Page 1

Instruction Manual

C 102

Multiparameter

Turbidity &

Ion Specific Meter

This Instrument is in Compliance with the CE Directives

www.hannainst.com

Page 2

Dear Customer,

Thank you for choosing a Hanna Product.

Please read this instruction manual carefully

before using the instrument.

This manual will provide you with the necessary

information for the correct use of the instrument,

as well as a precise idea of its versatility. If you

need more technical information, do not hesitate to e-mail us at tech@hannainst.com.

This instrument is in compliance with directives.

TABLE OF CONTENTS

General Description .................................... 4

Principle of Operation .................................. 6

Functional Description ................................. 9

Specifications ........................................... 13

Operational Guide ..................................... 14

Calibration ................................................. 22

Diagnostic mode ....................................... 30

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it to make sure that no

damage has occurred during shipping. If there

is any damage, notify your Dealer.

C102 is supplied complete with:

• 1.5V AA Size Batteries (4 ea.)

• Glass Cuvet

• Cap

In addition to the above items, an optional

starter kit HI 731327 is available, supplied

with:

• Measurement cuvets (2 pcs)

• Primary calibration standards:

HI 93102-0 AMCO-AEPA-1 0 NTU* cali-

bration solution, 30 mL

HI 93102-20 AMCO-AEPA-1 20 NTU* calibration solution, 30 mL

• HI 93703-50 Cleaning solution, 230 mL

• HI 731318 Tissue for wiping the cuvets

(4 pcs)

• HI 710031 Rugged carrying case

Logging with C 102.................................... 31

User-selectable Shutdown ......................... 33

Battery Replacement ................................ 34

Diagnostic Codes ...................................... 35

Accessories .............................................. 36

Warranty ................................................... 38

CE Declaration of Conformity .................... 39

2

Note: Save all packing material until you are

sure that the instrument functions correctly. Any defective item must be returned in its original packaging with

the supplied accessories.

* 1 NTU (Nephelometric Turbidity Unit) = 1 FTU (For-

mazine Turbidity Unit)

3

Page 3

GENERAL DESCRIPTION

The Hanna C 102 is a portable microprocessor driven, multiparameter, turbidity and ion

specific meter. It measures Free & Total Chlorine, Cyanuric Acid, pH, Iodine, Bromine, Low

Range Iron and Turbidity.

In the colorimetric mode, the user can select

either factory preprogrammed calibration settings or calibrate the meter using customized

calibration values based on the concentration

or relative absorbance of the sample. Calibration data is also stored in a non-volatile

EEPROM.

In the turbidity mode, periodic recalibration of

the meter with primary standards according

to regulatory requirements or personal experience is suggested. Turbidity ranges are 0.00-

9.99 NTU and 10.0-50.0 NTU.

C 102 complies with G.L.P. Standards (Good

Laboratory Practice), that is:

• When switched on, the LCD displays all

segments (display check).

• Battery status is monitored during every

measurement cycle warning the user if the

batteries become weak. In addition, C102

will turn itself off before low voltage causes

erroneous readings.

• It utilizes a real time clock and recalls

calibration data such as date, time and

calibration values.

There are eight keys for the different

operationals modes. The large Liquid Crystal

Display is dual-level: the upper level has four

digits and can display the measured parameter in hundredths. The lower level has three

characters and indicates current mode (e.g.

F CL for free chlorine or TR for turbidity).

Different LCD segments indicate low battery,

logging mode, date, time, etc.

A pure Green LED has been utilized as a

light source for both turbidimetric and colorimetric measurements. A silicon photocell is

used to receive transmitted light from colorimetric channel while another photocell receives scattered light from the turbidimetric

(nephelometric) channel.

In order to measure colorimetric parameters,

all the operator has to do is zero the blank

sample and then add 1 packet of reagent (for

Bromine, Chlorine, Cyanuric Acid, Iodine and

Low Range Iron) or 0.2 mL of Phenol Red (for

pH). After placing the cuvet back in the meter

and pressing READ, the measurements are

shown directly on the LCD.

The instrument operates with four AA batteries and may be operator-programmed to turn

itself off automatically after 10, 20, 30, 40, 50

or 60 minutes of inactivity.

C 102 and all accessories such as sample

vials, reagent pillows, primary standards, can

be easily stored in the optional carrying case

(HI 710031).

To facilitate field tests, the meter provides a

logging mode. In this mode, the user can

store up to twenty five time-tagged measurements in RAM and scroll the memory at any

time.

