....................................24

CALCIUM HARDNESS .....................26

FREE CHLORINE ............................ 28

TOTAL CHLORINE .......................... 30

FREE COPPER ............................... 32

TOTAL COPPER .............................. 34

CYANURIC ACID ............................ 36

IRON ........................................... 38

OZONE ......................................... 40

pH ............................................... 44

INTERFACE WITH PC ..................... 46

STANDARD METHODS ................... 48

BATTERY REPLACEMENT ................ 48

ACCESSORIES ............................... 49

CE DECLARATION OF CONFORMITY .... 50

WARRANTY ................................... 51

HANNA LITERATURE ......................51

All rights are reserved. Reproduction in whole or in part is prohibited without

the written consent of the copyright owner, Hanna Instruments Inc.,

Woonsocket, Rhode Island, 02895 , USA.

2

Page 3

PRELIMINARY EXAMINATION

Please examine this product carefully. Make sure that the instrument

is not damaged. If any damage occured during shipment, please

notify your Dealer.

Each Meter is supplied complete with:

• Four Sample Cuvets and Caps

• Two 9V Batteries

• One pair of scissors

• Instruction Manual

• Rigid carrying case

Note: Save all packing material until you are sure that the instrument

works correctly. Any defective item must be returned in its

original packing with the supplied accessories.

3

Page 4

GENERAL DESCRIPTION

C 99 & C 200 Series is a line of 17 different bench, microprocessorbased photometers to measure more than 50 different parameters in

water and wastewater. These multipurpose meters are manufactured

to measure the most important parameters of the application they

have been especially designed for:

C 99 Laboratories, with COD C 200 Laboratories

C 203 Aquaculture C 205 Boilers & Cooling Towers

C 206 Environmental Testing C 207 Industrial Wastewater

C 208 Water Conditioning C 209 Education

C 210 Pulp & Paper Mills C 211 Chemical Manufacturers

C 212 Power Plant Utilities C 213 Municipal Wastewater

C 214 Wastewater Treatment Applic. C 215 Nutrient Analyses C 216

Pool & Spa Applic. C 218 Environmental Applic.

C 226 Pool & Spa Applic.

All meters use an exclusive positive-locking system to ensure that the

cuvet is in the same position every time it is placed into the measurement

cell.

The reagents are in liquid or powder form and are supplied in bottles

or in packets. The amount of reagent is precisely dosed to ensure the

maximum repeatability.

Display codes aid the user in routine operations.

The meters have an auto-shut off feature that will turn off the

instrument after 10 minutes of non-use.

The C 99 & C 200 Series can be connected to a personal computer via

the HI 920010 three wire RS 232 cable. The HI 92000 Hanna

Windows® Compatible Software aids the user to manage all test data.

ABBREVIATIONS

°C: degree Celsius

EPA: US Environmental Protection Agency

°F: degree Fahrenheit

g/L: grams per liter. g/L is equivalent to ppt (part per

thoushand)

mg/L: milligrams per liter. mg/L is equivalent to ppm (part per

million)

mL: milliliter

µg/L: micrograms per liter. µg/L is equivalent to ppb (part per

billion)

4

Page 5

SIGNIFICANCE OF

POOL AND SPA TESTING

A major family leisure pursuit is the enjoyment of Swimming Pool and

Spa facilities world-wide. A basic necessity of Pool water treatment, to

ensure such enjoyment, is to maintain the water in a safe and pleasant

condition for the bathers.

In order to achieve such an objective, swimming pool water requires

testing on daily, and sometimes hourly bases for disinfection residuals

and pH. Equally important, Calcium Hardness and Alkalinity parameters

should be monitored on weekly bases to ensure the pool water is

maintained in a balanced condition, thus to avoid system failure because

of corrosion or scale formation.

DISINFECTION RESIDUAL AND pH CONTROL

In terms of swimming pool treatment, disinfection or sanitizing basically

means to rid the pool of bather pollution, destroy bacteria, and control

nuisance organisms like algae, which may occur in the pool, filtration

equipment, and piping.

There are a number of techniques used, namely, chlorine, bromine and

ozone dosing systems, of which chlorine is the most common.

Chlorine

Chlorine is a strong oxidizing agent that destroys mostly organic pollutants,

bacteria and can combine with nitrogen containing compounds, forming

chloramines. Only a part of the original quantity dosed chlorine, remains

active and continues its disinfecting action.

From the free chlorine you can distinguish combined chlorine, as that

part which combines with nitrogen containing compound and that is less

efficient as a disinfectant. The addition of these two parts gives total

chlorine. A pool manager needs to aim perfection where free equals

total chlorine, and thus to maintain the combined chlorine concentration

near zero. The presence of chloramines is not desired because of the

distinctive ‘swimming pool’ smell caused by combined chlorines like dichloramines. Beside this unpleasant odour it does irritate the eyes and

the mucous membranes.

Commercially chlorine for disinfection may be available as a gas (Cl2), a

liquid like sodium hypochlorite or bleach (NaOCl) or in a solid state like

calcium hypochlorite, chloro-hydantoins or chloro-cyanuric acid

compounds.

These compounds, once dissolved in water do establish equilibrium

5

Page 6

between the hypochlorous acid (HOCl) and the hypochlorite ions

(OCl-).

Although both forms are considered free chlorine, it is the hypochlorous

acid that provides the strongest disinfecting and oxidising characteristic

of chlorine solutions.

The amount of hypochlorous acid in chlorinated water dependends upon

the pH value of the solution. Changes in pH value will effect the HOCl

equilibrium in relation to the hydrogen and hypochlorite ion.

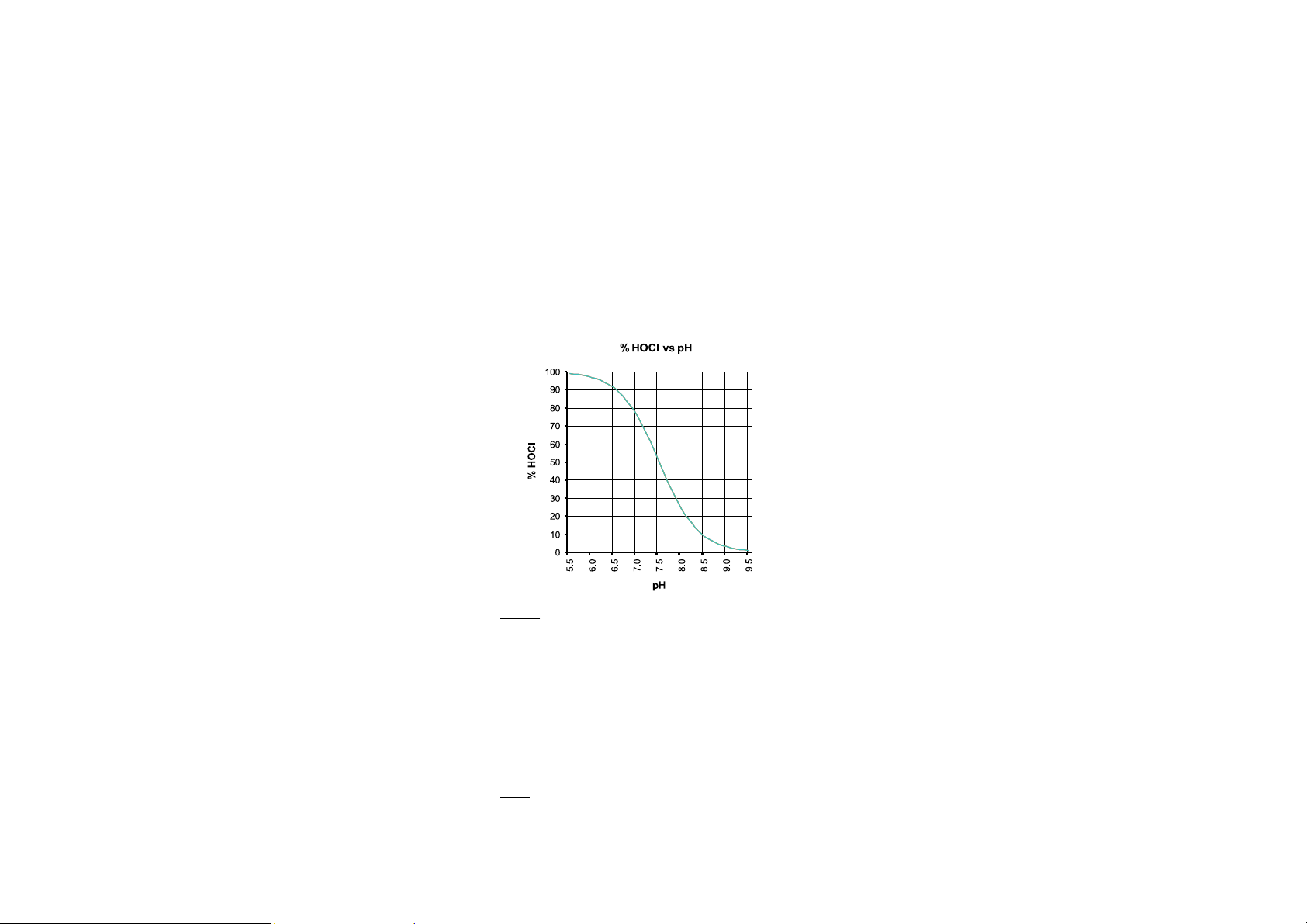

As depicted by the curve below, HOCl decreases and OCl- increases as pH

increases. At a low pH, almost all the free chlorine is in the molecular

form HOCl and at a pH of around 7.5, the ratio between HOCl and OCl- is

50:50. Since the ionic form OCl- is a slow acting sanitizer while the

molecular HOCl is a fast acting, it is important to measure regularly the

pH. As a general rule a pH of about 7.2 is recommended to maintain fast

acting disinfection conditions.

Bromine

In many countries bromine sanitizing has been introduced as an

alternative for chlorine, although it is a less strong sanitizer. The advantage

of bromine is its stability at higher temperatures (advantageous for hot

well pools), and its maintained disinfection power at higher pH. Further

it does hardly react with nitrogen compounds, reducing the unpleasant

odour, and eye irritation problems. The main disadvantage of bromine is

the slower acting disinfecting power, making it less suitable for larger

pools.