4

5

Page 4

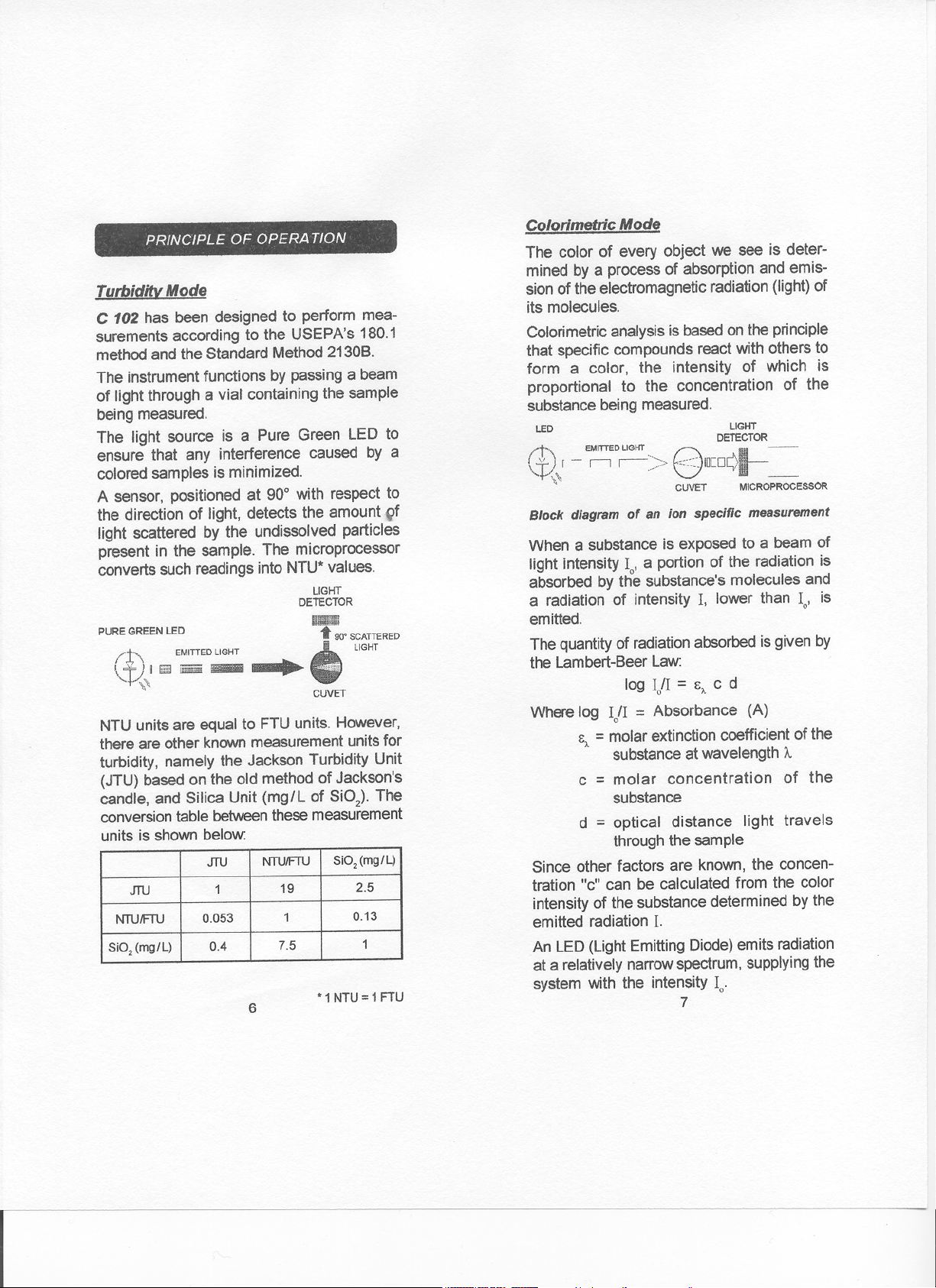

Page 5

Page 6

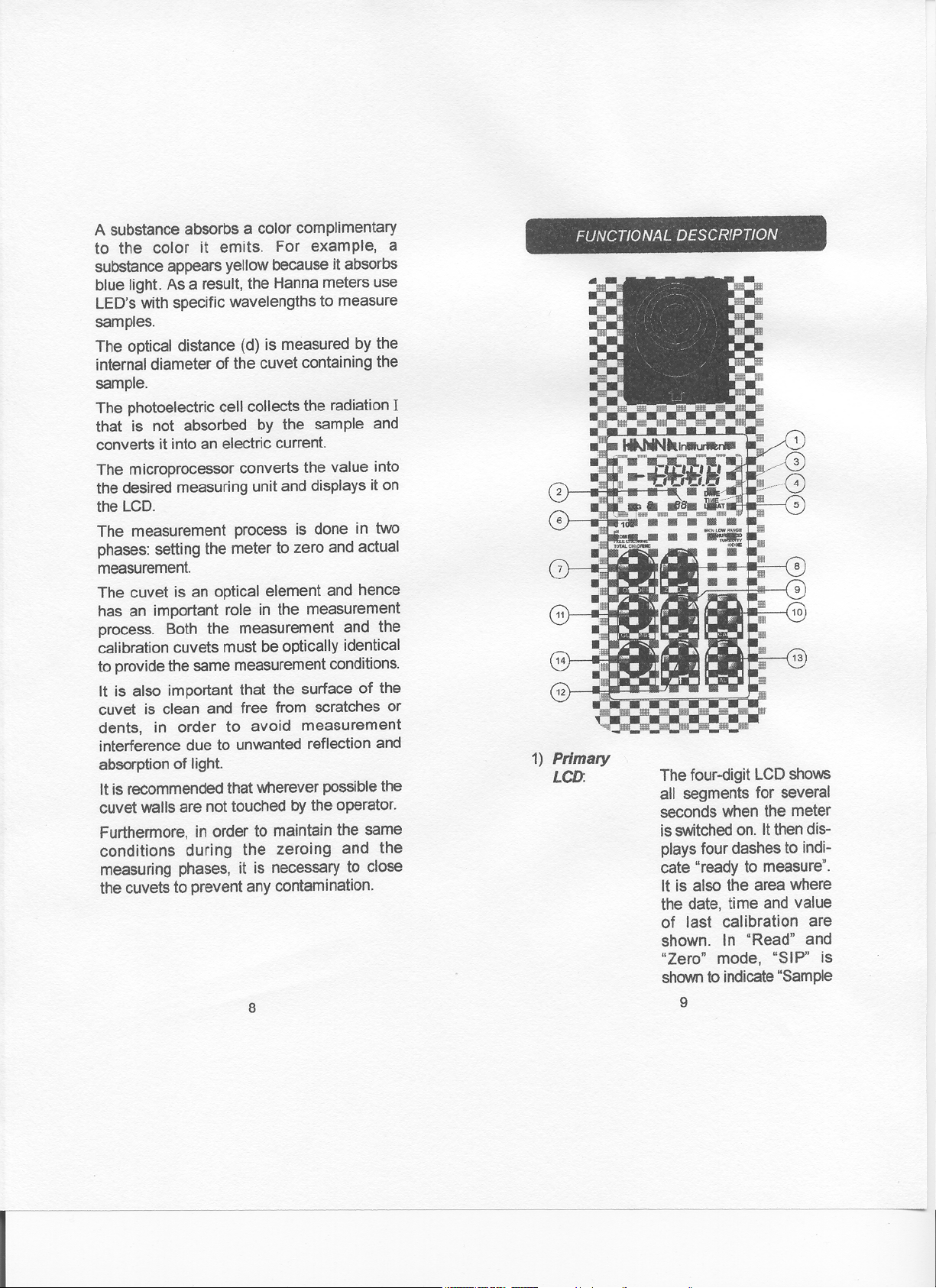

In Progress”. The upper

level also indicates the

concentration or turbidity

of the sample, as well as

different diagnostic modes,

such as “-BA-” for low battery.

2) Secondary

LCD: The three-digit LCD shows

the current mode of measurement that is “F CL”,

“t CL”, “CY”, “PH”, “Id”,

“Br”, “L FE”, “tr”, and diagnostic or calibration

modes, such as “d 11”,

“2 Fn”, “5 c1”.

3) DATE: Indicates that the upper

level of LCD is showing

the current date, the date

of last calibration or the

date of logged measurement in memory.

4) TIME: Indicates that the upper

level of LCD is showing

the current time, the time

of last calibration or the

time of logged measurement in memory.

5) LOBAT: Blinking segment warns

user of low battery voltage.

6) LOG: If intermittent, it indicates

that the user is in the scroll

mode viewing the logged

measurements. If fixed, it

indicates that the meter

is in the log mode and

every reading taken will be

stored in memory.

7) ON/OFF key: Turns the meter on and

off.

8) ZERO / key: In ion specific (colorimetric) mode, it zeros the

sample. In calibration and

diagnostic modes, it functions as ENTER (not used

in turbidity mode).

9) READ / key: Takes the measuremnt of

concentration/turbidity of

the sample which is shown

on the LCD. In diagnostic

or calibration mode, shifts

the flashing digit to the

right.

10) CAL key: If pressed during calibration, the calibration procedure will be aborted and

the last calibration data will

be reinstated. If pressed

together with the ALT key

for less then 3 seconds,

the diagnostic mode will

be entered. If pressed together with the ALT key

again, the meter will quit

diagnostic mode. If

pressed for more then 3

seconds, an intermittent

“CAL” prompt will appear

on the upper LCD level

and the calibration procedure is entered.

11) GLP / Abs key: In ion specific mode, it will

toggle concentration/absorbance readings on the

upper LCD. In turbidity

mode, date, time and the

two calibration values of

the current mode will be

10

11

Page 7

shown. If pressed in

time/date setup mode, the

meter will quit current

mode without making any

changes to current time/

date.

12) key Scrolls upwards through

the parameters to be measured. In calibration/diagnostic mode, increments

the blinking digit by one.

If pressed together with

ALT while the meter is in

logging mode, the upper

LCD will show the data

(date/time/value) in the

memory.

13) ALT key: Alternative functions.

14) key: Scrolls downwards through

the parameters to be measured. In calibration/diagnostic mode, decreases

the blinking digit by one.

If pressed together with

ALT while the meter is in

logging mode, the upper

LCD will show the current

lot number.