Ozone

Ozone is a very strong oxidizing agent that does destroy most difficult to

oxidize organic compounds and chloramines. It thus allows the pool

manager to remove very efficiently combined chlorine without refreshing

6

Page 7

frequently large amounts of pool water. In general its application is found

just before water passes through the filter units. Its sanitizing power is

not pH related.

Mainly because of its strong oxidizing power the return water may contain

only trace concentrations of ozone. It has to be mentioned that ozone is

very unstable and there is anyway the need for low-level chlorination to

ensure sanitizing throughout the whole pool.

THE WATER BALANCE AND LANGELIER INDEX (LI)

The pool water characteristics need to be maintained in a balanced

condition to avoid system failure. Measuring the water balance is

extremely important to predict if the water is corrosive, scaling or balanced.

A saturation index developed by Dr. Wilfred Langelier is widely used to

predict the balance of swimming pool waters. It is an estimation of the

solutions ability to dissolve or precipitate calcium carbonate deposits. A

certain level of this precipitation (filming) is desired to insulate pipes

and boilers from contact with water. When no protective filming is formed,

water is considered to be corrosive. On the other hand scaling does cause

failure because of incrustation problems.

In the treatment and monitoring of pool water, the pool manager must

ensure that related parameters as alkalinity, hardness and pH are duly

taken into consideration.

Calcium Hardness

The presents of calcium in the system is desired to ensure filming on

those places where the temperature is relatively high, like in boilers and

pipes transporting warm water. Scaling must be avoided because it

reduces heat transfer and pump capacity. Beside the calcium carbonate

deposits in the pipes, high scaling values do cause cloudy water.

It is recommended to maintain the calcium hardness value within the

range from 200 to 400 ppm as calcium carbonate (CaCO3).

Alkalinity

Alkalinity is the measure of the total concentration of alkaline substances,

mostly bicarbonates, dissolved in the water. The higher the alkalinity the

more resistant the water is to pH change, the alkalinity buffers the water.

At the same time, high alkaline water is a major contributor to scaling

problems like incrustation in filtration equipment, pumps, and piping.

It is recommended to maintain the alkalinity value within the range

from 80 to 125 ppm as calcium carbonate (CaCO3).

pH

The pH of the water is an important factor since at lower pH the corrosion

7

Page 8

rate increases. If the alkalinity values are sufficiently high it will not be

difficult to control the pH. Most pools managers do prefer to keep the pH

between 7.2 and 7.4, that does ensure low corrosion rates and a sufficient

activity of chlorine.

Langelier Index (LI)

The Langelier Index is a powerful tool to calculate the water balance,

and to predict corrosion or scaling problems. Theoretically, a LI of zero

indicates perfect water condition for swimming pools. If LI>0, scaling

and staining of the water is present, and if LI<0 the water is corrosive

and highly irritating. A tolerance of ±0.4 is normally acceptable.

The Langelier formula is expressed as:

LI = pH + TF + HF + AF – 12.5

where:

LI = Langelier Index (also called Saturation Index)

pH = pH of the water

TF = temperature factor

HF = hardness factor, log(Ca Hardness, ppm as CaCO3)

AF = alkalinity factor, log(Alkalinity, ppm as CaCO3)

To calculate the exact Langelier Index of your water please use the WATER

INDEX reference tables at the end of this chapter to find the Temperature,

Hardness and Alkalinity factors.

Recommendations

For most pools, water is balanced if:

• The pH value is maintained within the recommended ranges of

pH 7.2 - 7.6

• Ideally the Alkalinity should be maintained within a range of

80 - 125 ppm

• The Calcium Hardness should be maintained within a range of

200 - 400 ppm.

To calculate your water balance three tests are required, measure the

Calcium Hardness, the Alkalinity and the pH of the pool water. Find the

Hardness and Alkalinity Factor in the WATER INDEX reference tables

below.

The water temperature is in general controlled between 24oC (76oF) and

34oC (94oF) to ensure pleasant bather comfort. The Temperature Factor

in this temperature range has minor importance; therefore an average

value of 0.7 may be used

..

.

..

A simple calculation classifies your water in corrosive, scaling, acceptable

or ideal balanced, with treatment recommendations:

Water Balance = pH + TF + HF + AF

8

Page 9

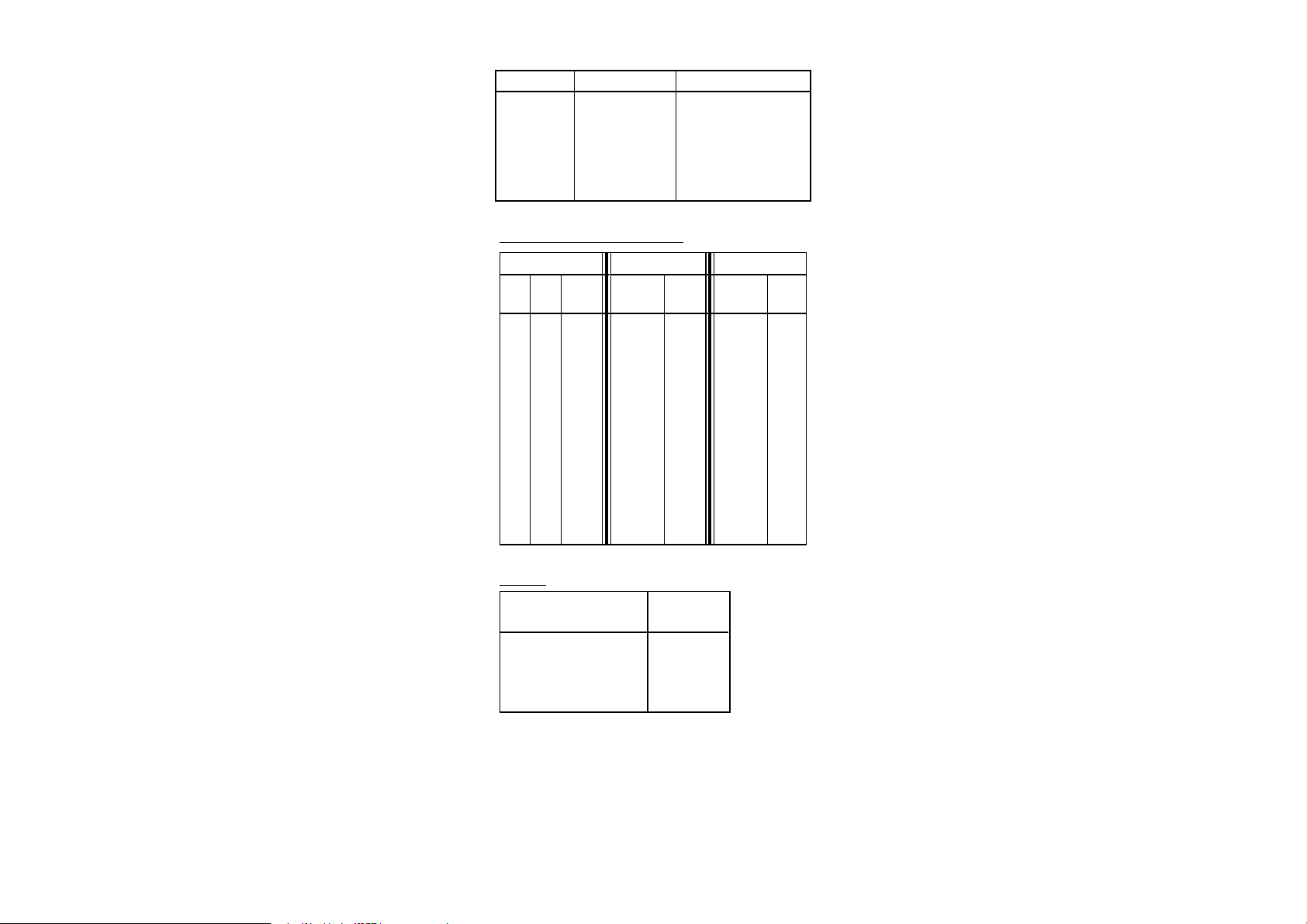

Water Balance

11.0 – 12.0

12.1 – 12.3

12.4 – 12.6

12.7 – 12.9

13.0 – 14.0

Condition of Water

Corrosive

Acceptable Balance

Ideal Balance

Acceptable Balance

Scale forming

Recommendation

Increase pH and/or Alkalinity

Retest water frequently

Retest water frequently

Reduce pH and/or alkalinity

WATER INDEX REFERENCE TABLES

Temperature Calcium Hardness Alkalinity

°C

°F

TF

0

32

0

4

39

0.1

8

46

0.2

12

54

0.3

16

60

0.4

20

68

0.5

24

75

0.6

28

82

0.7

32

90

0.7

36

97

0.8

40

104

0.9

50

122

1.0

mg/L

(as CaCO3)

5

25

50

75

100

150

200

250

300

400

500

1000

HF

0.7

1.4

1.7

1.9

2.0

2.2

2.3

2.4

2.5

2.6

2.7

3.0

mg/L

(as CaCO3)

1000

25

50

75

100

150

200

250

300

400

500

AF

5

0.7

1.4

1.7

1.9

2.0

2.2

2.3

2.4

2.5

2.6

2.7

3.0

EXAMPLE:

Pool water conditions

Temperature 30°C

pH 7.2

Alkalinity 80 mg/L

Hardness 230 mg/L

Water Balance = pH + TF + HF + AF

= 7.2 + 0.7 + 2.4 + 1.9 = 12.2

Conclusion: the water is acceptable balanced but there is some risk

that the water becomes corrosive; frequently testing is recommended.

The Hanna C216 and C226 are the ideal instruments to meet your

monitoring requirements….

Factor value

(nearest values)

TF = 0.7

pH = 7.2

AF = 1.9

HF = 2.4

9

Page 10

SPECIFICATIONS

Light Life Life of the instrument

Light Detector Silicon Photocell

Environment 0 to 50°C (32 to 122°F);

max 90% RH non-condensing

Power Supply 2 x 9 V batteries / 12 to 20 VDC through

voltage adapter (optional)

Auto-Shut off After 10' of non-use

Dimensions 230 x 165 x 70 mm (9.0 x 6.5 x 2.8")

Weight 640 g (22.6 oz.)

For specifications related to each single parameter (e.g. range, precision,

etc.), refer to the related measurement section.

PRECISION AND ACCURACY

Precision is how closely repeated measurements agree with each other.