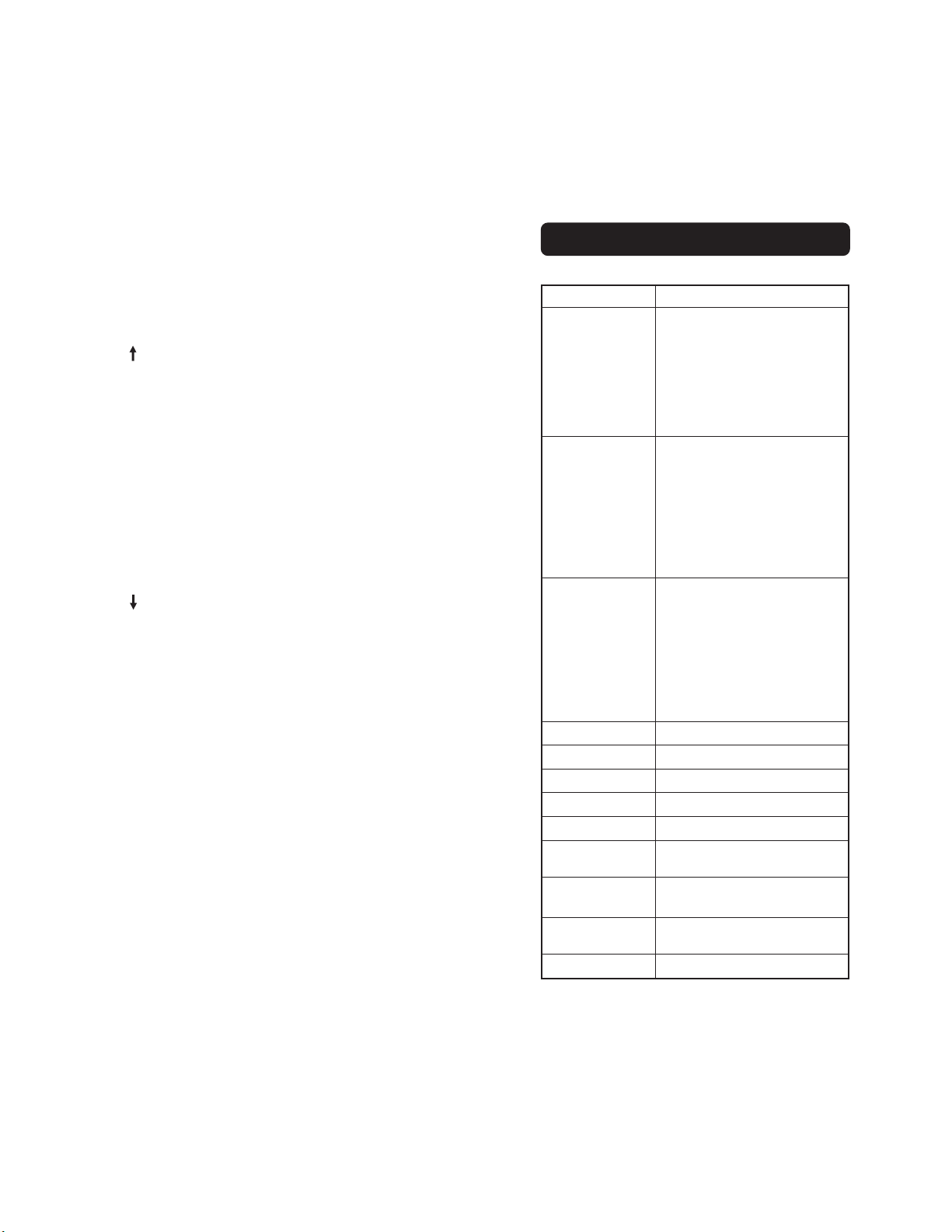

SPECIFICATIONS

C 102

Range Turbidity 0.00 to 50.0 NTU*

Bromine 0.00 to 8.00 mg/L

Free Cl 0.00 to 2.50 mg/L

Total Cl 0.00 to 3.50 mg/L

CYS 0 to 80 mg/L

Iodine 0.0 to 12.5 mg/L

LR Iron 0.00 to 1.00 mg/L

pH 5.9 to 8.5

Resolution

Turbidity 0.01 and 0.1 NTU*

Bromine 0.01 mg/L

Free Cl 0.01 mg/L

Total Cl 0.01 mg/L

CYS 1 mg/L

Iodine 0.1 mg/L

LR Iron 0.01 mg/L

pH 0.1

Accuracy

Turbidity ±0.5 NTU* or ±5% (whichever greater)

Bromine ±0.08 mg/L; ±3%

Free Cl ±0.03 mg/L; ±3%

Total Cl ±0.03 mg/L; ±3%

CYS ±1 mg/L; ±15%

Iodine ±0.1 mg/L; ±5%

LR Iron ±0.02 mg/L; ±3%

pH 0.1 pH

Light Source Pure Green LED

Light Source Life Life of the instrument

Light Detector Two Silicon Photocells

Power Source 4 x 1.5V AA alkaline batteries

Battery Life 60 hours or 1000 measurements

Automatic Selectable

Shutdown 10, 20, 30, 40, 50 or 60 min.

Operating 0 to 50°C (32 to 122°F)

Conditions 95% RH max (non-condensing)

Dimensions 220 x 82 x 66 mm

(8.7 x 3.2 x 2.6")

Weight 510 g (18 oz.)

12

13

* 1 NTU = 1 FTU

Page 8

OPERATIONAL GUIDE

SET CURRENT TIME/DATE

To set or change the current time, turn on the

meter. After initialization routine, the LCD will

show:

CURRENT TIME/DATE RECALL

To recall current TIME/DATE press and hold

the ALTand READ keys together. The current

time and an intermittent “TIME” will be displayed.