Precision is usually expressed as standard deviation (SD).

Accuracy is defined as the nearness of a test result to the true value.

Although good precision suggests good accuracy, precise results can be

inaccurate. The figure explains these definitions.

For each parameter, the precision is expressed in the related measurement

section as standard deviation at a specific concentration value of the

analite. The standard deviation is obtained with a single instrument using

a representative lot of reagent.

10

Page 11

PRINCIPLE OF OPERATION

Absorption of Light is a typical phenomenon of interaction between

electromagnetic radiation and matter. When a light beam crosses a

substance, some of the radiation may be absorbed by atoms, molecules

or crystal lattices.

If pure absorption occurs, the fraction of light absorbed depends both

on the optical path length through the matter and on the physicalchemical characteristics of substance according to the Lambert-Beer

Law:

-log I/Io = ελ c d

or

A = ε

c d

λ

Where:

-log I/Io=Absorbance (A)

Io=intensity of incident light beam

I =intensity of light beam after absorption

ελ=molar extinction coefficient at wavelength λ

c =molar concentration of the substance

d =optical path through the substance

Therefore, the concentration "c" can be calculated from the absorbance

of the substance as the other factors are known.

Photometric chemical analysis is based on the possibility to develop

an absorbing compound from a specific chemical reaction between

sample and reagents.

Given that the absorption of a compound strictly depends on the

wavelength of the incident light beam, a narrow spectral bandwidth

should be selected as well as a proper central wavelength to optimize

measurements.

The optical system of Hanna's C 99 & C 200 Series multiparameter

photometers is based on special subminiature tungsten lamps and

narrow-band interference filters to guarantee both high performance

and reliable results.

Four measuring channels (at four different wavelengths) allow a wide

range of tests.

C 200 Series block diagram (optical layout)

11

Page 12

A microprocessor controlled special tungsten lamp emits radiation

which is first optically conditioned and beamed to the sample contained

in the cuvet. The optical path is fixed by the diameter of the cuvet.

Then the light is spectrally filtered to a narrow spectral bandwidth, to

obtain a light beam of intensity Io or I.

The photoelectric cell collects the radiation I that is not absorbed by

the sample and converts it into an electric current, producing a

potential in the mV range.

The microprocessor uses this potential to convert the incoming value

into the desired measuring unit and to display it on the LCD.

The measurement process is carried out in two phases: first the meter

is zeroed and then the actual measurement is performed.

The cuvet has a very important role because it is an optical element

and thus requires particular attention. It is important that both the

measurement and the calibration (zeroing) cuvets are optically identical

to provide the same measurement conditions. Whenever possible use

the same cuvet for both.

It is necessary that the surface of the cuvet is clean and not scratched.

This is to avoid measurement interference due to unwanted reflection

and absorption of light. It is recommended not to touch the cuvet

walls with hands.

Furthermore, in order to maintain the same conditions during the

zeroing and the measuring phases, it is necessary to close the cuvet to

prevent any contamination.

12

Page 13

FUNCTIONAL DESCRIPTION

FRONT PANEL

1) Cuvet Holder

2) Dual Level Liquid Crystal Display (LCD)

3) Programs List

4) READ DIRECT, to perform measurement immediately

5) TIMER, to perform measurement after a preprogrammed

countdown

6) ZERO, to zero the meter prior to measurement

7) Program ▼ and ▲, to select the desired parameter

8) ON/OFF, to turn the meter on and off

REAR PANEL

1) Power Supply 12 VDC 2.5 Watt

2) RS 232 Socket

3) Batteries Compartment

13

Page 14

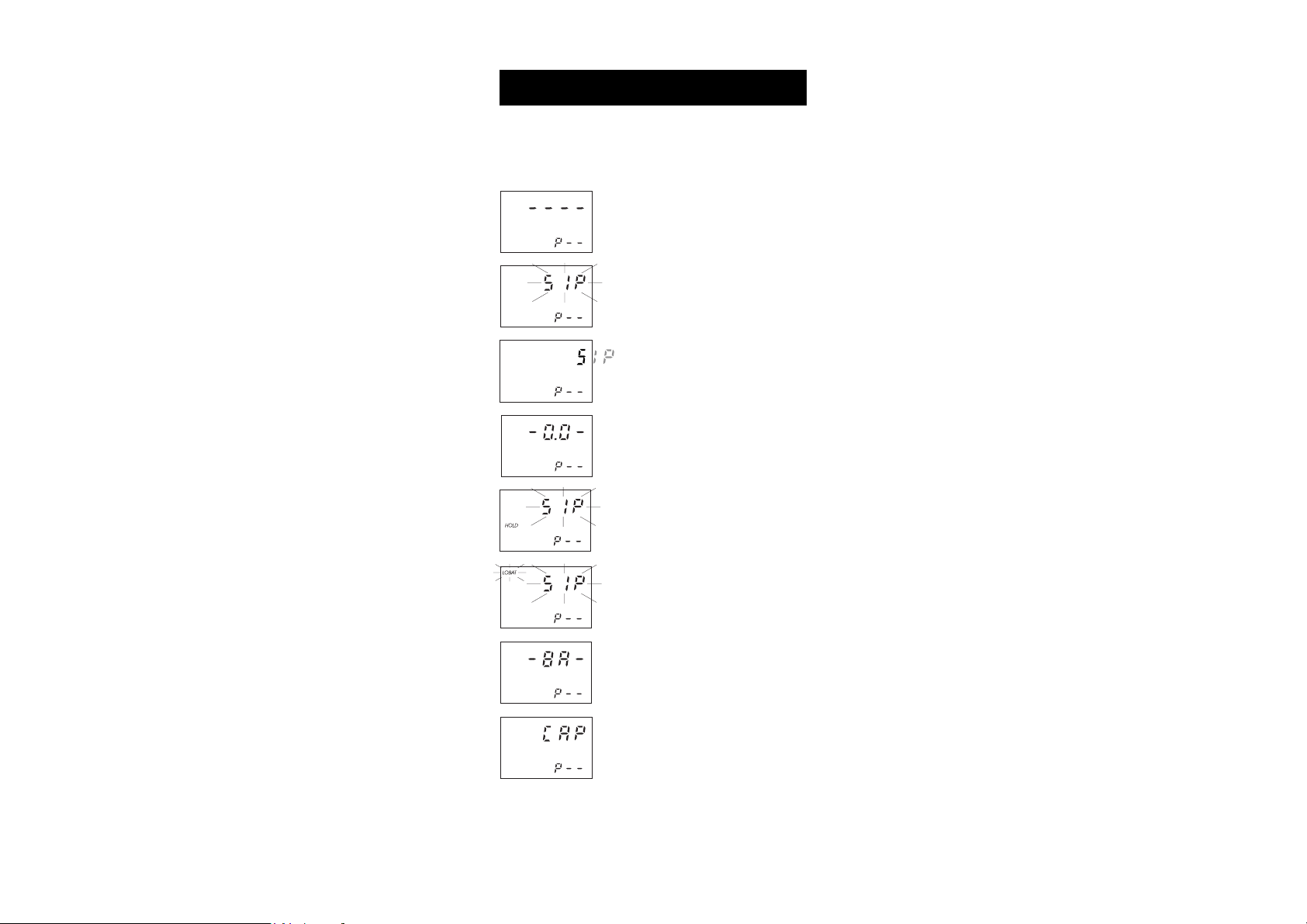

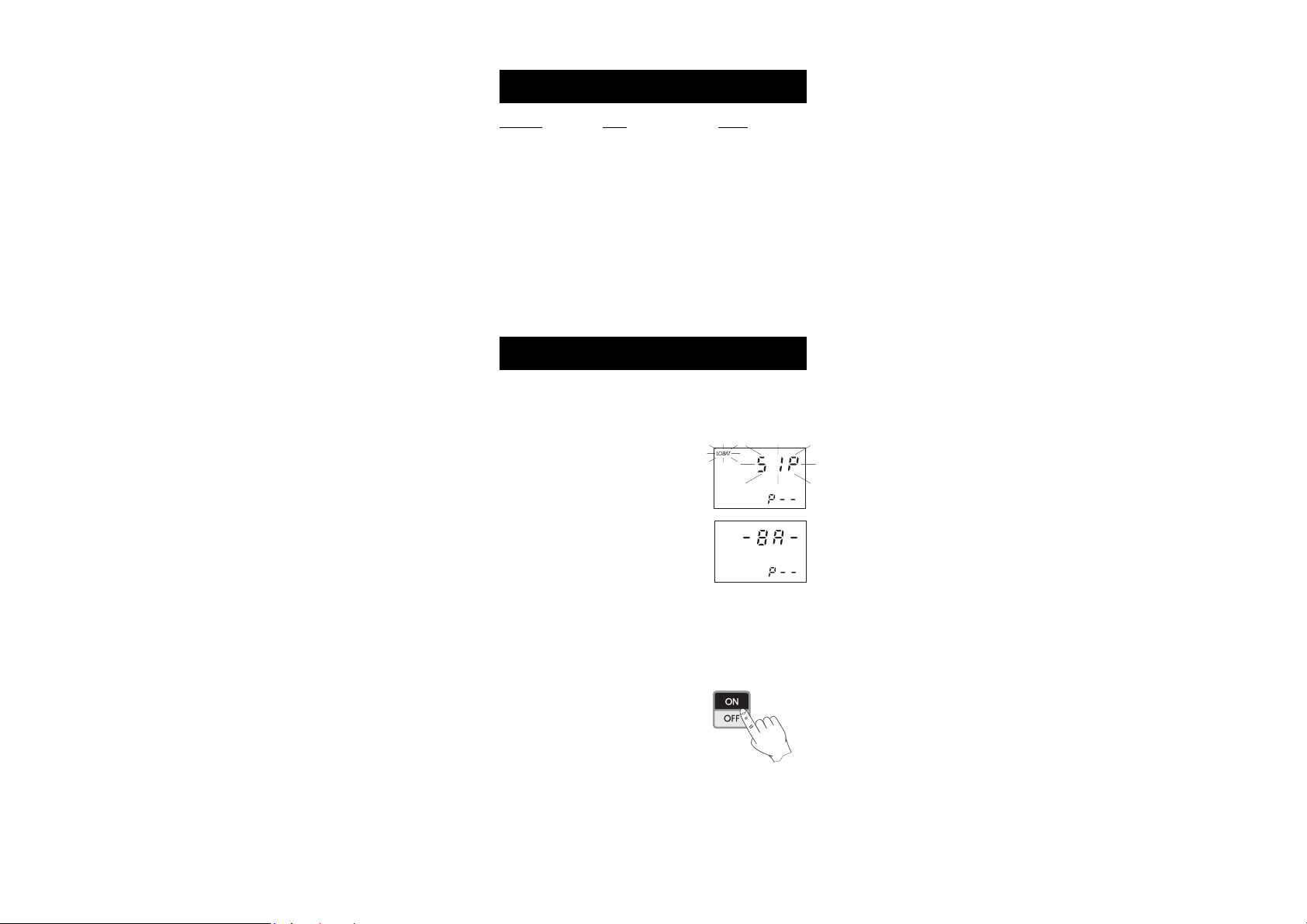

GUIDE TO DISPLAY CODES

Note: The secondary LCD below shows a generic "P– –", whereas the

meter will indicate the exact program number (e.g. in C 216, "P1"

for Alkalinity).

This indicates that the meter is in a ready

state and zeroing can be performed.

Sampling in progress. This flashing prompt

appears each time the meter is performing

a measurement.

The microprocessor is adjusting the light

level, indicated by a scrolling "SIP".

This indicates that the meter is in a zeroed

state and measurement can be performed.

The instrument is performing an internal

check-up.

The blinking "LOBAT" indicates that the

battery voltage is getting low and the

batteries need to be replaced.

This indicates that the batteries are dead

and must be replaced.

Light over range. The cuvet is not inserted

correctly and an eccess ambient light is

reaching the detector. If the cuvet is properly

inserted, then contact your dealer or the

nearest Hanna Customer Service Center.

14

Page 15

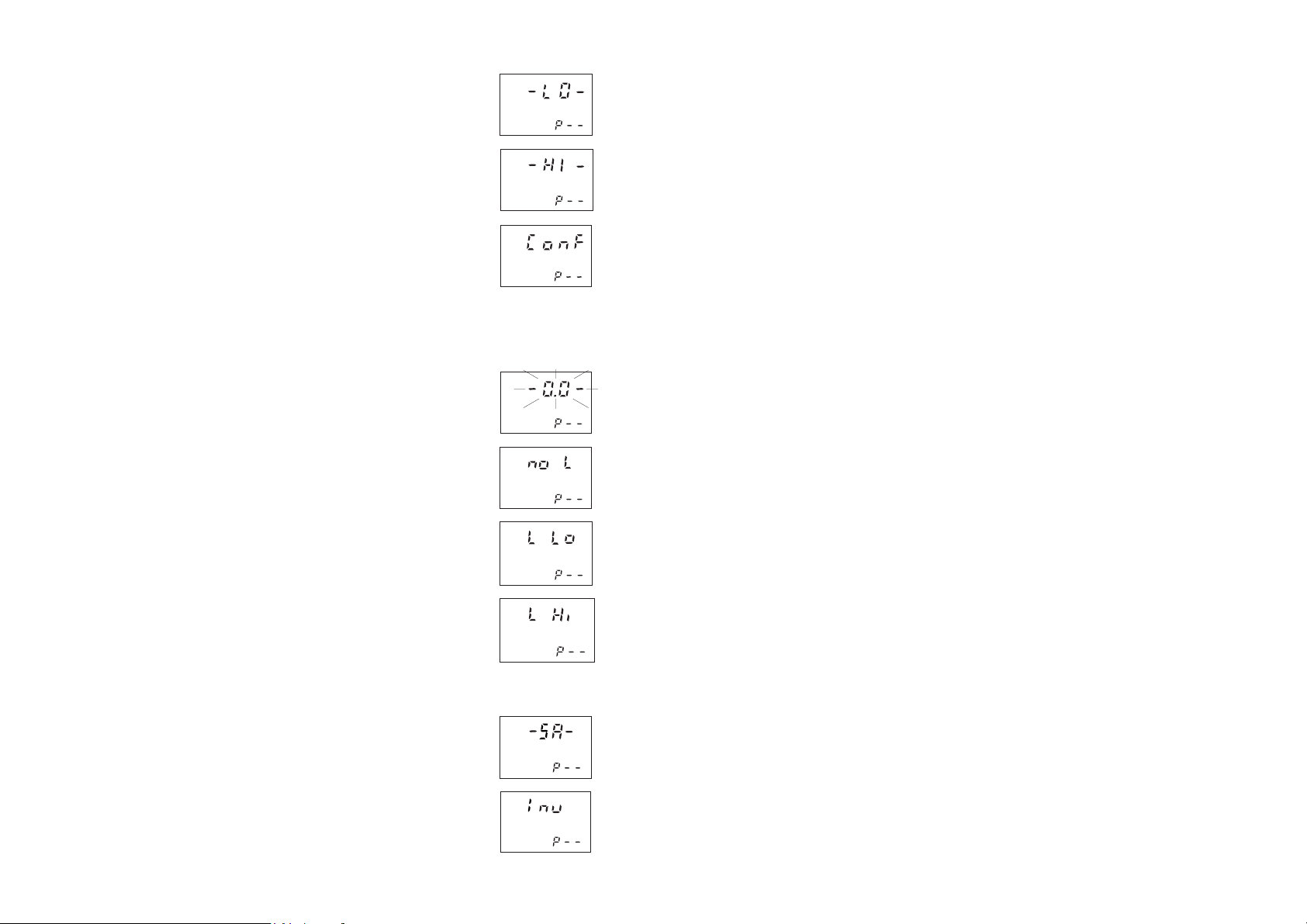

ERROR MESSAGES

a) on zero reading:

The lamp is not working properly. Contact

your dealer or the nearest Hanna Customer

Service Center.

The lamp is not working properly. Contact

your dealer or the nearest Hanna Customer

Service Center.

This indicates that the meter has lost its

configuration. Contact your dealer or the

nearest Hanna Customer Service Center.

This indicates that the zeroing procedure

failed due to a low signal-to-noise ratio. In

this case press ZERO again.

The instrument cannot adjust the light level.

Please check that the sample does not

contain any debris.

There is not enough light to perform a

measurement. Please check the preparation

of the zero cuvet.

b) on sample reading:

There is too much light to perform a

measurement. Please check the preparation

of the zero cuvet.

There is too much light for the sample

measurement. Please check if the right

sample cuvet is inserted.

The sample and zero cuvet are inverted.

15

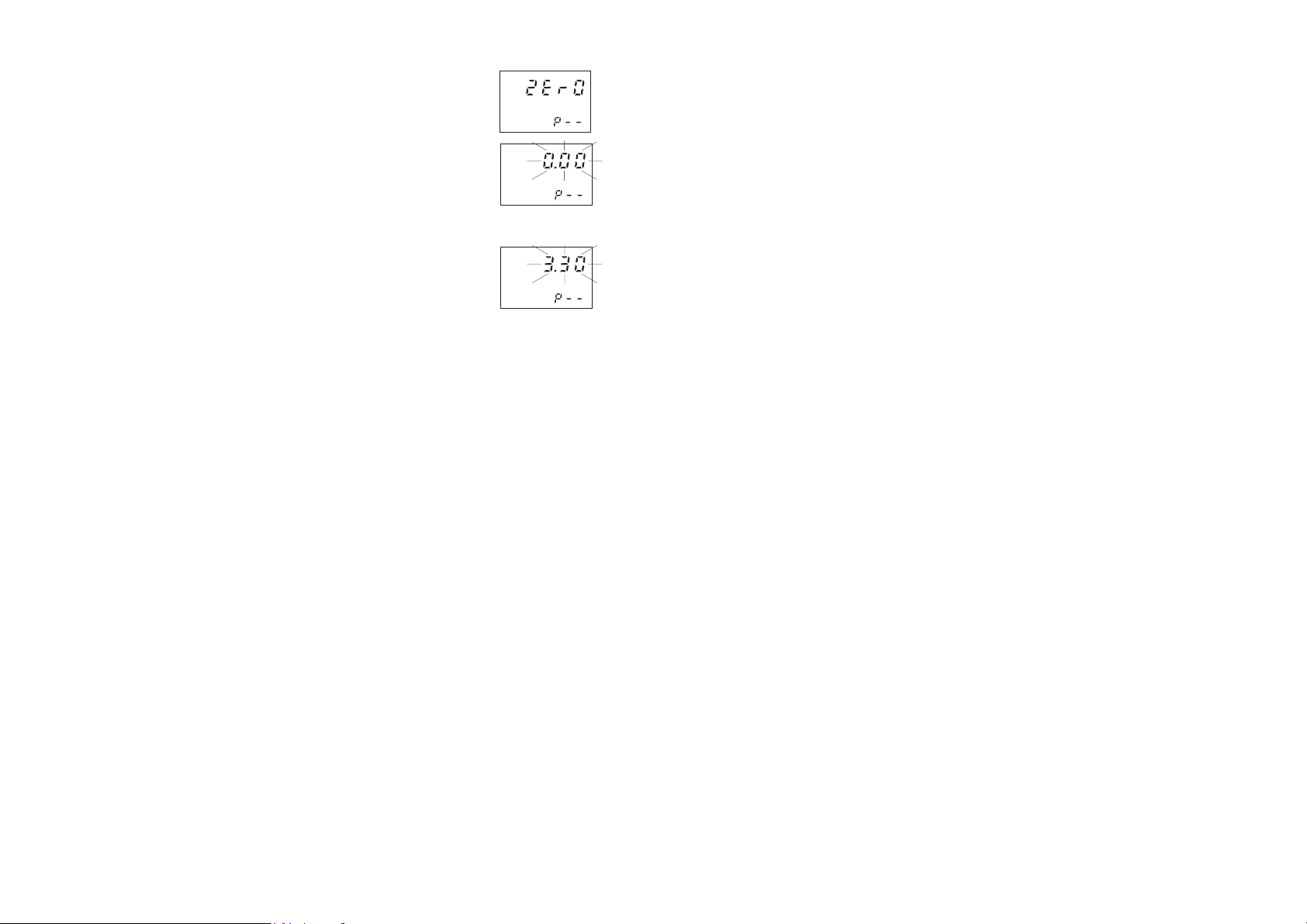

Page 16

A zero reading was not taken. Follow the

instruction described in the measurement

procedures for zeroing the meter.