+

Release the keys.

Press and hold the ALT and GLP keys together. Display will show the current date in

MM.DD format (e.g. August 28 is shown as

08.28).

+

Release the keys. The month digits will blink.

Make the necessary adjustments with the

and keys. To skip to the day digits, press

the key.

After the adjustments, press the key. The

unit will store the newly set month-day data

in its EEPROM and will show the current

time by a 24 hour clock HH.MM format, e.g.

2:28 pm is:

Press and hold the ALT and READ keys

again and the meter will show the current

date together with an intermittent “DATE”.

+

TURBIDITY MEASUREMENTS

Fill the vial with the sample. The

surface of the vial should be clean

and scratch free.

Turn the meter on. After the initialization routine, the LCD will show:

Use the and keys to set the lower level of

the LCD to turbidity (tr).

Similarly, make the necessary adjustments

as described above and press . The newly

set up “month - day - hour - minute” data will

be stored in memory.

14

Insert the sample into the cuvet

holder and ensure that the

notch on the cap is positioned

securely into the groove.

15

Page 9

m

Press READ. The meter will intermittently

display “SIP” on the upper level of the LCD.

The meter will show “SIP” for a few seconds

and then a zero indication:

After a few seconds the display will show the

turbidity value, e.g. 5.34 NTU:

COLORIMETRIC MEASUREMENTS

Turn the meter on. After the initialization routine, the LCD will display:

Use the and keys to

choose the desired parameter:

F CL Free Chlorine t CL Total Chlorine

CY Cyanuric Acid PH pH

Id Iodine Br Bromine

L FE Iron

Measuring Chlorine, Cyanuric Acid, pH, Iodine,

Bromine

Fill the vial with the sample (blank).

The surface of the vial should be

clean and scratch free.

Insert the blank sample into the cuvet holder

and ensure that the notch on the cap is positioned securely into the groove. Press ZERO.

For pH, add 0.2 mL of

HI 93710-01:

For Chlorine, Iodine

and Bromine, add the

content of their respective packet:

1 x1 x

1 x

1 x1 x

For Cianuric Acid only, add the content of one packet of HI 93722 reagent to a beaker filled up to the

25mL mark with unreacted sample

up to the 25 mL mark. Stir gently

to mix and then fill the cuvet up to

1.5 c

1.5 cm (¾“) below the rim with 10

mL of the reacted sample.

Replace the cap, shake the cuvet and allow a

few seconds for color to develop. For best

results, wait 2½ mins. for Total Chlorine, Bromine, Iodine, and 45 secs. for Cyanuric Acid.

Insert the reacted sample into the cuvet holder

and ensure that the notch on the cap is positioned securely into the groove. Press READ.

The meter will show “SIP” for a few seconds

and then the concentration:

16

17

Page 10

m

Measuring Iron

m

Fill one graduated mixing cylinder up to the 25 mL mark with

deionized water.

Add the content of one packet of HI 93746

TPTZ reagent, close the cylinder and agitate

for 30 seconds. This is the blank.

30"

12

9

3

6

Fill a cuvet with 10 mL of

1.5 c

the blank up to 1.5 cm (¾")

below the rim and replace

the cap.

Insert the blank into the cuvet holder and

make sure that the notch on the cap is

positioned securely into the groove. Press

ZERO.

Add the content of one packet of HI 93746

TPTZ reagent, close the cylinder and agitate

for 30 seconds.

30"

12

9

3

6

Fill a cuvet with 10 mL of the

reacted sample up to 1.5 cm

1.5 c

(¾") below the rim and replace the cap. This is the

sample.

Insert the reacted sample into the cuvet holder

and make sure that the notch on the cap is

positioned securely into the groove. Wait 30”

and then press READ.

The meter will show “SIP” for about a few

The meter will show “SIP” for a few seconds

seconds and then the concentration:

and then a zero indication:

Note: To review the relative absorbance of

Fill one graduated mixing cylinder up to the 25 mL mark

with the sample.

the sample, wait until the concentration measurement is completed, and

then press GLP/Abs. The display will

show the absorbance in milliunits to-

18

19

Page 11

gether with the “Ab” indicator, e.g.:

533 Ab = 533 milliabs. units

Note: Absorbance readings may have a nega-

tive sign if the transmittance of the

“ZERO” sample is less then that of the

reacted sample.

Note: For better accuracy wash glassware

with HCl 6N.

Measurements in user-customized mode

Note: The meter must be calibrated for this

purpose. Follow the two-point customized calibration on page 26 before

proceeding.

Turn the meter on and by momentarily pressing both ALT and CAL.

+

The LCD will show four

dashes on the upper

and “d 00” on the lower

part of the LCD with

the second “0” flashing:

Using the , and

keys change the lower

row of the display to

show “d 11”:

Press the key. This key is also used as a

toggle between

(FCT) programmed functions. Select the USER

mode (if necessary by pressing the key

more than once):

USER

(USR) and

FACTORY

Press ALT and CAL until four dashes are

displayed on the upper display and “# fn” are

shown in the lower part of the LCD.