Under range. A blinking "0.00" indicates

that the sample absorbs less light than the

zero reference. Check the procedure and

make sure that you use the same cuvet for

reference (zero) and measurement.

1) A flashing value of the maximum

concentration indicates an over range

condition. The concentration of the sample

is beyond the programmed range: dilute

the sample and rerun the test.

2) A flashing value lower than the

maximum concentration indicates a low

signal-to-noise ratio condition. In this case

accuracy of the result is not guaranteed.

Repeat the reading procedure.

16

Page 17

TIPS FOR AN ACCURATE MEASUREMENT

The instructions listed below should be carefully followed during testing

to ensure best accuracy.

• Color or suspended matter in large amounts may cause interference,

therefore, these should be removed by treatment with active

carbon and by prior filtration.

• For a correct filling of the cuvet: the liquid

in the cuvet forms a convexity on the top;

the bottom of this convexity must be at

the same level of the 10 mL mark.

• Proper use of the dropper:

(a) to get good reproducible results, tap the dropper on the table

for several times and wipe the outside of the dropper tip with

a cloth.

(b) always keep the dropper bottle in a vertical position while

dosing the reagent.

10 mL

(a) (b)

• Proper use of the powder reagent packet:

(a) use scissors to open the powder packet;

(b) push the edges of the packet to form a spout;

(c) pour out the content of the packet.

(c)(a) (b)

• It is important that the sample does not contain any debris. This

would corrupt the reading.

17

Page 18

• In order to avoid reagent leaking

and to obtain more accurate

measurements, it is recommended

to close the cuvet first with the

supplied HDPE plastic stopper and

then with the black cap.

• Each time the cuvet is used, the

cap must be tightened to the same

degree.

• Whenever the cuvet is placed into

the measurement cell, it must be

dry outside, and completely free of

fingerprints, oil or dirt. Wipe it

thoroughly with HI 731318 (tissue

for wiping cuvets, see chapter

ACCESSORIES) or a lint-free cloth

prior to insertion.

• Shaking the cuvet can generate bubbles in the sample, causing

higher readings. To obtain accurate measurements, remove such

bubbles by swirling or by gently tapping the vial.

• Do not let the reacted sample stand too long after reagent is

added, or accuracy will be lost.

• It is possible to take multiple readings in a row, but it is

recommended to take a new zero reading for each sample and to

use the same cuvet for zeroing and measurement.

• After the reading it is important to discard immediately the sample,

otherwise the glass might become permanently stained.

• All the reaction times reported in this manual are referred to 20°C

(68°F). As a general rule of thumb, they should be doubled at

10°C (50°F) and halved at 30°C (86°F).

18

Page 19

PARAMETERS REFERENCE TABLES

C 216 - POOLMETER C 226 - POOLMETER

Code Parameter Page

1 Alkalinity 22

2 Ca Hardness 26

3 Free Chlorine 28

4 Total Chlorine 30

5 Cyanuric Acid 36

6pH 44

Code Parameter Page

1 Alkalinity 22

2 Bromine 24

3 Ca Hardness 26

4 Free Chlorine 28

5 Total Chlorine 30

6 Free Copper 32

7 Total Copper 34

8 Cyanuric Acid 36

9 Iron 38

10 Ozone 40

11 pH 44

19

Page 20

OPERATIONAL GUIDE

POWER CONNECTION

Remove the battery cover on the back of the meter; attach 2 fresh 9V

batteries and replace the cover.

Alternatively, plug the optional 12VDC adapter (HI 710005 - 110VDC,

or HI 710006 - 220VDC) into the DC socket. Plug the adapter into the

outlet.

Note: Insure the main line is surge protected.

Note: Always turn the meter off before unplugging it to insure no data

is lost.

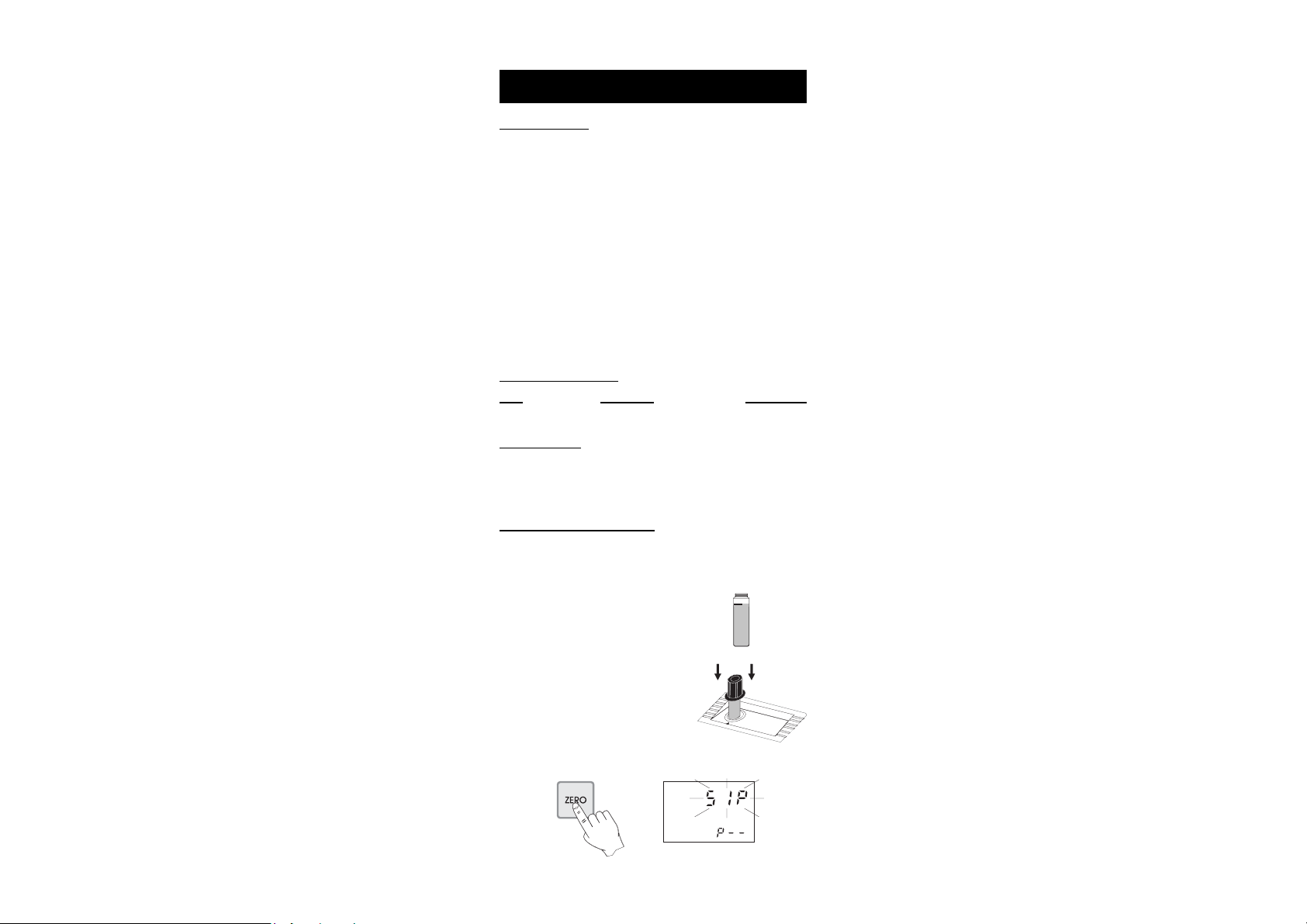

MEASUREMENT PROCEDURE

• Turn the meter on by pressing ON/OFF.

• The meter will first perform an LCD auto

diagnostic test by displaying a full set of

figures.

• Then it will show a scrolling

"c --- Hanna Inst", whereas

the meter will indicate the

exact meter code (C 216 or

C 226) .

• When the LCD displays “----”, the meter

is ready. On the secondary LCD "P1" will

appear to inform that the first parameter

measurement procedure (Alkalinity both

for C 216 and C 226) can be performed.

• Press the PROGRAM ▼ and PROGRAM ▲ keys to select the

desired parameter.

For the program number, see the parameters reference tables on

page 19 or look at the list printed on the mask of the meter.

20

Page 21

• After the desired program number appears on the secondary

display, follow the measurement procedure described in the related

chapter.

• Select a new parameter measurement procedure by pressing the

PROGRAM ▼ and PROGRAM ▲ keys.

Note: in the following measurement

sections, a generic "P– –" will be placed

on the secondary LCD instead of the exact

related message (e.g. in C 226, "P2" for Bromine).

• Before performing a test read carefully all the instructions related

to the selected parameter.

21

Page 22

ALKALINITY

SPECIFICATIONS

Range 0 to 500 mg/L (as CaCO3)

Resolution 5 mg/L

Precision ±10 @ 100 mg/L

Typical EMC ±5 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 575 nm

Method Colorimetric Method. At different alkalinity levels

a distinctive range of colors from yellow to green

and greenish blue will develop.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93755-0 Alkalinity Indicator Reagent 1 packet

REAGENT SETS

HI 93755-01 Reagents for 100 tests

HI 93755-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Alkalinity on the

secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Alkalinity

22

10 mL

Page 23

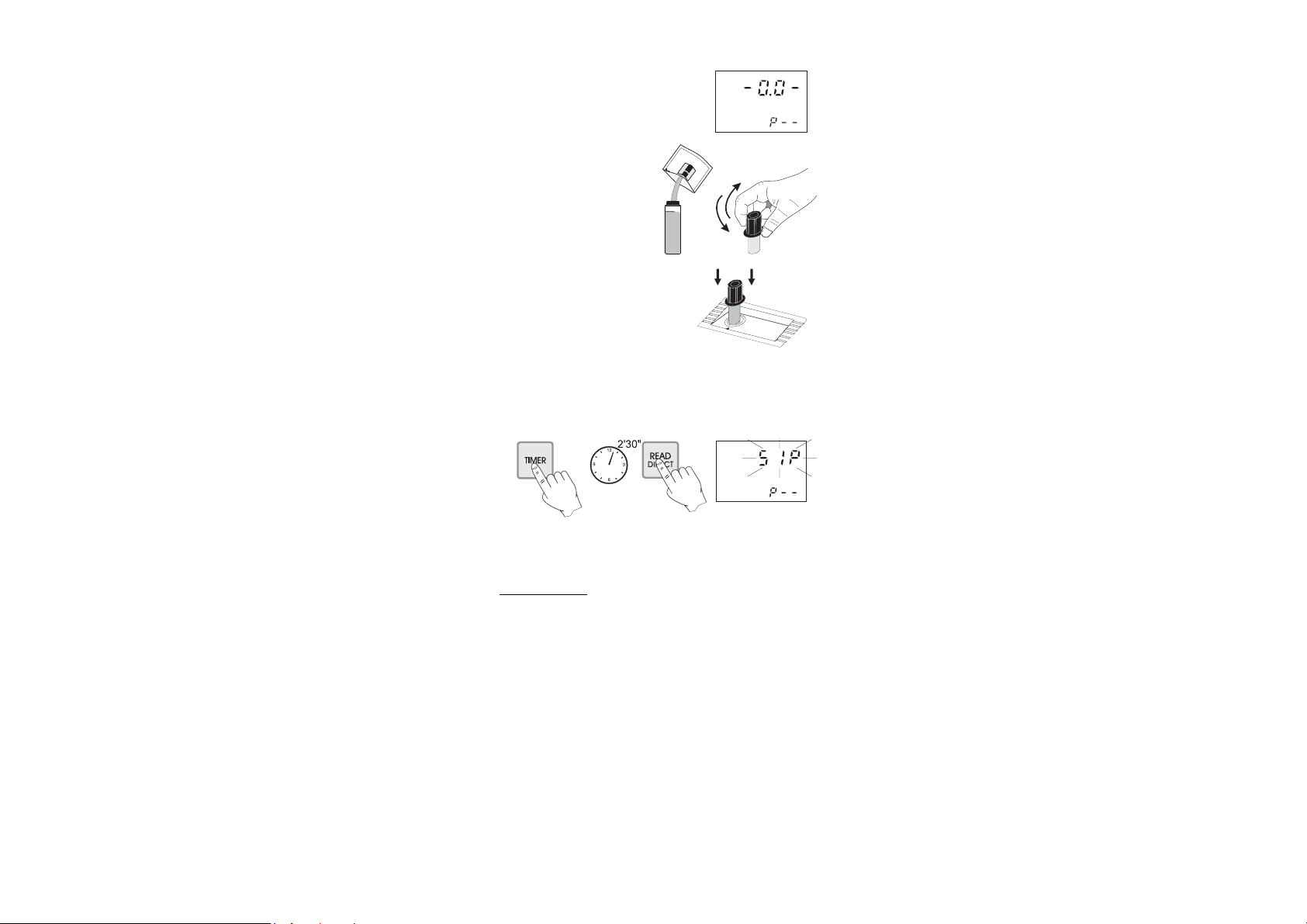

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add carefully the content of

one packet of HI 93755-0

Alkalinity Indicator Reagent.

Replace the cap and shake

vigorously for 30 seconds.

Note: Pay attention not to

spill reagent otherwise full

color development may be

inhibithed.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 2 minutes and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays the alkalinity in mg/L of CaCO

on the Liquid Crystal Display.

23

Alkalinity

3

Page 24

BROMINE

SPECIFICATIONS

Range 0.00 to 10.00 mg/L

Resolution 0.01 mg/L

Precision ±0.05 mg/L @ 2.00 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Adaptation of the Standard Methods for the

Examination of Water and Wastewater, 20

edition, DPD method. The reaction between bromine

and the reagent causes a pink tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93716-0 DPD Powder Reagent 1 packet

REAGENT SETS

HI 93716-01 Reagents for 100 tests

HI 93716-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Bromine on the

secondary LCD by pressing PROGRAM ▼ and ▲.

th

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Bromine

24

10 mL

Page 25

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93716-0 Bromine

Reagent. Replace the cap and

shake gently for about 20

seconds to dissolve most of

the reagent.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 2 minutes and 30 seconds

and press READ DIRECT. In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of bromine

on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Chlorine, Chlorine Dioxide, Ozone.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the reagent.

In case of water with alkalinity greater than 250 mg/L CaCO3, the

color of the sample may develop only partially, or may rapidly fade.

To resolve this, neutralize the sample with diluted HCl.

25

Bromine

Page 26

CALCIUM HARDNESS

SPECIFICATIONS

Range 0 to 500 mg/L (as CaCO3)

Resolution 5 mg/L

Precision ±10 mg/L @ 200 mg/L

Typical EMC ±5 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Colorimetric Method. The reaction between calcium

and the reagents causes a violet to orange tint in

the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93756A-0 Calcium Indicator Reagent 1 packet

HI 93756B-0 Calcium Buffer Reagent 1 packet

REAGENT SETS

HI 93756-01 Reagents for 100 tests

HI 93756-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to calcium Hardness on

the secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP”

will blink on the display.

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

Calcium Hardness

26

10 mL

Page 27

• Remove the cuvet.

• Add carefully the content of

one packet of HI 93756A-0

Ca Hardness 1 Reagent.

Replace the cap and shake

vigorously for 10 seconds.

Note: Pay attention not to

spill reagent otherwise full

color development may be

inhibithed.

• Add the content of one packet

of HI 93756B-0 Ca Hardness

2 Reagent. Replace the cap

and shake vigorously for 10

seconds.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 2 minutes and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays concentration in mg/L of calcium

as CaCO3 on the Liquid Crystal Display.

• To convert the result to mg/L of calcium (Ca2+), multiply by a

factor of 0.4.

INTERFERENCES

Interference may be caused by:

Orthophosphate: precipitate Calcium at the pH of the test.

Alkalinity above 150 mg/L CaCO3 may cause cloudiness. To resolve

this, neutralize the sample with diluted HCl.

27

Calcium Hardness

Page 28

FREE CHLORINE

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L from 0.00 to 2.50 mg/L;

0.10 mg/L above 2.50 mg/L

Precision ±0.03 mg/L @ 1.00 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Adaptation of the USEPA method 330.5 and

Standard Methods for the Examination of Water

and Wastewater, 20th edition, 4500-Cl G. The

reaction between free chlorine and the DPD reagent

causes a pink tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93701-0 DPD Powder Reagent 1 packet

REAGENT SETS

HI 93701-01 Reagents for 100 tests

HI 93701-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Free Chlorine on the

secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Free Chlorine

28

10 mL

Page 29

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93701-0 Free Chlorine

Reagent. Replace the cap and

shake gently for 20 seconds.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Wait for 1 minute and press READ DIRECT. “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of free

chlorine on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Bromine, Chlorine Dioxide, Iodine,

Ozone (all these interferences give positive errors).

Alkalinity above 250 mg/L CaCO3 will not reliably develop the full

amount of color or it may rapidly fade. To resolve this, neutralize the

sample with diluted HCl.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the powder

reagent.

29

Free Chlorine

Page 30

TOTAL CHLORINE

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L from 0.00 to 2.50 mg/L;

0.10 mg/L above 2.50 mg/L

Precision ±0.03 mg/L @ 1.00 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Adaptation of the EPA method 330.5 and Standard

Methods for the Examination of Water and

Wastewater, 20th edition, 4500-Cl G. The reaction

between chlorine and the DPD reagent causes a

pink tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93711-0 DPD Powder Reagent 1 packet

REAGENT SETS

HI 93711-01 Reagents for 100 tests

HI 93711-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Total Chlorine on the

secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Total Chlorine

30

10 mL

Page 31

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93711-0 Total Chlorine

Reagent. Replace the cap and

shake gently for 20 seconds

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

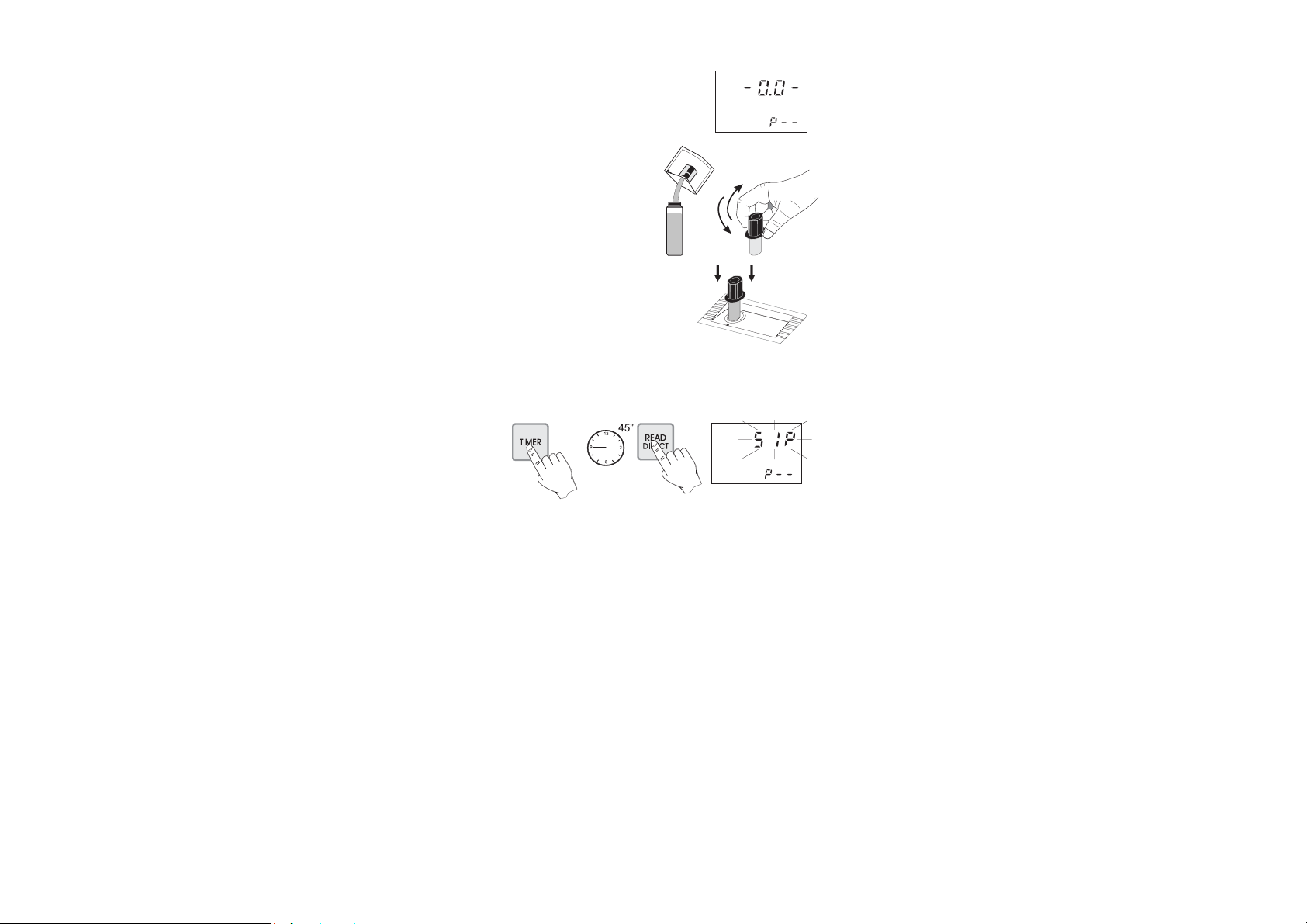

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 2 minutes and 30 seconds

and press READ DIRECT. In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration in mg/L of total

chlorine on the Liquid Crystal Display.