Using the and keys select the number

from 0 to 7 where the appropriate calibration

data have been stored.

Add the appropriate reagent into the blank

sample cuvet. Shake and allow a few sec-

onds for color to develop.

Insert the reacted sample into the cuvet holder

and make sure that the notch on the cap is

positioned securely into the groove. Press

READ.

The meter will first show “SIP” for a few

seconds and afterwards the sample concen-

tration:

20

21

Page 12

CALIBRATION

TURBIDITY CALIBRATION

The meter should be properly calibrated with

a standard prepared as described in USEPA

method 180.1.

Span calibration

To calibrate the span of the meter,

fill the cuvet with the primary turbidity formazine standard of 50 NTU.

Inspect and clean thoroughly the surface of the vial.

Shake the standard vigorously for a

few seconds and wait a few minutes

for the bubbles to disappear.

Turn the meter on and press both ALT and

CAL momentarily.

The display will blink

“-Lt-” for several sec-

onds, indicating that the

LED is being adjusted

for the turbidimetric channel.

Afterwards, a sequence of numbers between

-511 to 512 will appear on the upper part of

the LCD indicating different levels of LED light

intensity.

In approximately one minute, the adjustment

will be made and the calibration data stored

in the non-volatile memory.

The display will show four

dashes again indicating

the end of the span cali-

bration procedure.

Press the ALT and CAL

keys together again to

leave the diagnostic mode.

+

+

The LCD will show four

dashes on the upper

and “d 00” on the lower

part of the LCD with

the second “0” blinking.

Using the , and

keys change the lower

row of the display to

show “d 21”.

Insert the previously prepared 50 NTU standard into the cuvet holder and make sure that

the notch on the cap is positioned securely

into the groove. Press .

22

Two-point customized calibration

To enter the turbidity calibration mode, the

meter should be in “turbidity” mode.

Use the and keys

to set the lower level of

the LCD to “tr”.

To enter the calibration mode, press and hold

the ALT and CAL keys together for at least

three seconds. The upper display will start

flashing “CAL” for approximately three sec-

onds.

+

To confirm entry into the calibration

mode, press the CAL key again

while “CAL” is blinking.

23

Page 13

If the CAL key is not

pressed, the upper display will show “----”, indicating that calibration

mode was not entered. In which case, hold

down the ALT and CAL keys together for 3

seconds to restart the procedure.

After entering the calibration mode, the display will show the first

point of the previous

calibration. The most

significant digit will also be blinking.

Using the , , keys, set the turbidity of

first calibration standard (from 0.00 to 50.0 NTU).

Insert the standard vial into the cuvet holder

and ensure that the notch is positioned securely into the groove. Press the key. The

display will indicate Sample In Progress (SIP).

After the first calibration point is memorized, the LCD will indicate the second point

of the previous calibration with the most significant digit blinking.

Using the , , keys, set the turbidity of the

second calibration standard (from 0.00 to 50.0

NTU). Insert the standard into the cuvet holder

and make sure that the notch is positioned

securely into the groove. Press the key.

The display will indicate “SIP” again.

24

After the second calibration point is memo-

rized, the unit will store the calibration data

together with time and date in the EEPROM

while intermittently indicating “CAL” and “Stor”

for several seconds.

Subsequently, the up-

per display will show

“----”, indicating that the

meter is calibrated and

ready to measure turbidity of an unknown

sample.

By pressing CAL during calibration,

user can quit the calibration mode

at any time without changing the

previously stored calibration data.

COLORIMETRIC CALIBRATION

Zero calibration

To calibrate the span of the meter, fill the

cuvet with a clean deionized water sample.

Inspect and thoroughly clean the surface of

the vial.

Turn the meter on and press both ALT and

CAL momentarily.

+

The display will show

four dashes and “d 00”.

The second “0” will blink

to allow the user to

make a selection.

25

Page 14

Using , , keys set

the lower part to “d 31”.

Insert the previously prepared deionized water standard into the cuvet holder and make

sure that the notch on the cap is positioned

securely into the groove. Press the key.

The display will blink

“-Lc-” for several seconds, indicating that

adjustment of the LED

for the colorimetric measurements is in

progress.

After this, a sequence of numbers between

-511 to 512 will appear on the upper LCD

indicating the different levels of LED light

intensity. In approximately one minute, the

adjustment will be made and the calibration

data will be stored in the non-volatile memory.

Display will show four

dashes again indicating

the end of the zero calibration procedure.

Press the ALT and CAL

keys again to leave the

diagnostic mode.

Two-point customized calibration

To enter the colorimetric calibration mode, press

momentarily both the ALT and CAL keys. The

LCD will show four dashes and “d00”.

+

+

Using the and keys,

set the lower part of

the LCD to “d 11” and

then press the key.

The key is used as a toggle function in

this mode and allows the user to select be-

tween

USER

(USR) or

grammed functions.

Select the USER mode and press ALT and

CAL keys together to leave the diagnostic

mode. The display of the meter will indicate

four dashes together with a number from 0 to

7 on the lower part of the LCD.