INTERFERENCES

Interference may be caused by: Bromine, Chlorine Dioxide, Iodine,

Ozone (all these interferences give positive errors).

Alkalinity above 250 mg/L CaCO3 will not reliably develop the full

amount of color or it may rapidly fade. To resolve this, neutralize the

sample with diluted HCl.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the powder

reagent.

31

Total Chlorine

Page 32

FREE COPPER

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L

Precision ±0.03 mg/L @ 1.00 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 575 nm

Method Adaptation of the USEPA approved method. The

reaction between free copper and the bicinchoninate

reagent causes a purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93702-0 Bicinchoninate 1 packet

REAGENT SETS

HI 93702-01 Reagents for 100 tests

HI 93702-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Free Copper on the

secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Free Copper

32

10 mL

Page 33

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93702-0 Copper

Reagent. Replace the cap and

shake gently for 15 seconds.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 45 seconds and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays concentration in mg/L of free

copper on the Liquid Crystal Display.

33

Free Copper

Page 34

TOTAL COPPER

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L

Precision ±0.03 mg/L @ 1.00 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 575 nm

Method Adaptation of the USEPA approved method. The

reaction between free copper and the bicinchoninate

reagent causes a purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93702-0 Bicinchoninate 1 packet

HI 93702T-0 Decomplexing Agent 1 packet

REAGENT SETS

HI 93702T-01 Reagents for 100 tests

HI 93702T-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Total Copper on the

secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Total Copper

34

10 mL

Page 35

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93702-0 Copper

Reagent. Replace the cap and

shake gently for 15 seconds.

• Add the content of one packet

of HI 93702T-0 Copper Total

Reagent. Replace the cap and

shake vigorously for 15

seconds.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 45 seconds and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays concentration in mg/L of total

copper on the Liquid Crystal Display.

35

Total Copper

Page 36

CYANURIC ACID

SPECIFICATIONS

Range 0 to 200 mg/L

Resolution 1 mg/L from 0 to 100 mg/L;

10 mg/L above 100 mg/L

Precision ±5 mg/L @ 60 mg/L

Typical EMC ±1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Turbidimetric method. The reaction between

cyanuric acid and the reagent causes a white

turbidity in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93722-0 Cyanuric Acid Reagent 1 packet

REAGENT SETS

HI 93722-01 Reagents for 100 tests

HI 93722-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Cyanuric Acid on the

secondary LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Cyanuric Acid

36

10 mL

Page 37

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93722-0 Cyanuric Acid

Reagent. Replace the cap and

shake gently for about 10

seconds (dissolution is not

complete).

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 45 seconds and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays concentration in mg/L of cyanuric

acid on the Liquid Crystal Display.

INTERFERENCES

Turbidity preexisting in the sample causes interference during

measurement.

37

Cyanuric Acid

Page 38

IRON

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L

Precision ±0.02 mg/L @ 1.50 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Adaptation of the EPA method 315B and Standard

Methods for the Examination of Water and

Wastewater, 20th edition, 3500-Fe B. The reaction

between iron and the phenantroline reagent causes

an orange tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93721-0 Iron High Range Reagent 1 packet

REAGENT SETS

HI 93721-01 Reagents for 100 tests

HI 93721-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to Iron on the secondary

LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

Iron

38

10 mL

Page 39

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93721-0 Iron High

Range Reagent. Replace the

cap and shake until

dissolution is complete.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 3 minute and press READ

DIRECT. In both cases “SIP” will blink during measurement.

Note: for the majority of samples a reading may be taken already

after 1 minute, because color development in the sample is in

general very fast (full color development within 1 minute).

• The instrument directly displays concentration in mg/L of iron on

the Liquid Crystal Display.

INTERFERENCES

Copper does not interfere: reagent contains a masking agent.

39

Iron

Page 40

OZONE

SPECIFICATIONS

Range 0.00 to 2.00 mg/L

Resolution 0.01 mg/L

Precision ±0.03 mg/L @ 1.00 mg/L

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Colorimetric DPD Method. The reaction between

ozone and the DPD reagent causes a pink tint in

the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93757-0 DPD Powder Reagent 1 packet

HI 93703-52-0 Glycine Powder (Optional Reagent) 1 packet

REAGENT SETS

HI 93757-01 Reagents for 100 tests

HI 93757-03 Reagents for 300 tests

HI 93703-52 Glycine Powder, Optional Reagent for 100 tests

For other accessories see page 49.

IMPORTANT NOTE: chlorine is a strong positive interference for the

ozone determination. If the sample is suspected to contain chlorine

residues (free or total chlorine), please follow the alternative

measurement procedure described below:

• Perform the Standard Measurement Procedure and take note of

the reading: value A.

• On a fresh sample perform the Additional Measurement Procedure

and take note of the reading: value B.

• Subtract reading B from reading A to obtain the ozone concentration

in mg/L:

mg/L (O3) = value A – value B.

Ozone

40

Page 41

STANDARD MEASUREMENT PROCEDURE

• Select the program number corresponding to Ozone on the secondary

LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP”

will blink on the

display.

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one packet

of HI 93757-0 Ozone

Reagent. Replace the cap and

shake gently for 20 seconds.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

10 mL

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 2 minutes and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays concentration in mg/L of ozone

on the Liquid Crystal Display (chlorine free samples only).

41

Ozone

Page 42

ADDITIONAL MEASUREMENT PROCEDURE

For samples containing chlorine

• Select the program number corresponding to Ozone on the secondary

LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP”

will blink on the

display.

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

• Add the content of one

packet of the optional

reagent HI 93703-52-0

Glycine Powder. Replace the

cap and shake gently until

dissolution is complete.

10 mL

• Add the content of one

packet of HI 93757-0

Ozone Reagent. Replace

the cap and shake gently

for 20 seconds.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

Ozone

42

Page 43

• Press TIMER and the display will show the countdown prior to

measurement. Alternatively, wait for 2 minutes and press READ

DIRECT. In both cases “SIP” will blink during measurement.

• The instrument directly displays a concentration value refering to

chlorine interference, on the Liquid Crystal Display. Subtract this

value from the reading from the Standard Measurement Procedure:

this will be the concentration in mg/L of ozone in the sample.

INTERFERENCES

Interference may be caused by: Bromine, Chlorine Dioxide, Iodine.

Alkalinity above 250 mg/L CaCO3 will not reliably develop the full

amount of color or it may rapidly fade. To resolve this, neutralize the

sample with diluted HCl.

In case of water with hardness greater than 500 mg/L CaCO3, shake

the sample for approximately 2 minutes after adding the powder

reagent.

43

Ozone

Page 44

pH

SPECIFICATIONS

Range 6.5 to 8.5 pH

Resolution 0.1 pH

Precision ±0.1 pH

Typical EMC ±0.1 pH

Deviation

Light Source Tungsten lamp with narrow band interference filter

@ 525 nm

Method Adaptation of the Phenol Red method. The reaction

between the sample and the reagent causes a

yellow to a red tint in the sample.

REQUIRED REAGENTS

Code Description Quantity/test

HI 93710-0 Phenol Red Indicator 1 packet

REAGENT SETS

HI 93710-01 Reagents for 100 tests

HI 93710-03 Reagents for 300 tests

For other accessories see page 49.

MEASUREMENT PROCEDURE

• Select the program number corresponding to pH on the secondary

LCD by pressing PROGRAM ▼ and ▲.

• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace

the cap.

• Place the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

pH

44

10 mL

Page 45

• Wait for a few seconds and the display

will show “-0.0-”. Now the meter is

zeroed and ready for measurement.

• Remove the cuvet.