FACTORY

(FCT) pro-

+

Press and hold the ALT and CAL keys to-

gether for at least three seconds. The upper

display will start flashing “CAL” for approxi-

mately three seconds.

+

To confirm entry into the calibration

mode, press the CAL key again

while “CAL” is still blinking.

If the CAL key is not

pressed, the upper row

of the display will show

“----”, indicating that the

calibration mode was

not entered. In which case, hold down the

ALT and CAL keys together for 3 seconds to

restart the procedure.

26

27

Page 15

After entering the calibration mode, the display will show the first

point of the previous

calibration with the most

significant digit blinking.

Using the , and keys, choose the

concentration of the first calibration standard.

Insert the known standard into the cuvet holder

and make sure that the notch is positioned

securely into the groove. Press the key.

The display will indicate sample in progress.

After the first calibration point is memorized, the LCD will indicate the second point

of the previous calibration with the most significant digit blinking.

Using the , , keys, choose the known

concentration of the second calibration standard.

Insert the standard into the cuvet holder and

make sure that the notch is positioned securely into the groove. Press the key. The

display will blink “SIP” again.

Subsequently, the up-

per display will show

“----”, indicating that the

meter is calibrated and

ready to measure the

concentration of an unknown sample.

By pressing the CAL key during

calibration, user can leave the cali-

bration mode at any time without

changing the previously stored calibration data.

After the second calibration point is memorized, the unit will store the calibration data,

time and date in the EEPROM while intermittently indicating “CAL” and “Stor” for several

seconds.

28

29

Page 16

DIAGNOSTIC MODE

C 102 facilitates operations by providing a

diagnostic mode. In this mode, user can set

or verify different parameters necessary to

ensure optimum performance of the meter.

To enter the diagnostic mode, turn the meter

on and momentarily press ALT and CAL together. The display will show four dashes together with “d 00”:

+

Using the , and keys, select the required diagnostic mode and press the key.

The meter will execute one of the following

user-diagnostic functions:

10 Customizes automatic shutdown

11 Selects User or Factory functions

12 Turns logging mode on or off

21 Calibrates span in turbidimetric mode

31 Calibrates span in colorimetric mode

40 Clears the logged memory

To quit diagnostic mode,

press the ALT and CAL

keys together again.

LOGGING WITH C 102

C 102 allows user to log 25 time/day-tagged

measurements. User can easily turn the log-

ging mode on and off, review the logged

memory, review the current lot number and

clean the buffer (memory). C 102 also re-

minds user if its memory is full.

TURNING THE LOG MODE ON OR OFF

Enter the diagnostic

mode by pressing ALT

and CAL together.

Select mode 12 and press the

key.

The display will show the current (vacant) lot

together with “LOG” if the log mode is on.

Otherwise it will show “----” if the log mode is

off.

+

+

The following diagnostic modes are reserved

for authorized service technicians:

00 Shows the

01 Shows the

02 Shows the

05 Shows the

06 Shows 5V on-board level

07 Shows battery voltage level

08 Shows 1.23V reference voltage level

09 Shows -5V on-board level

99 Shows software version number

Blank

level in colorimetric mode

Sample

level in colorimetric mode

Dark

level in colorimetric mode

Ground

voltage

30

By pressing the key, the meter toggles

between the Log on and off positions. If the

log on mode is selected, every time a mea-

surement is taken (READ pressed) the rel-

evant values will be stored in the current

(vacant) lot number.

To quit diagnostic mode,

press the ALT and CAL

keys together again.

The LCD will then show “CAL” and “Stor” for a

few seconds. If the log on mode was selected

“LOG” will appear on the bottom left hand side

31

+

Page 17

of the display to remind the user that every time

a measurement is taken, the value is stored in

the next available lot number.

REVIEWING THE LOGGED BUFFER

To review the memorized values, press to-

gether ALT and .

+

To clear the buffer, press

the ALT and CAL keys.

Select mode 40. Press the key. The dis-

play will show the “Cln” message, indicating

that memory is being cleaned.

+

The meter will scroll all the data in the buffer

showing the lot number, value, date and time.

e.g. The first recorded reading in the buffer is

lot # 0, 0.35 mg/L of Iron, memorized on

23rd August at 3:34 pm;

The second logged data relates to lot

# 1, 1.35 mg/L of the customized parameter, logged on 23rd August at 3:55 pm.

First lot Second lot

The lot number will be reset to 00 automatically.

REVIEWING THE CURRENT LOT NUMBER

To check the current

(vacant) lot number,

while in log mode,

press ALT and to-

gether.

USER-SELECTABLE SHUTDOWN

With C 102, the users can customize the

shutdown time to save power.

To change the shutdown

time, enter the diagnos-

tic mode by momentarily

pressing the ALT and CAL keys together.

Select mode 10 and press the key repeat-

edly to set the desired shutdown time from

10 to 60 minutes with 10 minute increments,

or disable the shutdown mode by choosing

the OFF selection.

+

CLEARING THE MEMORY

After all the buffer (memory) is taken up, the

LCD will blink “Full”.

32

After the selection is com-

pleted, exit the diagnos-

tic mode by pressing

ALT+CAL together.