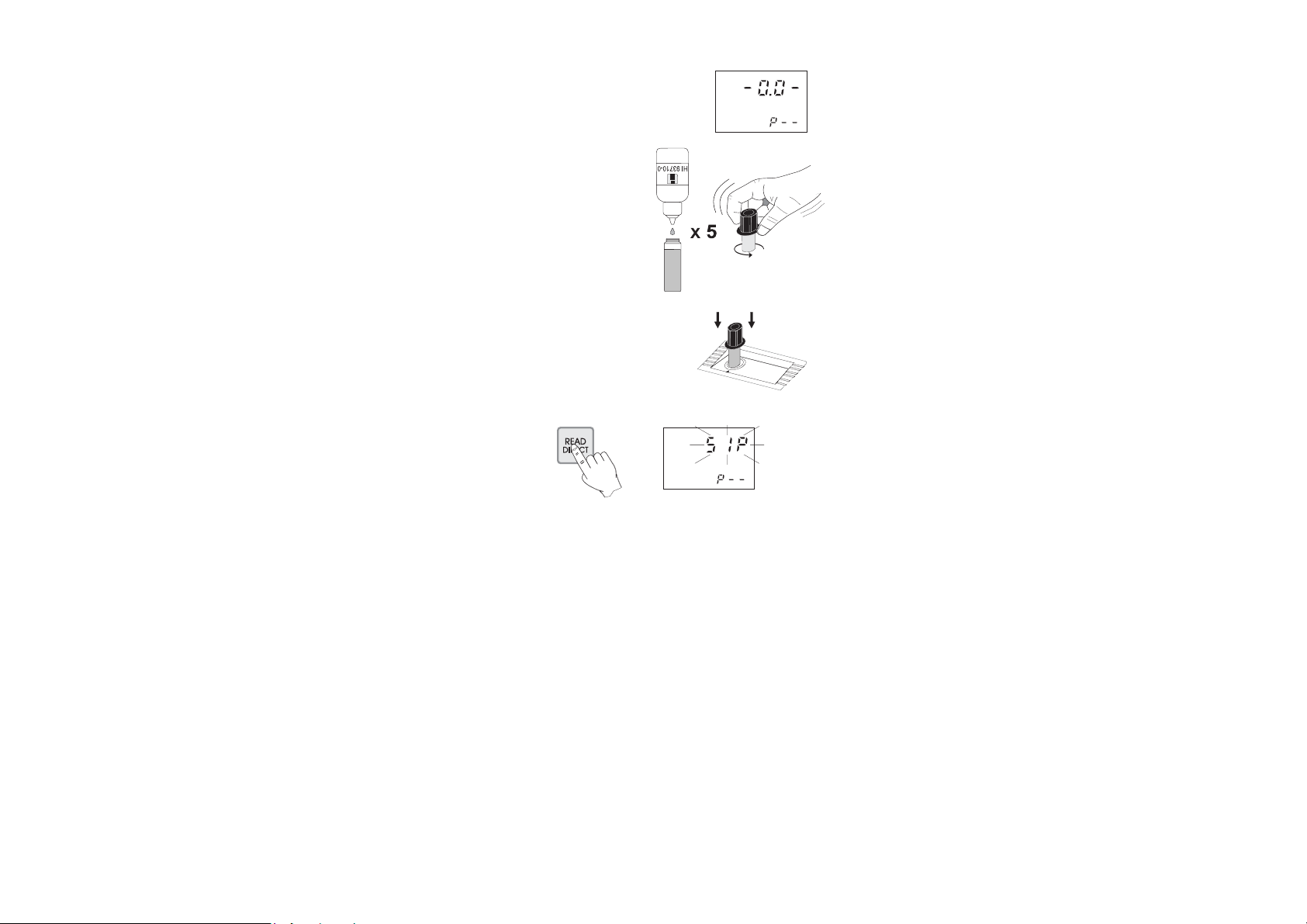

• Add 5 drops of HI 93710-0

pH Reagent. Replace the cap

and swirl the cuvet.

• Replace the cuvet into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

• Press READ DIRECT and “SIP” will blink during measurement.

• The instrument directly displays the pH measured value on the

Liquid Crystal Display.

45

pH

Page 46

INTERFACE WITH PC

To connect your meter to the PC use the optional HI 920010 (available

from your Hanna Dealer). Make sure that your meter is switched off

and plug the connectors, one into the meter RS 232C socket, the other

into the serial port of your PC.

Note: Cables other than HI 920010 may use a different configuration,

in which case, communication between the meter and the PC

may not be possible.

SETTING THE BAUD RATE

The transmission speed (baud rate) of the meter and the external

device must be identical. The meter is factory set to 2400.

If you wish to change this value, please contact your nearest Hanna

Center.

SENDING COMMANDS FROM PC

With terminal programs such as, for example, Telix®, Windows Terminal®, it is possible to remotely control your Hanna Instruments bench

meter. Use HI 920010 cable to connect the meter to the PC, start the

terminal program and set the communication options as follows: 8, N,

1, no flow control.

Command Types

To send a command to the meter the scheme is:

<DLE> <command> <CR>

This line makes the computer send a Data Link Escape character (/ or

?), the command expressed as a number or a 3-character sequence

and a CR character.

Note: Windows Terminal® and all the other terminal programs that

support the ANSI escape sequence, represent the DLE character

by the string ‘^P’ and the CR character by the string ‘^M’.

Type of Commands

/OFF - Turn the meter OFF

/PDR - Press Read Direct

/PTR - Press Timer

/PZR - Press Zero

Excel© Copyright of "Microsoft Co."

Lotus 1-2-3© Copyright of "Lotus Co."

Windows® and Windows Terminal® are registered Trademark of "Microsoft Co."

TELIX® is registered Trademark of "Deltacomm"

46

Page 47

/PUP - Program Up

/PDN - Program Down

/PTM - Turn Test Mode On

/Brx - Set the baud rate

1 - 300 2 - 600

3 - 1200 4 - 2400

/KBL - Lock Keyboard

/KBU - Unlock Keyboard

?PR# - Send Current Program Number

?BRQ - Send current baud rate

1 - 150 2 - 300

3 - 600 4 - 1200

5 - 2400

?CNQ - Send Concentration (three bytes)

conc

decimal point

unit

m - ppm b - ppb

t - ppt u - pcu

h - pH

?ERR - send error / status information

0 - No error

1 - CAP

2 - HI

3 - ZERO

4 - LO

5 - IDLE

6 - ZERO DONE

7 - TIMED READ

47

Page 48

STANDARD METHODS

Description Range Method

Alcalinity 0 to 500 mg /L Colorimetric

Bromine 0.00 to 10.00 mg / L DPD

Calcium Hardness 0 to 500 mg/ L Colorimetric

Chlorine, Free 0.00 to 5.00 mg/L DPD

Chlorine, Total 0.00 to 5.00 mg /L DPD

Copper, Free 0.00 to 5.00 mg/L Bicinchoninate

Copper, Total 0.00 to 5.00 mg /L Bicinchoninate

Cyanuric Acid 0 to 200 mg/ L Turbidimetric

Iron 0.00 to 5.00 mg/ L Phenantroline

Ozone 0.00 to 2.00 mg/ L DPD

pH 6.5 to 8.5 pH Phenol Red

BATTERY REPLACEMENT

To prolong battery life, switch your meter off after use. However, the

meter has an auto-shut off feature that will turn itself off after 10

minutes of non-use.

A blinking "LOBAT" on the display, while a

measurement is in progress, indicates low

voltage and the batteries should be replaced.

If the batteries are not replaced immediately,

in order to prevent erroneous readings due to

low voltage, "-BA-" is displayed soon

afterwards. At this point the batteries must

be changed.

Battery replacement must only take place in a non-hazardous area

using two 9V alkaline batteries.

Remove the battery cover on the back of photometer, attach two fresh

9V batteries, while paying attention to the correct polarity, and replace

the cover.

The meter will turn on automatically when a

new battery is connected. You can turn it off

by pressing ON/OFF.

Besides to 9V batteries, these meters can also be fed by the optional

12 to 20 VDC through voltage adapter.

48

Page 49

ACCESSORIES

REAGENT SETS

HI 93701-01 100 free chlorine tests (powder)

HI 93701-03 300 free chlorine tests (powder)

HI 93702-01 100 free copper tests

HI 93702-03 300 free copper tests

HI 93702T-01 100 total copper tests

HI 93702T-03 300 total copper tests

HI 93703-52 100 glycine powder packets (optional reagent)

HI 93710-01 100 pH tests

HI 93710-03 300 pH tests

HI 93711-01 100 total chlorine tests (powder)

HI 93711-03 300 total chlorine tests (powder)

HI 93716-01 100 bromine tests

HI 93716-03 300 bromine tests

HI 93721-01 100 iron tests

HI 93721-03 300 iron tests

HI 93722-01 100 cyanuric acid tests

HI 93722-03 300 cyanuric acid tests

HI 93755-01 100 alkalinity tests

HI 93755-03 300 alkalinity tests

HI 93756-01 100 calcium hardness tests

HI 93756-03 300 calcium hardness tests

HI 93757-01 100 ozone tests

HI 93757-03 300 ozone tests

OTHER ACCESSORIES

C115-00300 5 mL graduated syringe

HI 710005 110VAC to 12VDC voltage adapter

HI 710006 220VAC to 12VDC voltage adapter

HI 721310 9V battery (10 pcs)

HI 731318 Tissue for wiping cuvets (4 pcs)

HI 731321 Glass cuvets (4 pcs)

HI 731325N New cap for cuvet (4 pcs)

HI 740034 Cap for 100 mL beaker (6 pcs)

HI 740036 100 mL plastic beaker (6 pcs)

HI 740038 60 mL glass bottle and stopper

HI 740142 1 mL graduated syringe

HI 740143 1 mL graduated syringe (6 pcs)

HI 740144 Pipette tip (6 pcs)

HI 740157 Plastic refilling pipette (20 pcs)

HI 740220 25 mL glass cylinders with caps (2 pcs)

HI 92000 Windows® Compatible Software

HI 920010 PC connection cable

HI 93703-50 Cuvets cleaning solution (230 mL)

49

Page 50

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are entirely suitable for your specific application

and for the environment in which they are used.

Operation of these instruments may cause unacceptable interferences to other electronic equipments, this requiring the operator to take all necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instruments' EMC

performance.

To avoid damages or burns, do not put the instrument in microwave ovens. For yours and the

instrument safety do not use or store the instrument in hazardous environments.

50

Page 51

WARRANTY

All Hanna Instruments meters are warranted for two years against

defects in workmanship and materials when used for its intended

purpose and maintained according to the instructions.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact your dealer. If under warranty, report the

model number, date of purchase, serial number and the nature of the

failure. If the repair is not covered by the warranty, you will be

notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service

Department and then send it with shipment costs prepaid. When

shipping any instrument, make sure it is properly packaged for complete

protection.

To validate your warranty, fill out and return the enclosed warranty

card within 14 days from the date of purchase.

Hanna Instruments reserves the right to modify the design, construction

and appearance of its products without advance notice.

HANNA LITERATURE

Hanna publishes a wide range of catalogs and handbooks for an

equally wide range of applications. The reference literature currently

covers areas such as:

• Water Treatment

• Process

• Swimming Pools

• Agriculture

• Food

• Laboratory

and many others. New reference material is constantly being added to

the library.

For these and other catalogs, handbooks and leaflets contact your

dealer or the Hanna Customer Service Center nearest to you. To find

the Hanna Office in your vicinity, check our home page at

www.hannainst.com.

51

Page 52

www.hannainst.com

52

MANC216R2 01/03

Loading...

Loading...