33

+

Page 18

The meter will store new settings in its nonvolatile memory and the display will flash

“CAL” and “Stor” alternatly for several seconds.

BATTERY REPLACEMENT

A “LOBAT” indication

appears on the lower

right hand side of the

display when the batteries are weak and require replacement. At

this point the instrument is still able to perform approximately 50 additional measurements.

A “-BA-” indication will

appear on the display

when the batteries are

too weak to perform

accurate measurements. This message appears for a few seconds and then the meter

will completely switch itself off. At this point

the batteries must be replaced.

Batteries should only

be replaced in a safe

area using 1.5V AA alkaline type.

In order to replace the

batteries, simply remove the two screws

on the rear cover of the

instrument and replace

all four 1.5V AA batteries with new ones,

while paying attention

to their polarity.

34

DIAGNOSTIC CODES

LOBAT Weak batteries. Change all batter-

ies as soon as possible.

-BA- Exhausted batteries. Change all

batteries immediately.

-LO- Low level of light is received during

the zeroing procedure.

Check for scratches on the cuvet

and ensure that sample is not excessively turbid. Repeat the readings. If the problem persists,

recalibrate the meter using deionized water in the diagnostic mode

“31” (see Calibration).

-CAP- Light intensity is high during last

measurement. Make sure the cuvet

is capped and placed properly in

the holder, and that ambient light

does not reach the photodetector.

Repeat the measurement. If the

problem persists, contact your dealer

or the nearest Hanna Office.

Er 1 Hardware error. Repeat the mea-

surement. If the error message appears again, contact your dealer or

the nearest Hanna Office.

rnG Out of range. Check the measuring

procedure and verify the

concentration of the sample to

ensure that is not too high.

35

Page 19

ACCESSORIES

HI 731327 Starter kit includes:

Rugged carrying case;

HI 93102-0 AMCO-AEPA-1

0 NTU* calibration solution,

30 mL;

HI 93102-20 AMCO-AEPA-1

20 NTU* calibration solution,

30 mL;

HI 93703-50 Cleaning solution,

230 mL;

HI 731318 Tissues for wiping

the cuvet (4 pcs);

Two measurement cuvets

HI 93102-0 AMCO-AEPA-1 0 NTU* cali-

bration solution, 30 mL

HI 93102-20 AMCO-AEPA-1 20 NTU* cali-

bration solution, 30 mL

HI 93701-01 Reagents for 100 Free Chlo-

rine tests

HI 93701-03 Reagents for 300 Free Chlo-

rine tests

HI 93703-50 Cleaning solution, 230 mL

HI 93710-01 Reagents for 100 pH tests

HI 93710-03 Reagents for 300 pH tests

HI 93711-01 Reagents for 100 Total Chlo-

rine tests

HI 93711-03 Reagents for 300 Total Chlo-

rine tests

HI 93716-01 Reagents for 100 Bromine

tests

HI 93716-03 Reagents for 300 Bromine

tests

HI 93718-01 Reagents for 100 Iodine tests

HI 93718-03 Reagents for 300 Iodine tests

HI 93722-01 Reagents for 100 Cyanuric

Acid tests

HI 93722-03 Reagents for 300 Cyanuric

Acid tests

HI 93746-01 Reagents for 100 Low Range

Iron tests

HI 93746-03 Reagents for 300 Low Range

Iron tests

HI 710031 Rugged carrying case

HI 731318 Tissue for wiping the cuvets

(4 pcs)

36

* 1 NTU = 1 FTU.

37

Page 20

WARRANTY

Hanna Instruments meters are guaranteed

for two years against defects in workman-

ship and materials when used for their intended purpose and maintained according to

instructions.

This warranty is limited to repair or replacement free of charge. Damages due to accidents, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact the dealer from

whom the instrument was purchased. If under

warranty, report the model number, date of

purchase, serial number and the nature of the

failure. First obtain a Returned Goods Authorization number from the Customer Service

department and then return the instrument

indicating the Authorization # with shipment

costs prepaid.

If the repair is not covered by the warranty,

you will be notified of the charges.

When shipping any instrument, make sure it

is properly packaged for complete protection.

To validate your warranty, fill out and return

the enclosed warranty card within 14 days

from the date of purchase.

CE DECLARATION OF CONFORMITY

All rights are reserved. Reproduction in whole

or in part is prohibited without the written

consent of the copyright owner,

Hanna Instruments Inc., Woonsocket, Rhode

Island, 02895, Tel. (401) 765-7500 –

Fax (041) 765-7575.

Hanna Instruments reserves the right to

modify the design, construction and appearance of its products without advance notice.

38

Recommendations for Users

Before using this product, make sure that it is entirely suitable for the environment

in which it is used.

Operation of this instrument in residential areas could cause unacceptable interference to radio and TV equipment, requiring the operator to take all necessary steps

to correct the interference.

Any variation introduced by the user to the supplied equipment, may degrade the

instrument's EMC performance.

To avoid electrical shocks, do not use this instrument when voltage at the measurement surface exceeds 24VAC or 60VDC.

To avoid damage or burns, do not perform any measurement in microwave ovens.

39

Page 21

www.hannainst.com

MANC102R3 07/01

Loading...

Loading...